Patents

Literature

252results about How to "Prevent restore" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst for dehydrogenation of propane for preparing propylene and preparation method thereof

ActiveCN101972664BHigh propane conversionExcellent anti-coke performanceMolecular sieve catalystsHydrocarbonsChemistryMolecular sieve

The invention discloses a catalyst, which is carried by an AlSn-SBA-15 molecular sieve with SnAl double metal-containing framework, for dehydrogenation of propane for preparing propylene. In the catalyst, the AlSn-SBA-15 molecular sieve with SnAl double metal-containing framework is used as a carrier, platinum-group element metal is used as a main catalyst, IVA-group, IA-group or IIA-group element metal is used as an auxiliary agent, and high-temperature-resistant inorganic oxide is used for forming an adhesive. A multi-step dipping method is used in the preparation of the catalyst, namely the alkaline metal auxiliary agent is dipped, so that the acidity and alkalinity of the catalyst and the types of cations in pores of the molecular sieve are effectively modulated by cation exchange technology, and the platinum-group element metal is dipped. The catalyst has superior anti-carbon deposit performance, high propane conversion rate under the reaction conditions of high temperature and low pressure, propylene selectivity and reaction stability.

Owner:CHINA PETROLEUM & CHEM CORP

Novel method for preparing load nano zero valent iron

InactiveCN102205419AUniform size distributionPrevent restoreMaterial nanotechnologyCoalReducing agent

The invention discloses a novel method for preparing load nano zero valent iron. The iron source is iron-containing compounds of Fe<2+> and Fe<3+>, such as ferric oleate, ferric hydroxide oxide, ferric chloride, ferric nitrate and the like; and the loads are carbon black, active carbon, kieselguhr, zeolite and other load materials. The method is characterized in that: the iron-containing compounds on the loads are reduced into nano zero valent iron under the atmosphere condition and under the reduction action of reducing agents, such as H2, CO, and reduction carbon (such as coke, reduction coal and the like). The preparation method is environment-friendly, and simple and is low in cost; the expensive reducing agents (such as NaBH4 and the like) are avoided, and organic pollutants (such as halogenated hydrocarbon, pesticide, polychlorinated biphenyls (PCBs) and polycyclic aromatic hydrocarbons (PAHs), inorganic negative ions (such as NO<3->), and heavy metal (such as Cr<6+>, As<3+>, As<5+>, Cu<2+>, Pb<2+>) and the like can be efficiently removed effectively.

Owner:BEIJING NORMAL UNIVERSITY

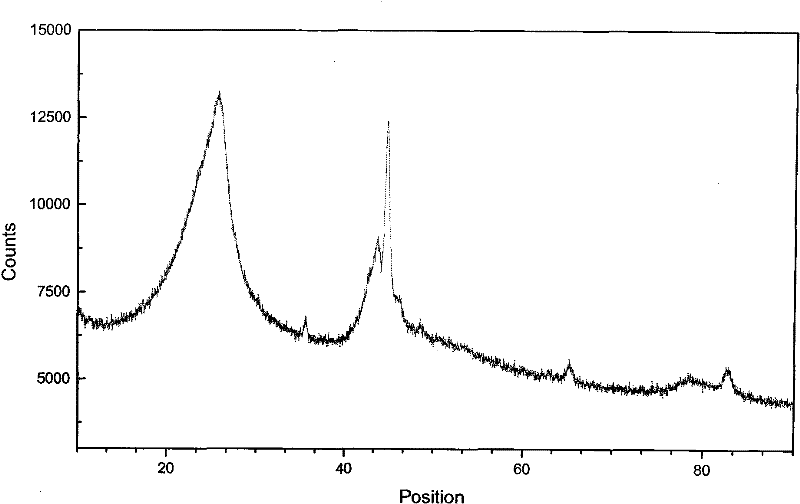

Preparation method of nickel-graphene complex phase

InactiveCN103938255AAvoid the restore processSimple processElectrolytic coatingsCvd grapheneChemistry

The invention discloses a preparation method of a nickel-graphene complex phase, which comprises the following steps: cleaning a base plate with an alkali solution, and activating with hydrochloric acid; 2) preparing nickel sulfate, nickelous chloride, boric acid and a surfactant into a nickel plating solution; 3) adding graphene nanosheets into the nickel plating solution to obtain an electroplating solution containing graphene nanosheets; and 4) electroplating in the electroplating solution by using a nickel sheet as an anode and the base plate as a cathode to obtain the nickel-graphene complex phase. The graphene and nickel are directly compounded, thereby avoiding the GO (graphene oxide) reduction process in the traditional method. The method has the advantages of simple technique, favorable controllability and wide application range; and the prepared nickel-graphene complex phase has favorable mechanical properties and corrosion resistance.

Owner:ZHEJIANG UNIV

High voltage lithium battery cell and preparation method therefor, and lithium ion battery

ActiveCN105470576AHigh ion conductivityPrevent restoreFinal product manufactureElectrolyte accumulators manufactureElectrolytic agentPolymer electrolytes

For overcoming the problem of degradation of lithium battery performance caused by high probability of oxidization of an electrolyte of a high voltage lithium battery in the prior art, the invention provides a high voltage lithium battery cell. The high voltage lithium battery cell comprises a positive electrode, a negative electrode and an electrolyte positioned between the positive electrode and the negative electrode; the electrolyte comprises an inorganic electrolyte layer and a polymer electrolyte layer positioned on the surface of the inorganic electrolyte layer; the inorganic electrolyte layer is positioned on the surface of the positive electrode; and the polymer electrolyte layer is positioned on the surface of the negative electrode. Meanwhile, the invention also discloses a preparation method for the high voltage lithium battery cell and a lithium ion battery adopting the high voltage lithium battery cell. The high voltage lithium battery cell provided by the invention can overcome a large amount of negative problems caused by oxidization of the electrolyte, and the safety performance and the cycling performance of the lithium battery can be improved.

Owner:BYD CO LTD

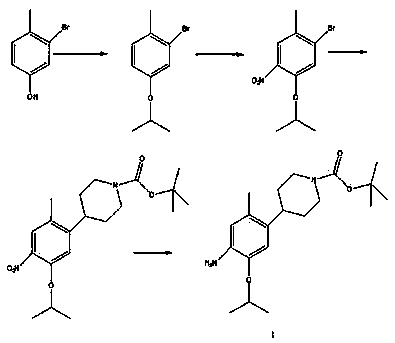

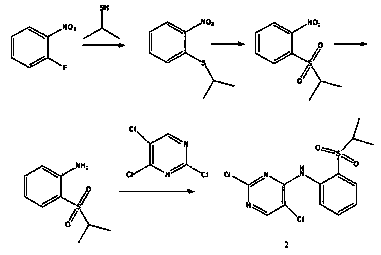

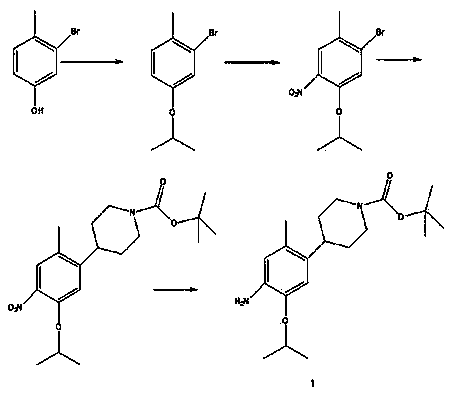

Method for preparing ceritinib

ActiveCN104356112AReduce pollutionReduce manufacturing costOrganic chemistryBulk chemical productionTert-Butyloxycarbonyl protecting groupBromine

The invention discloses a method for preparing ceritinib, belonging to the field of chemical pharmacy. The method comprises the following steps: by taking 3-bromine-4-methylphenol as an initial raw material, performing phenolic hydroxyl isopropylation, nitration, coupling and reduction reaction, obtaining a midbody 1, by further taking o-nitro fluorobenzene as another initial raw material, performing isosulfhydrylation, oxidation, reduction and pyrimidine, obtaining a midbody 2, performing coupling reduction on the midbody 1 and the midbody 1, obtaining ceritinib which is protected by BOC acid anhydride, and finally removing a t-butyloxycarboryl protecting group, and obtaining ceritinib. The method is simple and feasible to operate, relatively high in yield, small in pollution and applicable to industrial production.

Owner:安庆奇创药业有限公司

In-situ presulfurization method of hydrogenation catalyst

ActiveCN102051205AHigh activityHigh vulcanization rateCatalyst activation/preparationRefining to eliminate hetero atomsHydrogenOxidation state

The invention discloses an in-situ presulfurization method of a hydrogenation catalyst. The method comprises the following steps: in the wetting stage of the catalyst, introducing sulfurized oil and hydrogen gas from the bottom of a reactor; when the reactor is full of the sulfurized oil, introducing the sulfurized oil and the hydrogen gas from the top of the reactor for closed cycle; and fillinga vulcanizing agent into the sulfurized oil gradually to complete sulfurization. In the method provided by the invention, the mode of introducing the sulfurized oil from the bottom of the reactor into the reactor is adopted for the wetting process of the catalyst, thus the wetting of the catalyst is more sufficient and complete, and the dry area in a catalyst bed can be effectively prevented; andmeanwhile, as the catalyst is fully wetted, the condition that the catalyst in the oxidation state is reduced by hydrogen gas thus the sulfurization is difficult to perform can be effectively avoided. The sulfurization method provided by the invention is simple in process and is convenient to operate, and the sulfurization effect is better than that of the conventional method, thereby being favorable for improving the activity of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

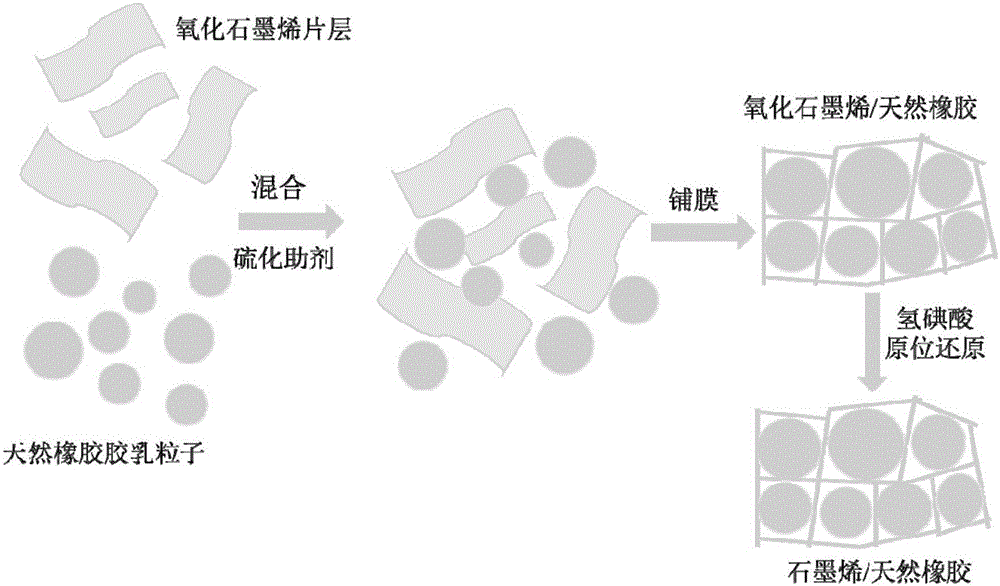

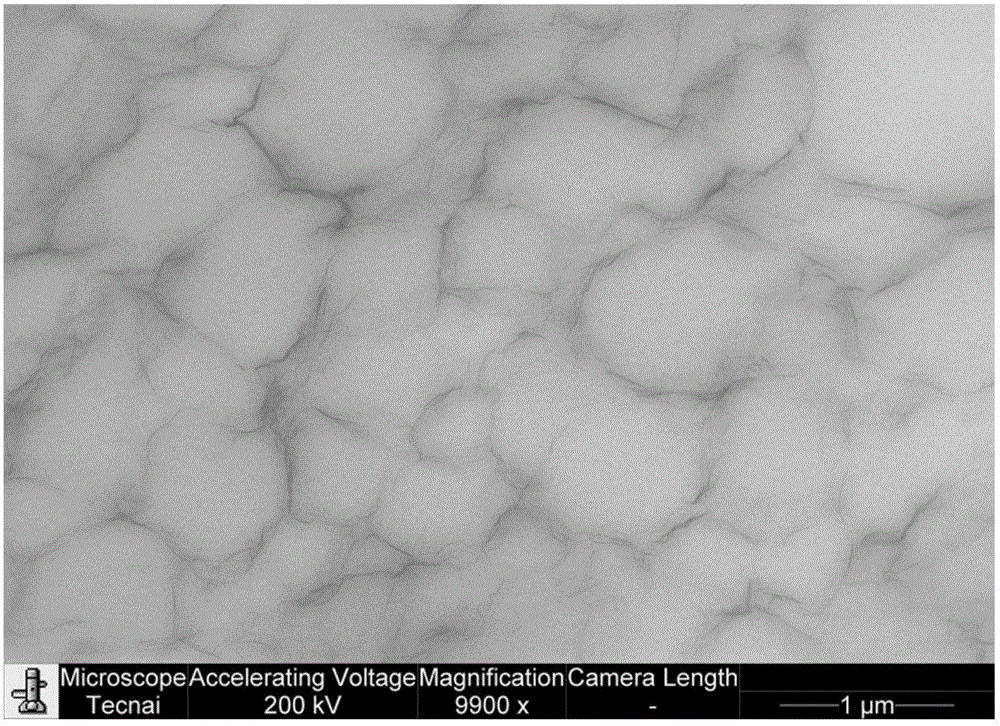

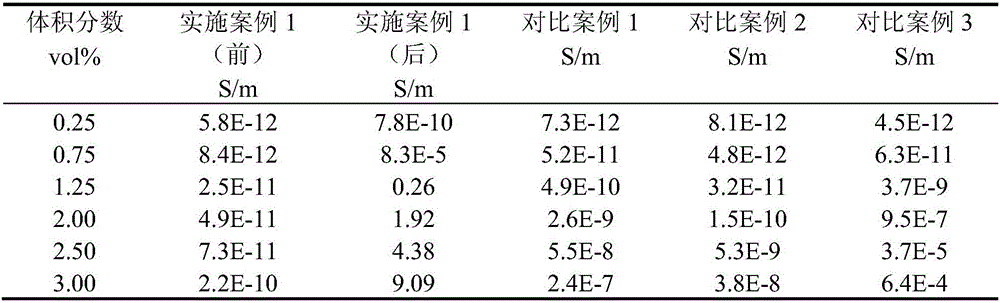

Preparation method of high-electric-conductivity graphene/natural rubber nano-composite

A preparation method of a high-electric-conductivity graphene / natural rubber nano-composite is applicable to the field of strain-sensitive sensors, solvent-sensitive sensors and other sensors. The preparation method includes: first, preparing graphene oxide / natural rubber nano-composite by means of solution film-spreading, and reducing in situ graphene oxide in the composite at room temperature by using hydrogen iodate; the prepared graphene / natural rubber composite has three-dimensionally continuous graphene conductive grid structure and has very low conductivity threshold and excellent conductivity. The problem that the graphene oxide easily aggregate during reduction and graphene is difficult to disperse in a rubber matrix, and a preparation technology is greatly simplified.

