Patents

Literature

204results about How to "Save time and energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

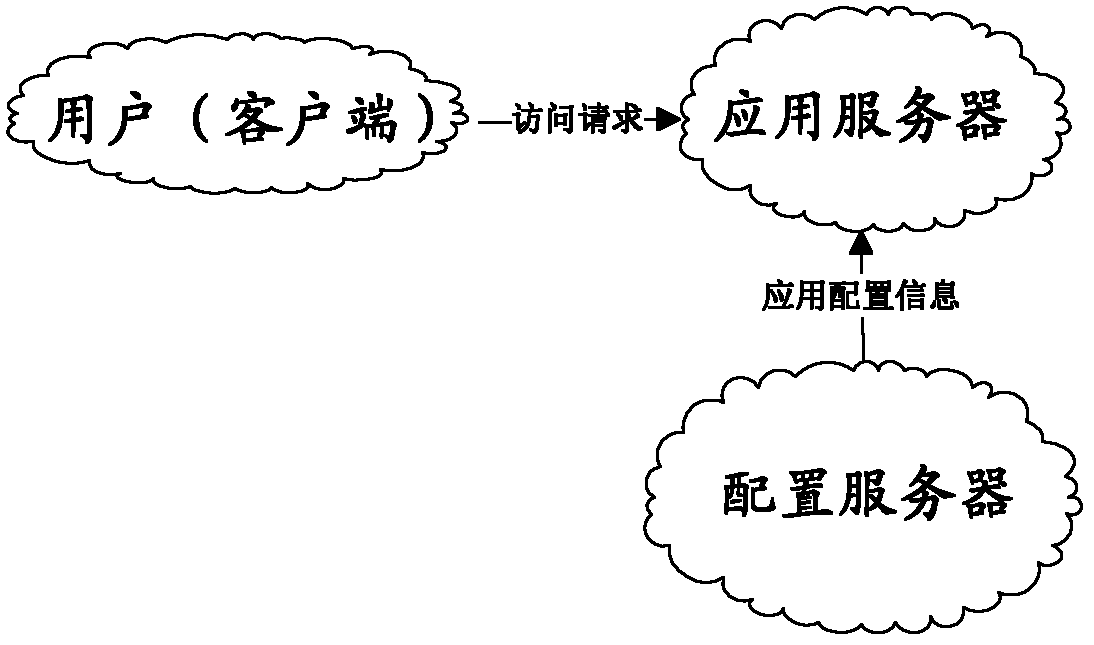

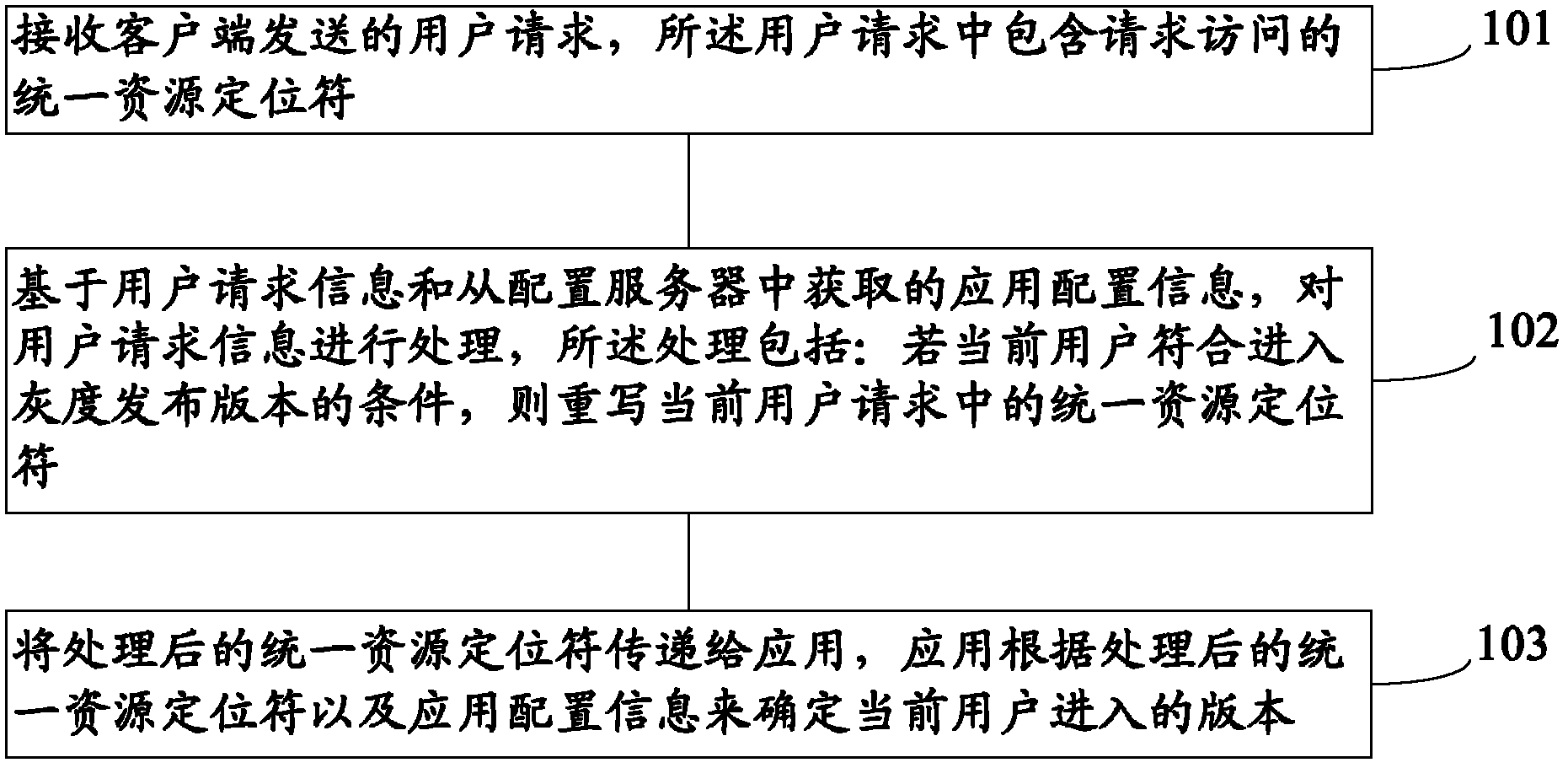

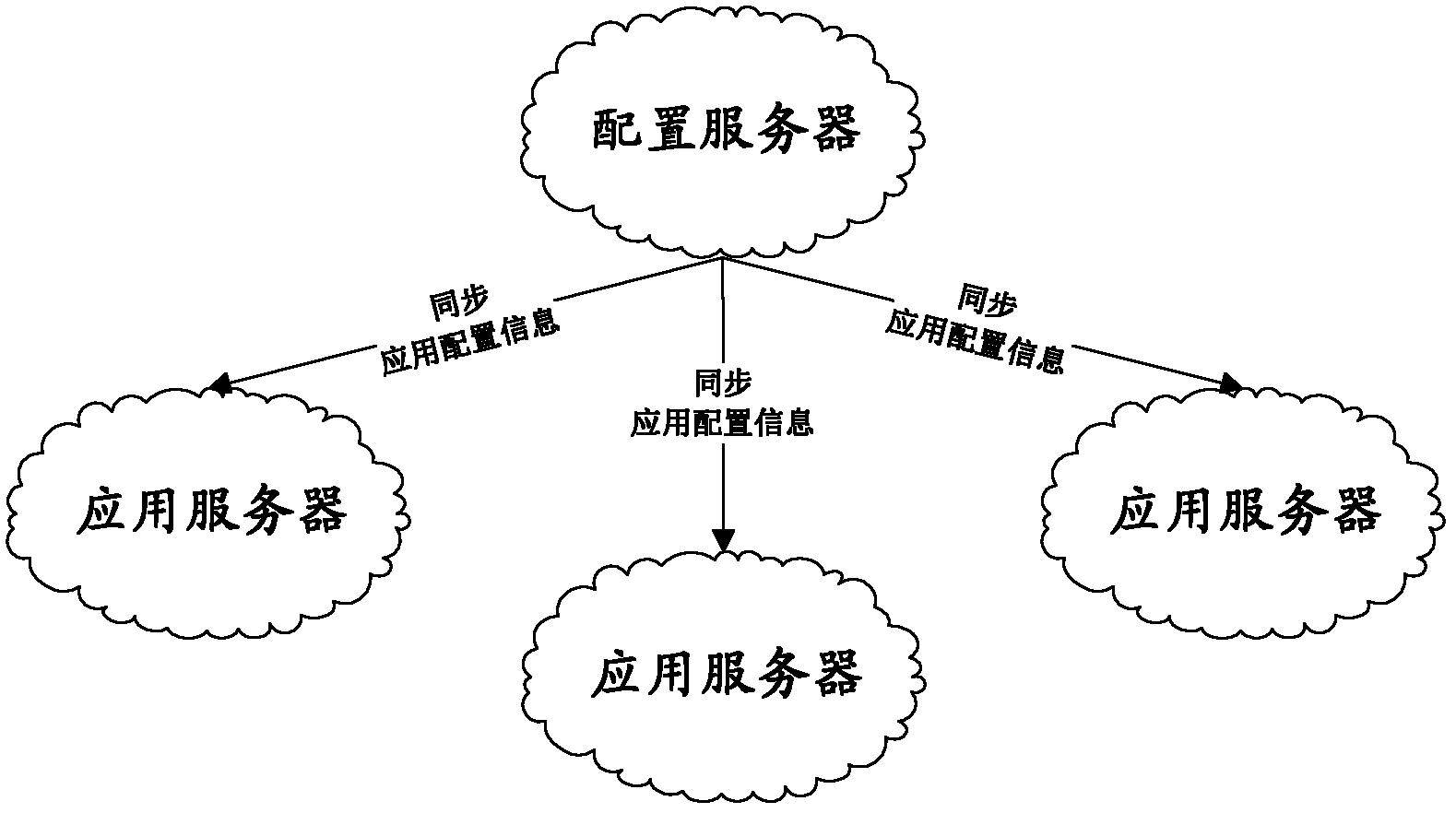

Application releasing method and application releasing system

ActiveCN103176790ASave time and energyEasy to manageTransmissionSpecific program execution arrangementsClient-sideGray level

The invention provides an application releasing method. The method comprises the following steps: user requests sent by a client side are received, the user requests comprise a uniform resource locator requiring to access; the user request information is processed according to the user request information and application configuration information obtained from a configuration server, and the processing comprises the following steps: if a present user accords with the conditions of entering a gray release version, the uniform resource locator required by the present user is rewritten; and the processed uniform resource locator is transmitted to an application, and the version in which the present user enters is confirmed by the application according to the processed uniform resource locator and configuration information of the application. The invention further provides an application releasing system for achieving the application releasing method. According to the application releasing method and the application releasing system, uniform control and management to application gray level releasing are achieved, and time and cost of the application gray level releasing are saved.

Owner:ALIBABA GRP HLDG LTD

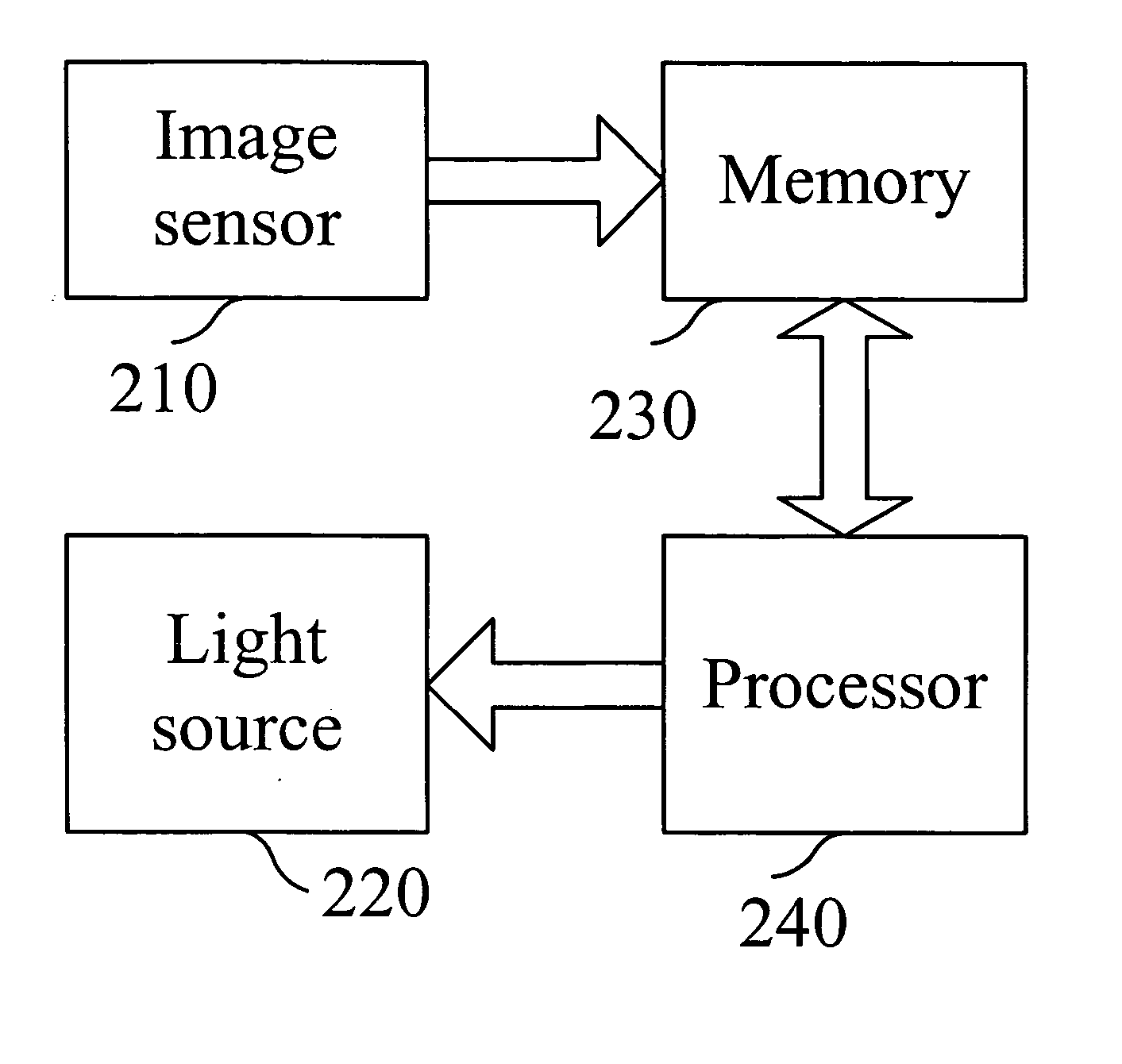

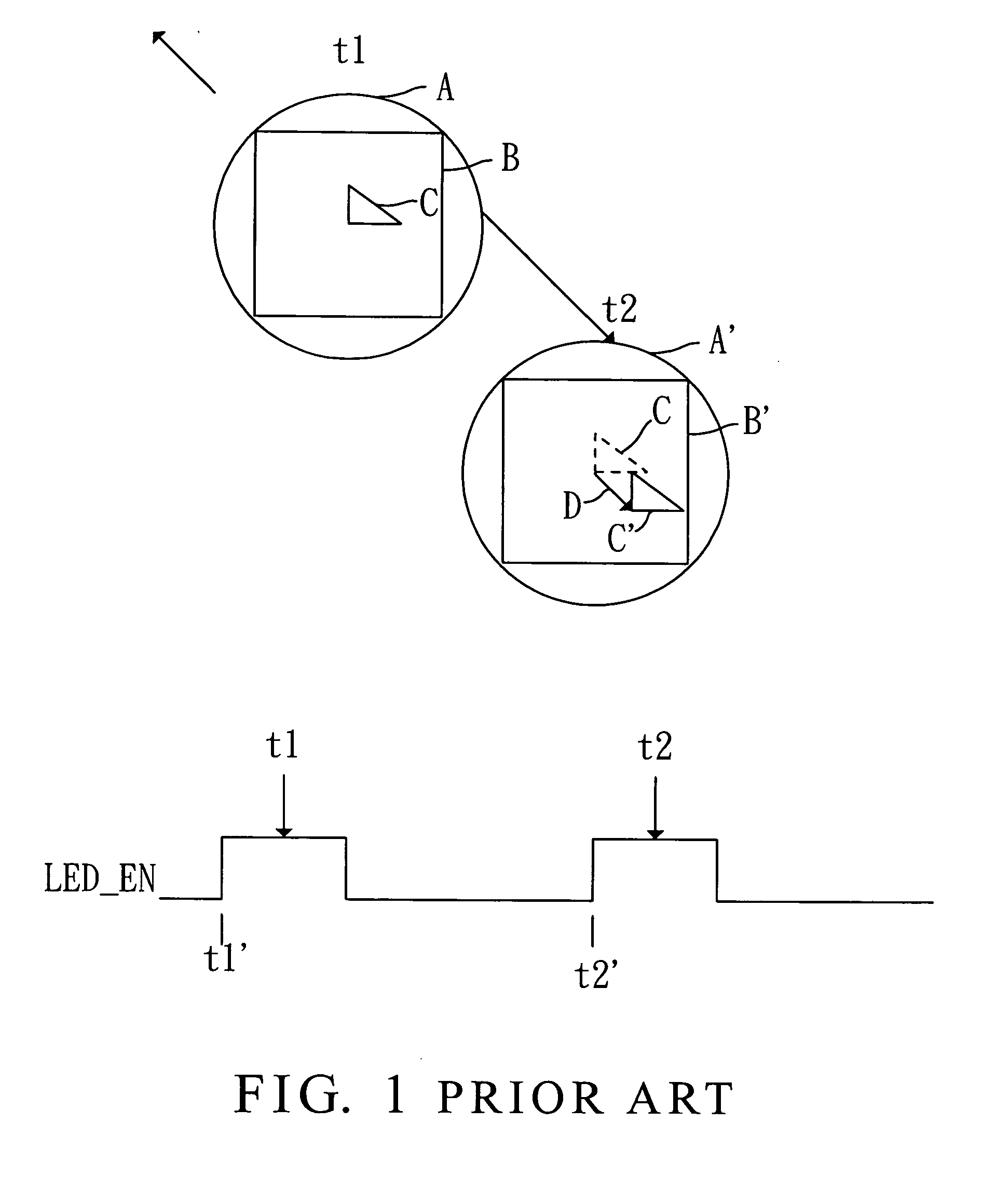

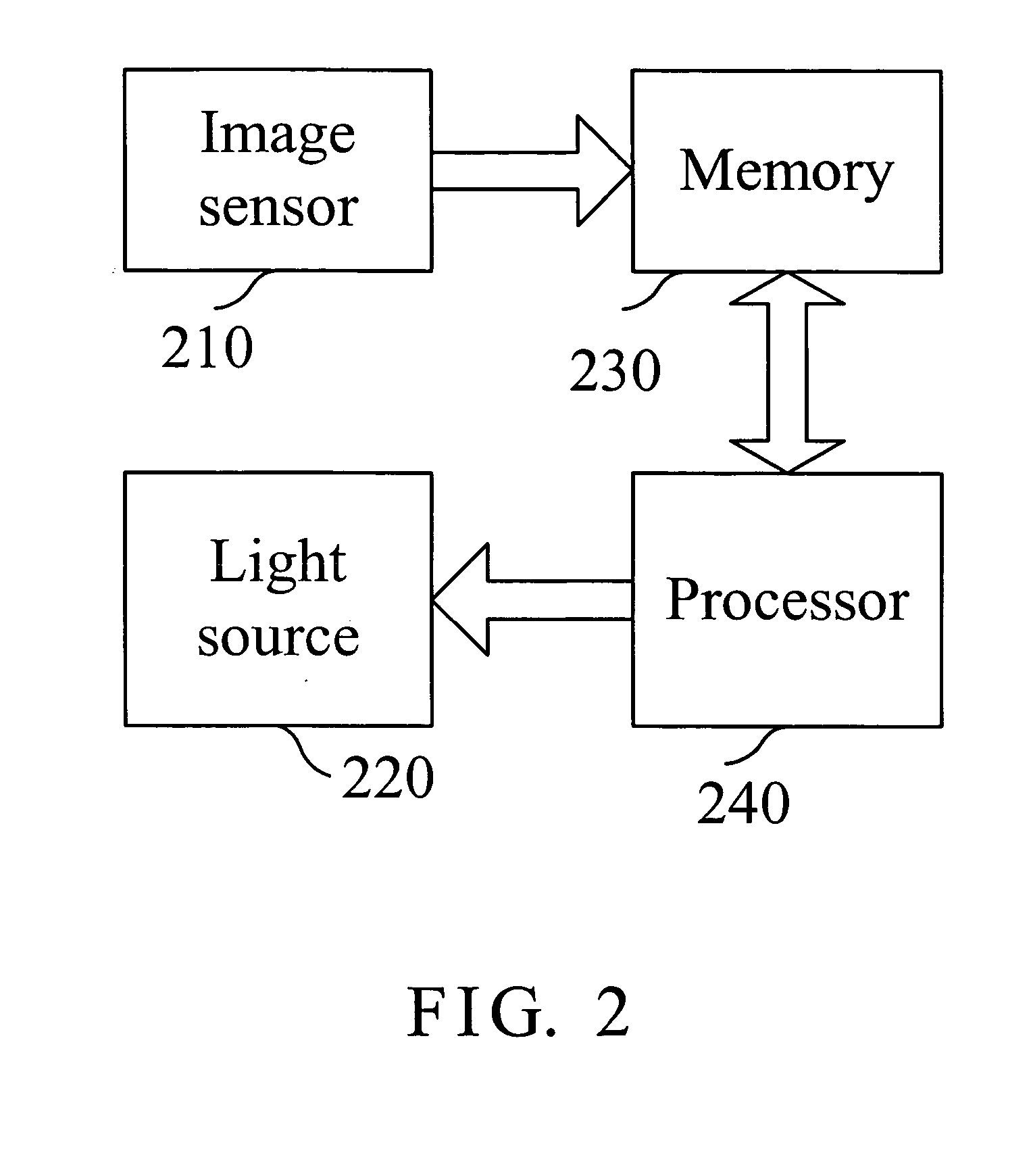

Method and apparatus for controlling dynamic image capturing rate of an optical mouse

InactiveUS20050068300A1Reduce power consumptionSave time and energyInput/output for user-computer interactionCathode-ray tube indicatorsImage sensorMoving speed

A method and apparatus for controlling dynamic image capturing rate of an optical mouse is disclosed. The optical mouse has a light source and an image sensor. The light source is lighted at a lighting frequency such that the image sensor can capture an external image. The method includes the steps: capturing a first image; capturing a second image at a next sampling time for comparing the first image and the second image and thus finding match parts to determine moving distance and speed of the optical mouse; and proportionally adjusting the lighting frequency of the light source and an image capturing rate based on the moving speed.

Owner:SUNPLUS TECH CO LTD

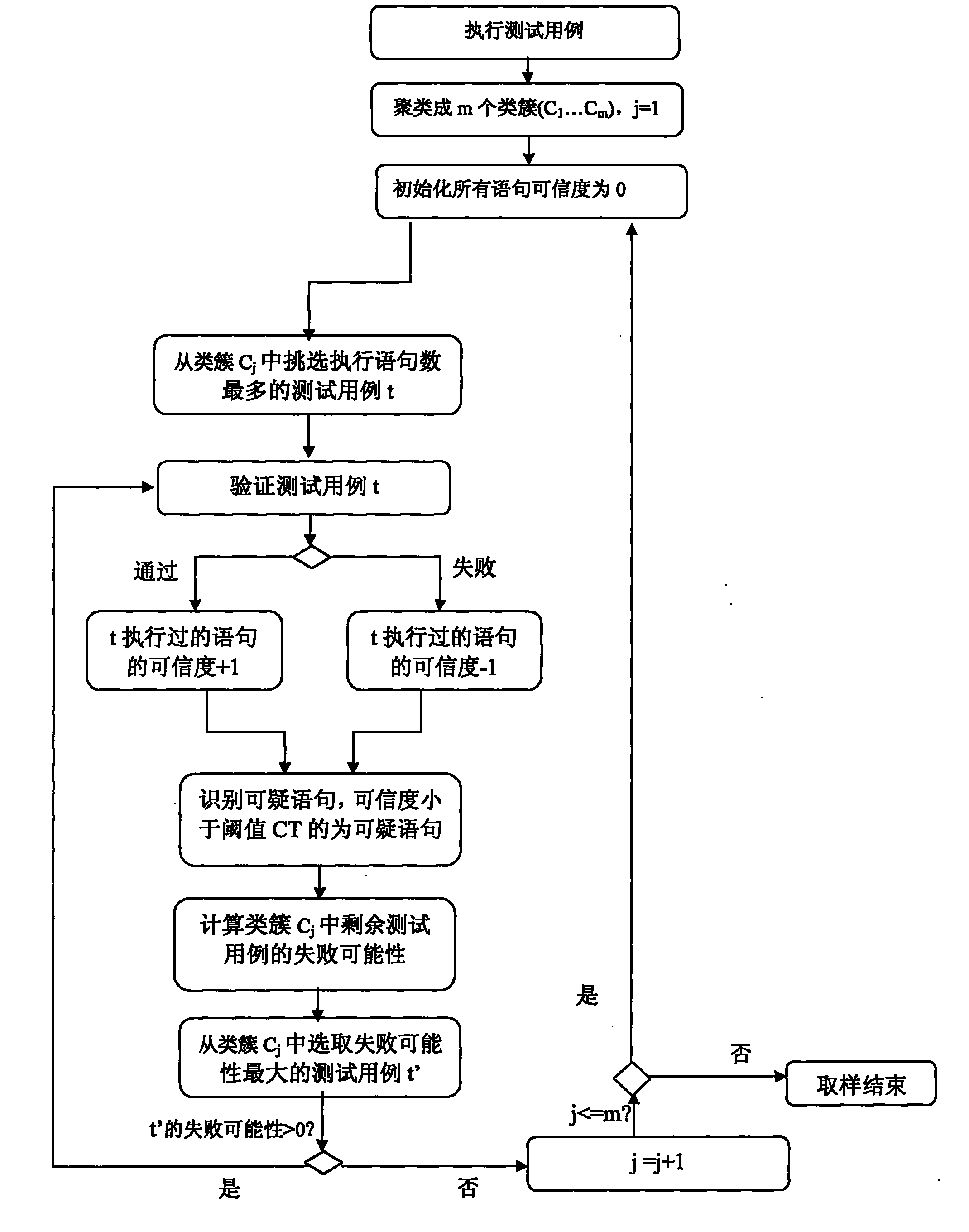

Sampling method for test cases in clusters

InactiveCN101814055ASave human effortSave time and energySoftware testing/debuggingTest caseSoftware testing

The invention discloses a stamping method for test cases in clusters, which comprises the following steps of: selecting the test cases in the clusters to test based on a technology for filtrating the clusters in an observed software test technology; computing the reliability of excused sentences according to a test result; judging whether the excused sentences are doubtful sentences, wherein the doubtful sentences form a doubtful sentences set; computing the failure probability of remainder test cases in the clusters according to the doubtful sentences set; selecting the test case with the highest failure probability; testing the result and recomputing the reliability of each sentence; updating the doubtful sentences set; and repeating the step of sampling to the untested test cases till that the failure probability of all remainder test cases in the clusters are 0. As the results of the test cases after sampling do not need to be tested, the method simples the test cases, saves the time and the energy for manually testing the test cases, and guarantees that the failure test cases in the test cases to be sampled has significant proportion and the reliability value of the sentences can be used for helping test persons to perform error locating.

