Patents

Literature

679results about How to "Eliminate shock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

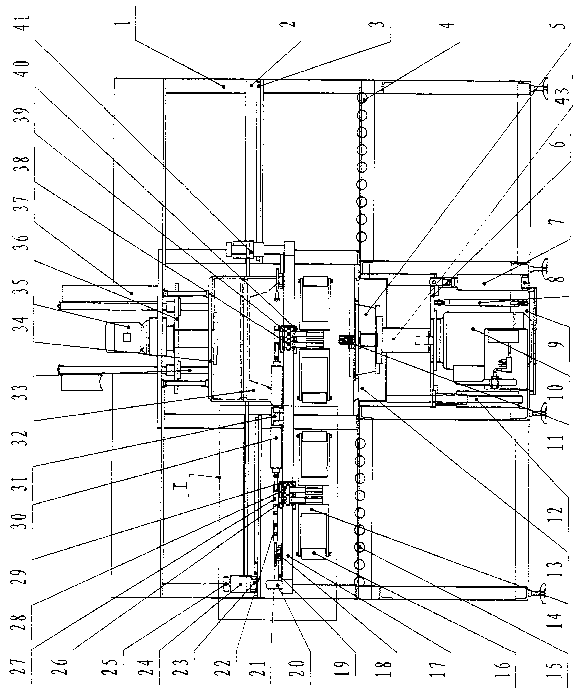

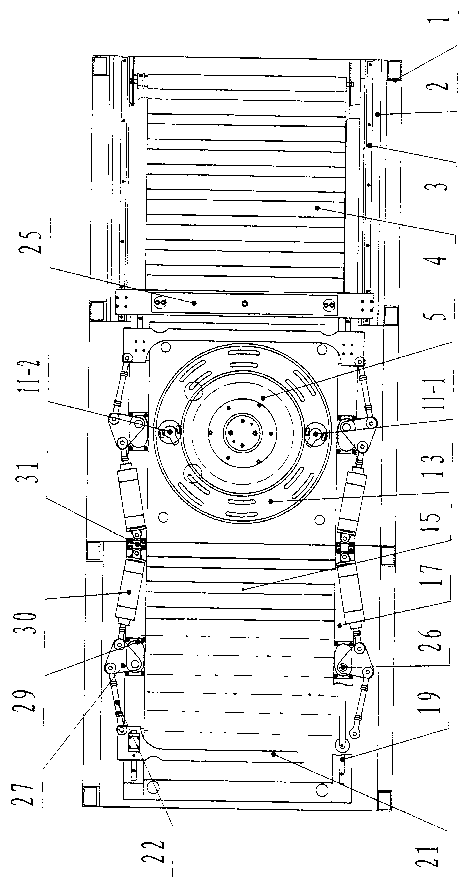

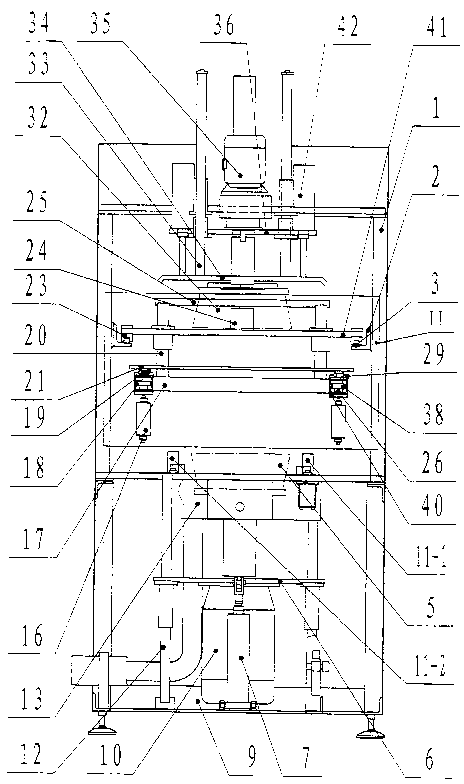

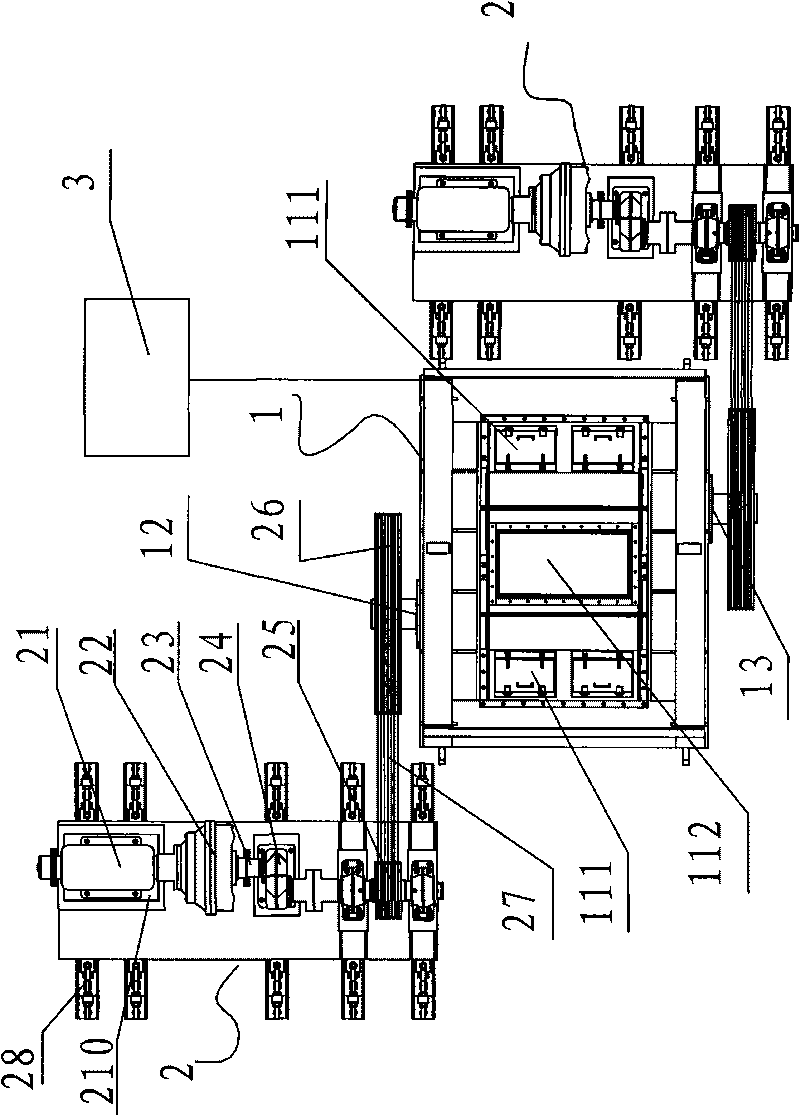

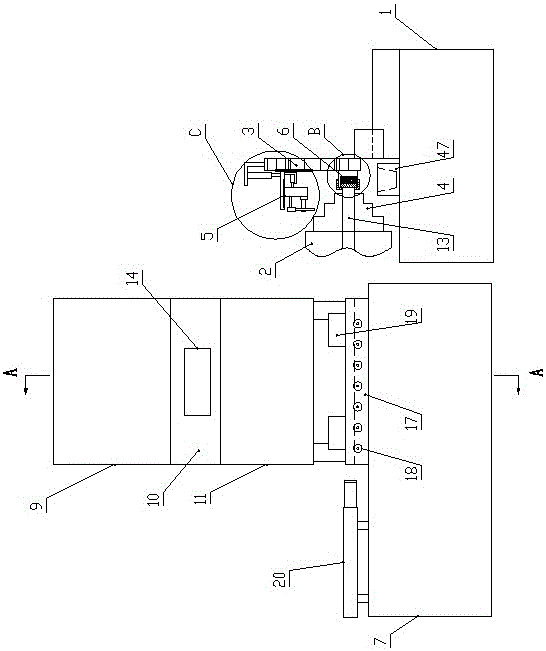

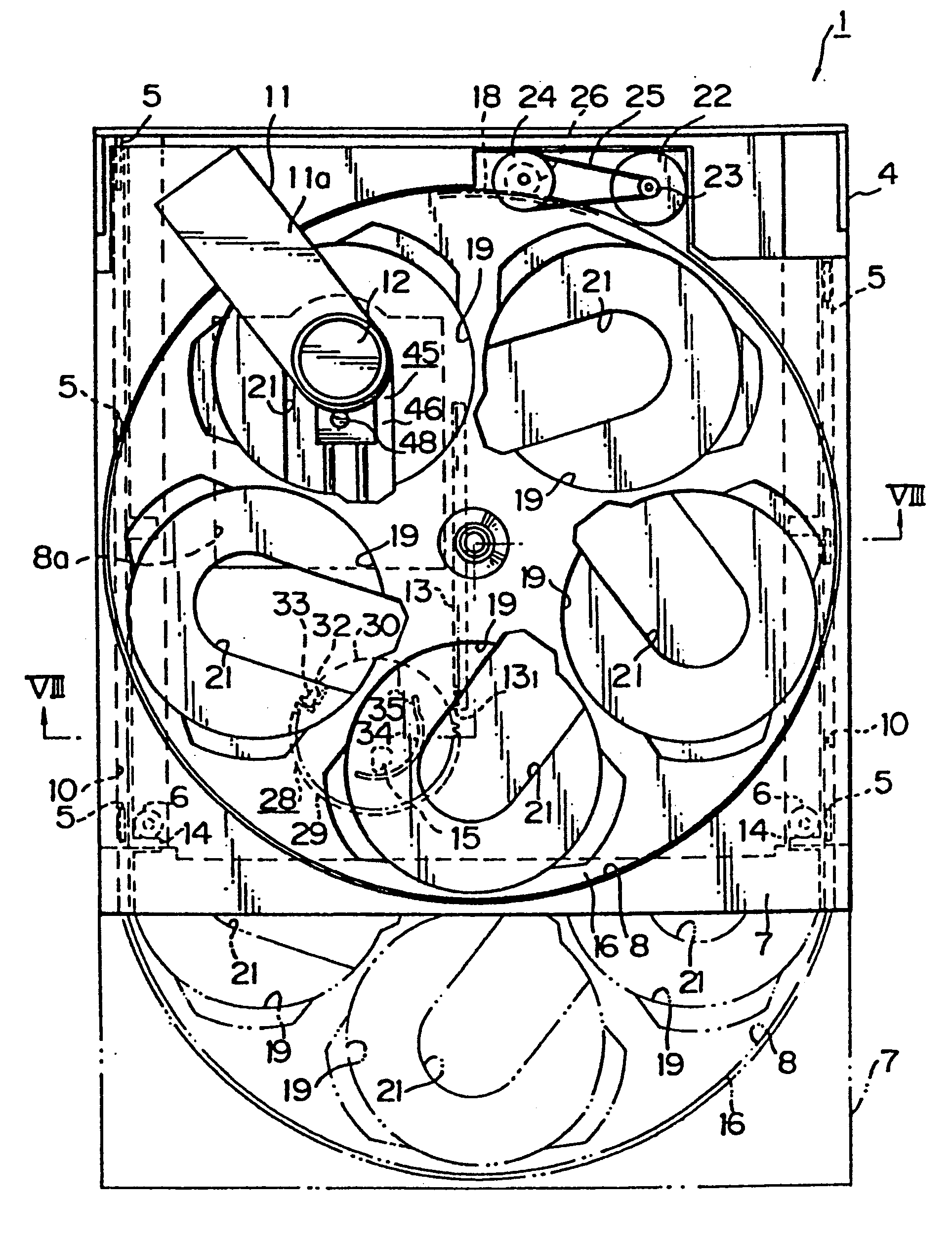

Full-automatic wheel hub deburring machine

InactiveCN102848282AImprove processing qualitySolve the problem of declining production efficiencyEdge grinding machinesCouplingElectric machinery

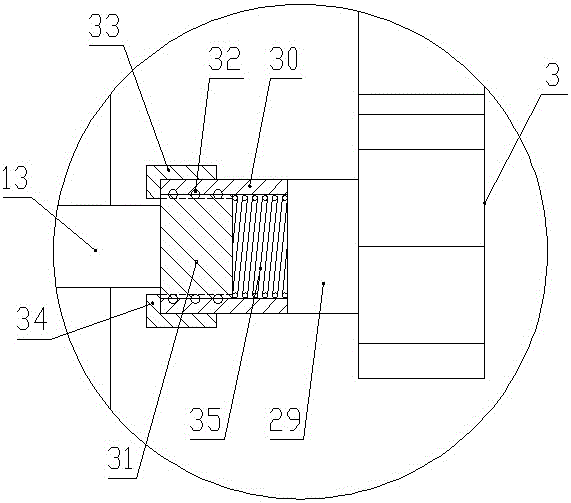

The invention belongs to technical equipment for machine manufacturing, and particularly relates to a full-automatic wheel hub deburring machine. The lower end of a lower brush feed rod (12) is vertically mounted on a bottom plate of a shell (1), and the upper end is fixed on a machining platform (13); upper and lower brush motor lifting plates (6) and a lower brush motor support plate (9) are respectively hinged on the upper end and the lower end of a support plate connection bar (8); a lower brush (5) is connected with the output shaft of a lower brush motor (10) through a coupling (43); a left locking device (11-1) and a right locking device (11-2) of a wheel hub lock (11) are respectively mounted at the left side and the right side of the machining platform (13); an upper brush motor support plate (36) provided with an upper brush motor (35) is movably sleeved on an upper brush feed rod (33) through a feed rod sleeve; an upper brush (32) is arranged in a dust shield (34) and is connected with the output shaft of the upper brush motor (35) through the coupling (43); and the shell (1) is provided a feeding path (15) and a discharging path (4) which are arranged at the left side and the right side of the machining platform (13). The full-automatic wheel hub deburring machine realizes the automatic unmanned production and improves the production efficiency.

Owner:FUXIN TONGSHENG HYDRAULIC MACHINERY MFGCO

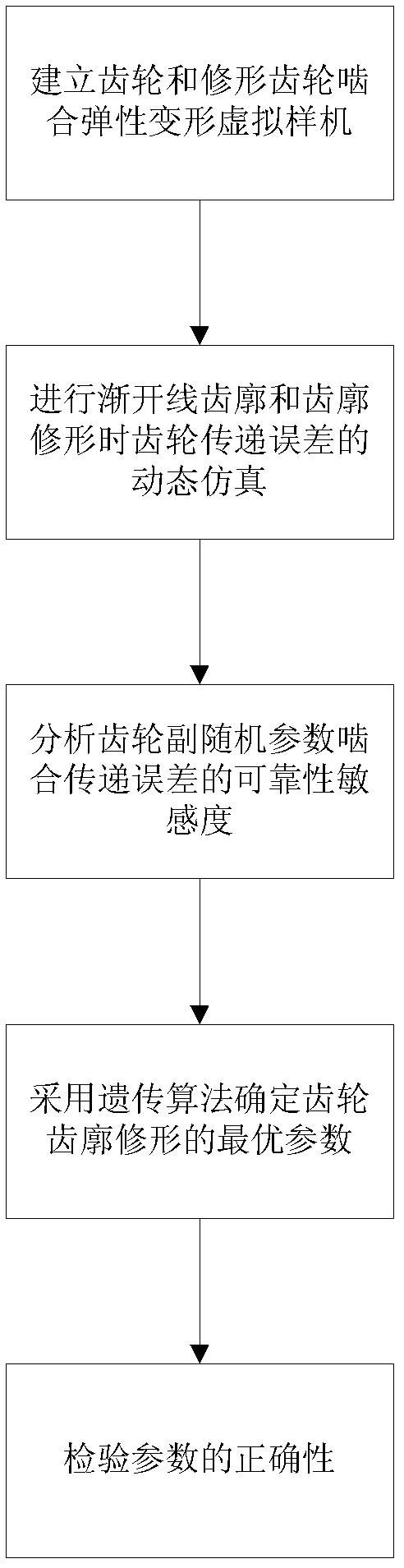

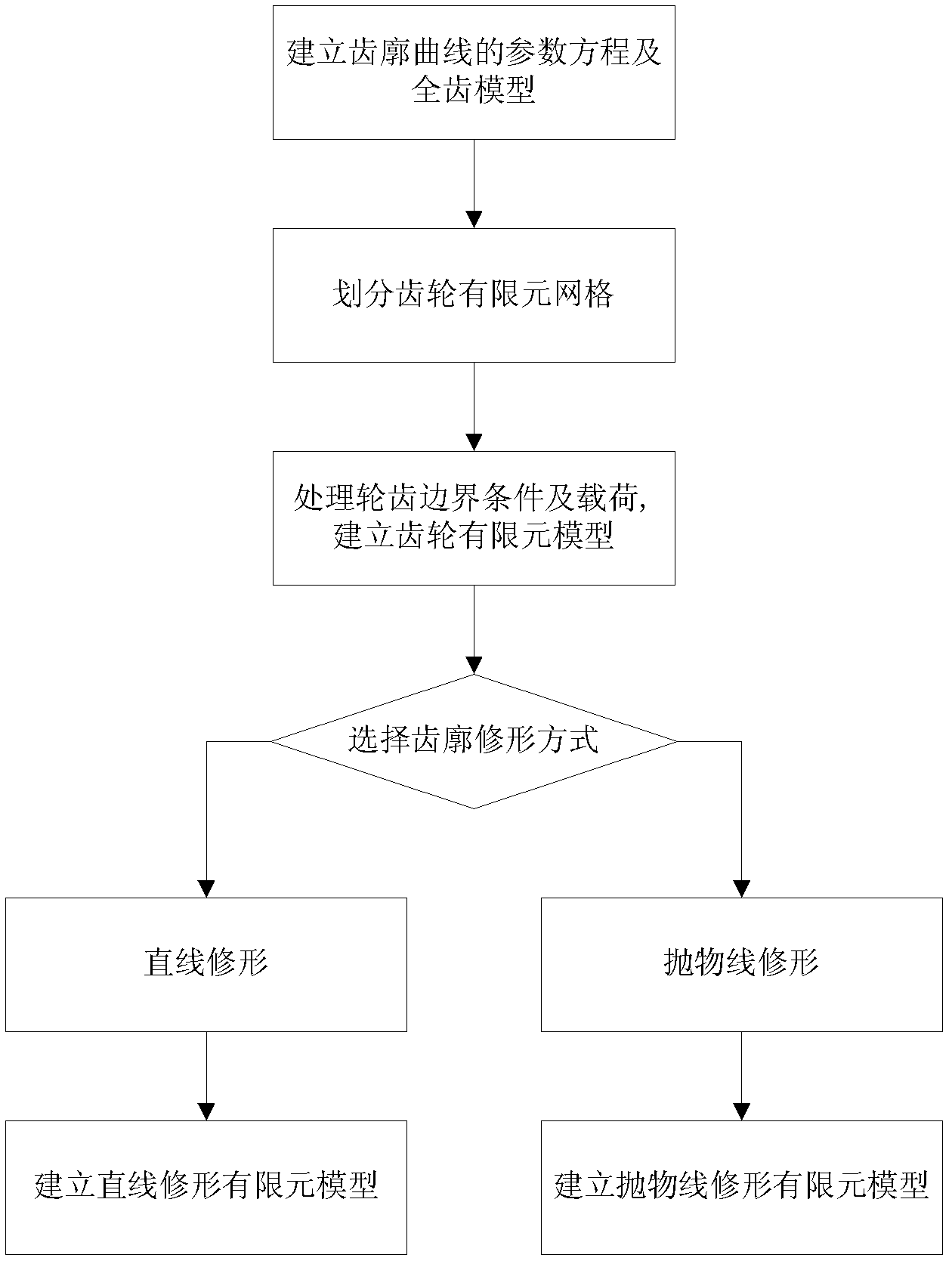

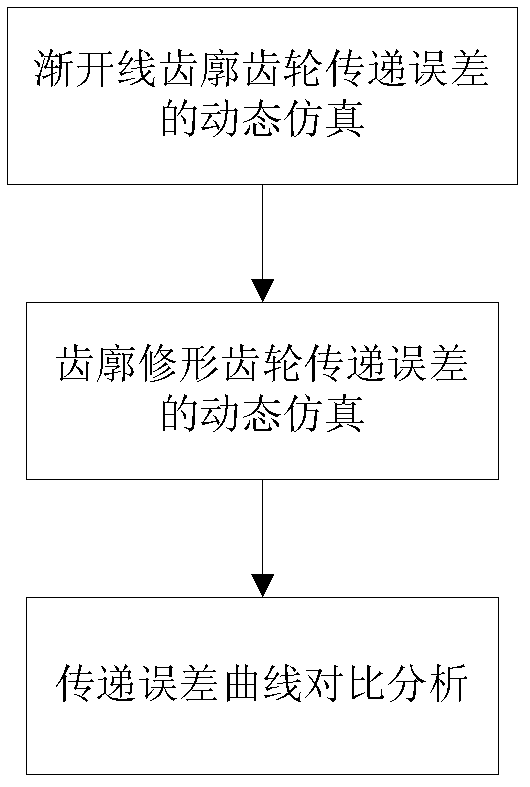

Gear profile modification method based on vibration reliability and genetic algorithm

InactiveCN102314534AImprove transmission error reliabilityEliminate shockSpecial data processing applicationsGear systemGenetic algorithm

The invention discloses a gear profile modification method based on vibration reliability and a genetic algorithm, belonging to the technical field of reliability designs. The gear profile modification method can not only reduce meshing impact due to elastic deformation and manufacturing errors, but also reduce the meshing excitation of a gear so that a gear system has smooth transmission, the vibration and the noises are reduced, and the reliability and service life of the gear system can be improved. The gear profile modification method comprises the following steps of: (1), establishing an elastic modification virtual prototype for meshing between a gear and a modifying gear; (2) carrying out dynamic simulation on gear transmission errors in the process of an involute profile and the profile modification; (3) analyzing the reliability sensitivity of the transmission errors at the time of gear pair random parameter meshing; (4) determining optimal parameters of the gear profile modification by utilizing the genetic algorithm; and (5) verifying the correctness of the parameters.