Owner:BEIJING UNIV OF CHEM TECH

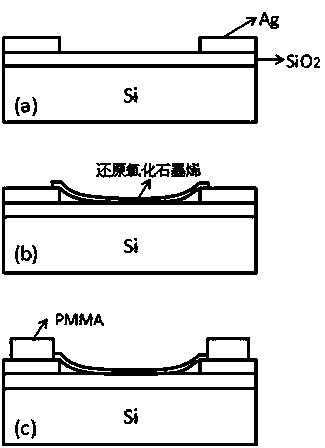

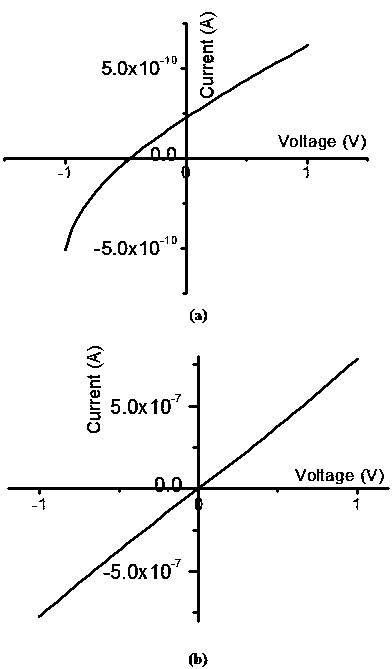

pH sensor based on reduced graphene oxide (RGO) and pH value detection method using same

InactiveCN103364463AThe recovery method is simpleExperimental conditions are not highMaterial electrochemical variablesPolymethyl methacrylateThin membrane

The invention discloses a pH sensor based on reduced graphene oxide (RGO) and a manufacturing method thereof, and a pH value detection method using the sensor. The manufacturing method of the sensor comprises the following steps: directly synthesizing a graphene oxide film from a graphene oxide (GO) sheet, coating a silver (Ag) or gold (Au) layer on a silicon dioxide (SiO2) / silicon (Si) substrate by vacuum coating to obtain electrodes, transferring the previously synthesized graphene oxide film between the electrodes, and naturally drying in air at room temperature; putting the prepared sample into a reaction kettle, evacuating air with nitrogen, and reducing by heat treatment; and making a trench along the edge of the reduced graphene oxide film with PMMA (polymethyl methacrylate) or any other insulating polymer to constitute a complete device for detecting the pH value variations.

Owner:SOUTHEAST UNIV

Preparation method of copper-graphene complex phase

InactiveCN104060317AAvoid the restore processSimple processElectrolytic coatingsCvd grapheneOxidation resistant

The invention discloses a preparation method of a copper-graphene complex phase. The preparation method comprises the following steps of: (1) removing oxides from the surface of a base plate by using hydrochloric acid; (2) preparing copper sulfate, sulfuric acid, the hydrochloric acid and a surfactant into a copper plating solution; (3) adding a graphene nanosheet to the copper plating solution to obtain a plating solution which contains the graphene nanosheet; and (4) placing a phosphorus copper sheet serving as an anode and the base plate serving as a cathode into the plating solution for plating to obtain the copper-graphene complex phase. The preparation method disclosed by the invention prevents the GO reduction process of the traditional method by directly compounding graphene and copper and therefore has the advantages of simple process, good controllability and wide application range; the prepared copper-graphene complex phase has good electrical property, antioxidation property, mechanical property and anti-corrosive property.

Owner:ZHEJIANG UNIV

Silicon-containing high-energy-density lithium ion battery

ActiveCN109713367AEnhanced complexationEnergy barrier increaseFinal product manufactureSecondary cells servicing/maintenanceSolubilityHigh energy

The invention relates to a silicon-containing lithium ion battery with high energy density. The lithium ion battery comprises a positive electrode, a silicon-containing negative electrode, a fluorine-containing electrolyte, a diaphragm, electrode lugs and a packaging material. The silicon-containing negative electrode takes a silicon-based material as a whole or a part of electrochemical active substances. The electrolyte contains lithium salt, a non-aqueous organic solvent capable of dissolving the lithium salt, an SEI film-forming additive and hydrofluoroether. The solubility of the lithiumsalt in the non-aqueous organic solvent capable of dissolving the lithium salt is higher than 2 mol / L. The solubility of the lithium salt in the hydrofluoroether is lower than 0.3 mol / L, wherein the non-aqueous organic solvent capable of dissolving the lithium salt is mutually dissolved with the hydrofluoroether, the non-aqueous organic solvent capable of dissolving the lithium salt and the liquidSEI film-forming additive are mutually dissolved, so the solid SEI film-forming additive can be dissolved. The silicon-containing lithium ion battery has the advantages of high energy density, long cycle life, good rate capability, high safety performance, difficulty in expansion and deformation and the like.

Owner:BERZELIUS (NANJING) CO LTD +1

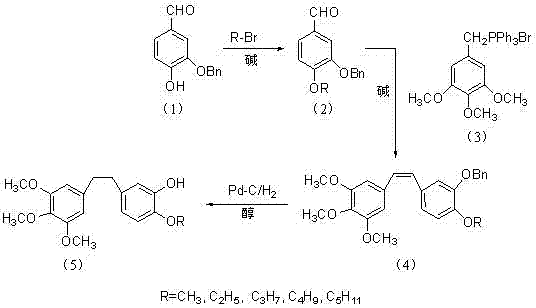

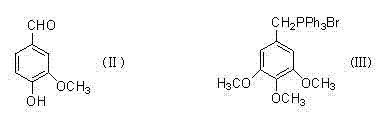

Method for preparing 3,4,5-trimethoxy-3'-hydroxy-4'-alkoxy diphenylethane

InactiveCN103539642AImprove protectionSignificant technological progressOrganic compound preparationCarbonyl compound preparationPalladium on carbonBenzaldehyde

Owner:SHANGHAI INST OF TECH

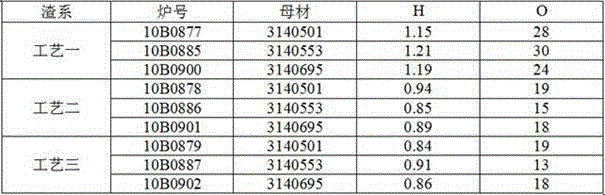

Preparation and use process for electroslag remelting slag

The invention belongs to the technical field of electroslag metallurgy, in particular a preparation and use process for electroslag remelting slag. The process comprises the following steps: firstly preparing fluorite powder, alumina powder and lime blocks in a proportion of (5-30wt%): (30-50wt%): (30-50wt%) into pre-melted slag; and during slagging, firstly adding the fluorite powder, wherein after the fluorite powder is processed, a slag bath is available in a crystallizer; and alternately and slowly adding the alumina powder and lime. The invention provides the preparation and use process for electroslag remelting slag for synthesizing slag charge by using self-smelted pre-melted slag, wherein the process requirement is satisfied and the cost is controlled.

Owner:ZHONGYUAN SPECIAL STEEL

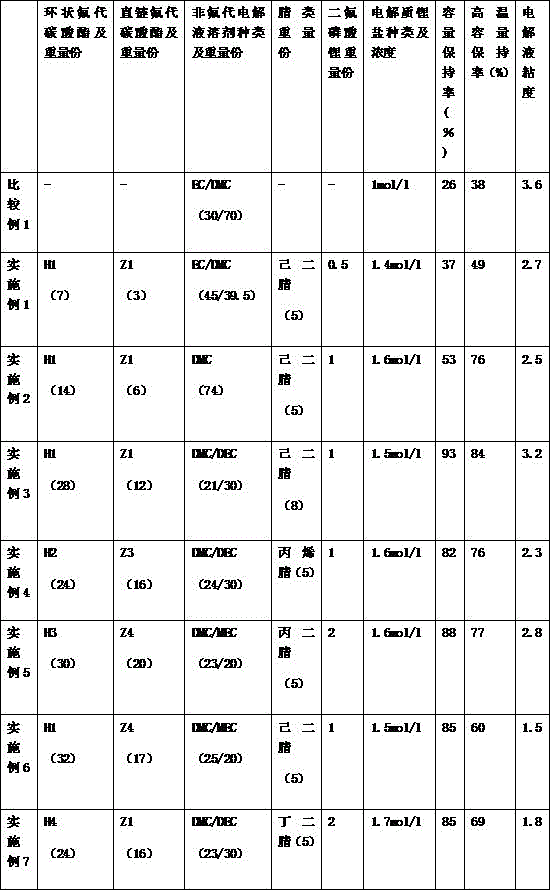

High-voltage electrolyte for lithium ion battery

InactiveCN106159328ALow viscosityImprove wettabilitySecondary cells servicing/maintenanceOrganic electrolytesHigh temperature storageDifluorophosphate

The invention provides high-voltage electrolyte for a lithium ion battery. The high-voltage electrolyte is composed of an electrolyte lithium salt, fluorocarbonate, nitriles, a solvent and an additive, wherein the electrolyte lithium salt is LiPF6 with the concentration of 1.2mol / L-1.6mol / L; a fluorocarbonate solvent accounts for 10%-60% of the total mass of the solvent; the nitriles account for 5%-15% of the total mass of the solvent; a non-aqueous organic solvent accounts for 23%-84.5% of the total mass of the solvent; the additive is lithium difluorophosphate and accounts for 0.5%-2% of the total mass of the solvent. By compounding and combining cyclic fluorocarbonate, straight-chain fluorocarbonate, the nitriles, the additive and the like, the high-voltage heat stability of the electrolyte is prone to improve and the problems that the high-temperature circulating stability of conventional electrolyte is poor and the high-temperature storage is not ideal are improved. Meanwhile, the electrolyte has small viscosity when the materials are matched; the wetting property of an electrode material is facilitated, the liquid injection time of the lithium ion battery is shortened and the rate performance of the battery is improved.

Owner:湖北诺邦科技股份有限公司

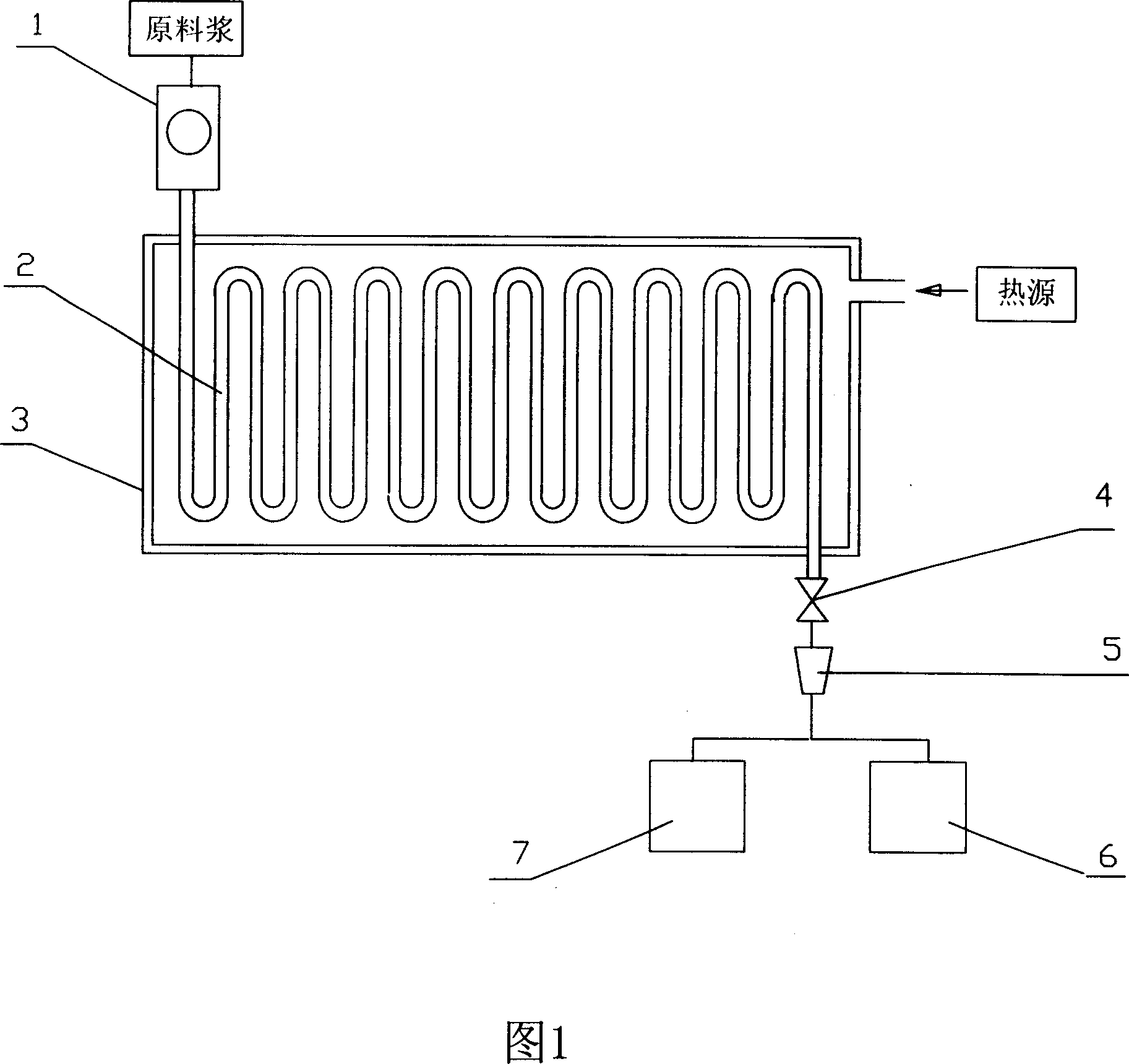

Continuous production method and apparatus for alpha semi-water gypsum

The invention discloses an alpha-semi-hydrated gypsum continuous producing method and device. And the traditional 'liquid phase process' has disadvantages of high equipment investment, wide occupied land, complex to operate and high labor strenghth. But the invention changes the traditional reaction kettle into a reaction pipe with a certain length, which is coilded in a heating box, one end of the reaction pipe connected with raw material pulp high pressure pump and the other end connected with a drying separation tower or gypsum blend-mouding device, thus implemnting continuous production of alpha-semi-hydrated gypsum. Therefore, the invention has advantages of saving reaction equipment investment and reducing production energy consumption.