Owner:NANJING UNIV

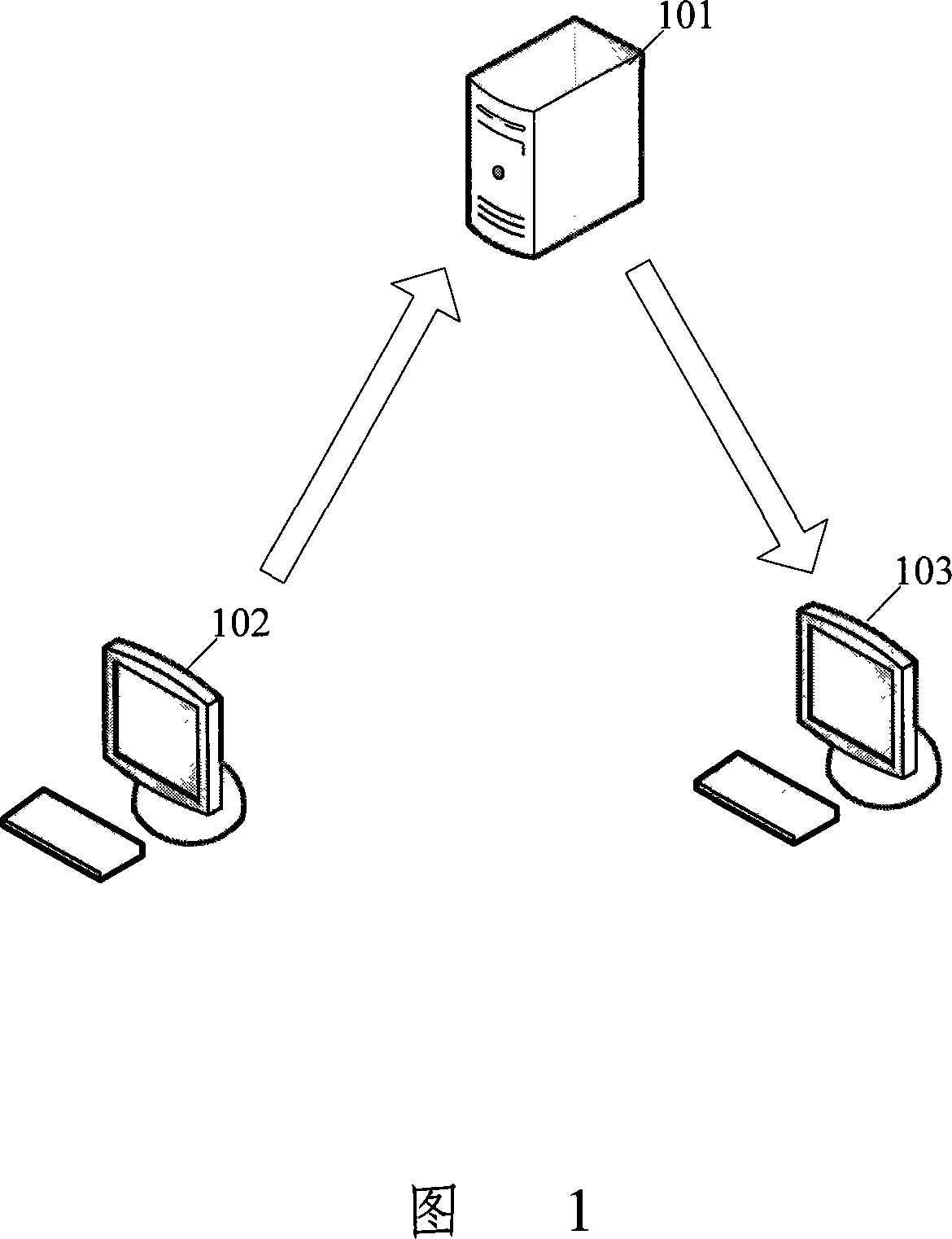

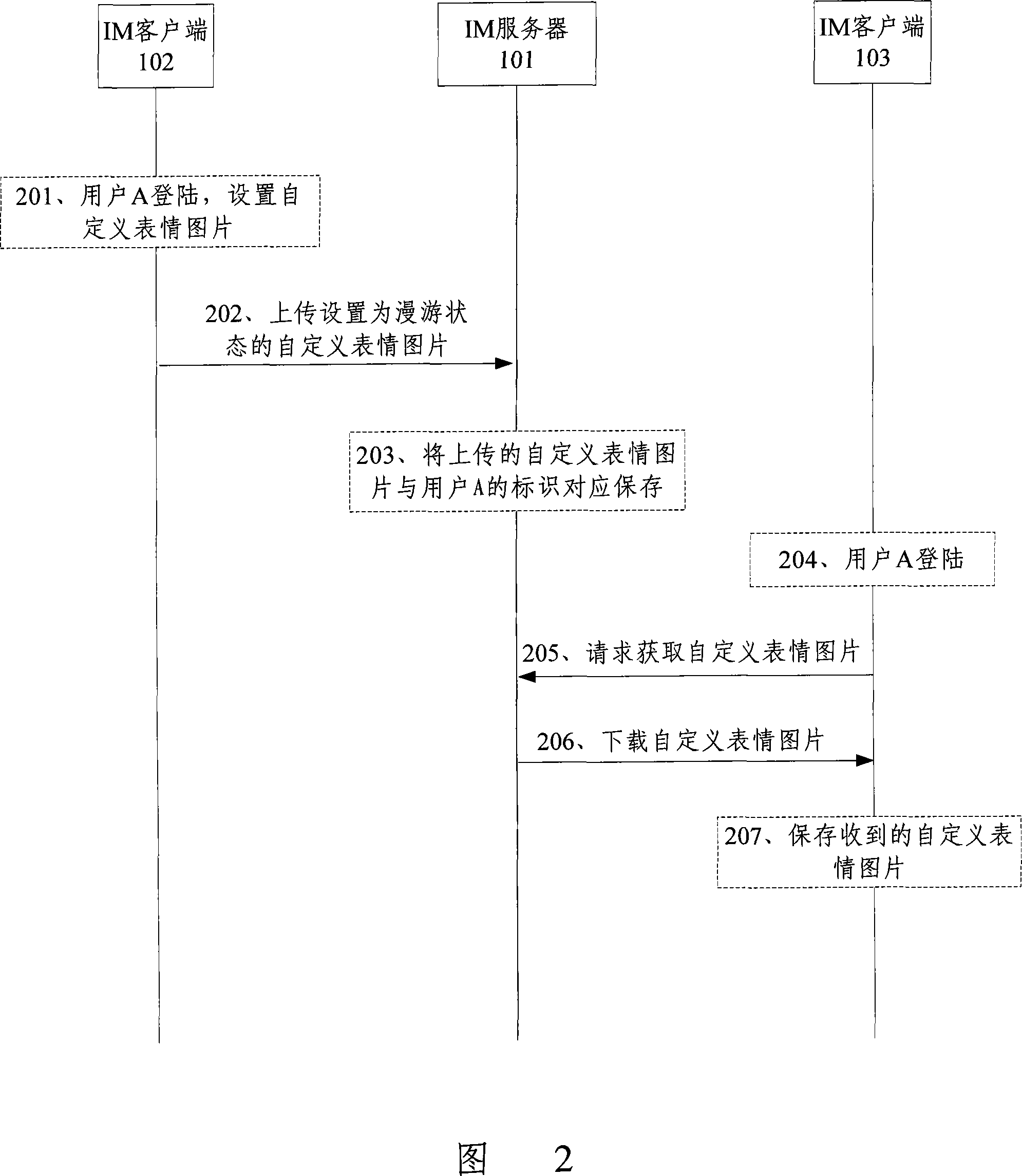

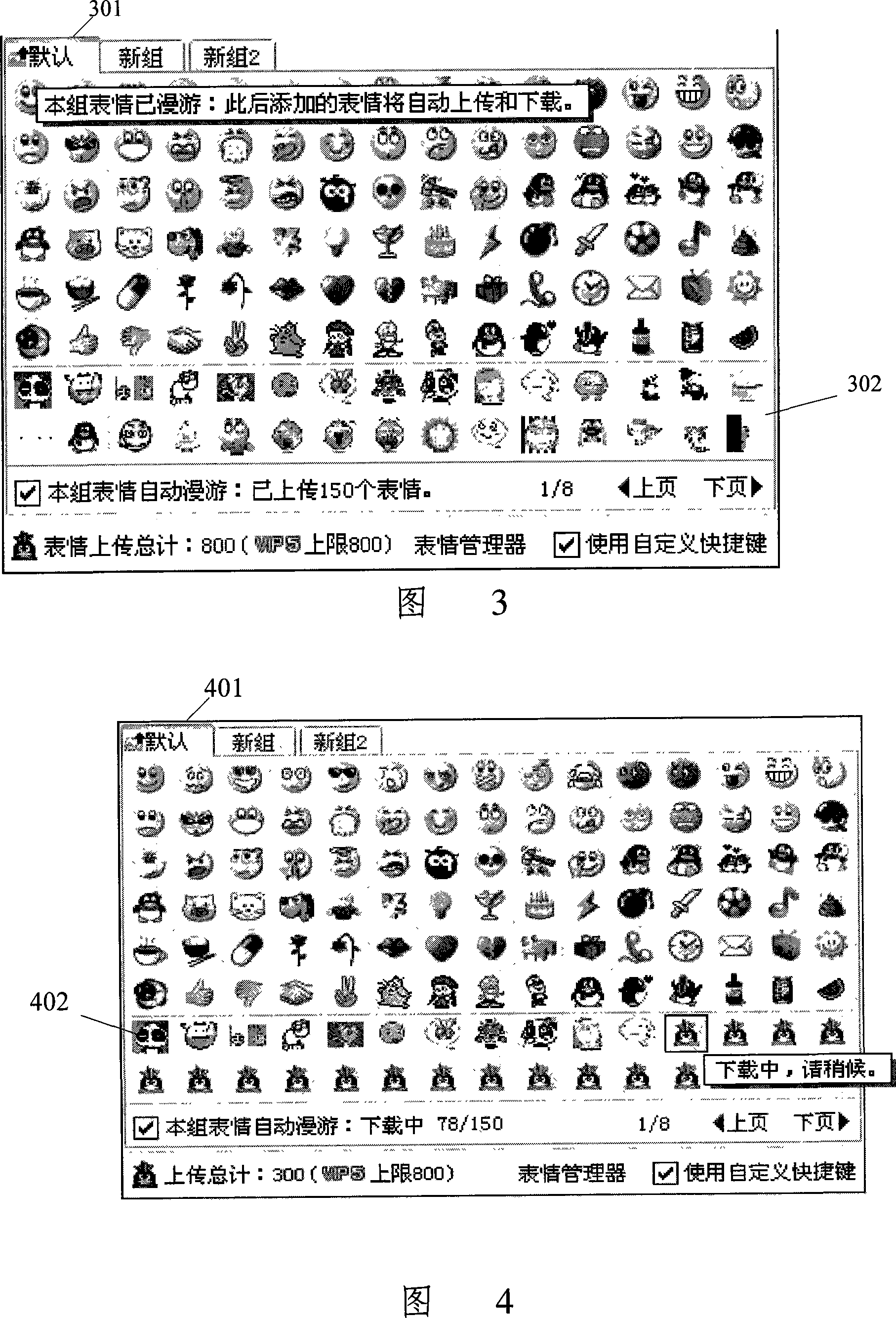

An instant communication system and transmission method of self-defined information

ActiveCN101123568AEasy instant messagingSave time and energyStore-and-forward switching systemsClient-sideCommunications system

The present invention discloses a transmission method of the customized information in an instant message (IM) system and an IM system, and the method includes three steps. Firstly, a local IM client receives and stores the customized information configured by a user; secondly, the local IM client uploads the customized information configured by the user to an IM server for storage; thirdly, when the user logs on to an IM client at a different location, the IM client at the location obtains and stores the corresponding customized information of the user from the IM server. By utilizing the present invention, the roaming function of the customized information can be realized, therefore a user can still use the customized information configured on a local IM client on an IM client at a different location, and as a result, the user can conveniently use the customized information to carry out the instant communication.

Owner:TENCENT TECH (SHENZHEN) CO LTD

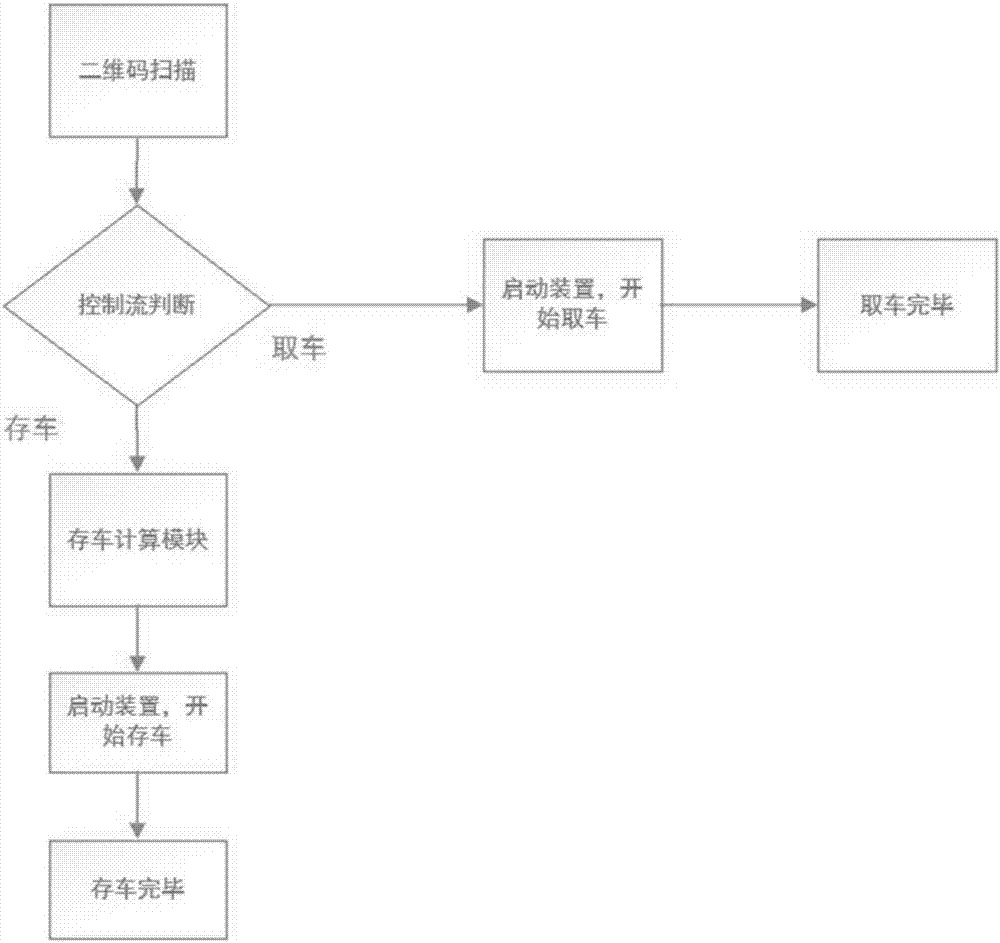

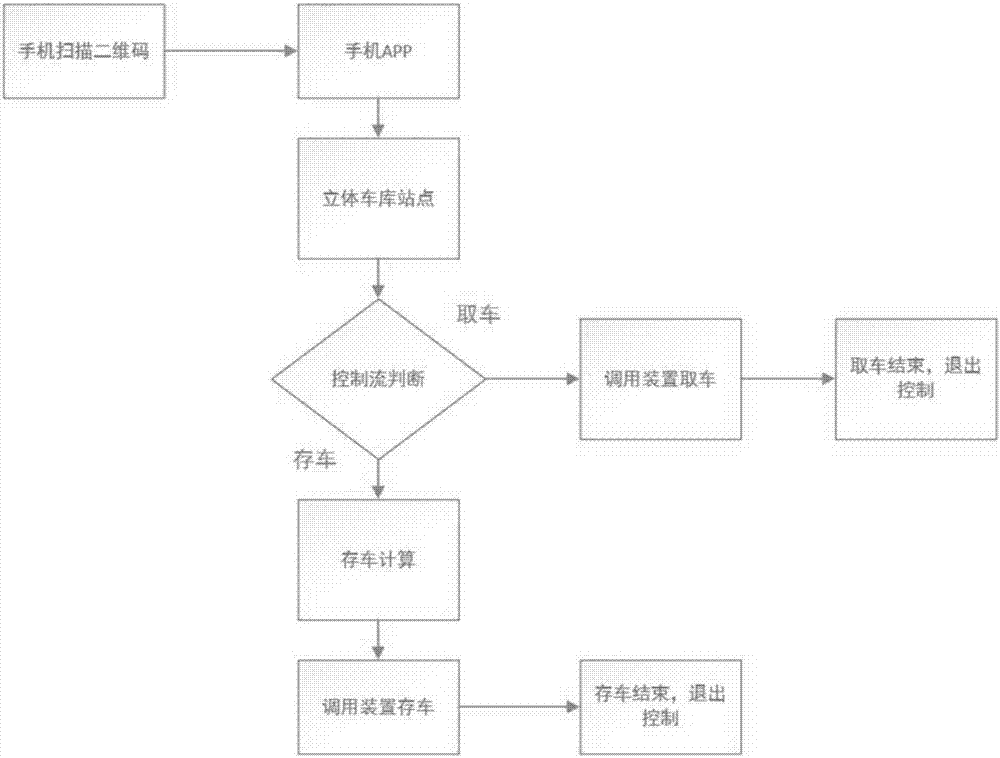

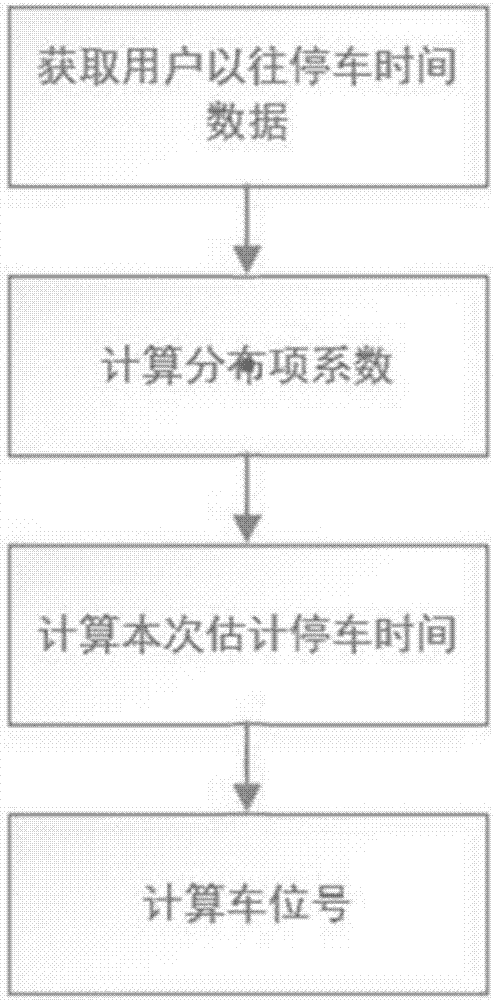

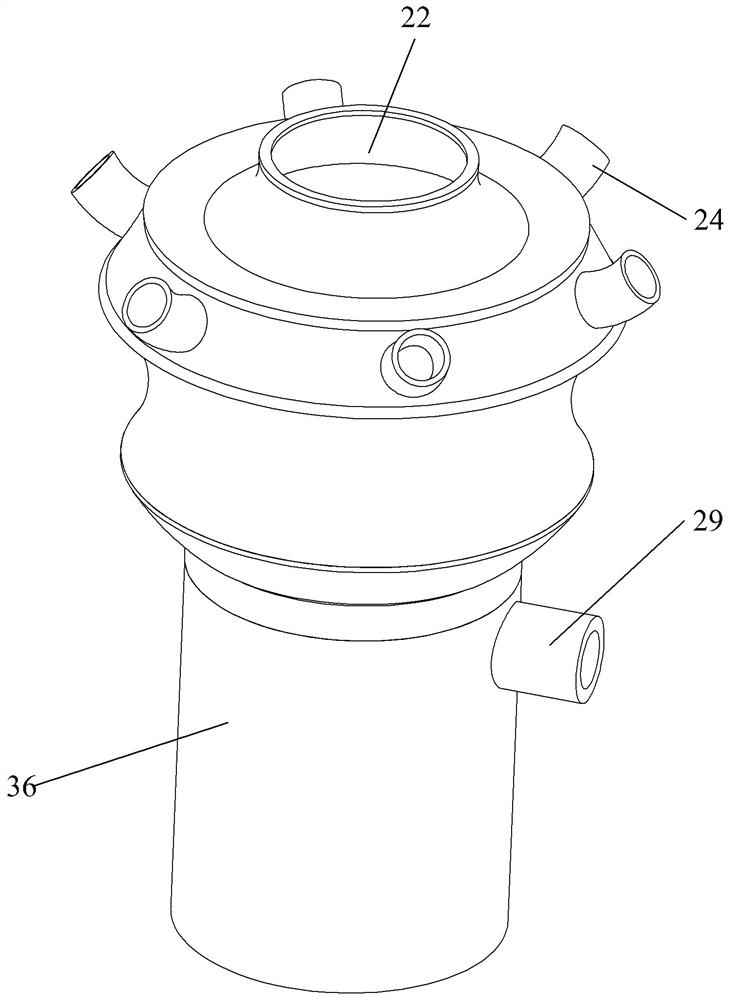

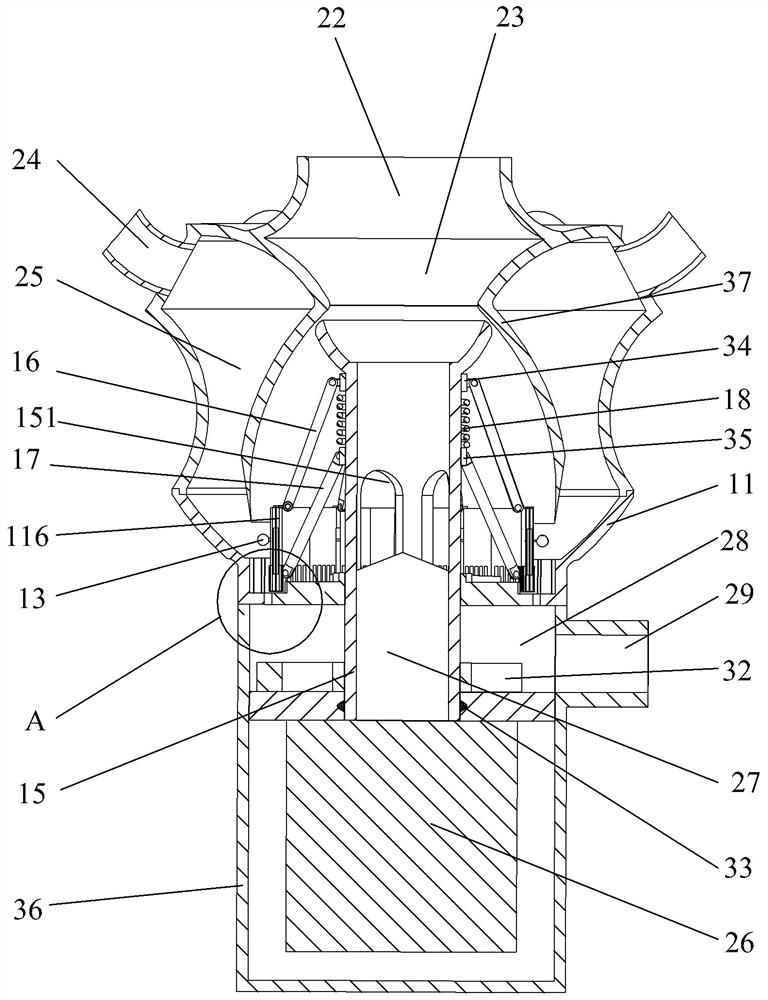

Rapid vehicle storing-taking method for vertical stereo garage

The invention discloses a rapid vehicle storing-taking method for a vertical stereo garage and belongs to the technical field of garage management. Rapid vehicle storing-taking is completed by a vehicle storing-taking system. The rapid vehicle storing-taking method comprises the following steps that a two-dimensional code is scanned, and a vehicle storing or taking instruction is sent; the two-dimensional code is scanned to confirm vehicle storing or taking; the vehicle storing or taking instruction is confirmed; the vehicle storing time is calculated through a vehicle storing allocation algorithm, and a vehicle storing position is allocated; a vehicle is stored to a designated parking space in a designated layer to complete vehicle storage; the two-dimensional code is scanned to confirm vehicle taking; a driving device moves and takes out the vehicle. The vehicle storing allocation algorithm comprises the following steps that previous parking time data of a client is obtained; distribution item coefficients are calculated; the estimated parking time this time is calculated; a parking space number is calculated. Parking positions are reasonably arranged by estimating the parking time of the clients, the parking modes of users are effectively analyzed, the storing-taking efficiency is improved, time and energy consumption are saved or reduced, and the method is suitable for stereo and rapid storage and taking of bicycles and other similar garage vehicles.

