Patents

Literature

97results about How to "Guaranteed production continuity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

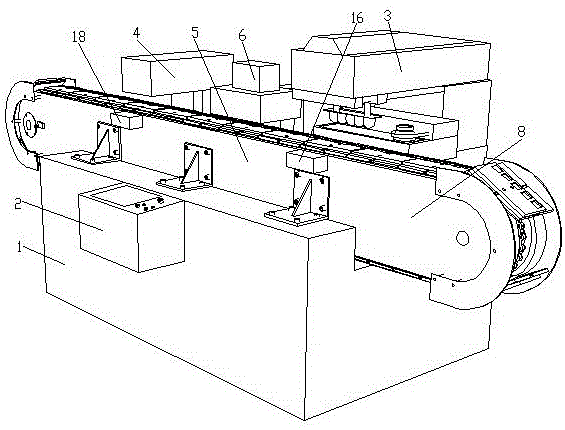

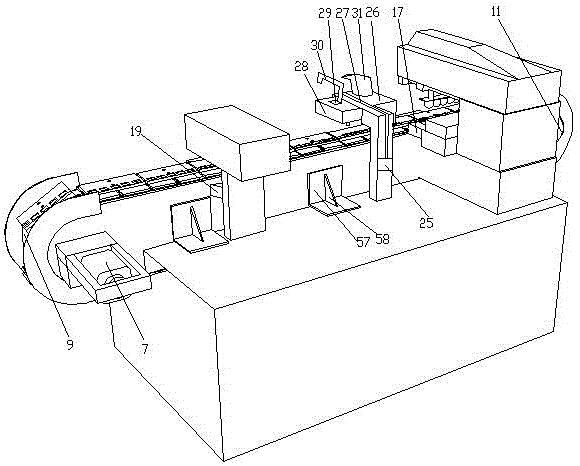

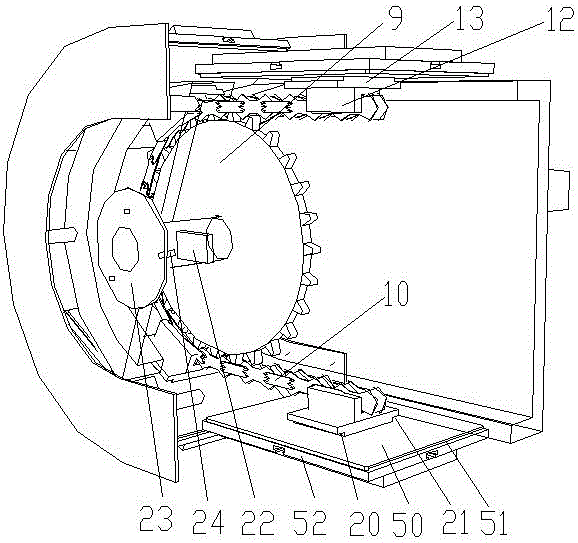

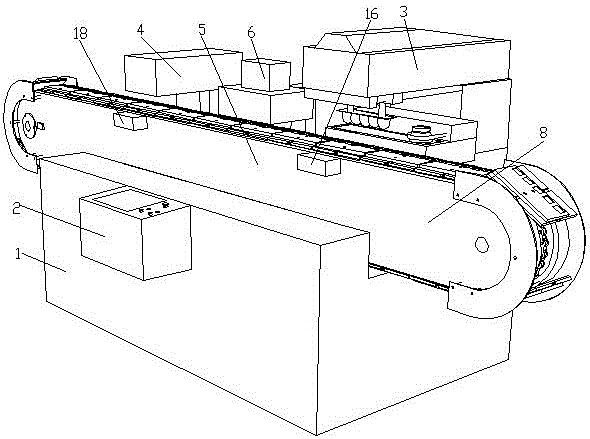

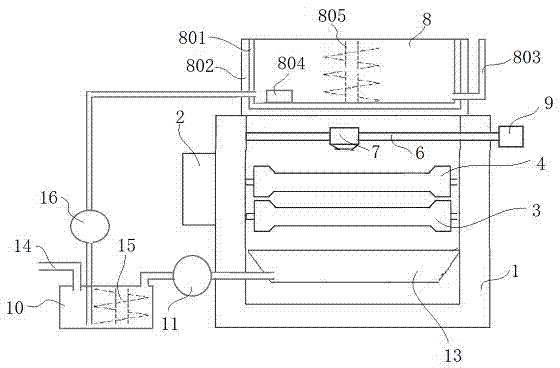

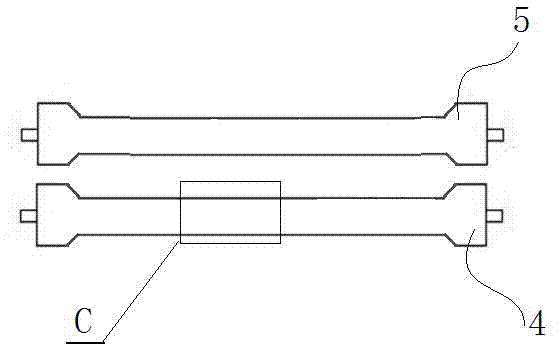

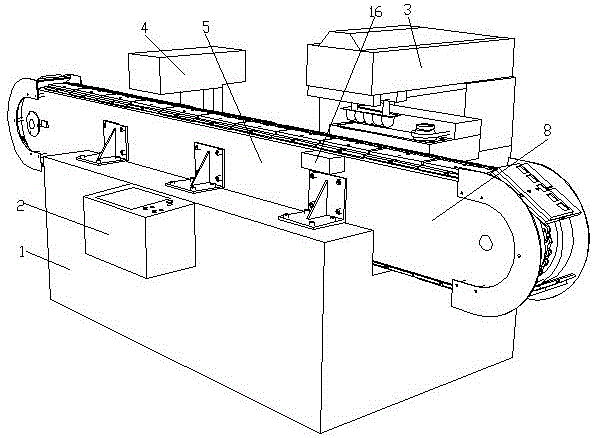

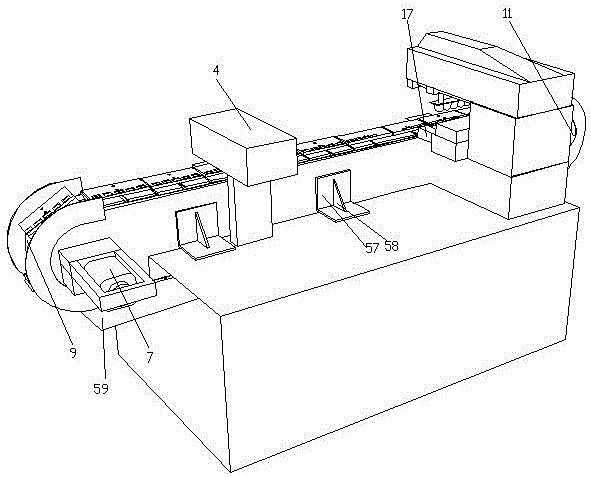

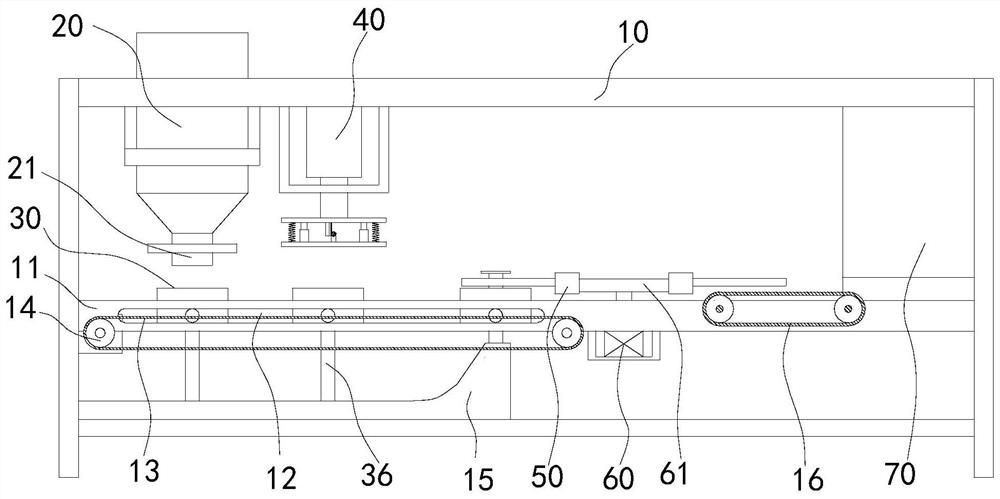

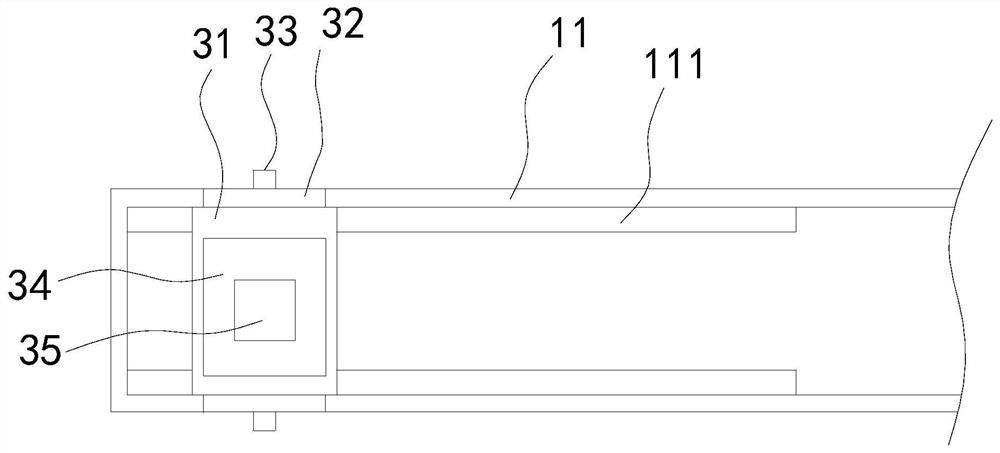

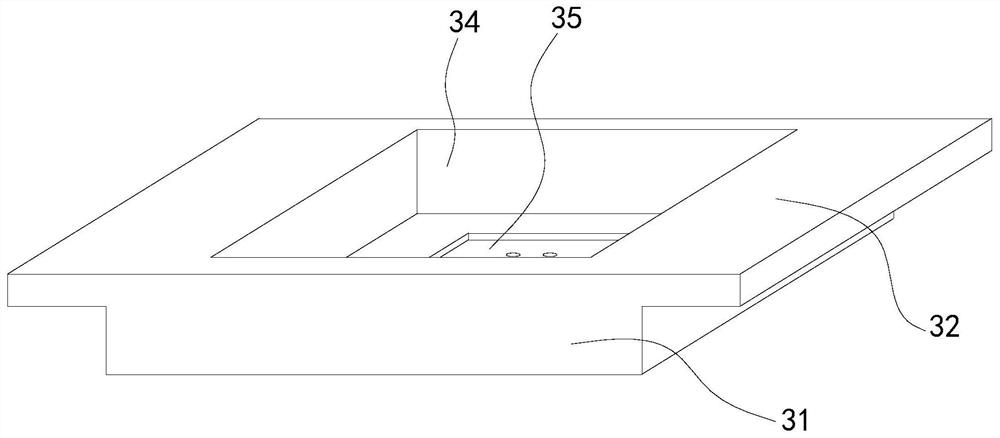

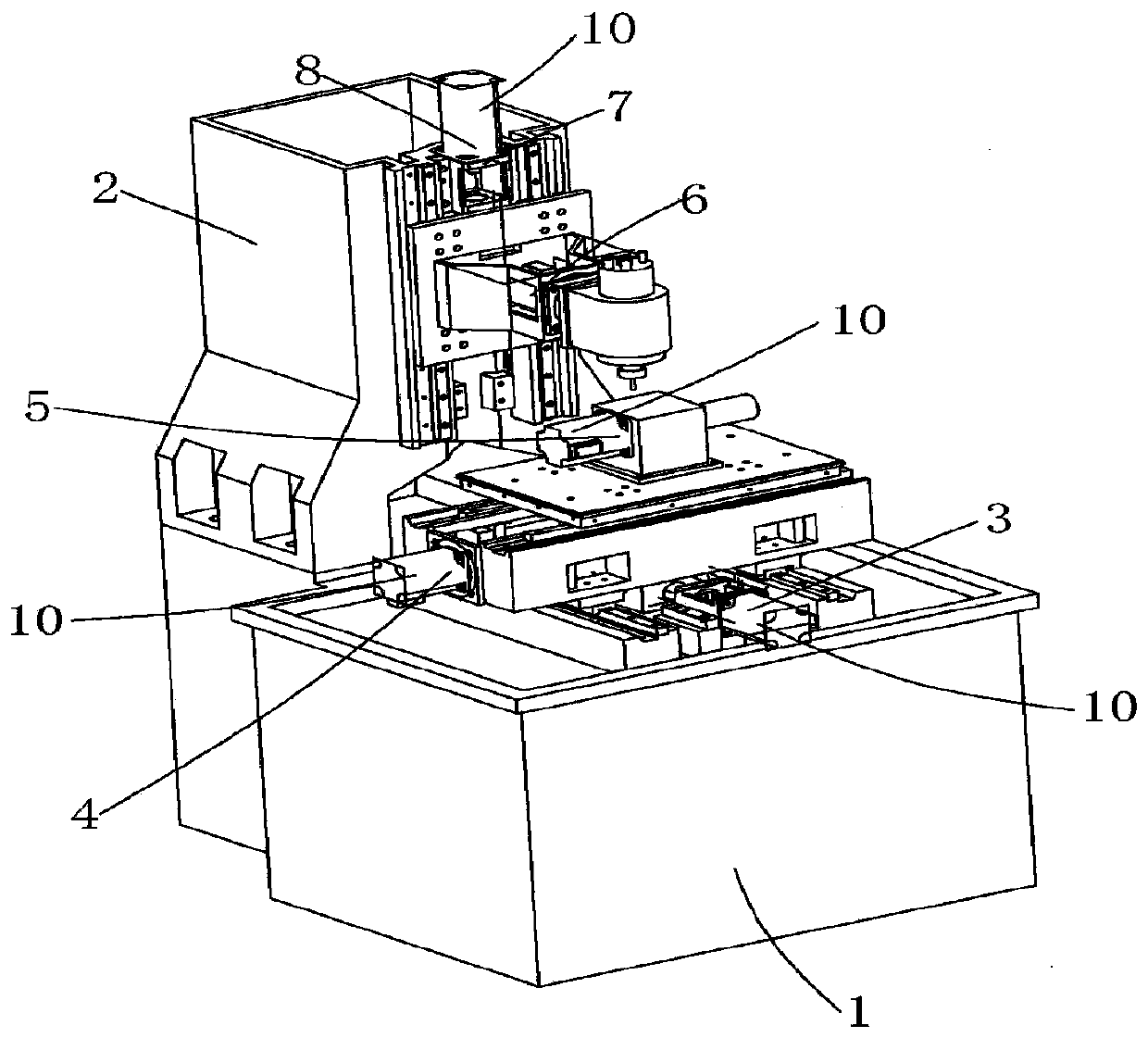

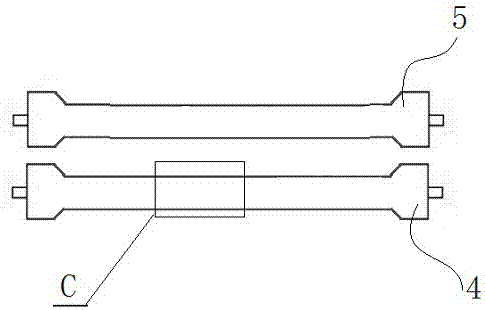

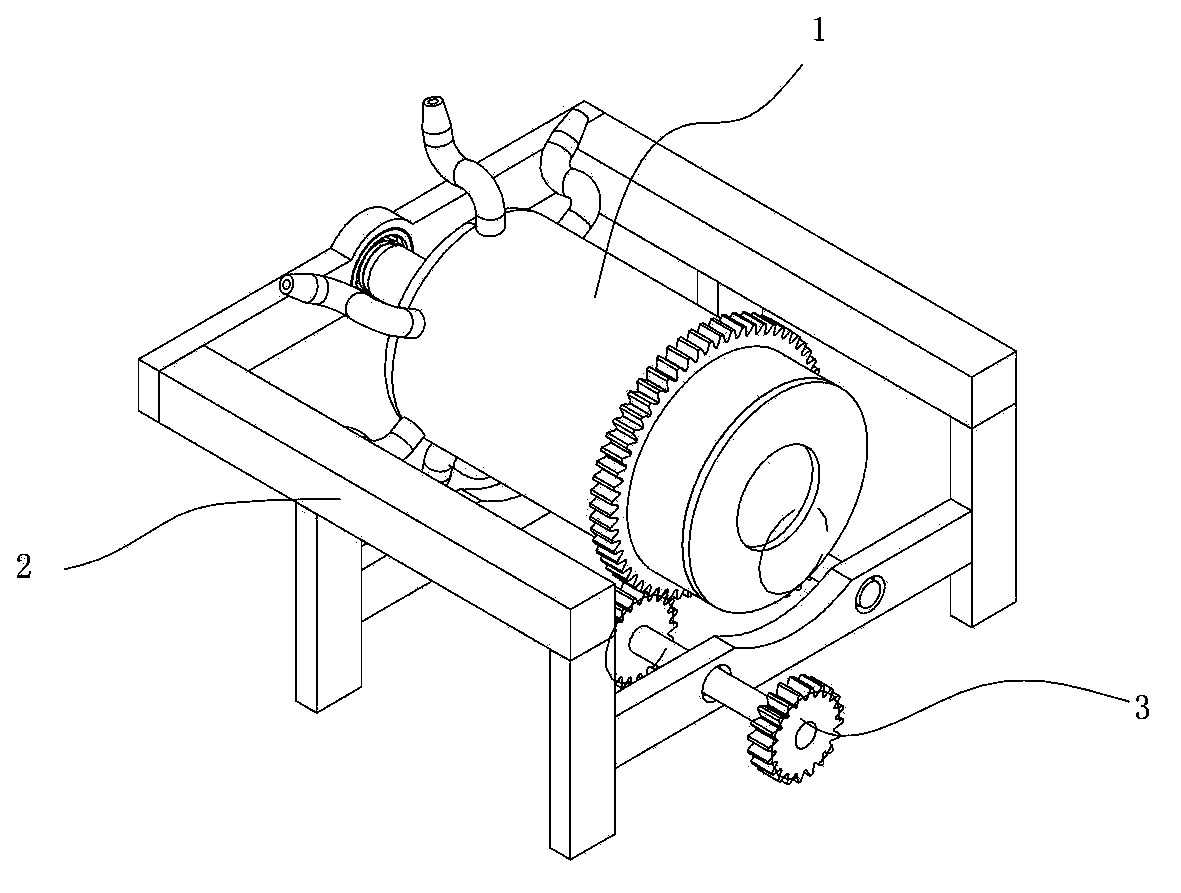

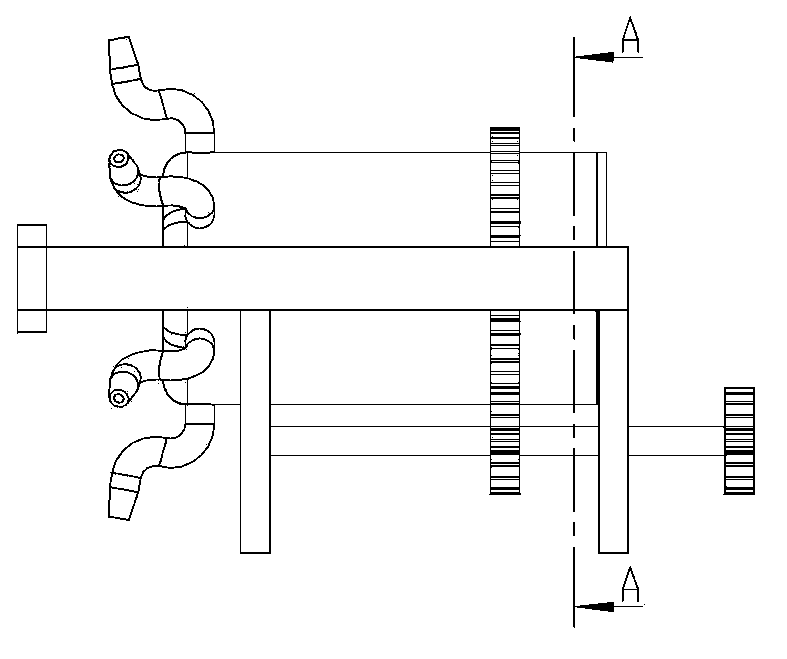

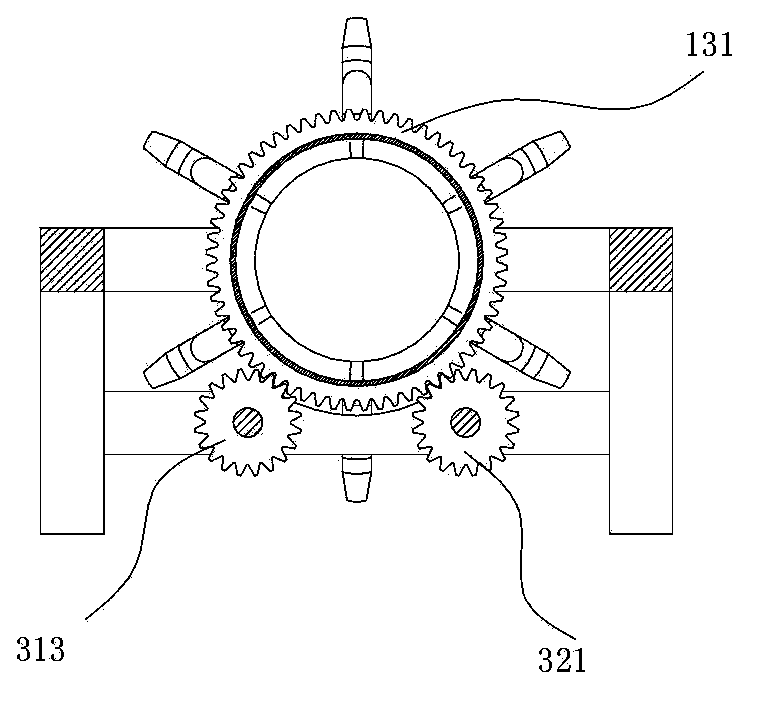

Continuous type pad printing and coding device

ActiveCN106364152APad printing stabilityPad printing precisionRotary pressesPrinting press partsPad printingEngineering