Owner:SHANXI BEIFANG GYPSUM IND

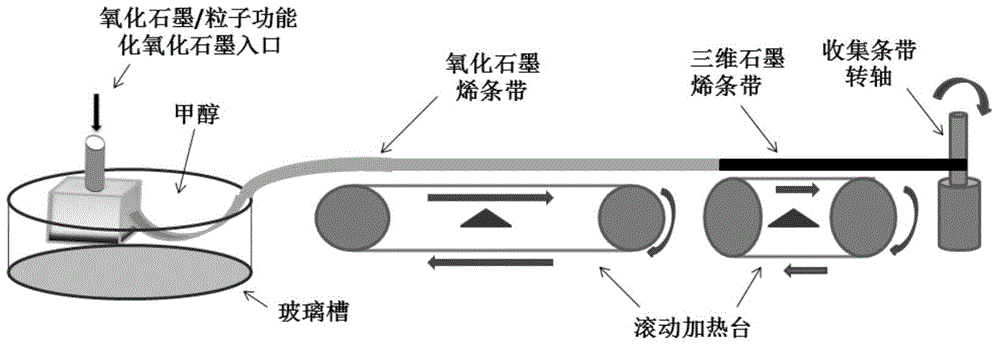

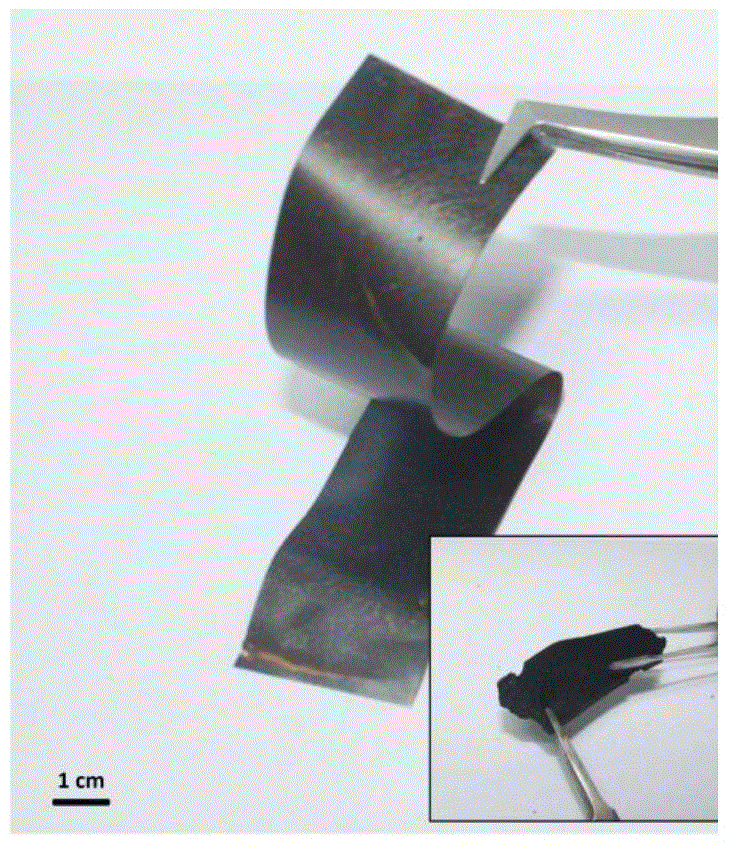

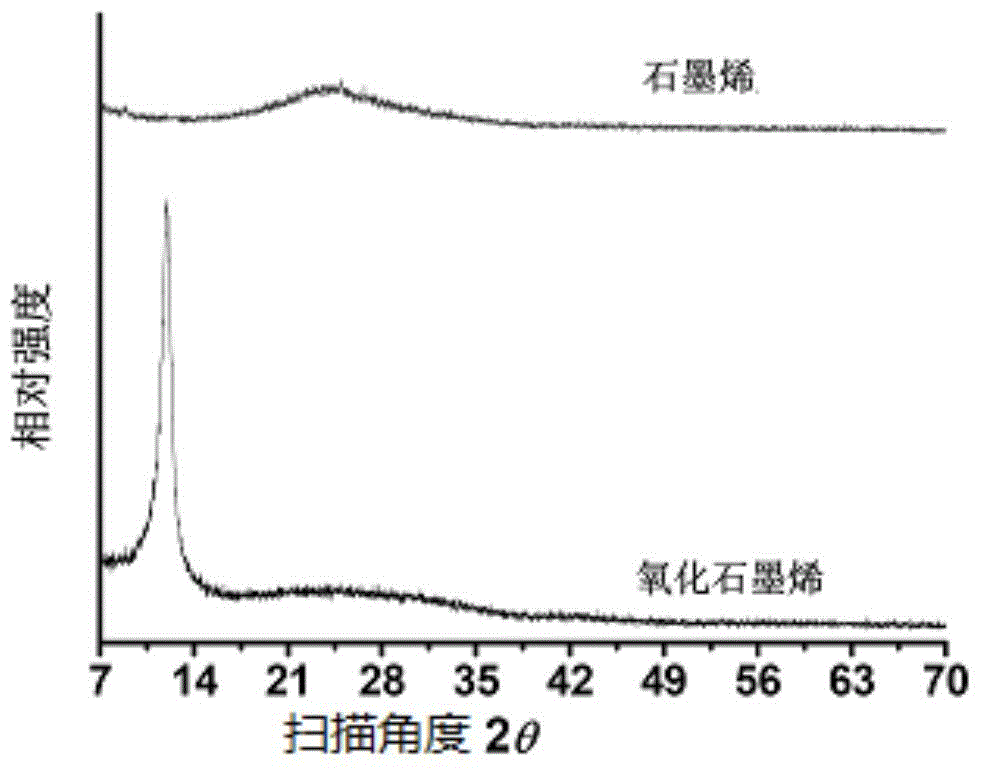

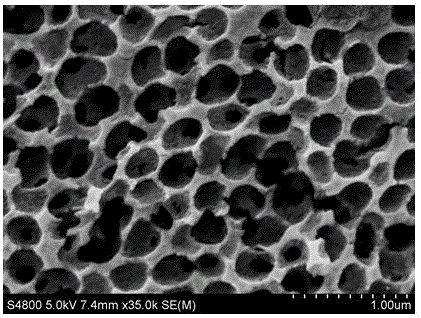

Method for on-scale continuous production of three-dimensional graphene membrane and application

ActiveCN104310381ALow costSynthetic technology is matureMaterial nanotechnologyFerroso-ferric oxidesNanoparticleCvd graphene

The invention discloses a method for on-scale continuous production of a three-dimensional graphene membrane and application, belonging to the field of functional materials. The method comprises the following steps: 1, preparing a graphene oxide solution; 2, stirring and concentrating; 3, soaking a polytetrafluoroethylene bath into methanol; 4, filling the concentrated graphene oxide solution into the polytetrafluoroethylene bath, thereby obtaining graphene oxide strips; 5, leading out the graphene oxide strips from the methanol solution, firstly drying, and further performing reduction expansion, thereby obtaining the three-dimensional graphene membrane; and 6, collecting the three-dimensional graphene membrane, and coiling. The graphene oxide solution and functional nanoparticles are mixed, and the functional three-dimensional graphene membrane can be prepared by performing the above preparation steps. The method is simple in preparation process, environment-friendly, low in cost and applicable to on-scale production, and the three-dimensional graphene membrane prepared by using the method is three-dimensional and porous and has the characteristics of light mass, large specific surface area and good flexibility.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

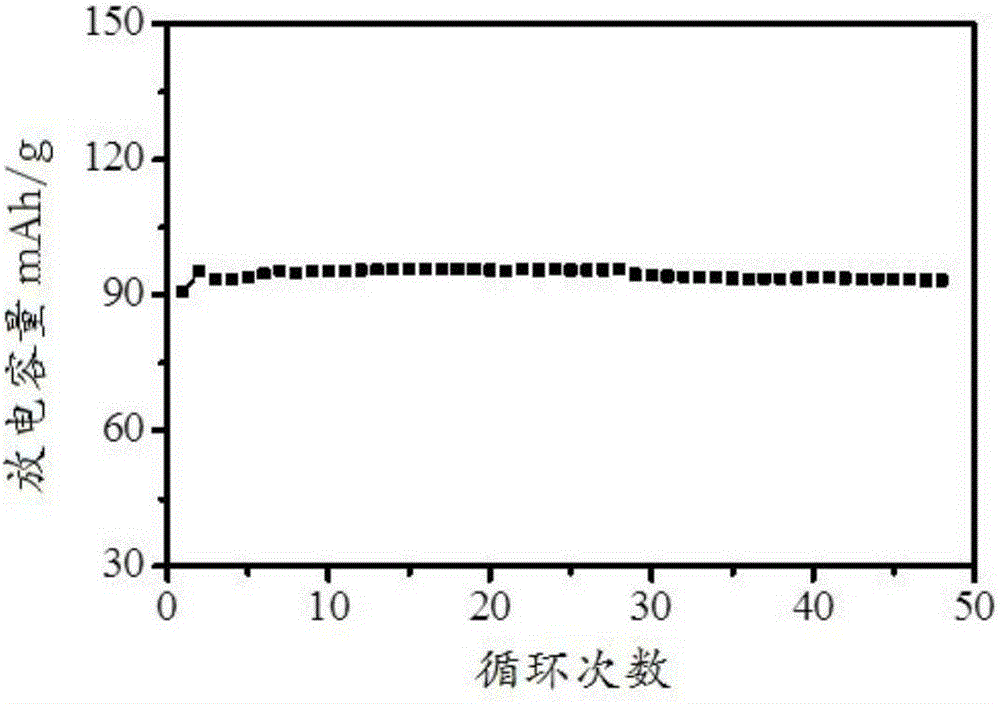

Method for preparing new lead-acid battery from active substances of waste and old lead-acid battery

ActiveCN105226342APrevent restoreEasy to handleFinal product manufactureSecondary cells manufactureElectricityEngineering

The invention discloses a method for preparing a new lead-acid battery from active substances of a waste and old lead-acid battery. The method comprises the following steps of dismounting the waste and old lead-acid battery to obtain a positive electrode plate and a negative electrode plate; respectively processing the positive electrode plate and the negative electrode plate to obtain positive electrode powder and negative electrode powder; respectively performing desulfurization and calcination on the obtained positive electrode powder and the negative electrode powder to obtain new positive electrode powder and new negative electrode powder with high electrochemical performance; using the obtained new positive electrode powder and the new negative electrode powder for manufacturing the new lead-acid battery. The prepared new positive electrode powder and the prepared new negative powder can be directly used for manufacturing the new lead acid battery; the method is simple; the implementation is easy. The method has the advantages that the reduction process in the traditional waste and old lead-acid battery positive powder processing process is avoided; the electrochemical performance of the positive electrode powder can be obviously improved; the formation process of the lead acid battery is accelerated; the preparation process conforms to clean production requirements; the battery production period is shortened; the production cost is reduced.

Owner:SOUTHEAST UNIV

Prepn of zeolite carried polymer metal cluster

InactiveCN1398675AAvoid high temperature roastingPrevent restoreMolecular sieve catalystsCatalyst activation/preparationMolecular sieveZeolite

A preparation of zeolite-carried high-molecular metal cluster features that an alcohol-water solution containing Pt family metal inorganic compound and an alcohol-water solution of polymer are made to contact with superfine Beta zeolite molecular sieve fully and the Pt family metal is reduced through heating reflux. Then, powdered superfine Beta zeolite molecular sieve carrying high-molecular Pt family metal cluster is produced by drying in rotary decompress evaporation mode. The said process can disperse the metal cluster homogeneously on the surface of molecular sieve, and the metal particles have small and narrowly distributed size and are stable in the air. The metal cluster may be used in catalyst for the low temperature conversion of methane and has relatively high selectivity to high-carbon hydrocarbon.