Owner:INST OF INTELLIGENT MFG TECH JITRI

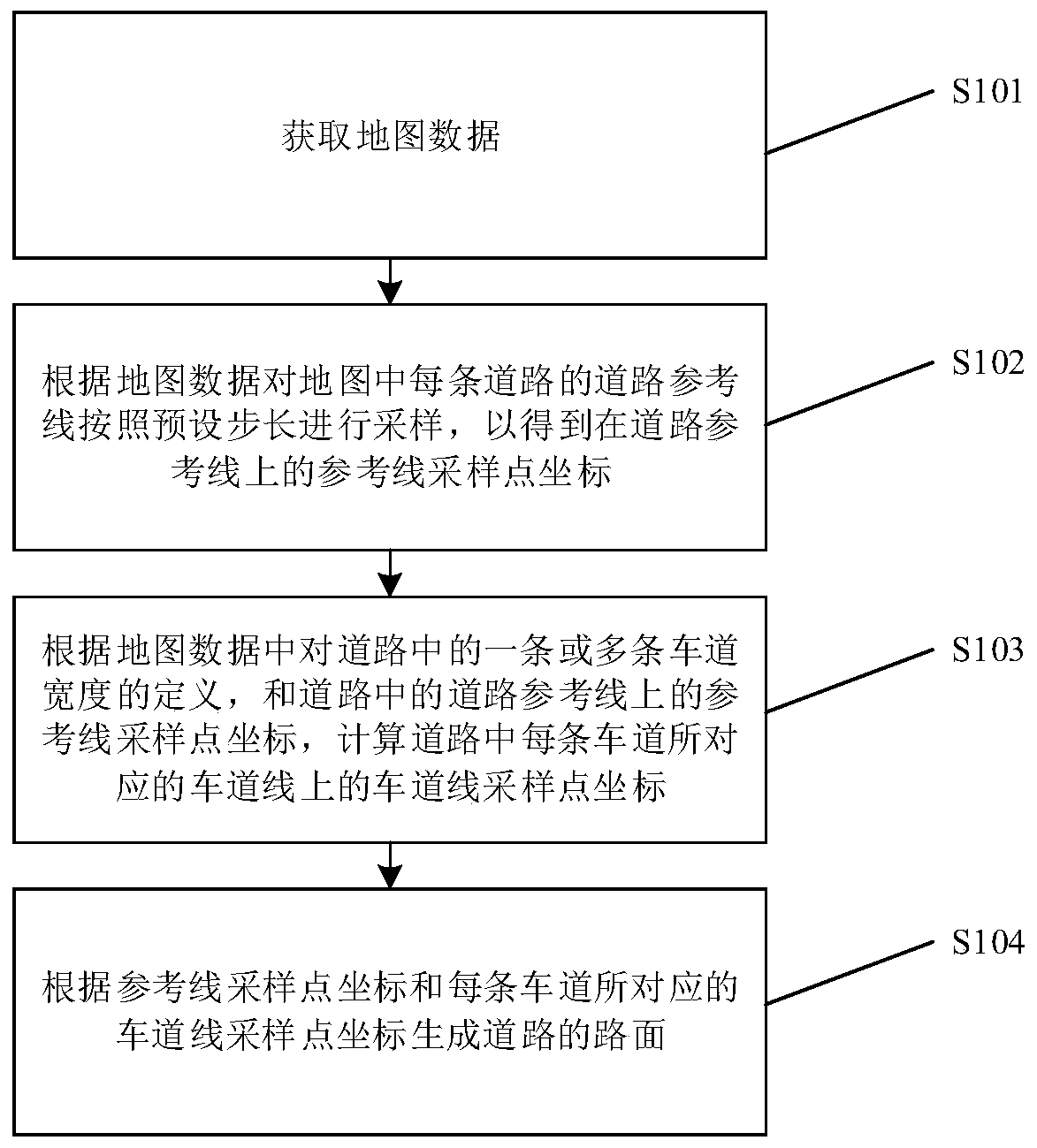

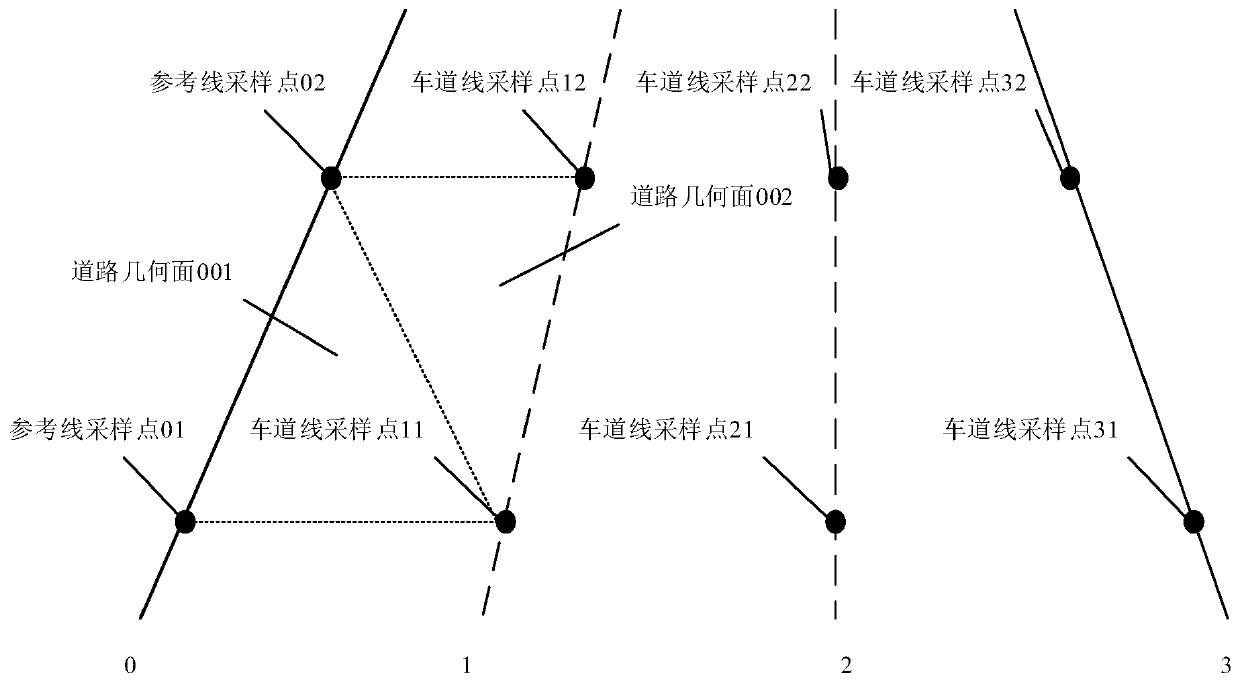

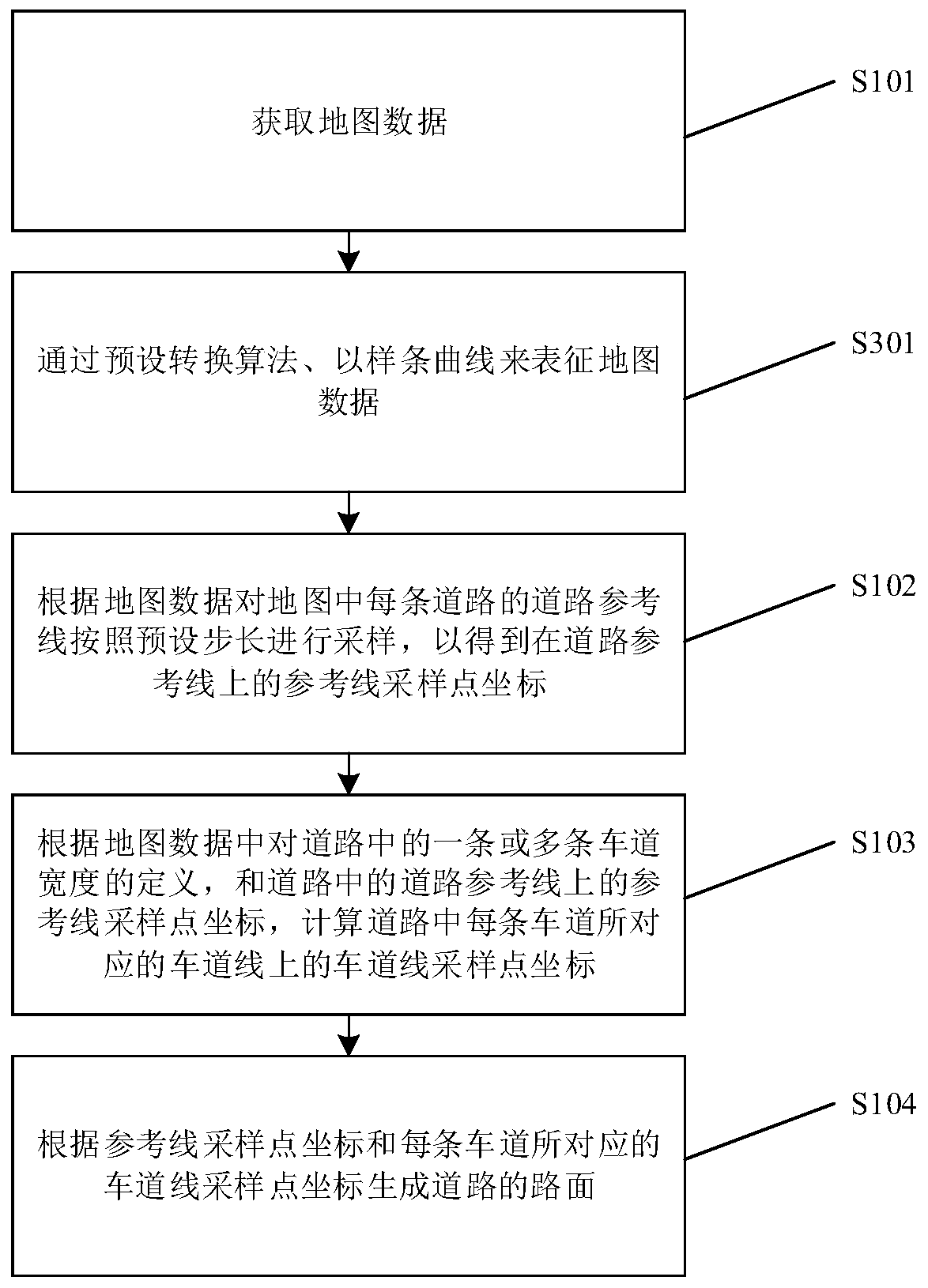

Road generation method and device, storage medium and electronic equipment

ActiveCN110415330ASave time and energyImprove efficiencyMaps/plans/chartsGeographical information databasesElectronic equipmentRoad surface

The invention relates to a road generation method and a device, a storage medium and an electronic device. The method comprises the steps of obtaining map data; sampling the road reference line of each road in the map according to the map data and a preset step length to obtain reference line sampling point coordinates on the road reference line; calculating lane line sampling point coordinates ona lane line corresponding to each lane in the road according to the definition of the width of one or more lanes in the road in the map data and reference line sampling point coordinates on a road reference line in the road; and generating the road surface of the road according to the reference line sampling point coordinates and the lane line sampling point coordinates corresponding to each lane. Thus, the road surface of the road can be formed directly through the sampling points obtained by sampling according to the map data, the road scene does not need to be constructed manually according to the map data, the problems of inaccurate manual construction and long consumed time are solved, the time and energy required for constructing the three-dimensional road scene are greatly reduced,and the efficiency is improved.

Owner:万物镜像(北京)计算机系统有限公司

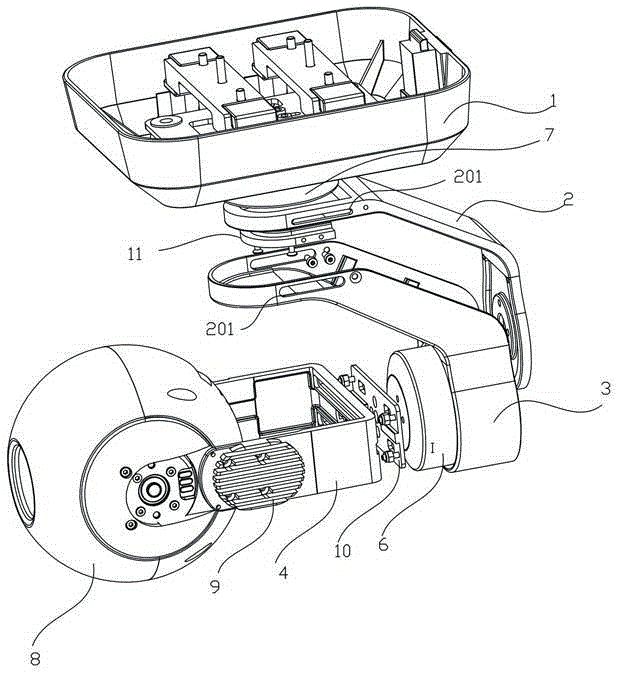

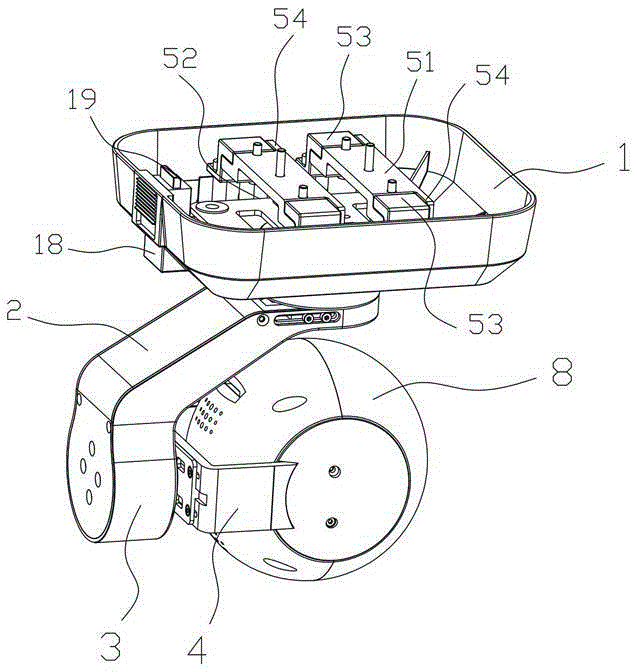

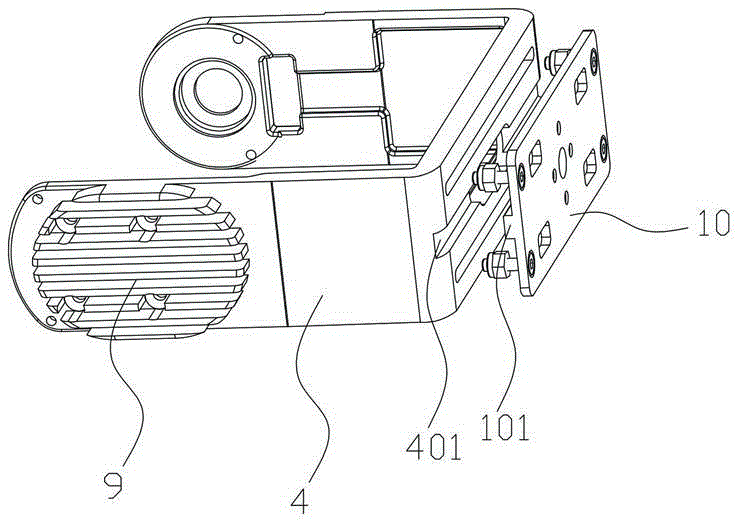

Holder device of unmanned airplane

ActiveCN105270646ASave time and energyExtended service lifeAircraft componentsAirplaneElectrical and Electronics engineering

The invention discloses a holder device of an unmanned airplane. The device comprises a holder installation seat and a device installation assembly, wherein the holder installation seat and the device installation assembly are connected together. The holder installation seat comprises an installation platform and a slide rail-type attachment mechanism. The slide rail-type attachment mechanism comprises more than one slide rails connected with the bottom of the unmanned airplane, and slide chutes arranged on the installation platform. When the holder installation seat is connected with the bottom of the unmanned airplane, the slide rails are sleeved inside the slide chutes to complete the mated connection. The holder device is simple and compact in structure, convenient in operation and long in service life. Meanwhile, the device can be installed or disassembled quickly, and the gravity center of the device can be adjusted.

Owner:HUNAN AIRTOPS INTELLIGENT TECH CO LTD

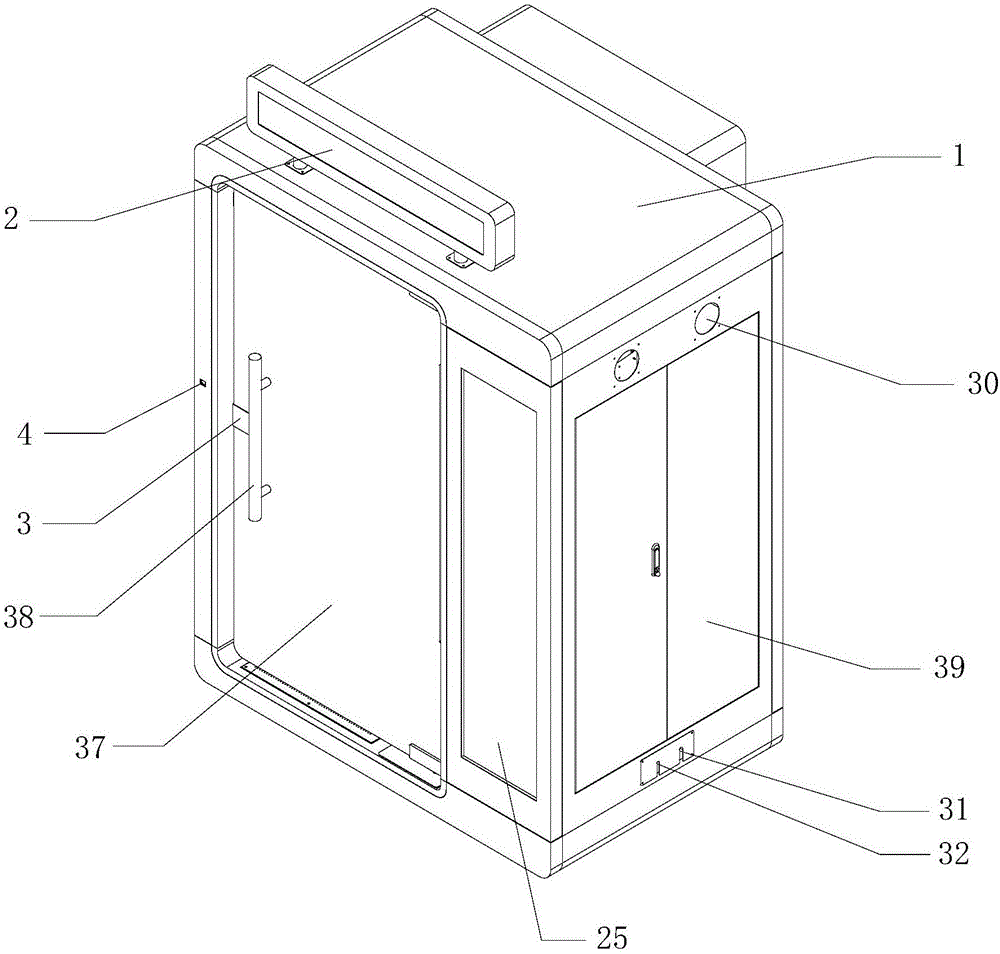

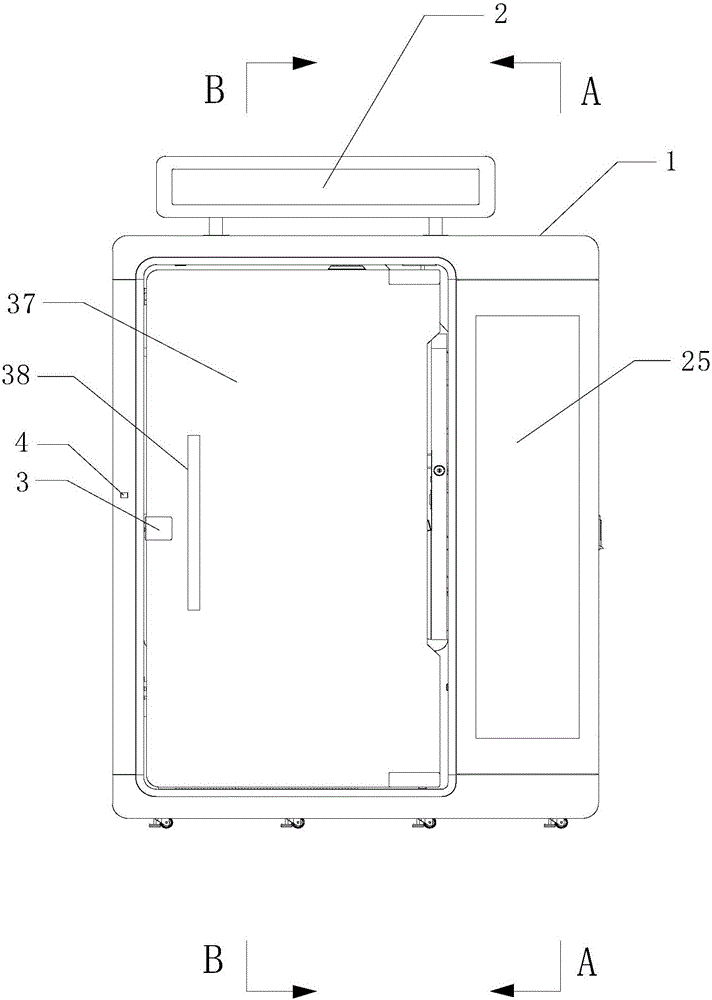

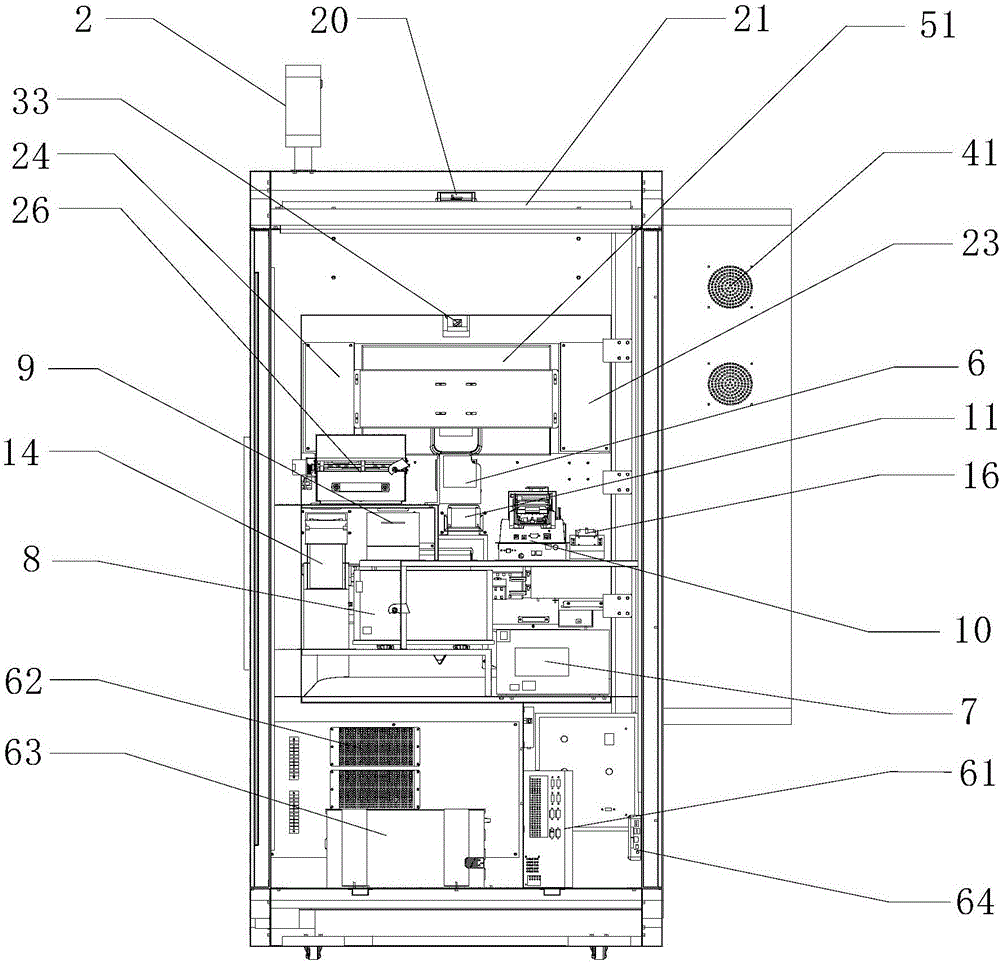

Automatic exit and entry certificate handling device and method thereof

PendingCN106846661AImprove the efficiency of certificate processingSave time and energyData processing applicationsApparatus for meter-controlled dispensingDigital cameraCard reader

The invention discloses an automatic exit and entry certificate handling device and a method thereof. The device comprises a shell, a touch display screen, a digital camera, a picture color printer, a laser printer, an identity card reader, an endorsement module, a control module, a lifting chair, and a lifting part, wherein the touch display screen, the digital camera, the picture color printer, the laser printer, the identity card reader, the endorsement module and the control module are arranged on the rear part in the shell, the lens of the digital camera faces to the front part in the shell, the lifting chair and the lifting part are arranged on the front part in the shell, and the lifting part is used for driving the lifting chair to go up or down; and the touch display screen, the digital camera, the picture color printer, the laser printer, the identity card reader, the endorsement module and the lifting part are respectively connected to the control module. The device disclosed by the invention can enable users to independently apply for new exit and entry certificates and endorse exit and entry certificates for the second time, and thereby, not only is the efficiency of certificate handling increased, but also the time and energy of the users are saved.