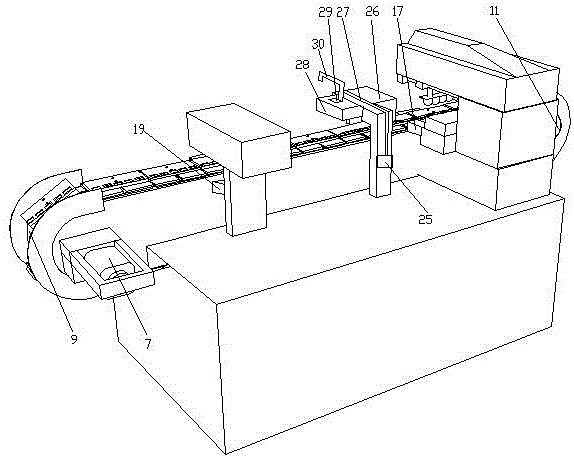

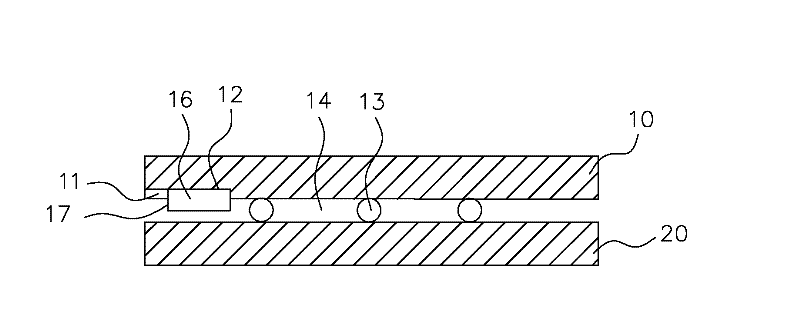

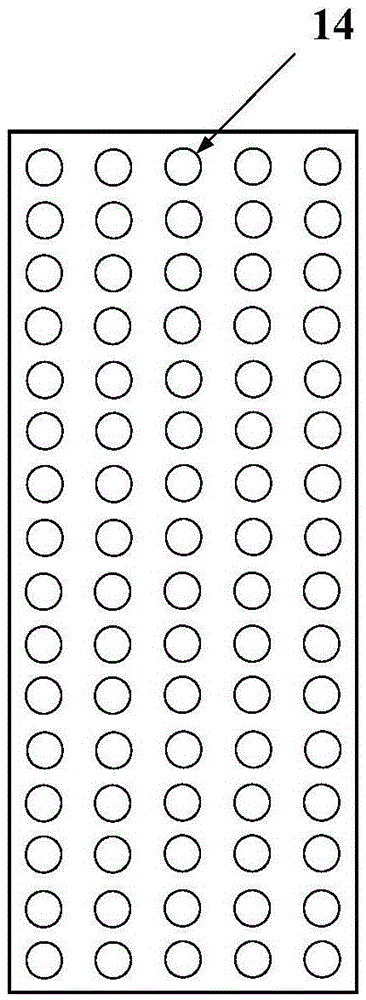

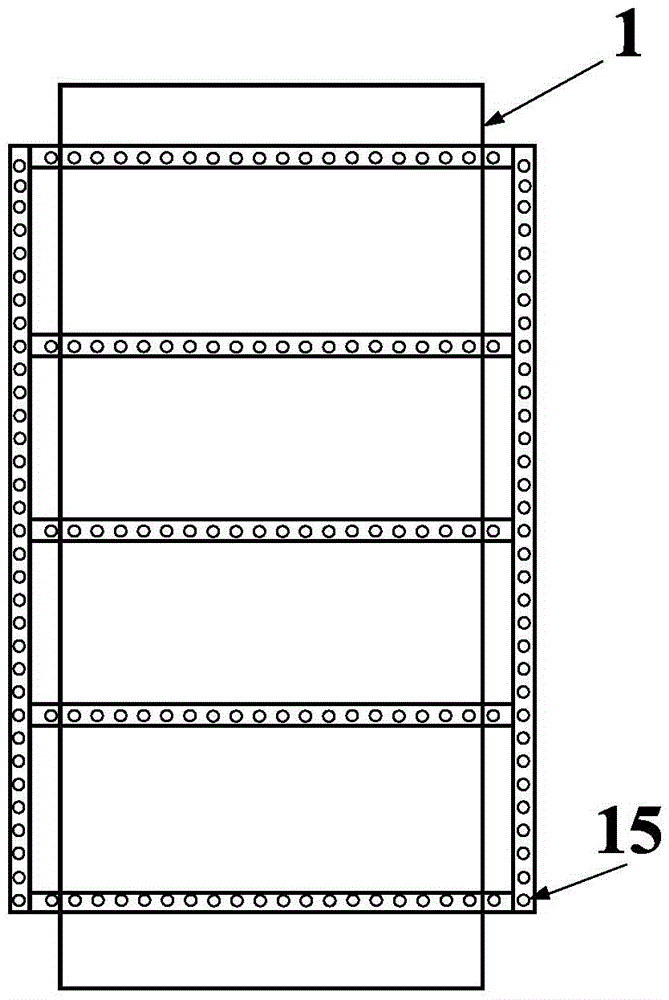

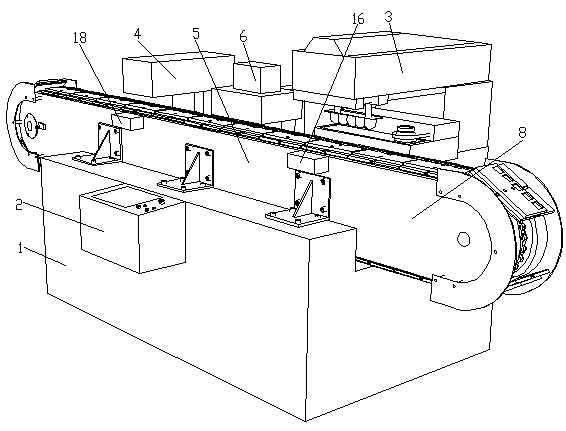

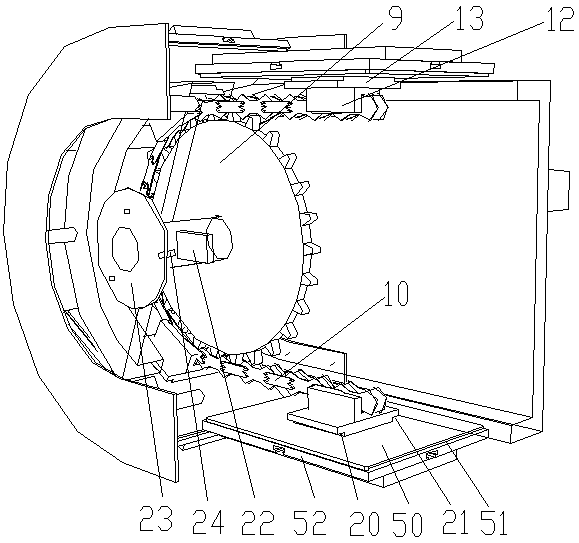

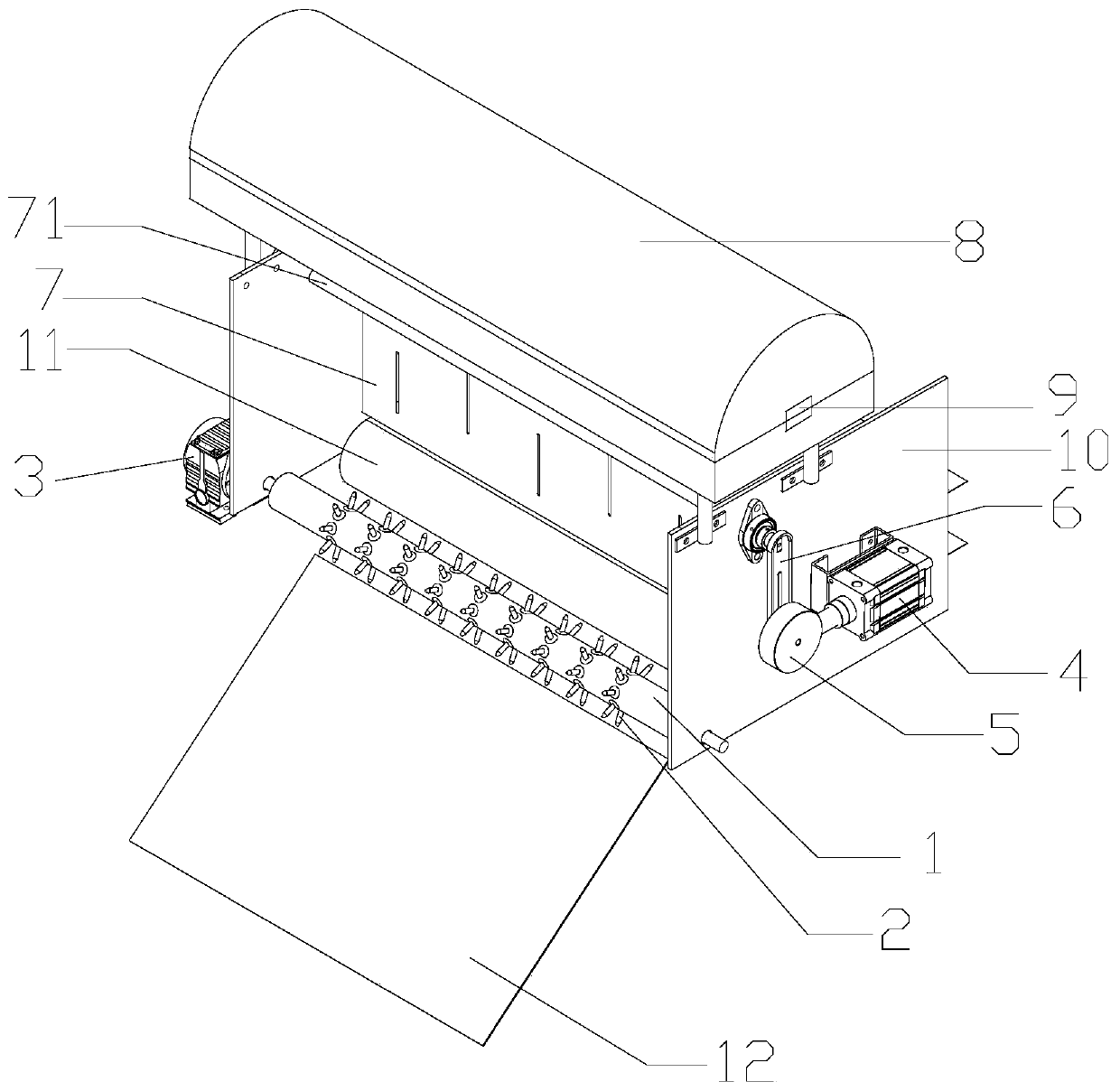

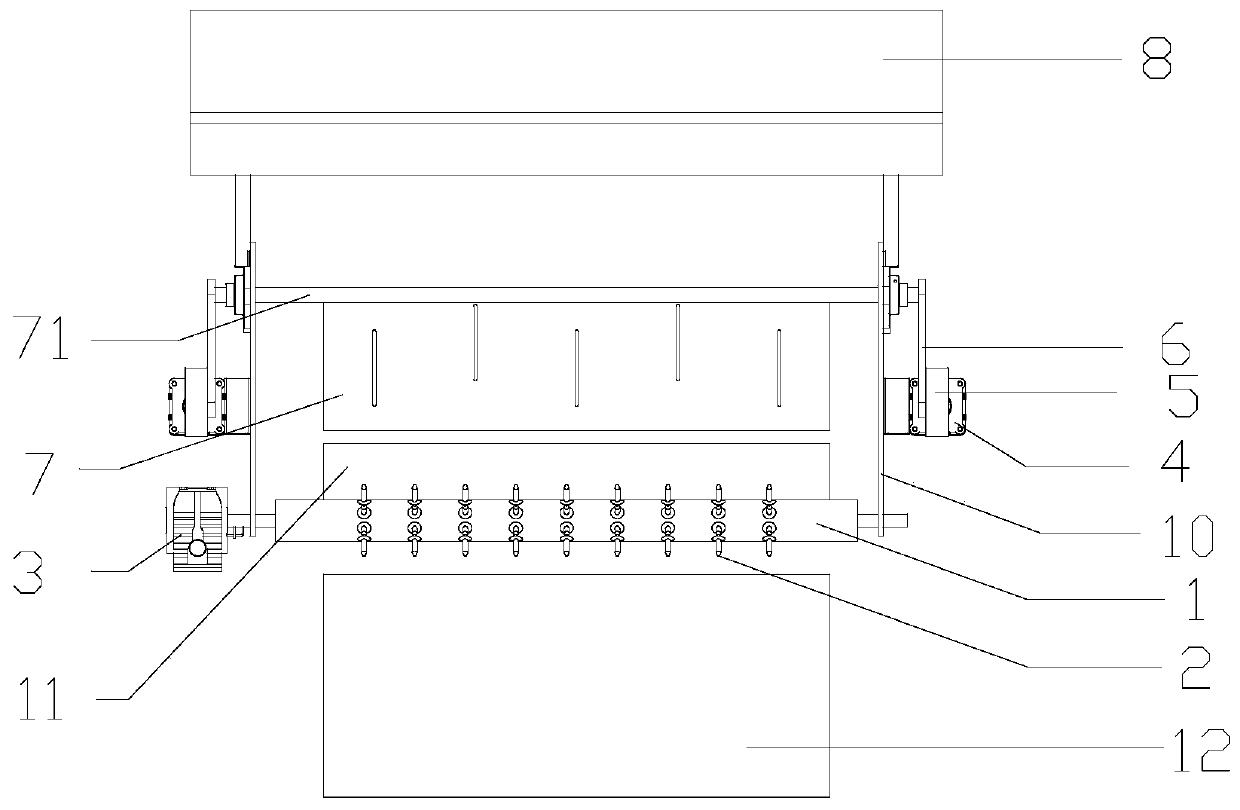

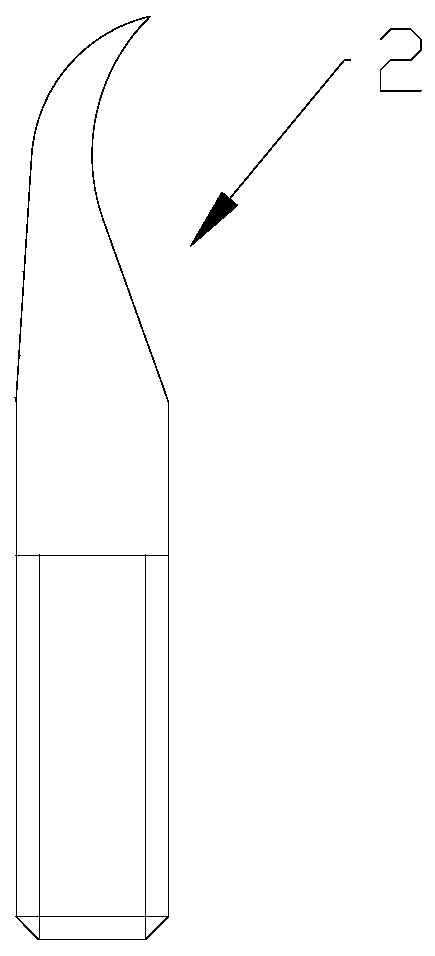

The invention discloses a continuous type pad printing and coding device. The continuous type pad printing and coding device comprises a workbench, a PLC controller and a pad printing machine. The continuous type pad printing and coding device further comprises a laser coding machine, a conveying component and a drying component. The conveying component comprises a motor, a transmission case, a main chain wheel, a chain and an auxiliary chain wheel. The chain is fixedly provided with multiple fixing seats. Locating blocks are connected to the fixing seats. Brackets are connected to the locating blocks, and the brackets are provided with mold grooves. The side wall of the transmission case is provided with a pad printing locating piece and a coding locating piece. Each locating block is provided with a left groove and a right groove. One end of the transmission case is provided with an infrared sensor. A motor shaft of the motor is sleeved with a wheel disk. Three sensing columns are distributed on the wheel disk. The infrared sensor, the pad printing machine and the laser coding machine are electrically connected with the PLC controller. The continuous type pad printing and coding device conducts continuous pad printing and coding operations on printed objects on a large scale and greatly improves the production efficiency; and pad printing and coding are clearer, the precision is high, the manufactured products are free from fading after being used for a long time and high in recognition capacity.

Owner:CHENGDU OJA AIRCRAFT CABIN EQUIP

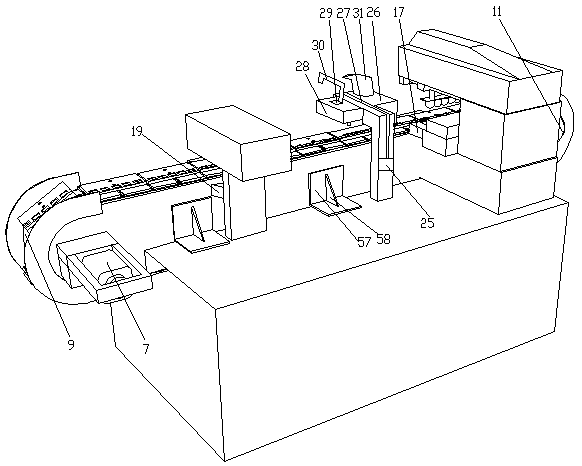

Continuous transfer-printing coding method

ActiveCN106379042AClear outlineSqueegee steps increaseRotary pressesPrinting press partsContinuous operationLaser

The invention discloses a continuous transfer-printing coding method. The continuous transfer-printing coding method comprises the following steps: step (a) inking an etching plate by using a sealed oil cup of a transfer-printing coding device; step (b) forwards pushing a rubber head of a transfer printing machine to the upper portion of the etching plate, subsequently driving the rubber head to move down to have contact with the etching plate, and downwards pressing the rubber head to make the rubber head be stained with ink with patterns; step (c) backwards pushing the rubber head to a transfer printing work position, and then driving the rubber head to be pressed downwards so that the rubber head is capable of printing the ink with patterns on a to-be-printed object inside a mold groove; step (d) moving the transfer-printed object to a drying work position for drying by using a conveying component; step (e) moving the transfer-printed and dried object to a coding work position and coding the transfer-printed and dried object by using a laser coding machine. The continuous transfer-printing coding method disclosed by the invention is capable of realizing continuous operation on large-batch to-be-printed objects and improving the production efficiency; the patterns are clearer after the printed objects are dried at the drying work position; a coded product is high in exquisite degree and is fadeless after being used for a long time.

Owner:CHENGDU OJA AIRCRAFT CABIN EQUIP

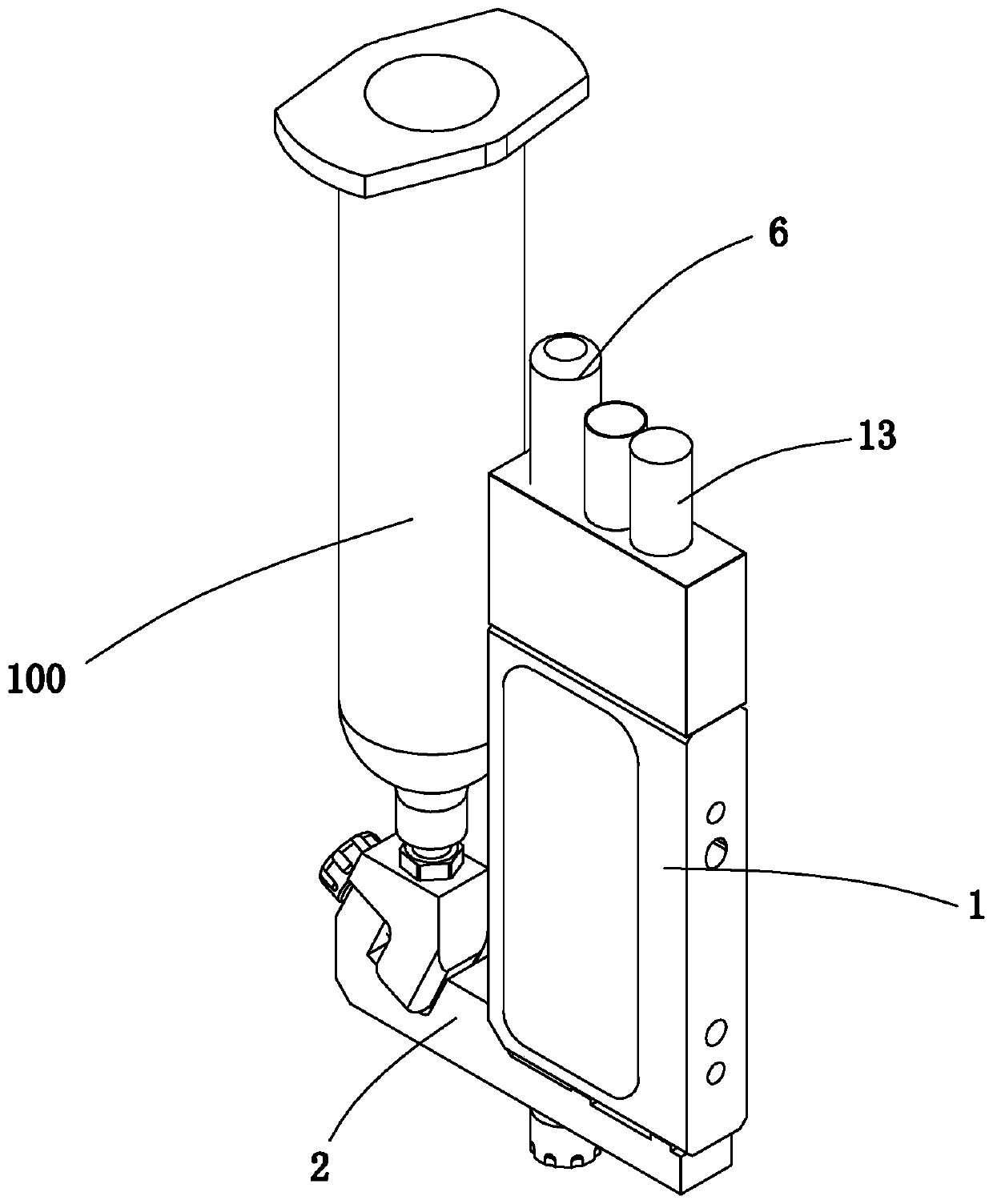

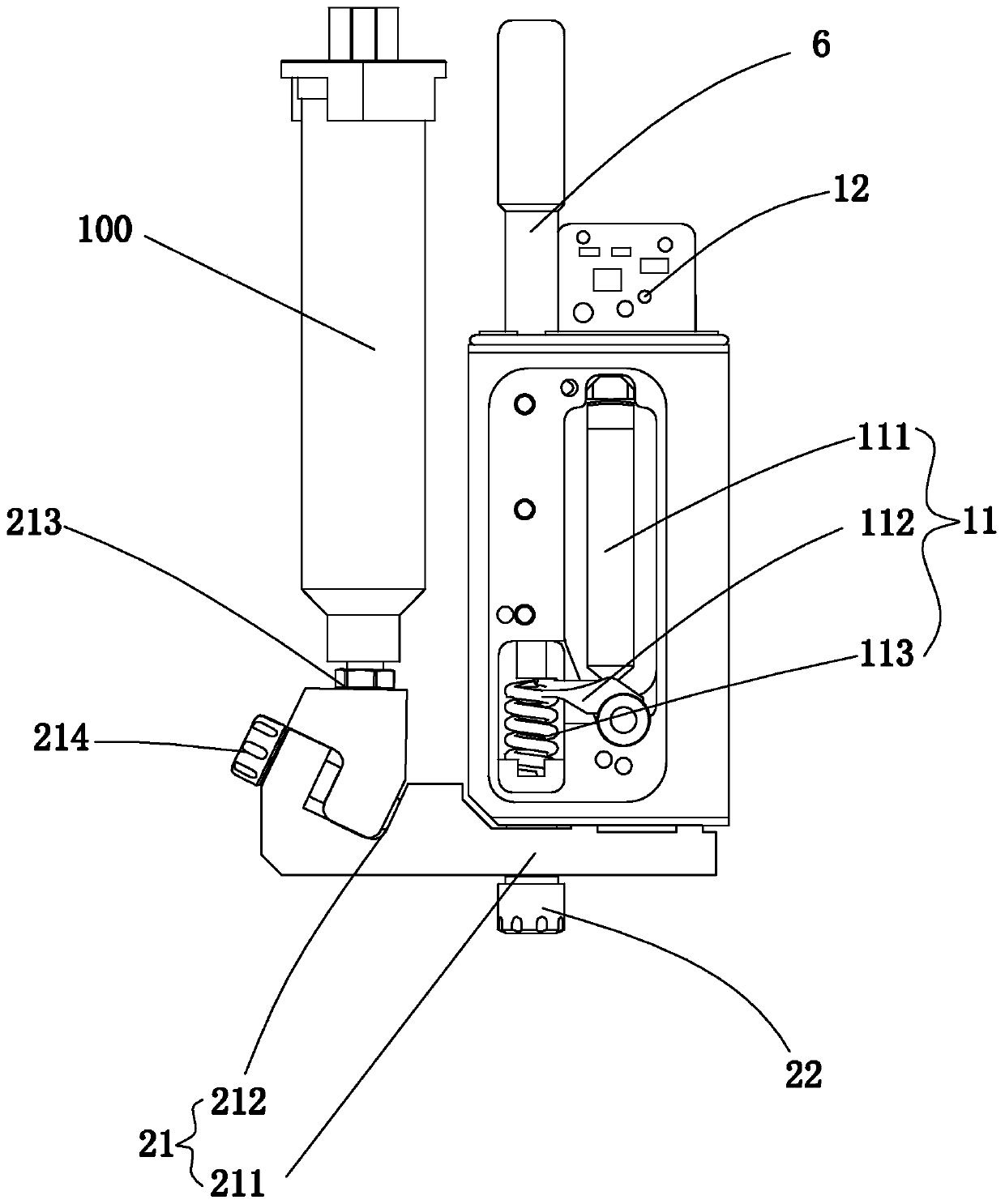

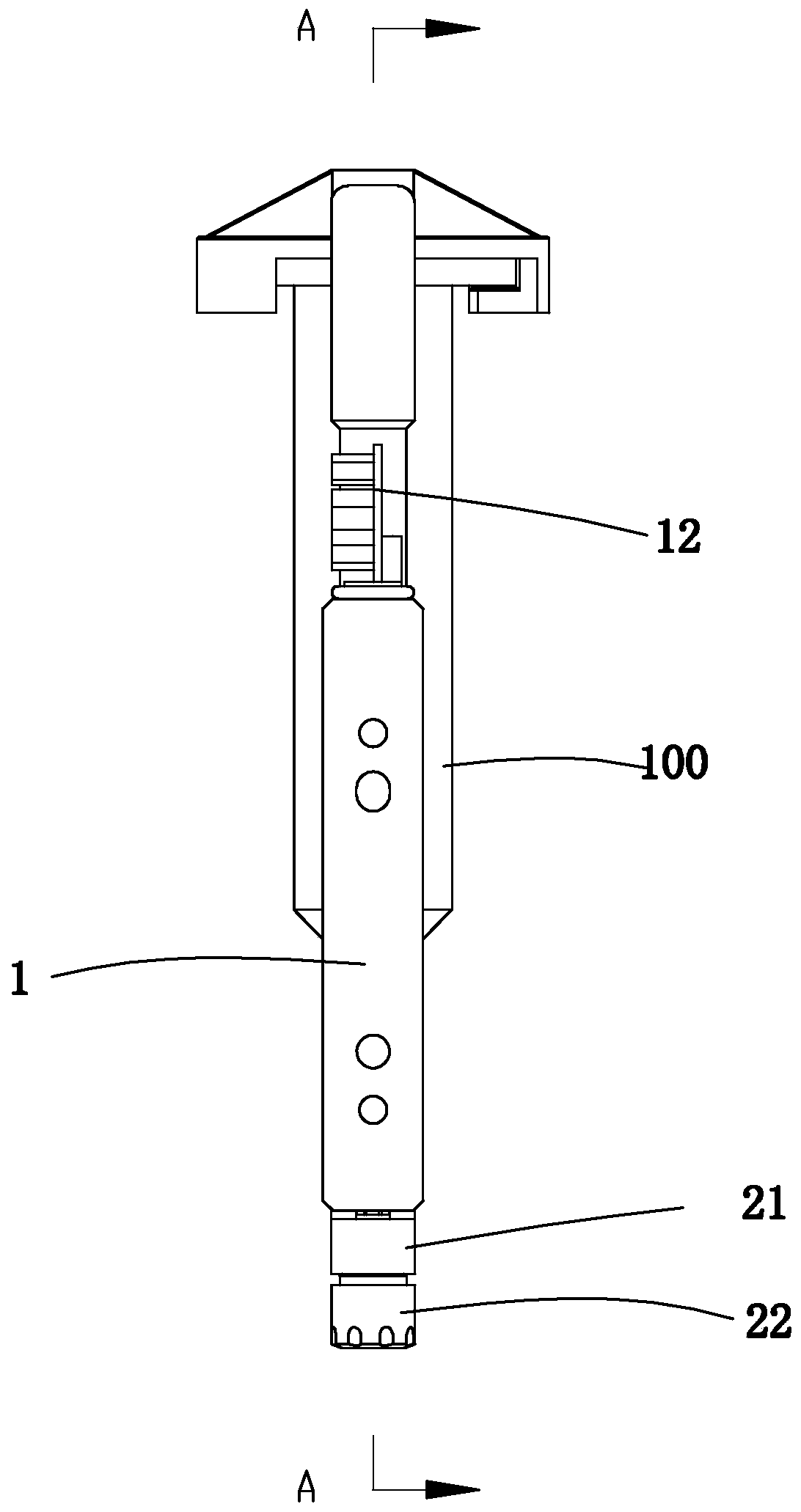

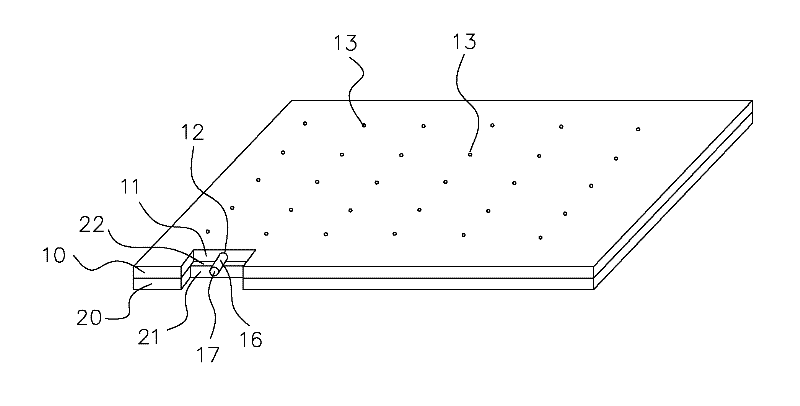

Piezoelectric jet valve

PendingCN109967305AExtended service lifeGuaranteed production continuityLiquid surface applicatorsCoatingsSpray nozzleValve seat

The invention relates to a piezoelectric jet valve comprising a valve body, a valve seat and a firing pin. The valve body and the valve seat are detachably fixed together. A piezoelectric drive mechanism is arranged in the valve body. The valve seat comprises a valve seat body and a spray nozzle. A liquid storage cavity located above the spray nozzle is arranged in the valve seat body. The firingpin is installed in the valve body through the firing pin installation seat. The upper end of the firing pin is connected with the piezoelectric drive mechanism. The lower end of the firing pin is matched with the spray nozzle. The opening, facing the liquid storage cavity, of the firing pin installation seat is provided with a spring seal. The spring seal comprises an annular body and an elasticpiece. The spring seal is characterized by further comprising a seal ring. The seal ring seals the elastic piece into the annular body. By changing the structure of the spring seal, the service life of the piezoelectric jet valve can be greatly prolonged, production continuity is guaranteed, and production and maintenance cost is lowered.