Owner:NORTHEASTERN UNIV LIAONING +1

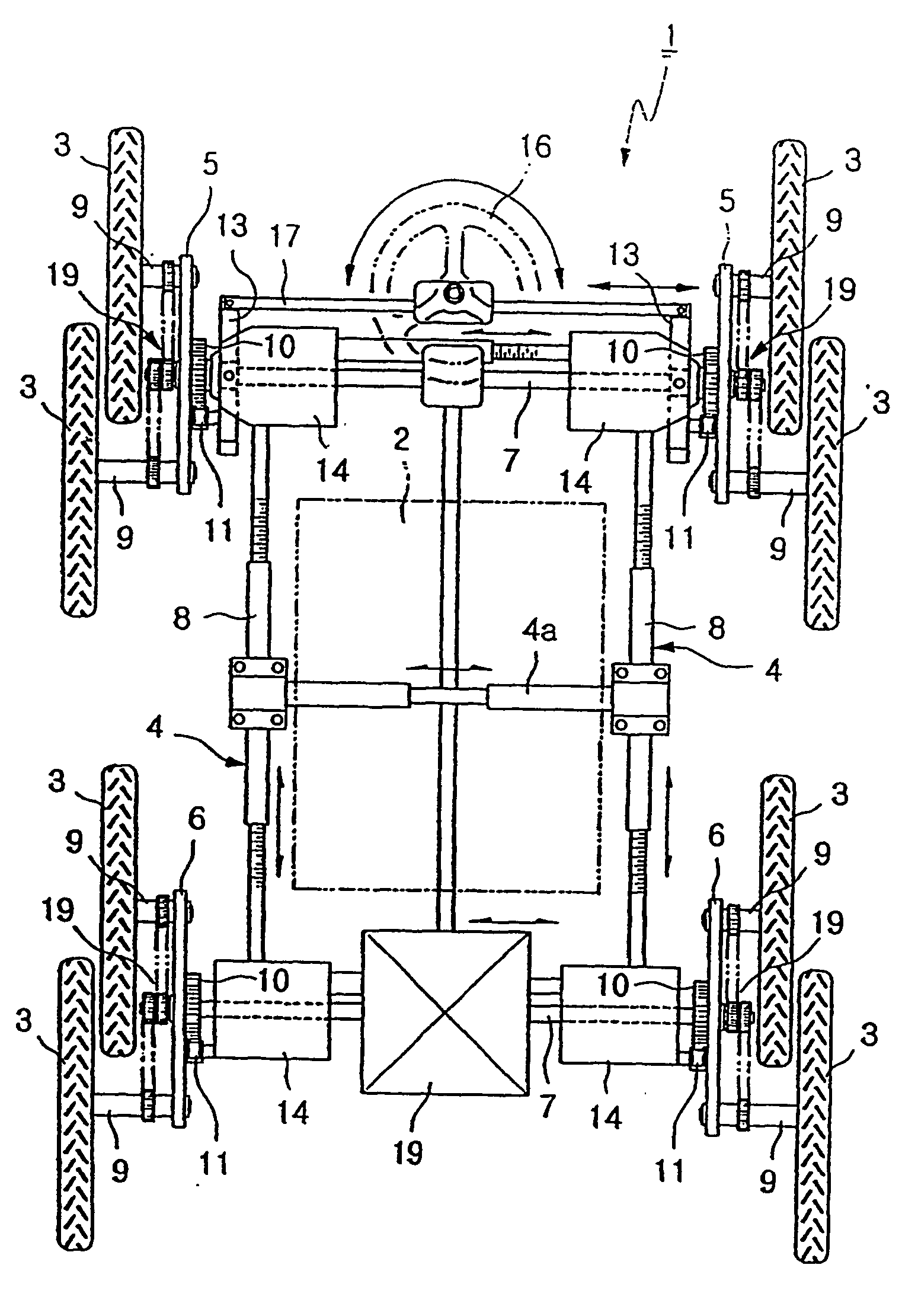

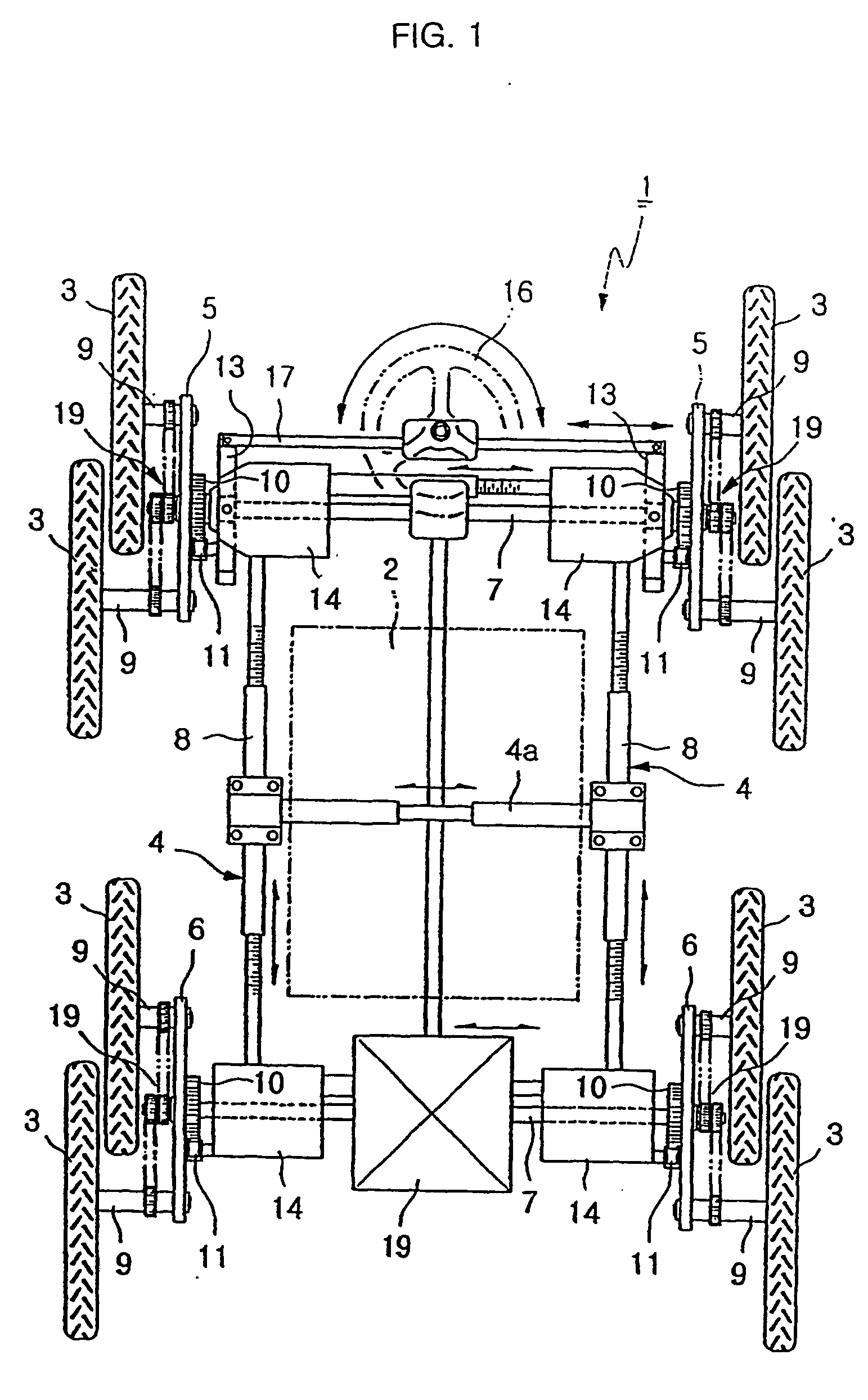

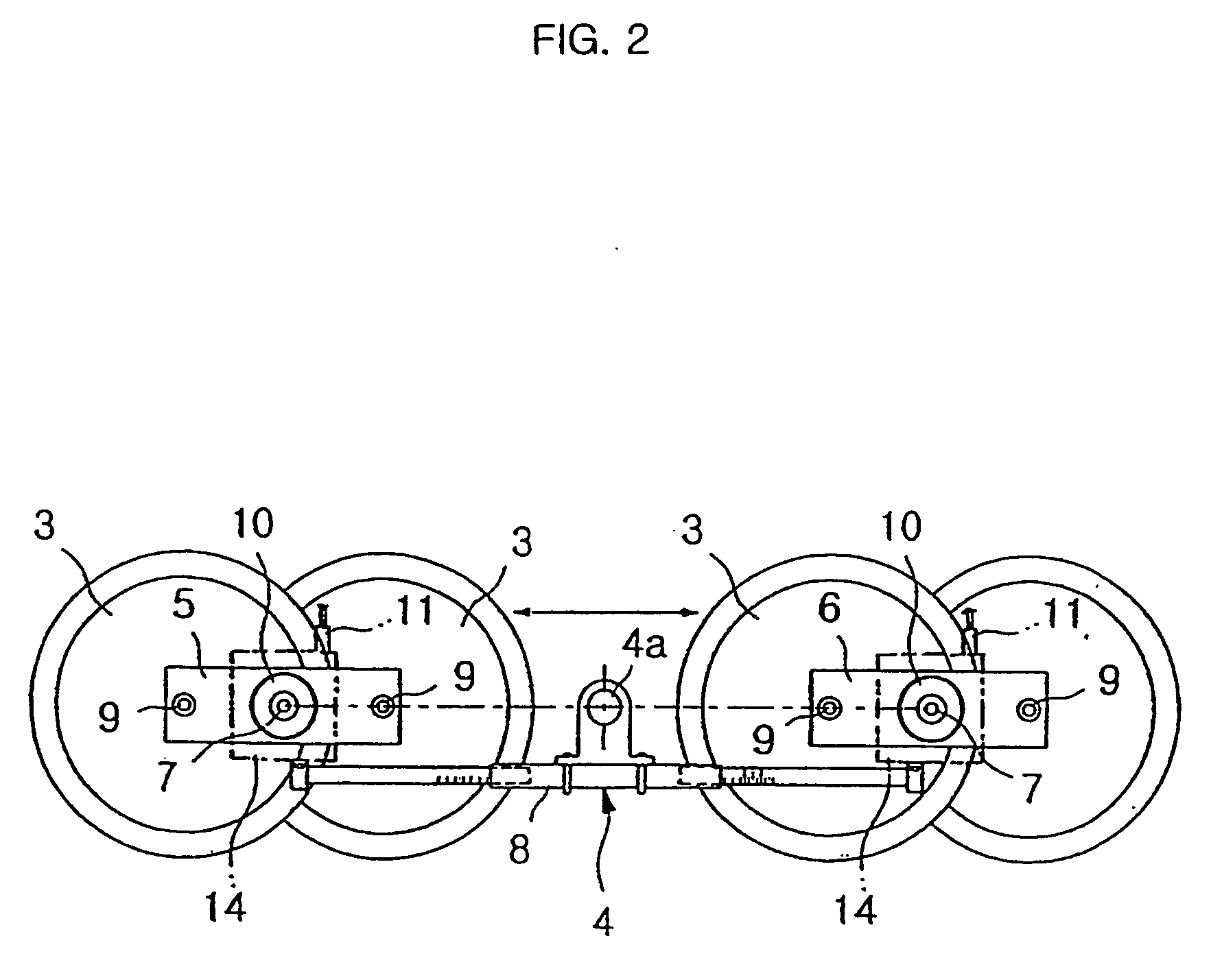

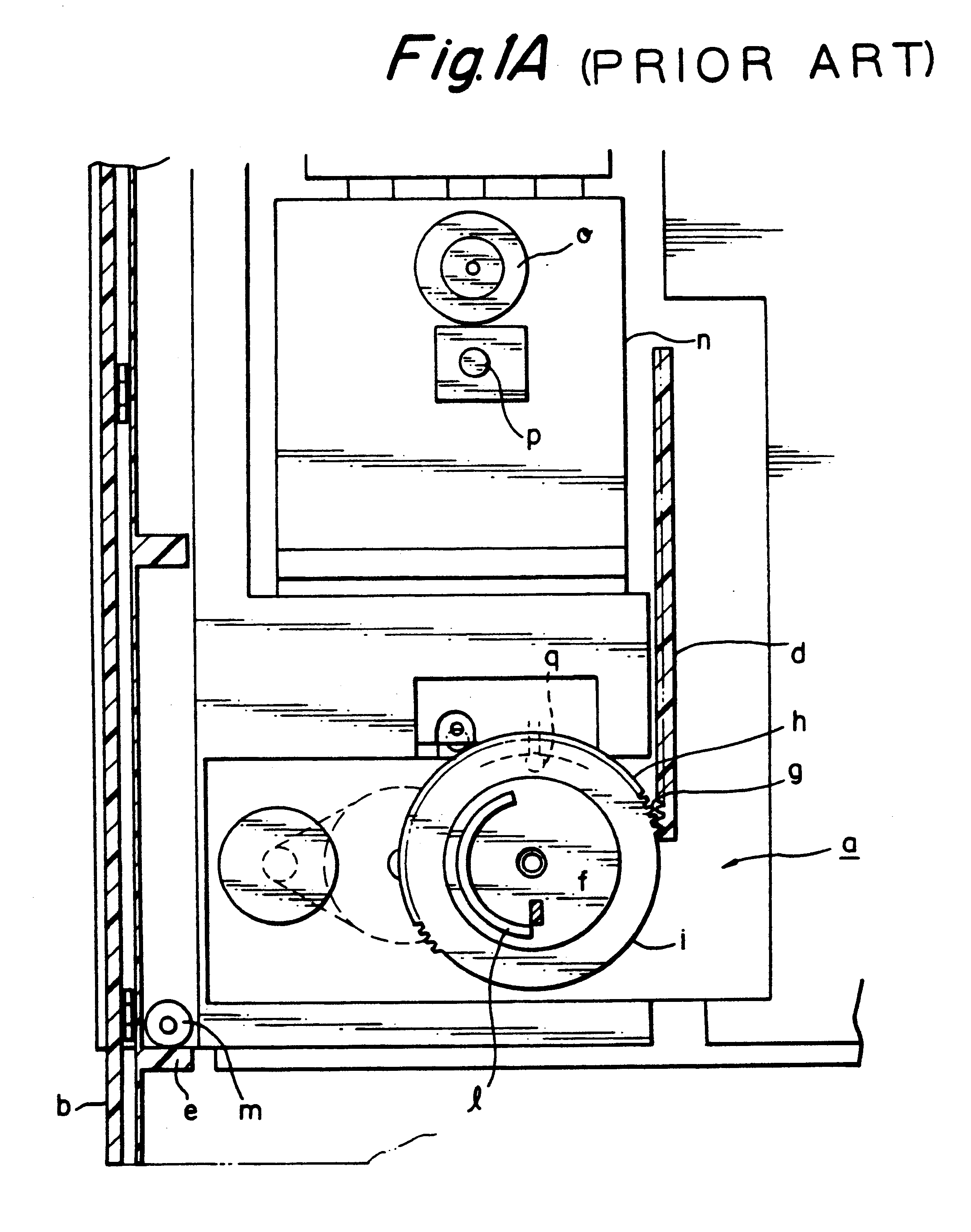

Running apparatus for stairs, ramps and off roads

InactiveUS20060145433A1Solve the real problemMinimize shockCarriage/perambulator accessoriesWheelchairs/patient conveyanceSteering wheelWheelchair

This running apparatus(1) has 4 wheels(3) operating seesaw type are axle installed on the first and second lever(4.5.6). This running apparatus can travel with its 8 wheels or sometimes 4 wheels touching grounds at any circumstances. This is very suitable for the wheel chair or truck carrying special cargo running on the stairs, ramps, sands, marshy muds, rocks, and so on. And comfortability and safety of this vehicle can be maximized by the seesaw movement of the first and second levers(4.5,6,) which diminish the shock according to the ground. When converting the second levers(5) of the front wheels which can axis operates according to the ground, with rack(11) and pinion(10) make one of front two wheels contact grounds and easily convert the steering wheel(16), and also possible to change the length and width of the vehicle cope with location and speed, and can travel with all good conditions

Owner:KIM SEO RIM

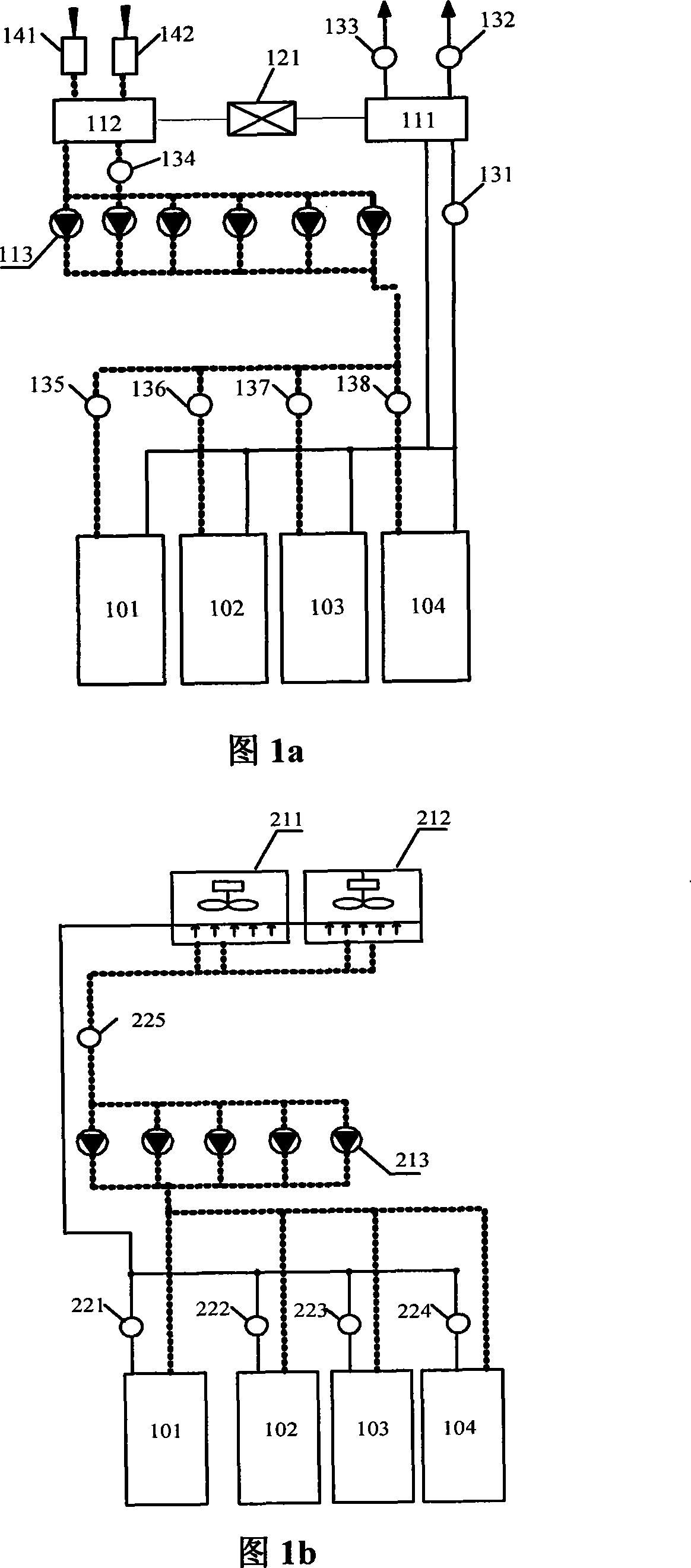

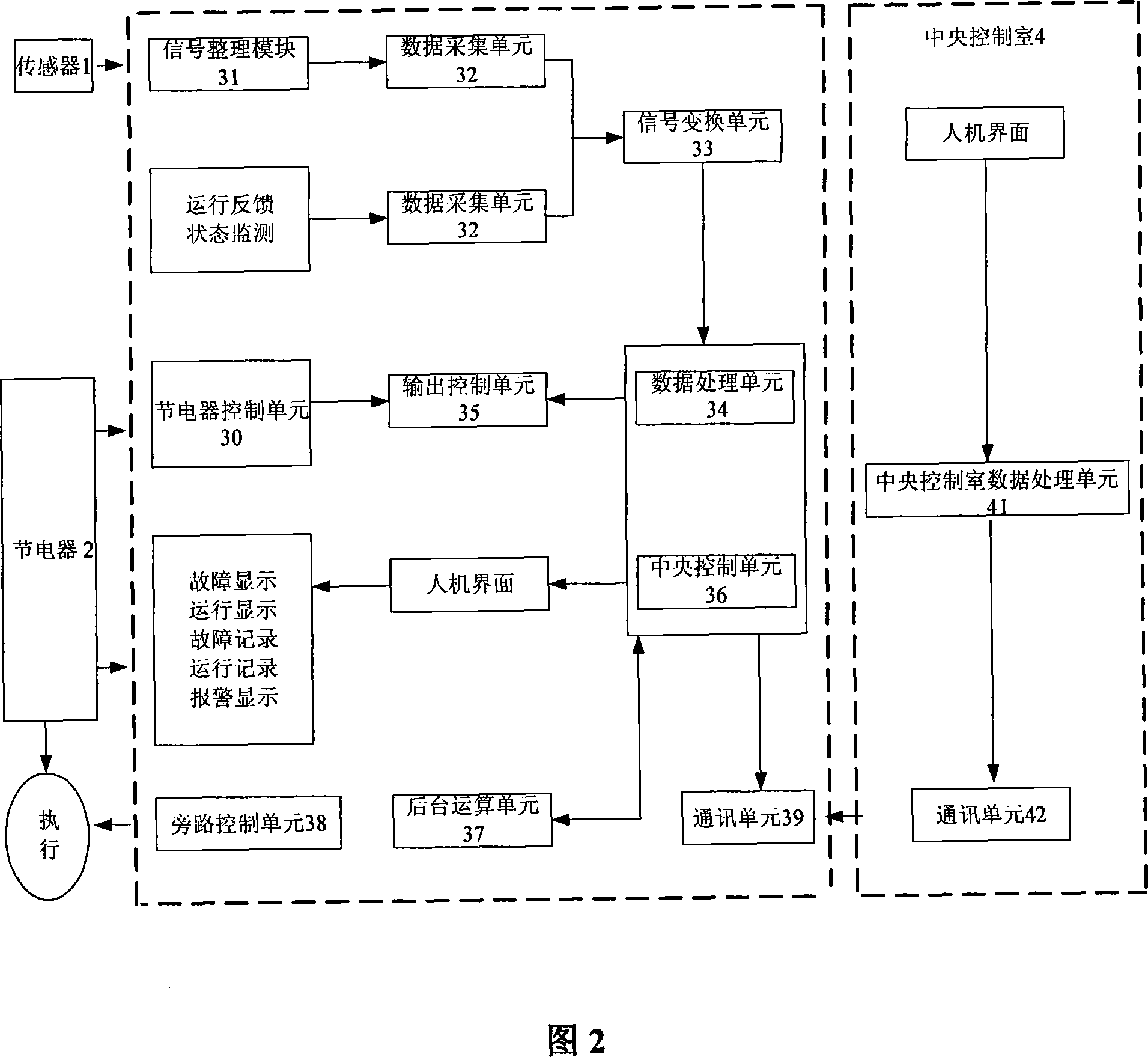

Electricity economizer centralized management method and system of central air-conditioning

InactiveCN101140096AEliminate shockReduce labor intensitySpace heating and ventilation safety systemsLighting and heating apparatusClosed loopEngineering

The invention relates to a method and a system for centralized management of an electric saver of a central air-conditioner; a water flow pressure difference sensor between a water supply main pipe and a return water main pipe of a central air-conditioner freezing water system, a flow meter for a two-way freezing water return pipe, a water temperature sensor for a back-way freezing water return pipe of a freezing water pump, the water temperature sensor for a freezing water outlet pipe of an air conditioning mainframe, the water temperature sensor for a cooling water outlet pipe of the air conditioning mainframe and the water temperature sensor for a cooling water inlet main pipe of the air conditioning mainframe respectively collect pressure difference, flow speed and water temperature of the corresponding position; collection values are transferred into a fuzzy controller, the fuzzy controller gains dynamic flow and speed parameters through the control of a fuzzy prediction model and an optimal algorithm model, the dynamic flow and speed parameters are transferred into each electric saver, and the speed and the flow of corresponding fans and water pumps are controlled through the frequency change of the electric saver. The invention has the advantages of the high temperature-adjusting precision, the good dynamic performance, the small mechanical loss, the fully-automatic remote monitoring, the closed-loop control of temperature, the soft starting and stopping of a motor and the optimum system electricity-saving rate.