Owner:广州市华标科技发展有限公司

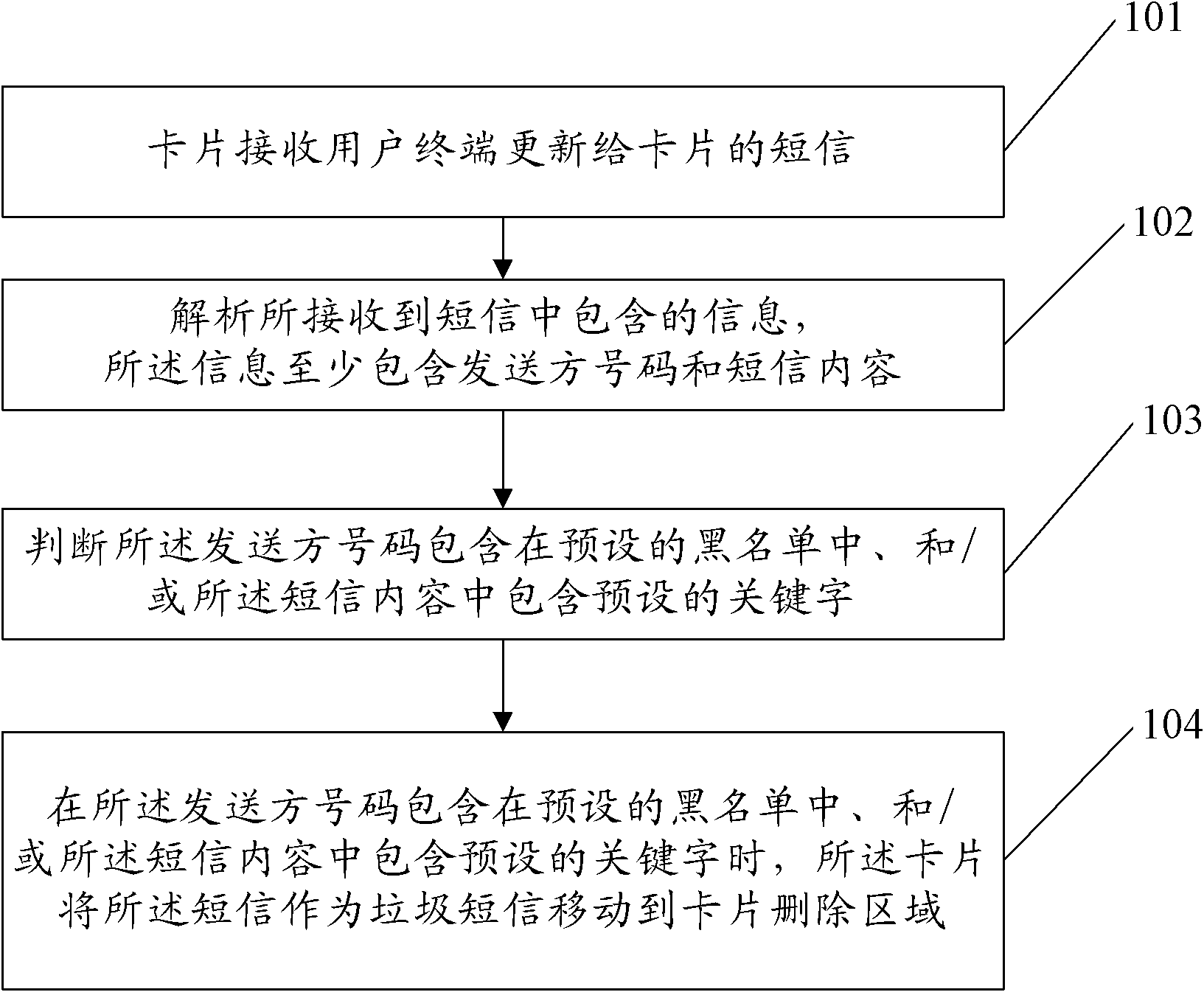

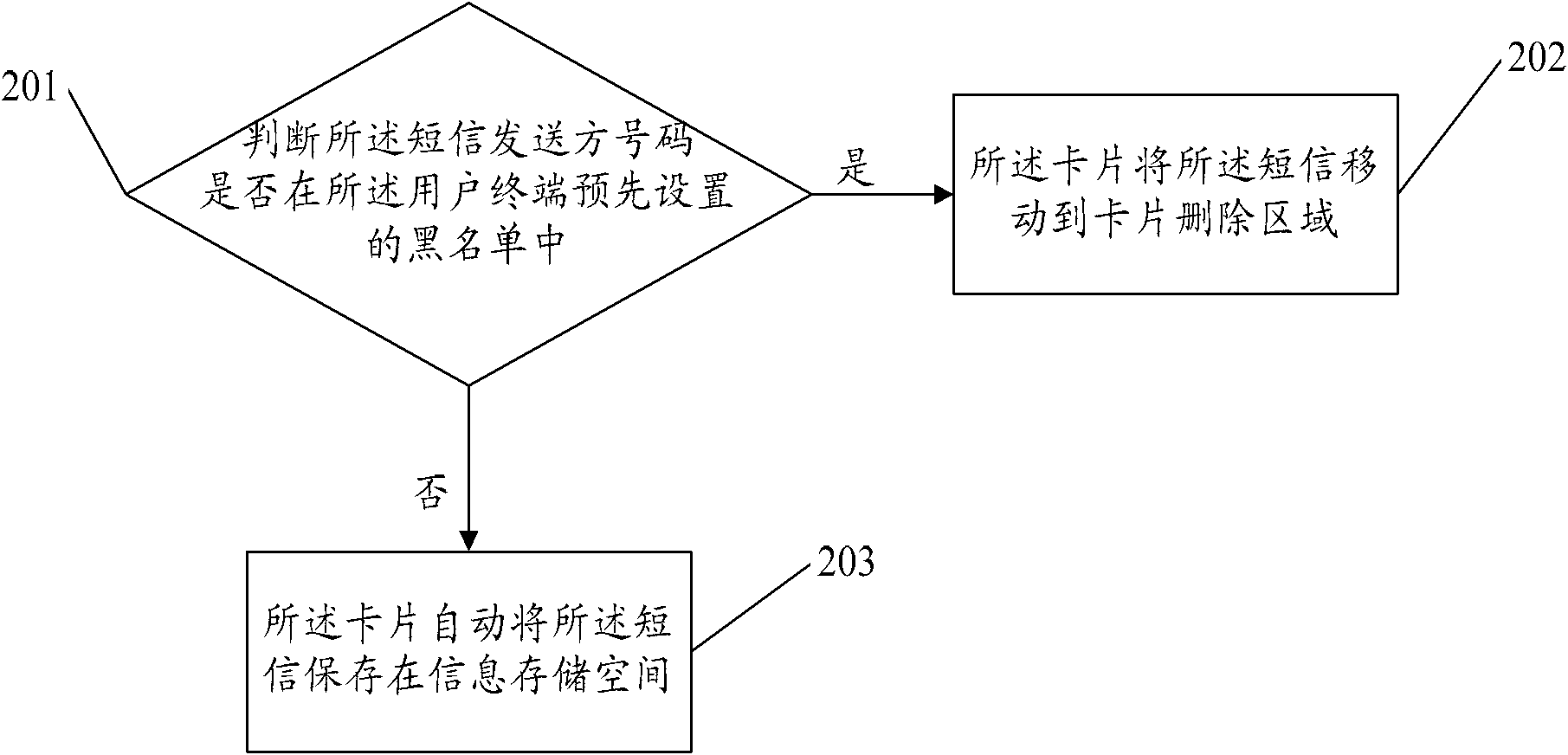

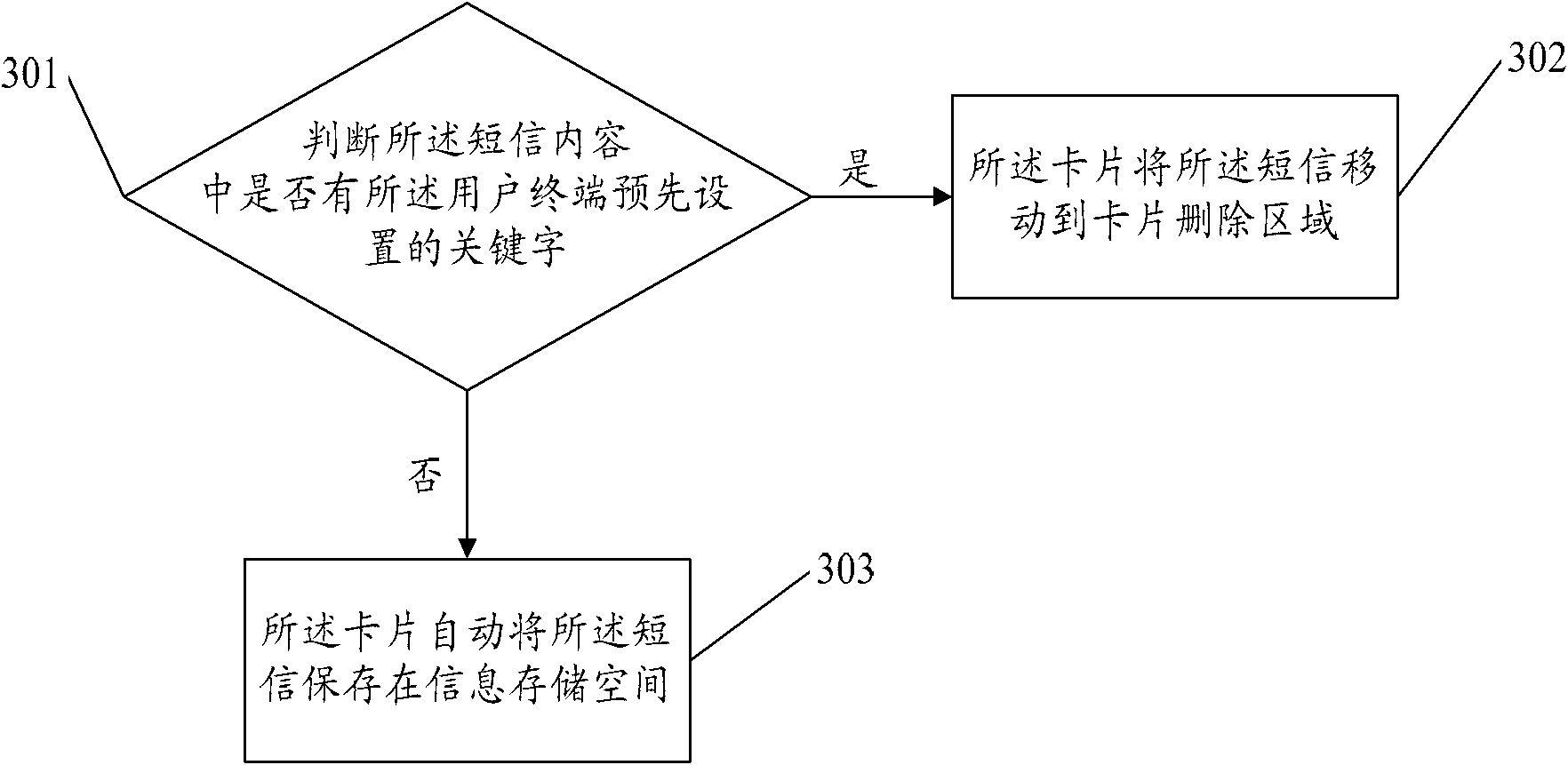

Short message management method and device thereof

Owner:FEITIAN TECHNOLOGIES

Refining method for probiotics-containing cassava feed

ActiveCN103859155ASimple processSave time and energyAnimal feeding stuffFood shapingWater contentProtein content

The invention discloses a refining method for a probiotics-containing cassava feed. A production method comprises the following steps: mixing cassava powder with water; inoculating with saccharomycetes seed liquid and fermenting under an anaerobic condition; taking following ingredients in parts by weight: 50-70parts of cured sweet vinasse, 10-15 parts of corn flour, 10-15 parts of soya bean meal, 10-15 parts of peanut bran, 2-5 parts of invertase and 10-15 parts of probiotics-containing seed liquid; agitating and mixing uniformly, and sealing and fermenting; adding microelements, vitamins, traditional Chinese medicine elements and amino acids, and agitating uniformly to obtain a nutrition activated crude protein feed; drying the crude protein feed until the water content is 10%-15%; and granulating the crude protein feed into a granulation machine to obtain multi-vitamin active cassava protein feed. According to the refining method, microorganisms are used for treating cassava wastes; compared with the feed prepared by a traditional method, the protein feed prepared by the method according to the invention has the advantages that the protein content is improved by 10-20%.

Owner:GUANGXI XINTIANDE ENERGY +1

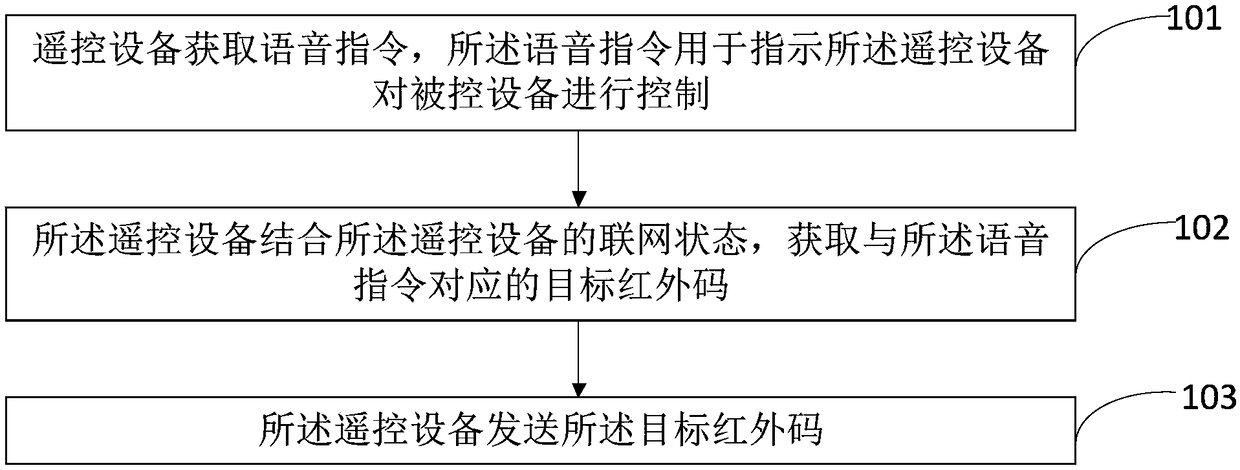

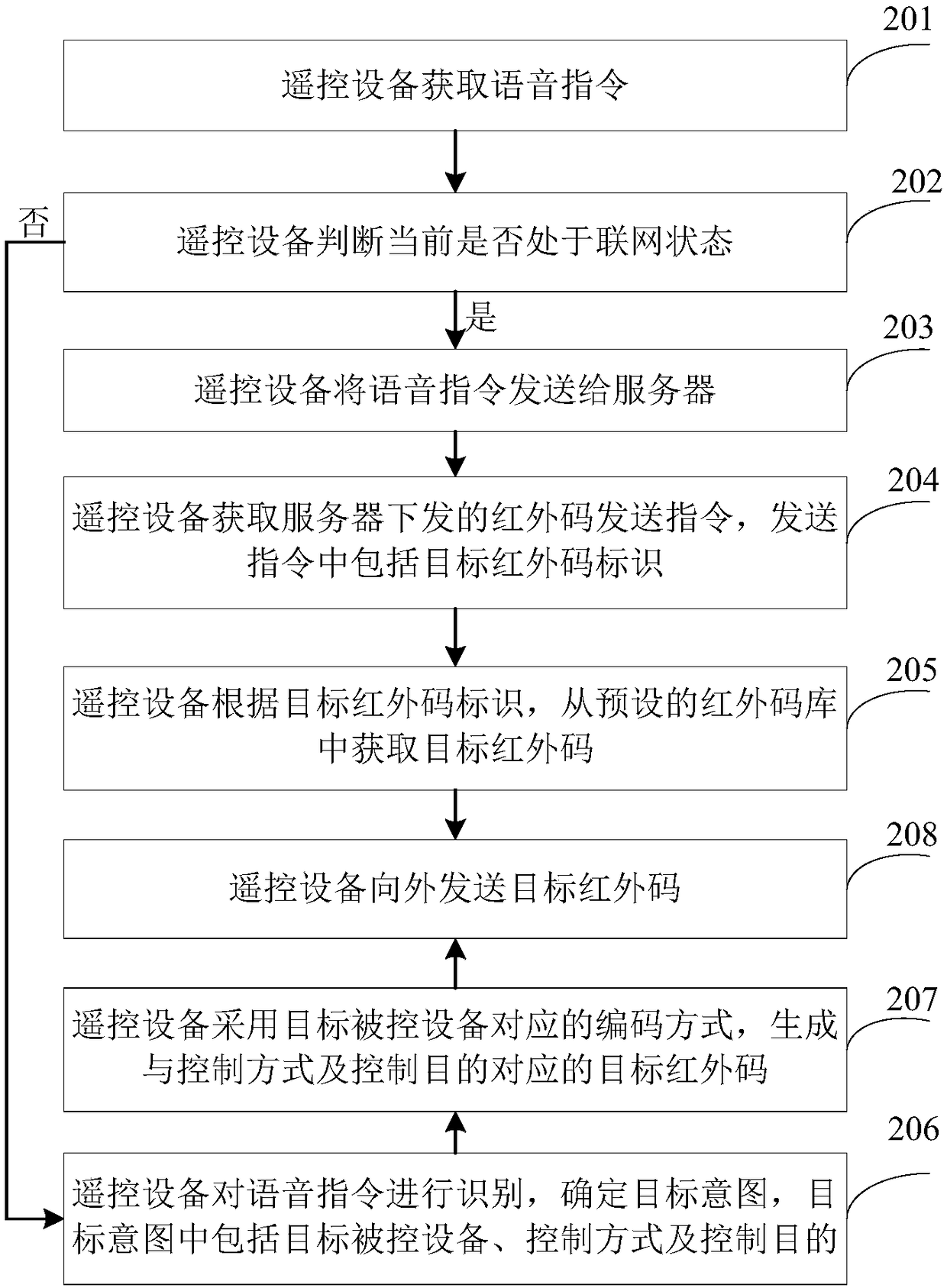

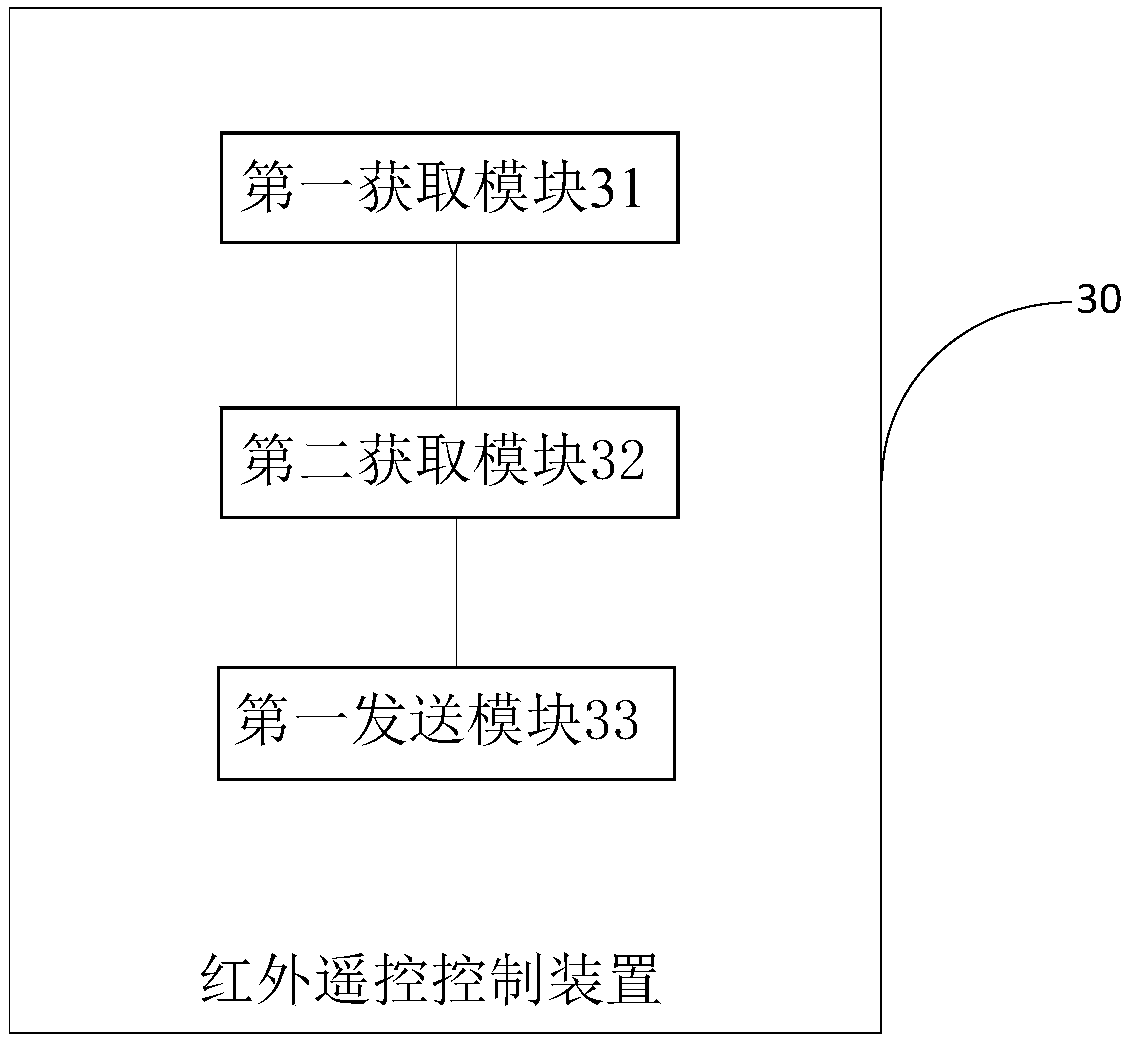

Infrared remote control method and device, remote control equipment and medium

InactiveCN108492545AEasy to operateSave time and energyNon-electrical signal transmission systemsSpeech recognitionControl equipmentMaterial resources

The invention provides an infrared remote control method, an infrared remote control device, remote control equipment and a medium. The infrared remote control method is applied to the remote controlequipment with a voice wake-up function, and comprises the following steps: acquiring a voice instruction by the remote control equipment, wherein the voice instruction is used for instructing the remote control equipment to control controlled equipment; in combination with the networking state of the remote control equipment, acquiring a target infrared code corresponding to the voice instructionby the remote control equipment; sending the target infrared code by the remote control equipment. According to the infrared remote control method, the controlled equipment is controlled by the remote control equipment with the voice wake-up function, so that the problem that the controlled equipment cannot be operated when a user cannot find the remote control equipment is avoided, and the usercan control the controlled equipment by voice, and thus the operating mode is simple and the time and the vigor of the user are saved; in addition, the user does not need to replace the existing controlled equipment, so that money and material resources are saved, and thus a user experience is improved.