Owner:XIAMEN WEISHENGBANG NETWORK SCI & TECH CO LTD

Soundproof-cotton gluing machine application method

ActiveCN104722450AImprove uniformityQuality improvementLiquid surface applicatorsCoatingsAdhesive glueLeather belt

The invention discloses a soundproof-cotton gluing machine application method and belongs to the technical field of gluing machines. The soundproof-cotton gluing machine application method includes the steps of 1), equipment starting, namely respectively starting a gluing mechanism, a glue discharging mechanism, a recycling mechanism and a belt conveying mechanism on a soundproof-cotton gluing machine; 2), gluing, namely allowing glue flowing out from a glue discharging device to flow down along a gap between a gluing roller and a glue mixing roller and a to-be-glued rubber skin to be driven by the gluing roller to move sequentially in gaps of between a glue applying roller and the glue roller as well as between the glue applying roller and the glue mixing roller for gluing; 3), gluing completion, namely allowing the rubber skin coated with the glue to be conveyed to the tail portion of a conveying platform through a conveying belt, wherein the lower surface of the rubber skin is in friction contact with the upper surface of a cushion block, movement speed of the rubber skin is reduced, the rubber skin is taken away by workers, and gluing is completed. With the method, problems that gluing is uneven, waste glue cannot be effectively recycled and the like are solved.