Owner:SUZHOU IRON TECH

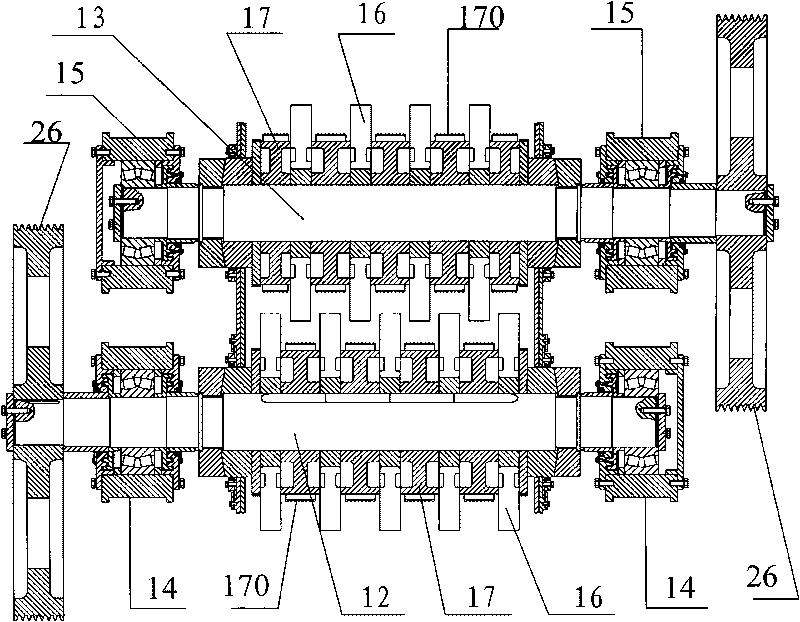

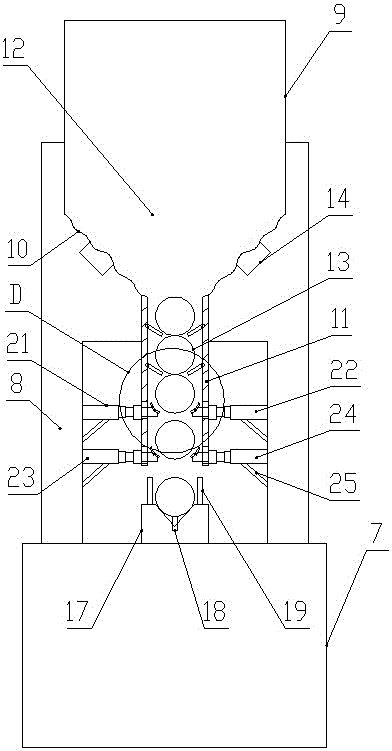

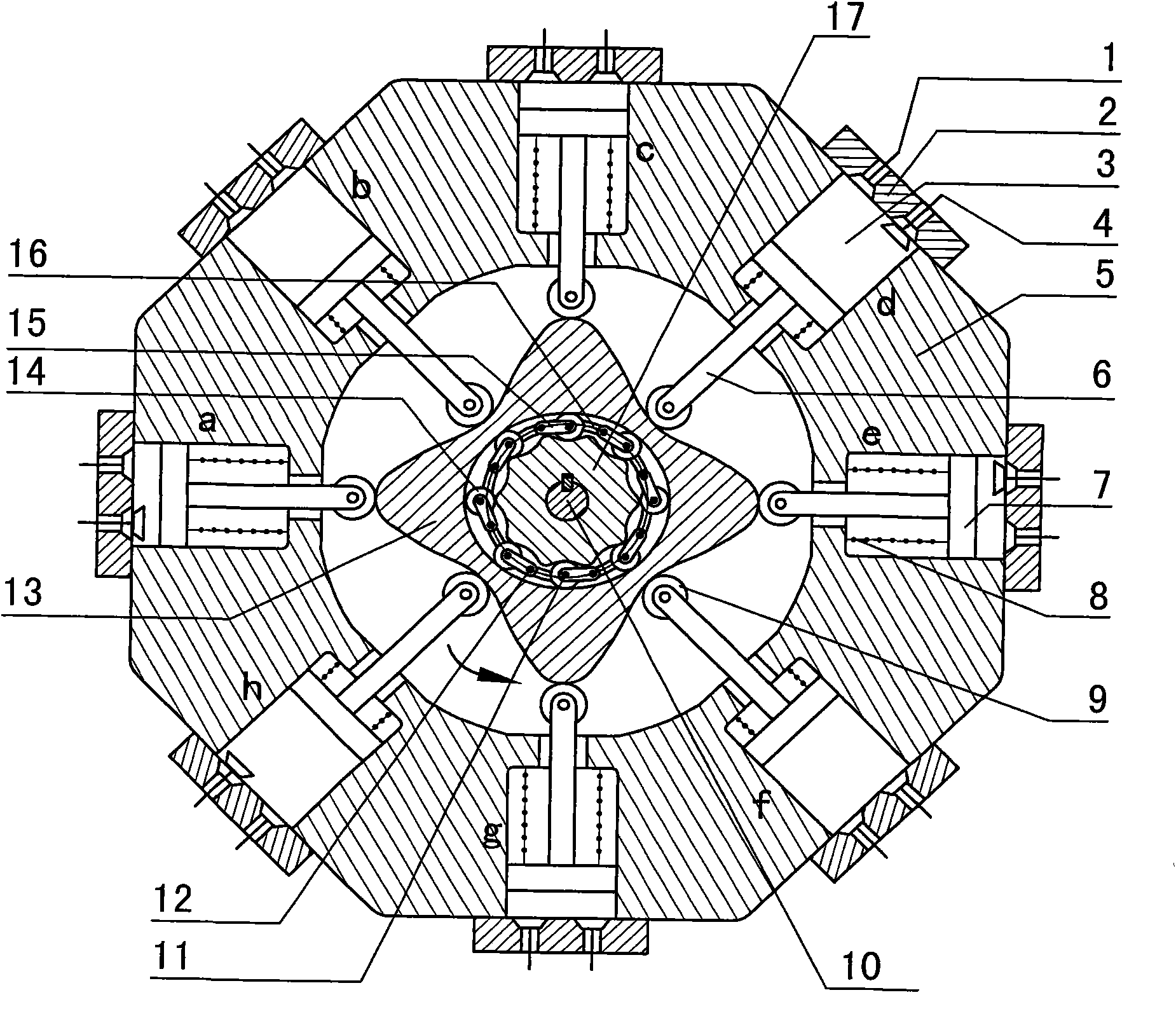

Wheel tooth type crusher

InactiveCN101745442AEliminate overload shock and vibrationGood overload protection performanceGrain treatmentsCrusherMechanical engineering

The invention discloses a wheel tooth type crusher which comprises a base, an casing, a main unit, two sets of drive mechanisms and a hydraulic adjustment safety system; wherein the casing is arranged on the upper side of the base; the main unit which comprises a rotor part is arranged in the casing; the two sets of drive mechanisms are arranged by both sides of the main unit; the rotor part consists of a fixed roll shaft, a movable roll shaft, fixed bearings and movable bearings; the fixed roll shaft and the movable roll shaft are arranged in parallel; the fixed bearings and the movable bearings respectively bear the fixed roll shaft and the movable roll shaft; the outer surfaces of the two roll shafts are respectively provided with a cluster of breaking teeth axially spaced from one another; the breaking teeth on the two roller shafts are axially arranged in a staggered way; the drive mechanisms respectively drive the two roll shafts to rotate in opposite directions; and the main unit also comprises a pair of cleaners and an adjustor for adjusting the gap between the two roll shafts. The wheel tooth type crusher can eliminate overload impact and vibration caused by non-breaking materials; after the breaking teeth on the two roll shafts are worn down, the relative gap and positions between the two roll shafts can be easily adjusted, thereby increasing the working efficiency of the breaking.

Owner:SHANGHAI JIANSHE LUQIAO MASCH CO LTD

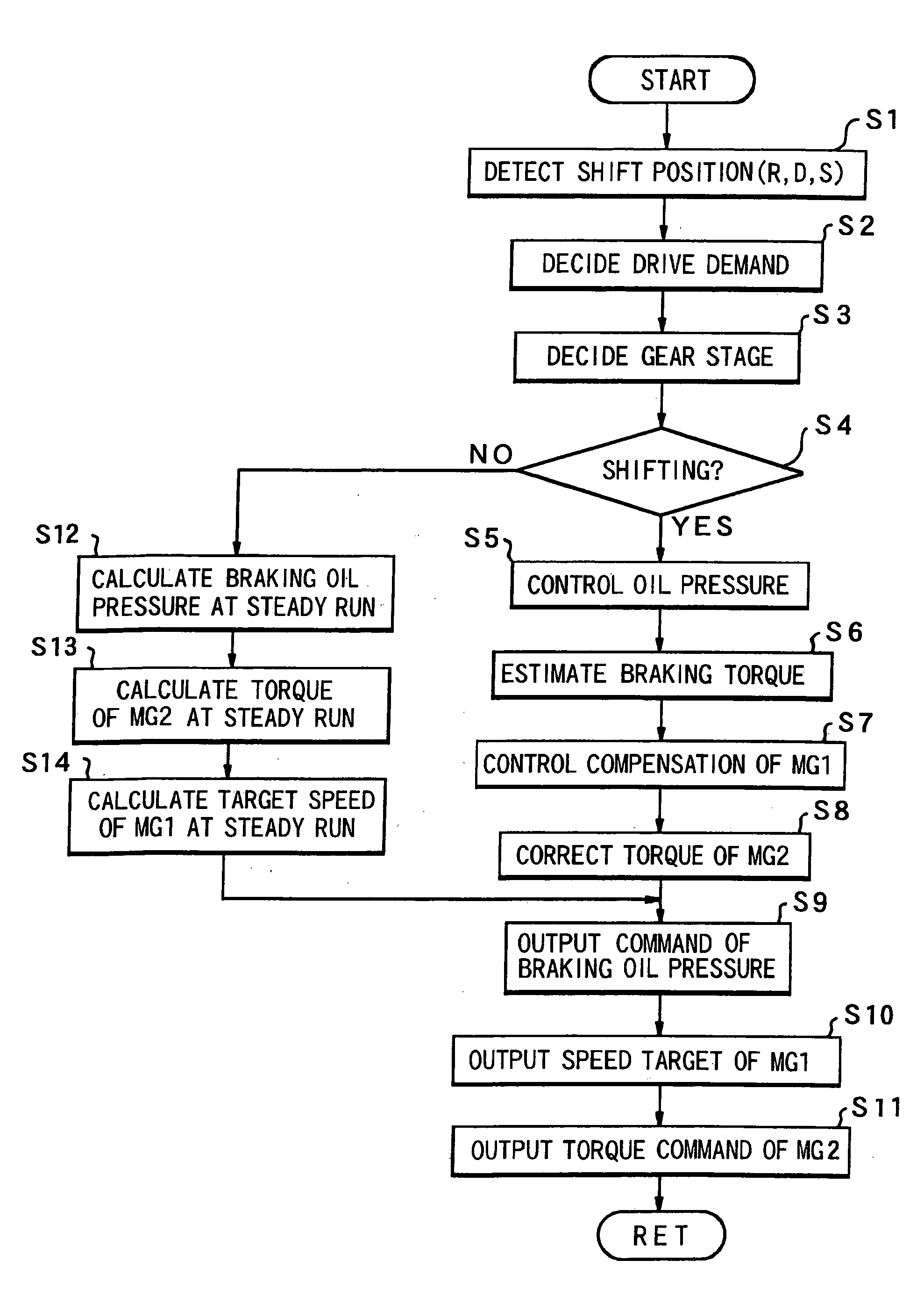

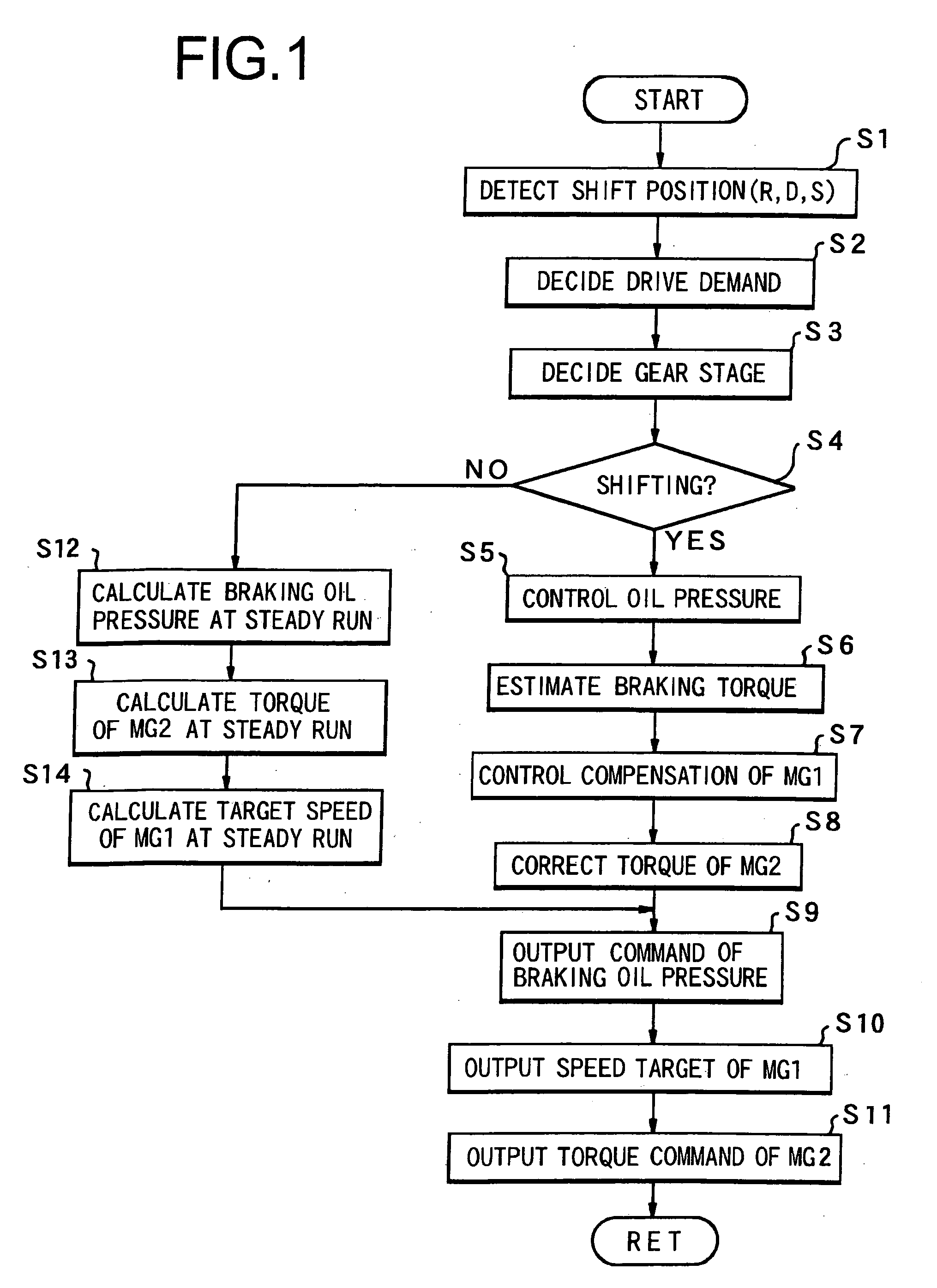

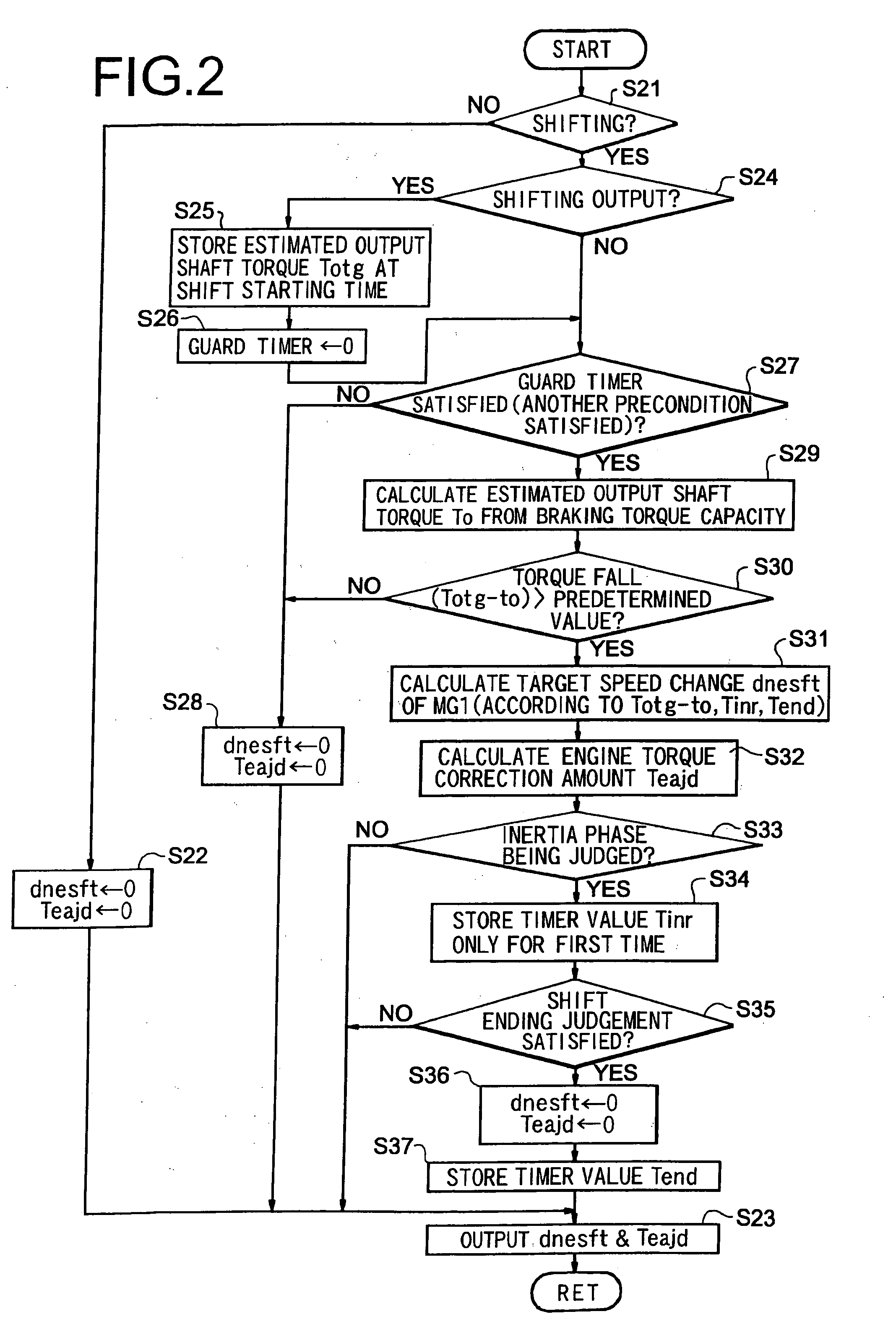

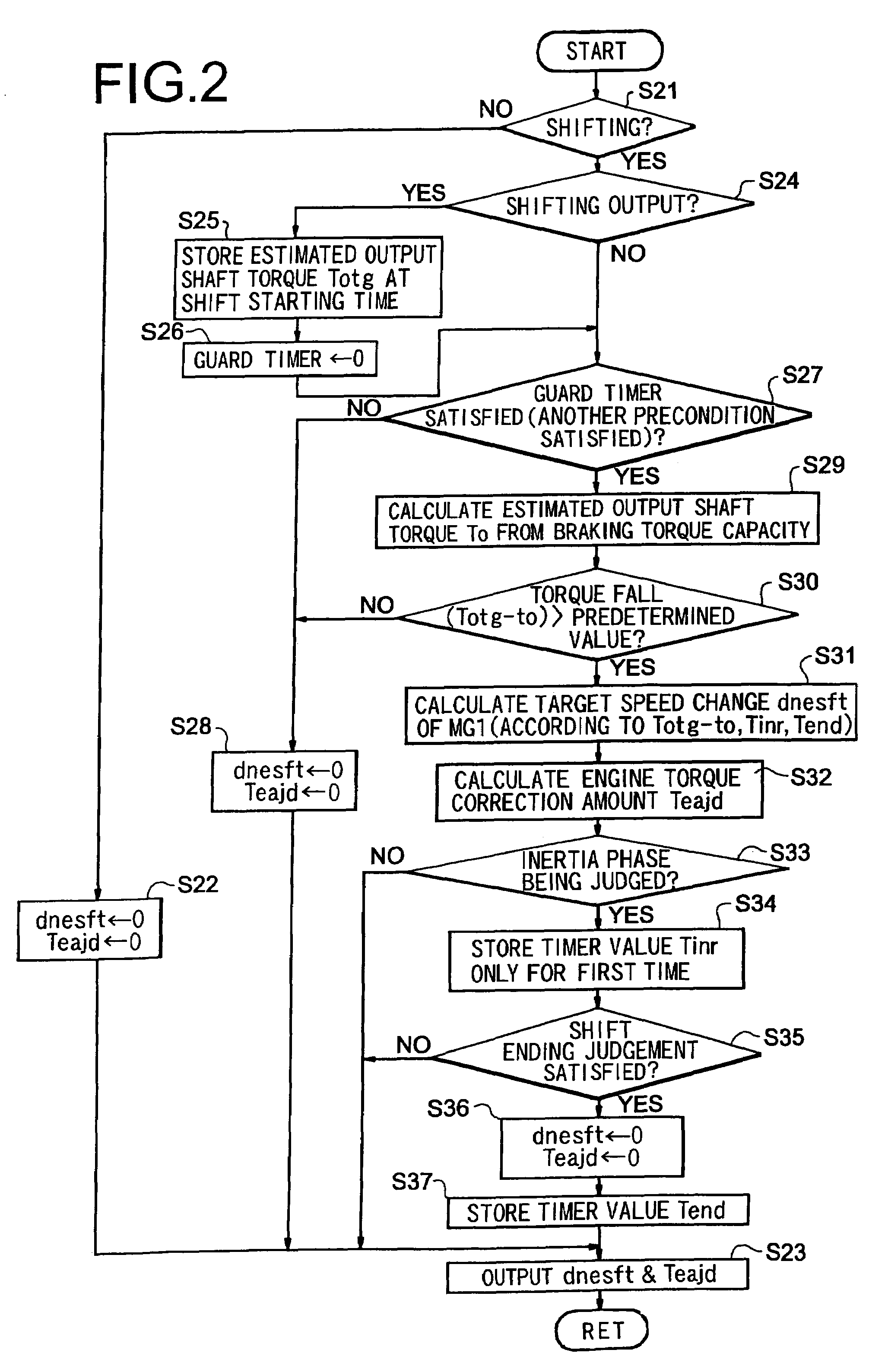

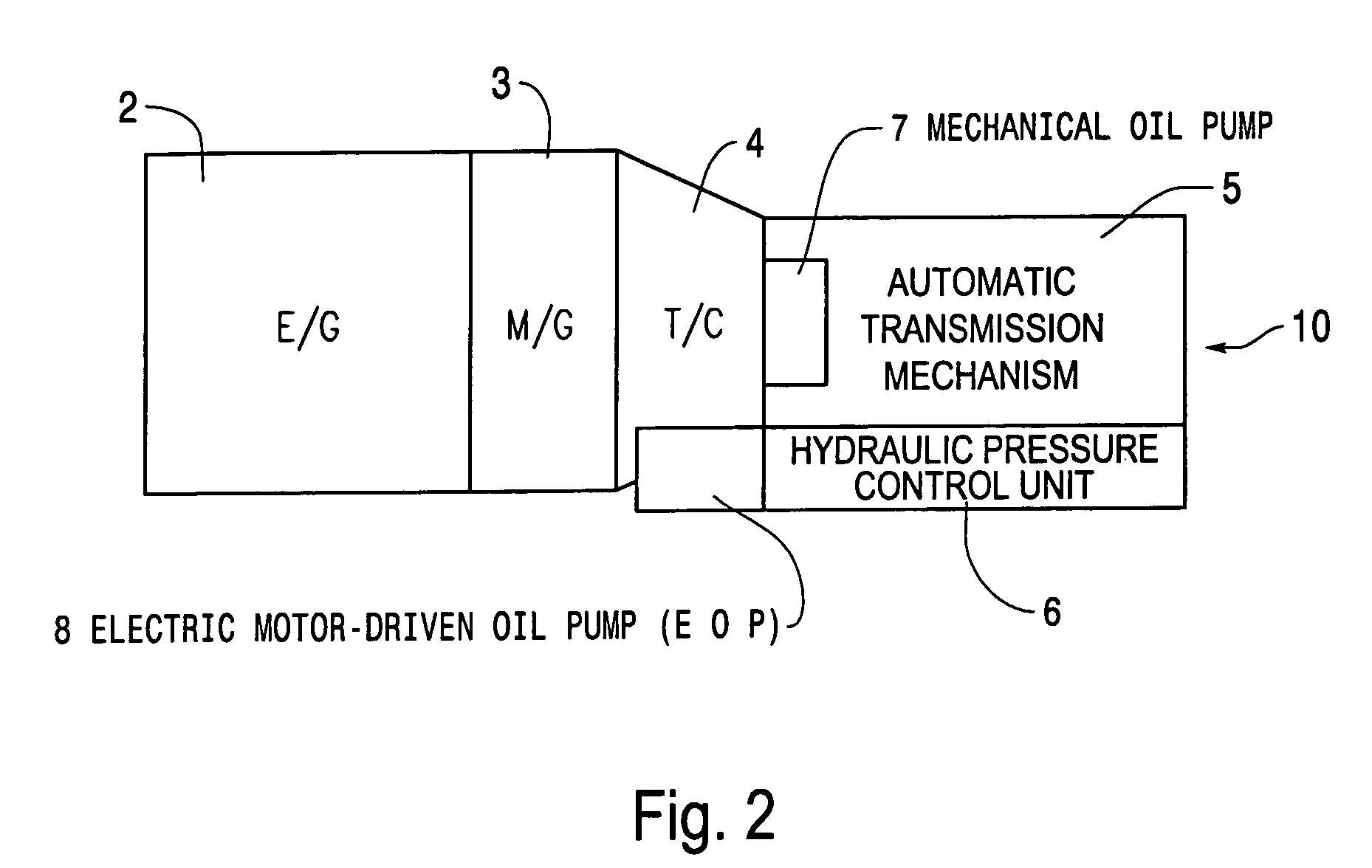

Control device of hybrid drive unit

A control device of a hybrid drive unit, wherein an assist prime mover is connected through a transmission to an output member, to which a torque outputted by a main prime mover is transmitted. The control device comprises a first torque correcting means for correcting the torque to be transmitted from the main prime mover to the output member during a gear shift by the transmission.

