Preparation method of all-solid-state lithium battery with high specific energy

A production method and all-solid-state technology, which is applied in the field of lithium-ion batteries, can solve problems such as large interface impedance, large specific capacity loss of pole pieces, and reduction of active material content of pole pieces, so as to achieve the effect of reducing interface resistance and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

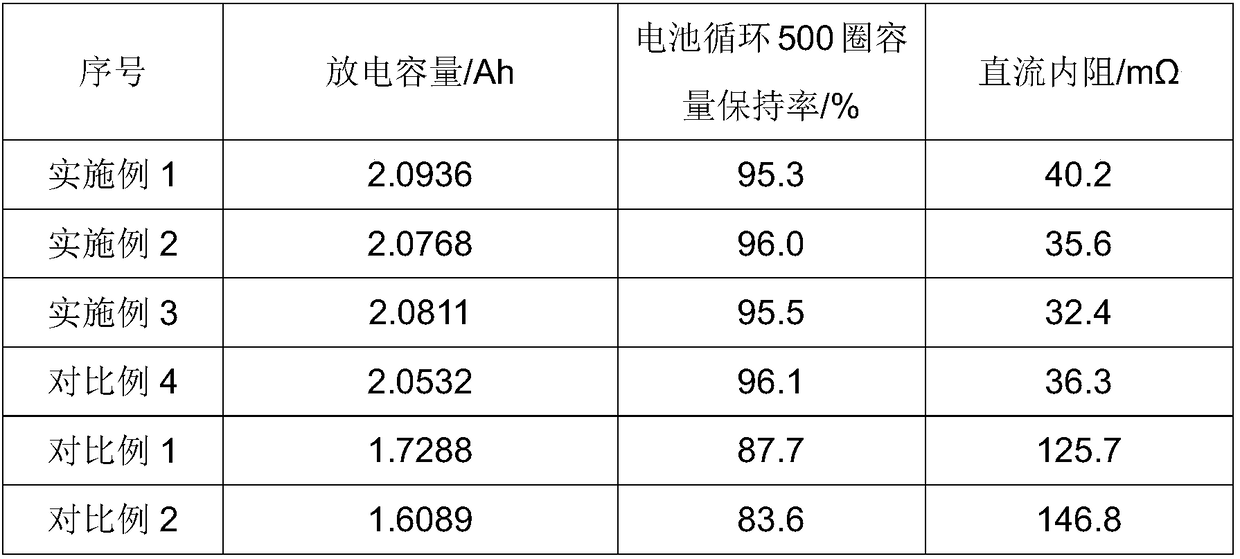

Embodiment 1

[0036] (1) Positive electrode pulping is according to the following mass ratio: nickel cobalt lithium manganese oxide (NCM523) positive electrode material 97.9%, Super P Li conductive agent 1%, PVDF (HSV-900) binder 1%; ammonium bicarbonate pore-forming agent 0.1%, through a double planetary mixer, using NMP as a solvent to prepare positive electrode slurry with a solid content of 65%. Coating the positive electrode slurry on the aluminum foil current collector, heat treatment at 140°C for 60s, and then roll pressing to obtain the positive electrode sheet;

[0037] (2) Negative electrode pulping is according to the following mass ratio: 98.4% of artificial graphite G9, 0.5% of Super P Li conductive agent, 1% of CMC (Daicel) binder, 0.1% of ammonium bicarbonate pore-forming agent, through a double planetary mixer , using deionized water as a solvent to prepare negative electrode slurry with a solid content of 45%. Coating the negative electrode slurry on the copper foil curren...

Embodiment 2

[0041] (1) Positive electrode pulping is in accordance with the following mass ratio: nickel cobalt lithium aluminate (NCA) positive electrode material 89%, acetylene black conductive agent 5%, PVA binder 3%; ammonium carbonate pore-forming agent 3%, through a double planetary mixer , using NMP as a solvent to prepare positive electrode slurry with a solid content of 80%. Coating the positive electrode slurry on the aluminum foil current collector, heat treatment at 80°C for 600s, and then roll pressing to obtain the positive electrode sheet;

[0042] (2) Negative electrode pulping is according to the following mass ratio: silicon carbon accounts for 91%, carbon nanotube conductive agent 3%, SBR binding agent 3%, ammonium carbonate pore-forming agent 3%, pass through double planetary mixer, take deionized water as The solvent was prepared into negative electrode slurry with a solid content of 60%. Coating the negative electrode slurry on the copper foil current collector, hea...

Embodiment 3

[0046] (1) Positive electrode pulping is according to the following mass ratio: 95% of lithium nickel manganese oxide positive electrode material, 2% of graphene conductive agent, 1.5% of PTFE binder; The solvent was prepared into positive electrode slurry with a solid content of 30%. Coating the positive electrode slurry on the aluminum foil current collector, heat treatment at 140°C for 60s, and then roll pressing to obtain the positive electrode sheet;

[0047] (2) Negative electrode pulping is according to the following mass ratio: hard carbon accounts for 93%, Super P Li conductive agent 2%, CMC (Daicel) binder 3.5%, ammonium acetate pore-forming agent 1.5%, pass through double planetary mixer, with Deionized water was used as a solvent to prepare negative electrode slurry with a solid content of 30%. Coating the negative electrode slurry on the copper foil current collector, heat treatment at 100°C for 350s, and then roll pressing to obtain the negative electrode sheet;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com