Owner:河北蓝格隔音材料有限公司

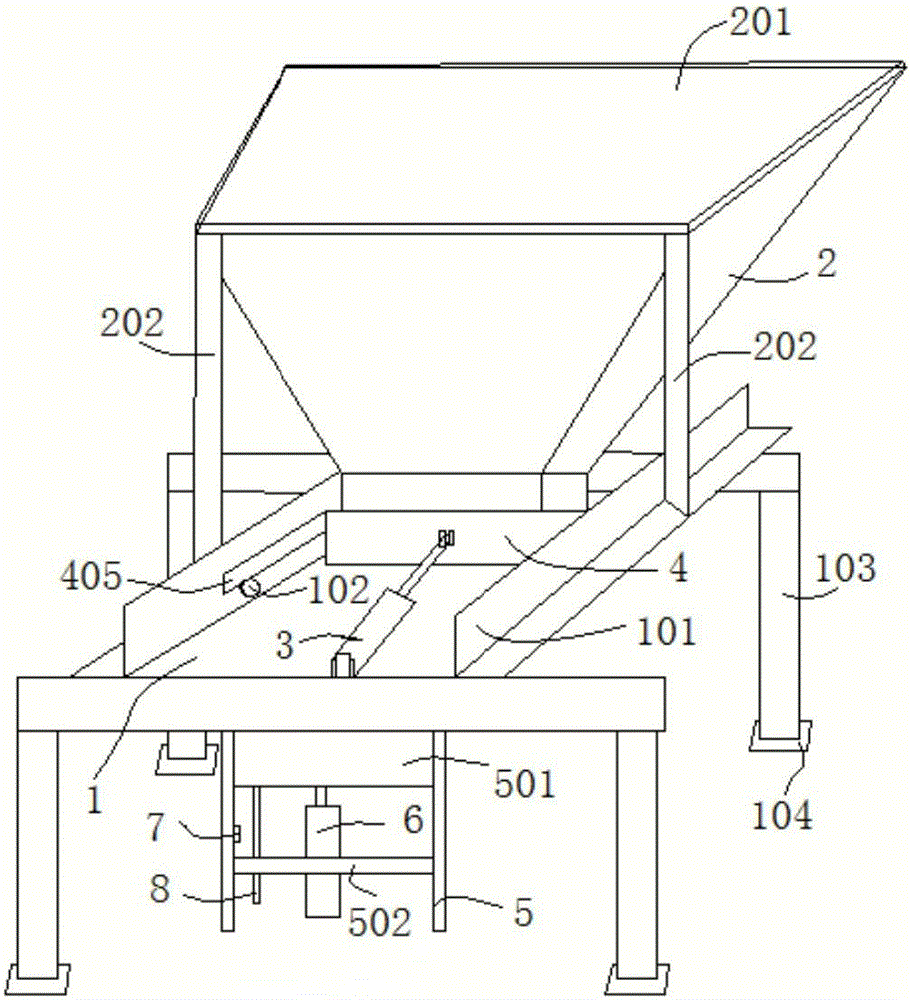

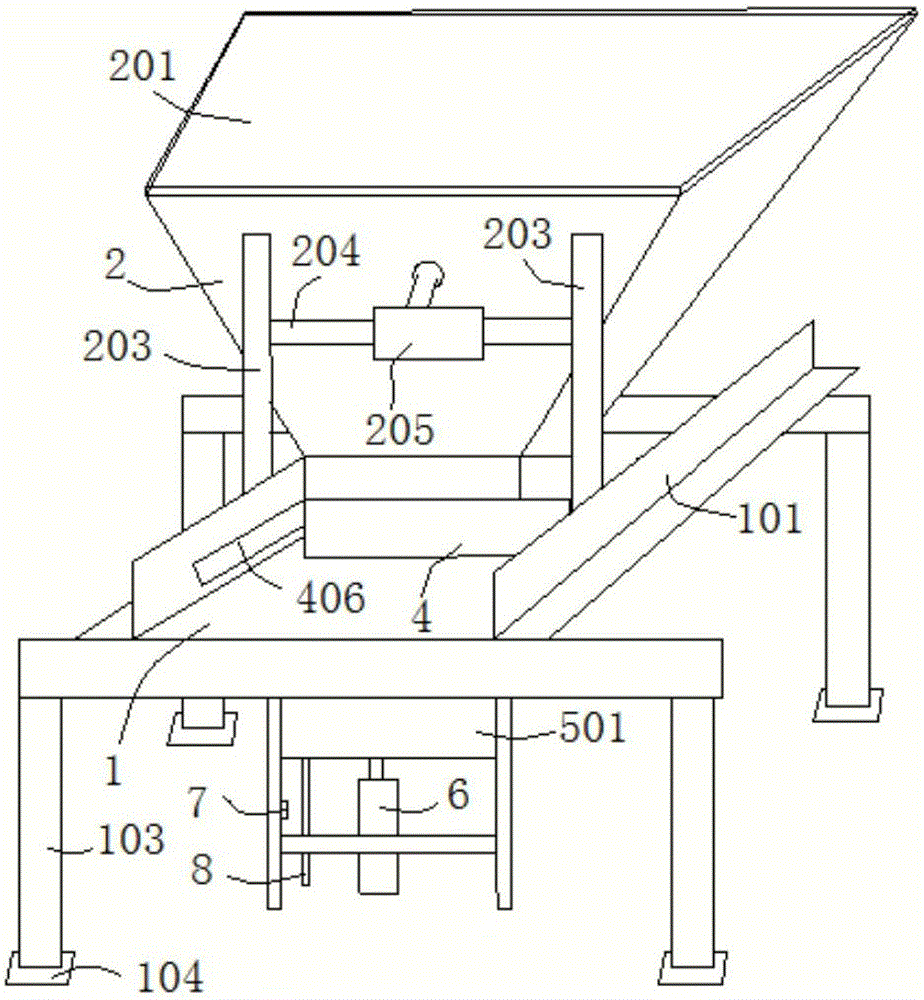

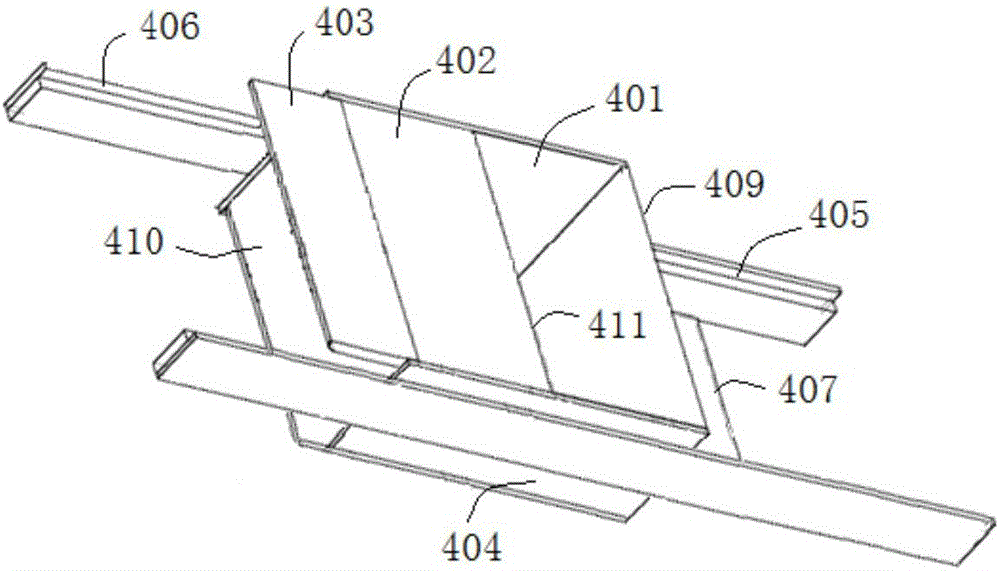

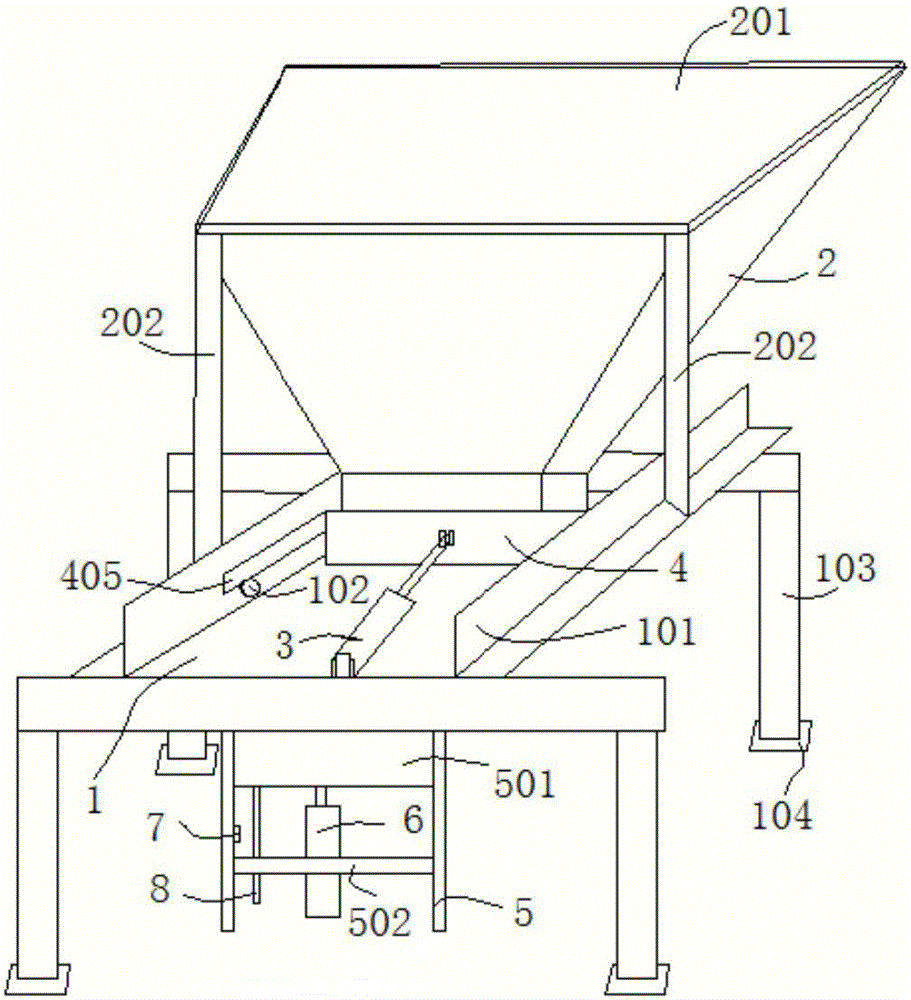

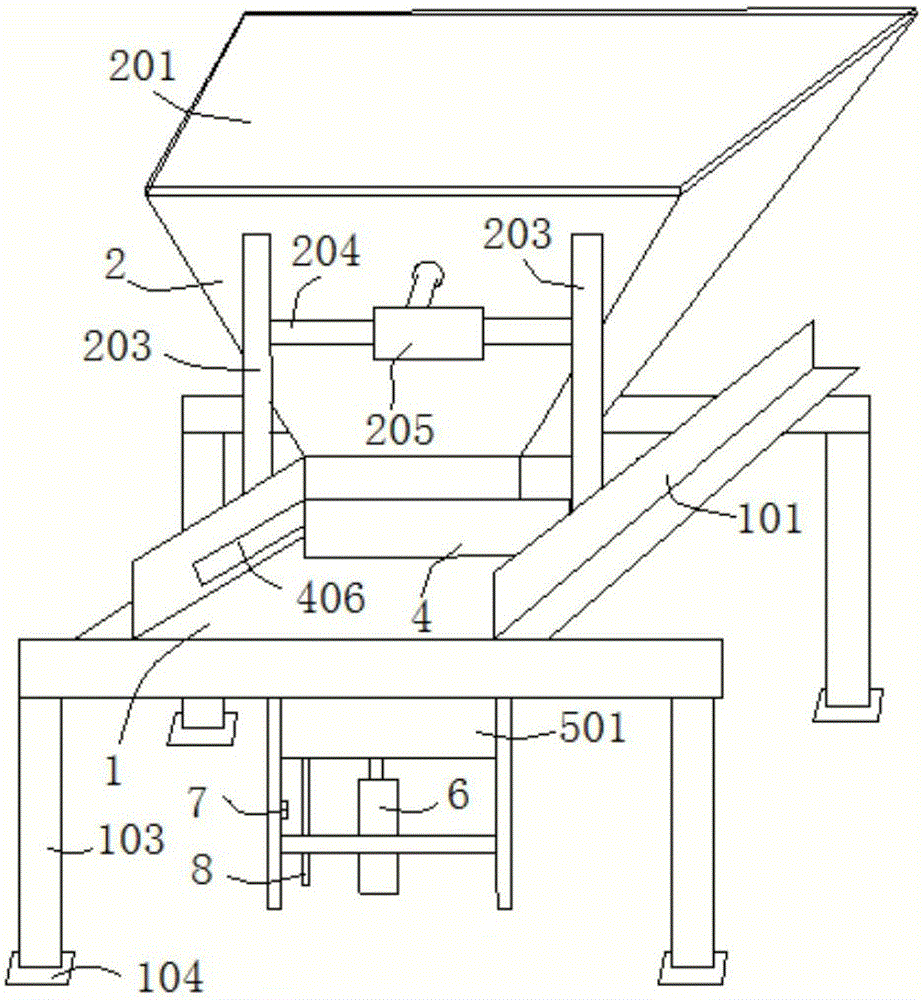

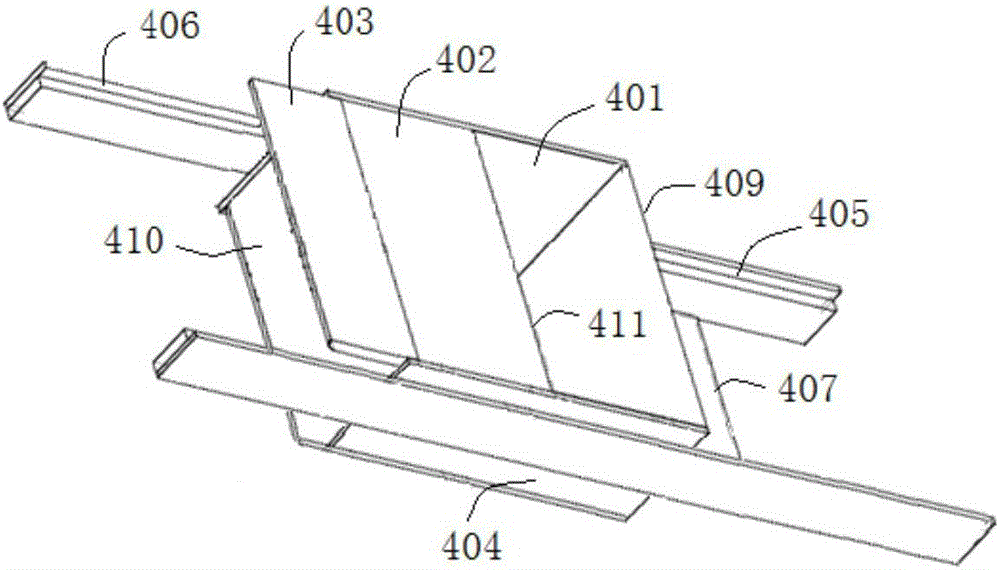

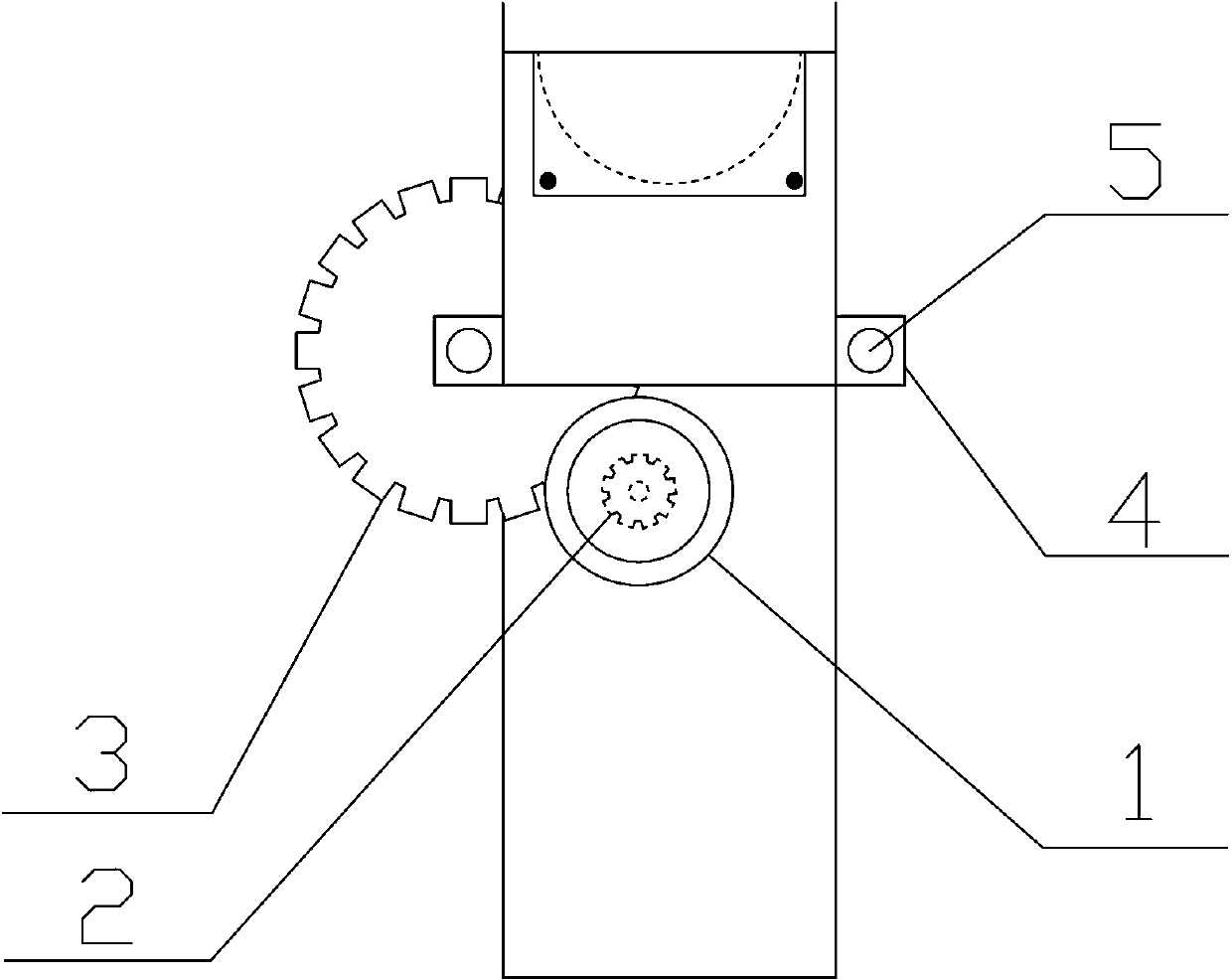

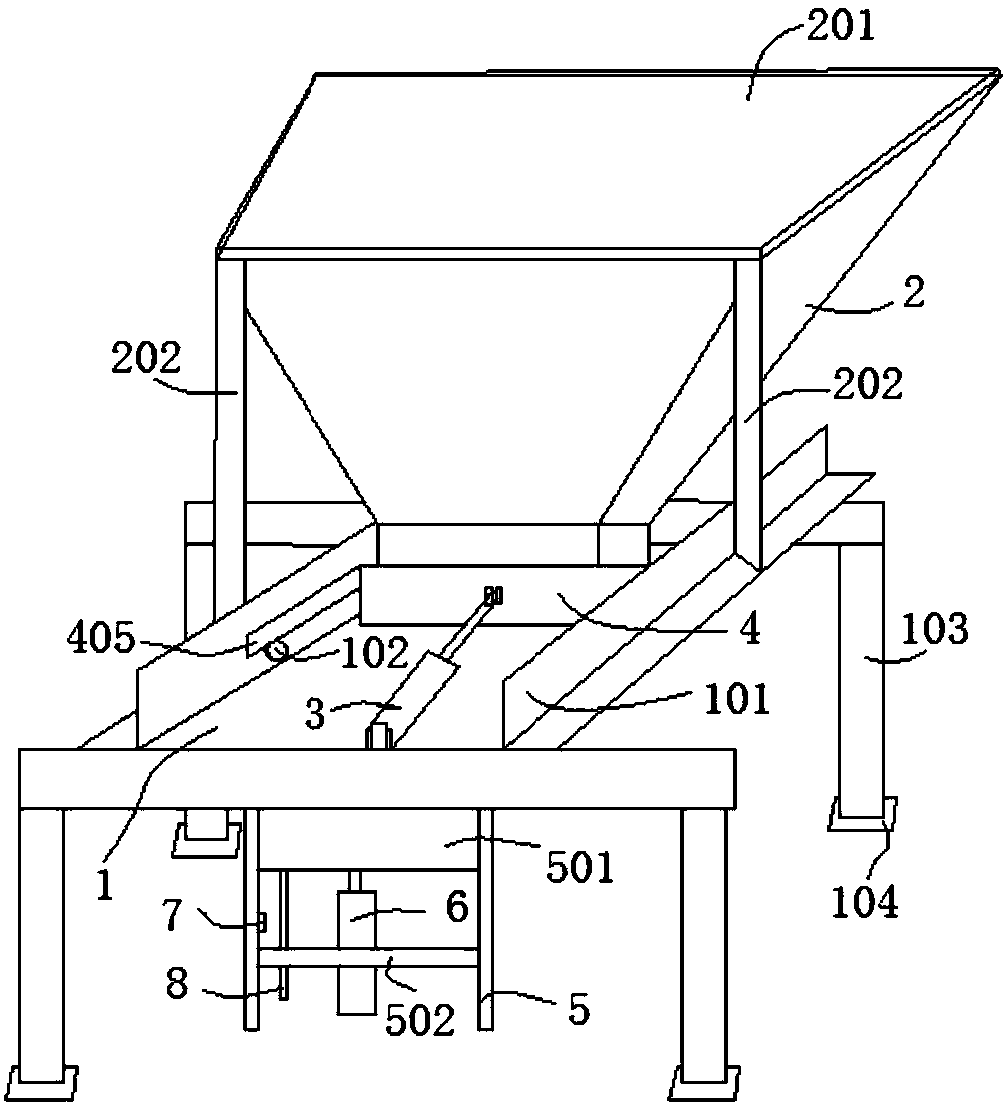

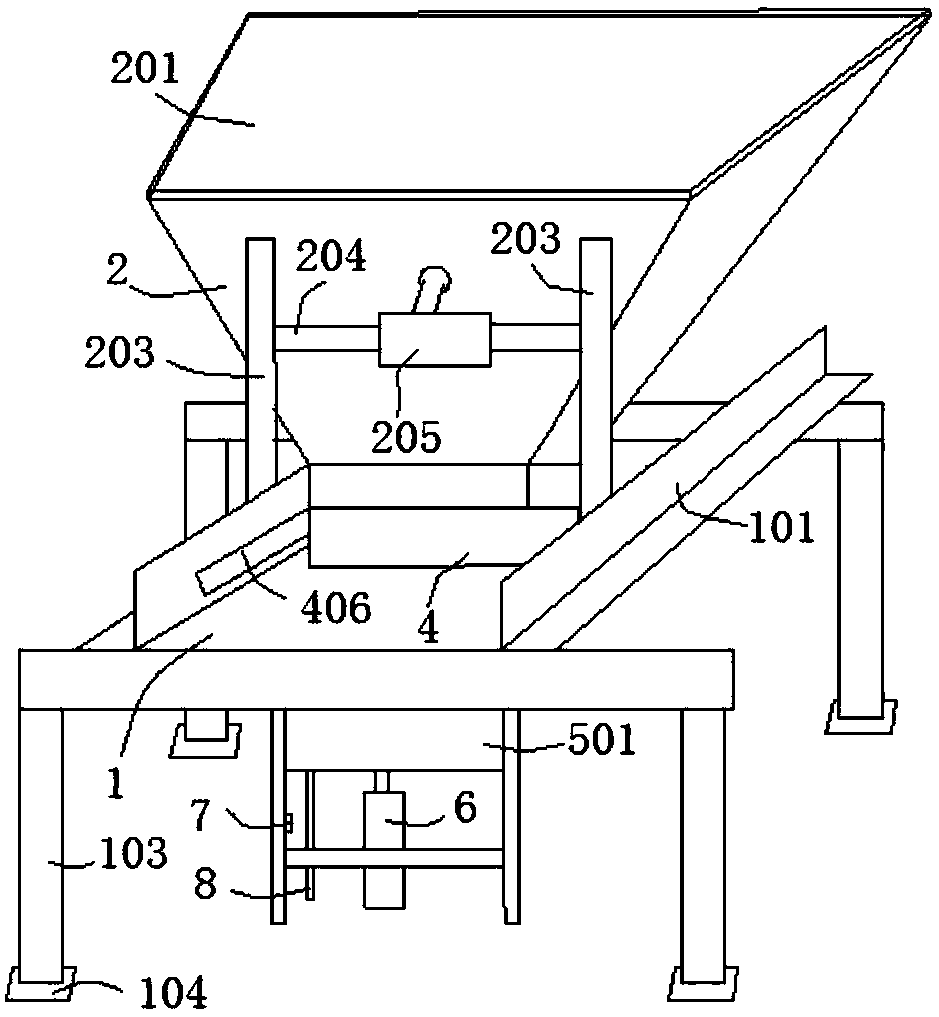

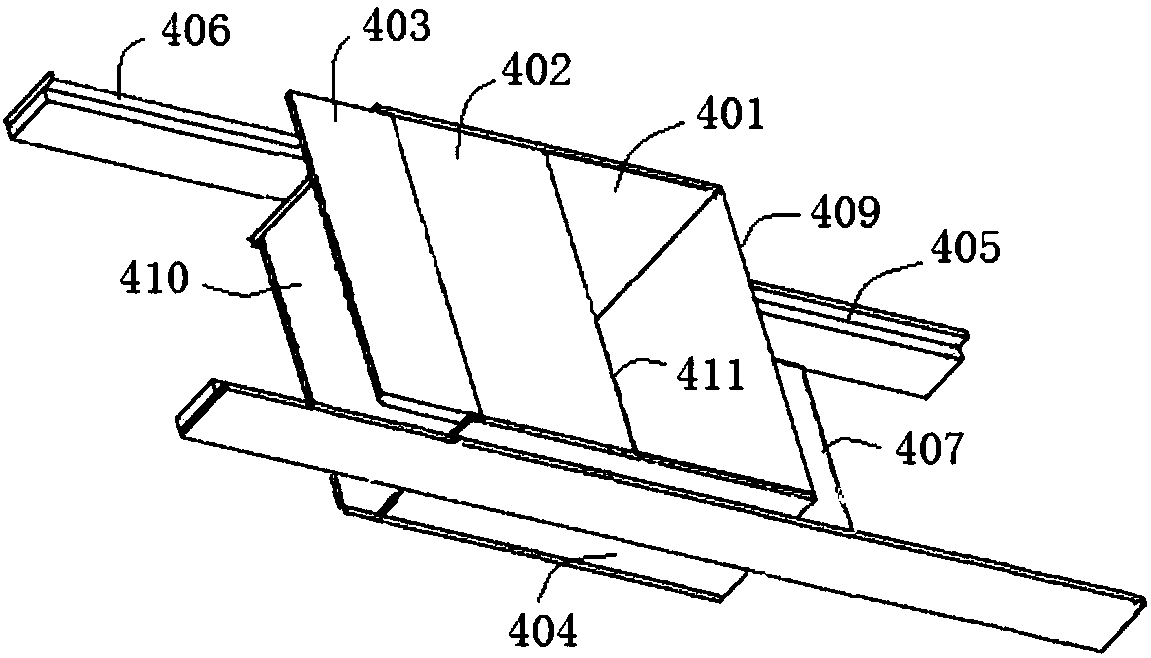

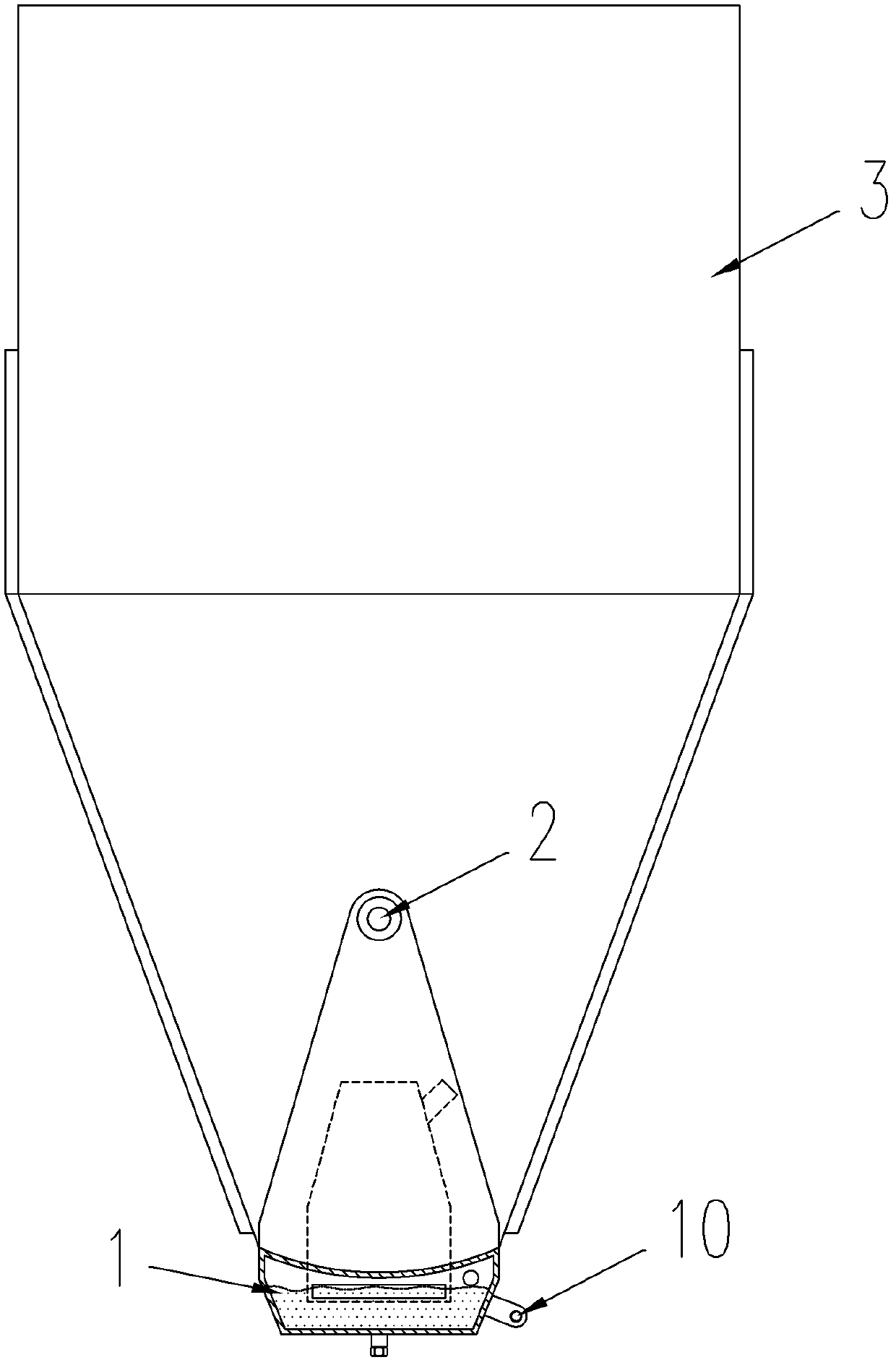

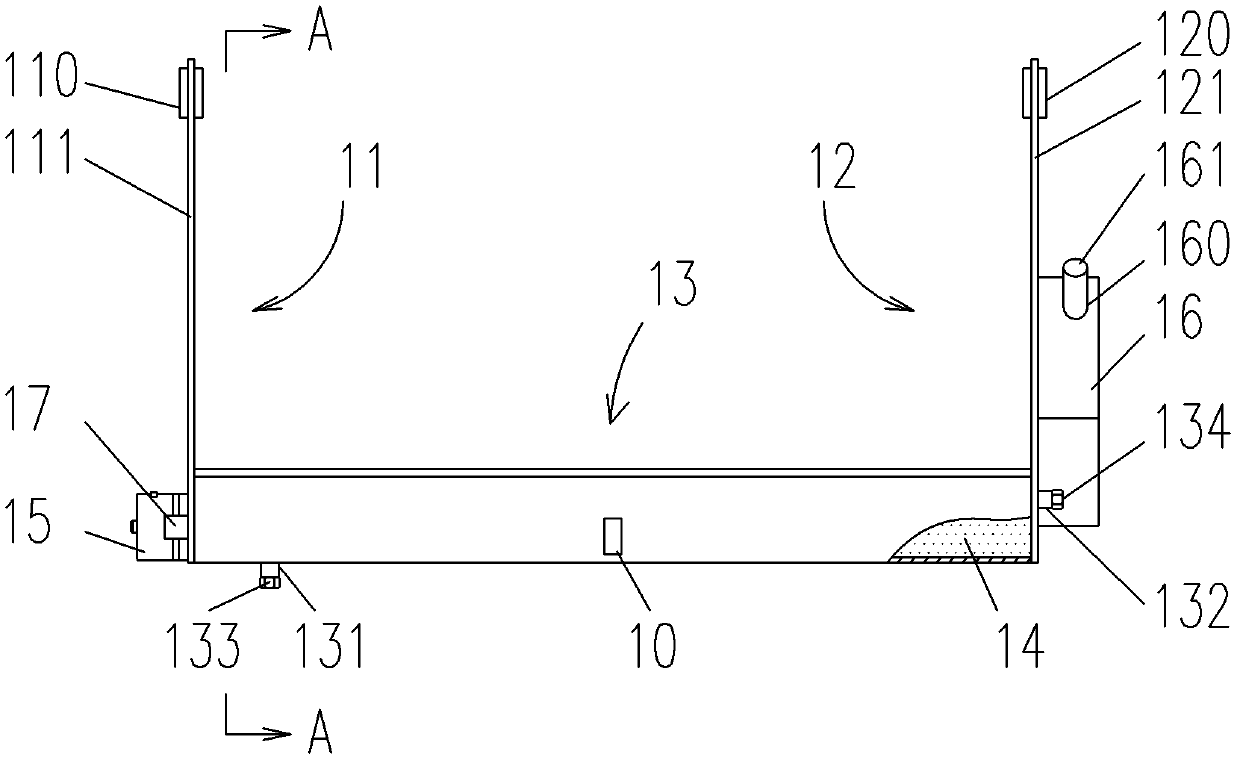

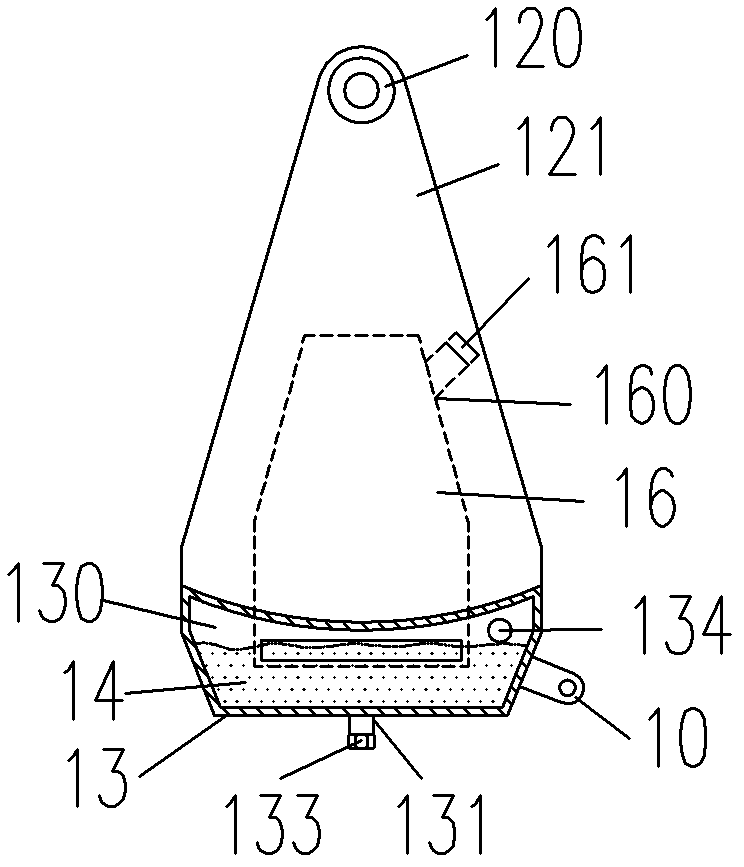

Automatic forming device for producing baking-free bricks

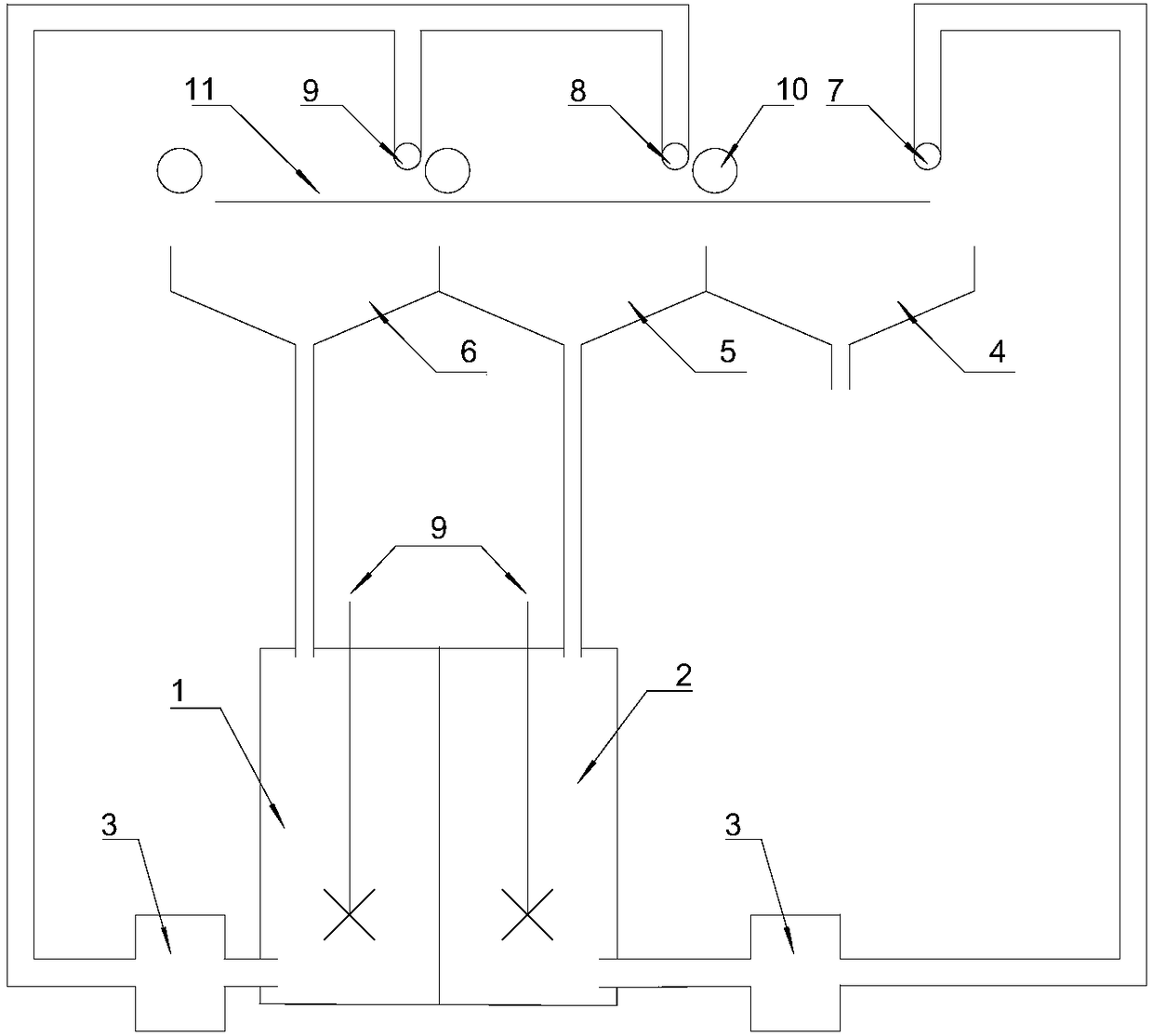

ActiveCN106313297AAchieve automationRealize continuous productionDischarging arrangementFeeding arrangmentsHydraulic cylinderBrick

The invention discloses an automatic forming device for producing baking-free bricks, and belongs to the field of brick making machines. The automatic forming device comprises a frame, a blanking opening is formed in the frame, a forming material pushing mechanism is arranged above the blanking opening and connected with a first hydraulic cylinder, a forming mechanism is arranged below the blanking opening and connected with a second hydraulic cylinder, raw materials penetrate the forming material pushing mechanism, enters the forming mechanism and squeezed into bricks by the second hydraulic cylinder, the bricks are pushed onto the frame by the second hydraulic cylinder, and the first hydraulic cylinder drives the forming material pushing mechanism, so that the bricks are pushed onto a delivery mechanism and conveyed. The automatic forming device helps to solve the problems of complicated structure and cumbersome production process of an existing brick making machine, the bricks can be continuously squeezed and formed, production efficiency is improved, the automatic forming device is simple in structure and low in machining cost, and productive benefits of enterprises can be improved.

Owner:ANHUI LINGFENG METALLURGICAL MACHINERY

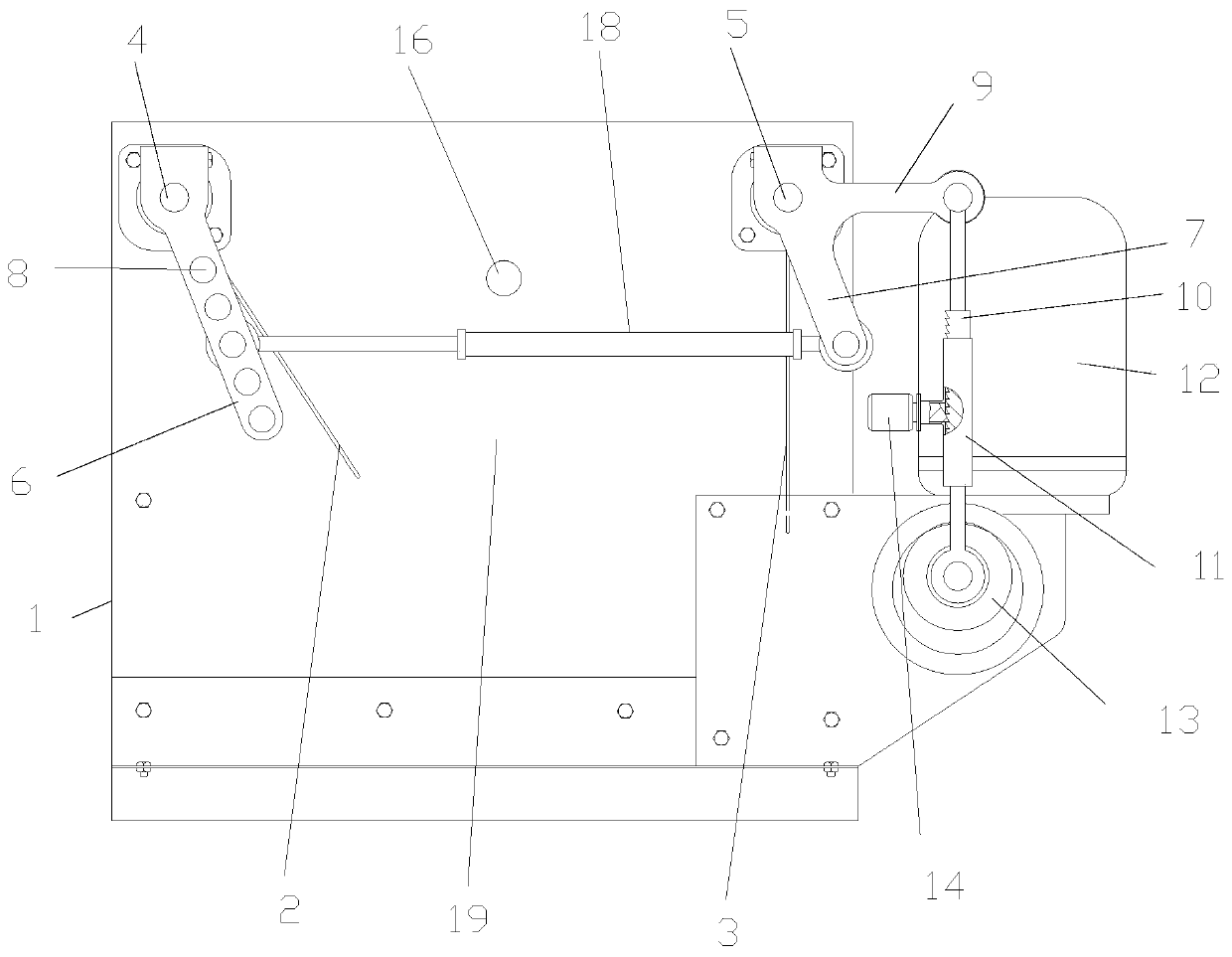

Transfer printing and coding equipment

ActiveCN106364151AEasy to clamp and positionGood pauseRotary pressesPrinting press partsElectricityFinesse

The invention discloses transfer printing and coding equipment which comprises a workbench, a PLC and a transfer printer, and further comprises a laser coding machine and a conveying component. The conveying component comprises a motor, a transmission case, a main chain wheel, a chain and an auxiliary chain wheel. Multiple fixing bases are fixed to the chain and connected with positioning blocks. A bracket is connected to the positioning blocks and provided with die grooves. The side wall of the transmission case is provided with a transfer printing positioning part. One end of the transmission case is provided with an infrared sensor. A motor shaft of the motor is sleeved with a wheel disc. Three sensing columns are distributed on the wheel disc. The infrared sensor, the transfer printer and the laser coding machine are electrically connected with the PLC. By means of organic combination of transfer printing and coding, continuous transfer printing and coding operation of large batches of printed products is achieved, the production efficiency is greatly improved, transfer printing and coding are clearer, and the finesses degree is higher.

