Dispenser

A liquid dispenser and liquid separation technology, which is applied in the direction of liquid distribution, distribution devices, special distribution devices, etc., to achieve the effect of improving the quality of finished products, simple structure, and ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

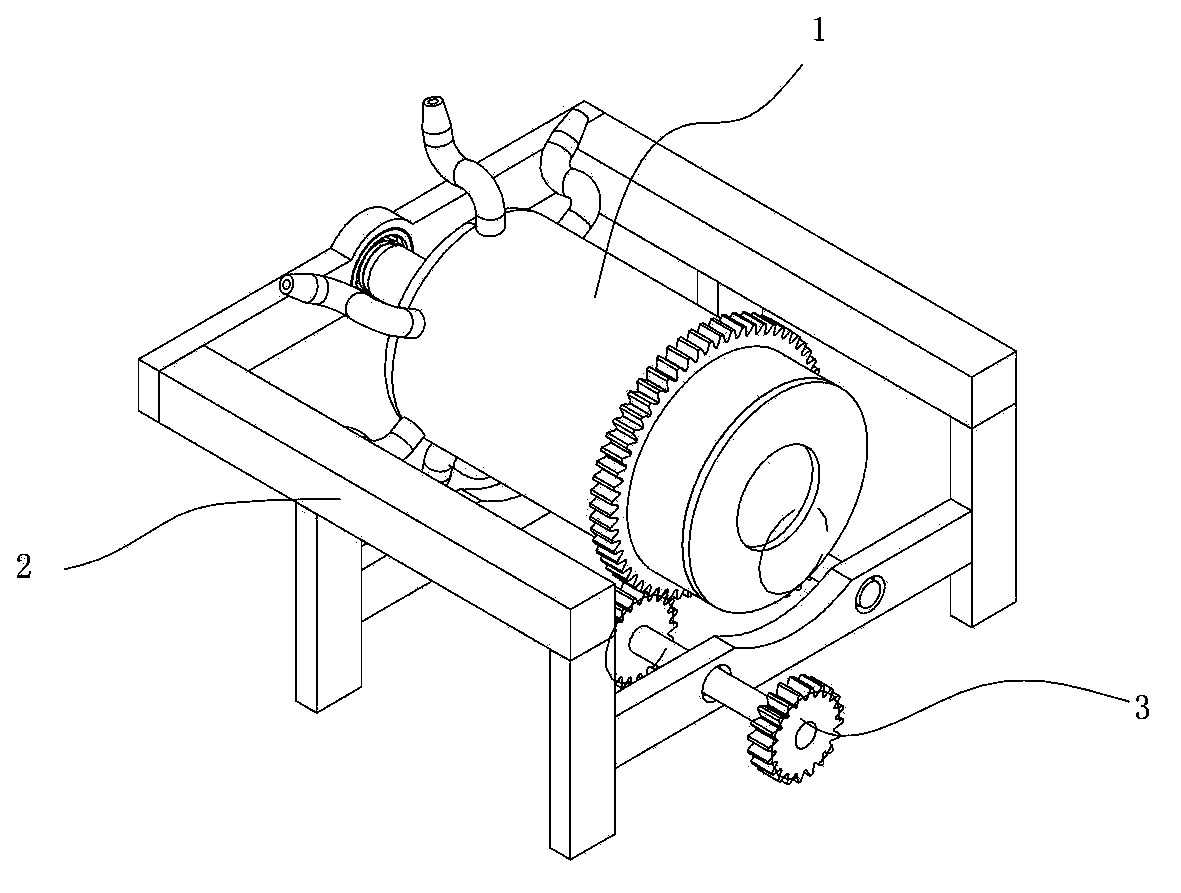

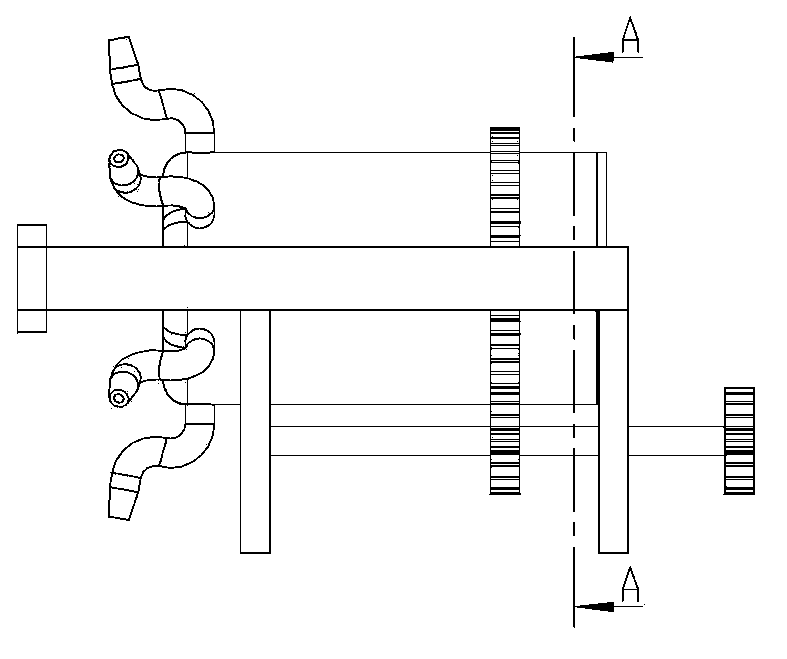

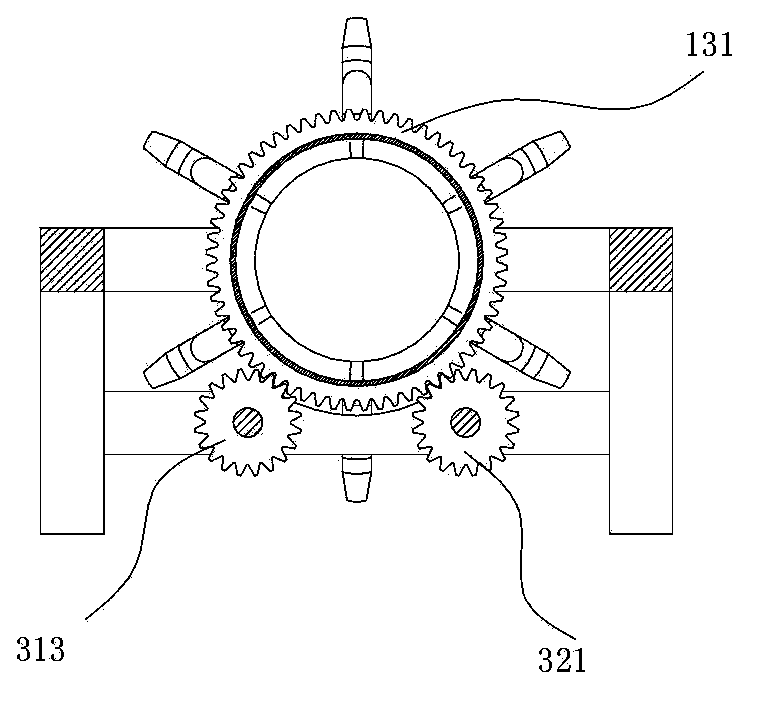

[0031] The present invention as Figure 1-9 As shown, it includes a liquid separation barrel 1, a bracket 2, and a transmission device 3, and the liquid separation barrel 1 includes a barrel body 13 and a liquid outlet 12;

[0032] The barrel 13 is a hollow cylinder with a closed low end; the bottom of the outer ring of the barrel 13 is evenly distributed with the liquid outlet 12; the liquid outlet 12 is connected to the inside of the barrel 13 through a liquid flow channel 14 cavity; the outer ring of the barrel body 13 is provided with a rotating gear 131 from the opening; the center of the bottom of the barrel body is provided with a rotating shaft 15;

[0033] Described support 2 comprises supporting leg one 211, supporting leg two 212, supporting leg three 213, supporting leg four 214, longitudinal bar one 221, longitudinal bar two 222, cross bar one 231, cross bar two 232, cross bar three 233; The first vertical rod 221 is fixedly erected on the top of the first leg 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com