Owner:KINGSOFT

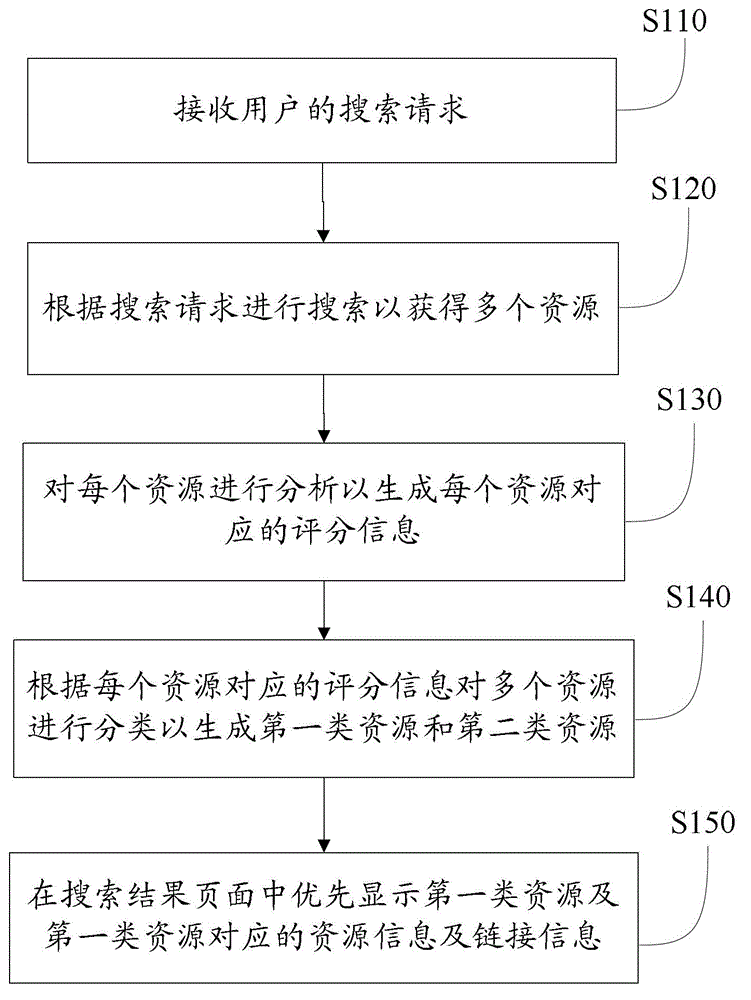

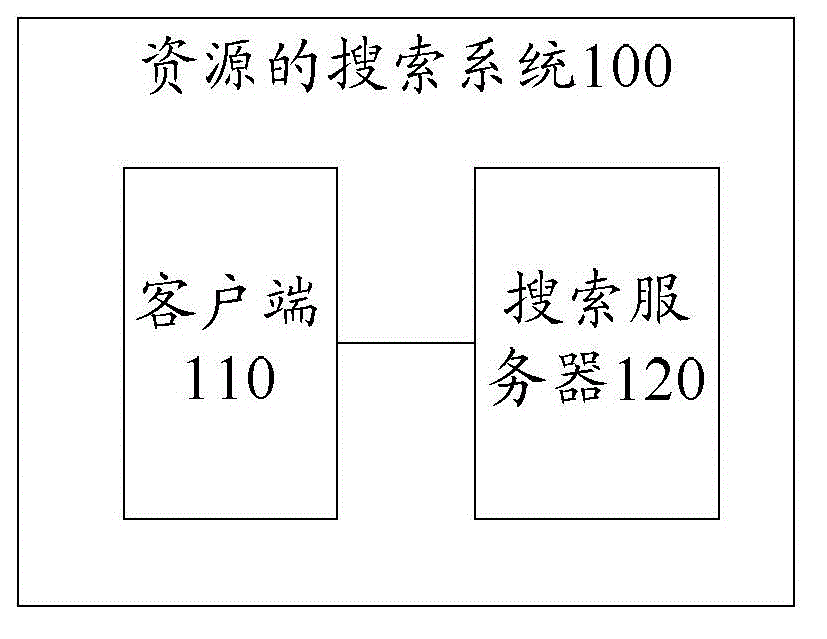

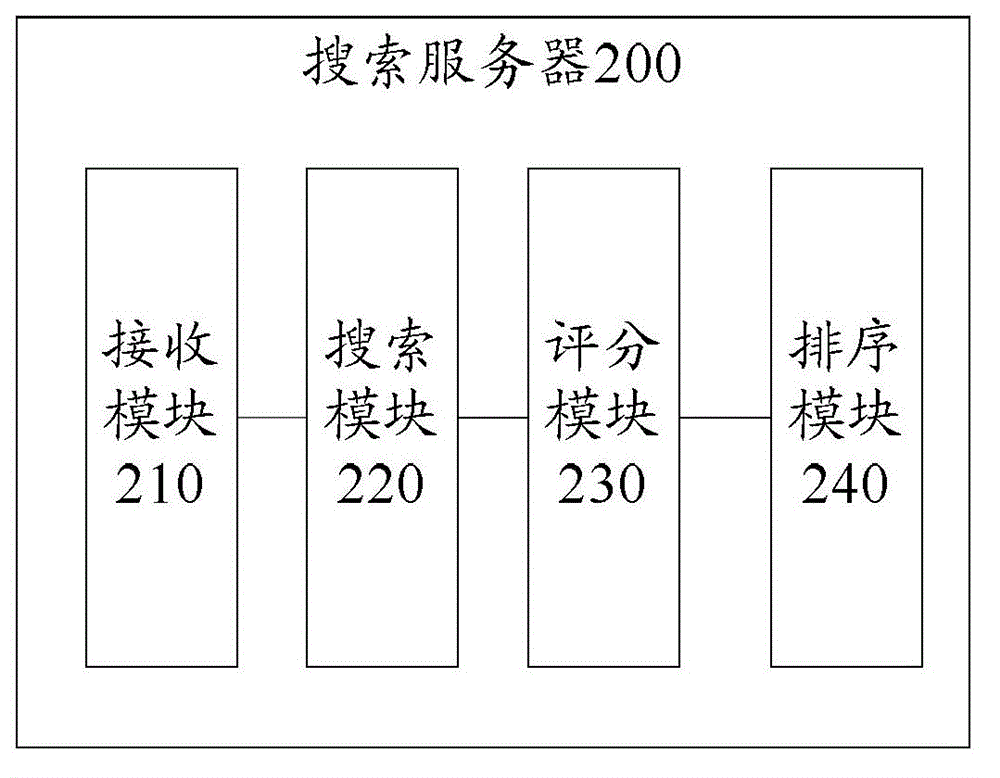

Method and system and device for resource searching

InactiveCN102982137AImprove quality, satisfactionSave time and energySpecial data processing applicationsUser satisfactionSearch engine results page

The invention provides a resource searching method which comprises that a searching request is received; searching is carried out according to the searching request so that a plurality of resources can be obtained; each resource is analyzed so that grading information corresponding to each resource is generated; the plurality of the resources are classified according to the grading information corresponding to each resource so that a first kind of resources and a second kind of resources are generated, wherein the grading information of the first kind of resources is higher than the grading information of the second kind of resources; the first kind of resources, the resource information and linkage information corresponding to the first kind of resources are preferentially displayed on a searching result page. Due to search engine excavating, good-quality resource grading and an optimized display mode provided on the result page according to the characteristic of a user, searching result is high in quality, and customer satisfaction is good. The invention further discloses a resource searching system and a searching server.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

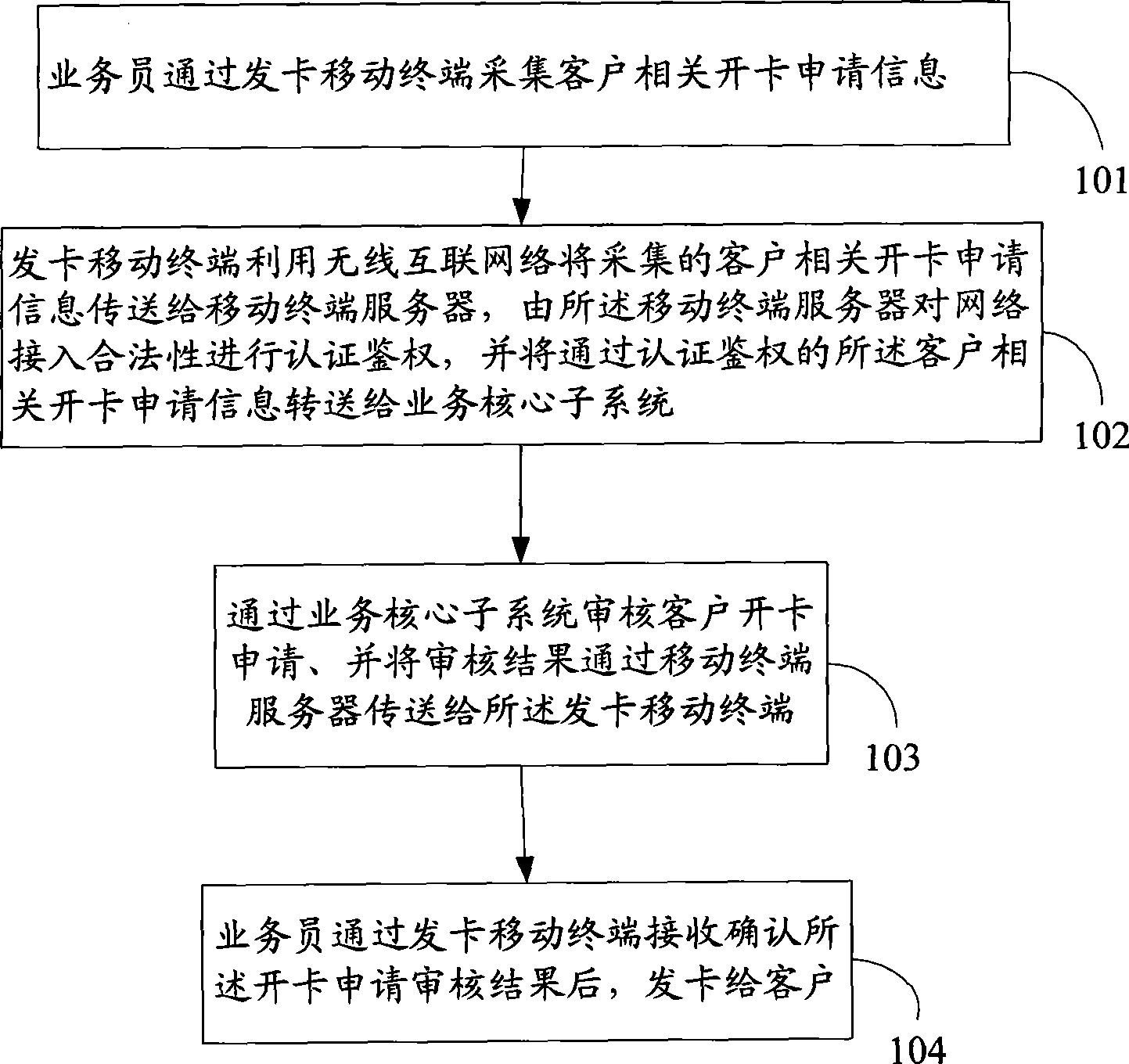

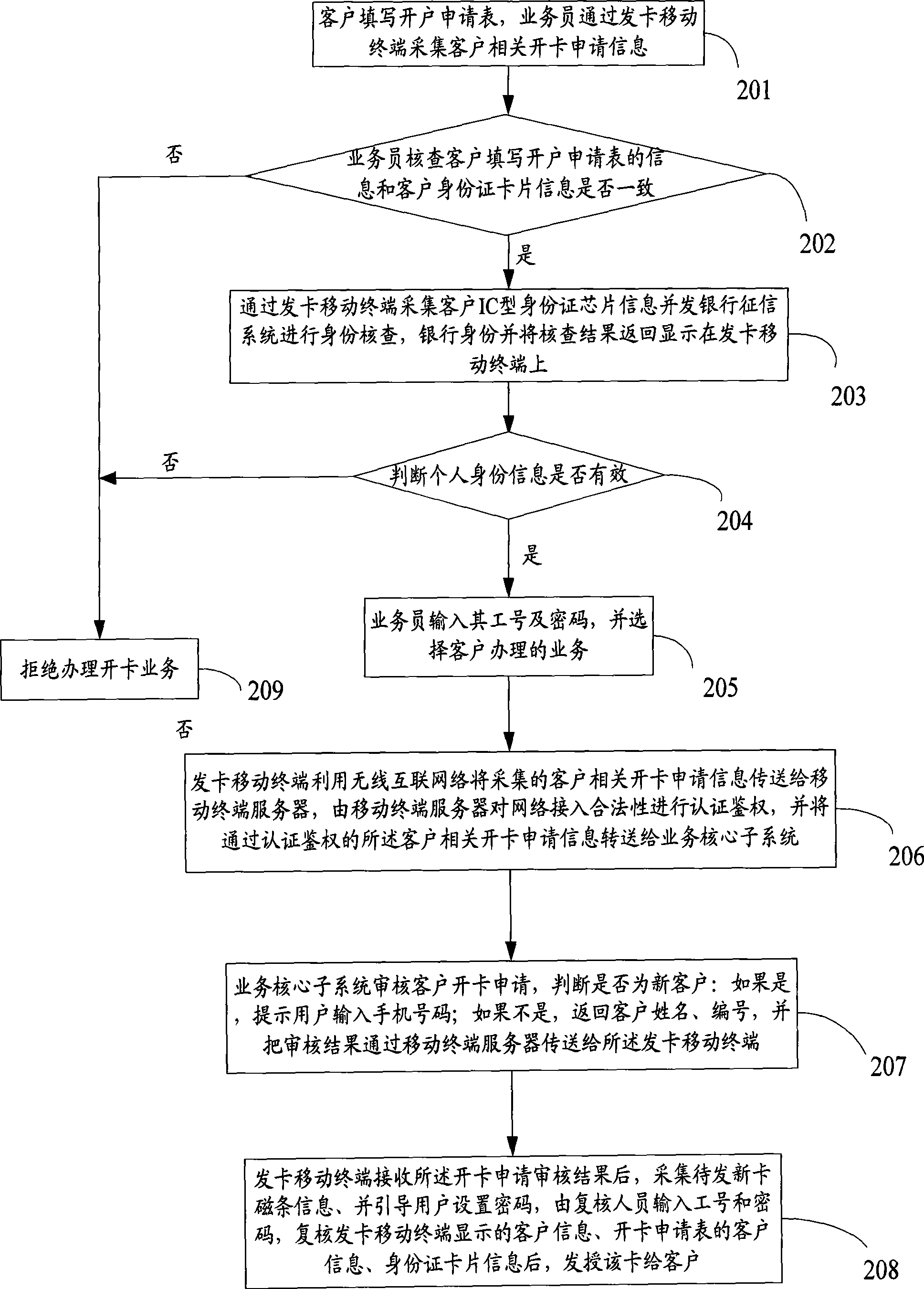

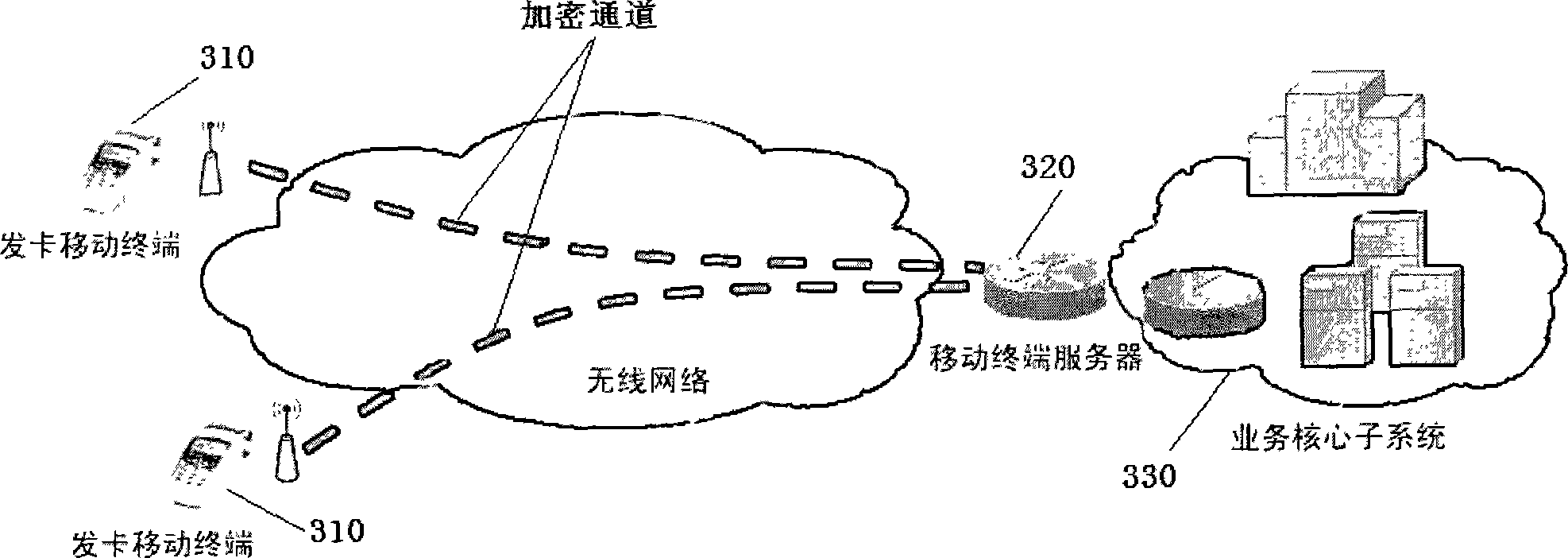

Method and system for card distribution through mobile terminal

InactiveCN101483526ASimple processSave time and energyCommerceData switching networksTerminal serverCredit card

A method for marketing credit card through mobile terminal comprises the following steps: a. collecting credit card activating application information related to client by a salesman through a credit card marketing mobile terminal; b. transmitting the collected client information to a mobile terminal server by the credit card marketing mobile terminal through a wireless interconnected network, executing authentication to the network access validity by the mobile terminal server, and forwarding the credit card activating application information related to client, which passes the authentication, to a service core sub-system; c. auditing the credit card activating application of client through the service core sub-system, and transmitting the auditing result to the credit card marketing mobile terminal through a mobile terminal server; and d. after confirming the auditing result of credit card application by the salesman through the credit card marketing mobile terminal, giving the credit card to the client. The invention transacts the credit card activating service at the credit card marketing mobile terminal through a mode of mobile communication. The method is simple and safe. The outdoor real-time credit card activating service is realized. The invention also discloses a system for activating credit card through the mobile terminal.

Owner:CHINA CONSTRUCTION BANK

Stewed meat and making method thereof

Owner:HEYUAN XINGRUI FOOD TECH DEV CO LTD

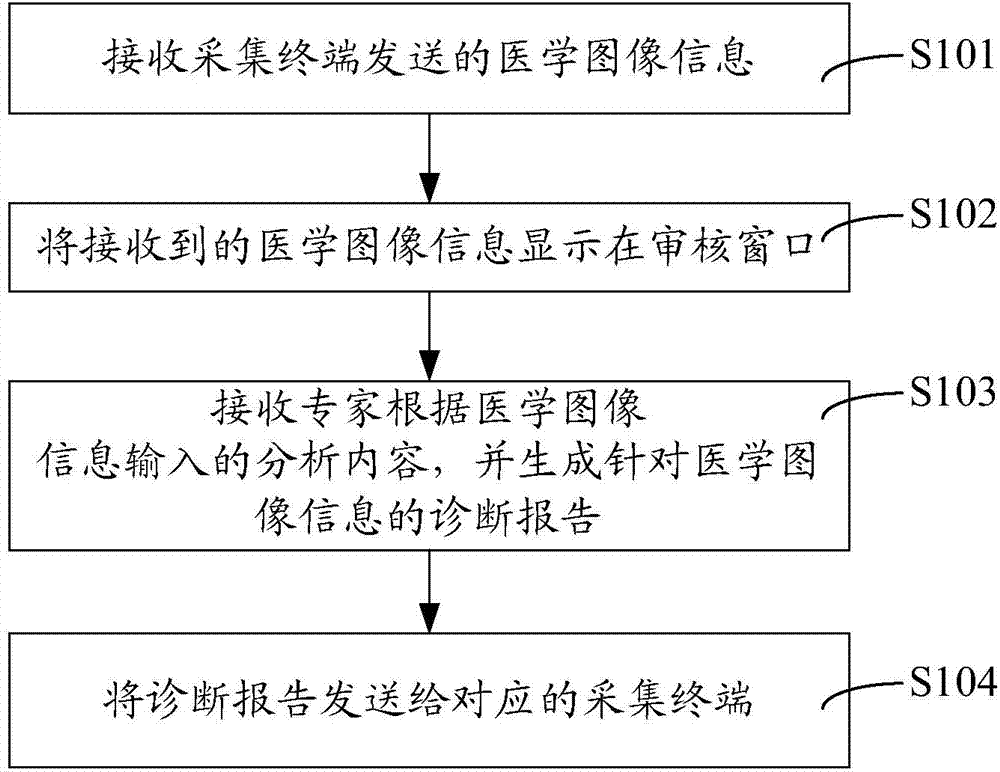

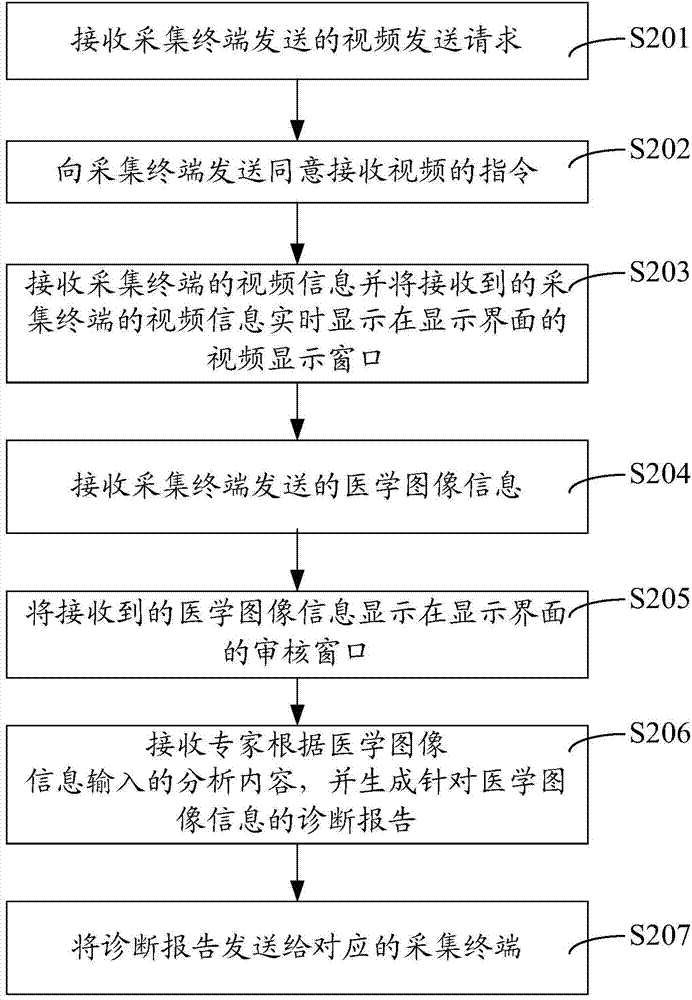

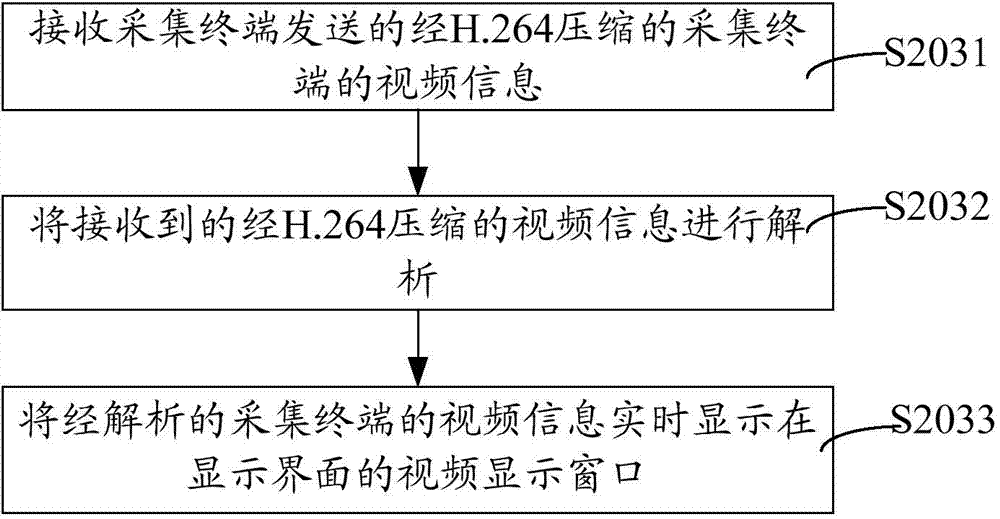

Remote diagnosis method, diagnosis terminal, acquisition terminal and system

InactiveCN104519324AExperienceSave time and energyClosed circuit television systemsSpecial data processing applicationsMedical emergencyComputer hardware

The invention provides a remote diagnosis method, a diagnosis terminal, an acquisition terminal and a system. The remote diagnosis method comprises the following steps of receiving medical image information transmitted by the acquisition terminal, displaying the received medical image information on a review window of a display interface, receiving analysis contents input by an expert according to the medical image information, generating a diagnosis report specific to the medical image information, and transmitting the diagnosis report to the corresponding acquisition terminal. Patients in remote regions with a lower medical level can obtain accurate diagnosis from the experienced expert by virtue of the remote diagnosis method, and the method has no spatial limitation. Further, since the remote diagnosis can be realized, the patients in the remote regions do not need to spend time and money in going out for seeing a doctor for the purpose of the accurate diagnosis, and the time and energy of the patients are saved.