Owner:CHENGDU OJA AIRCRAFT CABIN EQUIP

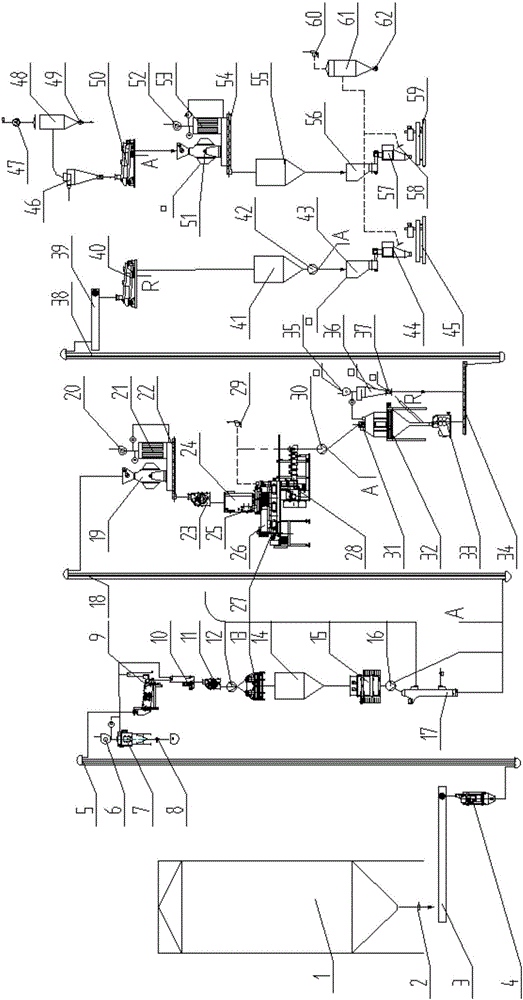

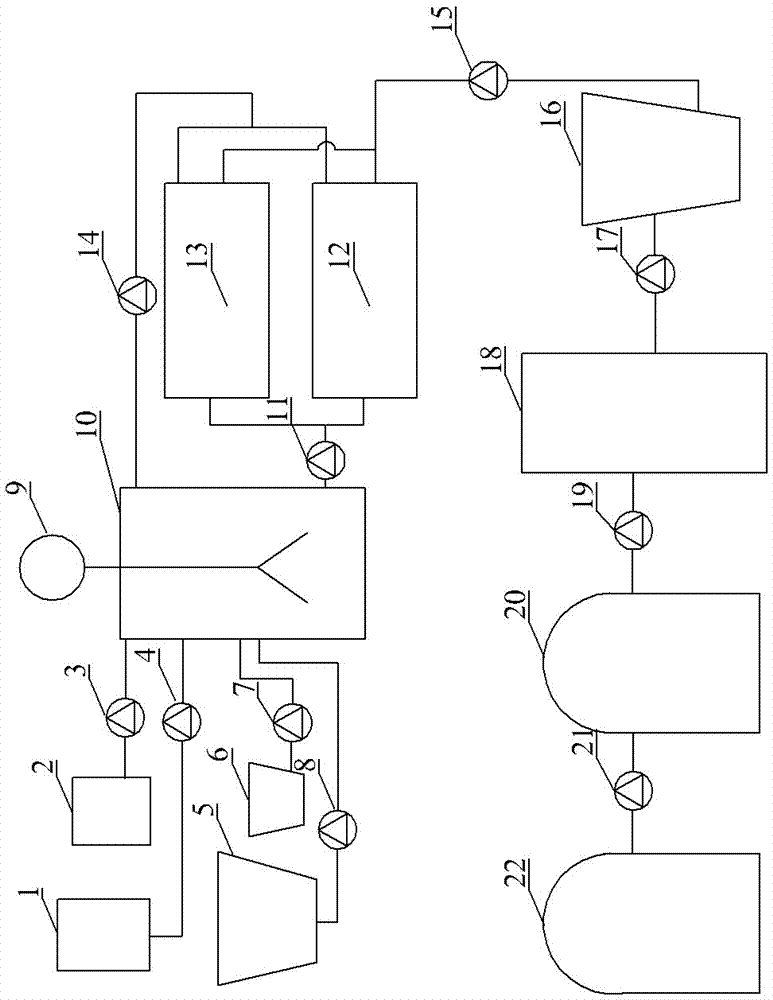

Full-fat extruded soybean production device and production technology

The invention discloses a full-fat extruded soybean production device and a production technology. The full-fat extruded soybean production device comprises a bulk bin, an impurity removal working section, a first crusher and a second tee, wherein a material outlet of the second tee is connected with a peel suction device for removing soybean peels, and another material outlet of the second tee is connected with the first crusher; an arch breaking feeding bin is connected with a tempering device; the material outlet end of the tempering device is connected with an extruding machine; the material outlet end of the extruding machine is connected with a cooler; the material outlet end of the cooler is connected with a second crusher; another material outlet of a third tee is connected with the first crusher; the material outlet end of the second crusher is connected with a first rotary vibration grading sieve; the first rotary vibration grading sieve is connected with a first packaging device. The full-fat extruded soybean production device has the advantages that soybeans are firstly broken and then crushed, so that the productivity of the first crusher is increased, the abrasion of a hammer blade is reduced, and the crushing effect is improved; the peel suction device is used for separating soybean peels from soybean halves, so that the quality of a finished extruded soybean product is mainly improved.

Owner:江苏丰尚油脂工程技术有限公司

Processing method for baking-free brick extrusion forming

ActiveCN106626003AAchieve automationRealize continuous productionDischarging arrangementFeeding arrangmentsHydraulic cylinderBrick

The invention discloses a processing method for baking-free brick extrusion forming and belongs to the technical field of brick making. By means of a continuous hydraulic brick making system, the processing method includes the following steps of feeding, wherein raw materials are added into a feeding hopper, penetrate through a feeding cavity and a feeding opening and enter a forming cavity; extrusion forming of the raw materials, wherein a first hydraulic cylinder drives a forming and pushing mechanism to move, so that a buffer cavity moves to the position under the feeding hopper, a second hydraulic cylinder drives an extrusion plate to move upward in the forming cavity, and the raw materials are extruded into bricks; pushing and conveying of the bricks, the first hydraulic cylinder drives the forming and pushing mechanism to move, and the second hydraulic cylinder drives the extrusion plate to push the bricks to a machine frame, and the first hydraulic cylinder drives the forming and pushing mechanism to push out the bricks. The defects that in the prior art, the brick continuous production degree is low and production efficiency is low are overcome easily, continuous extrusion forming of the bricks can be achieved, production efficiency is effectively improved, the operation process is simple, and the production cost is low.

Owner:ANHUI LINGFENG METALLURGICAL MACHINERY

Domestic sludge aerobic composting method and system thereof

PendingCN107089847AOptimizing dosageGuaranteed unobstructedBio-organic fraction processingClimate change adaptationSludgeSlag

The invention provides a domestic sludge aerobic composting method, which can solve the technical problems that the existing aerobic composting method is long in one-time composting period, and poor in sludge reduction effect. The method comprises the following steps: I. adding a conditioning agent for hardening and tempering, and then performing deep dehydration treatment to obtain a mud cake; II. crashing the mud cake to obtain mud cake particles; and III. composting and fermenting the mud cake particles. The composting method is characterized in that the conditioning agent contains a curing agent and a filtering aid, the addition quantity of each of the curing agent and the filtering aid is 10%-30% of solid content of sludge; the curing agent contains the following raw materials in percentage by mass: 5% -15% of incineration furnace slag, 50%-70% of carbide slag, and 20% -35% of desulfurization plaster, and the filtering aid is a porous biomass material. In addition, the invention further provides a domestic sludge aerobic composting system for realizing the method.

Owner:WUXI GUOLIAN ENVIRONMENTAL SCI & TECH

Thermal insulation material transfer device for thermal insulation board production line

ActiveCN112025964AGuaranteed production continuityIncrease productivityCeramic shaping plantsAuxillary shaping apparatusProduction lineDrive wheel

The invention discloses a thermal insulation material transfer device for homogeneous board production. The device comprises a rack, wherein a fixing frame is arranged at the upper middle portion of the rack, a feeding tank is arranged above the left end of the fixing frame, and a discharging pipe is arranged at the bottom of the feeding tank; a limiting plate is arranged on the inner wall of theleft end of the fixing frame, and forming dies are arranged on the limiting plate in a sliding manner; and a feeding mechanism, wherein the feeding mechanism comprises a pair of driving wheels arranged on the outer side of the fixing frame, a chain is connected between the driving wheels, limiting holes are formed in the outer walls of the two sides of the fixing frame correspondingly, limiting columns are movably arranged in the limiting holes, and the limiting columns are arranged on the two sides of the forming dies. Feeding, steering and discharging of thermal insulation material formed bypressing can be integrated, the seamless butt joint of the thermal insulation materials and a next processing procedure is achieved, the production continuity is guaranteed, and the production efficiency is improved.

