Highly conductive solid electrolyte prepared by coprecipitation method

A technology of solid electrolyte and co-precipitation method, which is applied in the field of high-conductivity solid electrolyte, can solve problems such as environmental pollution, many chemical reagents, and large safety hazards, and achieve easy control and simple operation, excellent electrochemical stability, and small environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

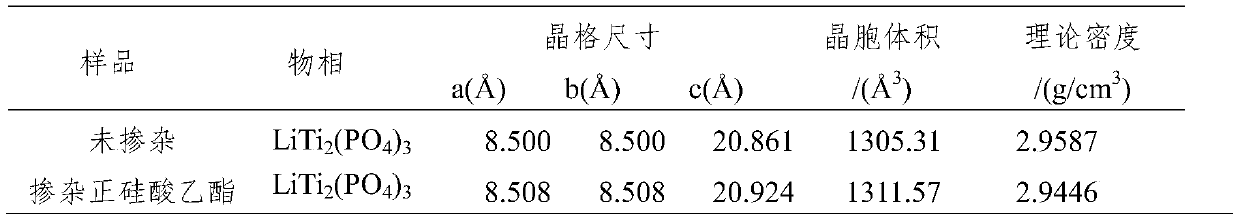

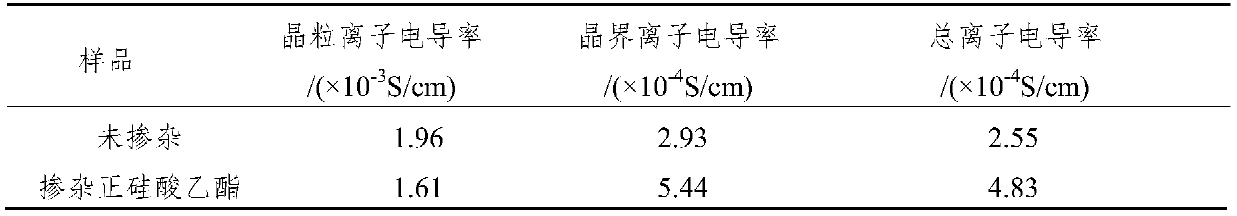

Embodiment 1

[0032] A method for preparing a high-conductivity solid electrolyte by coprecipitation, comprising the steps of:

[0033] Step 1: Weigh the dopant, aluminum nitrate, tetrabutyl titanate, and ammonium dihydrogen phosphate, put the raw materials into the reaction container in turn, and stir continuously at room temperature until a light yellow slurry is formed;

[0034] Step 2: Slowly add ammonia water to the light yellow slurry to dissolve, and adjust the pH to 12;

[0035] Step 3: Heat the reaction vessel to 88°C, and magnetically stir in a constant temperature water bath for 0.8h to form a uniform and stable layered white precipitate;

[0036] Step 4: transfer the white precipitate to a blast drying oven, and heat at 145°C for 9.7 hours to obtain a white precursor;

[0037] Step 5: Heat the white precursor to the pre-calcination temperature (650°C) at a heating rate of 3°C / min in the air, and keep it warm for 8 hours to obtain a white powder;

[0038] Step 6: Use a planetar...

Embodiment 2

[0045] A method for preparing a high-conductivity solid electrolyte by coprecipitation, comprising the steps of:

[0046] Step 1: Weigh the dopant, aluminum nitrate, tetrabutyl titanate, and ammonium dihydrogen phosphate, put the raw materials into the reaction container in turn, and stir continuously at room temperature until a light yellow slurry is formed;

[0047] Step 2: Slowly add ammonia water to the light yellow slurry to dissolve, and adjust the pH to 12;

[0048] Step 3: Heat the reaction vessel to 90°C, and magnetically stir in a constant temperature water bath for 1.1 hours to form a uniform and stable layered white precipitate;

[0049] Step 4: transfer the white precipitate into a blast drying oven, and heat at 155°C for 10.3 hours to obtain a white precursor;

[0050] Step 5: Heat the white precursor to the pre-calcination temperature (750°C) at a heating rate of 5°C / min in the air, and keep it warm for 12 hours to obtain a white powder;

[0051] Step 6: Use a p...

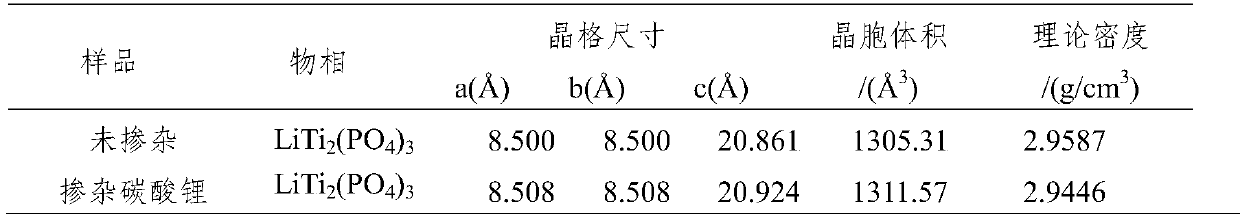

Embodiment 3

[0058] A method for preparing a high-conductivity solid electrolyte by coprecipitation, comprising the steps of:

[0059] Step 1: Weigh the dopant, aluminum nitrate, tetrabutyl titanate, and ammonium dihydrogen phosphate, put the raw materials into the reaction container in turn, and stir continuously at room temperature until a light yellow slurry is formed;

[0060] Step 2: Slowly add ammonia water to the light yellow slurry to dissolve, and adjust the pH to 7;

[0061] Step 3: Heat the reaction vessel to 88-90°C, and magnetically stir in a constant temperature water bath for 1 hour to form a uniform and stable layered white precipitate;

[0062] Step 4: transfer the white precipitate to a blast drying oven, and heat at 150°C for 10 hours to obtain a white precursor;

[0063] Step 5: Heat the white precursor to the pre-calcination temperature (700°C) at a heating rate of 5°C / min in the air, and keep it warm for 10 hours to obtain a white powder;

[0064] Step 6: Use a plan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com