Anode aluminum foil forming device

A chemical formation device and anode aluminum foil technology, applied in the direction of capacitor electrodes, capacitor parts, etc., can solve the problems of uneven concentration and temperature distribution of chemical forming liquid, poor cycle performance of chemical forming liquid, uneven oxide film thickness, etc., to improve performance and Its stability, temperature and concentration distribution uniformity are improved, and the effect of ensuring the continuity of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

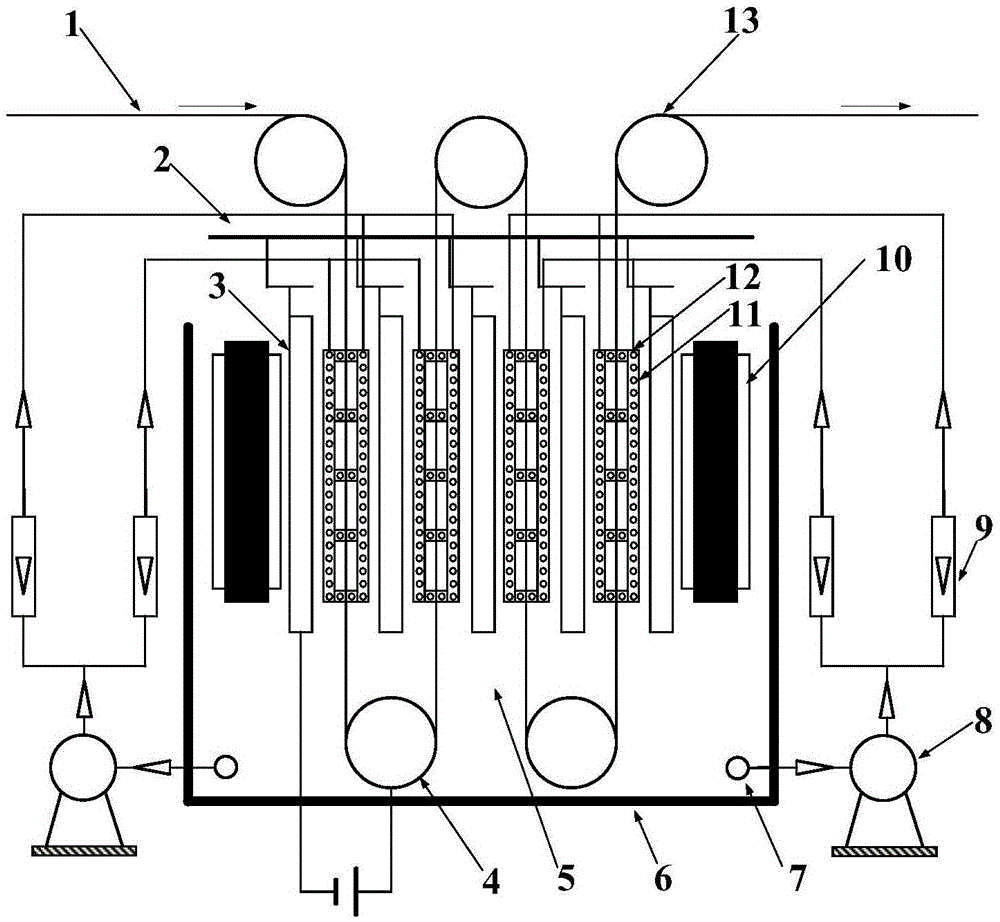

[0036] Such as figure 1 As shown, the anode aluminum foil formation device of the present invention includes a plurality of electrode plates 3 placed in the formation tank 6, an internal circulation pipe network 11 and a circulation pump 8 connected to the internal circulation pipe network, and also includes a A DC electromagnet 10, the DC electromagnet 10 is immersed in the chemical conversion solution 5 in the chemical conversion tank.

[0037] The reason for setting the DC electromagnet 10 is that the DC electromagnet will produce a magnetically induced eddy current effect, which will have the following effects on the formation:

[0038] (1) Enhance the mass transfer of charged ions. In the process of electrolytic corrosion superimposed external magnetic field, when charged particles such as H + and O 2- Lorentz force F will be applied when the cutting magnetic field line moves L (F L =J×B, J is the current density, B is the magnetic field strength), thus driving the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com