Owner:TAIYUAN UNIV OF TECH

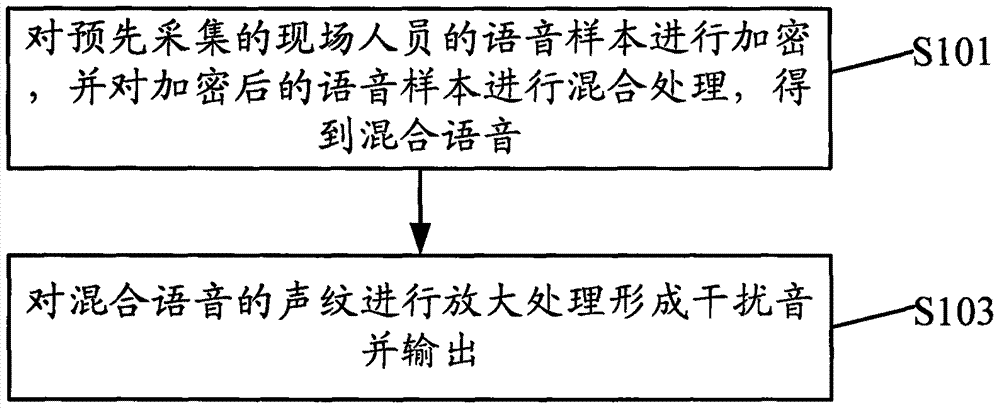

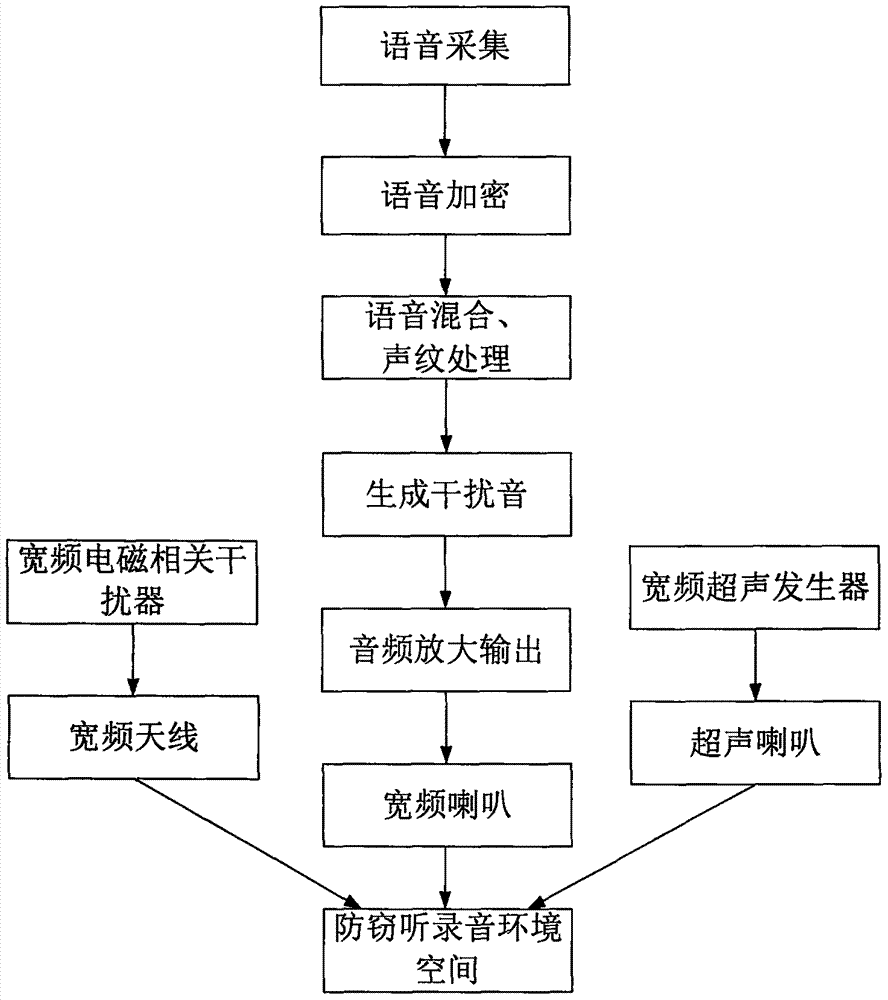

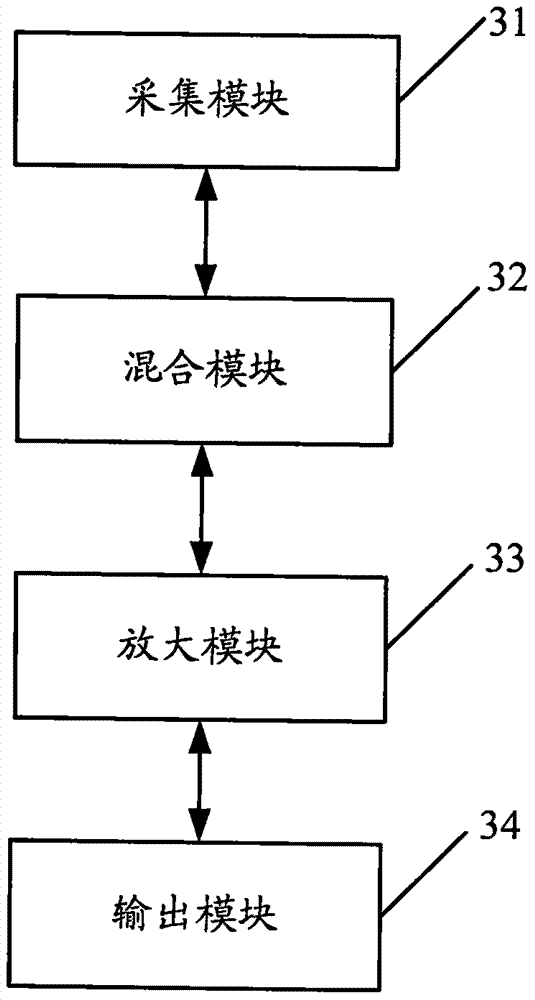

Eavesdropping-proof recording method and interference shielding device

InactiveCN107295148APrevent restoreAvoid interferenceEavesdropping prevention circuitsCommunication jammingSpeech soundDecibel

The invention discloses an eavesdropping-proof recording method and an interference shielding device. The eavesdropping-proof recording method comprises steps: pre-acquired speech samples of a field person are encrypted, the encrypted speech samples are mixed, and mixed speech is obtained; and the voiceprint of the mixed speech is amplified to form interference speech and the interference speech is outputted. When the generated interference speech is played, although the decibel is not high, the interference speech can be acquired easily by various types of pickups (the type of the pickup is not restricted), interference to the field person is prevented, and interference shielding can be extremely effectively carried out on an eavesdropping-proof recording device.

Owner:北京中密安信息安全技术有限公司

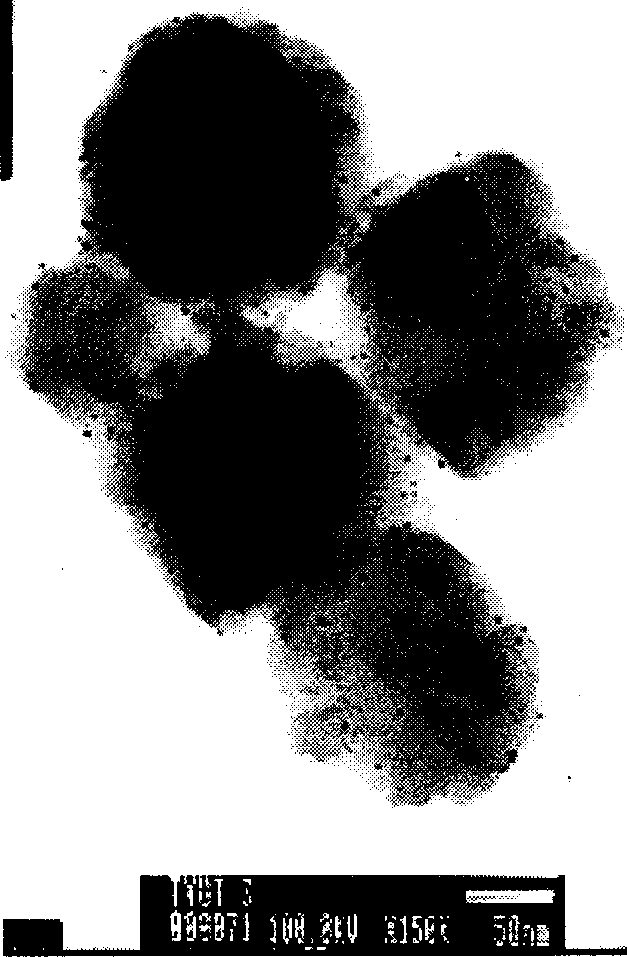

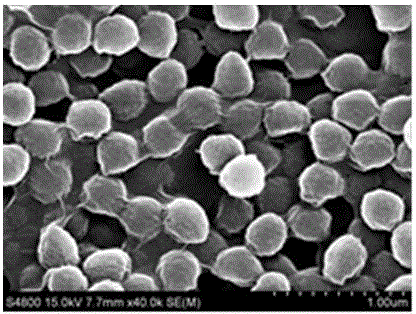

Preparation method and application of magnetic hollow graphene-based composite microsphere material

InactiveCN106378093ALarge specific surface areaFast transferOther chemical processesWater contaminantsMicrosphereDyeing wastewater

The invention discloses a preparation method and application of a magnetic hollow graphene-based composite microsphere material. The preparation method comprises the following steps: taking a polymer microsphere with positive charges as a template, and obtaining the magnetic hollow graphene-based composite microsphere material through a high-temperature heat treatment one-step method. The preparation method provided by the invention is simple and feasible and has no environment pollution, and industrial production is easy to realize; meanwhile, the prepared magnetic hollow graphene-based composite microsphere material has a relatively large specific surface area and a developed pore structure, and can be used for efficiently and rapidly adsorbing and separating dye molecules. The magnetic hollow graphene-based composite microsphere material prepared by the preparation method has a wide application prospect in the aspect of treating dye wastewater.

Owner:CHONGQING UNIV OF ARTS & SCI

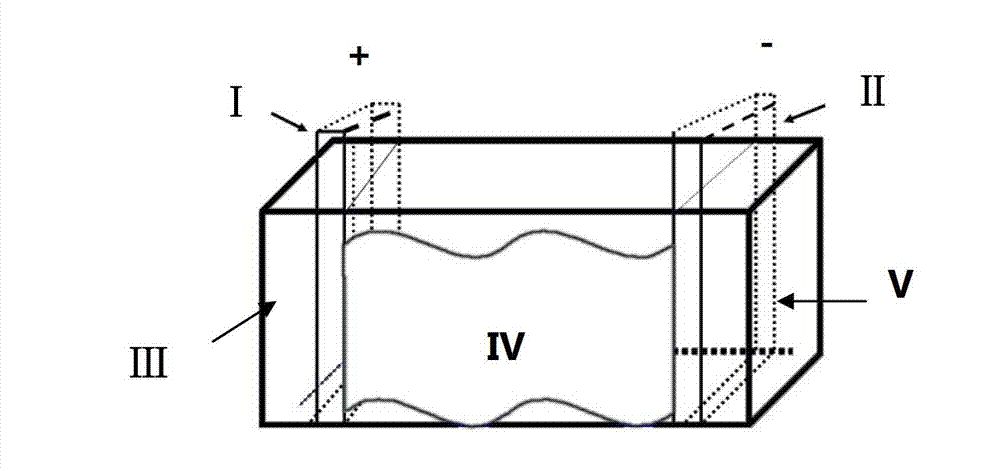

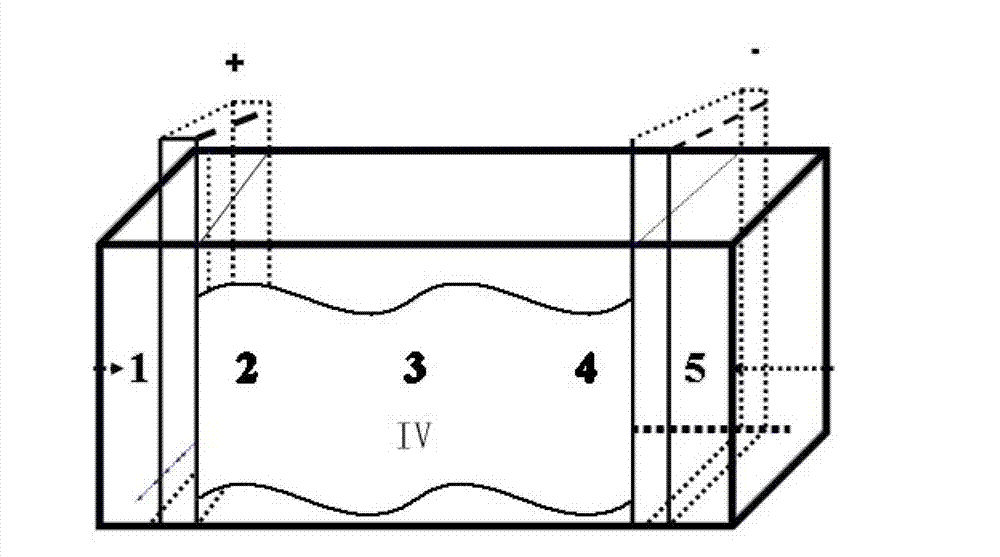

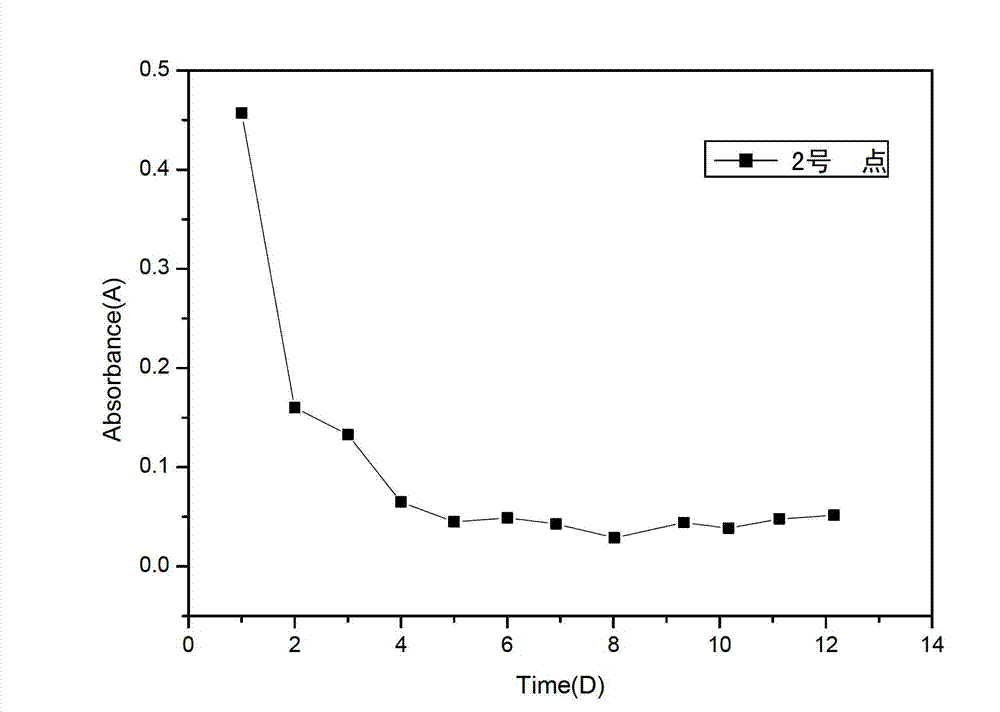

Method and device for electrically recovering phenol-contaminated soil by using three-dimensional porous carbon electrode

InactiveCN102921715AElasticEliminate "electric field dead angle"Contaminated soil reclamationPorous carbonPhenol

The invention discloses a method and a device for electrically recovering phenol-contaminated soil by using a three-dimensional porous carbon electrode. The technical scheme comprises (1) adopting the flexible three-dimensional porous carbon electrode to serve as a positive electrode and a negative electrode respectively; (2) placing the positive electrode and the negative electrode in a positive electrode area and a negative electrode area of an electrokinetic remediation tank, respectively filling soil-free neutral aqueous solution in the positive electrode area and the negative electrode area, and filling soil to be recovered between the positive electrode area and the negative electrode area; (3) exerting direct voltage which enables phenol to move towards the negative electrode area between the positive electrode area and the negative electrode area; (4) respectively replenishing Ca(OH)2 and oxalate in the positive electrode area and the negative electrode area; and (5) removing the aqueous solution in the negative electrode area after all the phenol in the soil to be recovered converges to the negative electrode area, and achieving recovering of the phenol-contaminated soil. The method and the device can effectively remove phenol from the soil, basically have no electric field dead angle, simultaneously can cause no secondary pollution, and accordingly achieve effective recovering of the phenol-contaminated soil.