Owner:TOYOTA JIDOSHA KK

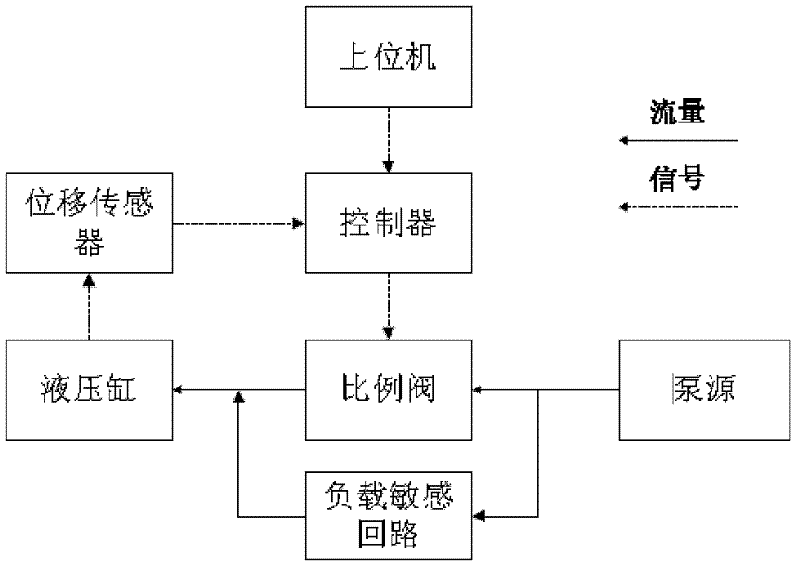

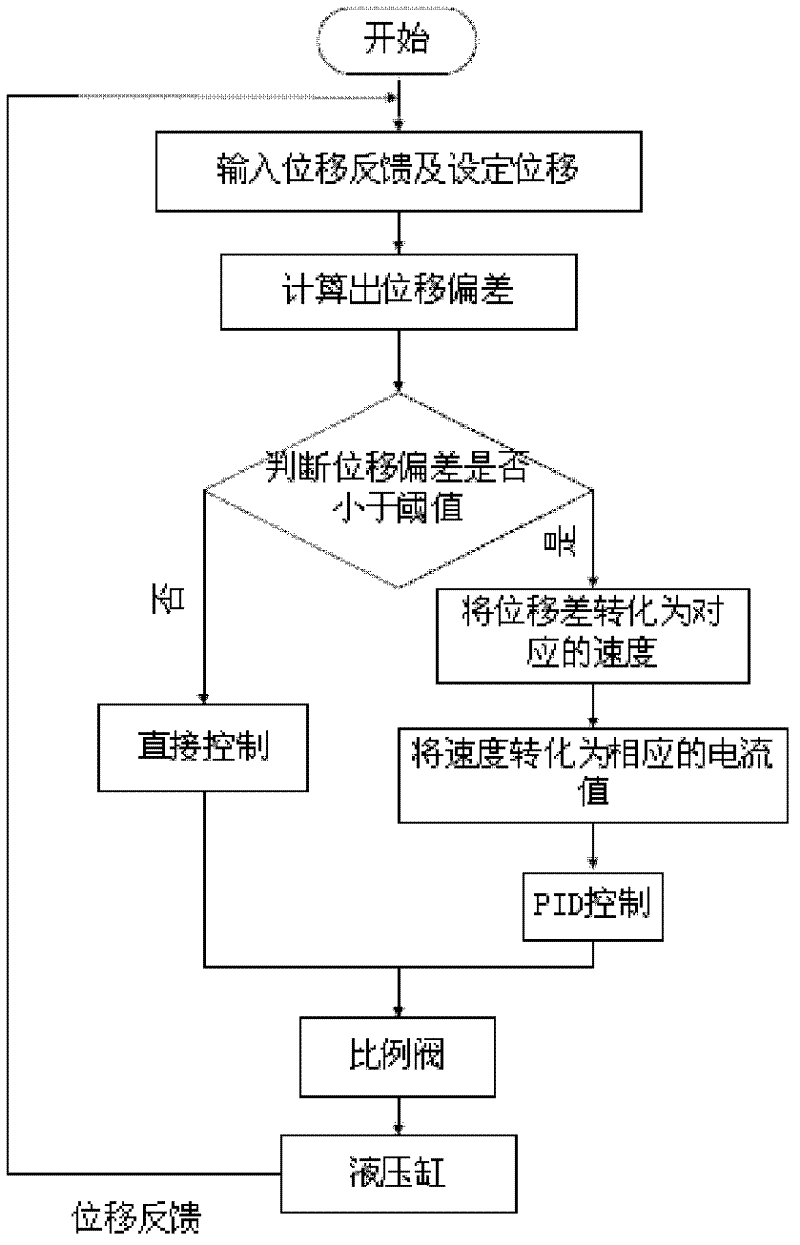

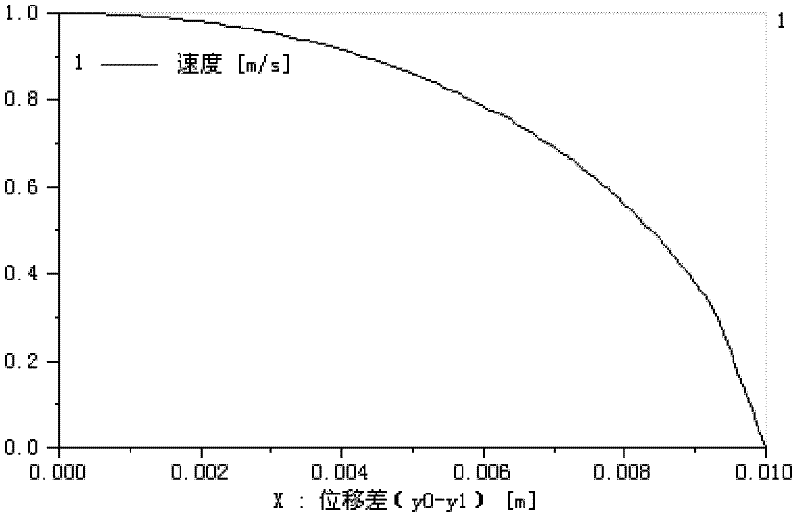

Compound control method of speed and position of hydraulic cylinder system based on displacement feedback

InactiveCN102562714AImprove riding performanceEliminate shockServomotorsHydraulic cylinderPower flow

The invention relates to a compound control method of a speed and a position of a hydraulic cylinder system based on displacement feedback, which comprises the following steps: 1) a displacement sensor transmits an acquired actual displacement value y1 of a hydraulic cylinder piston to a controller, 2) the controller compares the actual displacement value y1 of the hydraulic cylinder with a set displacement value y0 to obtain a displacement deviation absolute value of deltay, and judges whether the displacement deviation absolute value of deltay is smaller than the set threshold, if so, executing the step 3), if not, executing the step 4), 3) the current output by the controller is rated current of a proportional valve, namely the proportional valve is totally opened, the flow through the proportional valve is maximal, and the hydraulic cylinder piston quickly moves, and 4) the controller converts the displacement deviation absolute value of deltay into an output current i according to a preset relation function, and controls the proportional valve through the output current i so as to realize fast control for the speed following the displacement. The compound control method, disclosed by the invention, has the advantages of shorter control time, lower realization cost and the like in comparison with the prior art.

Owner:TONGJI UNIV

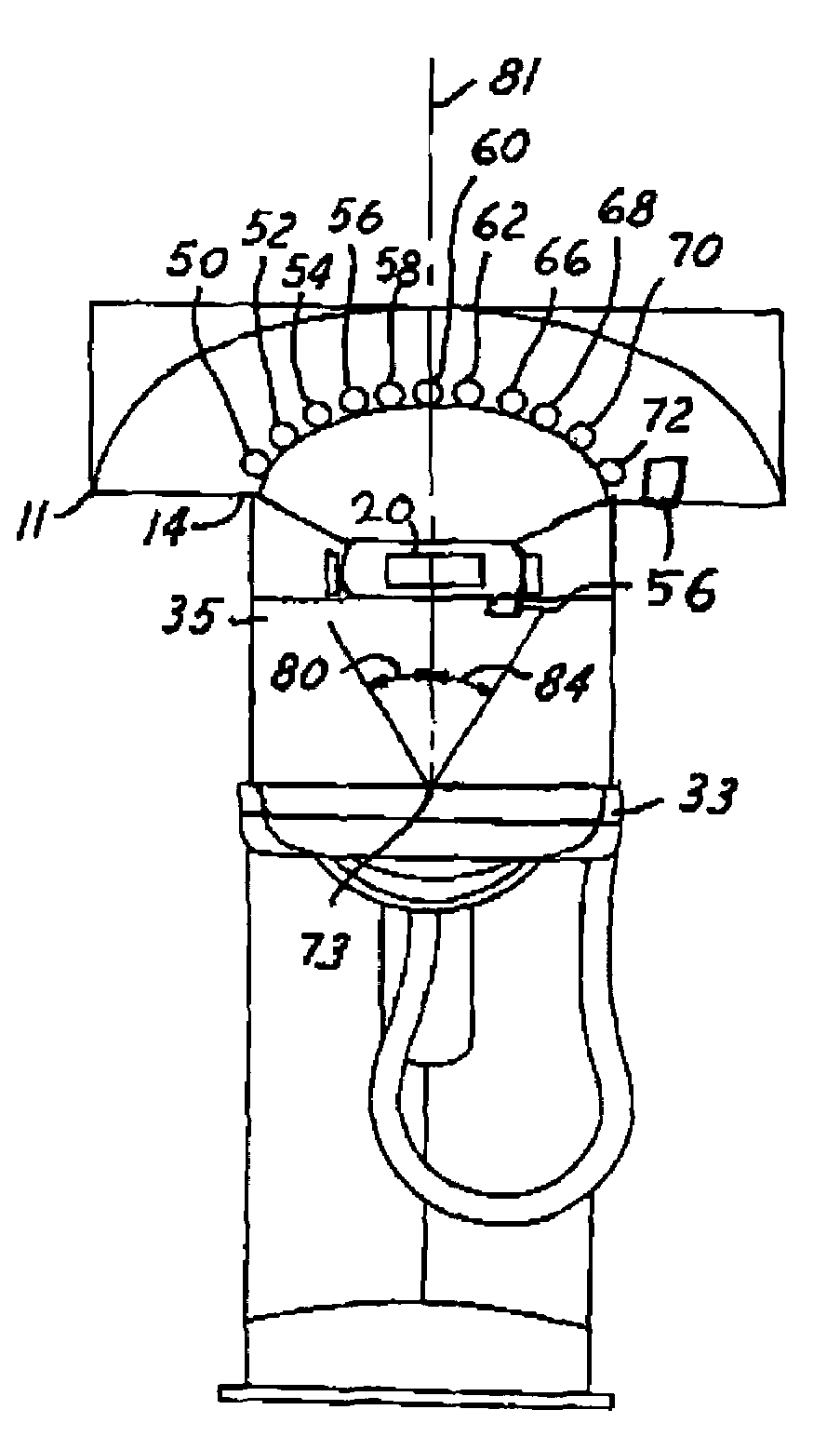

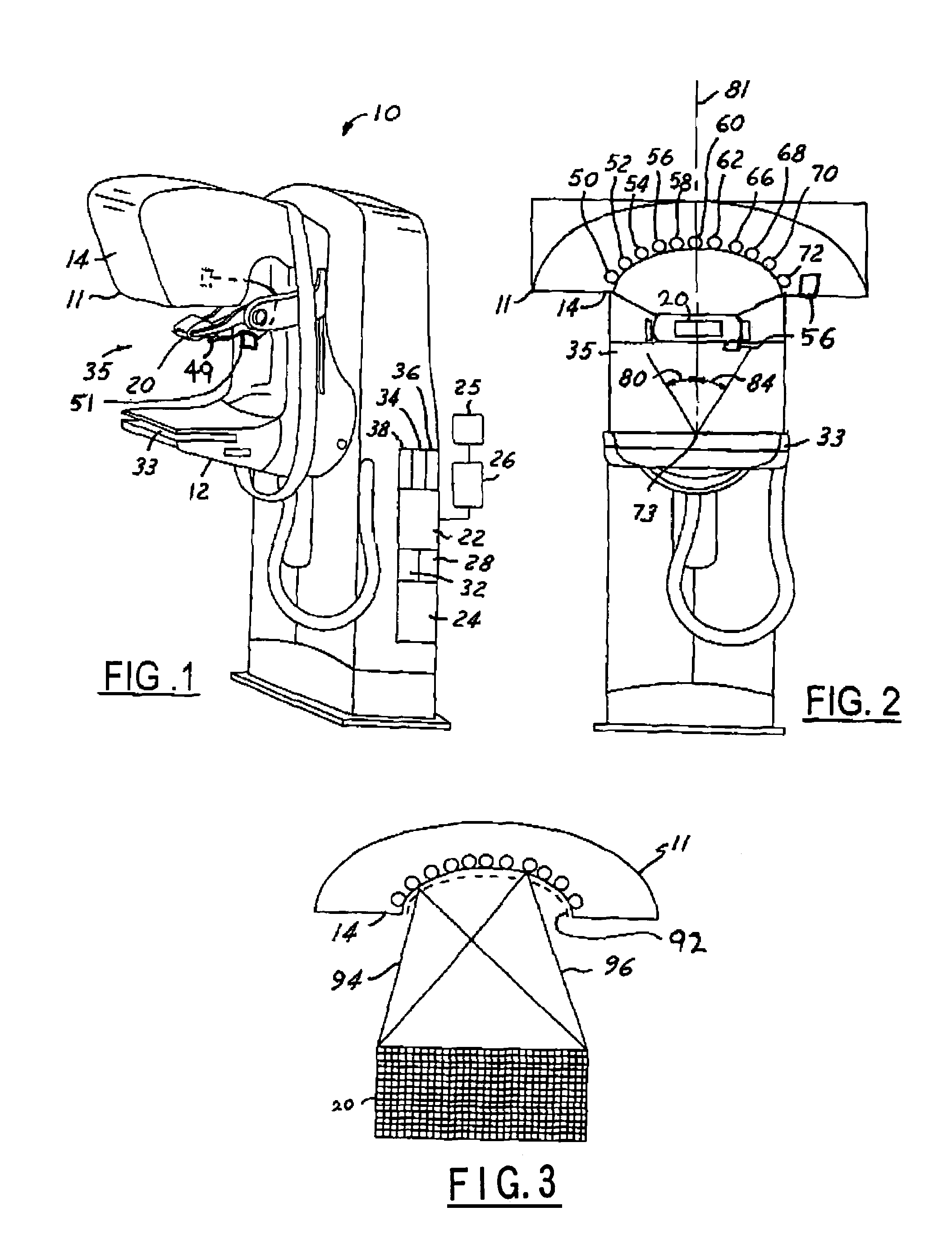

Stationary tomographic mammography system

ActiveUS7330529B2Eliminates mechanically induced artifactEliminate shockRadiation/particle handlingTomosynthesisX-rayField of view

A mammography scanning system having a detector includes an arc-shaped support system having a number of X-ray emitters coupled thereto. The X-ray emitters generate a plurality of X-ray fluxes towards a common focus at varying angles with respect to the focus. Also, each of the X-ray emitters is collimated to view an entire detector field of view.

Owner:GENERAL ELECTRIC CO

Automatic feeding numerical control lathe

InactiveCN105798332AAvoid shockPrevent flying outMetal working apparatusNumerical controlMaterial storage

The invention discloses an automatic feeding numerical control lathe. The automatic feeding numerical control lathe comprises a lathe body, wherein a hollow spindle is arranged on the lathe body; a sliding rail is arranged on the lathe body along the front and back horizontal direction; a knife rest is slidably arranged on the sliding rail; a hollow chuck is axially and fixedly connected to the front end of the hollow spindle; a cutting mechanism and an electromagnetic adsorption mechanism are arranged on the knife rest; an automatic feeding device is arranged behind the lathe body; the automatic feeding device comprises a material box base; a material box support is fixedly connected onto the material box base; a material storage box, a corrugated pipe elastic joint and a discharging box are sequentially arranged on the material box support from top to bottom in a fixed manner; a vibration motor is arranged on the outer wall of each of the left and right sides of the corrugated pipe elastic joint; a material baffle mechanism is arranged on the lower part of the discharging box; and a material pushing base which is right blow the discharging box is fixedly connected onto the upper surface of the material box base. The automatic feeding numerical control lathe is simple and convenient for operation, high in automatic degree and stable in work; automatic feeding can be realized; non-cutting time is effectively shortened; cutting can be performed rapidly; and the working efficiency is improved.

Owner:HUANGHE S & T COLLEGE

Testing system for nuclear reactor passive shutdown device and testing method thereof

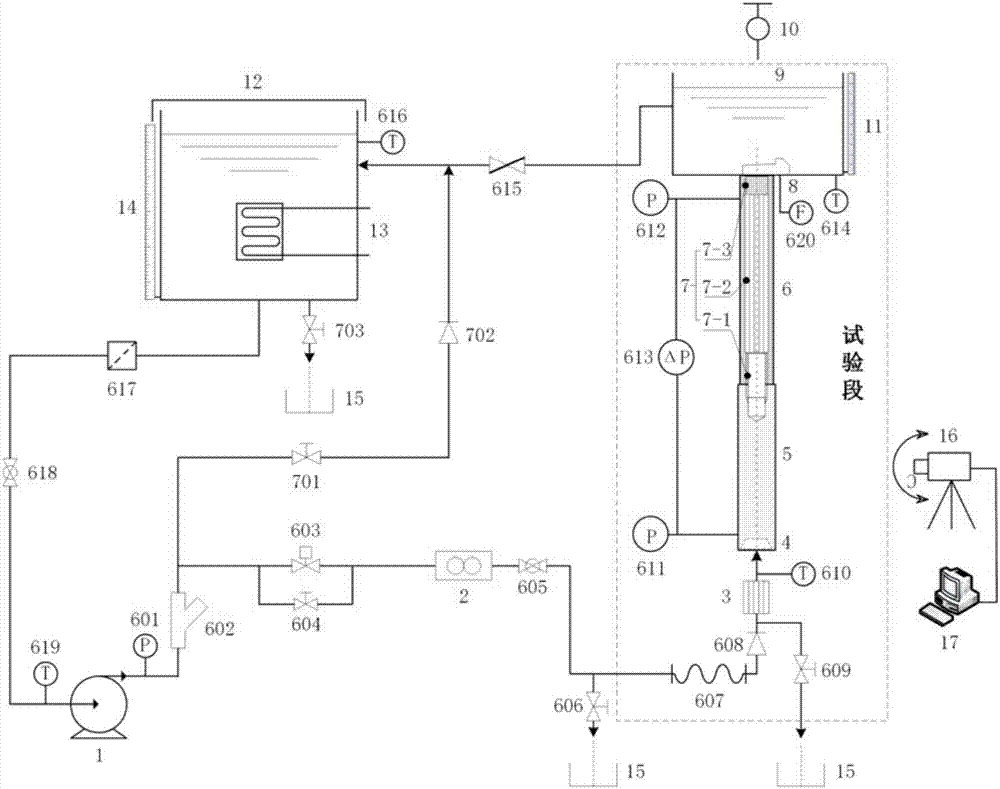

ActiveCN107481774AImprove steady state operationImplement testNuclear energy generationNuclear monitoringNuclear reactorRemote control

The invention provides a testing system for a nuclear reactor passive shutdown device and a testing method thereof. The system comprises a hydraulic loop system composed of a pump pre-regulation monitoring module, a main circulation loop module, a bypass loop module, a testing system discharging module and a related pipeline, and an instrument, a passive shutdown device testing body composed of a supporting steel platform, a control rod sleeve, a passive control rod model and a hoisting mechanism thereof, and a measurement control system composed of a rod position measurement module, an information monitoring and acquisition module, a remote control module and a related lead wire, and a cable; a working medium which is heated to a testing temperature value starts from a centrifuge pump and is subjected to flow regulation, and then enters a test section; the working medium is used for keeping the passive control rod model suspended in the control rod sleeve through hydraulic power, flows out from the testing body and then returns back to a water tank to form closed circulation; the invention provides the testing method of the system; and the testing system provided by the invention has the advantages that a whole structure is simple and easy to operate, the cost of materials and the working medium is low, and key parts and equipment of the testing section adopt detachable designs so that the testing system is convenient to upgrade and modify.