Owner:湖北美尔格电子股份有限公司

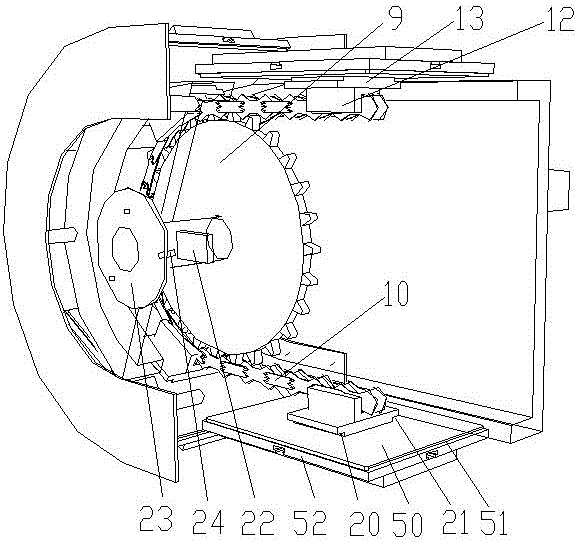

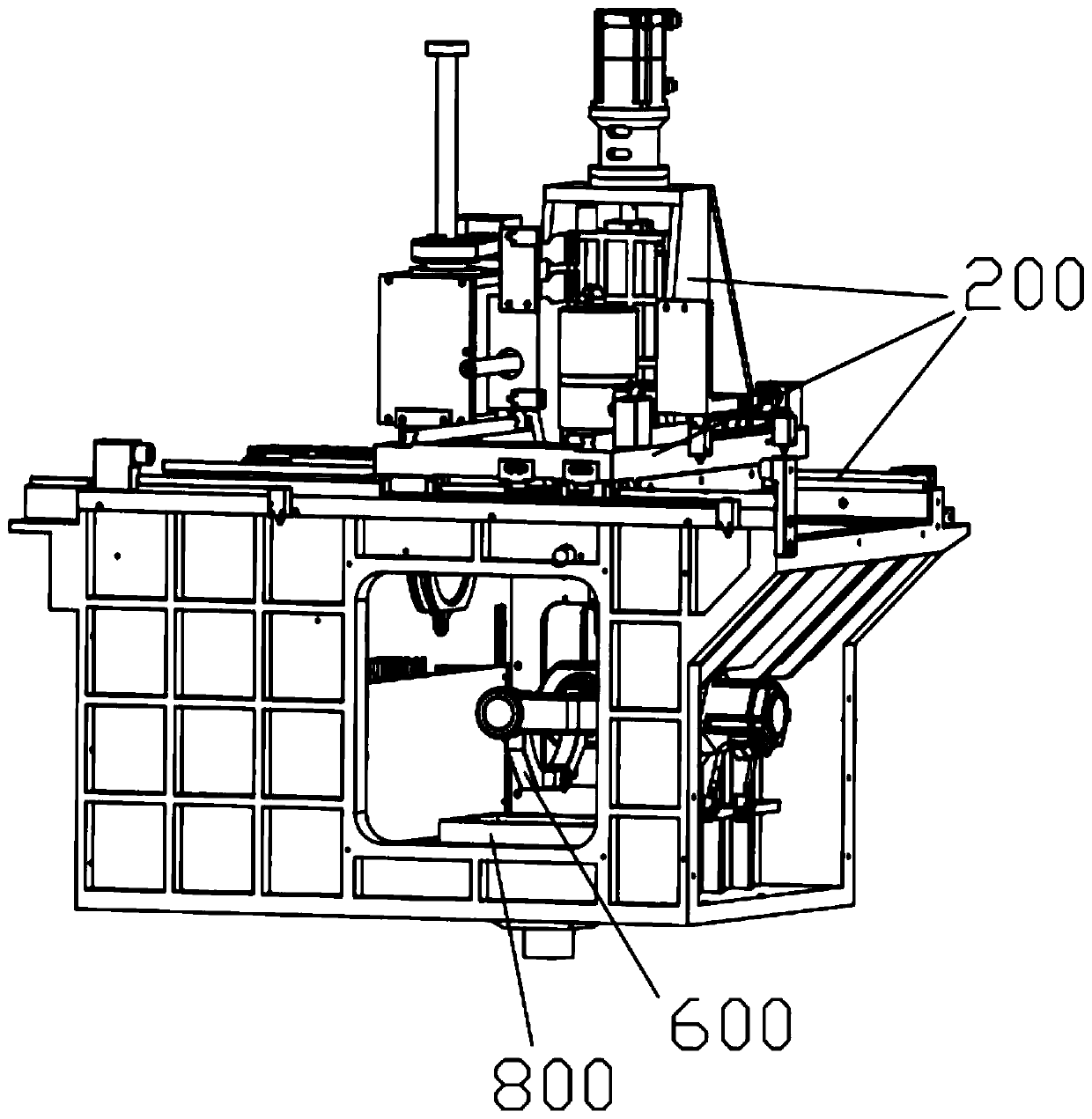

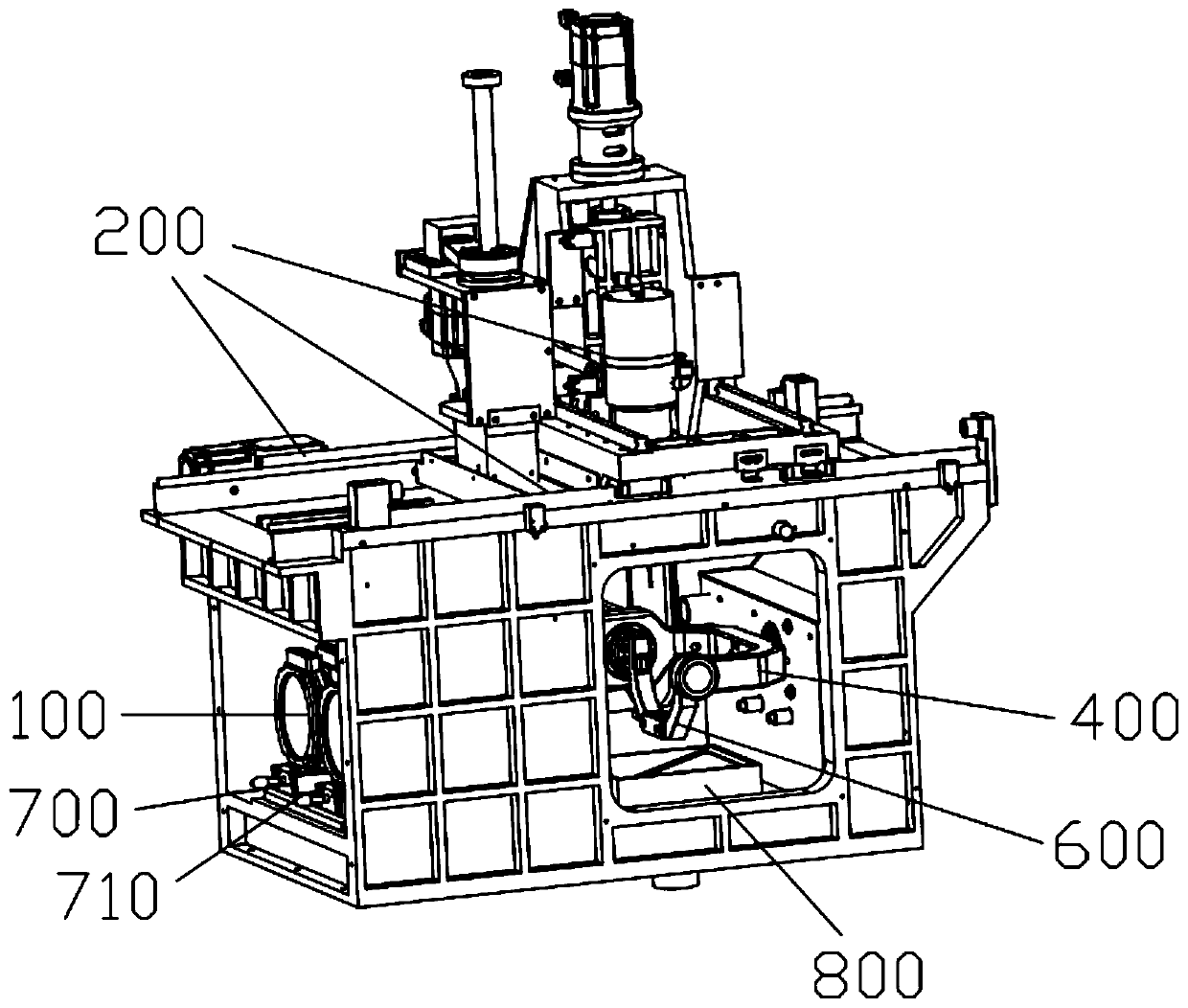

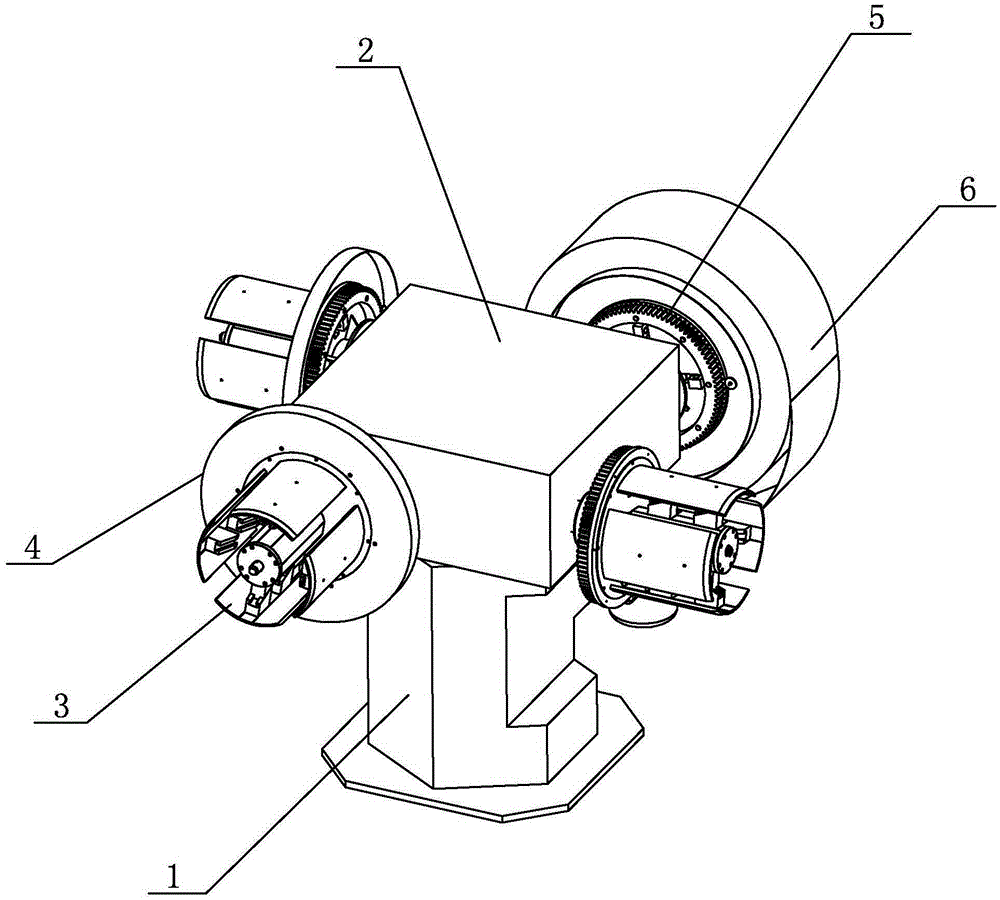

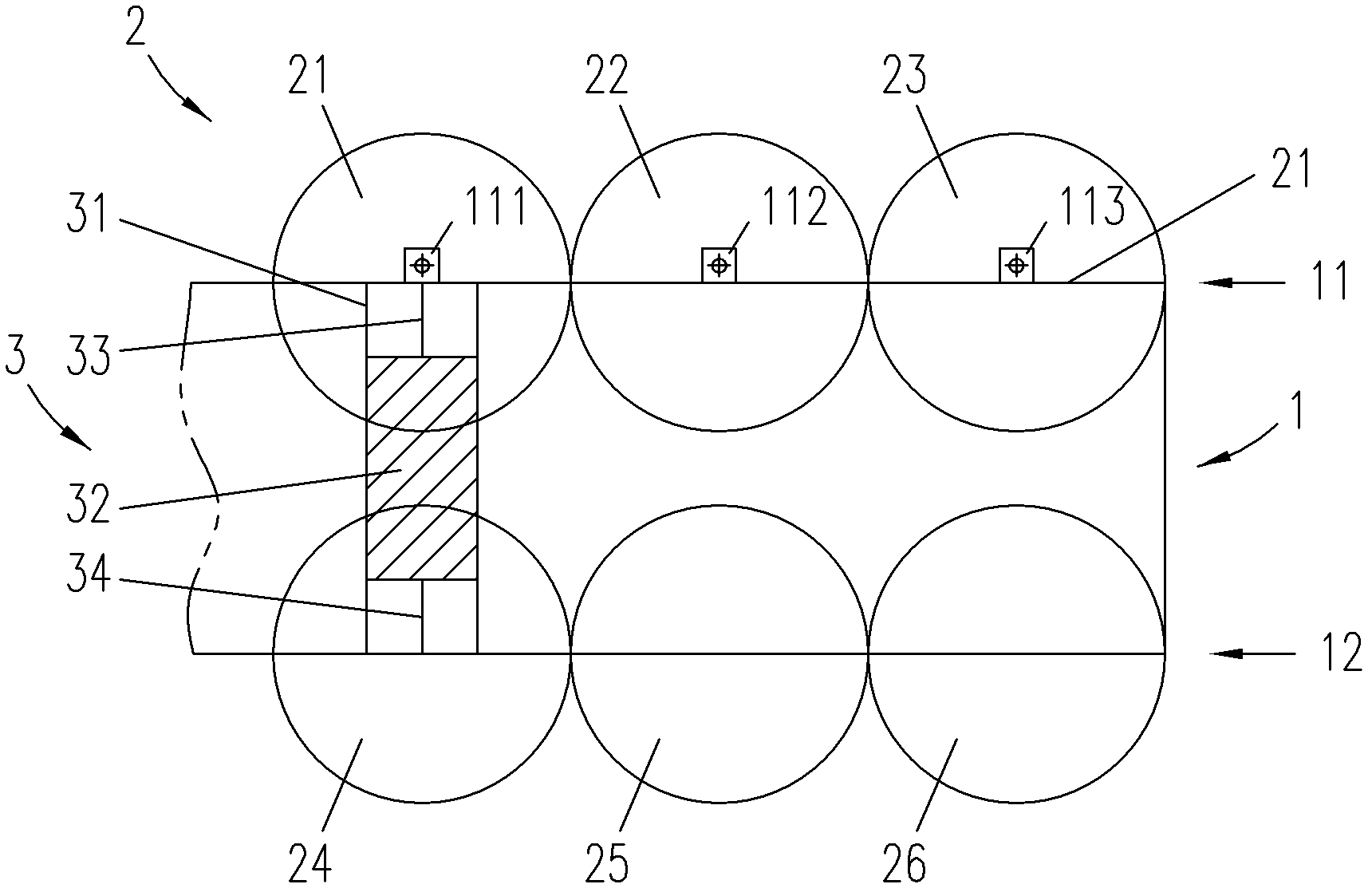

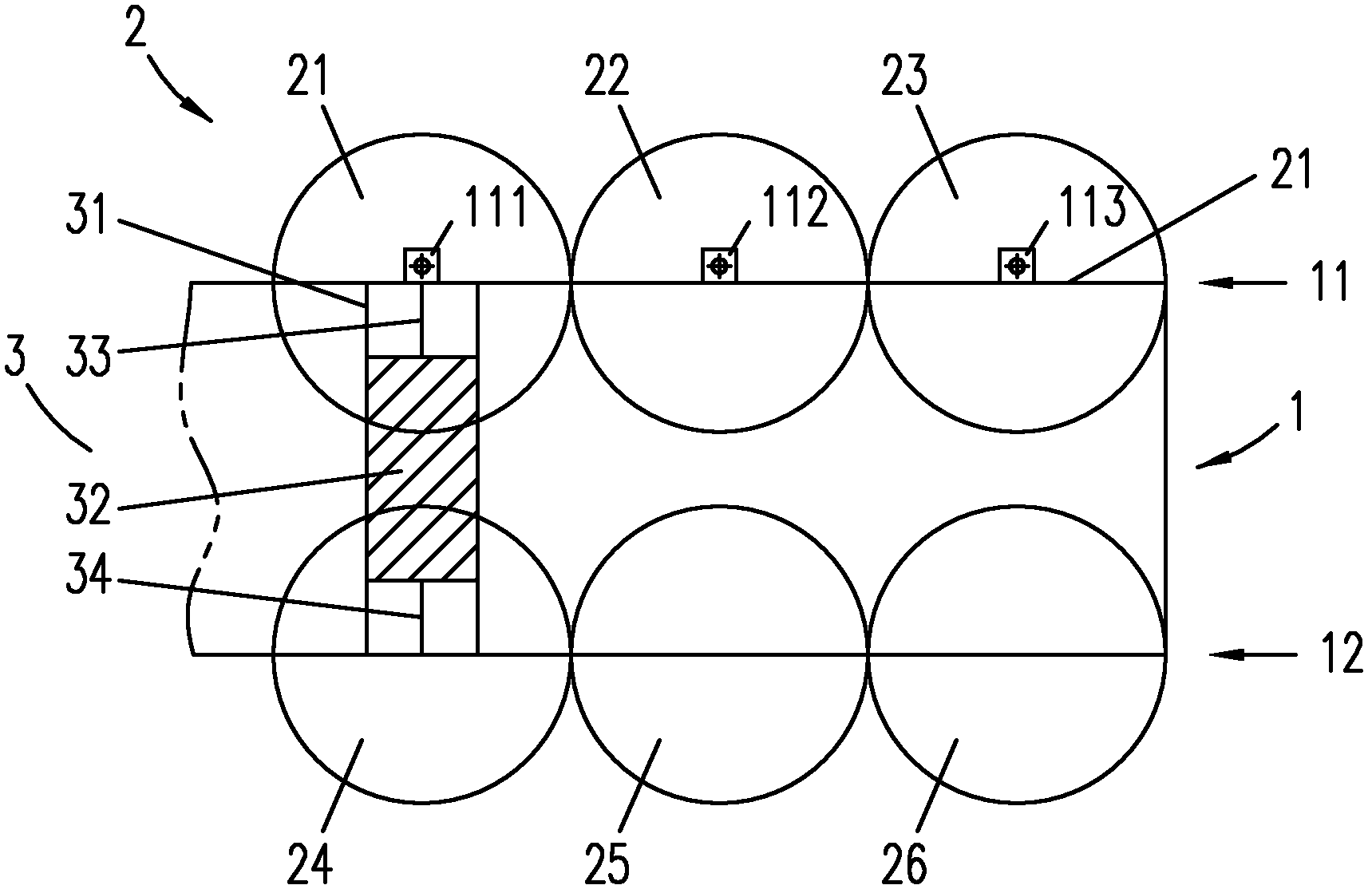

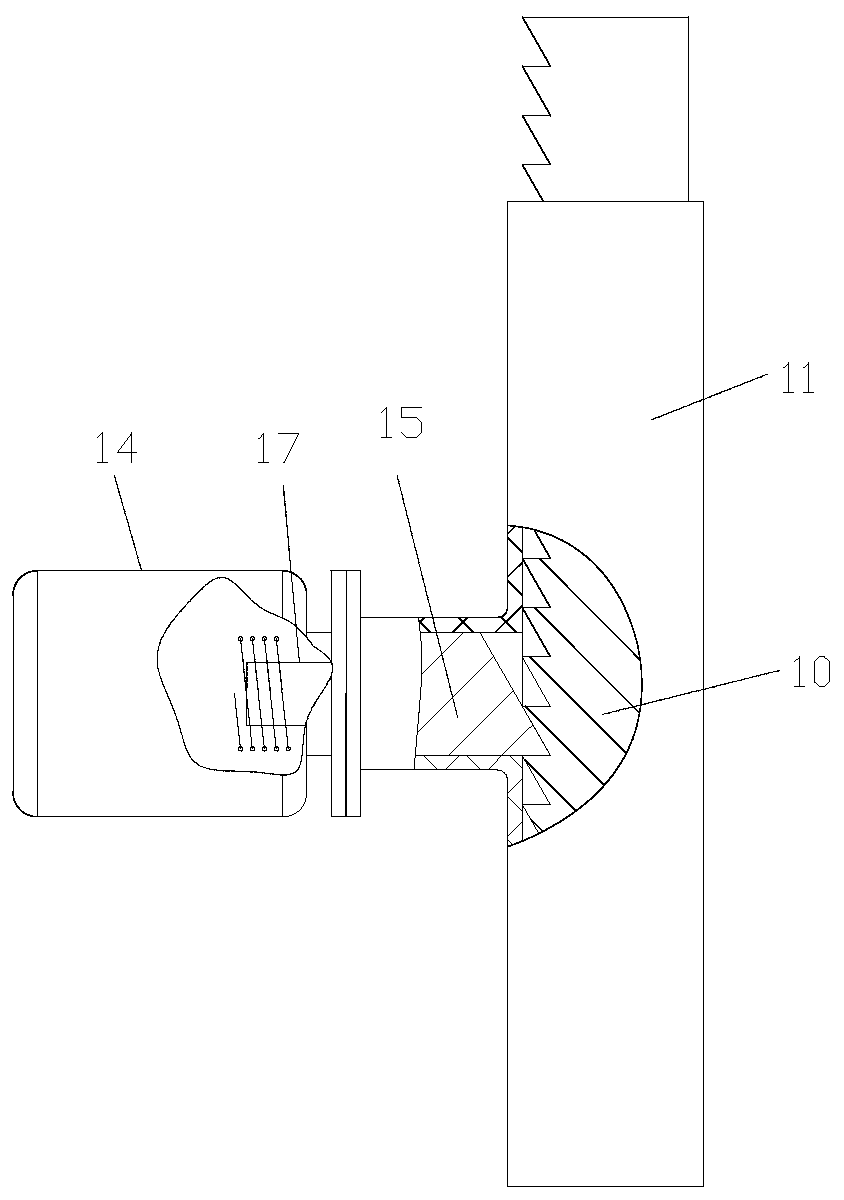

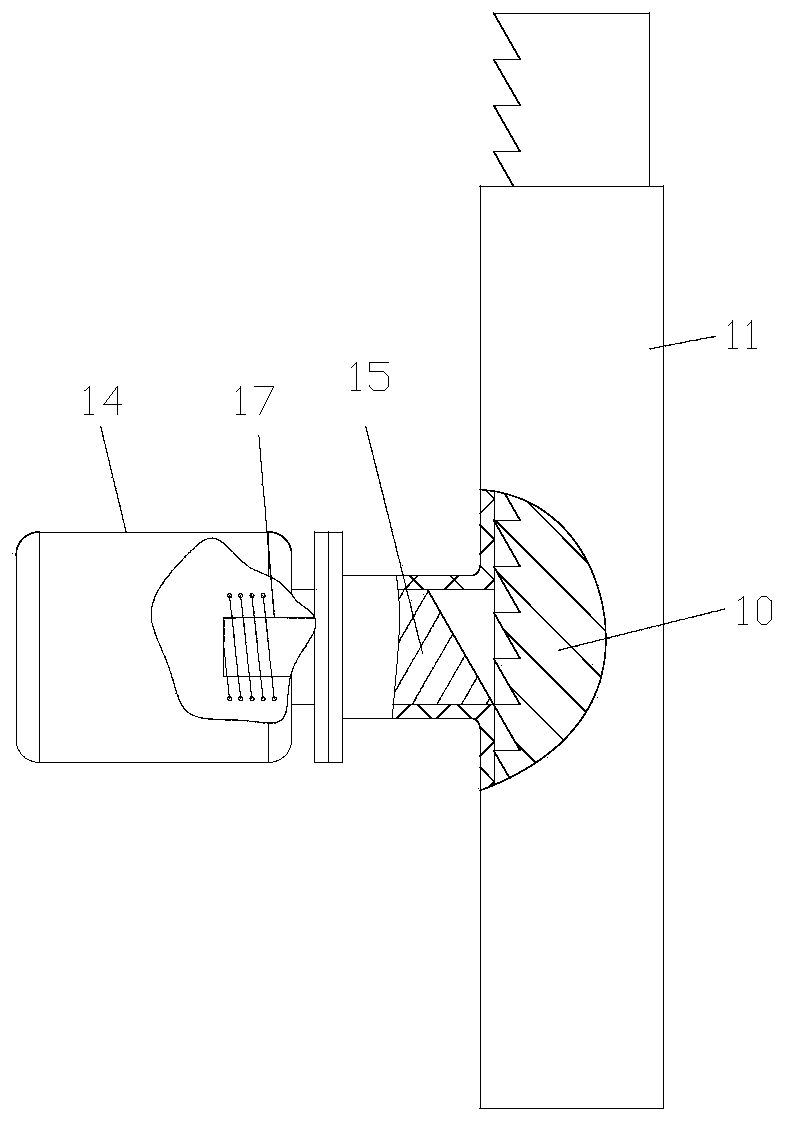

Novel denture carving machine and denture processing method

PendingCN111358587AAvoid retrievingRealize automatic reclaimingArtificial teethModel makingEngineeringDentistry

The invention provides a novel denture carving machine and a denture processing method. The novel denture carving machine comprises material carrying plates, a material clamping mechanism, a three-axis transfer mechanism, a processing frame, a rotary driving mechanism and a processing spindle; the material clamping mechanism is connected with the three-axis transfer mechanism, and is used for clamping the material carrying plates at a first preset position and loosening the material carrying plates at a second preset position so as to place the material carrying plates on the processing frame;the three-axis transfer mechanism is used for driving the material clamping mechanism to move back and forth between the first preset position and the second preset position; the processing frame islocated right below the processing spindle, is installed on the rotary driving mechanism, and is used for receiving materials when being in a first posture, and making the materials face towards the processing spindle when being in a second posture; and the rotary driving mechanism is used for driving the processing frame to rotate back and forth between the first posture and the second posture. Automatic material fetching, discharging and processing are realized, and thereby, manual operation is saved, and the mechanization degree of denture processing is improved.

Owner:美立得科技(深圳)有限公司

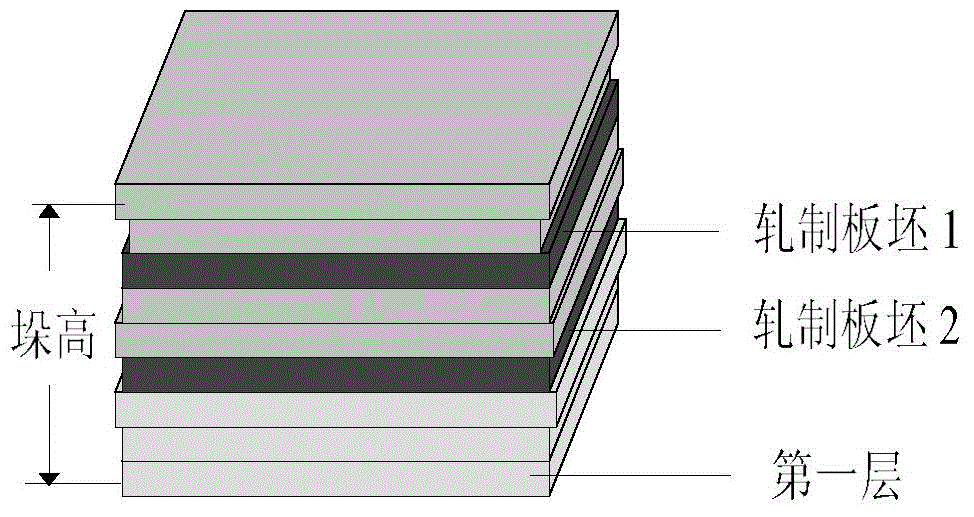

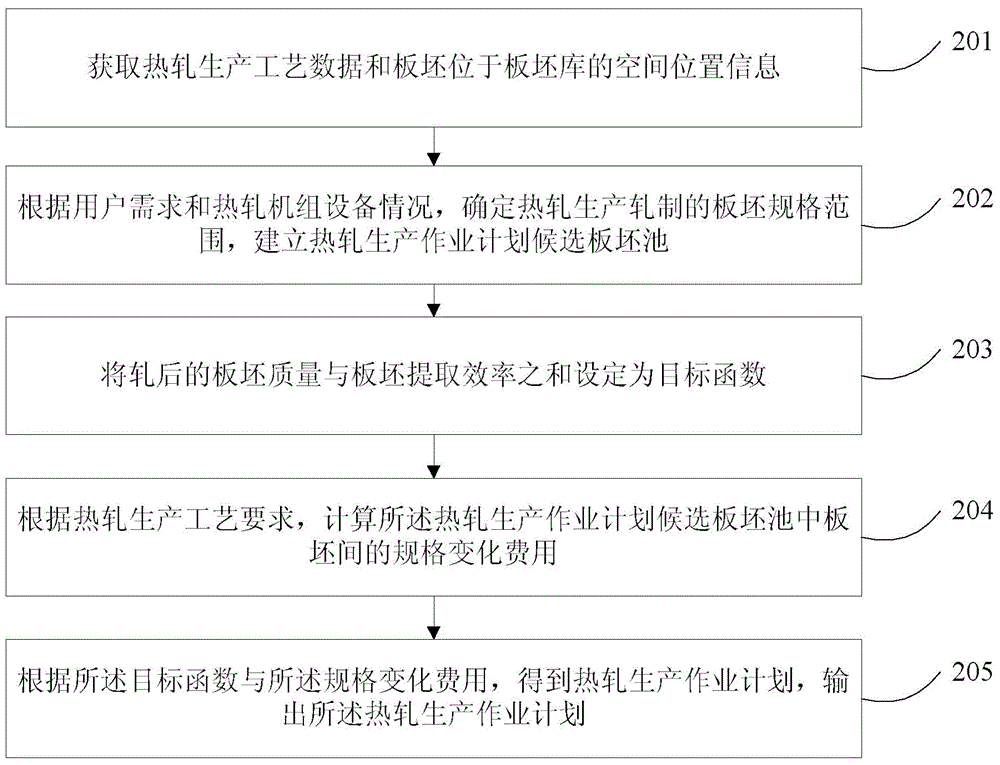

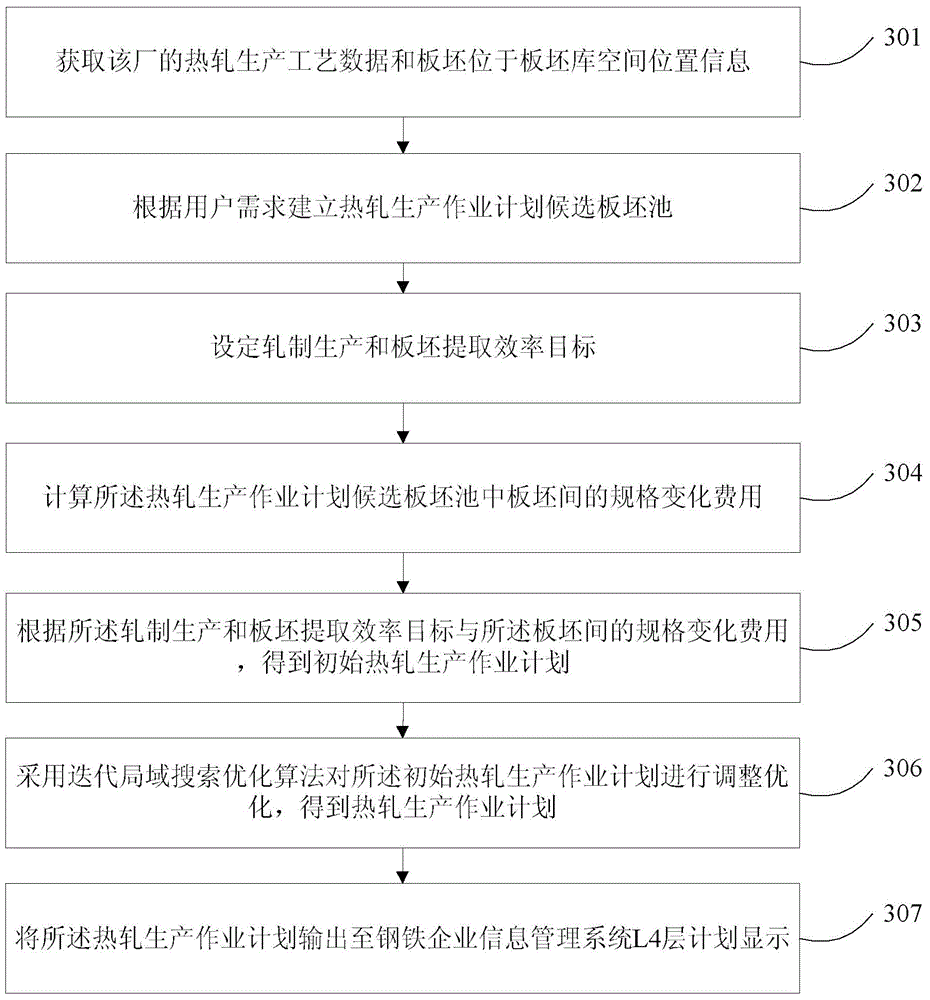

Production scheduling method and system for improving product quality and plate blank extraction efficiency

ActiveCN104624661AGuaranteed production continuityQuality improvementRoll mill control devicesMetal rolling arrangementsProcess requirementsManufacturing engineering

The invention provides a production scheduling method and system for improving product quality and plate blank extraction efficiency. Hot rolling production process data and space position information of plate blanks in a plat blank yard are obtained, the specification range of the plate blanks rolled through hot rolling production is determined, a hot rolling production operation plan candidate plate blank pool is built, the sum of the plate blank quality obtained after rolling and the plate blank extraction efficiency is set to an objective function, the specification change cost of the plate blanks in the hot rolling production operation plan candidate plate blank pool is calculated according to hot rolling production process requirements, then a hot rolling production operation plan is obtained according to the objective function and the specification change cost of the plate blanks, and the hot rolling production operation plan is output. The method is used for lowering production cost, improving the product quality and the plate blank extraction efficiency and guaranteeing hot rolling production continuity.

Owner:NORTHEASTERN UNIV

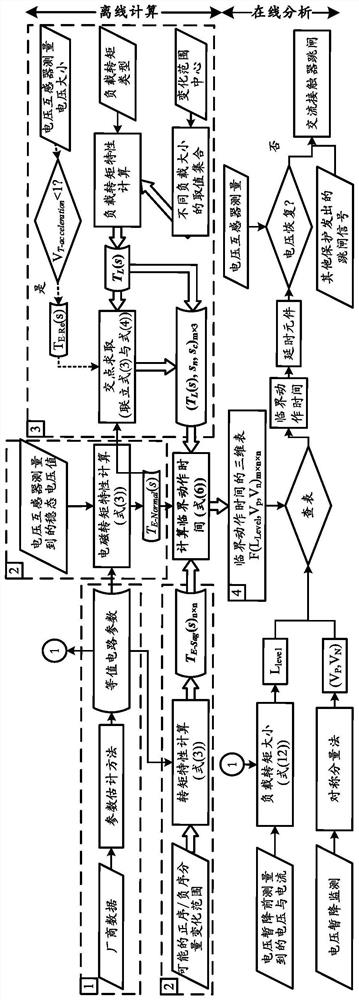

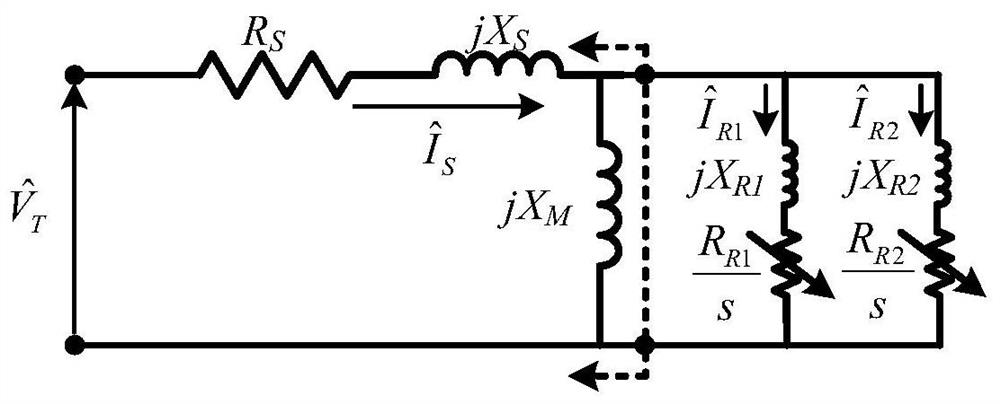

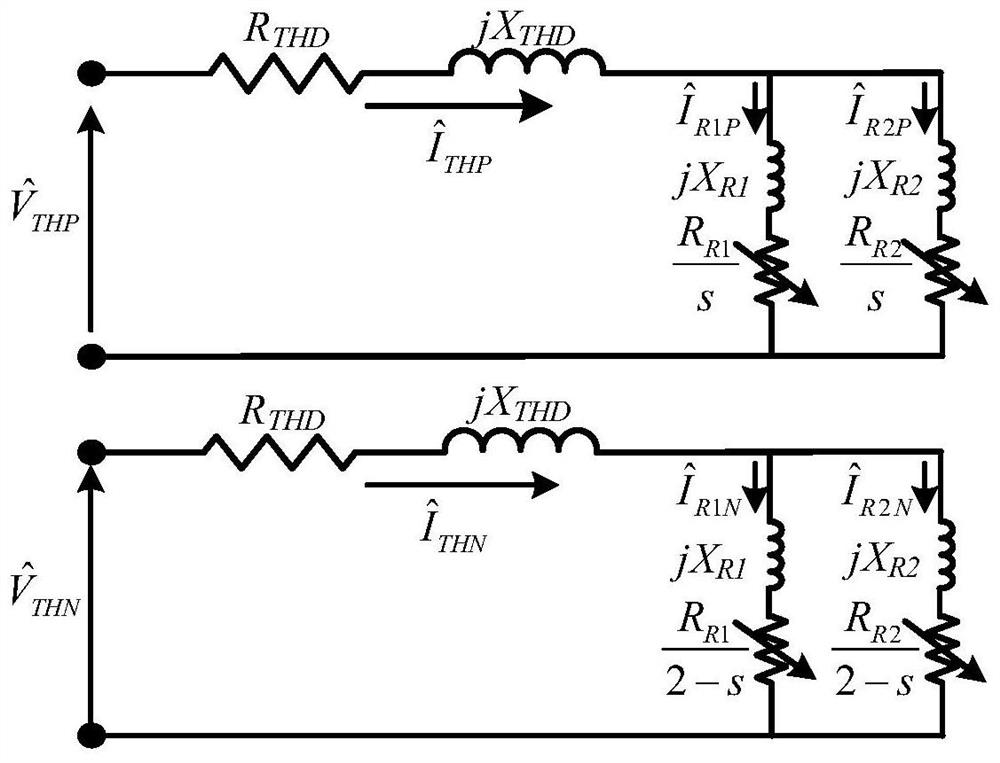

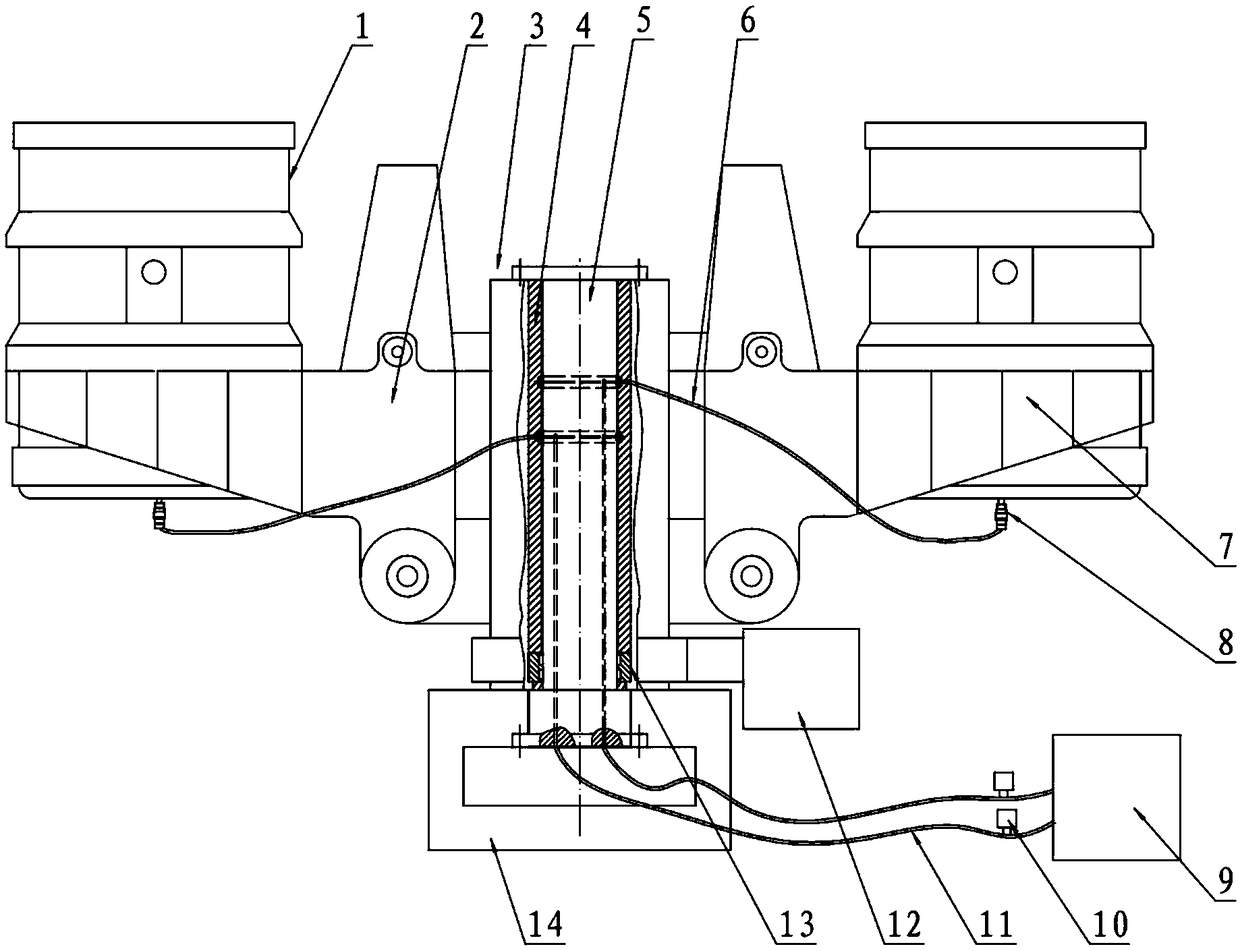

Self-adaptive action control method of alternating-current contactor

ActiveCN111969924AGive full play to fault ride-through capabilityImplement Adaptive ActionsElectric motor controlEmergency protective circuit arrangementsCapacitanceLoad torque

The invention discloses a self-adaptive action control method of an alternating current contactor and belongs to the technical field of electrical intelligent control. According to the self-adaptive action control method of the alternating current contactor, the fault ride-through capability of a motor can be given to full play, so that the alternating current contactor can realize self-adaptive action according to a fault type, duration time and the magnitude of load torque; off-line calculation and on-line analysis are combined, so that the alternating current contactor under voltage sag canmake a quick response, the production continuity under most voltage sag can be guaranteed, the alternating current contactor under severe voltage sag can trip off the motor in time, and the safe operation of the motor is guaranteed; a motor double-cage rotor model is adopted, changes of rotor parameters along with the rotating speed are considered, and dynamic behaviors of the induction motor inthe stall and acceleration process can be well represented. In the self-adaptive control process, the original structure and functions of the alternating current contactor are not damaged, only simplecapacitor type energy storage delay elements need to be additionally arranged, an economic effect is remarkable, and engineering practicability is achieved.