Owner:SUZHOU UNIV OF SCI & TECH

Iron ore tunnel kiln magnetizing roasting layering material distributing reduction method

The invention discloses an iron ore tunnel kiln magnetizing roasting layering material distributing reduction method. Iron ore is divided into different granularity degrees according to the granularity range; the reduction coal is flatly laid in the bottom of a tunnel kiln car according to the proportion that the reduction coal accounts for 4-6% of the total weight of iron ore; the iron ore of various granularity degrees is laid at the upper portion of the reduction coal of the tunnel kiln car, and the granularity range of each layer of iron ore is gradually increased from the bottom layer to the top layer in a layer-by-layer manner; facing materials are flatly laid at the upper portion of iron ore of various granularity degrees of the tunnel kiln car; the tunnel kiln car loaded with materials is pushed into a tunnel kiln for magnetizing roasting; and after magnetizing roasting is finished, the tunnel kiln car loaded with the materials is pushed out of the tunnel kiln. According to the method, over reduction of iron ore can be effectively prevented, the control means of iron ore magnetizing roasting is improved, and the surplus carbon recycling and utilizing cost is low. In addition, the mixing technology of iron ore and a reducing agent before magnetizing roasting of the iron ore tunnel kiln is reduced or eliminated, and the production cost of the roasted ore is reduced.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

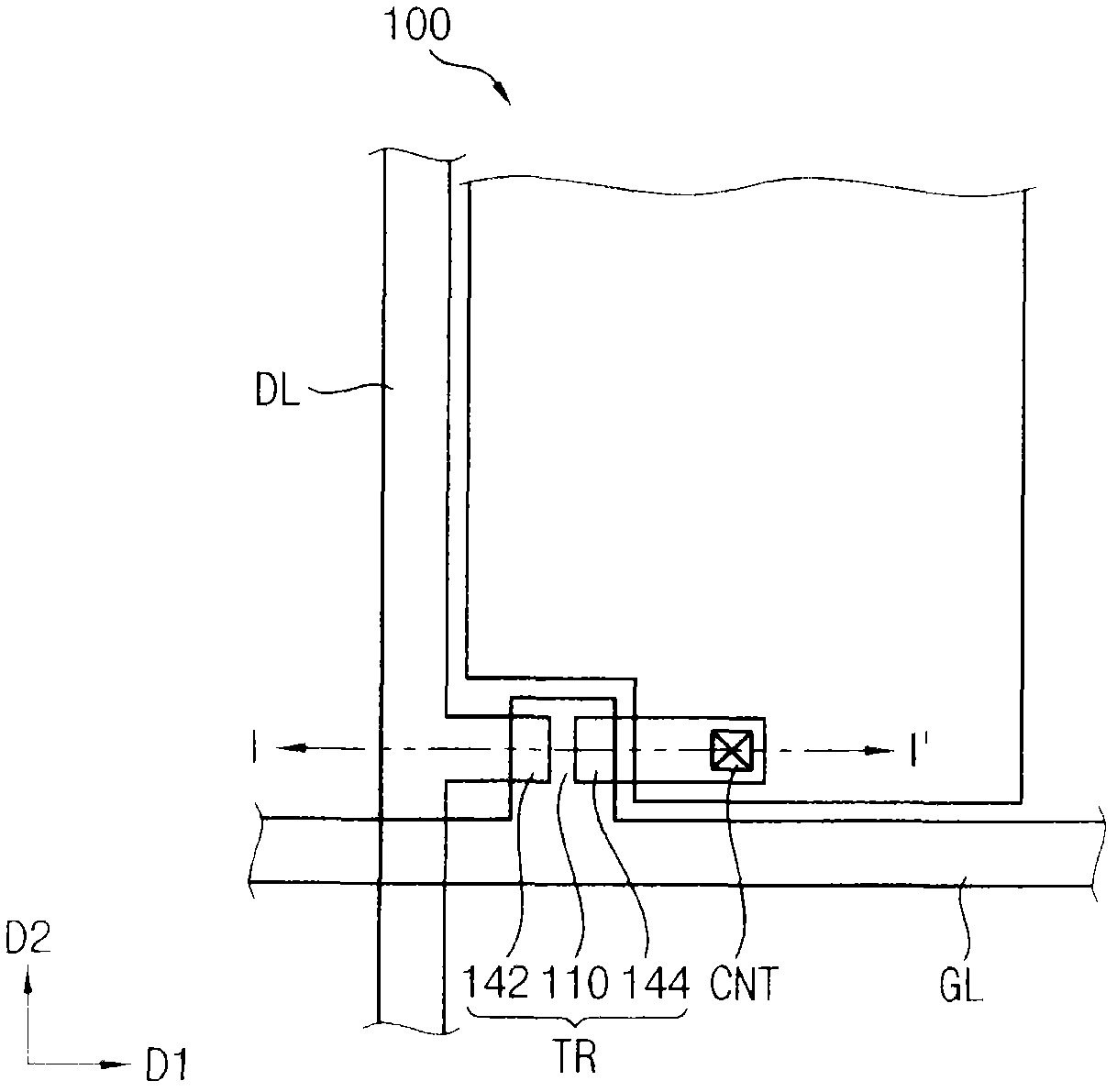

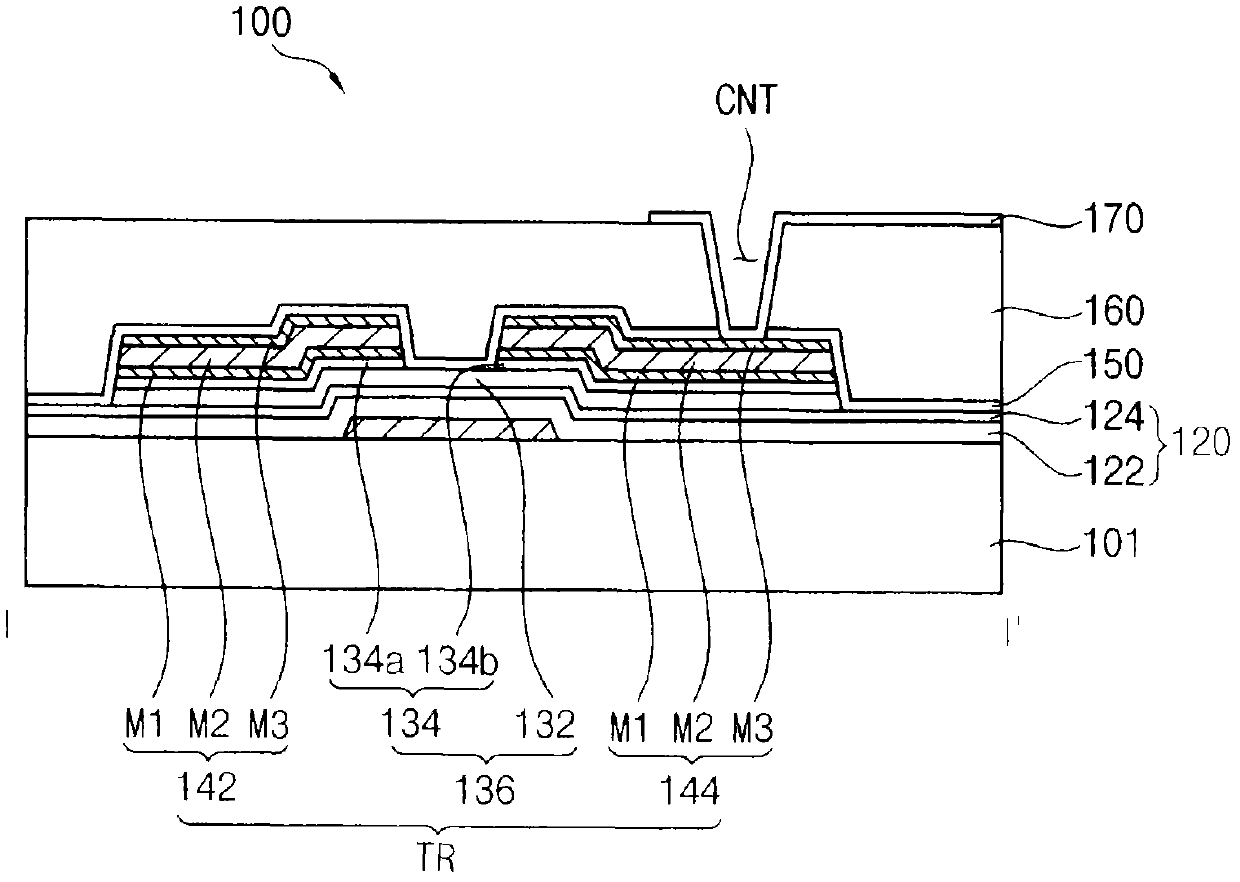

Display substrate and method of manufacturing same

ActiveCN102347335AReduce or effectively prevent revertingPrevent restoreSolid-state devicesSemiconductor/solid-state device manufacturingIndiumEngineering

The invention discloses a display substrate and a method of manufacturing the same. The display substrate includes a gate line extending in a first direction on a base substrate, a data line on the base substrate and extending in a second direction crossing the first direction, a gate insulating layer on the gate line, a thin-film transistor and a pixel electrode. The thin-film transistor includes a gate electrode electrically connected the gate line, an oxide semiconductor pattern, and source and drain electrodes on the oxide semiconductor pattern and spaced apart from each other. The oxide semiconductor pattern includes a first semiconductor pattern including indium oxide and a second semiconductor pattern including indium-free oxide. The pixel electrode is electrically connected the drain electrode.

Owner:SAMSUNG DISPLAY CO LTD

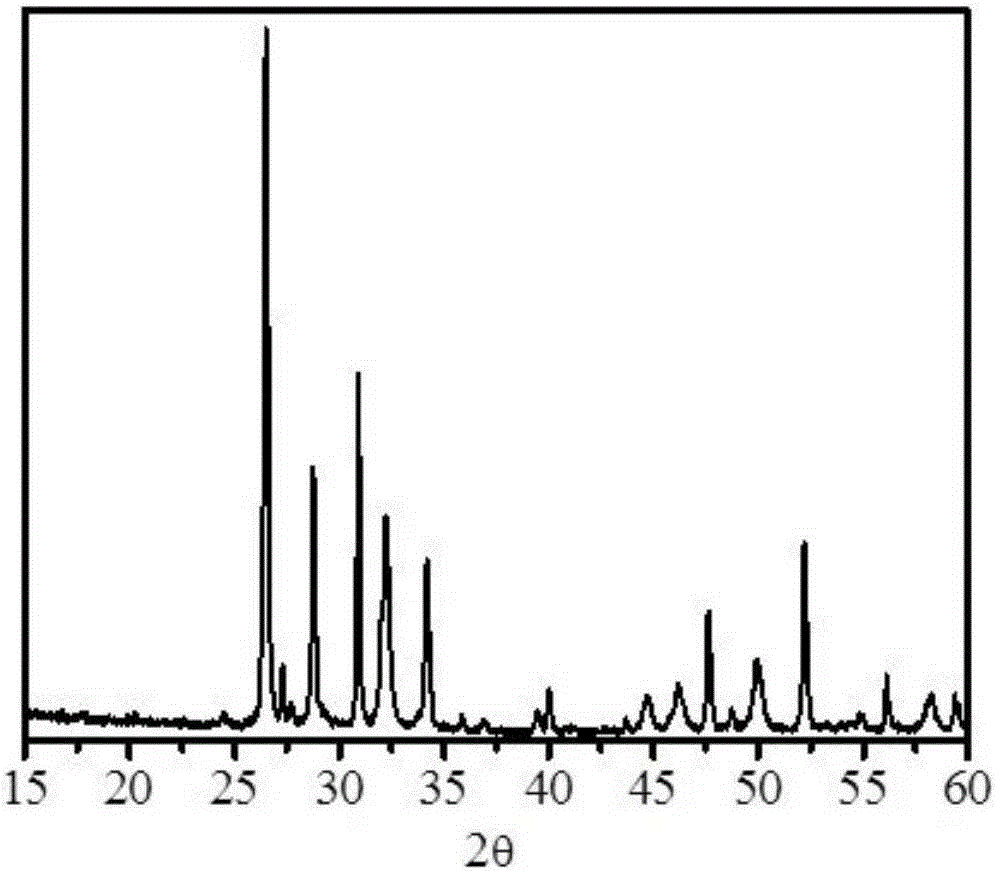

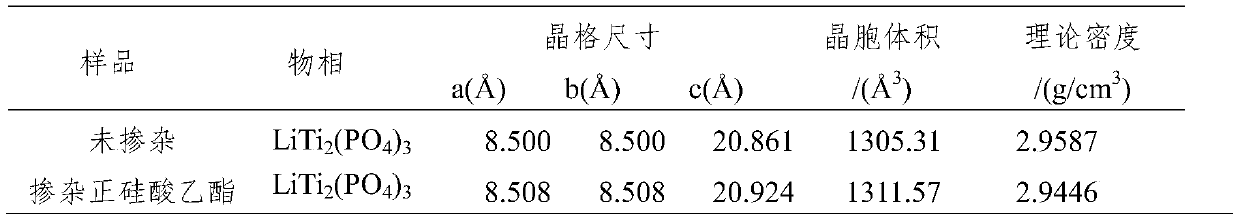

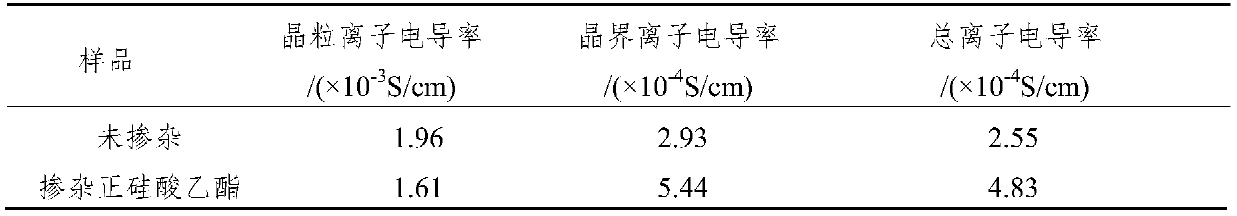

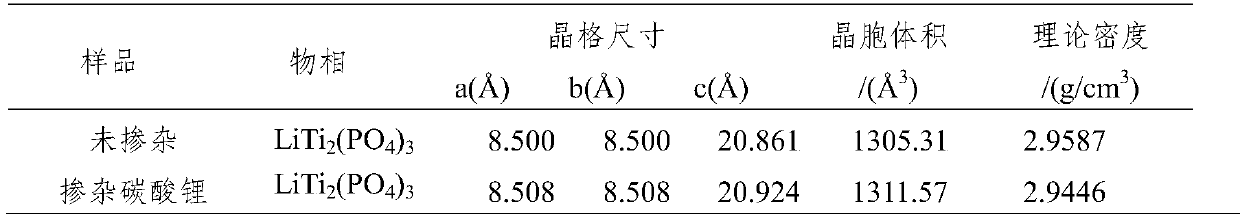

Highly conductive solid electrolyte prepared by coprecipitation method

InactiveCN110862259AReduce interface resistanceImprove electrochemical stabilitySolid electrolytesLi-accumulatorsSolid state electrolytePhysical chemistry