Owner:XI AN JIAOTONG UNIV

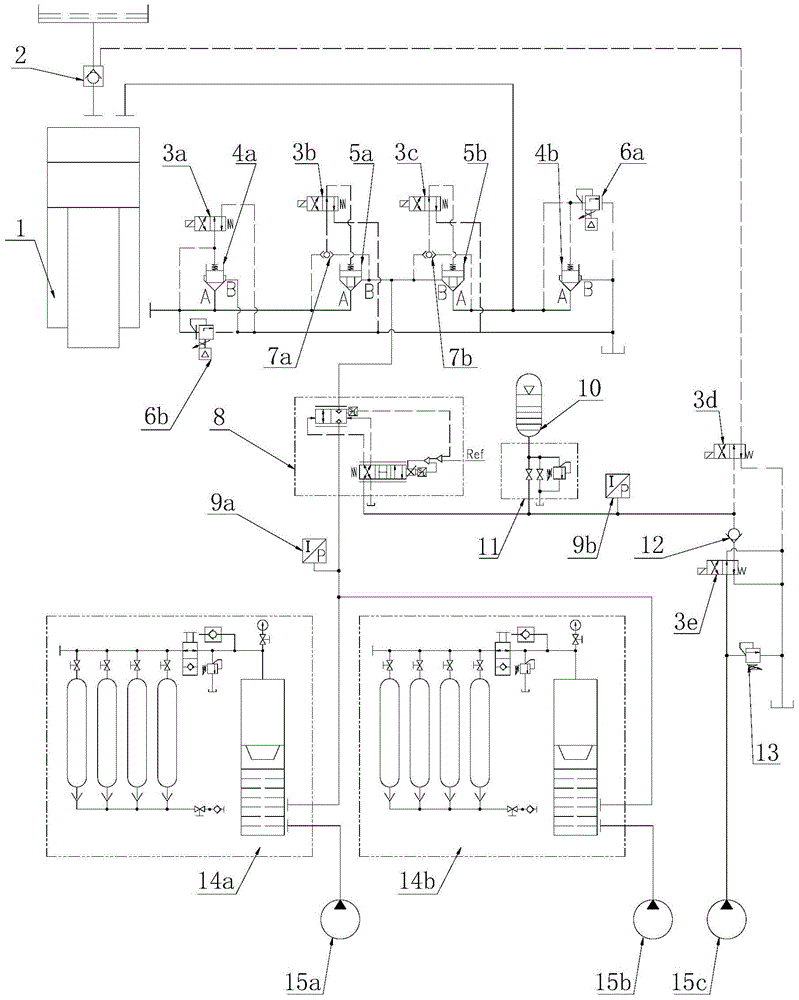

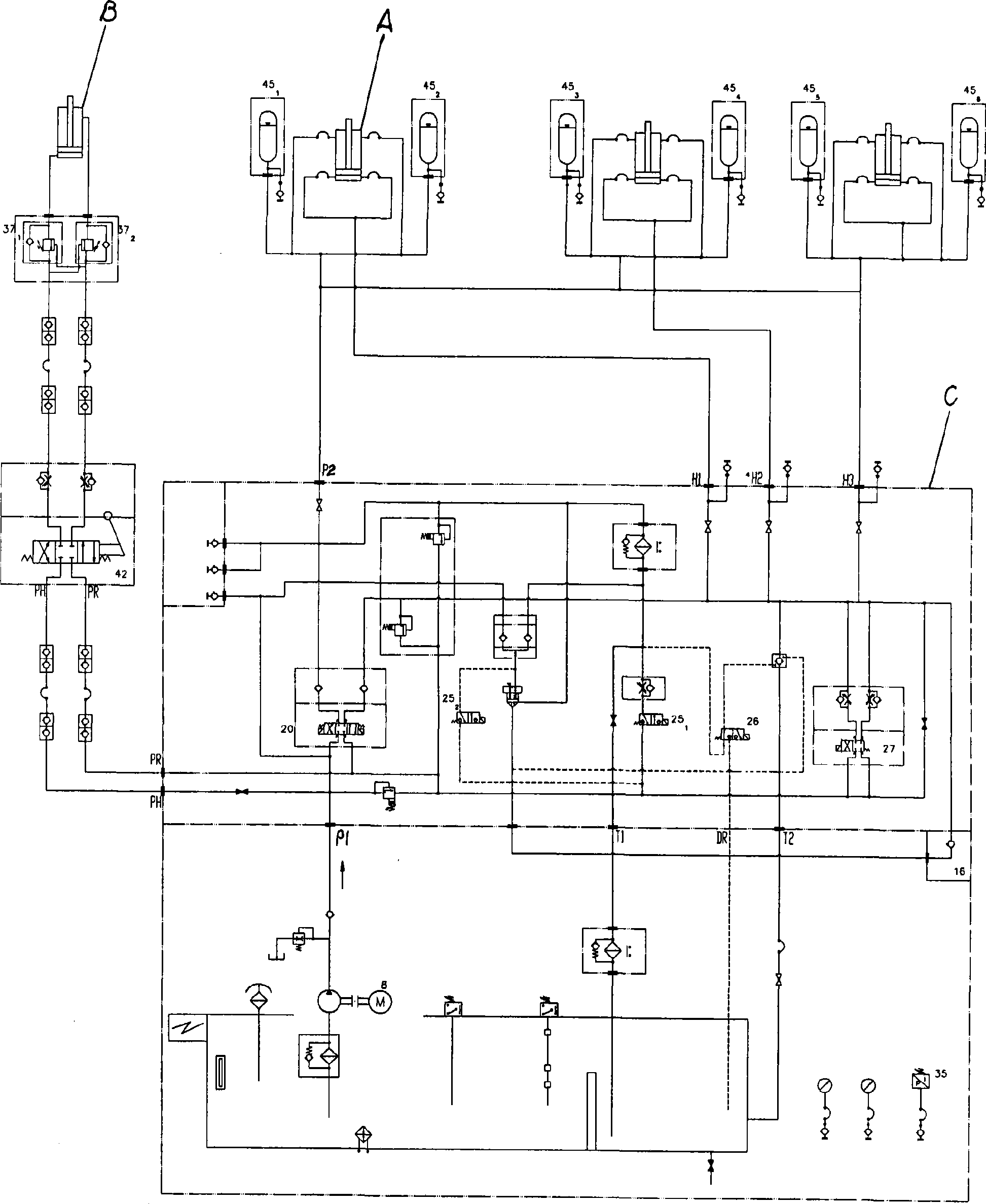

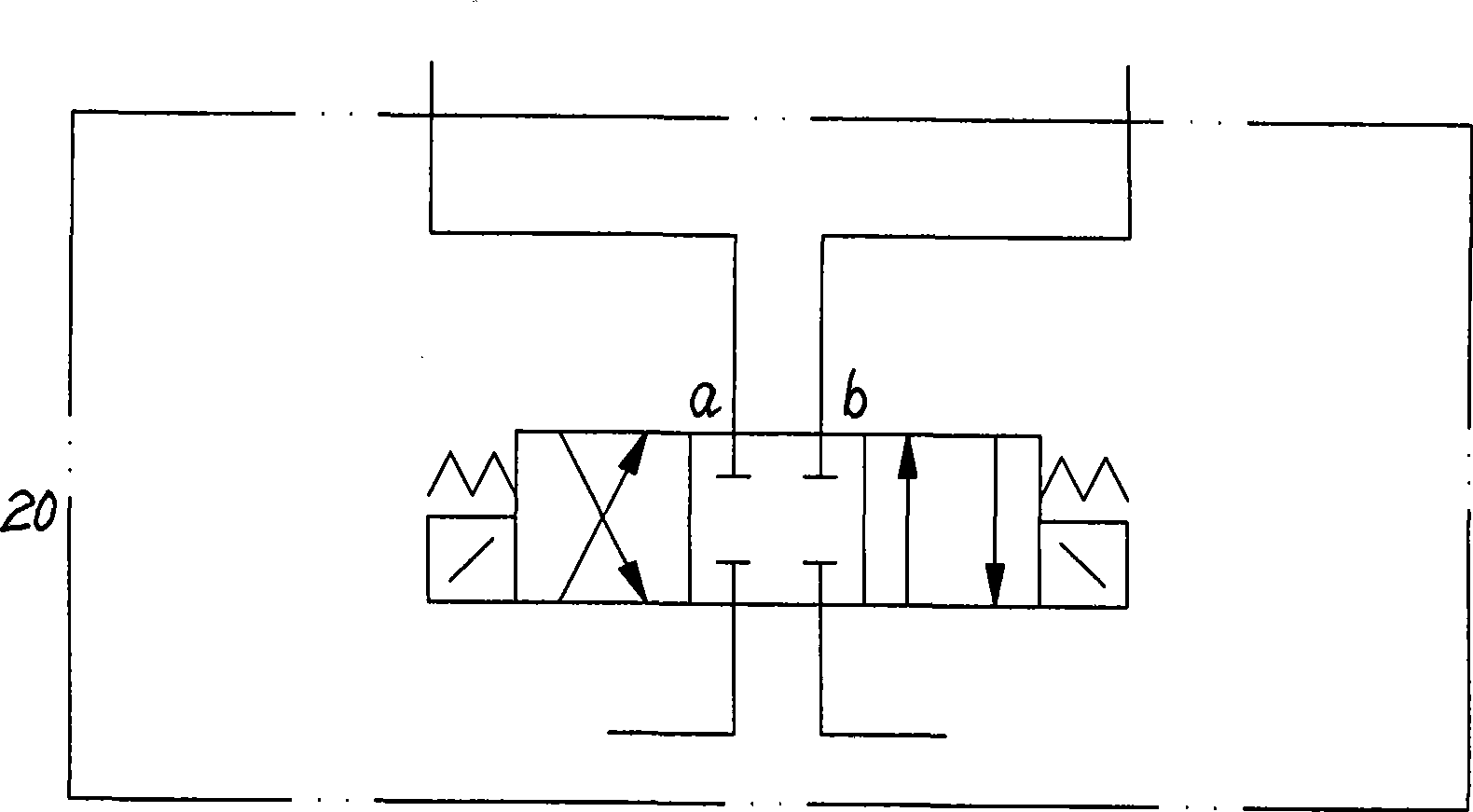

Hydraulic control system of high-speed performing hydraulic machine

ActiveCN105221497AHigh trafficWork fasterServomotor componentsServomotorsControl systemShuttle valve

The invention relates to a hydraulic control system of a high-speed performing hydraulic machine. The hydraulic control system is characterized by comprising a power source circuit, an operating cylinder oil supply circuit and a control oil circuit, wherein the power source circuit comprises a pump source, a piston type energy accumulator group and a first pressure sensor; the operating cylinder oil supply circuit comprises a proportional cartridge valve, a first direction control two-way cartridge valve, a second two-position two-way direction valve, a first shuttle valve, a first pressure control two-way cartridge valve, a second proportional overflow valve, a first two-position two-way direction valve, a second direction control two-way cartridge valve, a third two-position two-way direction valve, a second shuttle valve, a second pressure control two-way cartridge valve, a first proportional overflow valve and a prefill valve; and the control oil circuit comprises a third pump source, a fifth two-position two-way direction valve, a one-way valve, a fourth two-position two-way direction valve, a bladder type energy accumulator, an energy accumulator safety valve group, a proportional two-way cartridge valve and a second pressure sensor. The hydraulic control system has the advantages that the operating speed of the hydraulic machine can be increased, and the quality of a workpiece is ensured.

Owner:TIANJIN TIANDUAN PRESS CO LTD

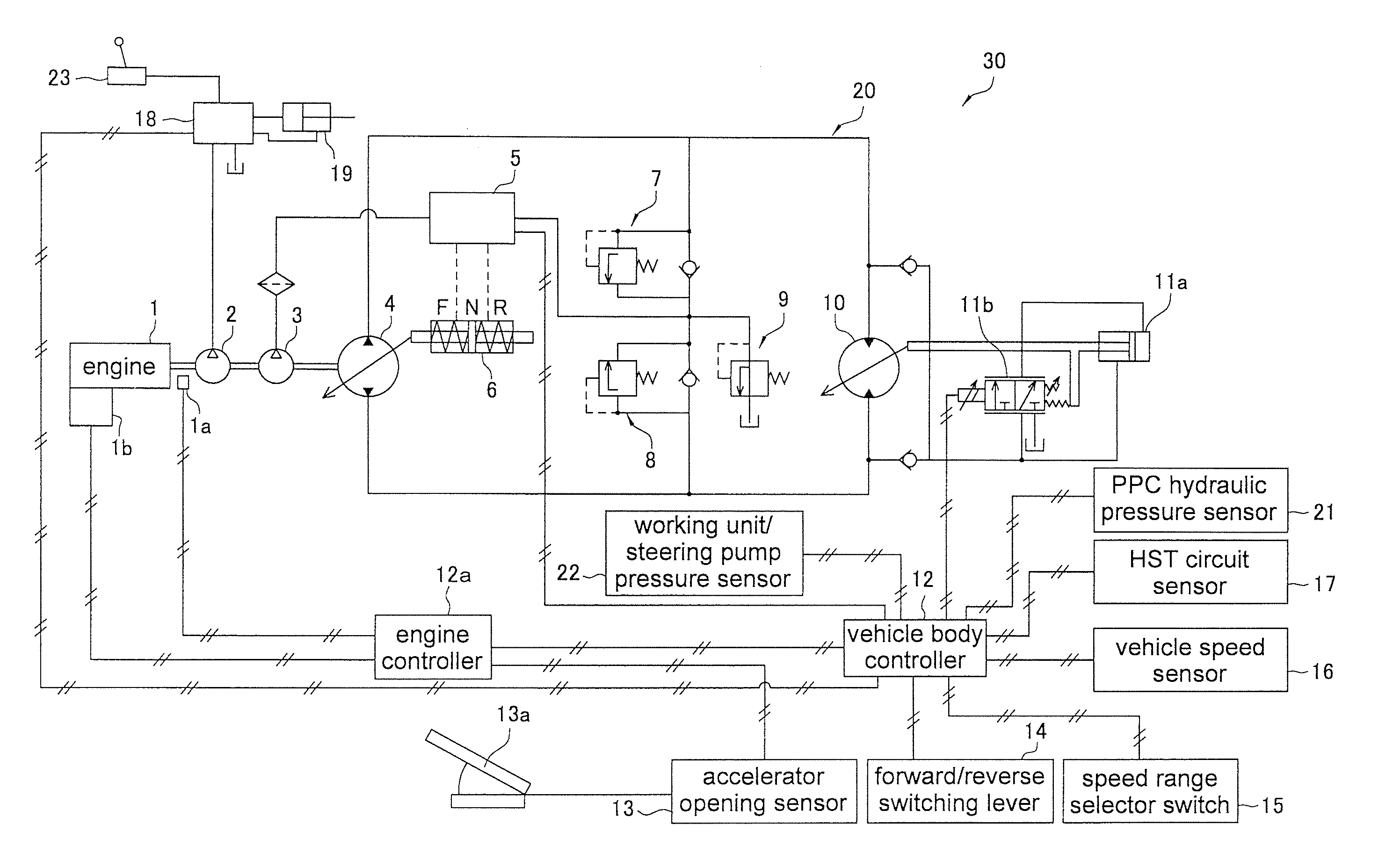

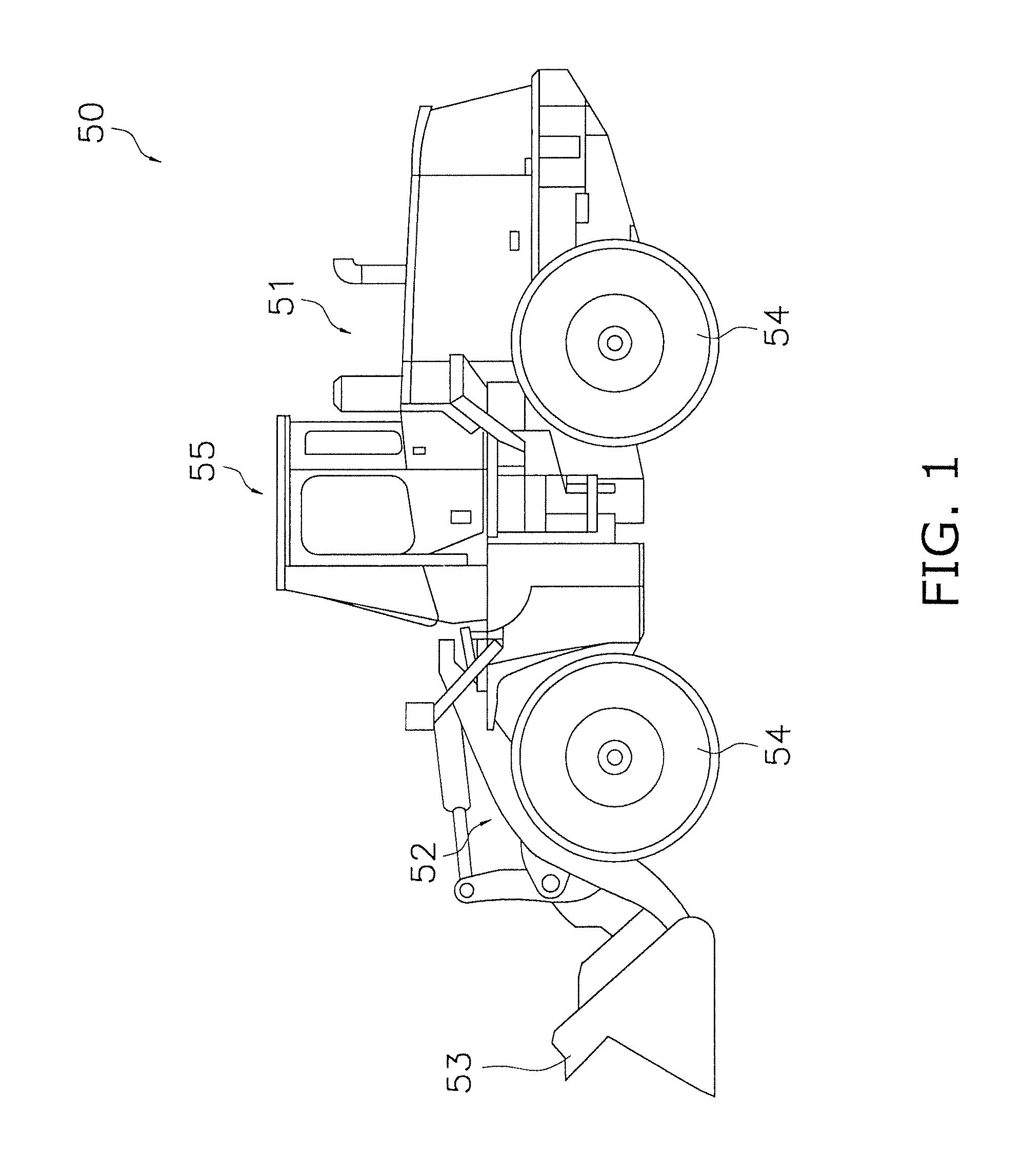

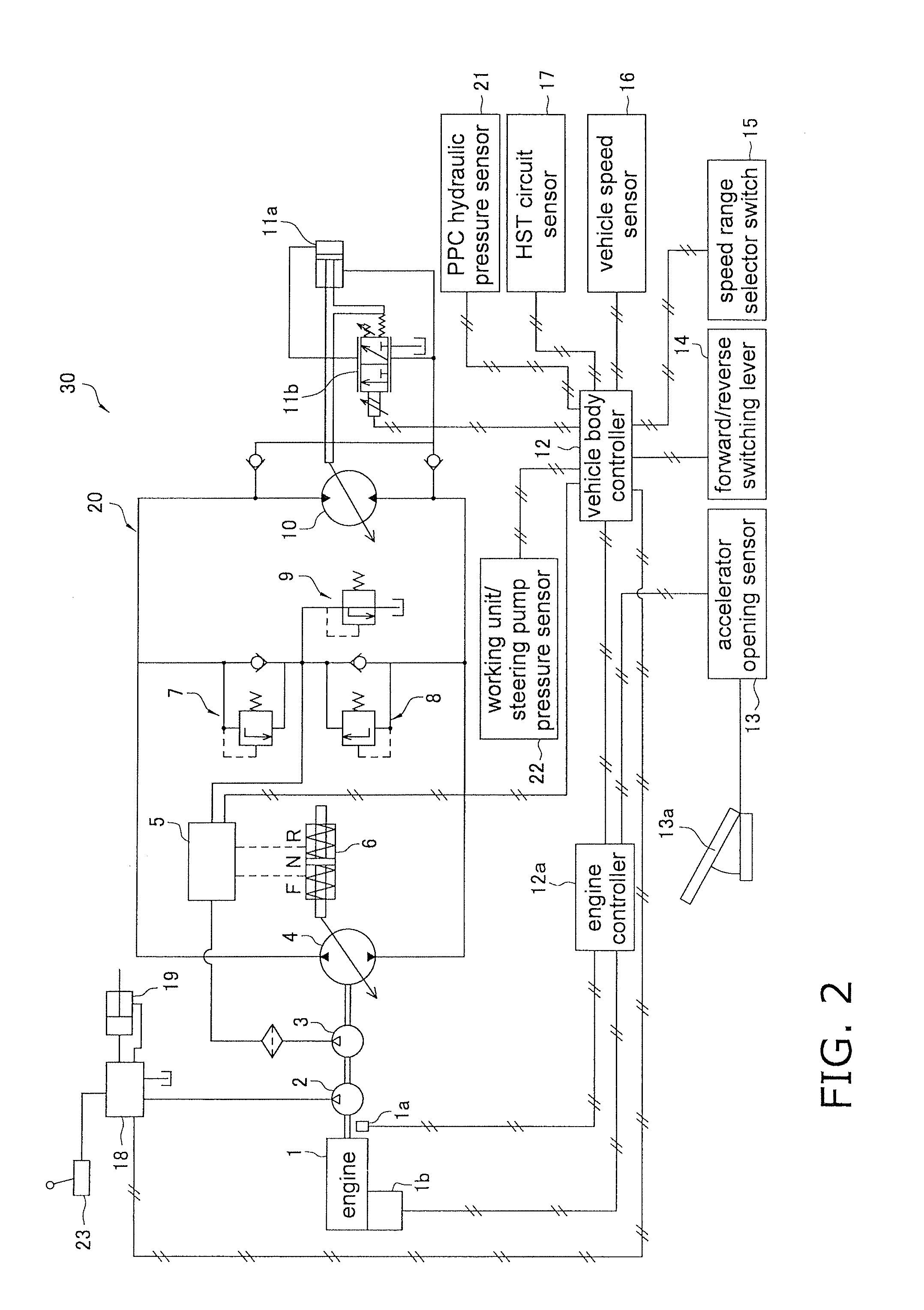

Construction vehicle

ActiveUS20110308879A1Improve fuel economyHigh horsepowerRoad transportGearing controlEngineeringExecution control

A wheel loader (50) is designed so that when a specific first condition is met for vehicle speed, accelerator opening, engine speed, and HST pressure, the engine absorption torque curve of an HST pump (4) is switched to shift the matching point from the low-engine speed side to the high-engine speed side. On the other hand, if a second condition is met for vehicle speed and HST pressure, control is performed so that the absorption torque curve of the HST pump (4) is returned from the high-engine speed side to the low-engine speed side.