Owner:SICHUAN UNIV

Argon blowing method of ladle turret and steel ladle argon blowing turret in continuous casting mode

The invention provides an argon blowing method of a ladle turret and a steel ladle argon blowing turret in continuous casting mode. The method comprises the following steps that a, molten steel tapping is carried out, specifically the molten steel tapping temperature of the converter procedure is controlled between 1620 DEG C and 1630 DEG C; b, argon station on oxygen feeding aluminium wire is carried out, specifically a steel ladle is moved to an argon station, the argon front temperature of molten steel is controlled between 1600 DEG C and 1610 DEG C; c, argon station stirring is carried out, specifically the molten steel is stirred for 3-4 min in the argon station after the molten steel on oxygen and feeding wire, the outgoing temperature of the molten steel is controlled between 1595 DEG C and 1600 DEG C; and d, steel ladle argon blowing is carried out, specifically the steel ladle is lifted and conveyed to a continuous casting machine steel ladle argon blowing turret, argon gas isput into a blowpipe of the steel ladle bottom, argon gas argon blowing is open, and the soft argon blowing time is controlled between 15 min and 20 min. The process of the steel ladle argon blowing is moved to the continuous casting turret for implementation, the contradictory problem that the molten steel argon blowing time and the production rhythm is solved. While the production continuity isensured, the purity degree of the molten steel and the yielding rate of alloy are improved, and it is ensured that the quality of the purity degree of the molten steel is met.

Owner:德龙钢铁有限公司

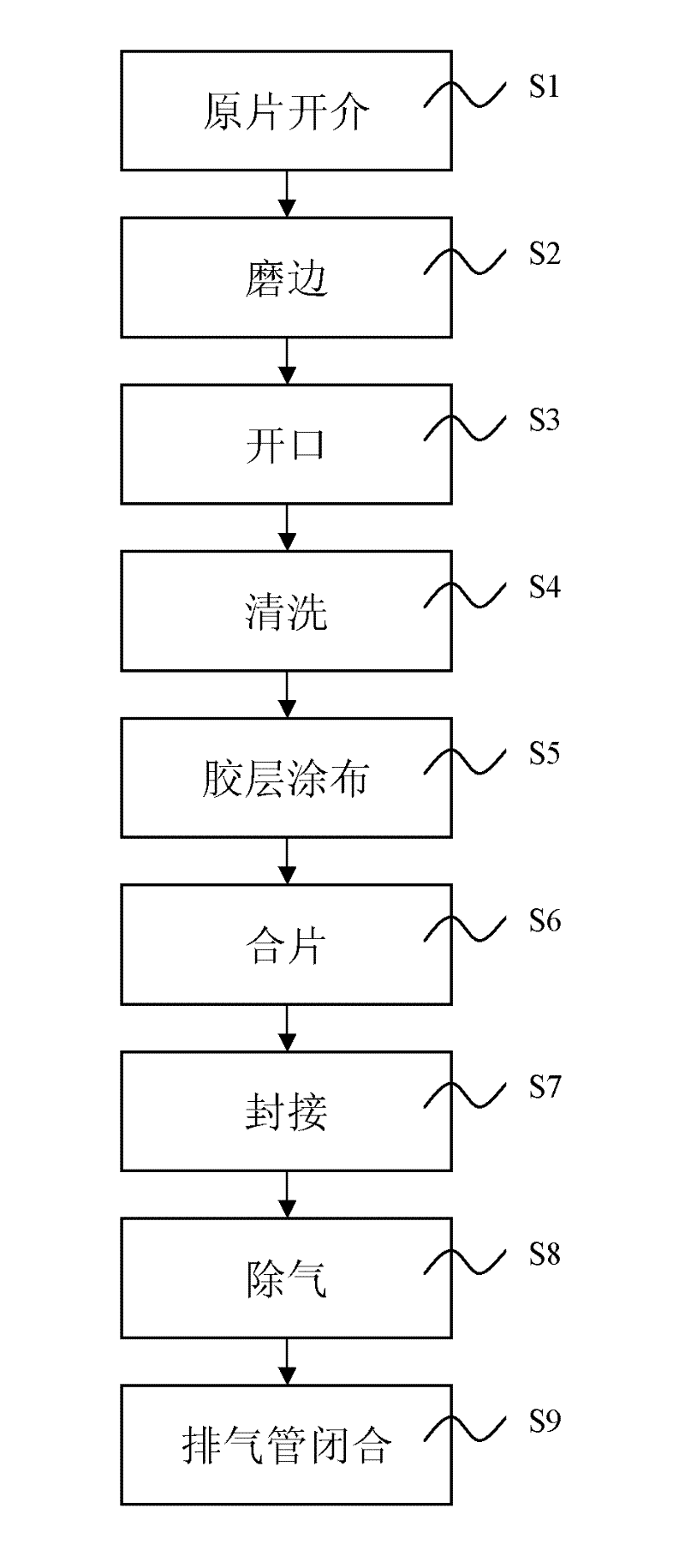

Process for preparing vacuum glass

The invention relates to a process for preparing vacuum glass, and the process comprises the following steps of: carrying out open-mediated process on raw pieces, polishing edges, opening a hole, cleaning, coating an adhesive layer, combining the pieces, sealing, degassing and closing an exhaust pipe, wherein the step of sealing is carried out in a continuous reheating furnace at the temperature of 350-500 DEG C; and the degassing step is carried out in a vacuum furnace at the temperature of 200-320 DEG C. After the process for preparing the vacuum glass, the production continuity of vacuum glass products can be guaranteed, the manufacturing time of the vacuum glass can be shortened, the production efficiency is greatly improved, the production cost is reduced, and a firm foundation is laid for mass production of the vacuum glass products.

Owner:YIN TONG DONGGUAN GLASS

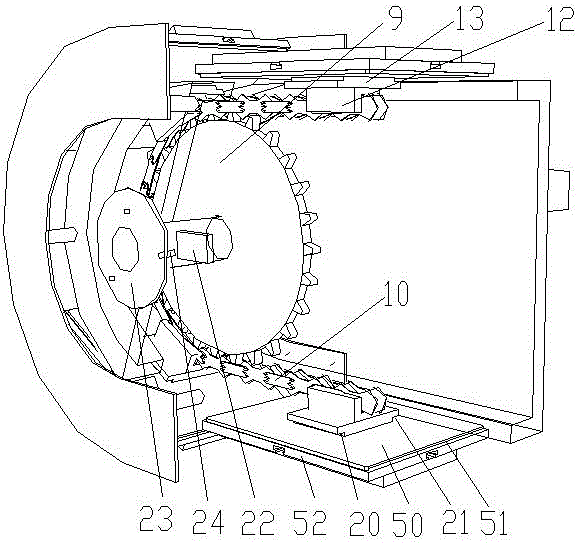

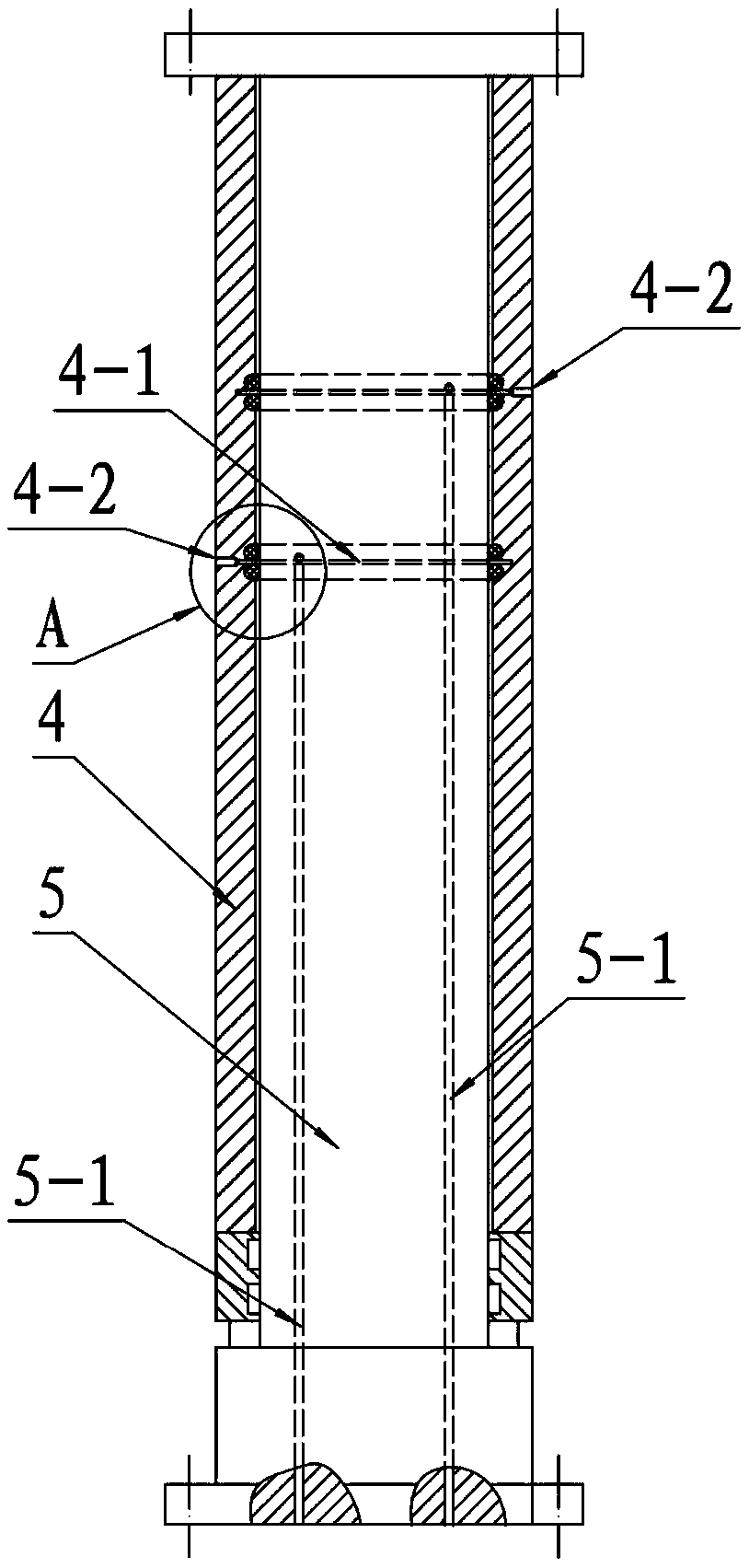

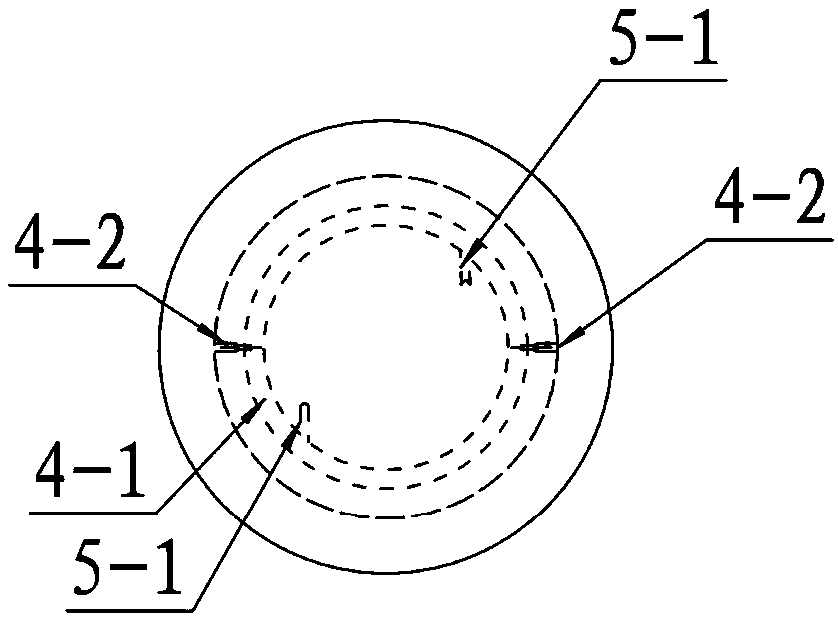

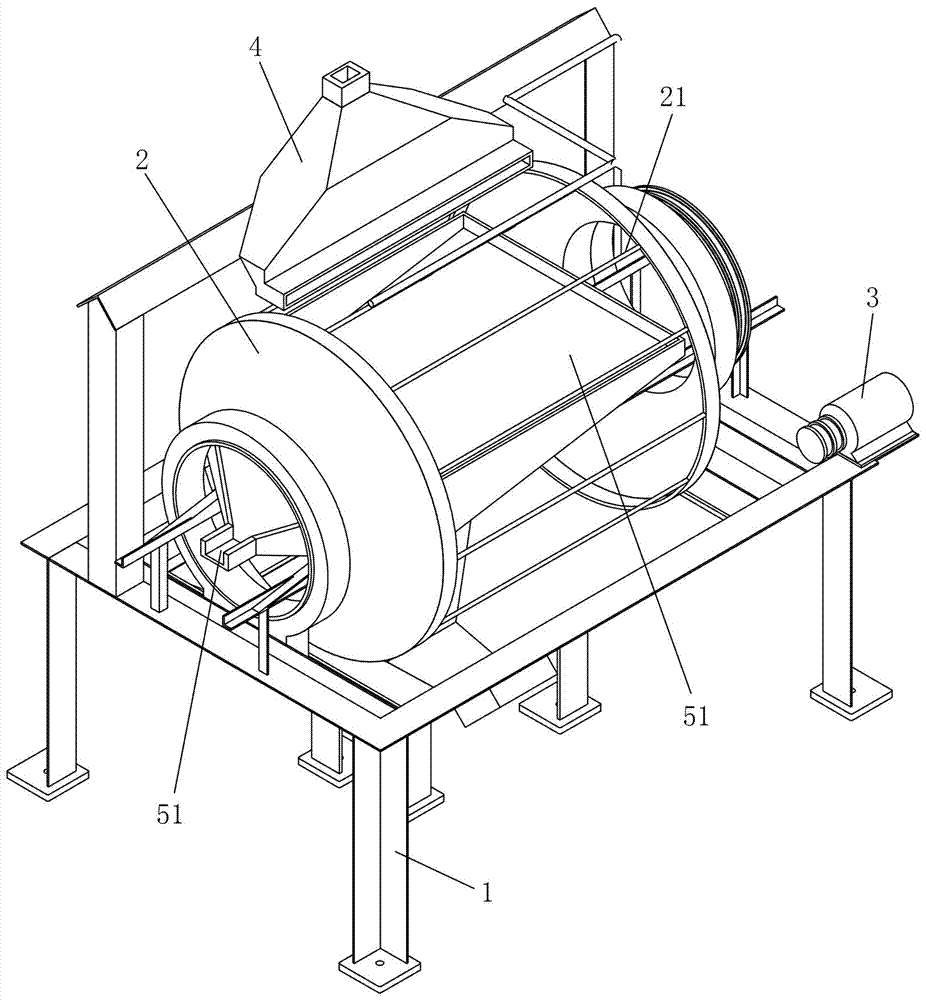

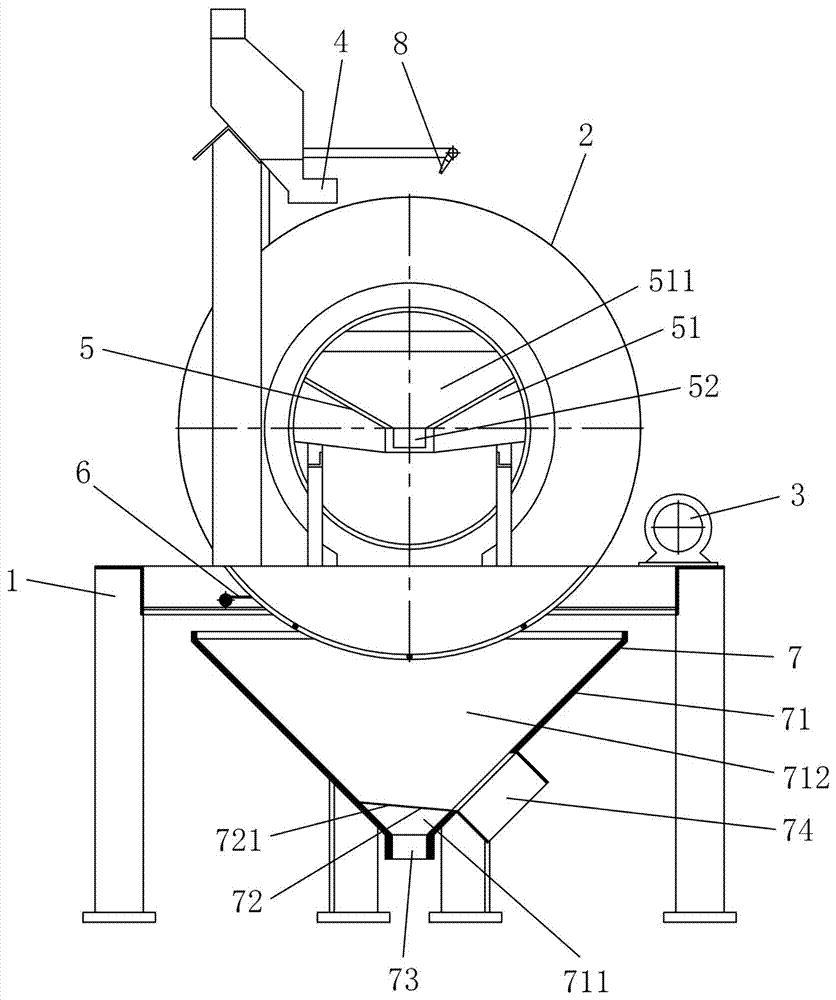

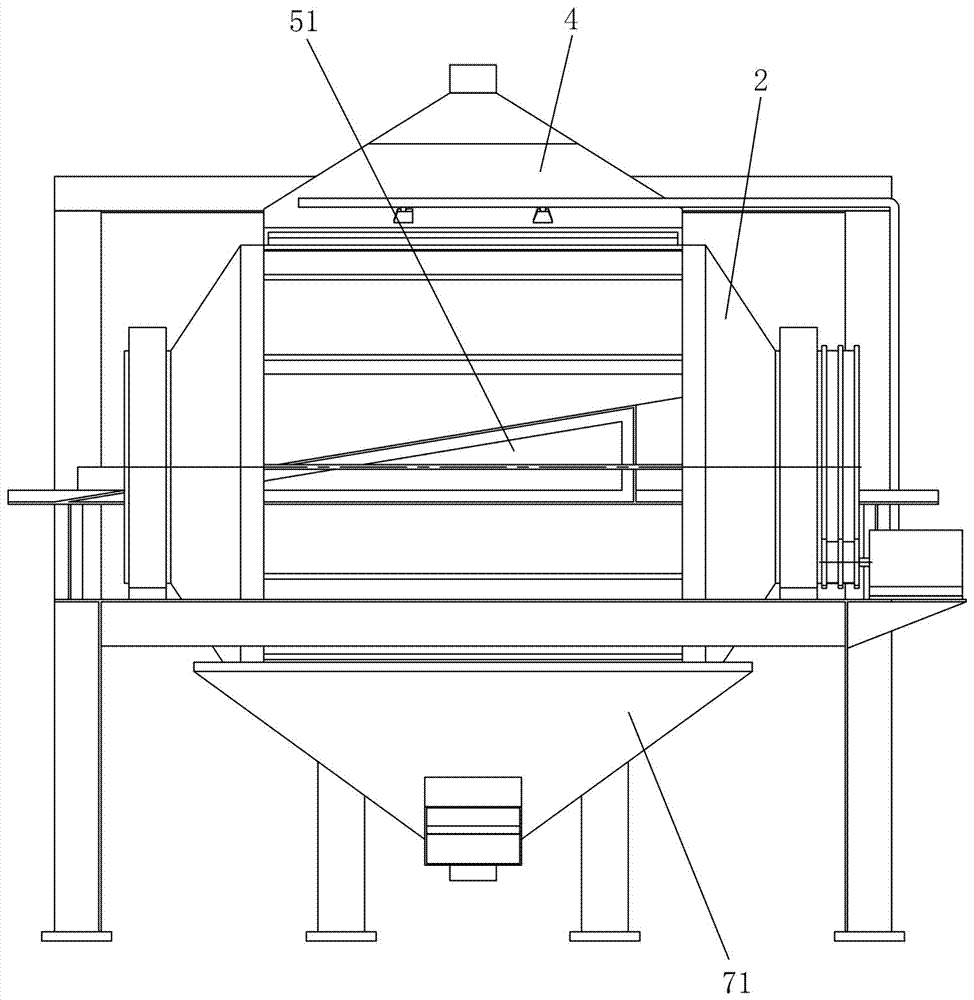

External type cylindrical residue isolating screen

PendingCN107185800ACompact structureEasy to manufactureSievingScreeningMechanical engineeringEngineering

The invention discloses an external type cylindrical residue isolating screen which comprises a machine frame, a screen cylinder rotationally installed on the machine frame and a rotary driving assembly installed on the machine frame and used for driving the screen cylinder to rotate. A feeding assembly used for feeding materials to be screened to the outer surface of the upper portion of the screen cylinder is arranged above the screen cylinder. A receiving assembly used for collecting screened materials and guiding out the screened materials is arranged in the screen cylinder. A residue removing assembly used for removing unscreened materials attached to the outer surface of the screen cylinder is arranged outside the screen cylinder. The external type cylindrical residue isolating screen has the advantages of being simple and compact in structure, easy to manufacture, convenient to assemble and maintain, capable of reducing the labor intensity, saving the labor cost, improving the screening efficiency and ensuing production continuity and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

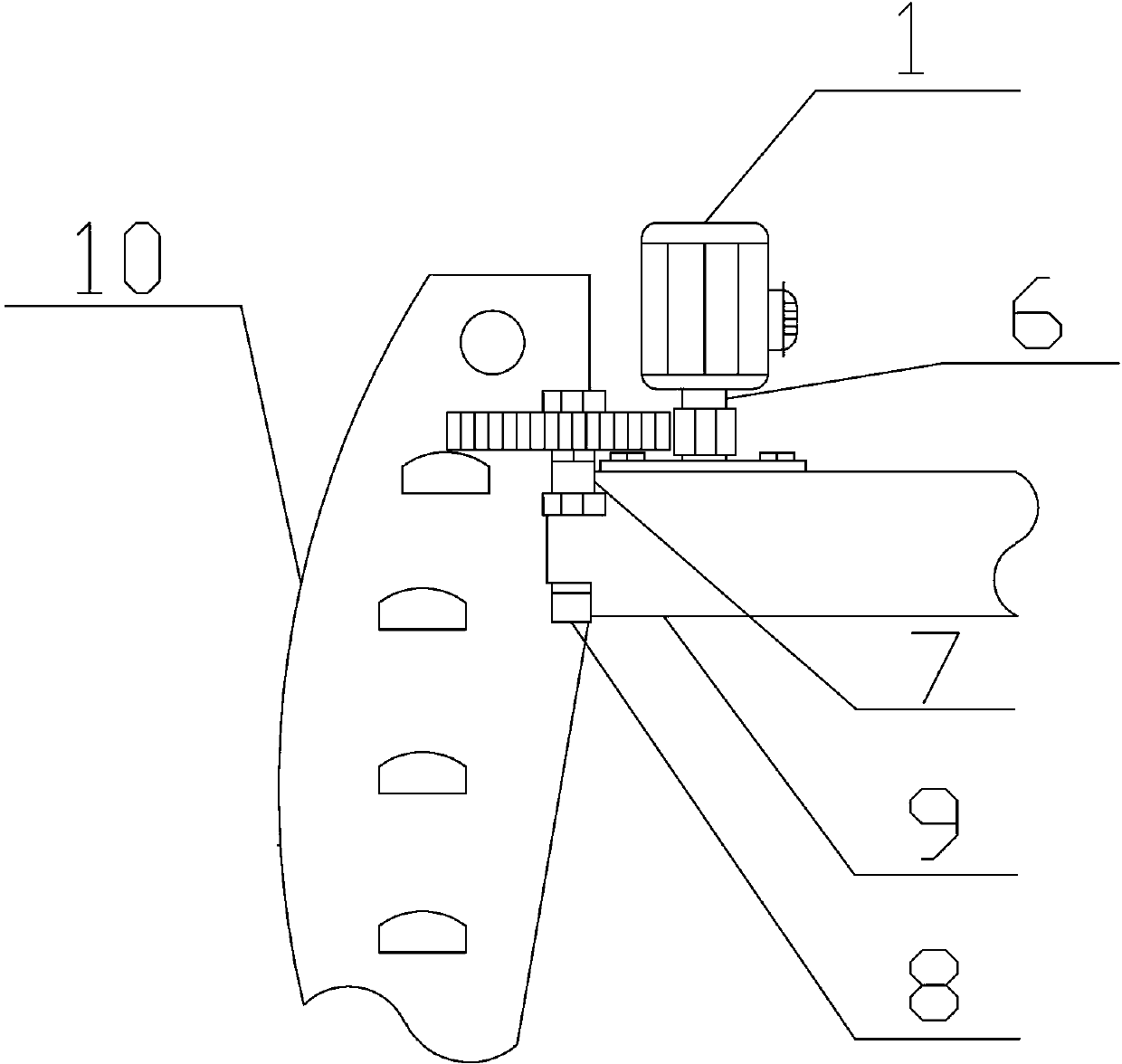

Horse-head overturning device of walking-beam type oil pumping unit

The invention discloses a horse-head overturning device of a walking-beam type oil pumping unit. The horse-head overturning device comprises an oil-pumping-machine horse head, an oil-pumping-machine walking beam, a motor, a horse-head pin seat and a horse-head pin, wherein the horse head is hinged to the walking beam by a pin shaft; the motor is arranged on the upper surface of the walking beam; the horse-head pin seat is fixed on the side surface of the horse head; the horse-head pin seat is matched with the horse-head pin; an output shaft of the motor is provided with a first gear; the upper end of the pin shaft is connected with a gear shaft of a second gear; the second gear is arranged on the other side surface of the horse head; and the first gear is meshed with the second gear. The horse-head overturning device disclosed by the invention has the beneficial effect that the motor is utilized for driving the horse head to overturn, so that the purpose of reducing the high-altitude operation of personnel is achieved; compared with the prior art, the horse-head overturning device disclosed by the invention has the advantages that the operation is simple, the use is safe, the workload of the personnel is reduced, and the like.