The invention relates to the technical field of solid electrolytes, and in particular, relates to a highly conductive solid electrolyte prepared by a coprecipitation method, wherein a preparation method comprises the steps: step 1, weighing a dopant, aluminum nitrate, tetrabutyl titanate and ammonium dihydrogen phosphate, sequentially putting the raw materials into a reaction container, and continuously stirring at room temperature until faint yellow slurry is formed; step 2, slowly adding ammonia water into the faint yellow slurry and dissolving; step 3, heating the reaction container to 88-90 DEG C, and carrying out constant-temperature water bath magnetic stirring for 0.8-1.1 h, to form a white precipitate; step 4, transferring the white precipitate into a blast drying oven, and heatingto obtain a white precursor; step 5, presintering the white precursor to obtain white powder; and step 6, carrying out ball milling on the white powder, tabletting, molding and calcining to obtain asolid electrolyte sintered body. The solid electrolyte provided by the invention has an NASICON structure, small interface resistance and excellent electrochemical stability, and the particle size reaches nanoscale.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

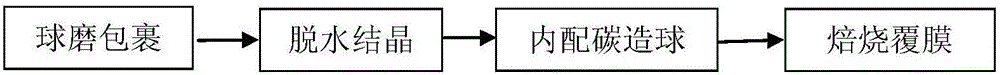

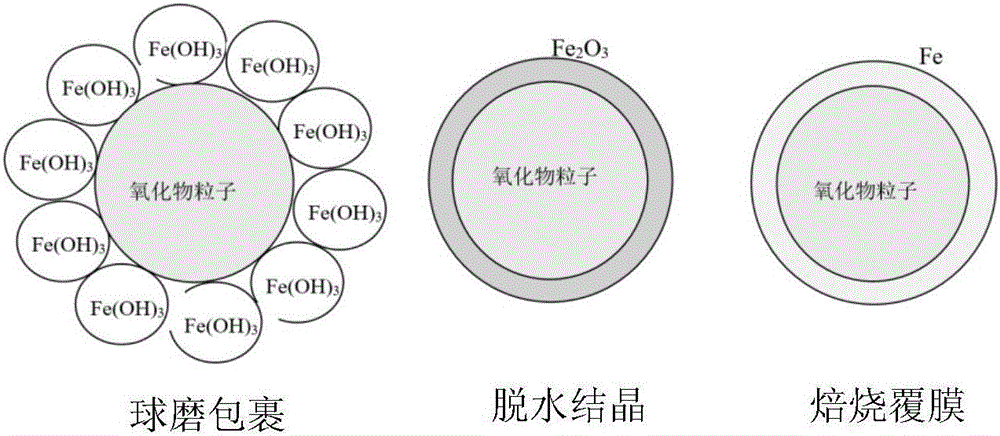

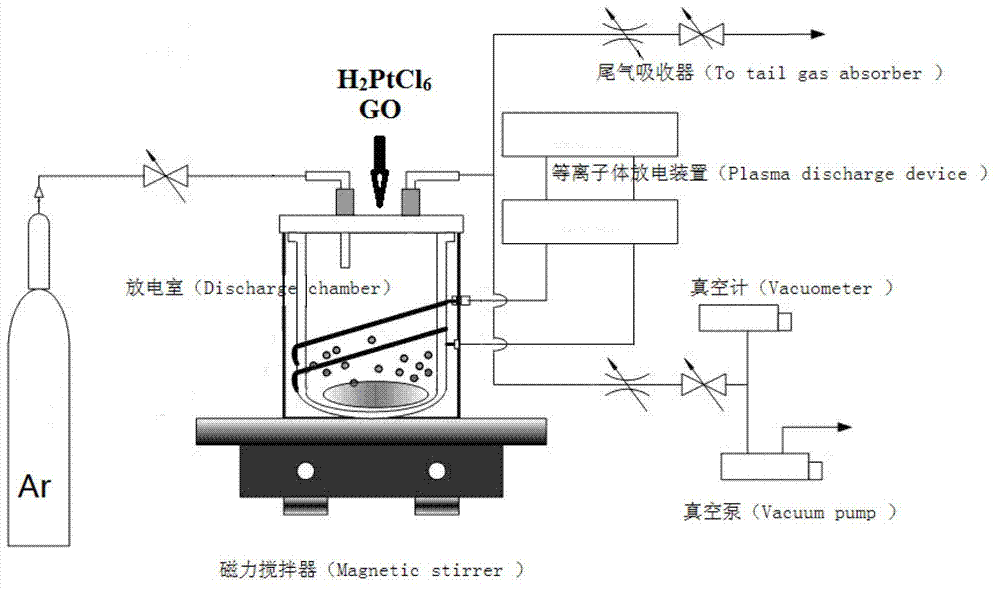

Additional nano enhancer capable of improving mechanical property of steel and preparation and using method thereof

The invention discloses an additional nano enhancer capable of improving the mechanical property of steel and a preparation and using method thereof, and belongs to the field of ferrous metallurgy. The additional nano enhancer contains nano oxide particles and Fe, and the nano oxide particles refer to one of Y2O3, ZrO2, Ti2O3 or Ce2O3. The preparation method includes the steps of ball-milling coating, dehydration and crystallization, carbon-containing pelletizing and roasting membrane coating. The using method includes the steps that the additional nano enhancer is preheated and pre-laid at the bottom of a mold, and molten steel is injected into the mold. By the adoption of the method, Fe(OH)3 is used for pre-dispersing the nano oxide particles, OH-action is effectively destroyed and removed, the Fe(OH)3 can be gradually turned into Fe in the preparing process, and accordingly the additional nano enhancer can be prepared. In the casting process, the additional nano enhancer cannot influence the degree of purity of the molten steel, the nano oxide particles cannot denature and grow, either, a disperse distribution phase is formed when the nano oxide particles are added into the molten steel, and thus the mechanical property of the steel is effectively improved.

Owner:NORTHEASTERN UNIV

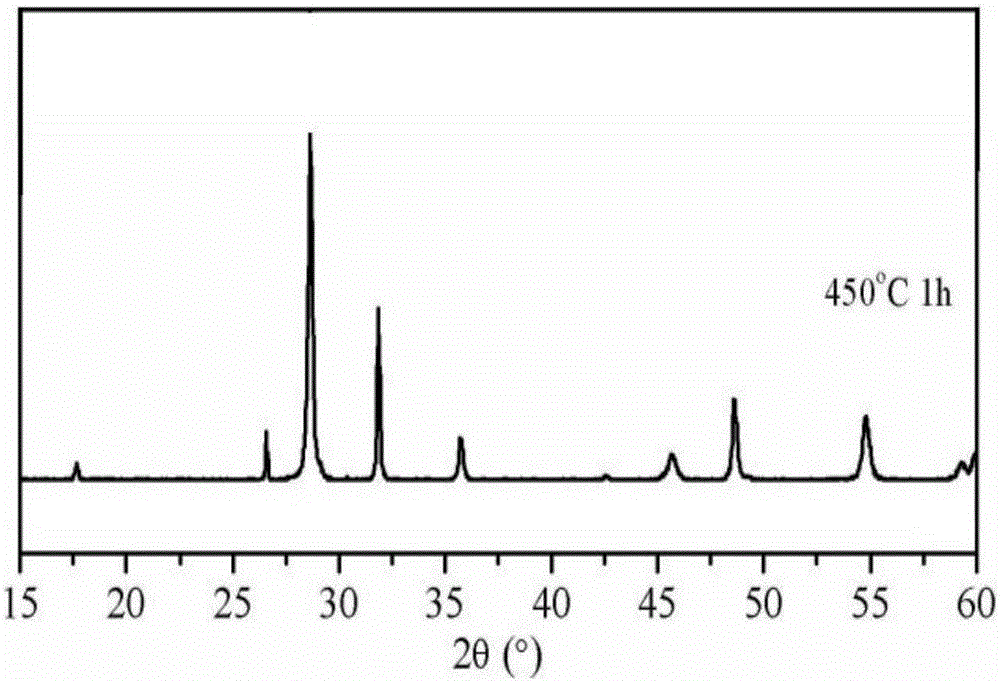

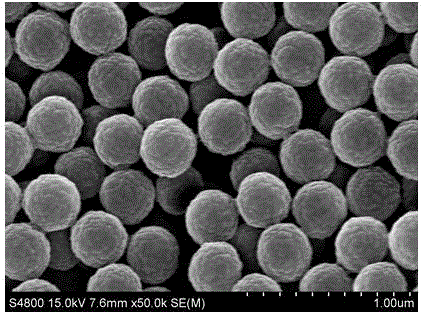

Preparation method of NiO/carbon nanospheres with core-shell structures

InactiveCN107195483AAvoid gatheringPrevent restoreMaterial nanotechnologyHybrid capacitor electrodesCapacitanceCarbonization

The invention relates to a preparation method of NiO / carbon nanospheres with core-shell structures. The preparation method comprises the steps of weighing aqueous ammonia, water, anhydrous ethyl alcohol, nickel(II) nitrate hexahydrate, tetraethyl orthosilioate, a formaldehyde solution, resorcinol and cetyl trimethyl ammonium bromide according to a mass part ratio of: 0.3-1.2:100:31.6:0.05-0.25:4.7:1.4:1:1, evenly mixing the aqueous ammonia, the water and the anhydrous ethyl alcohol and then adding the nickel(II) nitrate hexahydrate therein, stirring the mixture for 10 to 120 minutes, adding the resorcinol and the cetyl trimethyl ammonium bromide into the mixture in sequence, stirring the mixture for 30 min and then adding the formaldehyde solution and the tetraethyl orthosilioate into the mixture, stirring the mixture for 24 h and then subjecting the mixture to hydrothermal reaction for 24 h at the temperature of 100 DEG C, placing the reaction product in a tube furnace, increasing the temperature from room temperature to 700-900 DEG C at a rate of 1-10 DEG C / min in a nitrogen atmosphere for carbonization, removing SiO2 in the product by using a NaOH solution with the concentration of 3 mol / L to obtain the NiO / carbon nanospheres with the core-shell structures. The preparation method has the advantages of simple process and simple operation, and the prepared NiO / carbon nanospheres exhibit high specific capacitance and good cycling stability when serving as an electrode material of a supercapacitor.