Owner:AVE SCI & TECH CO LTD

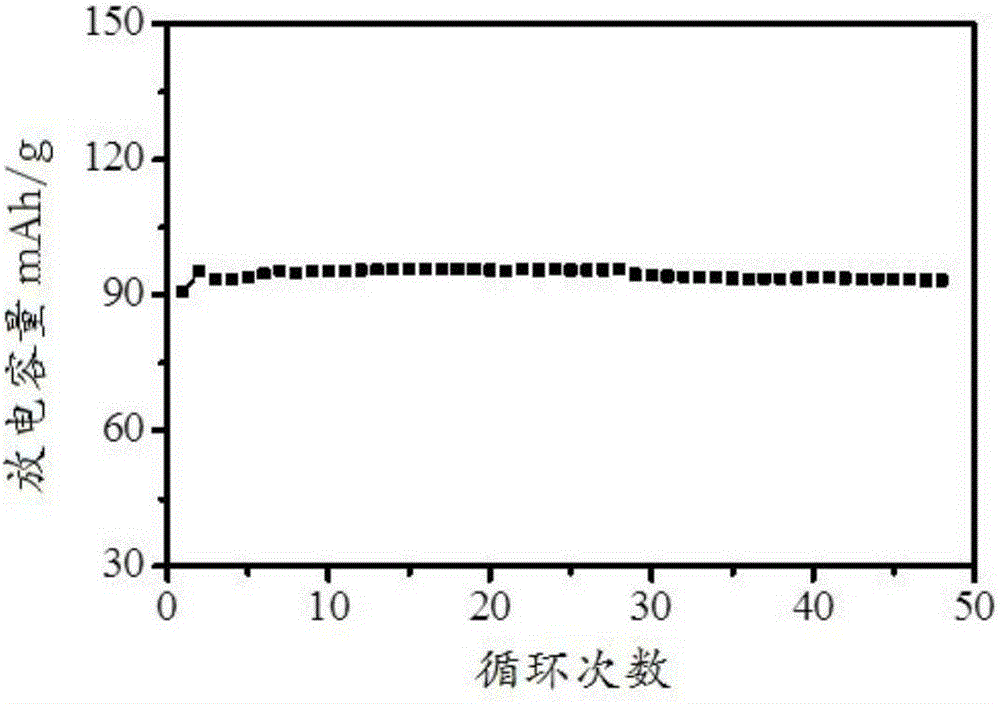

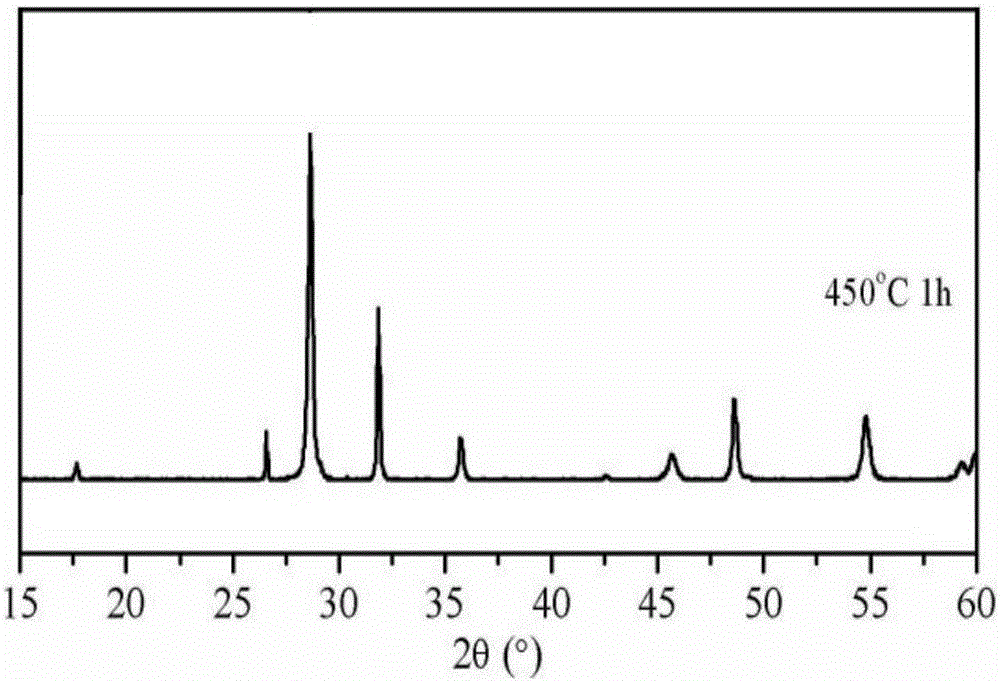

Method for preparing new lead-acid battery from active substances of waste and old lead-acid battery

ActiveCN105226342APrevent restoreEasy to handleFinal product manufactureSecondary cells manufactureElectricityEngineering

The invention discloses a method for preparing a new lead-acid battery from active substances of a waste and old lead-acid battery. The method comprises the following steps of dismounting the waste and old lead-acid battery to obtain a positive electrode plate and a negative electrode plate; respectively processing the positive electrode plate and the negative electrode plate to obtain positive electrode powder and negative electrode powder; respectively performing desulfurization and calcination on the obtained positive electrode powder and the negative electrode powder to obtain new positive electrode powder and new negative electrode powder with high electrochemical performance; using the obtained new positive electrode powder and the new negative electrode powder for manufacturing the new lead-acid battery. The prepared new positive electrode powder and the prepared new negative powder can be directly used for manufacturing the new lead acid battery; the method is simple; the implementation is easy. The method has the advantages that the reduction process in the traditional waste and old lead-acid battery positive powder processing process is avoided; the electrochemical performance of the positive electrode powder can be obviously improved; the formation process of the lead acid battery is accelerated; the preparation process conforms to clean production requirements; the battery production period is shortened; the production cost is reduced.

Owner:SOUTHEAST UNIV

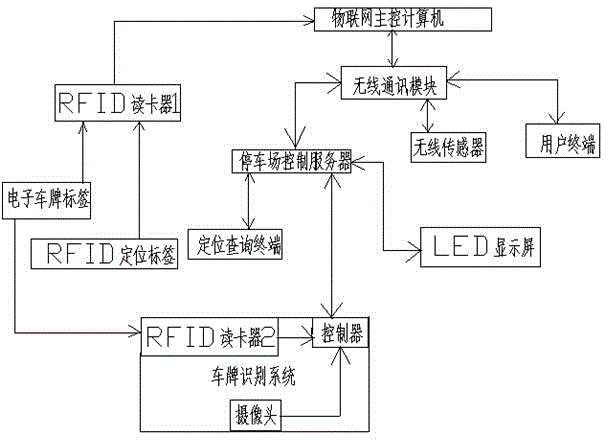

Internet of things-based positioning and parking guidance system

InactiveCN105741604ASave time and energyConvenient parking locationIndication of parksing free spacesGuidance systemParking space

The invention relates to an Internet of things-based positioning and parking guidance system. The Internet of things-based positioning and parking guidance system includes an Internet of things main control computer, an electronic license plate tag, an RFID positioning tag arranged on a parking space and an RFID card reader 1; the Internet of things main control computer is connected with a parking lot control server, a wireless sensor and a user terminal through a wireless communication module; and the parking lot control server is connected with a license plate identification system and a positioning query terminal. With the Internet of things-based positioning and parking guidance system of the invention adopted, time and energy for a vehicle owner to search an unoccupied parking space can be saved, and limited parking space resources can be fully utilized; a user can query the location of a vehicle through the positioning query terminal or a smart phone, and the user can be facilitated to quickly find a parking location in a parking lot. The Internet of things-based positioning and parking guidance system has the advantages of simple operation, convenient use, time-saving performance, high safety and the like.

Owner:SHAANXI ZIZHU ELECTRON

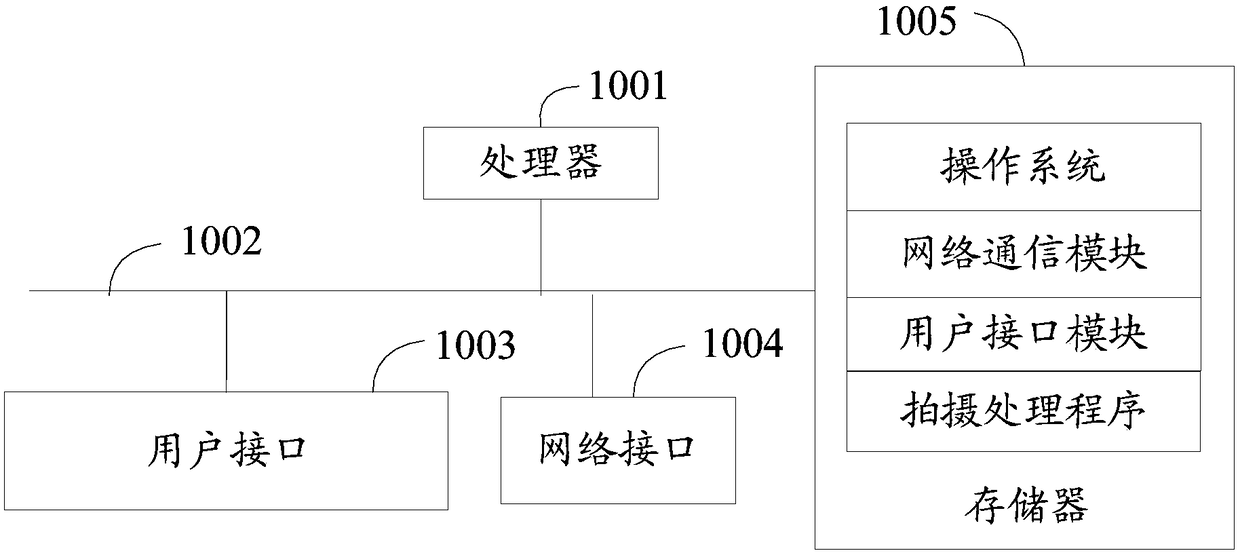

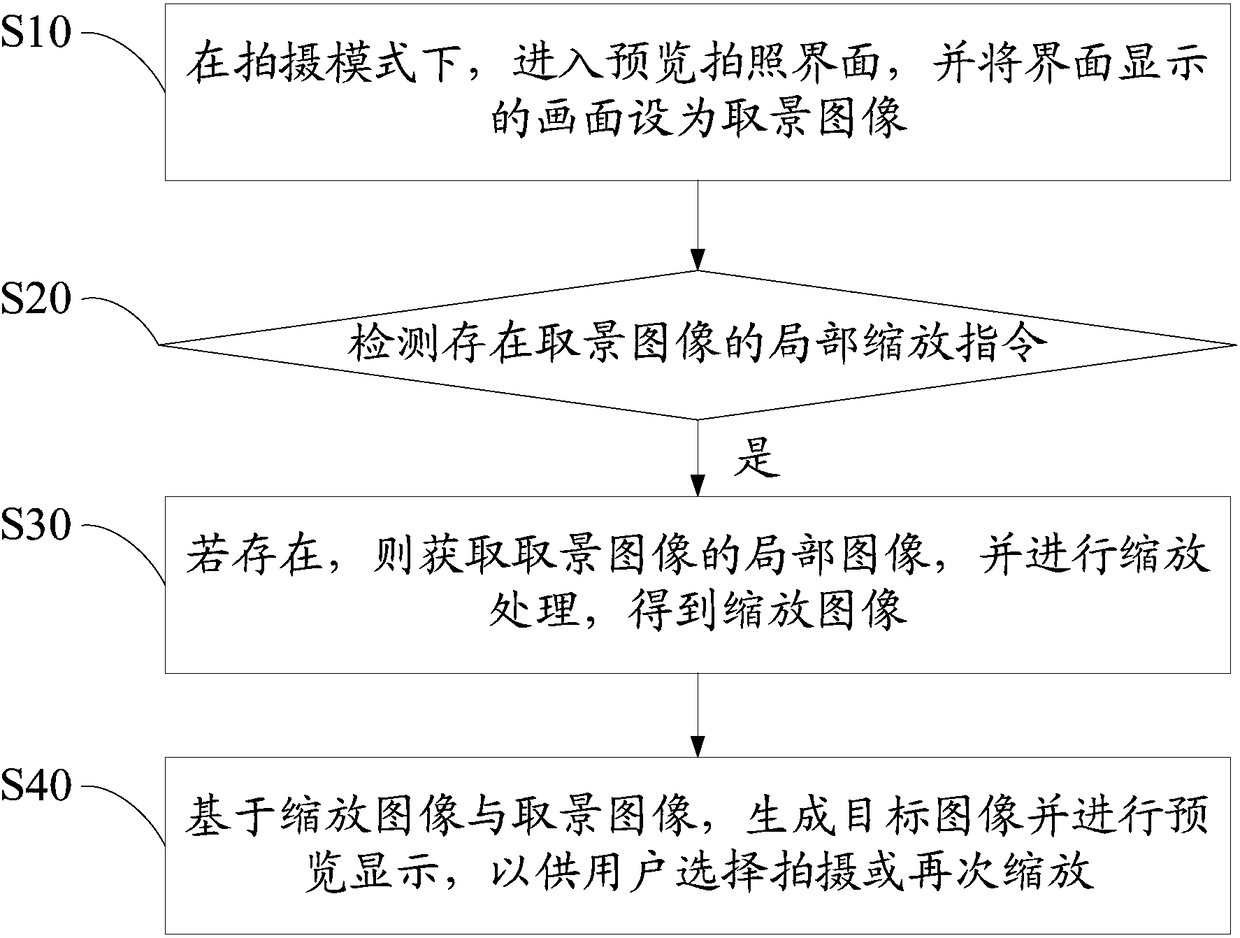

Photo shooting treatment method, shooting equipment and readable storage medium

PendingCN108184066AAvoid editing image manipulationsSave time and energyTelevision system detailsColor television detailsImage displayComputer science

Owner:SHANGHAI TRANSSION CO LTD

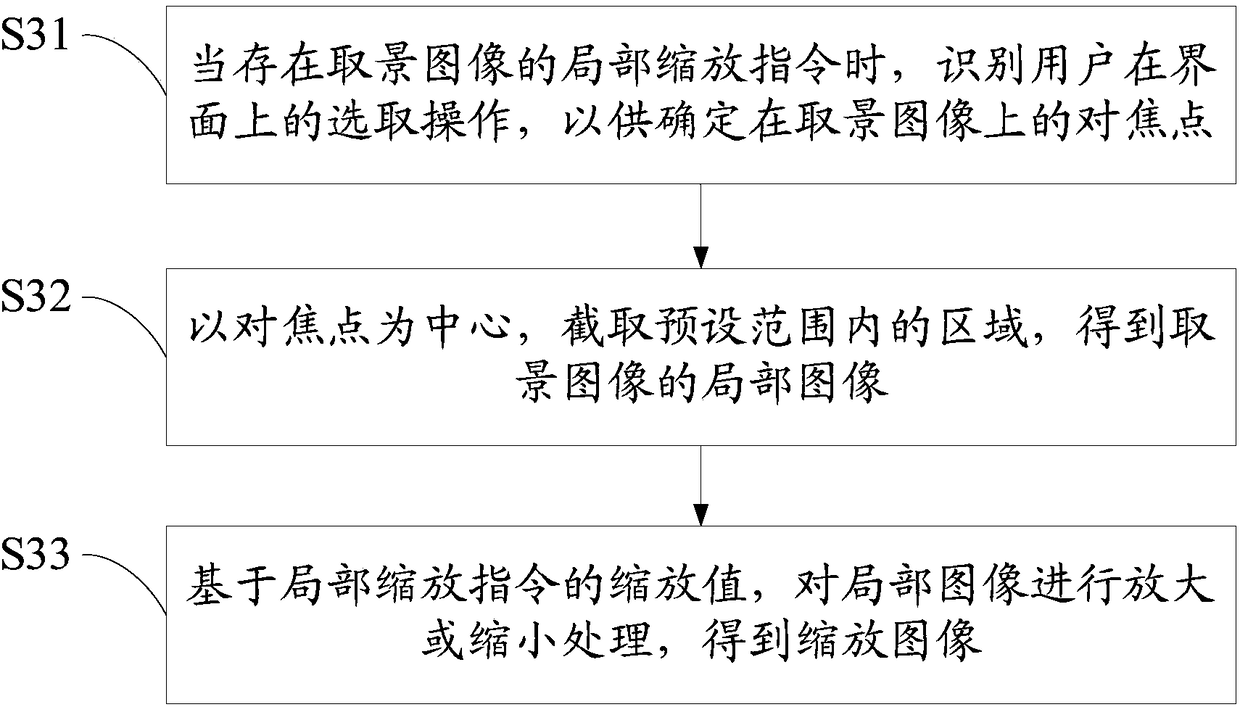

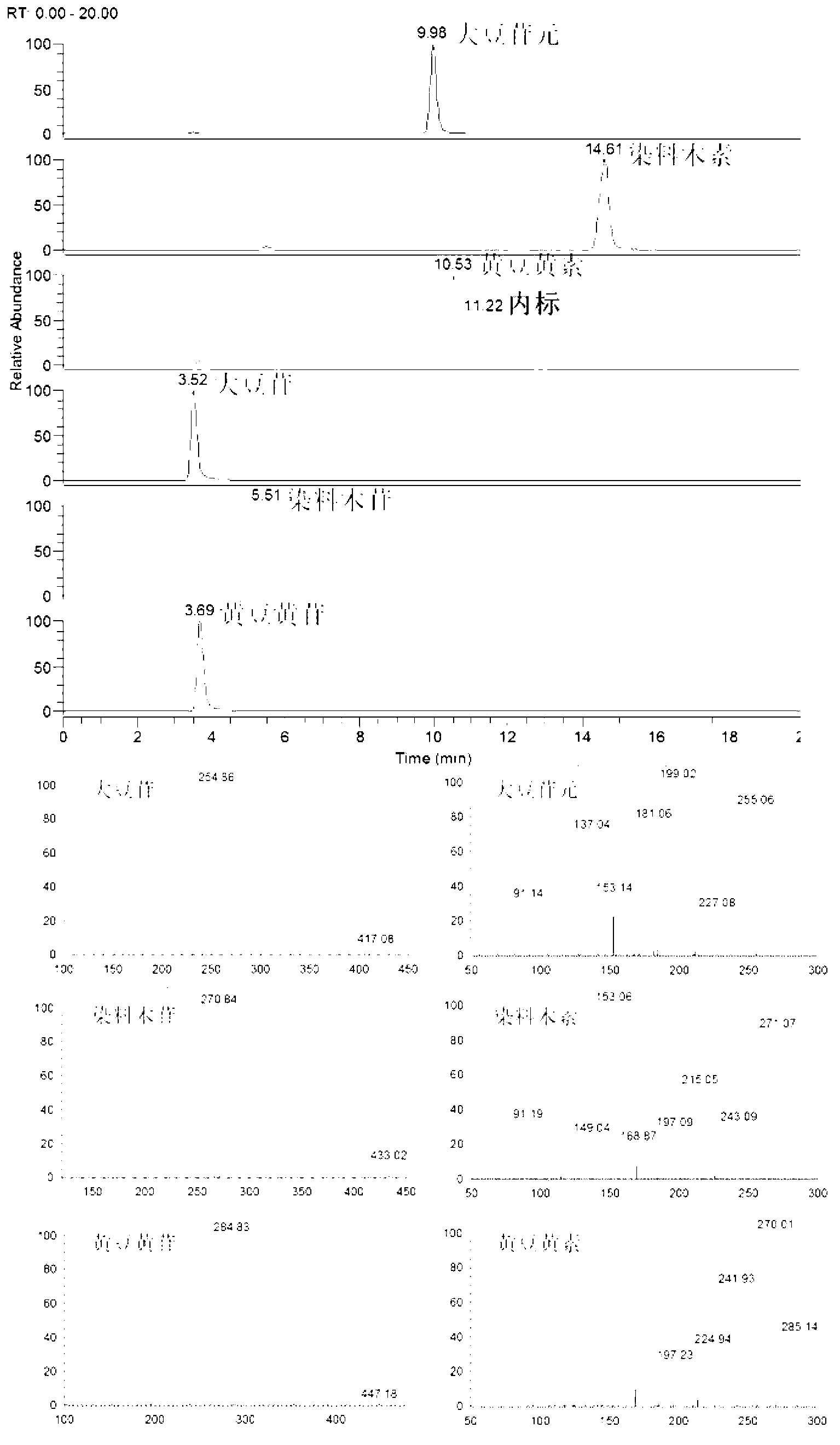

Method for analyzing isoflavone in soybeans and products thereof

InactiveCN103323557ASample preparation method is simpleSave time and energyComponent separationChemistryChemical technology

The invention belongs to the technical field of food chemistry, and specifically discloses a method for measuring the content of soybean isoflavone type components in soybeans and products thereof by using surface bonding baicalin magnetic nano-particles. The method comprises the following steps of: firstly, synthesizing amino terminal magnetic nano-particles and the surface bonding baicalin magnetic nano-particles; then preparing original solutions of the soybeans and the products thereof, adsorbing soybean isoflavone components by using the surface bonding baicalin magnetic nano-particles, separating the surface bonding baicalin magnetic nano-particles on which soybean isoflavone type compounds are adsorbed by using an external magnetic field, eluting soybean isoflavone from the surface bonding baicalin magnetic nano-particles, and adsorbing the surface bonding baicalin magnetic nano-particles together by using an external magnetic field; and finally, sucking the elution solution out to perform instrumental analysis. The method has the advantages of simplicity and convenience of operation, energy conservation and environmental protection.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

Processing technology and processing device for anti-deformation corundum-mullite high-temperature load bearing board

ActiveCN112934438ASave time and energyGood grinding effectTransportation and packagingMixersBall millMachining process

The invention relates to the technical field of load bearing board processing, and particularly relates to a processing technology and a processing device for an anti-deformation corundum-mullite high-temperature load bearing board. The processing device for the anti-deformation corundum-mullite high-temperature load bearing board comprises grinding and mixing equipment and a dry-method ball mill. The grinding and mixing equipment comprises a grinding device and a driving device. The grinding device comprises a grinding ring groove, a grinding cylinder and an expansion return device. According to the processing device for the anti-deformation corundum-mullite high-temperature load bearing board, when raw materials of the load bearing board are processed, the large raw materials are preliminarily ground firstly, the ground raw materials in an inner cavity and an outer cavity pass through the same position, and the raw materials can be fully mixed; and the particle size of the raw materials is smaller than a preset numerical value, the raw materials can be mixed and ground in advance before being fully ground, all the raw materials can be further mixed and ground conveniently, and a large amount of time and energy are saved. In addition, the grinding cylinder is in a dynamic change process in the grinding process, and therefore the grinding cylinder cannot be stuck.