Owner:KOMATSU LTD

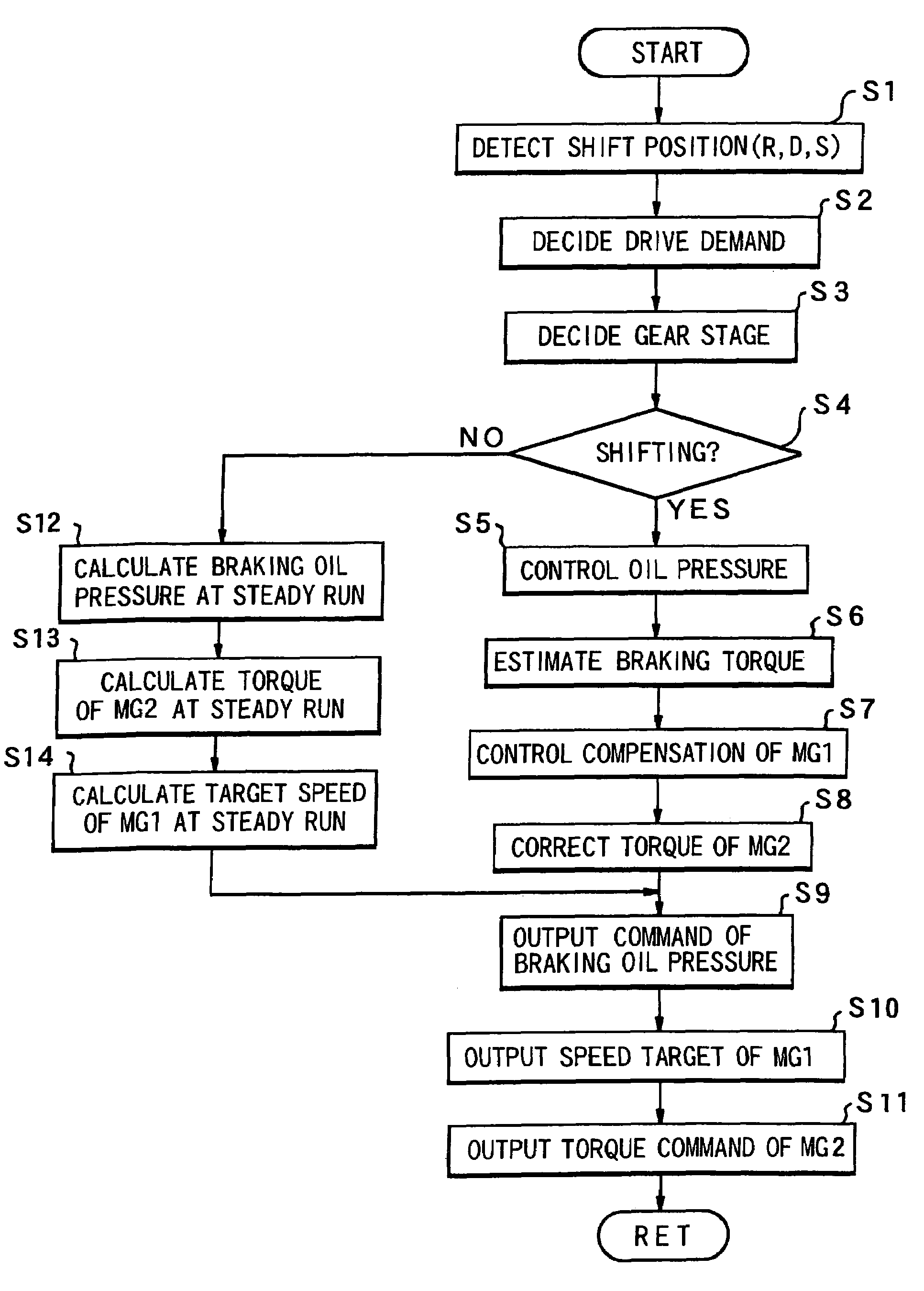

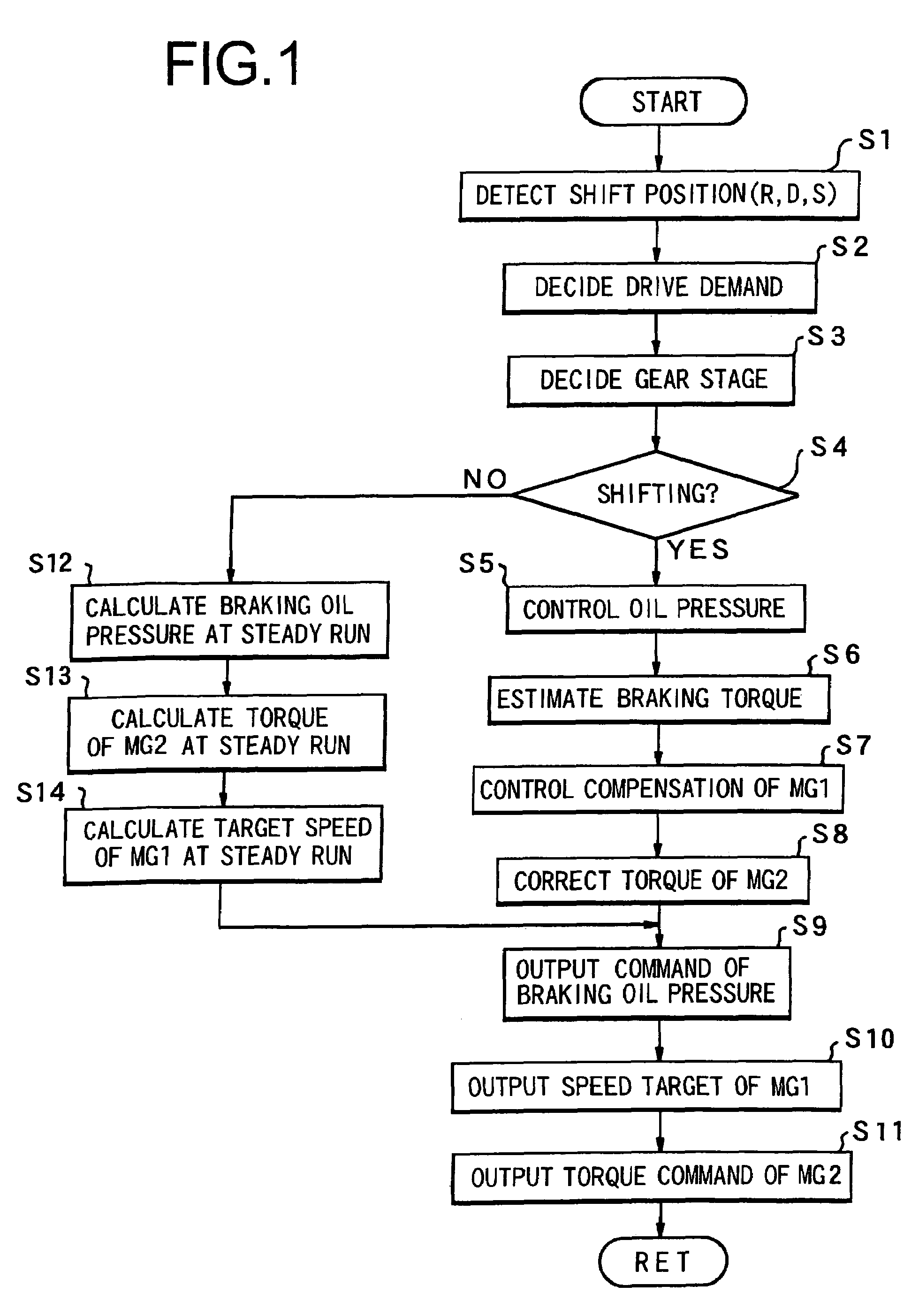

Control device of hybrid drive unit

Owner:TOYOTA JIDOSHA KK

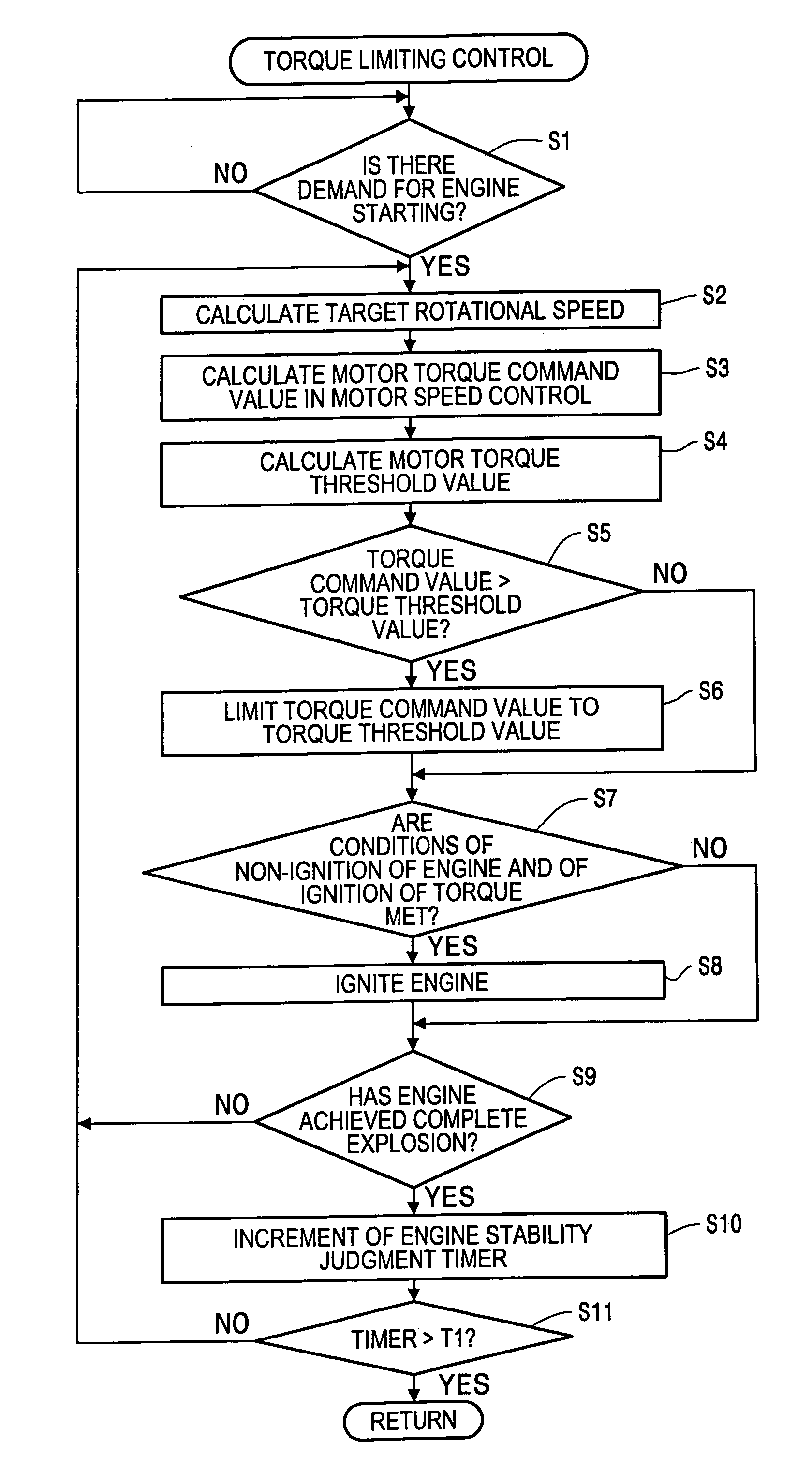

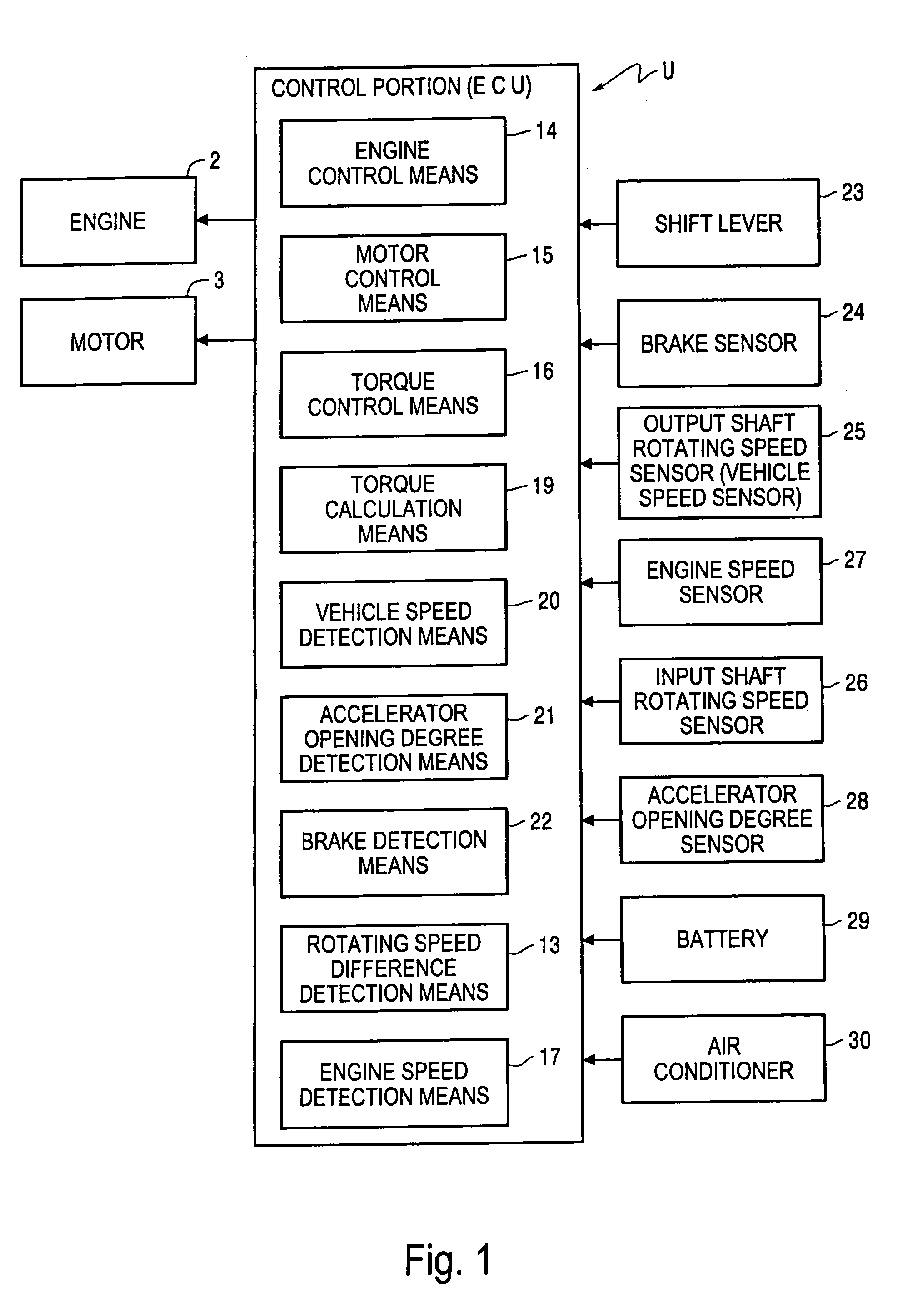

Control device for vehicles

ActiveUS6988974B2Eliminate shockAvoid it happening againDC motor speed/torque controlDigital data processing detailsTorque converterDrive wheel

A control device for a vehicle including a motor, an engine, wherein the motor can be drivingly connected with the engine, a torque converter, a transmission mechanism for transmitting the drive torque, which is transmitted via the torque converter from the engine and the motor, to drive wheels, and a controller that controls a driving state of the motor, controls a driving state of the engine, and outputs a torque reduction command for controlling a drive torque of the motor in order to place the drive torque of the motor within a maximum input torque of the transmission mechanism, wherein the maximum input torque is calculated based on a torque ratio of the torque converter when the engine begins driving after the motor begins driving.

Owner:AISIN AW CO LTD

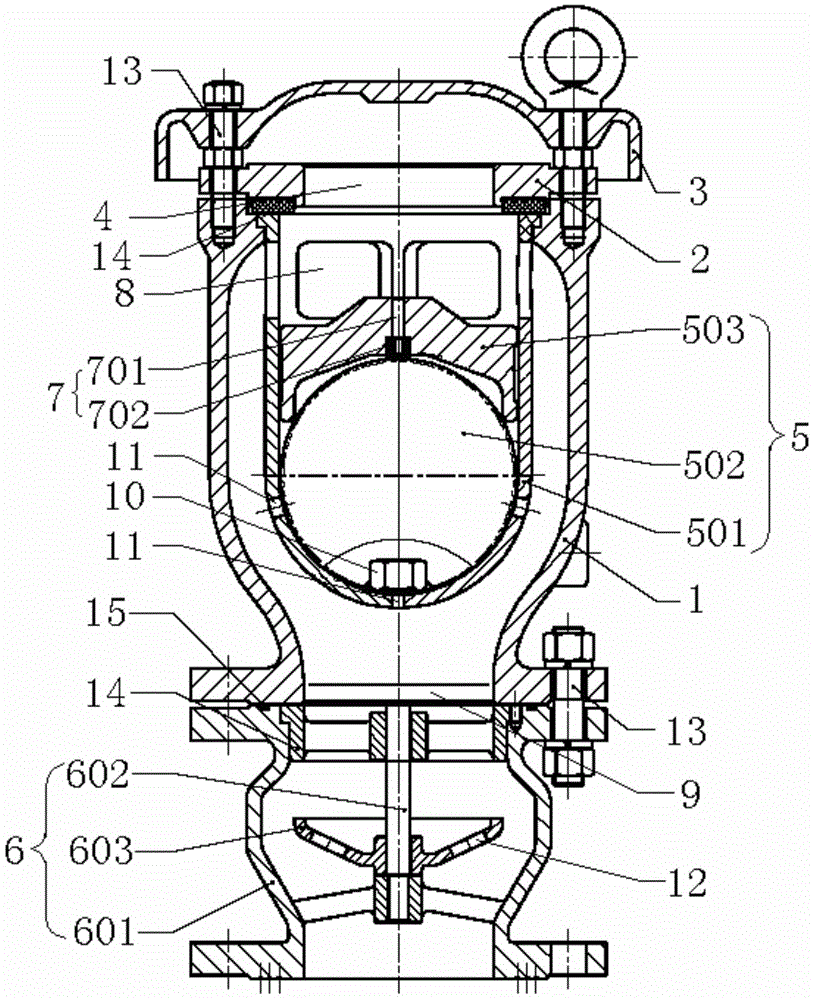

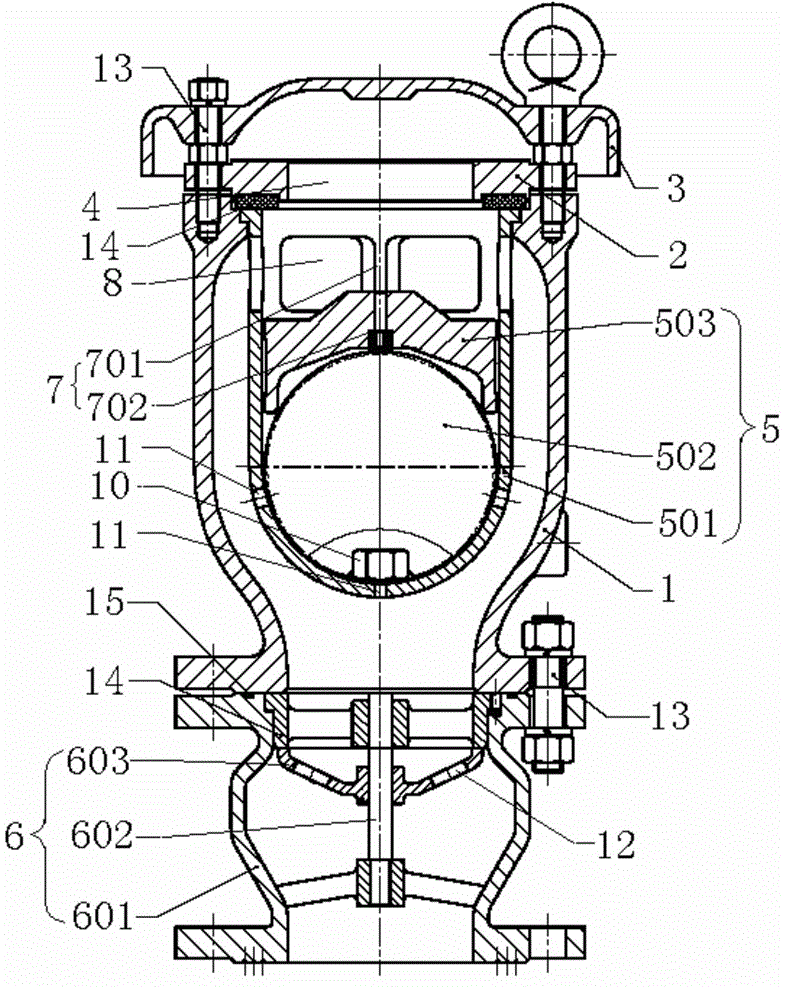

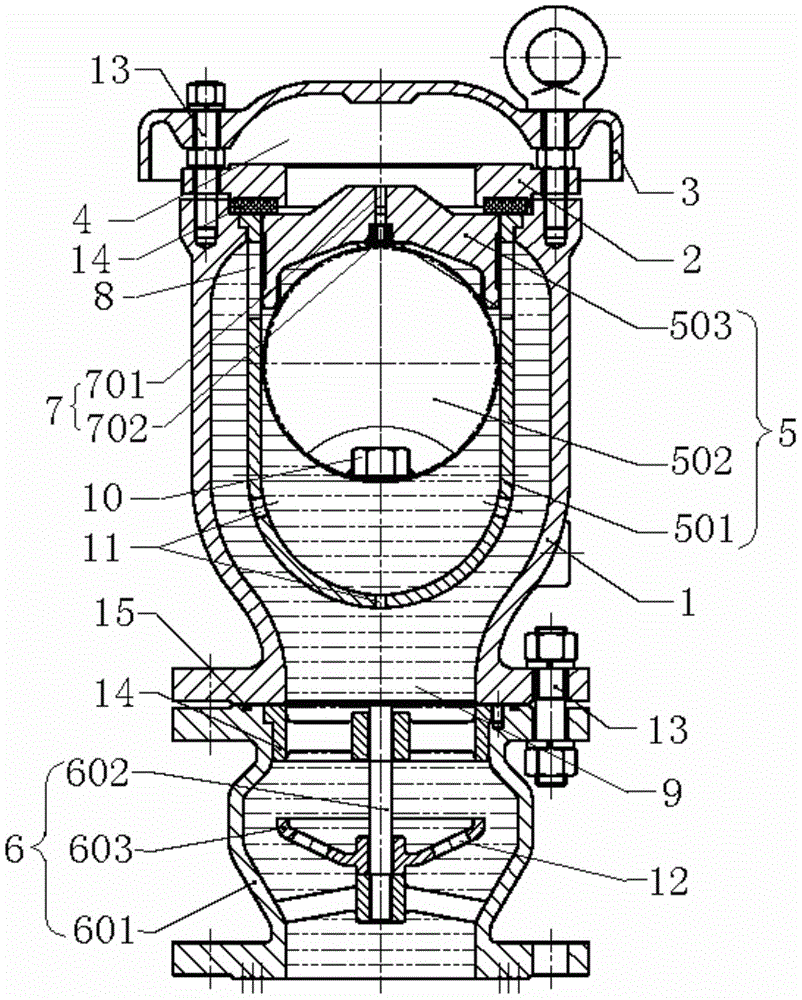

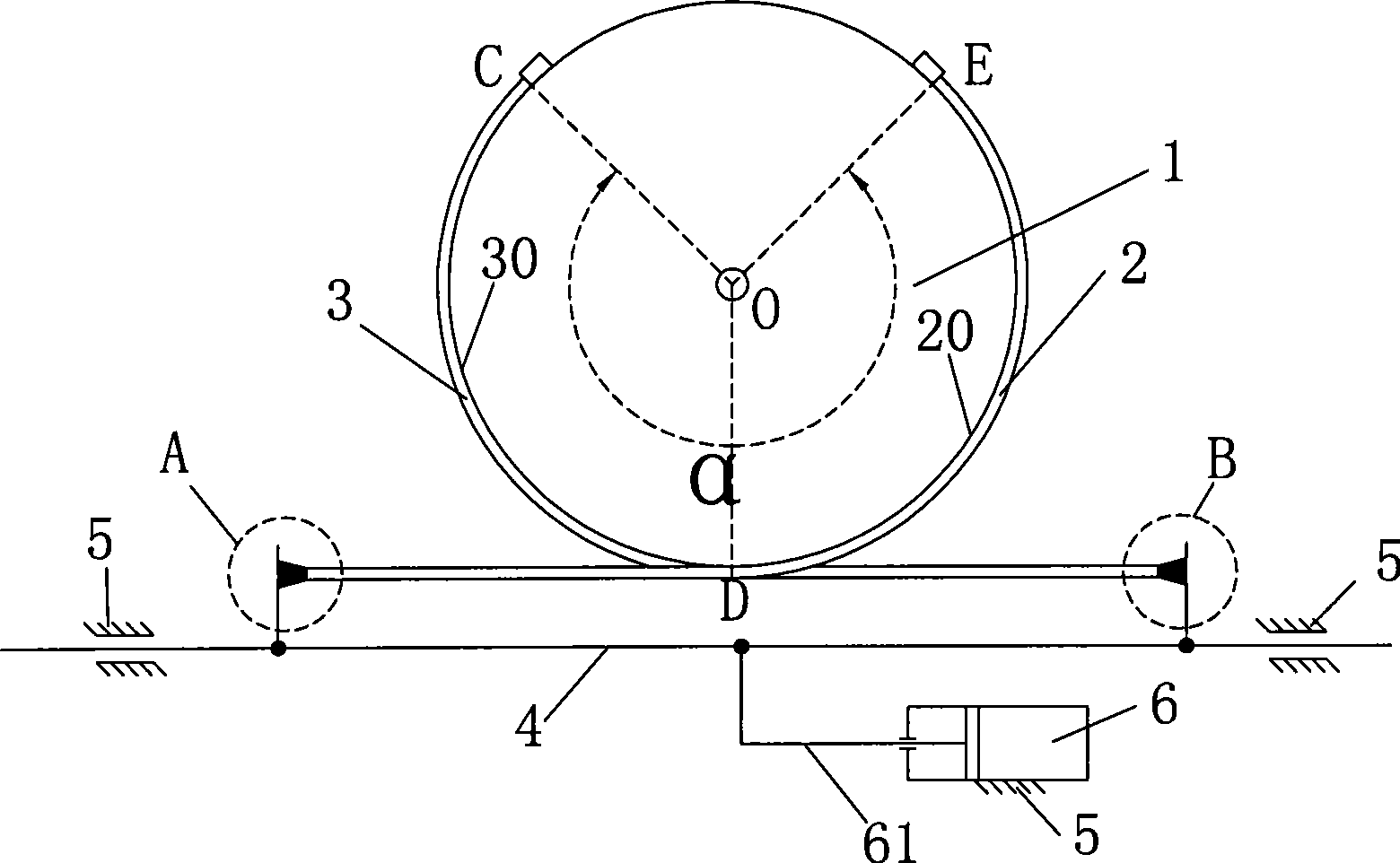

Water hammer air valve and water hammer gas discharging method during pipeline use

ActiveCN104896184AAvoid blowingAvoid air blockageValve members for absorbing fluid energyPipe elementsEngineeringWater hammer

The invention discloses a water hammer air valve and a water hammer gas discharging method during pipeline use. The water hammer air valve comprises a valve body, a bonnet and a protective cover, wherein the bonnet is provided with an opening, the protective cover is disposed on the opening, the valve body is provided with a valve opening for being communicated with a pipeline, a high-speed gas feeding and discharging device which is used for discharging gases stayed in the pipeline during water filling to the outside and shutting down the valve after pipeline water filling is completed is disposed in the inner cavity of the valve body, the output end of the high-speed gas feeding and discharging device is communicated with the outside through the opening of the bonnet, and the valve opening of the valve body is communicated with a bottom gas discharging throttling device for limiting the gas displacement of the pipeline to the inner cavity of the valve body; a trace gas discharging device for discharging mixed, residual and / or precipitated gases in the pipeline to the outside through the opening of the bonnet after the high-speed gas feeding and discharging device shuts down the valve is further disposed in the high-speed gas feeding and discharging device. By the water hammer air valve, water hammer reduction and pipeline safety protection are achieved, blowing blocking during high-speed gas discharging is avoided, and valve closing water hammer is eliminated.