Owner:TONGJI UNIV

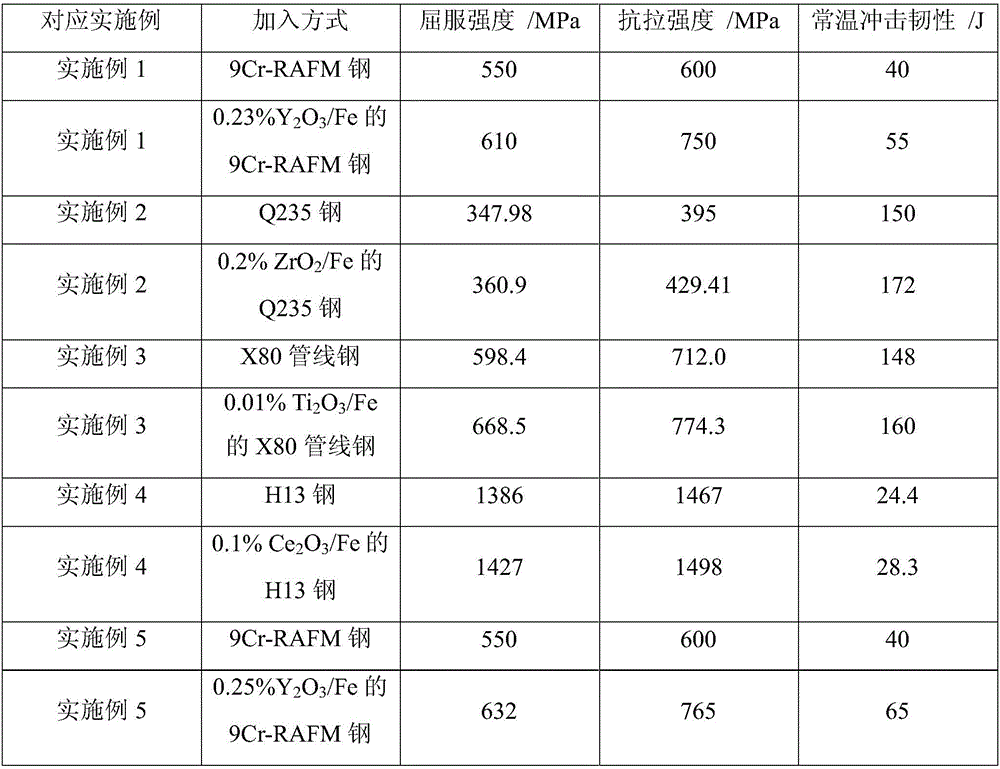

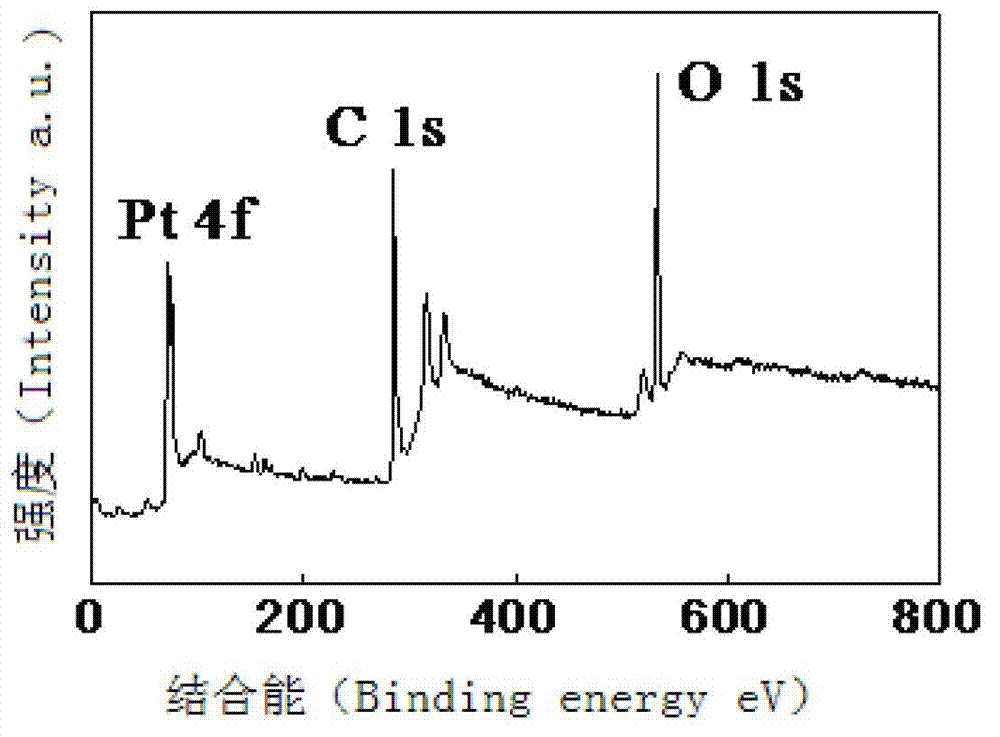

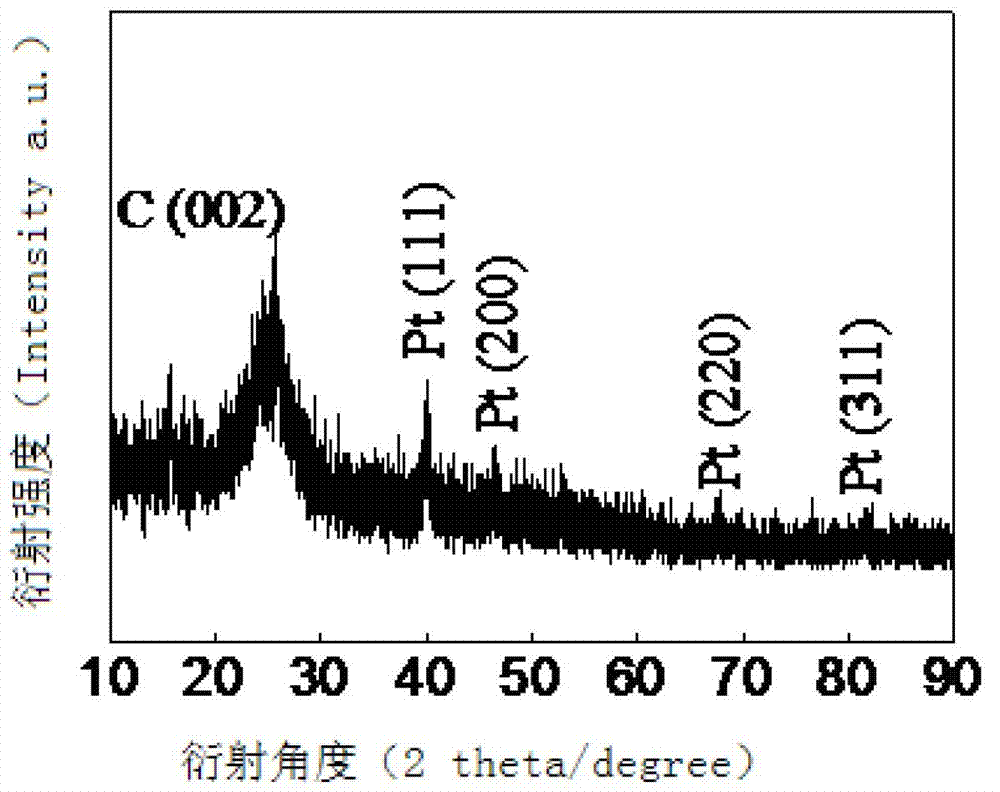

Method for preparing grapheme platinum nanocomposite material by using argon plasma

ActiveCN102698741AImprove electrocatalytic performanceShort manufacturing timeCell electrodesMetal/metal-oxides/metal-hydroxide catalystsPlasma flowVacuum pump

The invention discloses a method for preparing grapheme platinum nanocomposite material by using argon plasma. The method comprises the steps of: putting graphene oxide into a beaker, then adding chloroplatinic acid, drying the obtained mixture, then putting the mixture into a sealed container, wherein the container is connected with a graphite electrode, the electrode is connected with alternating current power supply, and the power supply can generate an inductive coupling plasma source; introducing argon into the container, removing air, then opening a vacuum pump to vacuumize until the vacuum degree is about 3Pa; opening the alternating current power supply to generate the argon plasma, enabling the plasma flow directly to act on the surface of the dried powder for 28-32 minutes, fully washing, filtering and drying the reaction product by deionized water and proper organic solvent to prepare the grapheme platinum nanocomposite material. According to the method, not only can uniformly distributed grapheme platinum nanocomposite material be prepared effectively, but also the preparation time is shortened greatly, and the process is simplified.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

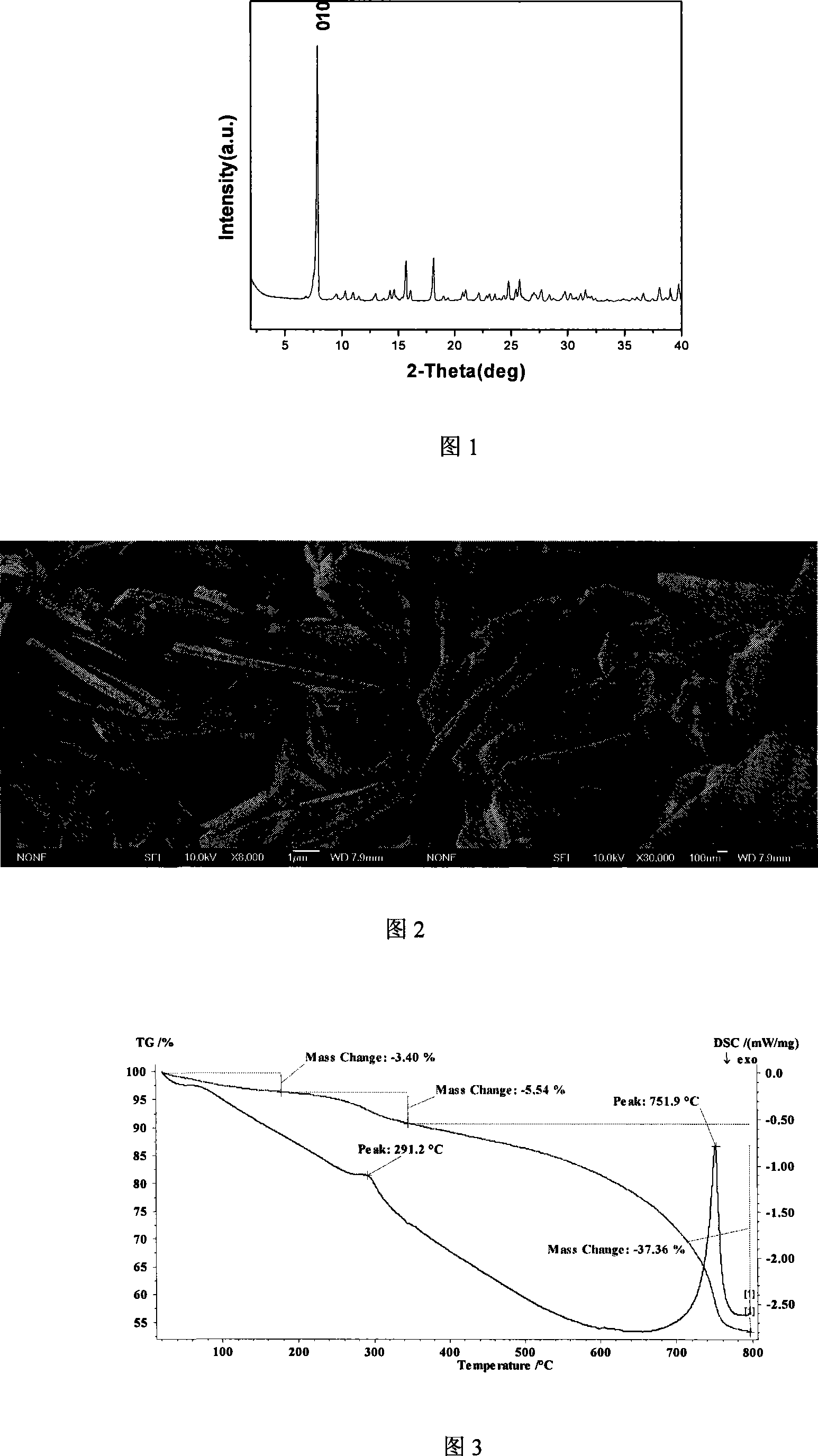

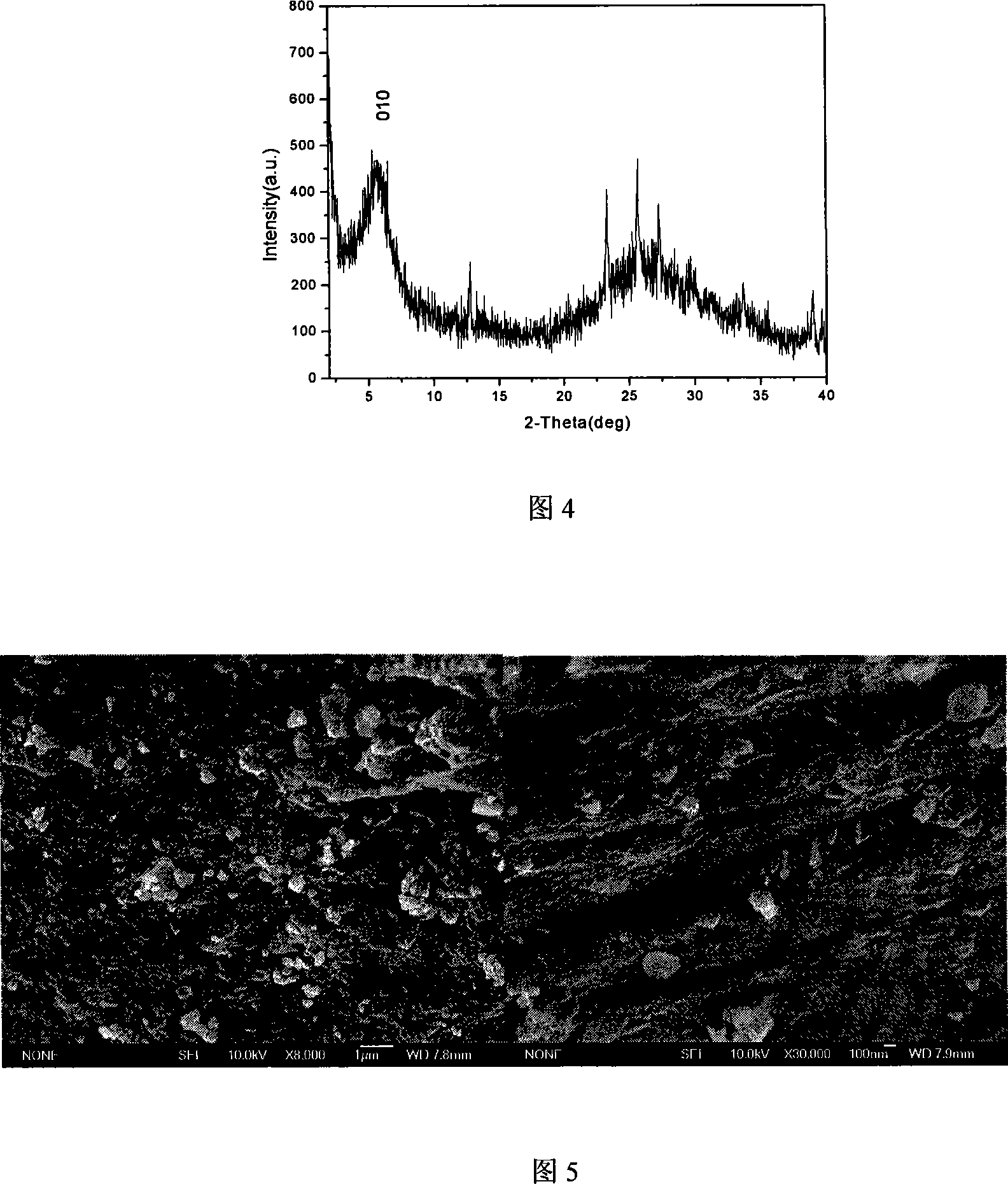

Process for preparing molybdenum trioxide/polyaniline laminated composite material

The invention relates to a preparation method of a molybdenum trioxide / polyaniline layer-shaped composite material and the method is that: an aniline monomer intercalation molybdenum trioxide composition is synthesized in a waterless acetic acid firstly, and then the molybdenum trioxide / polyaniline layer-shaped composite material can be obtained by triggering the aniline monomer polymerization at 150DEG C. The prepared molybdenum trioxide / polyaniline layer-shaped composite material has regular ordered layered structure, the even layer interval is 1.127nm, and the heat stability is high. The prepared molybdenum trioxide / polyaniline layer-shaped composite material is characterized in that the modified MoO3 of lauryl amine is used as an intermediate, and molybdenum need not to be reduced during the intercalation process; the waterless acetic acid is used as a solvent when the monomer is intercalated, and the whole reaction is carried out in a non-water system; air is used as an initiator during the polymerization stage, and no other impurity ions are introduced, therefore, the products prepared by the preparation method are high in purity, thus improving the product quality.

Owner:南通万宝磁石制造有限公司

Composite titanium removing agent and smelting method for reducing titanium content of molten steel

ActiveCN110317929AReduced activityPrevent restoreManufacturing convertersProcess efficiency improvementSmelting processTitanium

The invention relates to a composite titanium removing agent and a smelting method for reducing the titanium content of molten steel. The composite titanium removing agent comprises, by mass, 30%-40%of FeO2, 40%-50% of CeO2 and 10%-30% of CaF2, wherein the particle size D50 of all the components is smaller than or equal to 50 mm. During molten iron pretreatment desulfurization, the composite titanium removing agent is added into molten iron, double slag smelting is adopted during converter smelting, active lime, soft burnt lime and iron ore are added in the early stage of smelting, and activelime and iron ore are added during latter semisteel smelting; and before converter tapping, CeO2 is added to the bottom of a molten steel refining ladle, and after the molten steel enters a tundish,CeO2 is added during each time of casting. The titanium content in the molten steel can be controlled in the whole smelting process, and the target that the mass fraction of titanium in finished steelis lower than 0.001% is achieved.