Owner:河南蚂蚁新材料有限公司

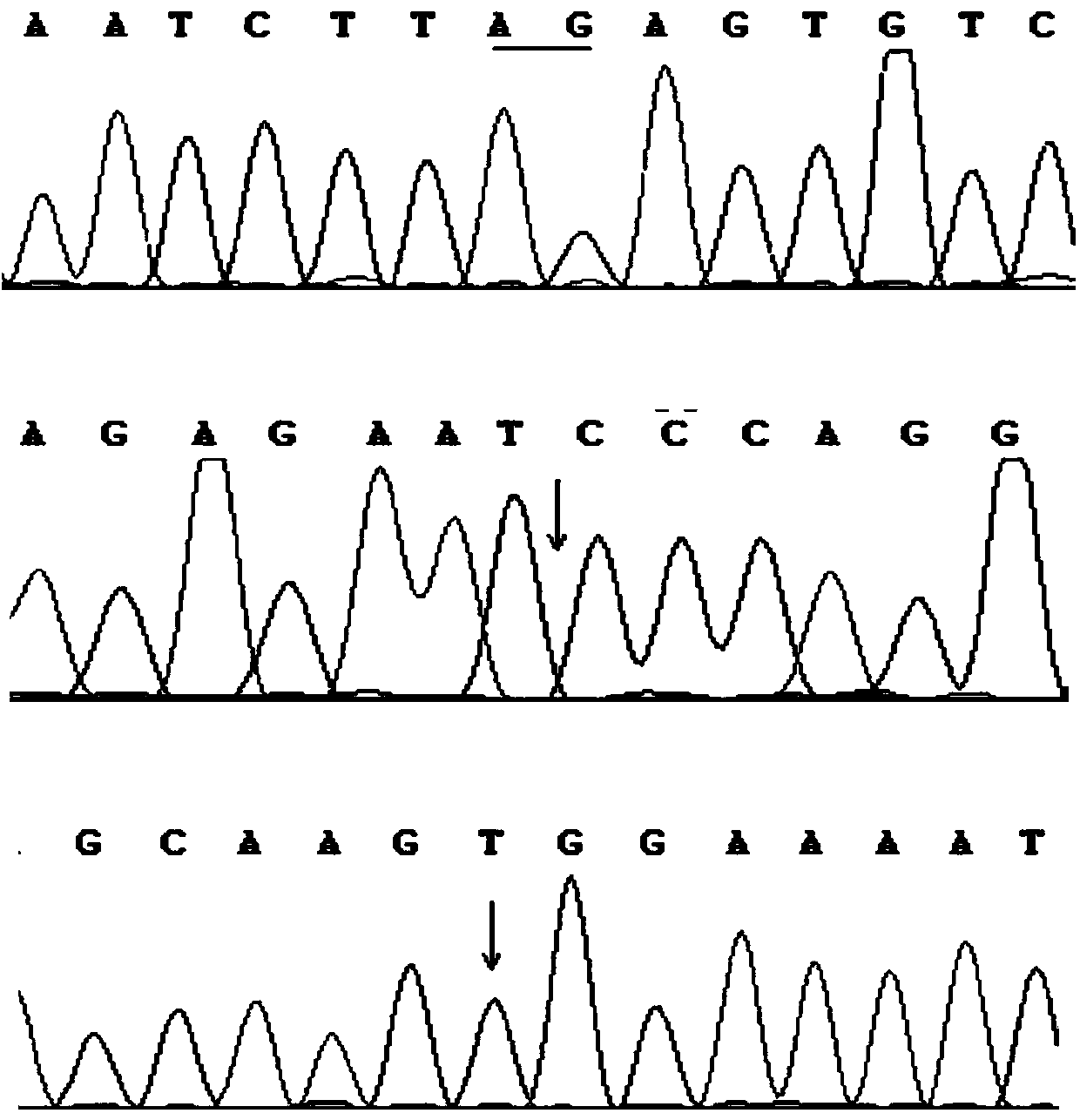

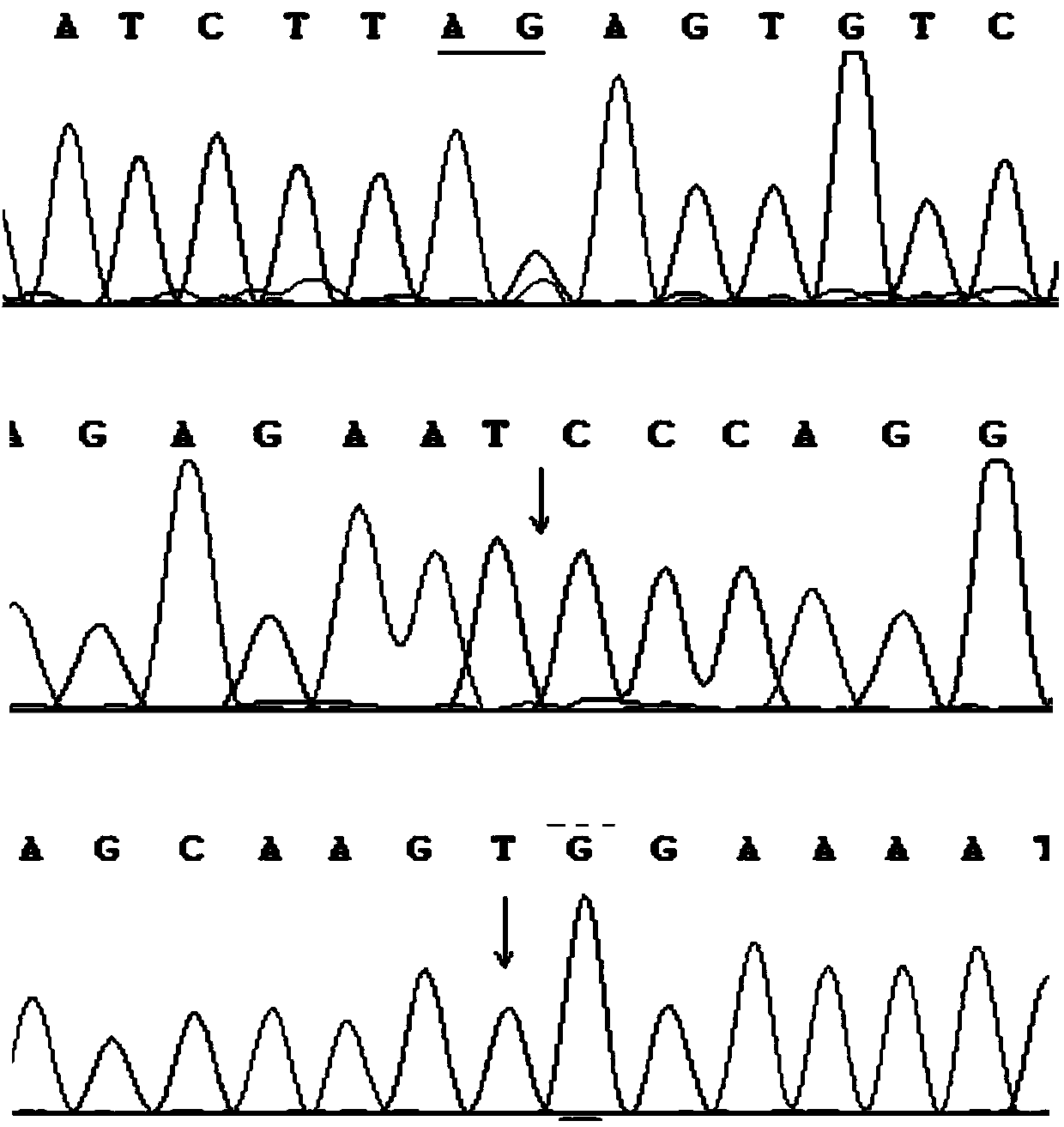

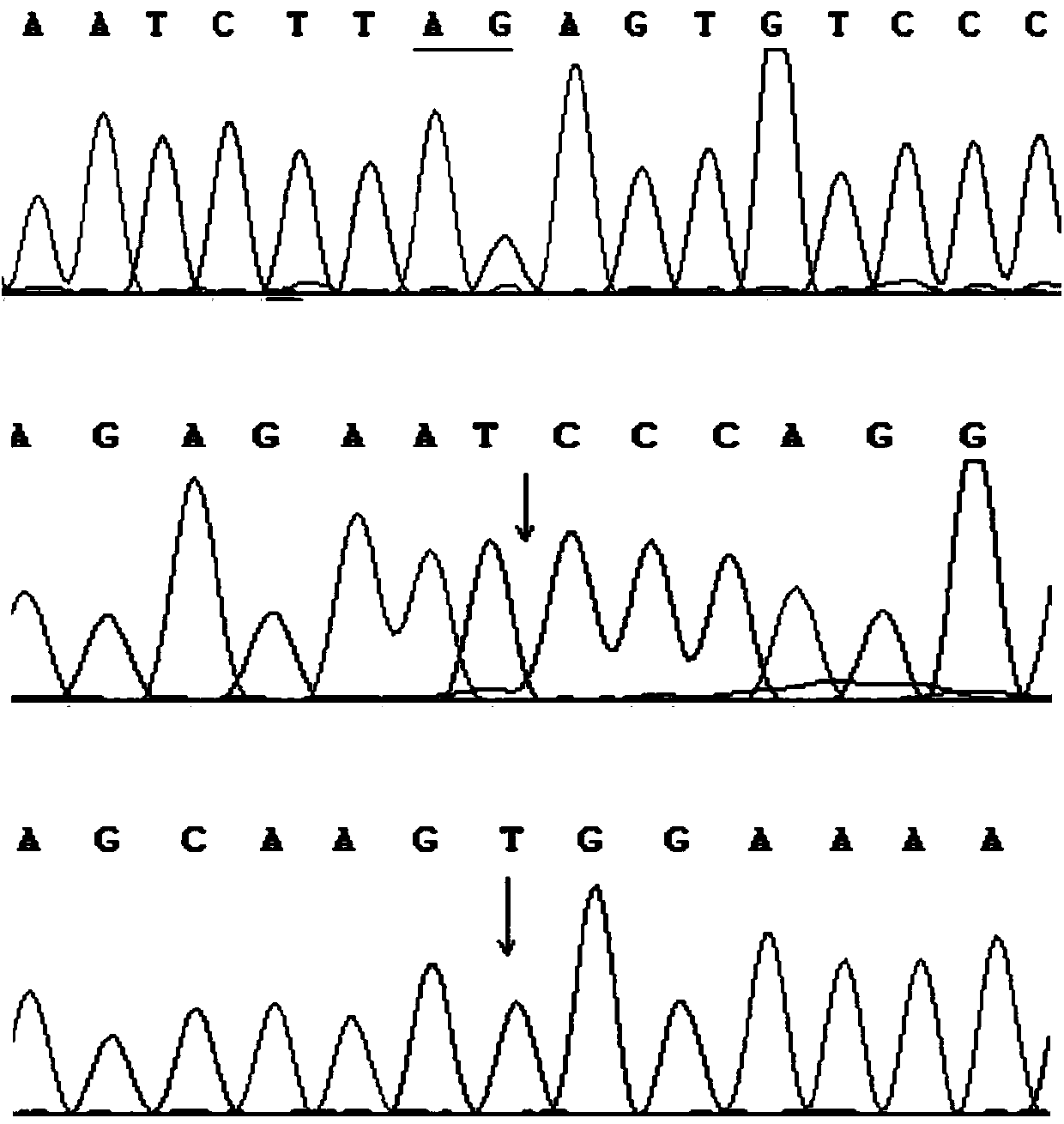

Breast carcinoma gene BRCA1/BRCA2 mutation detection kit and preparation method thereof

InactiveCN104017870AGuaranteed accuracySave time and energyMicrobiological testing/measurementBRCA2 MutationDirect sequencing

The invention discloses a breast carcinoma gene BRCA1 / BRCA2 mutation detection kit. The kit includes three primer pairs for specific amplification of BRCA1 / BRCA2 gene targeting sequences; a primer pair1 is F:GGTTGGCAGCAATATGTG; and R:AGAGGCAGAGTGGATGGA; a primer pair2 is: F:CTCTTATCCTGATGGGTTGT; and R:TCTCATCTGCTTAAAGTCCC; a primer pair 3 is: F:GGCAGGTTGTTACGAGGCAT; and R: GTGAGCTGGTCTGAATGTTCG. The produced fragments of the three primer pairs are more appropriate in size, the accuracy of direct sequencing of a PCR amplified product can be ensured. The kit has the advantages of simple operation, a site sequence can be amplified only by adding a template on a PCR instrument to obtain a specific product, and the kit is convenient and quick.

Owner:杭州美中疾病基因研究院有限公司

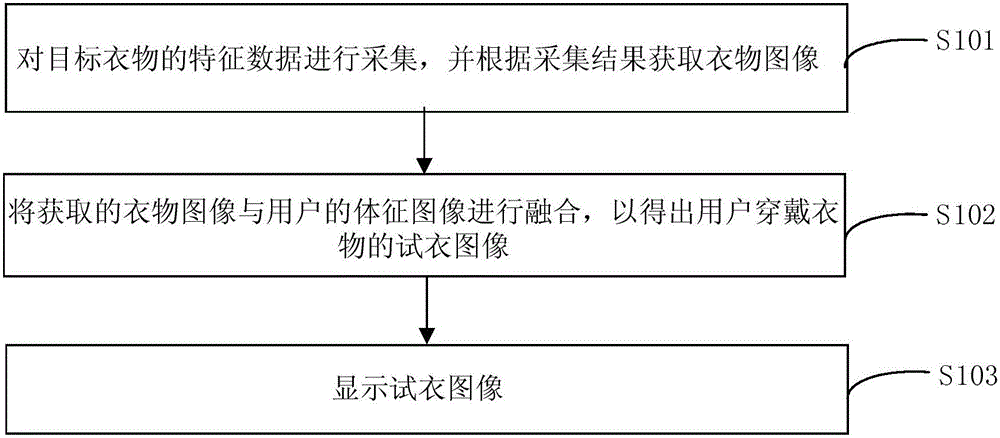

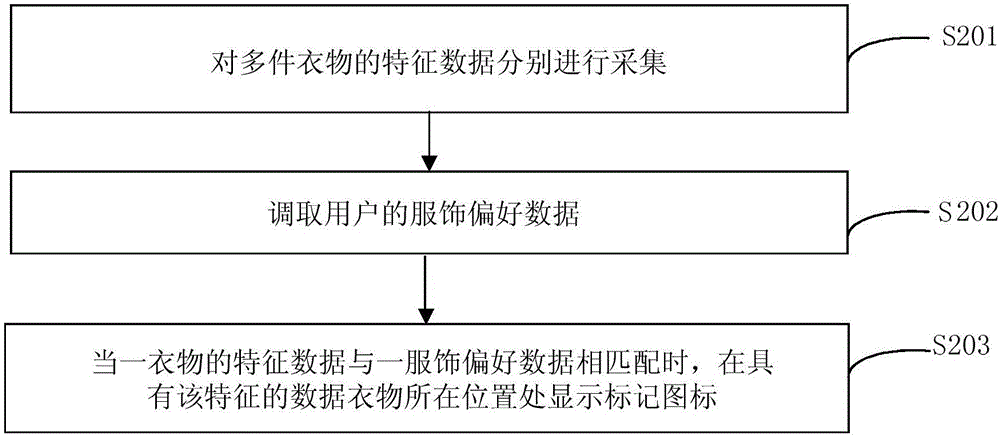

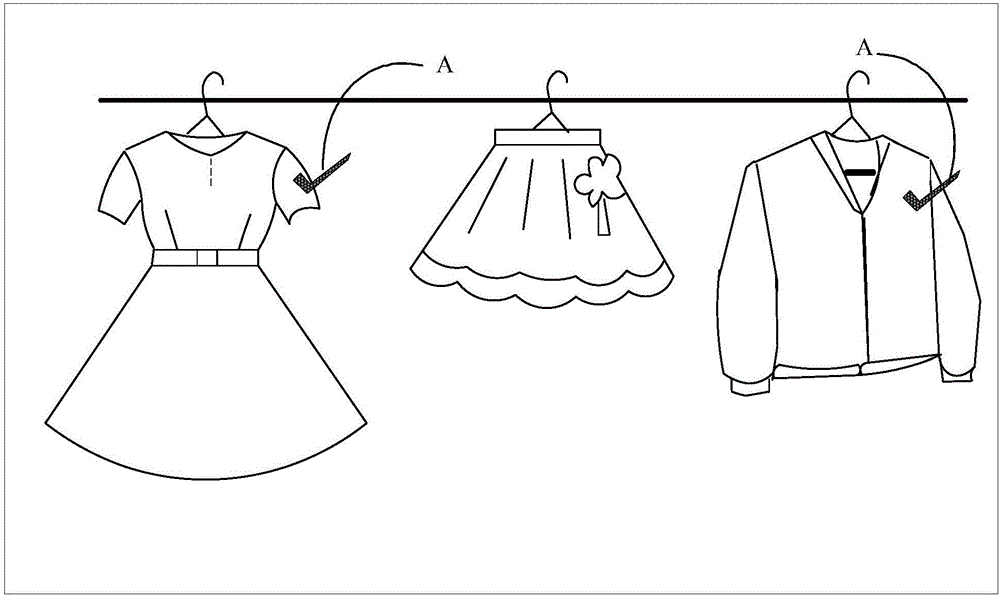

Virtual fitting method, virtual fitting glasses and virtual fitting system

InactiveCN106355479ASave time and energyShorten the timeImage enhancementImage analysisUser needsFeature data

The invention provides a virtual fitting method, a pair of virtual fitting glasses and a virtual fitting system, and relates to the technical field of display. The invention is used for solving the problem that a user needs to change clothes personally for many times during the fitting process. The virtual fitting method includes steps of collecting feature data of a target cloth, and obtaining a cloth image according to the collecting result; integrating the obtained cloth image with a physical sign image of the user, so as to obtain the fitting image of user in wearing the target cloth; displaying the fitting image. The invention is applied to the virtual fit.

Owner:BOE TECH GRP CO LTD

Fluorine carbon paint for express highway guard bar and preparation method thereof

The invention discloses a fluorocarbon paint for freeway guard bar and preparing method, which comprises the following steps: allocating mass ratio of fluoro-resin : cross linker : activator : mixed solvent as 30-75:3-30:0. 1-1. 5:10-40. This invention possesses high hardness, salt-mist-resistance property, weatherability and low cost, which can be fit for coating of freeway guard, aluminium section bar, anti-theft gate and mill process line.

Owner:邢台路桥交通设施有限公司

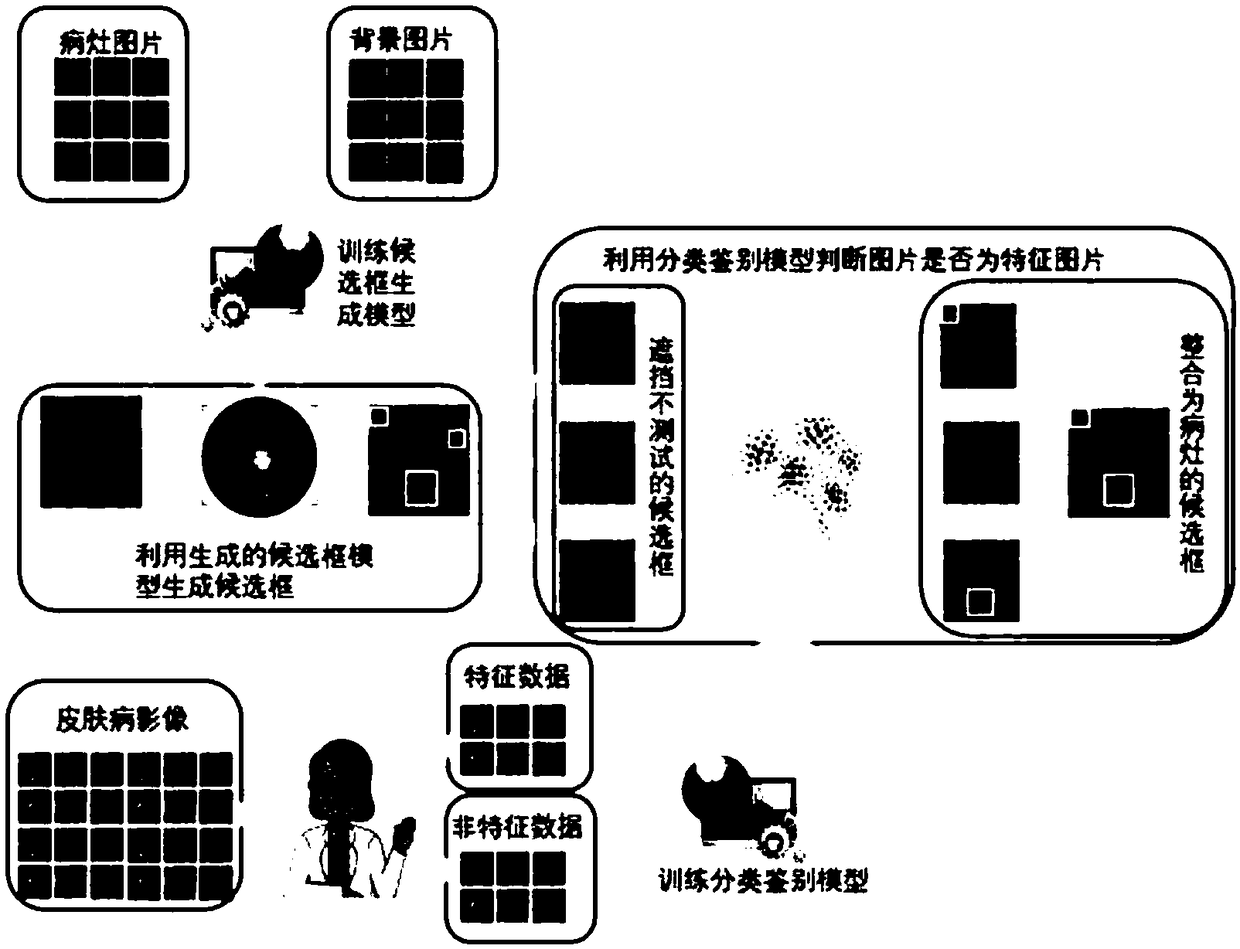

Lesion localization method for skin disease image

InactiveCN108596174ASave time and energyImprove efficiencyRecognition of medical/anatomical patternsDiseaseGenerative model

The invention discloses a lesion localization method for a skin disease image. By training an identification model of skin diseases and a generation model of a lesion candidate frame, a picture containing a candidate frame is processed by using a template shielding method to realize lesion localization. Google inception v3 architecture and migration learning are used for training. An OpenCV cascading training classifier is used for training positive and negative samples to generate an xml document. For the generated lesion candidate frame, the template shielding method is adopted; each of thecandidate frames is identified and judged by the identification model one by one, thereby filtering out the real lesion. According to the lesion localization method for the skin disease image in the invention, in the case that a doctor does not need to label the picture during test, the obtained lesion localization model still can circle the lesion area accurately and quickly, thereby saving the time and effort for the doctor to mark a large number of pictures.

Owner:CENT SOUTH UNIV

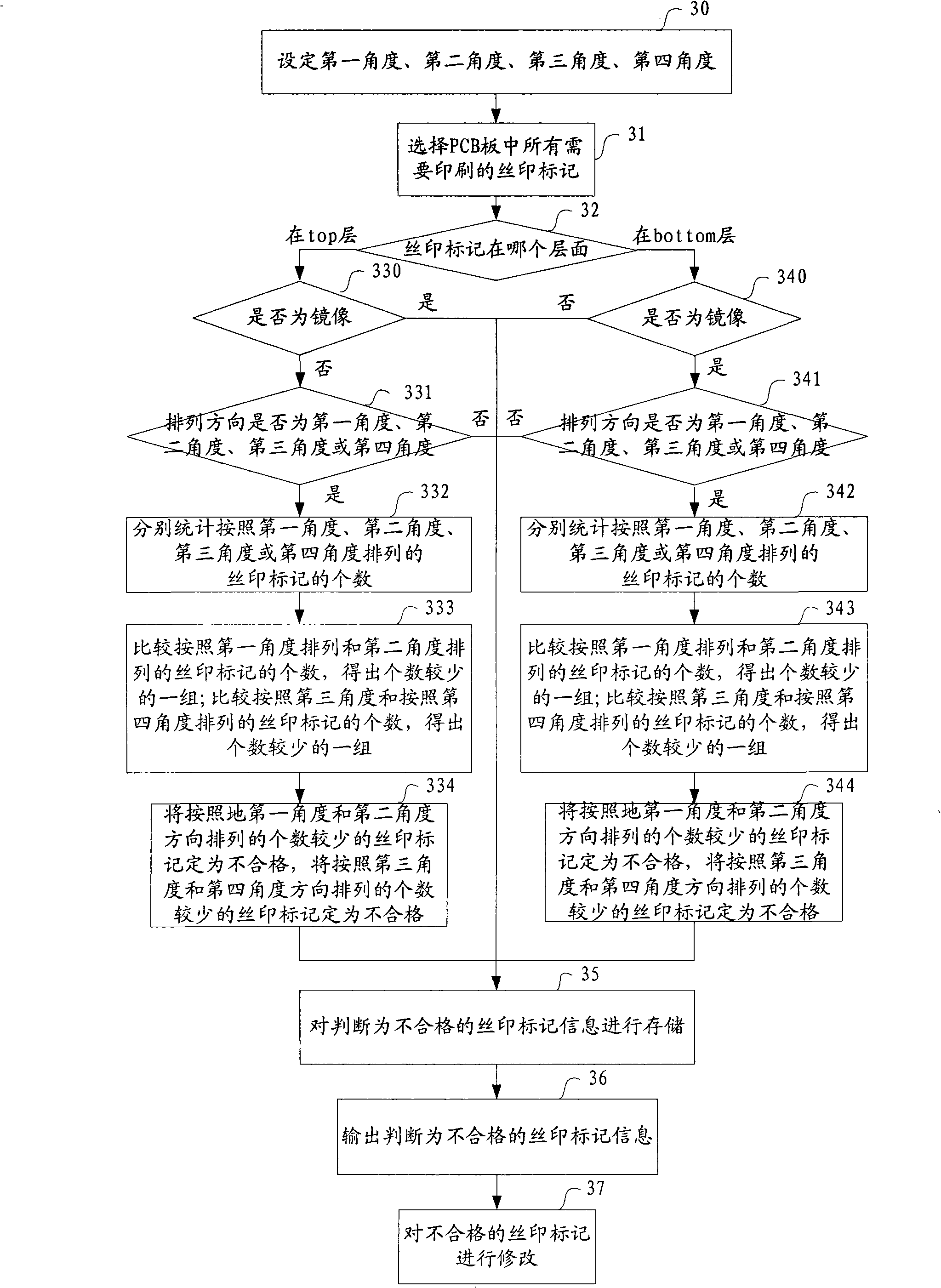

Method and apparatus for detecting unqualified silk screen printing mark

InactiveCN101281027ASave time and energyImprove efficiency and accuracyMeasurement devicesEngineeringMechanical engineering

