Device and method for improving laser connection strength of metal part and plastic part

A technology for connection strength and metal parts, which is applied in the field of devices for improving the laser connection strength of metal parts and plastic parts, can solve the problems of low quality joints between metal parts and plastic parts, increase the probability of chemical bonding formation, and promote mechanical fitting , The effect of scanning speed optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method for improving the laser connection strength of a metal part and a plastic part. The metal part is 304 stainless steel; the plastic part is carbon fiber reinforced nylon (CF-PA6).

[0053] (1) Pre-treat the surface of the metal parts; place the 304 stainless steel substrate to be connected in a mixed solution composed of 80% distilled water + 15% nitric acid + 5% hydrofluoric acid to clean for 30 seconds to remove the surface oxide film and then blow it with a hair dryer Dry, put the CF-PA6 board to be connected in an ultrasonic cleaning container, wash it with a mixed solution of 50% acetone + 50% alcohol for 180s, and then put the cleaned CF-PA6 board in an 80°C drying oven for 24 hours;

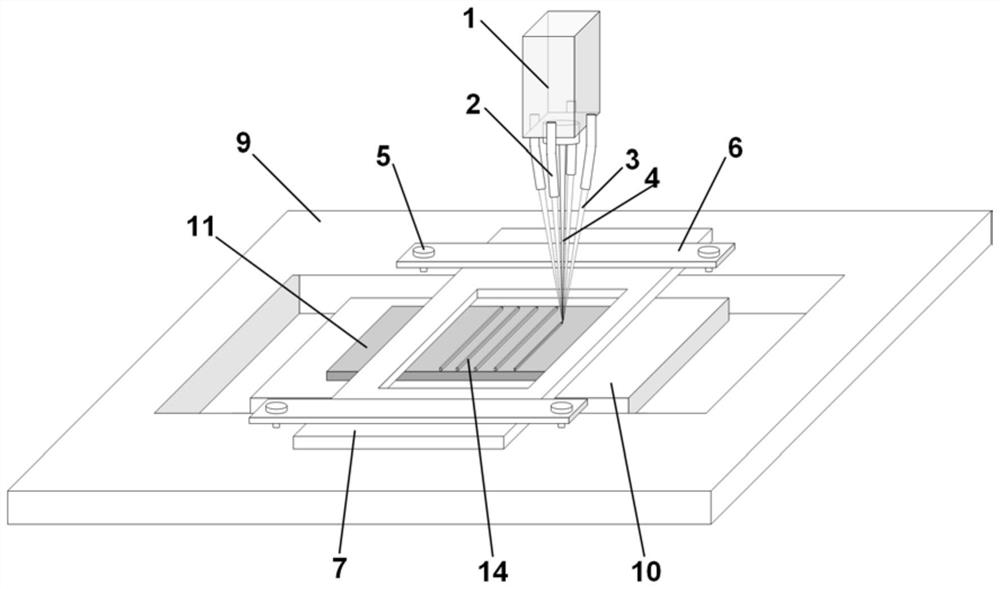

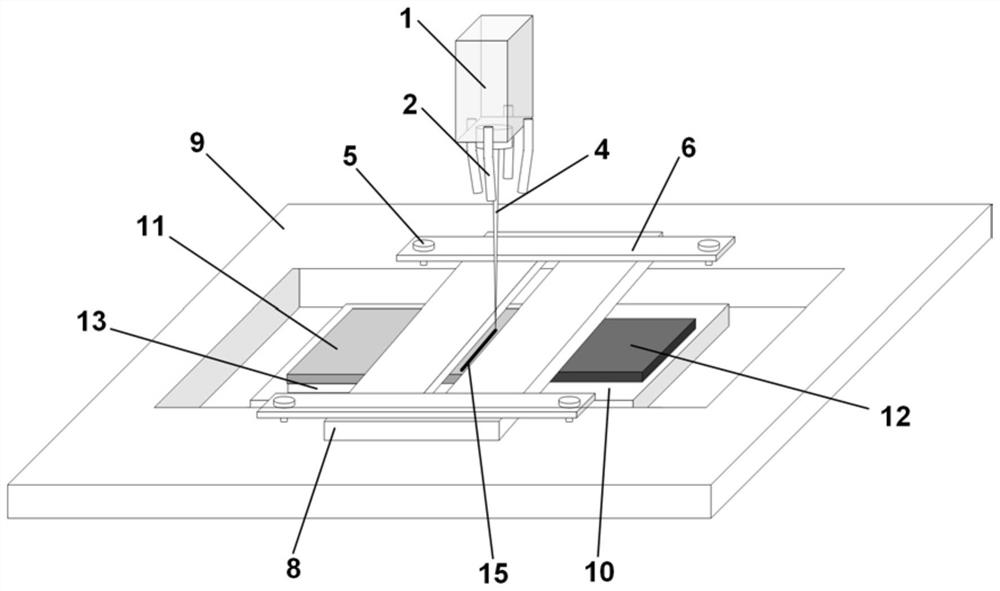

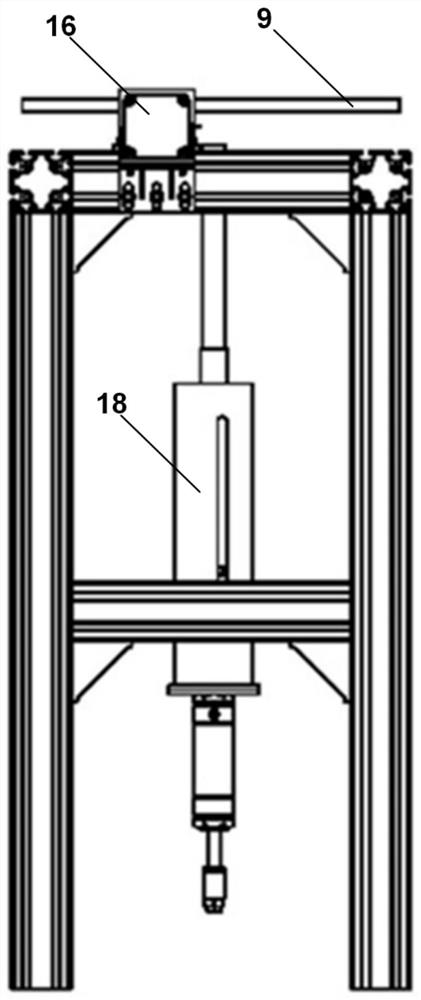

[0054] (2) Utilize the 304 stainless steel substrate 11 processed above figure 1 As shown in the clamping method, use the motor to move the mobile platform 9 to the center of the cylinder 18 and align it with the center line of the mobile platform 9, center the laser claddin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com