Novel method for reinforcing concrete pier by implanting prestressed high-performance rib material into surface layer

A concrete and high-performance technology, which is applied in the direction of bridges, bridge parts, bridge maintenance, etc., can solve the problems of destroying the inherent bearing capacity of bridge piers and foundations, complex processes, and stress lag of reinforcing layers, so as to reduce the phenomenon of cascade damage and improve the compensation Strong effect, avoid force lag effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

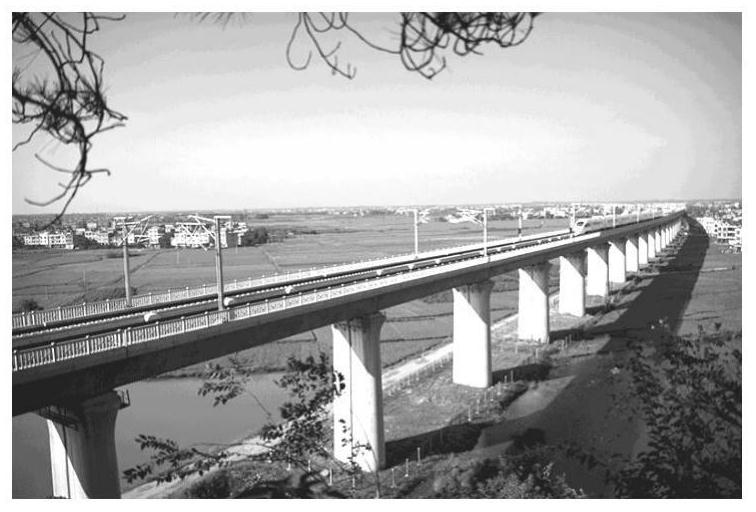

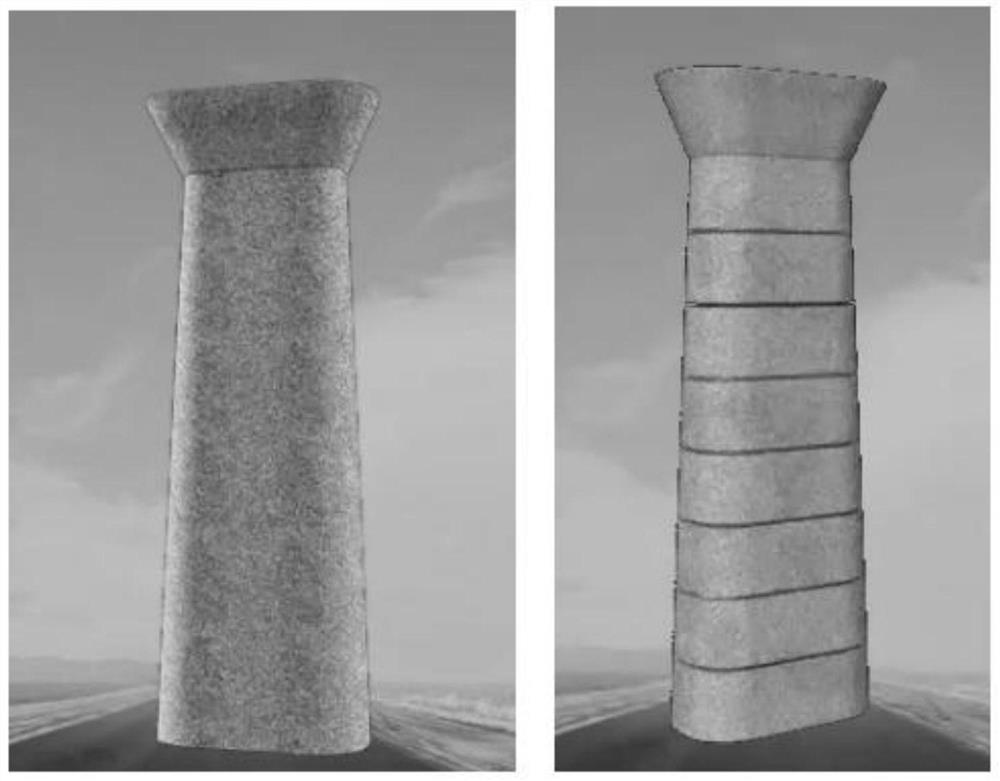

[0049] The bridge pier can be in the form of a column, which is a vertical load-bearing structure. This example introduces the analysis of the bearing capacity of a concrete circular section column pier implanted with prestressed spiral steel wire reinforcement as an example.

[0050] In the concrete column reinforcement project, a new method of embedding prestressed high-performance bars to reinforce the concrete column is to open a groove in the concrete protective layer on the surface of the concrete column that needs to be reinforced, and then implant it into the concrete groove High-performance reinforcement, and then apply prestress to the reinforcement through the tension jack. After the prestress is applied in place, the end of the reinforcement is butt-welded, and finally the channel is sealed with gel material, and the concrete surface is repaired to implement the concrete column. Implanted prestressed reinforcement. This method can increase the bearing capacity of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com