Owner:BEIJING XINWANG RUIJIE NETWORK TECH CO LTD

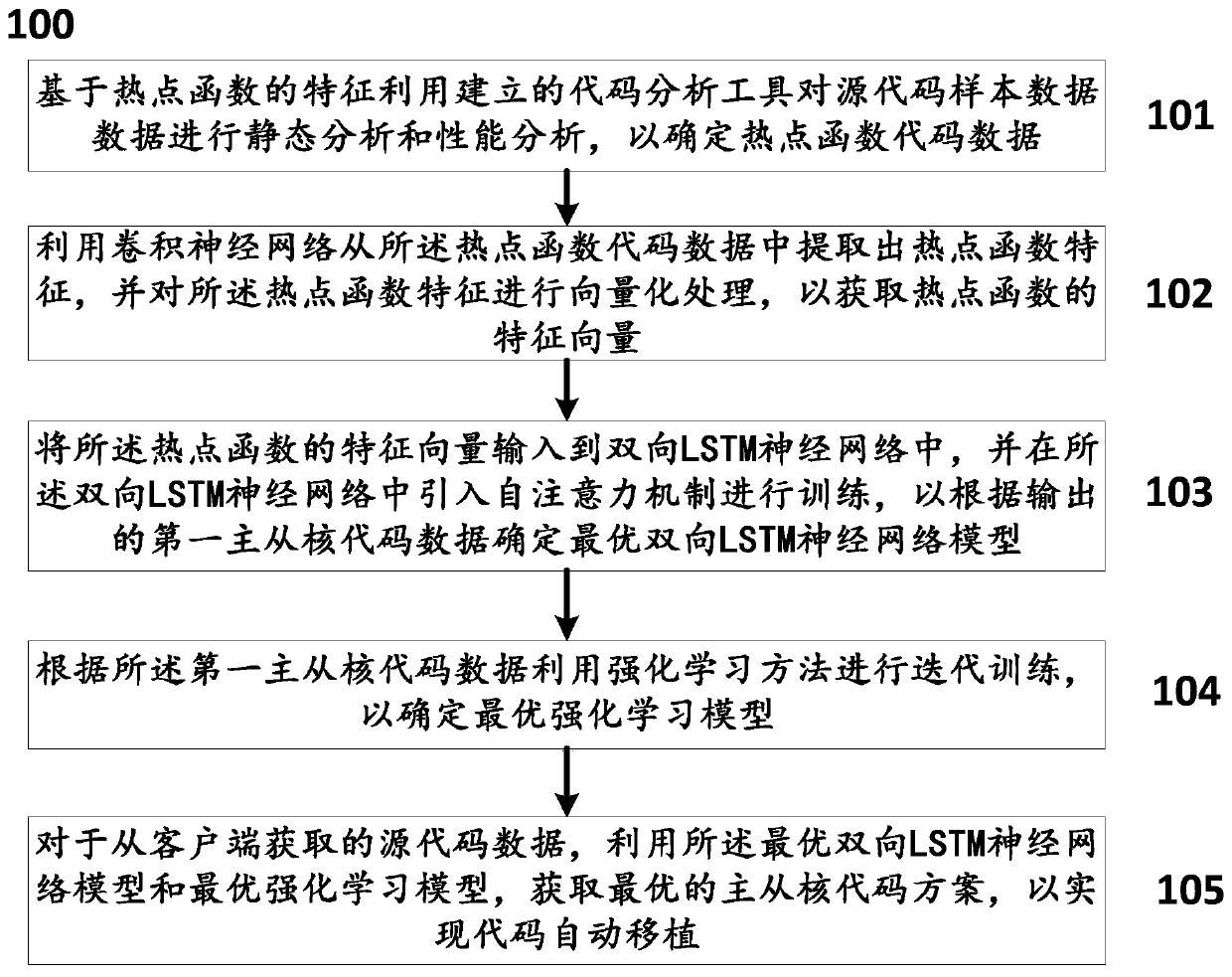

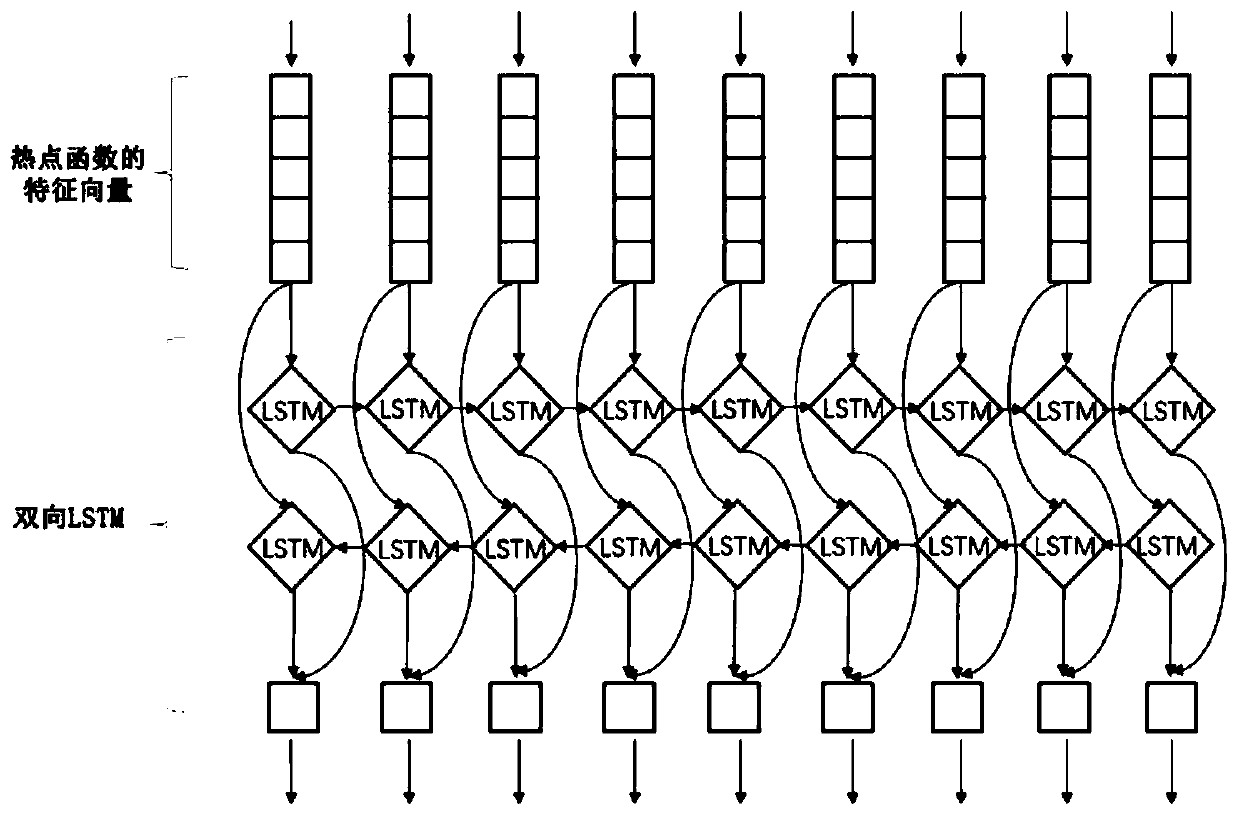

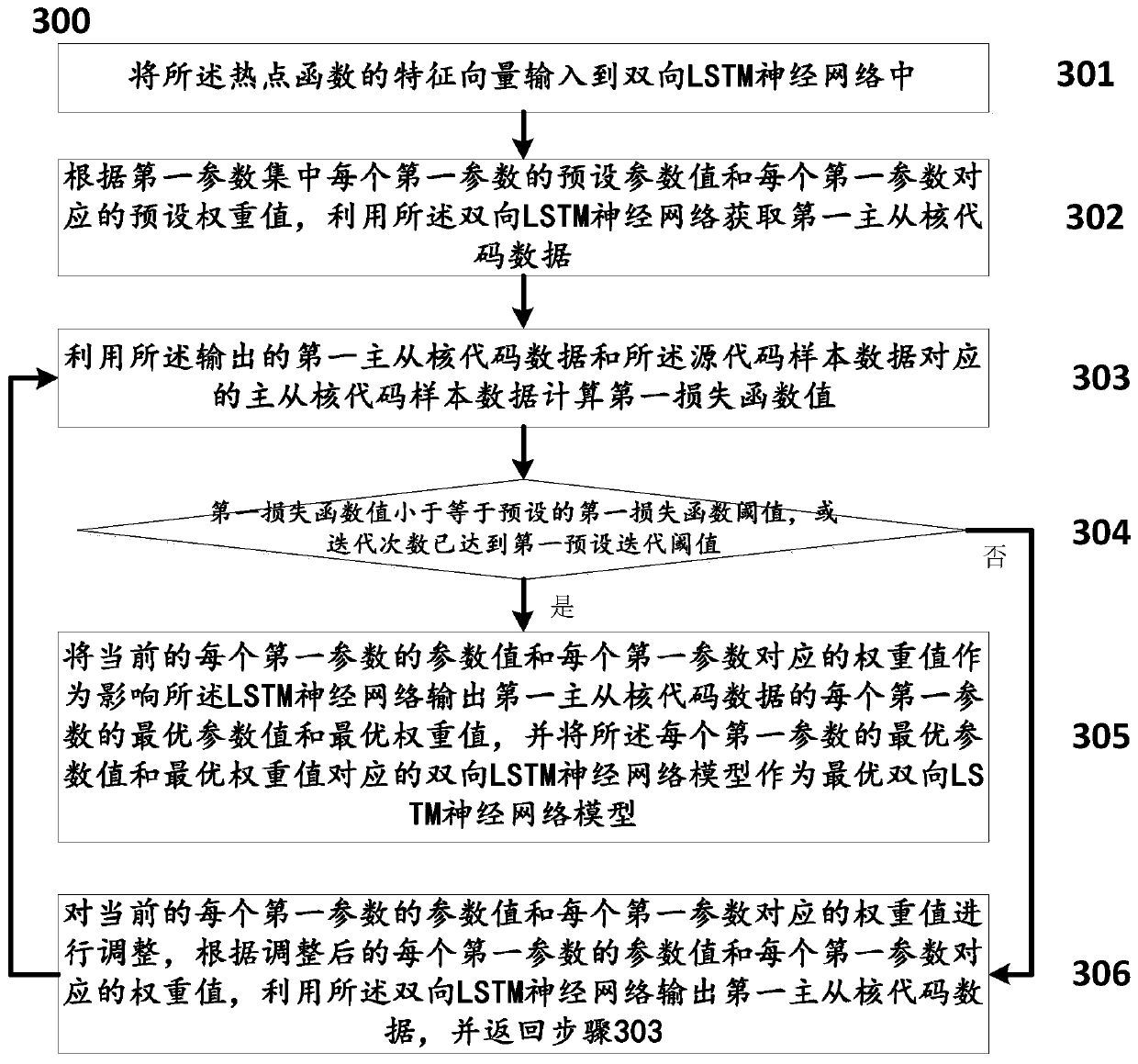

E-level supercomputing ocean mode automatic transplanting optimization method and system

ActiveCN109857459AAutomatic Migration ImplementationAdd self-attention mechanismReverse engineeringProgram code adaptionNetwork modelLearning methods

The invention discloses an E-level supercomputing ocean mode automatic transplanting optimization method. The method comprises the steps of determining hot spot function code data by utilizing an established code analysis tool based on characteristics of a hot spot function; extracting hot spot function characteristics from the hot spot function code data by using a convolutional neural network, and performing vectorization processing on the hot spot function characteristics to obtain a characteristic vector of a hot spot function; inputting the feature vector of the hotspot function into a bidirectional LSTM neural network, and introducing a self-attention mechanism into the bidirectional LSTM neural network for training, so as to determine an optimal bidirectional LSTM neural network model according to the output first master-slave core code data; performing iterative training by utilizing a reinforcement learning method according to the first master-slave core code data to determinean optimal reinforcement learning model; and for the source code data acquired from the client, acquiring an optimal master-slave core code scheme by utilizing the optimal bidirectional LSTM neural network model and the optimal reinforcement learning model to realize automatic code transplantation.

Owner:OCEAN UNIV OF CHINA

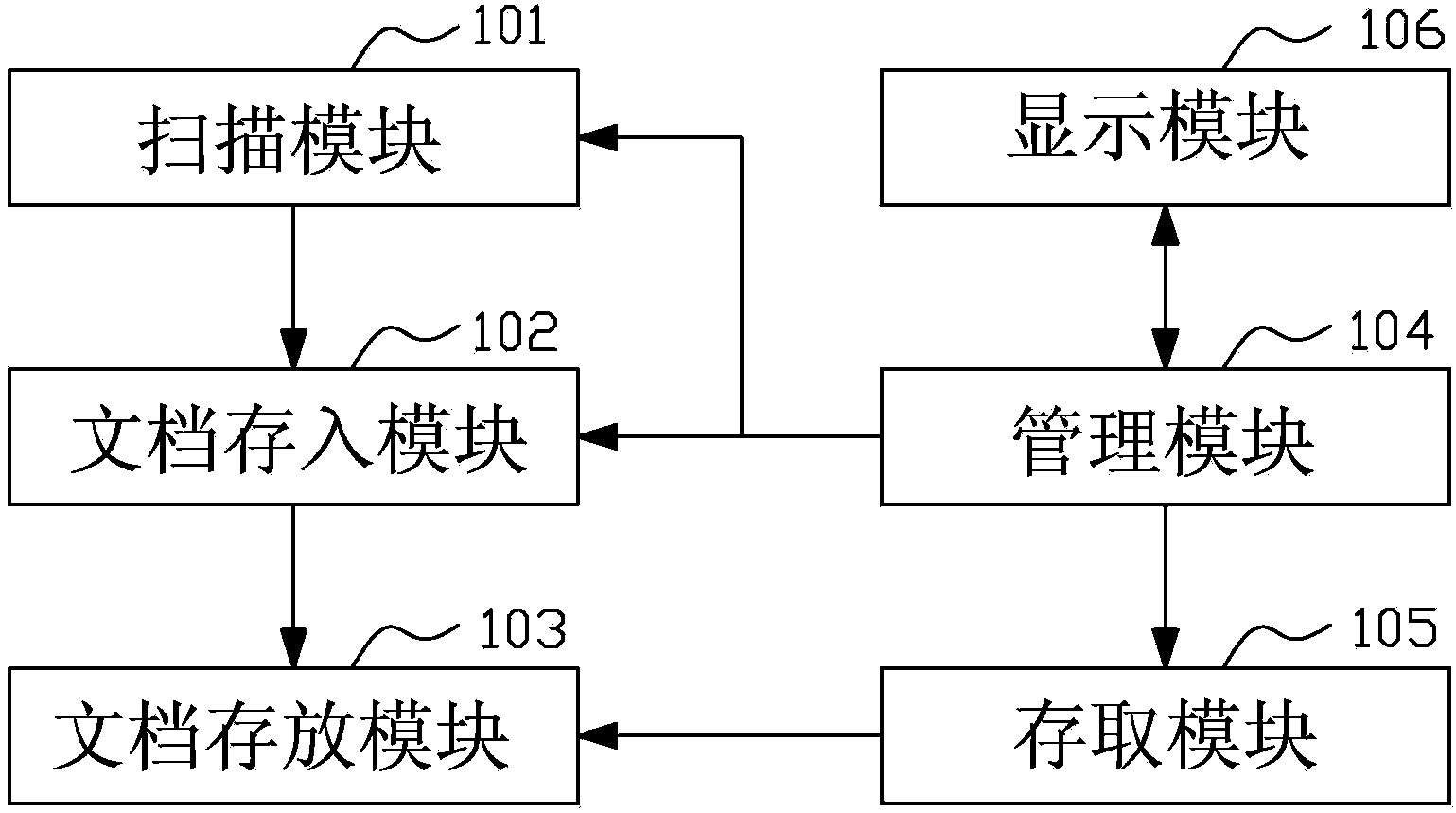

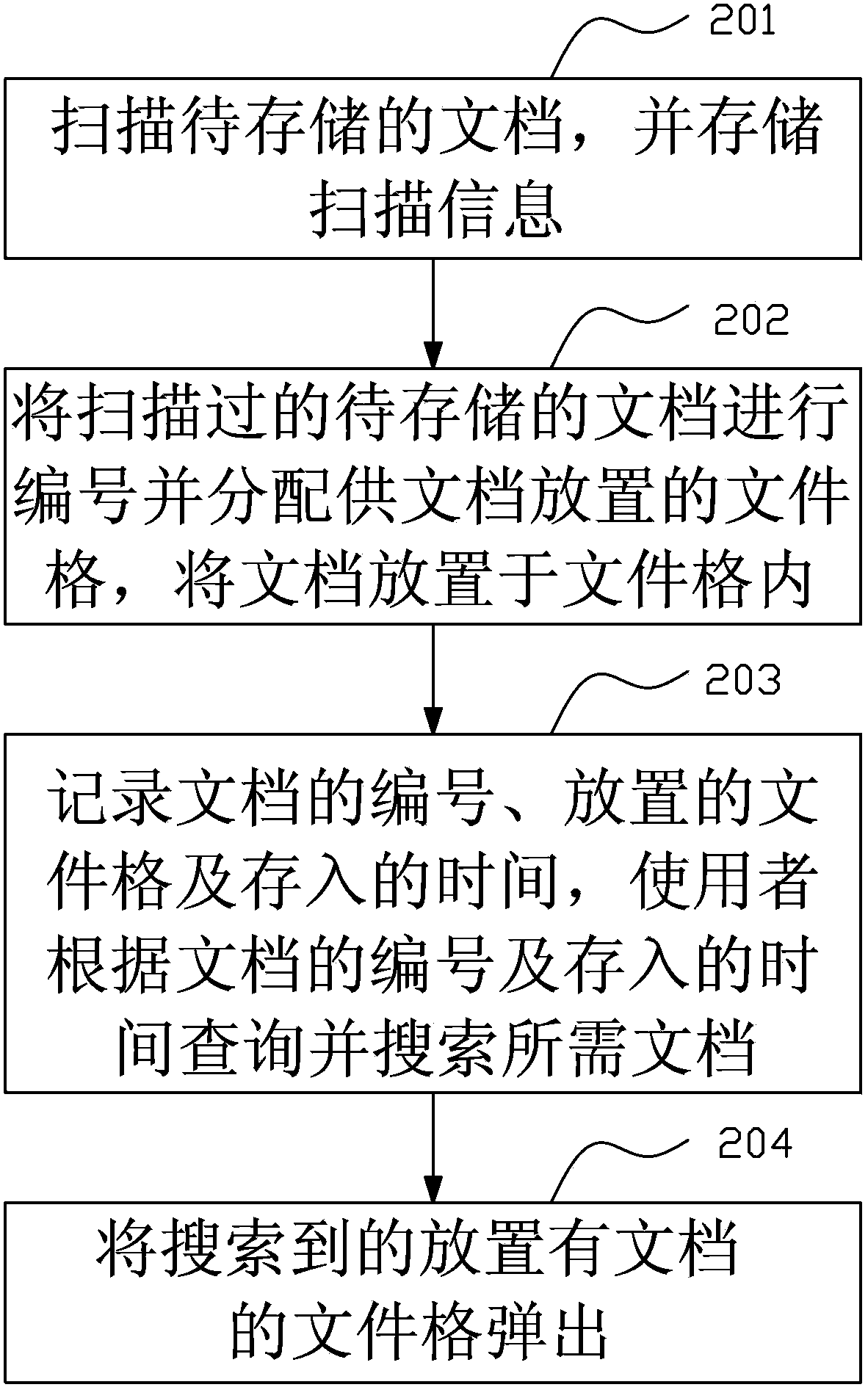

Automatic document classification device and automatic document classification method

The invention provides an automatic document classification device and an automatic document classification method. The automatic document classification device mainly comprises a scanning module, a document storage module, a document store-in module, a management module, an access module and a display module, wherein the scanning module is used for scanning a document to be stored; the document storage module is provided with a plurality of document trays used for placing documents; the document store-in module codes the scanned document to be stored, allocates the document trays, and places the document into the document trays; the management module records the document number, the placed document tray and the storing time so that a user can search the document according to the document number and the storing time; the access module pops up the searched document tray placing the document; and the display module is used for inquiring and displaying the searched document information. Compared with the prior art, the invention provides the automatic document classification device and the automatic document classification method with the advantages that the relationship between paper documents and electronic documents is built through software and hardware combination, so the paper documents can be conveniently and directly called out through searching and automation functions, and a great amount of time and effort can be saved.

Owner:MITAC COMP (SHUN DE) LTD

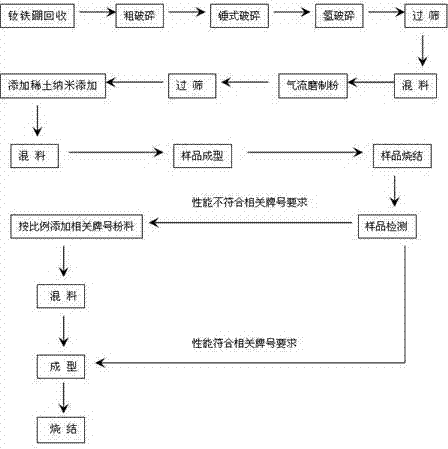

Method for reusing sintered reclaimed NdFeB material

The invention provides a method for reusing a sintered reclaimed NdFeB material. According to the method for reusing the sintered reclaimed NdFeB material, the sintered reclaimed NdFeB material becomes a powder material with a certain granularity after breaking, hydrogen decrepitation, sieving, mixing and crushing through an air stream mill are conducted, a Pr-Nd or Nd rare earth nanometer additive is added to the sieved powder material through a jet-propelled method in an argon atmosphere, and then the sieved powder material and the additive are evenly mixed; magnetic field orientation forming, isostatic pressing and sintering are conducted on the sampled powder material, so that a sintered sample is formed, then performance detection is conducted on the sintered sample, according to a sample detection result and the performance requirement, 0-60 wt% of powder of a relevant grade is added, even mixing is conducted, and after magnetic field orientation forming, isostatic pressing and sintering are conducted on the mixture, a NdFeB finished product is formed. According to the method for reusing the sintered reclaimed NdFeB material, roasting and remelting are not needed, it is only required that rare earth nanometer powder is directly added to reclaimed powder and evenly mixed with the reclaimed powder, and then the product can be prepared according to a conventional technology; in this way, the technology process is simple, task time is shortened, energy consumption is reduced, the amount of used rare earth is reduced by 50% relatively, and the coercivity is increased by 15%-20% relatively; due to the effect of the rare earth nanometer additive, liquid phase mobility is improved during sintering, magnet consistency is improved, the sintering temperature is lowered, and sintering time is shortened.

Owner:沈阳盛世五寰科技有限公司

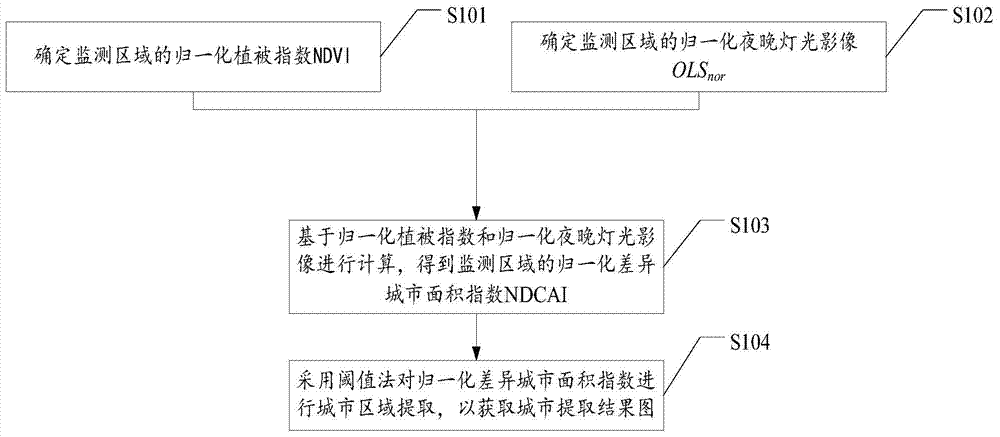

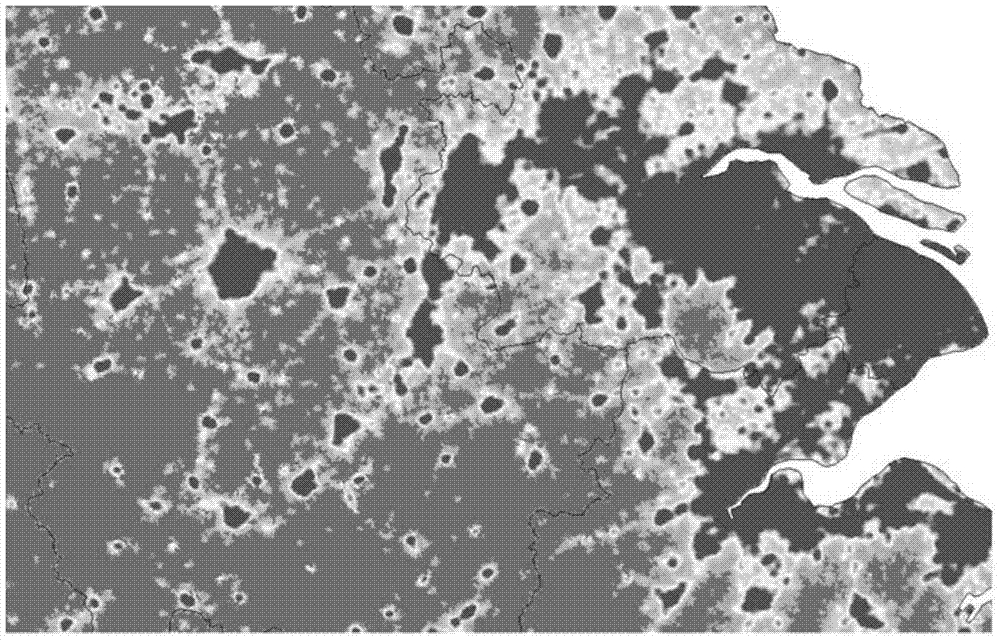

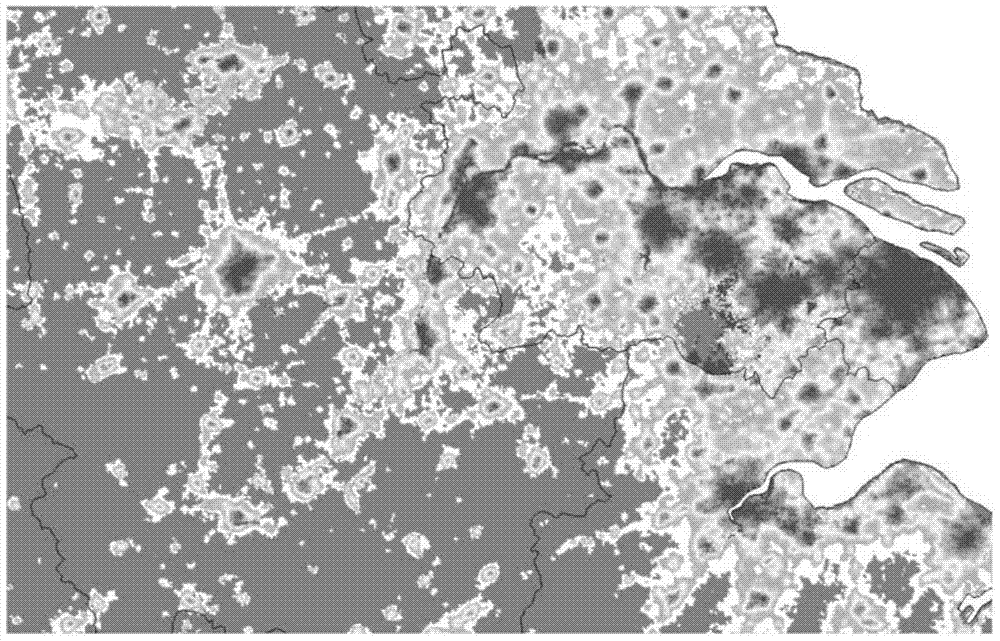

Rapid city extraction method and rapid city extraction device

InactiveCN104850853ASave time and energyQuick extractionCharacter and pattern recognitionNormalized Difference Vegetation IndexCity area

The invention relates to the field of remote sensing to-earth observation, and specifically relates to a rapid city extraction method and a rapid city extraction device. The rapid city extraction method disclosed by the invention comprises the following steps: determining the normalized difference vegetation index NDVI of a monitoring area; determining the normalized night light image OLSnor of the monitoring area; performing calculation based on the normalized difference vegetation index NDVI and the normalized night light image OLSnor to obtain the normalized difference city area index NDCAI of the monitoring area; and extracting a city area based on the normalized difference city area index NDCAI by a threshold method to get a city extraction result graph. By building the normalized difference city area index NDCAI, the technical problem that an extracted city area is not very accurate in the prior art is solved. Furthermore, a city area can be extracted accurately and rapidly.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

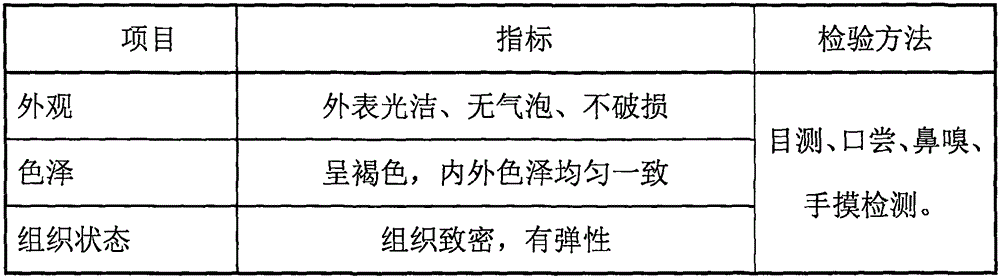

Production technology of dried eggs

InactiveCN105795370ASave time and energyReduce manufacturing costFood scienceSteam temperatureMaterials science

The invention discloses a production technology of dried eggs. The production technology comprises the following steps of S1, performing cleaning; S2, whipping eggs; S3, performing filling; S4, performing shaping; S5, performing marinating; S6, performing packaging; and S7, performing sterilization. According to the production technology disclosed by the invention, the dried eggs are made through technologies of performing cleaning, whipping eggs, performing filling, performing shaping, performing marinating, performing packaging and performing sterilization; table salt and seasoning for the dried eggs are added to egg liquid, after the egg liquid, the table salt and the seasoning are stirred so as to obtain a mixture, and the mixture is placed for 5-10 minutes so that the dried eggs are tasteful; in the step of performing shaping, the steaming temperature is adjusted to 90-100 DEG C, the air pressure is 1.3-1.5MPa, energy consumed by steaming is saved, steaming time is shortened, and the production cost is reduced; the dried eggs are put into brine to be marinated, so that the marinated dried eggs are tasteful, and the mouth feel is good; after the dried eggs are marinated, the marinated eggs are packaged and sterilized, so that the quality guarantee period is prolonged.

Owner:ANHUI SHUXIANG FOOD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com