Owner:ZHUZHOU SOUTHERN VALVE

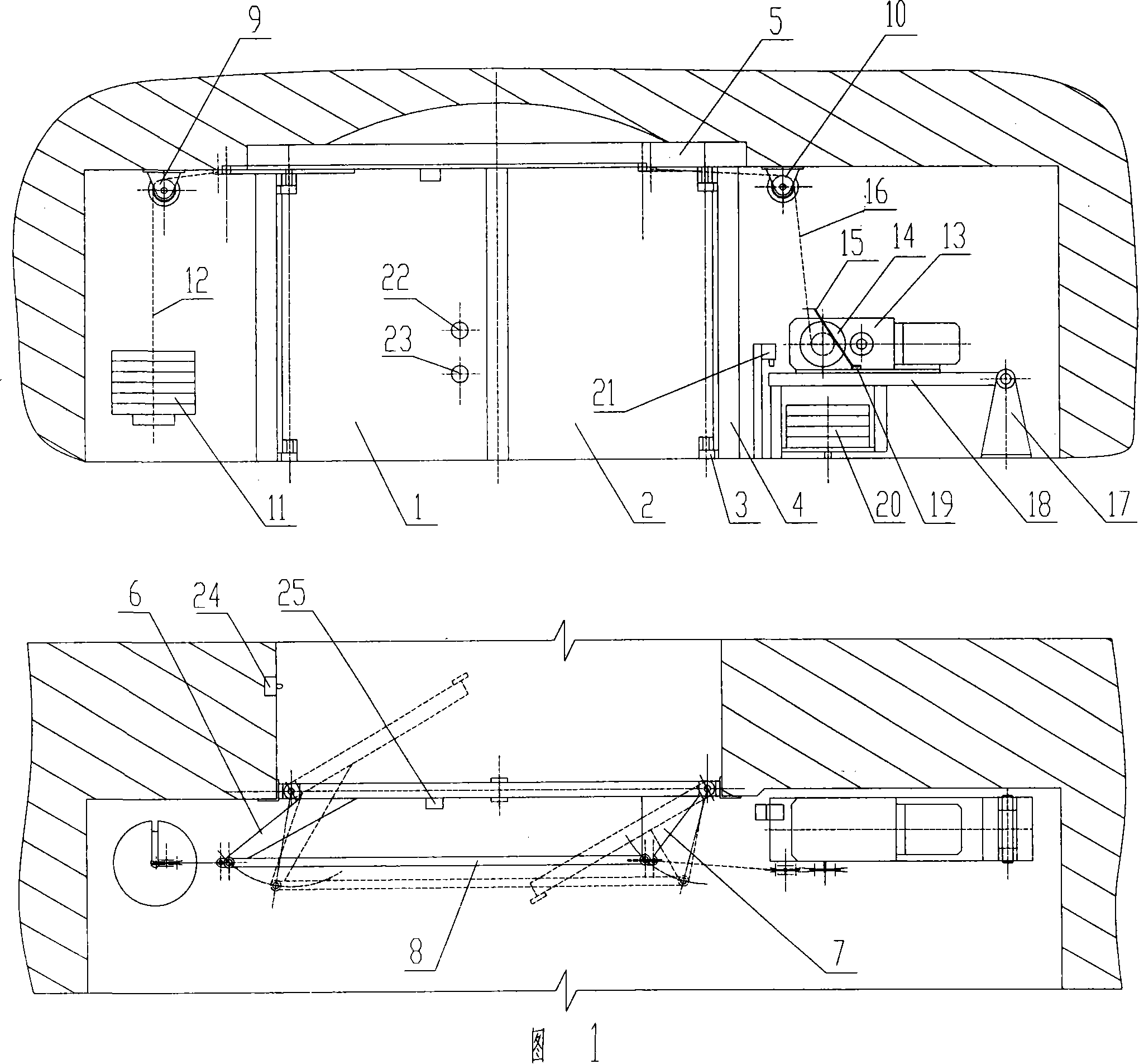

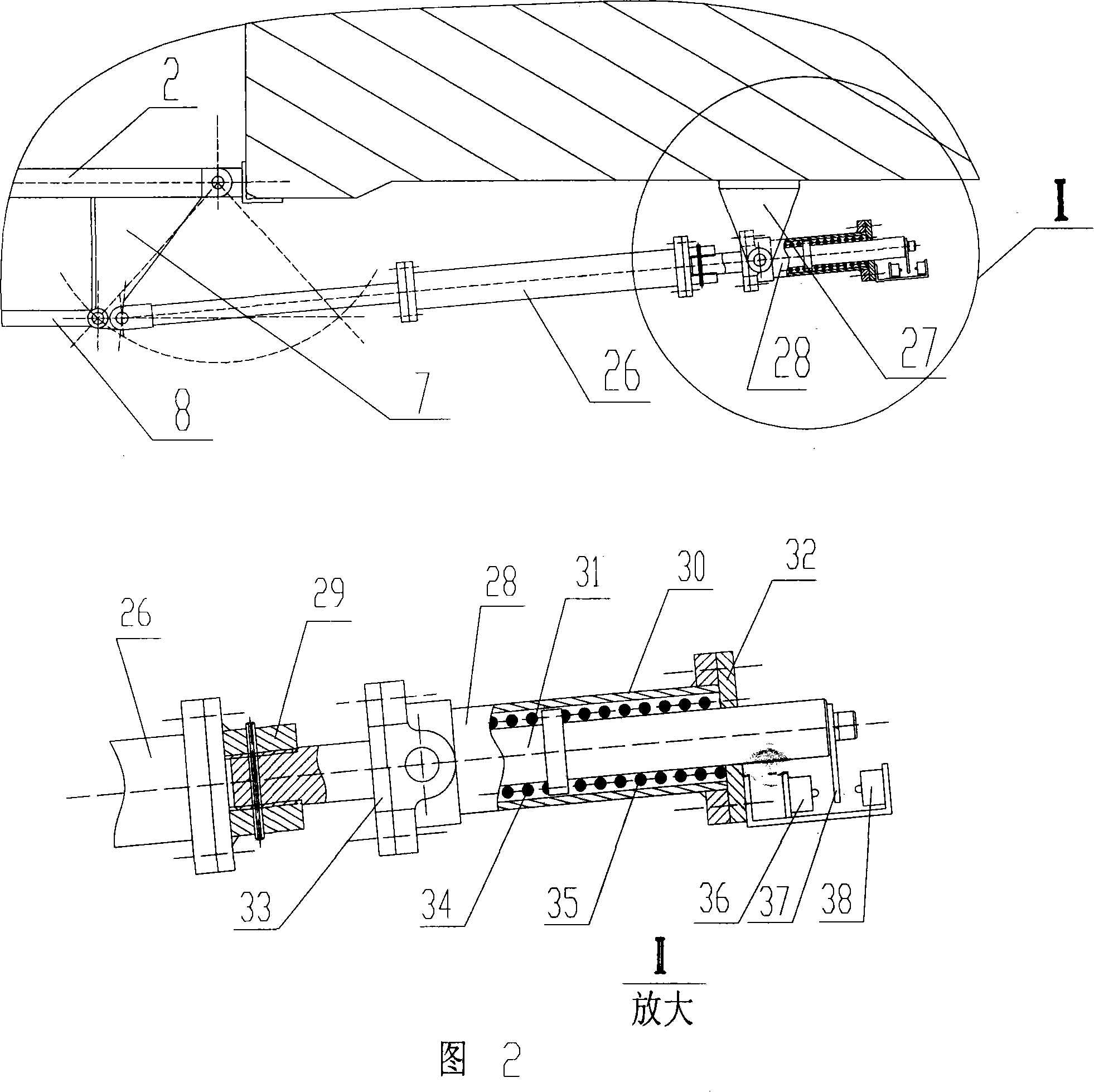

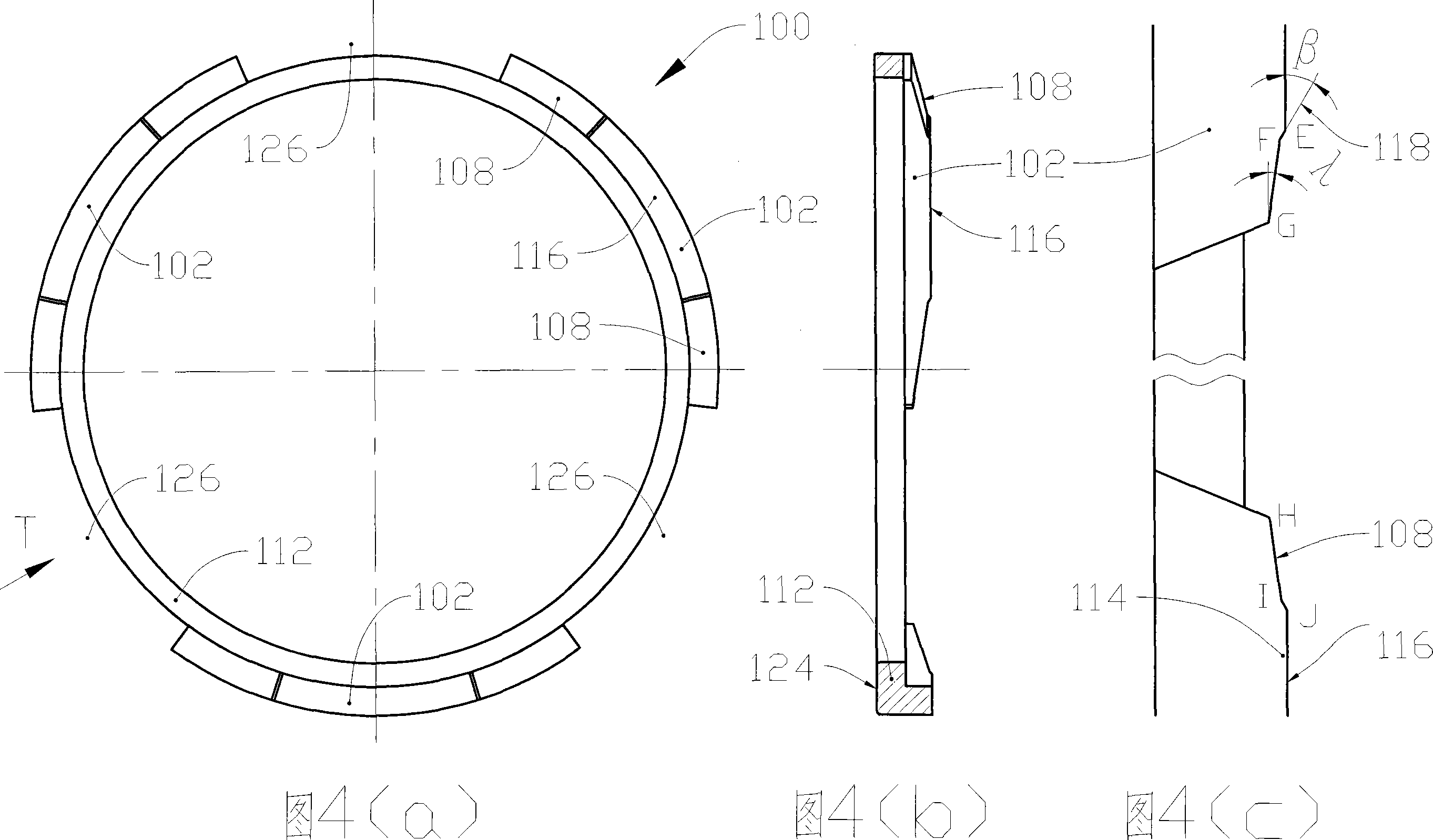

Wind motor vane propeller-changing device

InactiveCN101424249ARealize continuous pitch change without impactFlexible and convenient linear movementWind motor controlMachines/enginesPush and pullHydraulic cylinder

The invention provides a variable propeller device for a wind motor blade, which comprises a drive unit and a transmission gear which drives the blade to rotate, wherein the drive unit such as a hydraulic cylinder or a feed screw nut can generate linear propulsion to drive a push-and-pull rod in the transmission gear to perform linear movement; the push-and-pull rod drives a first flexible element and a second flexible element which are coated on the tail of the blade; and the first flexible element and the second flexible element drive the blade to rotate, so as to realize variable propeller. When the number of the blades of a wind motor is more than two, a linkage frame can be arranged between the drive unit and the push-and-pull rod of the transmission gear, and drives the transmission gear to perform linear movement, so as to realize synchronous variable propeller of various blades.

Owner:上海驰风机电科技有限公司

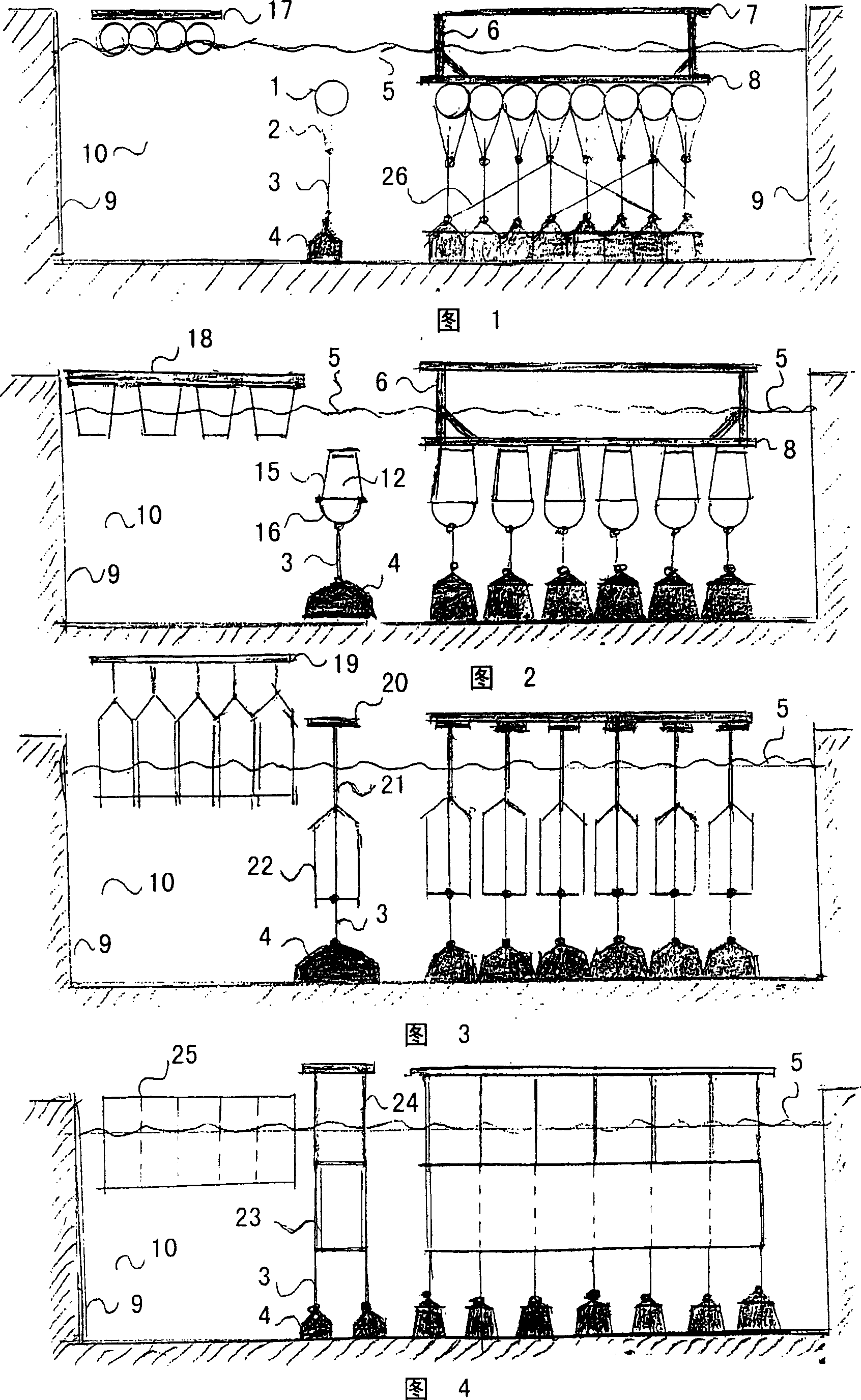

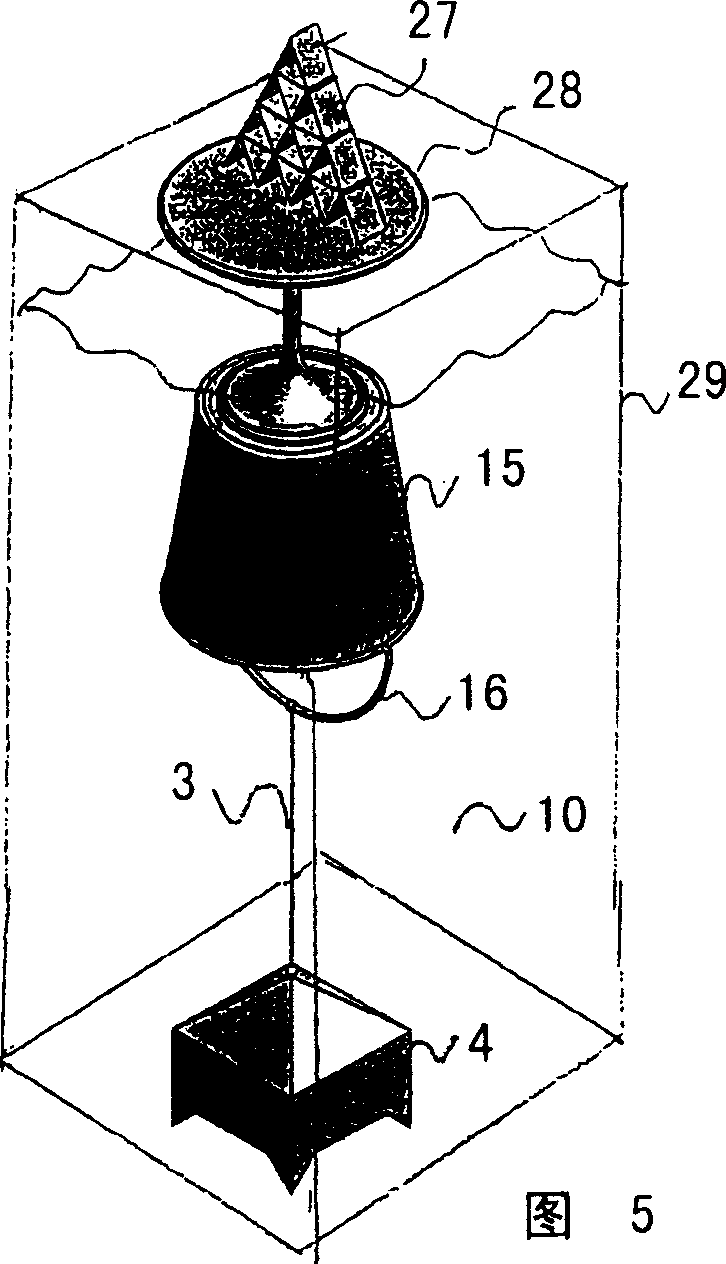

Fixed structure platform on water

InactiveCN101389527AEasy to manufactureEasy to assembleVessels for aircraftAnchorsComing outMarine engineering

The invention relates to a fixed platform which enables to locate on the water any fixed structure such as the house, garden, road, airport, car park, children's park and holiday village in the seas, lakes and rivers. Our invention comprises the platform (7) where the floats (22) thereof capable of floating are submerged up to a safe zone 3-5 m from the water (10) surface, the floats (22) spending energy to come out on the water surface (5) produce forces to try to maintain the platform (7) always at the same point owing to the tightness of the ropes (3) of the floats (22) and where said platform (7) is prevented from being drifted by the violent storms and huge waves and the currents in the sea, wherein the platform (7) which is manufactured in a manner suitable for its purpose comprises the weight (4) to the end of which the ropes (3) are connected, the connecting ropes (3) serving to maintain the floats (22) at a constant distance from the floor and in submerged state, the floats (22) producing the buoyancy carried over by the platform (7), the carrier columns (21) connecting the floats (22) with the platform (7) and the connecting pieces (20) that connect the columns (21) with the platform (7).