Owner:张健

Glue spreading method of soundproof cotton glue spreader

ActiveCN107362951AEvenly distributedImprove uniformityLiquid surface applicatorsCoatingsEngineeringRubber sheet

The invention discloses a glue spreading method of a soundproof cotton glue spreader and belongs to the technical field of glue spreaders. The glue spreading method of the soundproof cotton glue spreader comprises the following steps that (1) devices are started up, specifically, a glue spreading mechanism, a glue discharging mechanism, a recycling mechanism and a belt conveying mechanism on the soundproof cotton glue spreader are started up; (2) glue is spread, specifically, glue flowing out from the glue discharging device flows downwards along the gap between a gluing roller and a glue adjusting roller, a rubber sheet needing to be spread with glue is driven by the gluing roller to move in the gap between a glue spreading roller and the gluing roller as well as the gap between the glue spreading roller and the glue adjusting roller in sequence, and thus glue spreading is conducted; and (3) glue spreading is completed, specifically, the rubber sheet spread with the glue is conveyed to the tail of a conveying platform through conveying belts, the lower surface of the rubber sheet is in friction contact with the upper surfaces of cushion blocks, the moving speed of the rubber sheet is decreased, and glue spreading is completed after a worker takes the rubber sheet away. Through the glue spreading method, the purpose for overcoming the defects that glue spreading is uneven, and waste glue cannot be effectively recycled is achieved.

Owner:HEBEI LANGE SOUND INSULATION MATERIAL CO LTD

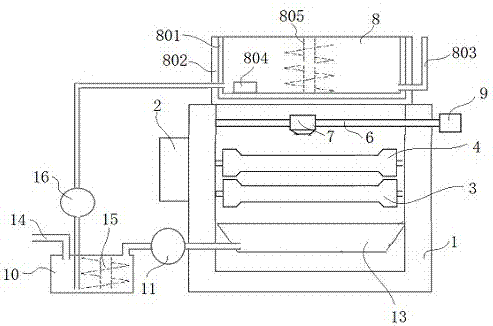

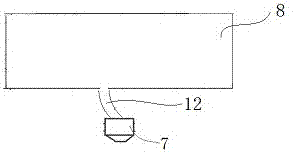

Dispenser

InactiveCN103626109AEnsure continuityQuality improvementLiquid flow controllersLiquid dispensingRotational axisProduction line

The invention discloses a dispenser, and relates to a dispenser which is used for automatic operation of a cosmetic production line. According to the dispenser, liquid separation can be automatically carried out, intervals of liquid separation of the dispenser can be adjusted at will, the dispenser can be well used in cooperation with the cosmetic production line, and production efficiency is improved. The dispenser comprises a liquid separation barrel, a support and a transmission device, wherein the liquid separation barrel comprises a barrel body and liquid outlets, the barrel body is a hollow cylinder, the lower end of the cylinder is closed, the liquid outlets are evenly distributed in the bottom end of the outer circle of the barrel body, and are connected with an inner cavity of the barrel body through liquid flow passages, a rotary gear is arranged on the outer circle of the barrel body and is close to an opening of the barrel body, and a rotary shaft is arranged in the center of the bottom of the barrel body. The dispenser is exquisite in conception, simpler in structure and convenient to control, and therefore liquid separation can be simple and easy to control.

Owner:YANGZHOU XINLANG DAILY CHEM TECH COMPANY

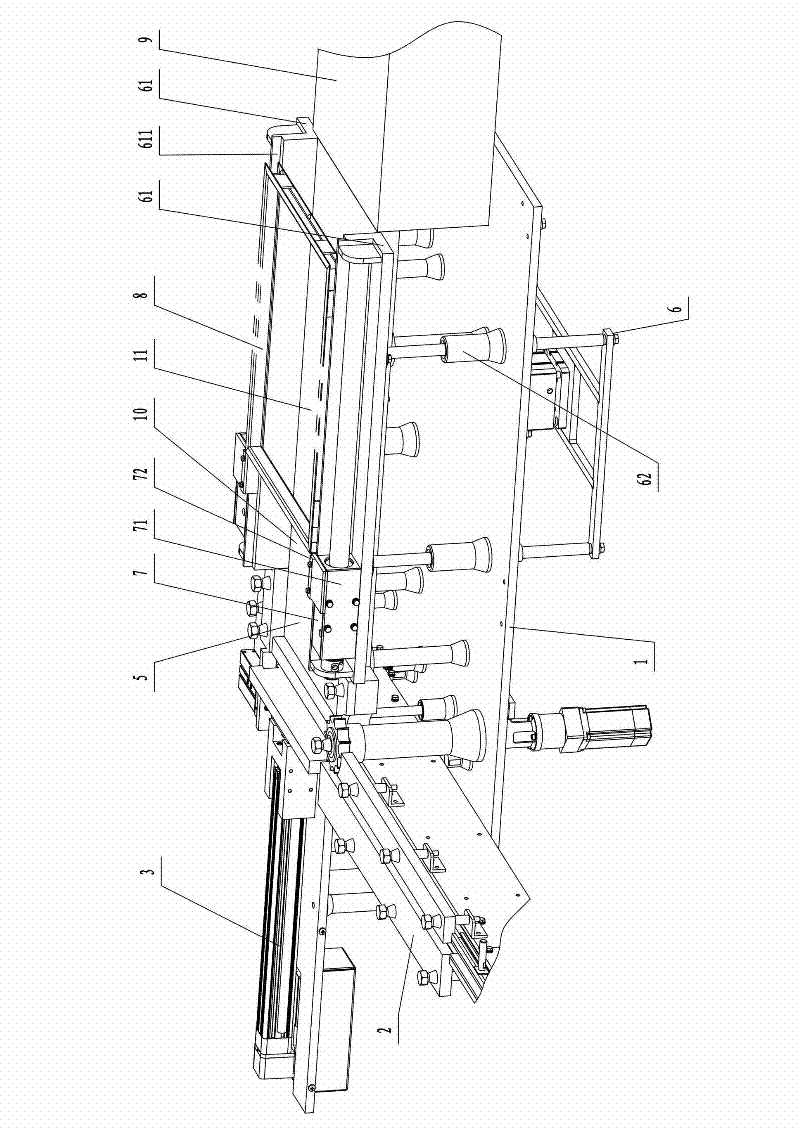

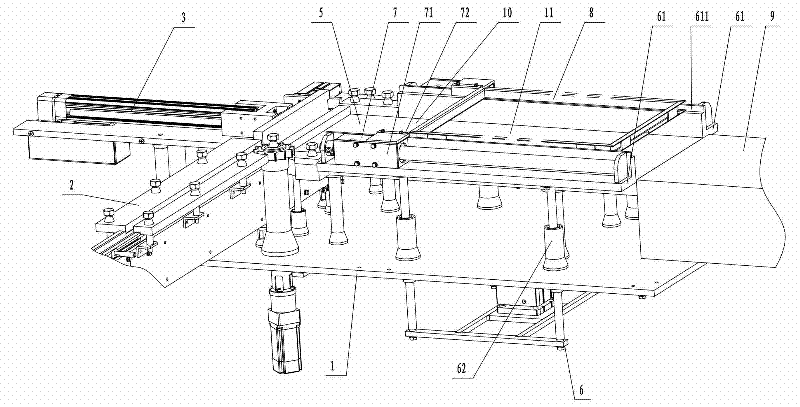

Novel coil stock placing device for transverse silicon steel sheet shearing line

ActiveCN105398848AReduce labor intensityGuaranteed production continuityWebs handlingShear lineEngineering

The invention discloses a novel coil stock placing device for a transverse silicon steel sheet shearing line. The novel coil stock placing device comprises a supporting piece internally provided with a drive motor. A rotary square lifting table is arranged above the supporting piece. Coil stock placing barrels are arranged on the four edges of the square lifting table respectively. The square lifting table can horizontally rotate to enable any coil stock placing barrel to be connected with the drive motor, and the coil stock placing barrels are driven by the drive motor to rotate for material placing. The four edges of the square lifting table of the novel coil stock placing device are provided with the coil stock placing barrels respectively, four coils of sheets can be placed at a time, and after one coil of sheets are used up, one coil stock placing barrel is replaced with another coil stock placing barrel for placing sheets through rotation of the square lifting table to be combined with the drive motor, fastness and convenience are achieved, production continuity is guaranteed, and the labor intensity of workers is relieved.

Owner:CANWIN AUTOMATIC EQUIP CO LTD

Mixed material temporary storage system of asphalt stirring device

ActiveCN102677571AGuaranteed production continuityGuaranteed production effectRoads maintainenceIntegrated operationsMixed materials

A mixed material temporary storage system of an asphalt stirring device comprises asphalt mixed material bins, bin body tracks which are erected above the asphalt mixed material bins and a material transporting device and is characterized in that the at least two bin body tracks are parellelly arranged, and the at least one asphalt mixed material bin is disposed below the bin body tracks; a left end and a right end of the material transporting device are erected on the adjacent bin body tracks respectively, and the material transporting device moves on the two bin body tracks and can blank materials into the asphalt mixed material bins below the bin body tracks at the left end and the right end of the material transporting device; and the bin body tracks are further provided with bin selecting switches which are used for controlling the material transporting device to blank the materials into the asphalt mixed material bins below the bin body tracks. According to the mixed material temporary storage system of the asphalt stirring device, by the aid of advantages of the multiple tracks and the multiple material bins, highly integrated operation of production and construction is effectively guaranteed, the production continuity of a stirring station is guaranteed, material receiving trolleys can enter into the site to receive the materials according to the requirement, and construction requirements of short required construction periods, large laying quantities and limited construction time are satisfied.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

A processing method for extruding unburned bricks

ActiveCN106626003BAchieve automationRealize continuous productionDischarging arrangementFeeding arrangmentsHydraulic cylinderBrick

The invention discloses a processing method for baking-free brick extrusion forming and belongs to the technical field of brick making. By means of a continuous hydraulic brick making system, the processing method includes the following steps of feeding, wherein raw materials are added into a feeding hopper, penetrate through a feeding cavity and a feeding opening and enter a forming cavity; extrusion forming of the raw materials, wherein a first hydraulic cylinder drives a forming and pushing mechanism to move, so that a buffer cavity moves to the position under the feeding hopper, a second hydraulic cylinder drives an extrusion plate to move upward in the forming cavity, and the raw materials are extruded into bricks; pushing and conveying of the bricks, the first hydraulic cylinder drives the forming and pushing mechanism to move, and the second hydraulic cylinder drives the extrusion plate to push the bricks to a machine frame, and the first hydraulic cylinder drives the forming and pushing mechanism to push out the bricks. The defects that in the prior art, the brick continuous production degree is low and production efficiency is low are overcome easily, continuous extrusion forming of the bricks can be achieved, production efficiency is effectively improved, the operation process is simple, and the production cost is low.

Owner:ANHUI LINGFENG METALLURGICAL MACHINERY

Bottle conveying mechanism for freeze-drying line

The invention discloses a bottle conveying mechanism for a freeze-drying line, which comprises a frame, a bottle feeding assembly, a bottle pushing assembly and a supporting platform arranged on the frame, the supporting platform is arranged along the bottle pushing direction of the bottle pushing assembly and It is divided into the bottle storage area and the upper frame area for placing the bottle collection frame in turn. The bottle storage area is close to the bottle pushing end of the bottle pushing assembly. The outlet end of the bottle feeding assembly is connected to the support platform and is located at the bottle pushing end of the bottle pushing assembly. It also includes a pushing frame assembly for pushing the bottle collecting frame out of the supporting platform along the bottle pushing direction of the bottle pushing assembly. The invention has the advantages of high degree of automation, less pollution, high drug production safety and the like.

Owner:TRUKING TECH LTD

Discharging door for stock bin of finished asphalt concrete

ActiveCN102535309BGuaranteed production continuityQuality assuranceRoads maintainenceHeat carrierHeat conducting

The invention relates to a discharging door for a stock bin of finished asphalt concrete, in particular to a discharging door capable of heating the asphalt concrete in the stock bin. The discharging door is arranged below a discharge opening of the stock bin of the finished asphalt concrete through a fixing shaft; and a driving mechanism, which is connected with the discharging door so as to control the discharging door to be opened or closed, is arranged on the stock bin for the finished asphalt concrete. The discharging door is characterized in that a heating system and a temperature-controlled device for controlling the heating system to work are arranged on the discharging door; a cavity for accommodating heat conducting oil is formed in the discharging door; the heating system comprises heat conducting oil arranged in the cavity and a heater communicated with the inside of the cavity; and the temperature-controlled device is used for controlling the heater to heat the heat conducting oil within a set temperature value. According to the discharging door, by means of reliable heat carrier performance of the heat conducting oil, the integral quality of heating is effectively ensured, and a favorable heat insulating effect is obtained; meanwhile, production continuousness of a mixing plant is ensured; a receiving cart can be used for receiving materials at variable intervals according to the requirement; and the construction requirement for storing the finished asphalt for a long time is met.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

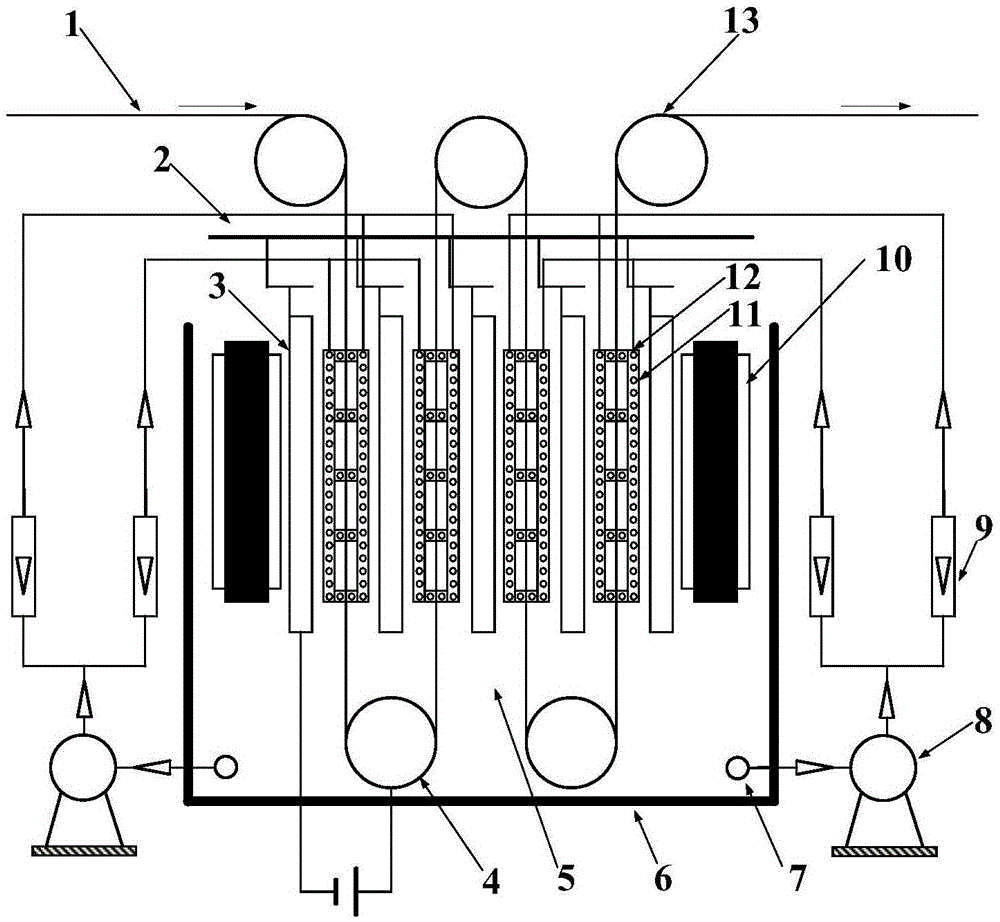

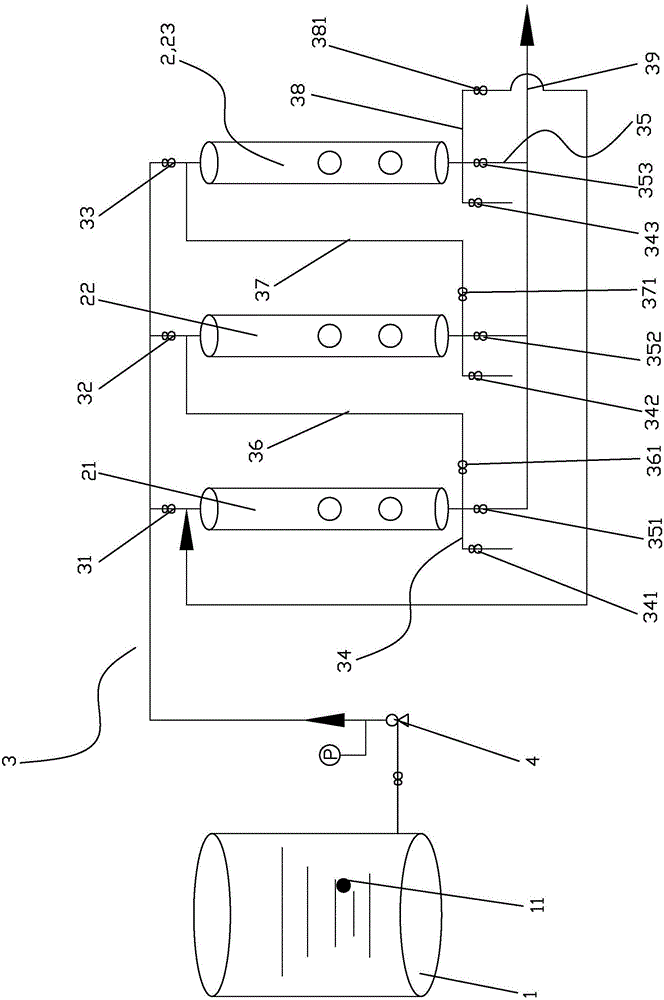

Anode aluminum foil forming device

InactiveCN105648515ATemperature controlControl concentrationCapacitor electrodesOxygen vacancySpecific volume

The invention discloses an anode aluminum foil forming device. The anode aluminum foil forming device comprises multiple electrode plates (3), inner circulation pipe networks (11) and a circulation pump (8) connected with the inner circulation pipe networks, wherein the electrode plates (3) and the inner circulation pipe networks (11) are arranged in a forming tank (6). The anode aluminum foil forming device further comprises direct-current electromagnets (10) arranged in the forming tank (6). The direct-current electromagnets (10) are soaked in forming liquid (5) in the forming tank. Multiple heat uniformization holes are evenly distributed in each electrode plate (3). The anode aluminum foil forming device has the beneficial effects that forming liquid circulating performance is good, electrical conductivity is high, interface tension is large, and the concentration and temperature of the forming liquid are uniform in distribution, so that the number of oxygen vacancies of forming films is small, the thickness of oxide films is uniform, the specific volume is large, bending performance is good, and the high-temperature service life is long.

Owner:YANGZHOU UNIV

A continuous pad printing coding equipment

ActiveCN106364152BPad printing stabilityPad printing precisionRotary pressesPrinting press partsElectricityPad printing

The invention discloses a continuous type pad printing and coding device. The continuous type pad printing and coding device comprises a workbench, a PLC controller and a pad printing machine. The continuous type pad printing and coding device further comprises a laser coding machine, a conveying component and a drying component. The conveying component comprises a motor, a transmission case, a main chain wheel, a chain and an auxiliary chain wheel. The chain is fixedly provided with multiple fixing seats. Locating blocks are connected to the fixing seats. Brackets are connected to the locating blocks, and the brackets are provided with mold grooves. The side wall of the transmission case is provided with a pad printing locating piece and a coding locating piece. Each locating block is provided with a left groove and a right groove. One end of the transmission case is provided with an infrared sensor. A motor shaft of the motor is sleeved with a wheel disk. Three sensing columns are distributed on the wheel disk. The infrared sensor, the pad printing machine and the laser coding machine are electrically connected with the PLC controller. The continuous type pad printing and coding device conducts continuous pad printing and coding operations on printed objects on a large scale and greatly improves the production efficiency; and pad printing and coding are clearer, the precision is high, the manufactured products are free from fading after being used for a long time and high in recognition capacity.

Owner:CHENGDU OJA AIRCRAFT CABIN EQUIP

Anti-blocking device of tobacco cutter vertical distributing mechanism

PendingCN110182477AAchieve cleanupIncrease the cross-sectional areaLarge containersEngineeringMechanical engineering

The invention discloses an anti-blocking device of a tobacco cutter vertical distributing mechanism. A left distributing plate and a right distributing plate are arranged in a hopper of a tobacco cutter, the upper end of the left distributing plate and the upper end of the right distributing plate are hung and fixed to a left rotating shaft and a right rotating shaft correspondingly, the left rotating shaft and the right rotating shaft are rotatably arranged on the hopper, a left swing rod and a right swing rod are hung on the left rotating shaft and the right rotating shaft correspondingly, the lower ends of the left swing rod and the right swing rod are connected through an air cylinder, the two ends of the air cylinder are rotatably connected with the left swing rod and the right swingrod correspondingly, a driving rod is arranged on the right swing rod, the outer end of the driving rod is connected with a rack, the rack is arranged in a sliding sleeve in a sliding manner, a driving mechanism drives the sliding sleeve to do reciprocated moving in the vertical direction, an electromagnetic valve is arranged on one side of the sliding sleeve, a one-way stop tongue is connected with a valve element of the electromagnetic valve, when the electromagnetic valve drives the one-way stop tongue to extend out, the work end of the one-way stop tongue tightly abuts against the rack, when the electromagnetic valve drives the one-way stop tongue to retract, the one-way stop tongue is separated from the rack, and the advantage of automatically clearing blockage is achieved.

Owner:CHINA TOBACCO ANHUI IND CO LTD

Device for improving loosening rate of tobacco block

ActiveCN110432528AIncrease loose rateGuarantee the quality of workmanshipTobacco preparationFinal product manufactureProduction lineProcess quality

The invention discloses a device for improving loosening rate of a tobacco block. The device comprises a rack fixedly arranged on two sides of an electronic belt scale, wherein a loose roller and a driving motor for driving the loose roller are arranged at the positions, close to an outlet of the electronic belt scale, of the rack, and the distance between the loose roller and a driving roller atthe outlet of the electronic belt scale is 1-3cm; a plurality of adjustable loosen roller needles which are arranged in the circumferential direction are uniformly located on the surface of the loosenroller in the axial direction at intervals of 15-20cm; an anti-toppling door plate is arranged above the driving roller at the outlet of the electronic belt scale; the anti-toppling door plate is movably connected with a bearing arranged on the rack through a connecting rod fixedly arranged at the upper end of the anti-toppling door plate; and the connecting rod is fixed to an adjusting rod witha balancing weight on the outer side of the rack. According to the device, the loose rate of the tobacco block can be effectively improved, the process quality of the tobacco leaves can be guaranteed,and a production line can be conveniently installed.

Owner:CHINA TOBACCO ZHEJIANG IND

Energy-saving polishing device and polishing powder solution recycling method

PendingCN108927735AReduce wasteGuaranteed long-term stabilityOptical surface grinding machinesLensMetallurgyRecovery mechanism

The invention discloses an energy-saving polishing device and a polishing powder solution recycling method. The energy-saving polishing device comprises a polishing mechanism, a polishing powder solution supply mechanism and a polishing powder solution recovery mechanism, wherein a polishing region in the polishing mechanism is divided into a pre-polishing region, a rough polishing region and a fine polishing region, and each polishing region is provided with a compression roller and a polishing brush. The polishing powder solution supply mechanism is composed of a batching tank, a recovery tank, a polishing powder solution pump, a conveying pipeline and spraying pipes, wherein a polishing powder solution of the batching tank is conveyed to the rough polishing region and the fine polishingregion through the spraying pipes, and through separation by the corresponding compression roller, the used polishing powder solution is respectively collected into the recovery tank and the batchingtank through a recovery mechanism. The polishing powder solution in the recovery tank is conveyed to the pre-polishing region through the corresponding spraying pipe, and through separation by the corresponding compression roller, the re-used polishing powder solution is discharged as a failure polishing powder solution. The energy-saving polishing device can realize cyclic utilization of the polishing powder solution, and the production is not required to be stopped when polishing powder and water are added, so that the production efficiency is improved.

Owner:TIANJIN BINHAI LIGHT & HEAT REFLECTING TECH CO LTD

Recovery system for noble metals for electroplating

ActiveCN105671317AImprove efficiencyReduce downtimeProcess efficiency improvementFiltrationWastewater

The invention discloses a recovery system for noble metals for electroplating. The recovery system comprises a gold-bearing wastewater collecting tank. A water outlet pipe of the gold-bearing wastewater collecting tank is connected with at least three filtration columns connected in series. A circulating pipeline, which is used for transporting wastewater and can adjust the filtering sequence, is arranged between the filtration columns and the gold-bearing wastewater collecting tank. The circulating pipeline is connected in series with the filtration columns in sequence, and can adjust the filtering sequence arbitrarily; three filtering modes are provided; the replaced new resin filtration column is considered as the last one exchange column; the maximal adsorption capacity of gold ions in wastewater is ensured; the circulating pipeline is connected with valves at all positions to control the cycling filtration sequence of sewage, so that the cost is reduced, and the filtering efficiency of the resin filtration columns is improved; and besides, the downtime during the filtering process is shortened, the production continuity is ensured, and the production cost is reduced.

Owner:ACKOTEC ZHONGSHAN ELECTRONICS PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com