Owner:ANGANG STEEL CO LTD

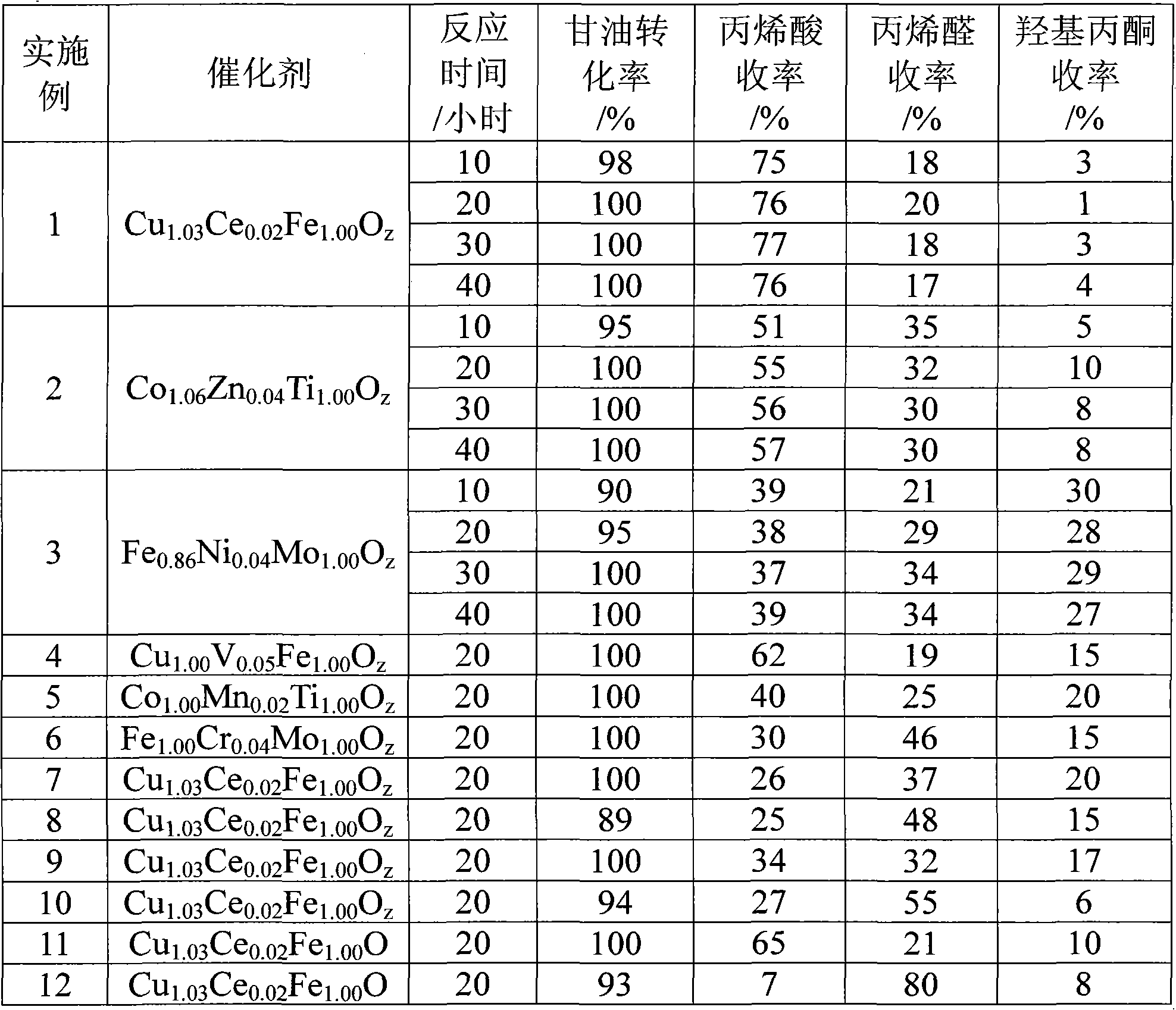

Method for preparing acrylic acid from glycerin as raw material

InactiveCN102249890AAvoid inactivationRemove in timeOrganic compound preparationCarboxylic compound preparationCatalytic oxidationGlycerol

A method for preparing acrylic acid from glycerin as a raw material. The method is characterized in that glycerin aqueous solution with mass concentration of 10 to 95% and mixed gas of inert gas and oxygen gas are mixed and then are fed into a reactor loaded with a solid catalyst to undergo a catalytic oxidation dehydration reaction so that glycerin is transformed into acrylic acid. The method adopts a single catalyst and a single reactor, and specifically adopts an oxysalt as a catalyst, wherein the oxysalts have double-function of oxidation and dehydration, prepares directly acrylic acid from glycerin, and realizes respectively a glycerin transformation rate of 100% and acrylic acid selectivity of 77%, thus improves acrylic acid selectivity and simplifies catalyst use processes.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Block chain data processing method and device, electronic equipment and medium

ActiveCN111310216ATake security into considerationImprove securityUser identity/authority verificationDatabase distribution/replicationComputer hardwareCiphertext

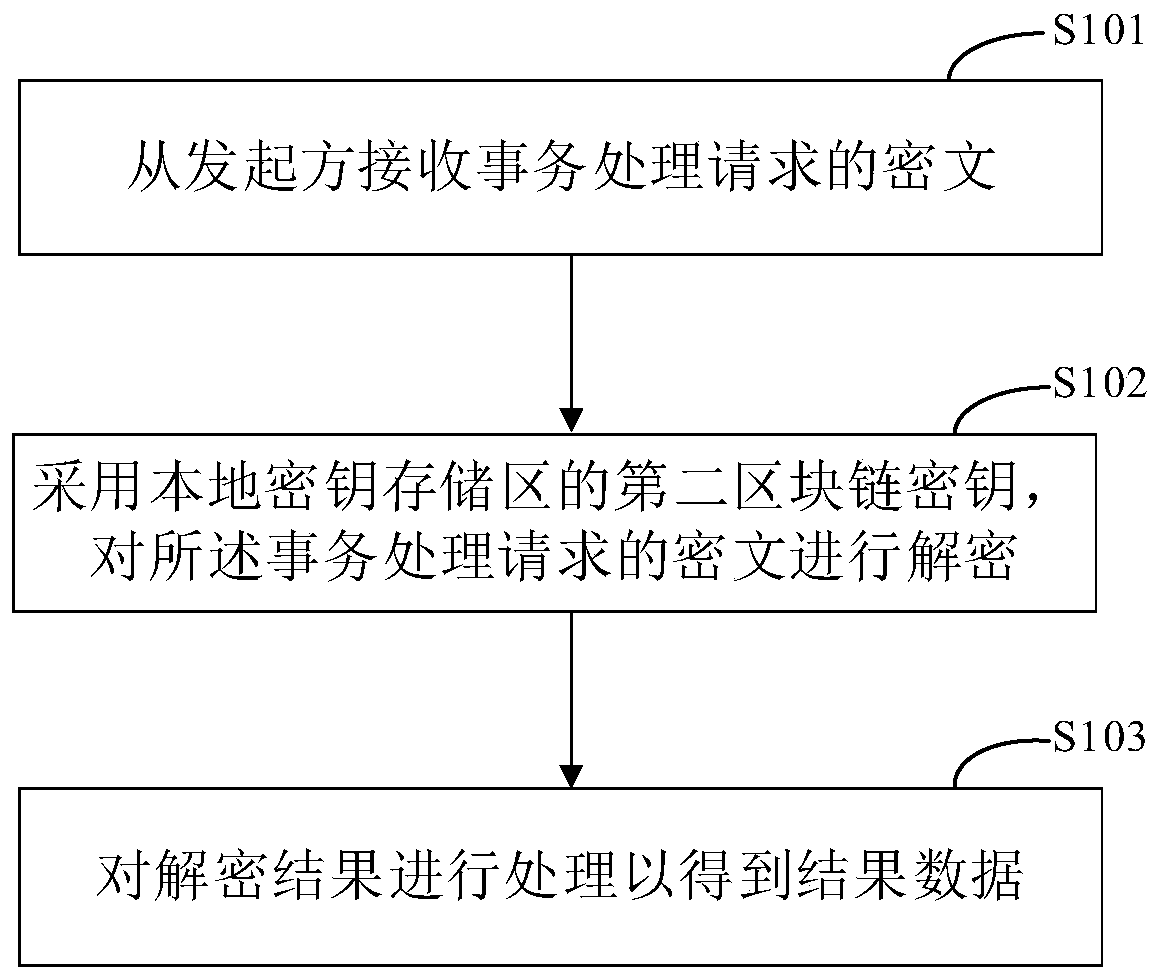

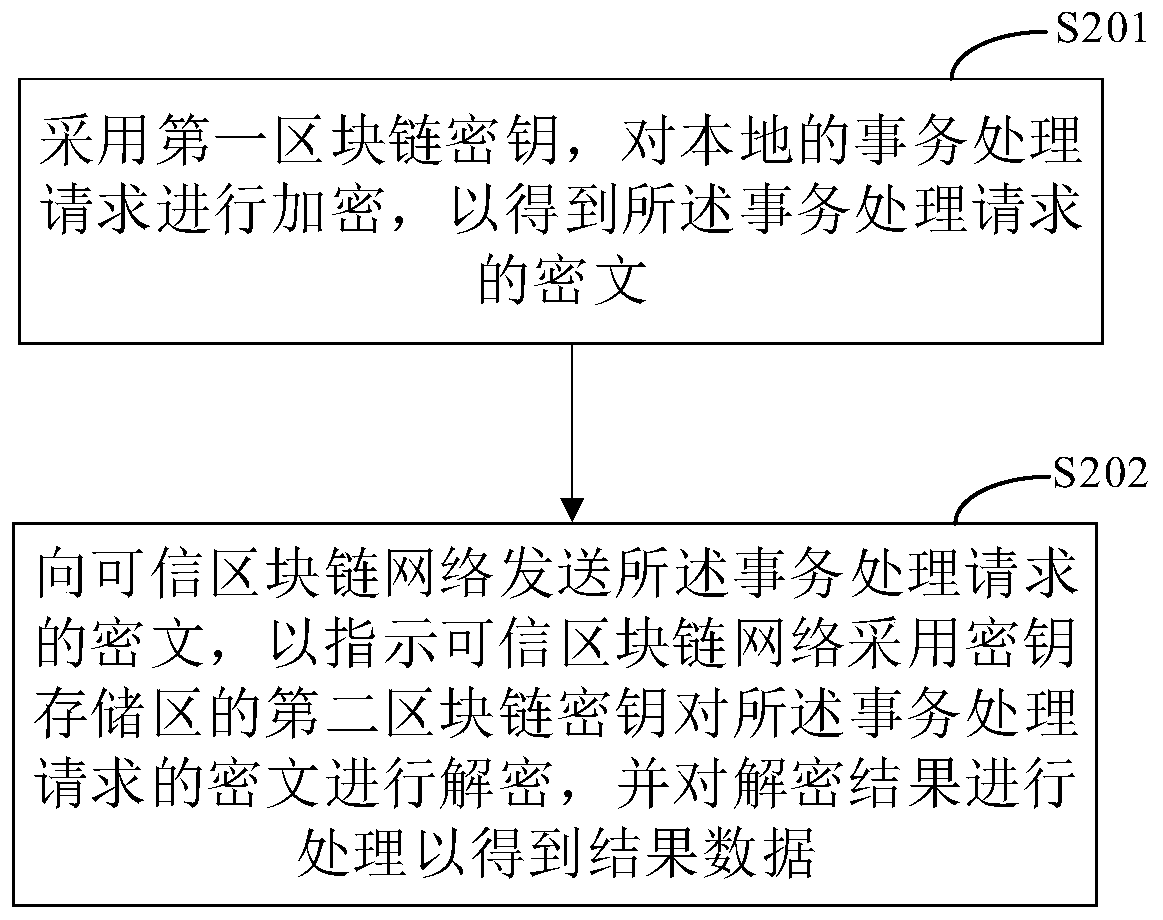

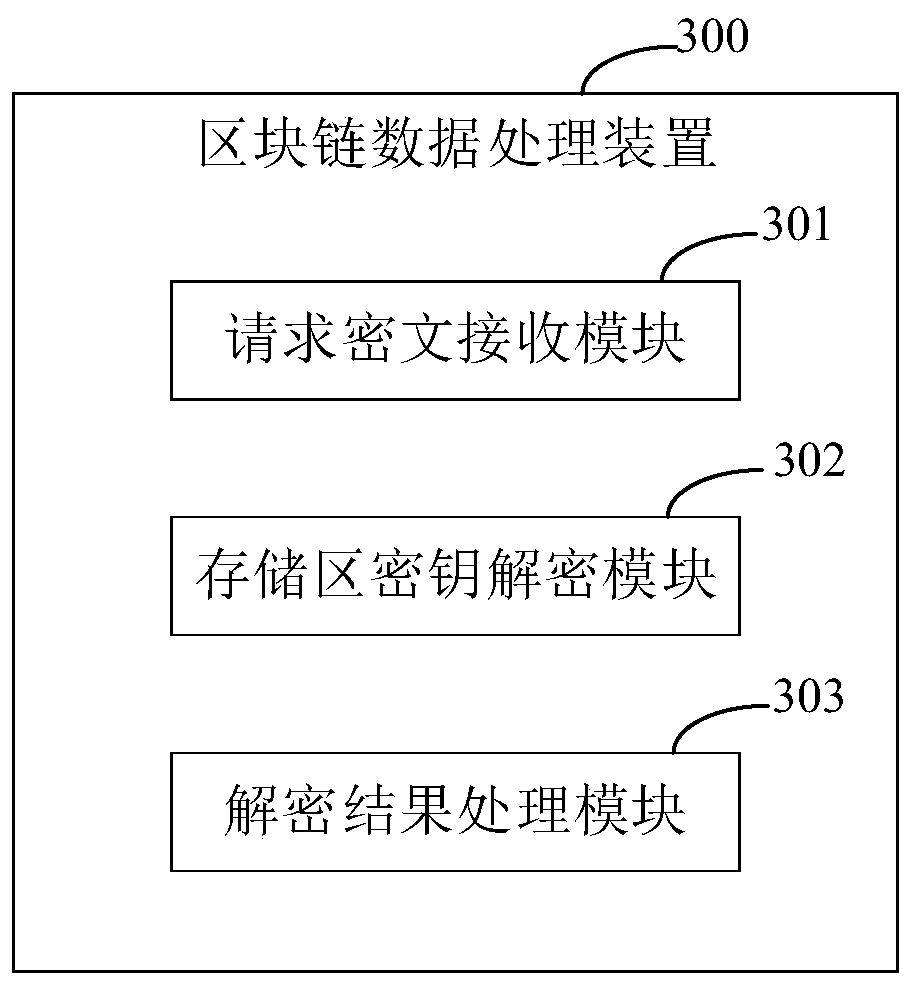

The invention discloses a blockchain data processing method and device, electronic equipment and a medium, and relates to a blockchain technology. The method is executed by a transaction processing node in a trusted blockchain network, and specifically comprises the following steps: receiving a ciphertext of a transaction processing request from an initiator; wherein the ciphertext of the transaction processing request is obtained by encrypting the transaction processing request by adopting a first blockchain key; decrypting the ciphertext of the transaction processing request by adopting a second blockchain key of a local key storage area; and processing the decryption result to obtain result data. According to the embodiment of the invention, the centralization of decryption in the dataaccess process can be reduced, and meanwhile, the data security is improved.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com