Owner:阿尔帕伊·英斯

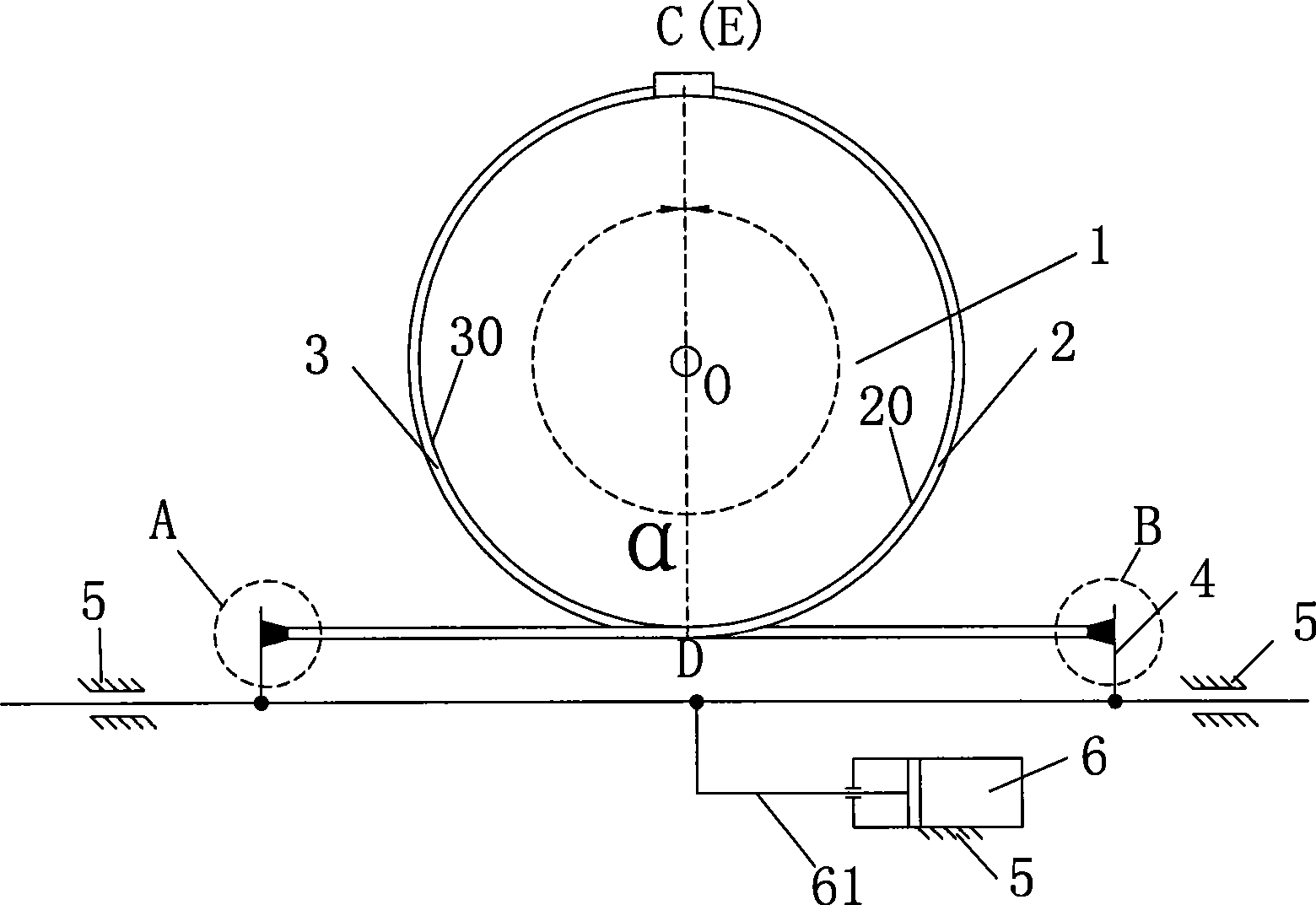

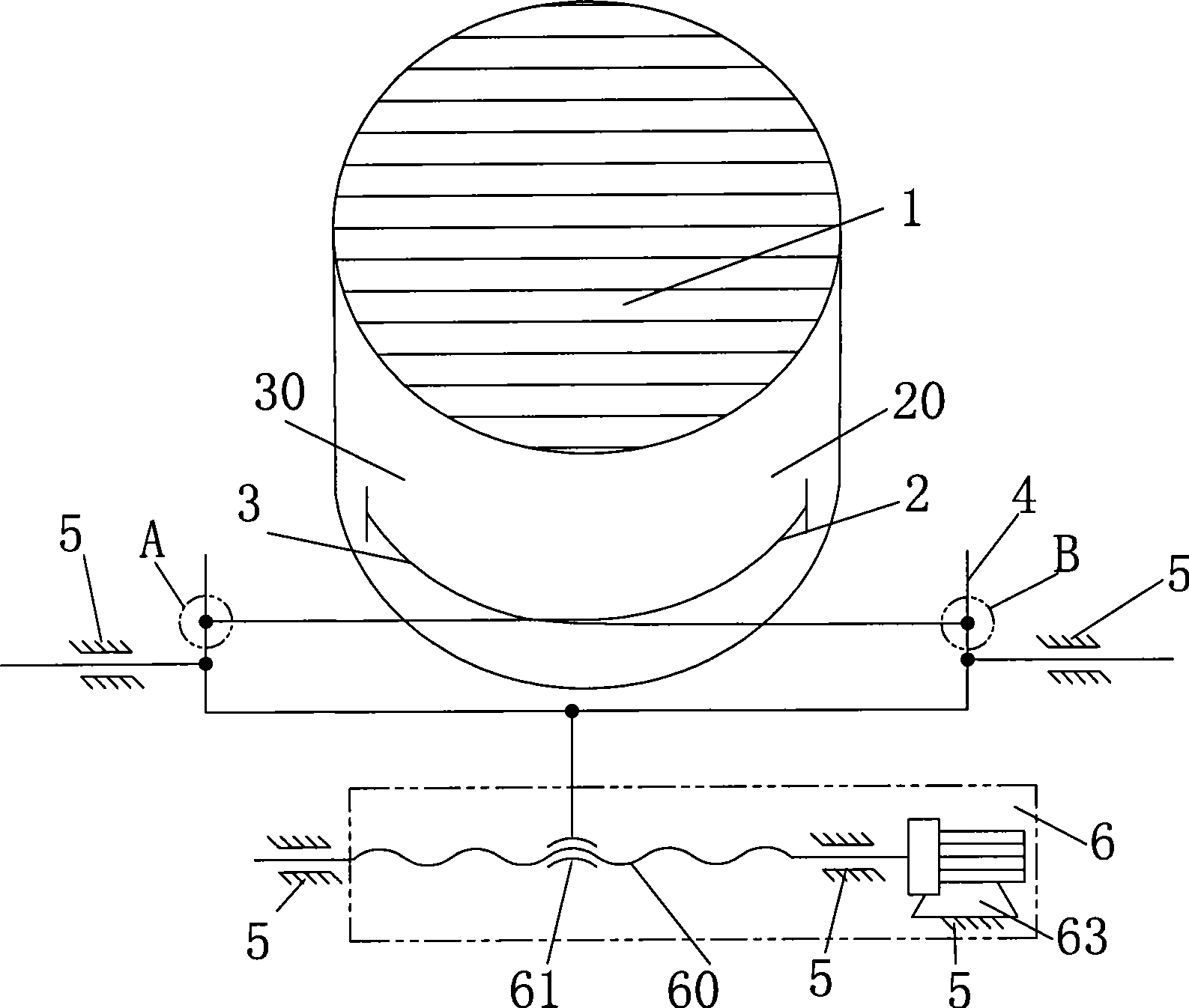

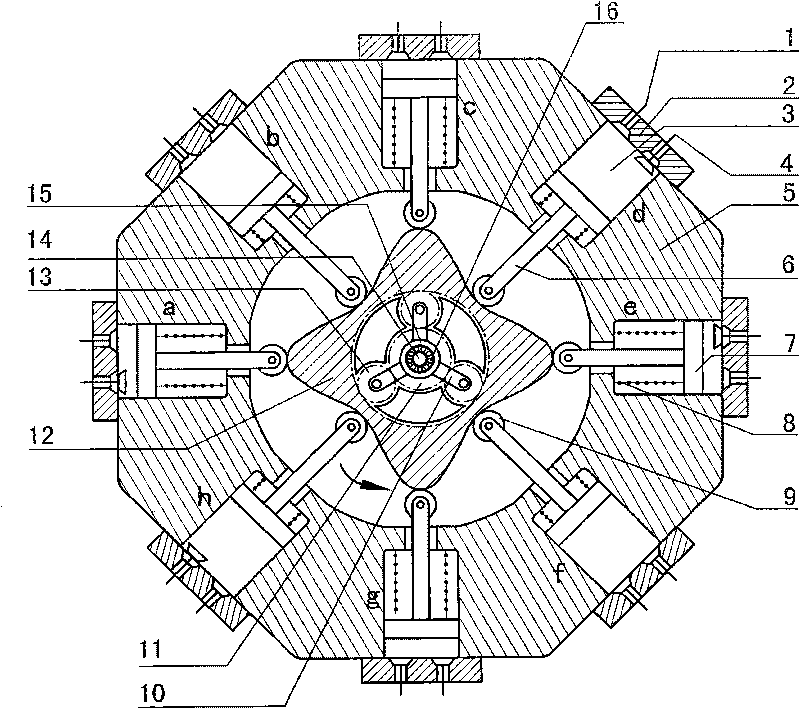

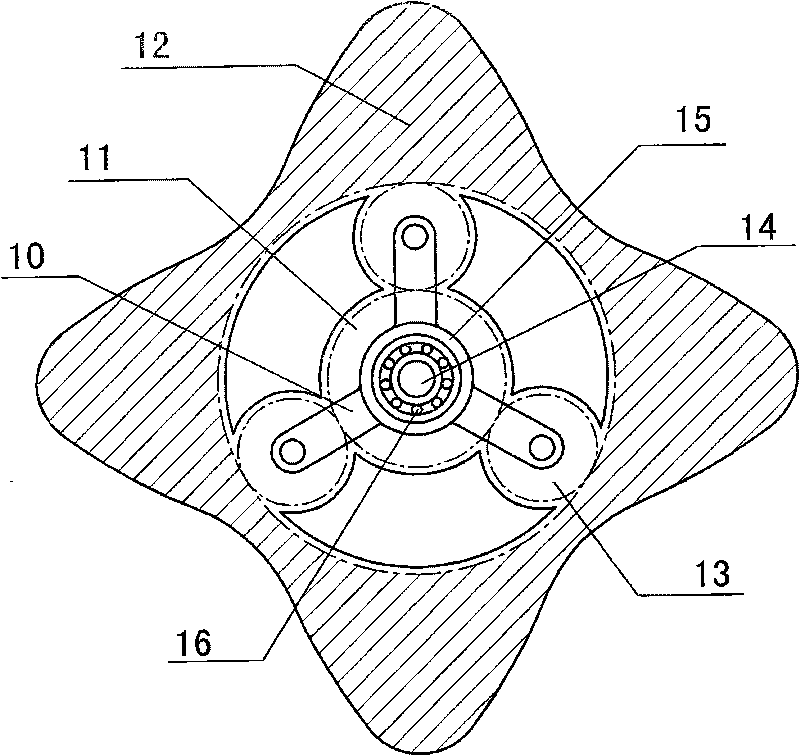

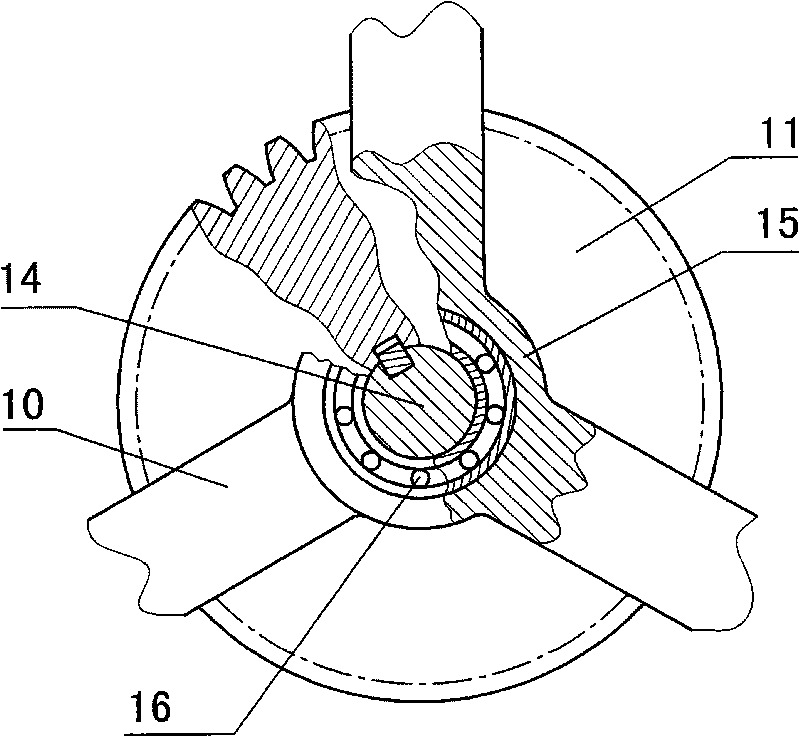

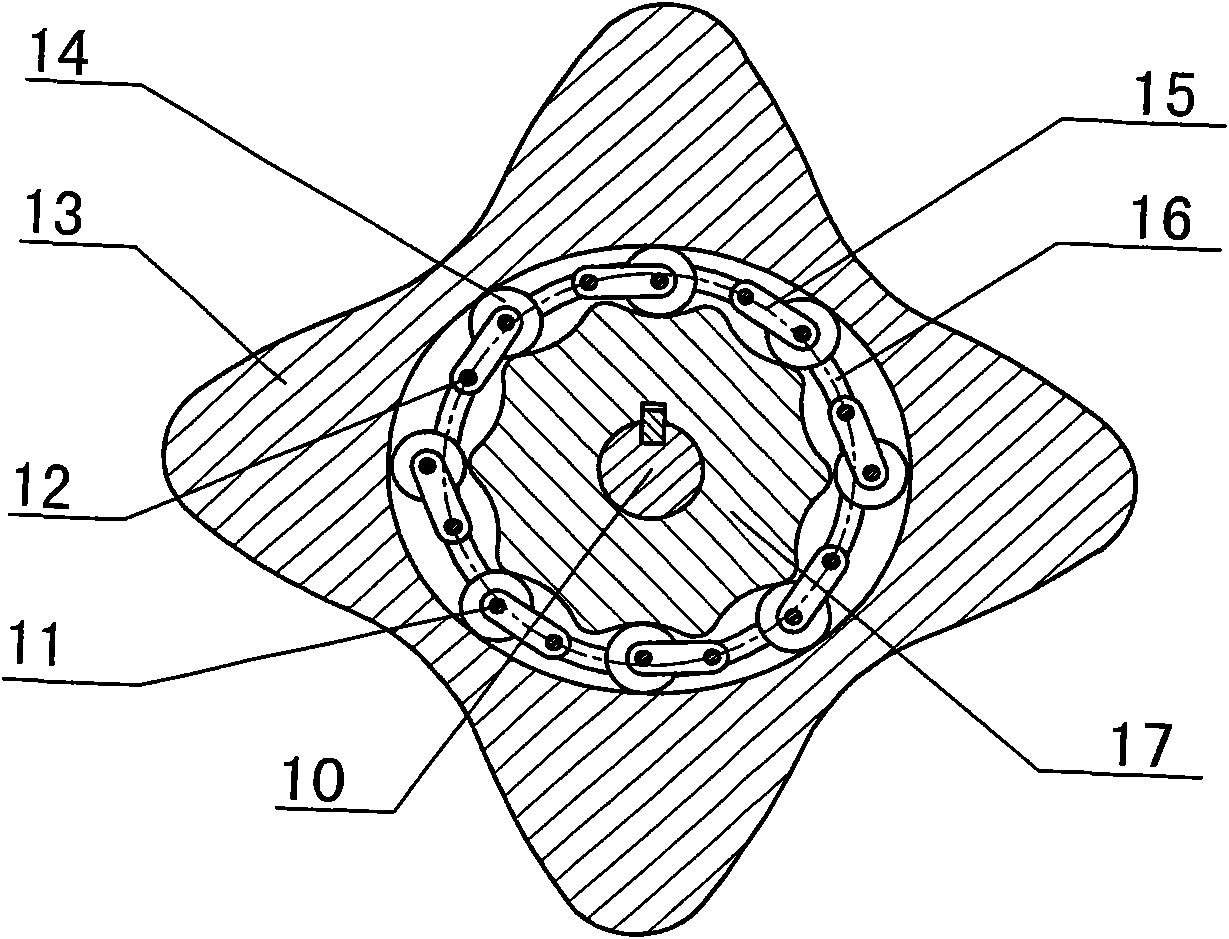

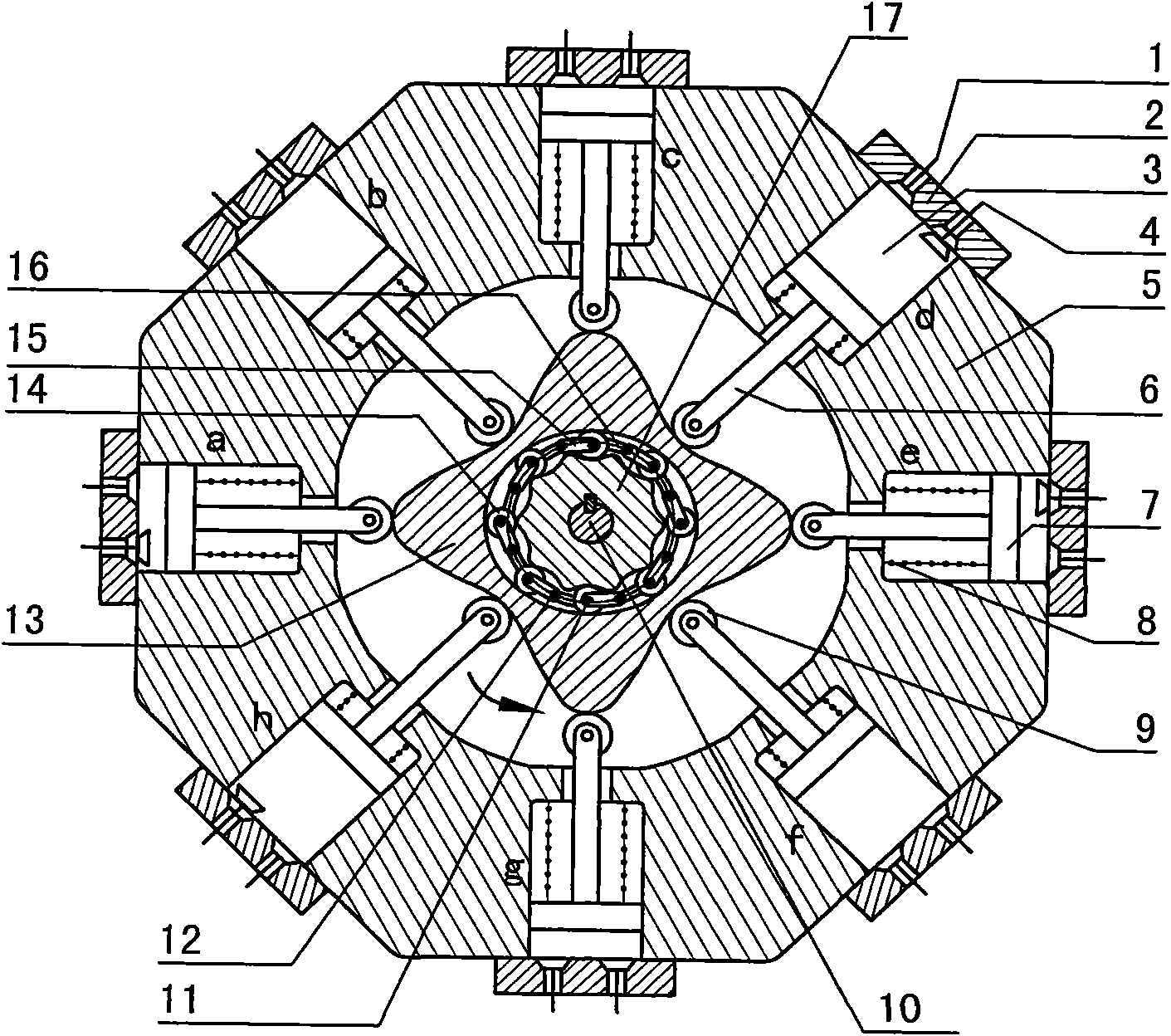

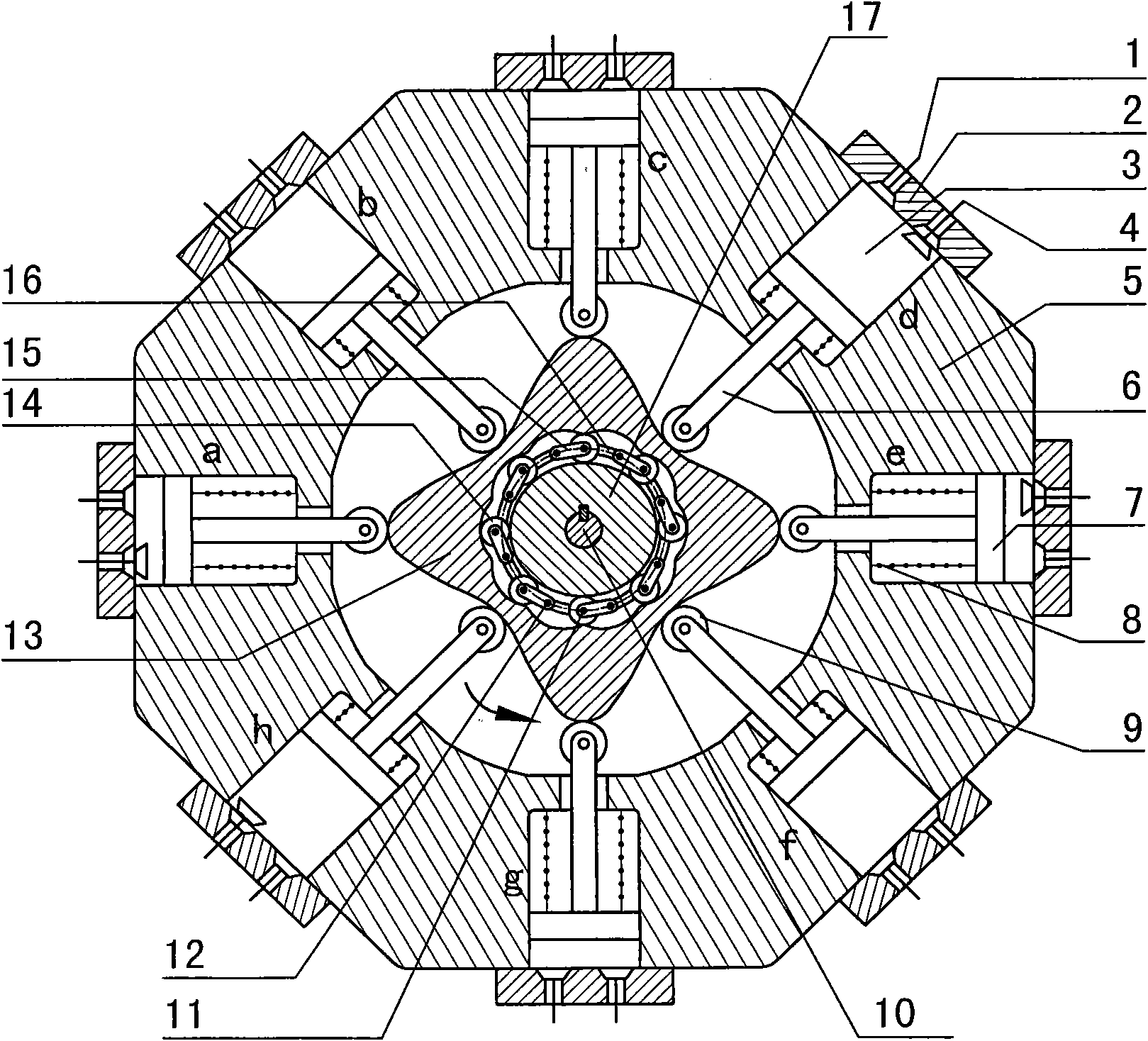

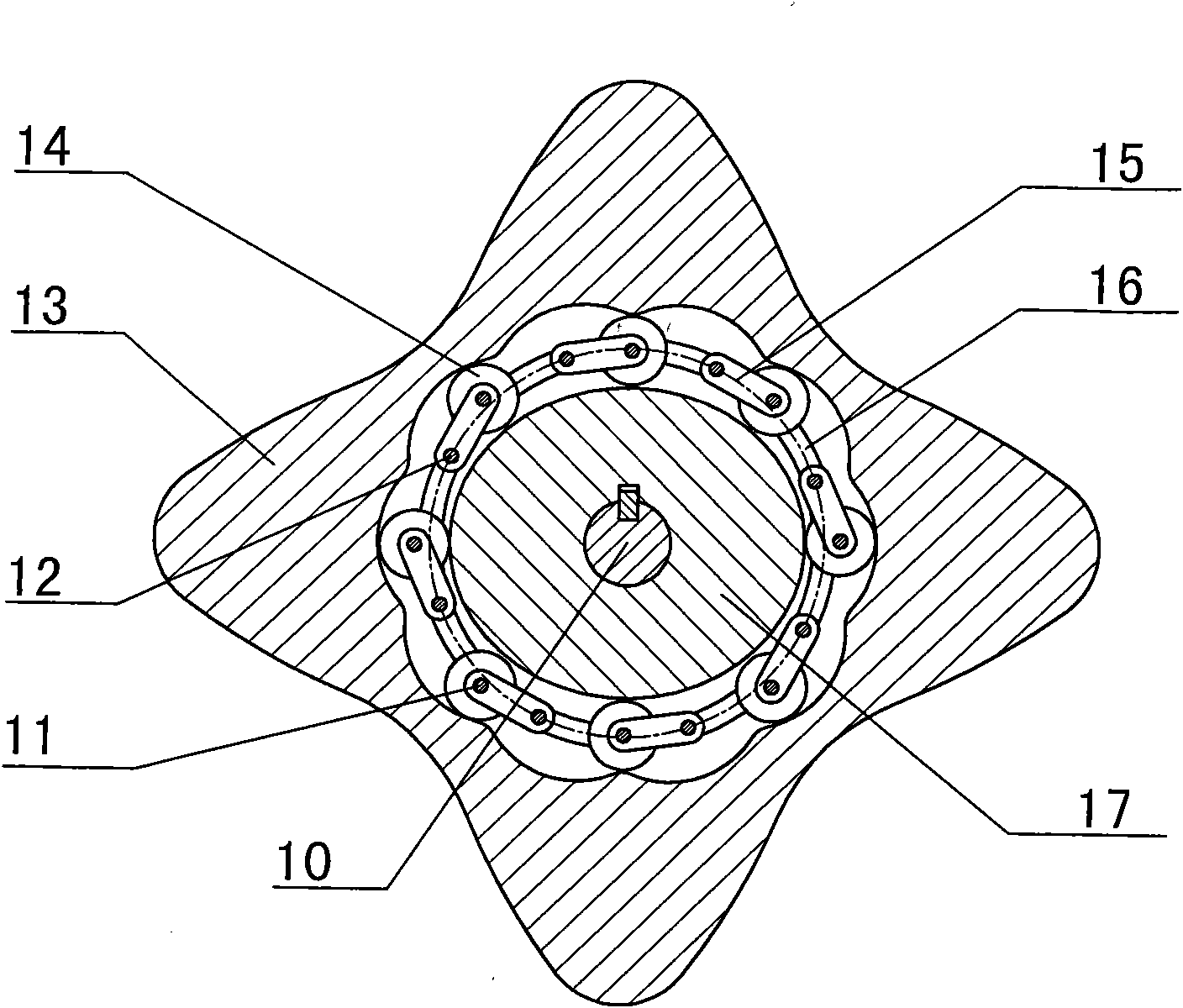

Crankshaft-free cam planetary transmission combustion engine

The invention discloses a crankshaft-free cam planetary transmission combustion engine, relating to the field of gas power and belonging to a multi-cylinder internal combustion engine. In the novel combustion engine, eight cylinders are evenly distributed around a cam sun wheel in a ring-shaped symmetrical way to lead the resultant force of the cam sun wheel to be zero, cylinder pistons act on the cam sun wheel through a push rod directly, the power is transmitted to an output shaft through planetary transmission by the cam sun wheel for outputting, and a sun wheel or a tie bar can be used as an outputting piece. The combustion engine saves a connecting rod and a crankshaft in the traditional combustion engine, each cylinder completes two work cycles each circle of the cam sun wheel; the rotation speed of the output shaft depends on the transmission ratio of the planetary transmission, when the sun wheel is fixed, the tie bar outputs with low speed and large torque, and can be widely applied to the fields such as engineering machinery; when the tie bar is fixed, the sun wheel outputs with high speed, and can be used as the power source of small generators and the like, and higher rotation speed can reduce the emission of harmful gas. The combustion engine has variable speed, simple and compact structure, small axial dimension, large power and stable operation.

Owner:SICHUAN UNIV

Vertical roller mill hydraulic system

ActiveCN101543797AQuick liftContact will notServomotorsGrain treatmentsHydraulic cylinderControl valves

The invention relates to a vertical roller mill hydraulic system, which comprises a plurality of grinding roll clamping hydraulic cylinders, a plurality of accumulator groups, a hydraulic station and connecting pipelines among the grinding roll clamping hydraulic cylinders, the accumulator groups and the hydraulic station, wherein the hydraulic station comprises an oil tank device, an oil pump device, a grinding roll clamping control valve group and connecting pipelines among the oil tank device, the oil pump device and the grinding roll clamping control valve group; a feedline of the oil pump device is connected with an inlet of the grinding roll clamping control valve group; an oil pump motor supplies oil for the grinding roll clamping control valve group; an outlet of the grinding roll clamping control valve group is connected with piston rod cavities of the grinding roll clamping hydraulic cylinders and the accumulator groups; rodless cavities of the grinding roll clamping hydraulic cylinders are connected with the grinding roll clamping control valve group through a plurality of oil return pipes; the grinding roll clamping control valve group controls the telescoping of piston rods of the grinding roll clamping hydraulic cylinders through a plurality of electromagnetic directional valves; and the accumulator groups absorb the vibration of the grinding roll clamping hydraulic cylinders respectively. The vertical roller mill hydraulic system solves the problem of loaded pressure boost of the system and improves the service life of grinding rolls and grinding discs and the maintenance efficiency.

Owner:BAOSTEEL ENG & TECH GRP

Front-and-back opening-closing split self-controllable power air door

InactiveCN101148991ASave powerEliminate shockTunnel/mines ventillationHydraulic cylinderControl power

The oppositely opened self-controlled powered double air door features two air doors interlinked through crank and link rod and opened or closed oppositely to counteract the acting forces mutually. It has lowered power for opening and closing the air door, no air flow impact, smooth running, no limit in the installation direction of air door and no need of altering the structure in changing the airflow direction. The air door may be driven with a winch or a hydraulic cylinder mechanism. The present invention has simple overall structure, sensitive protection, reliable running and favor to automatic control.

Owner:陈树林

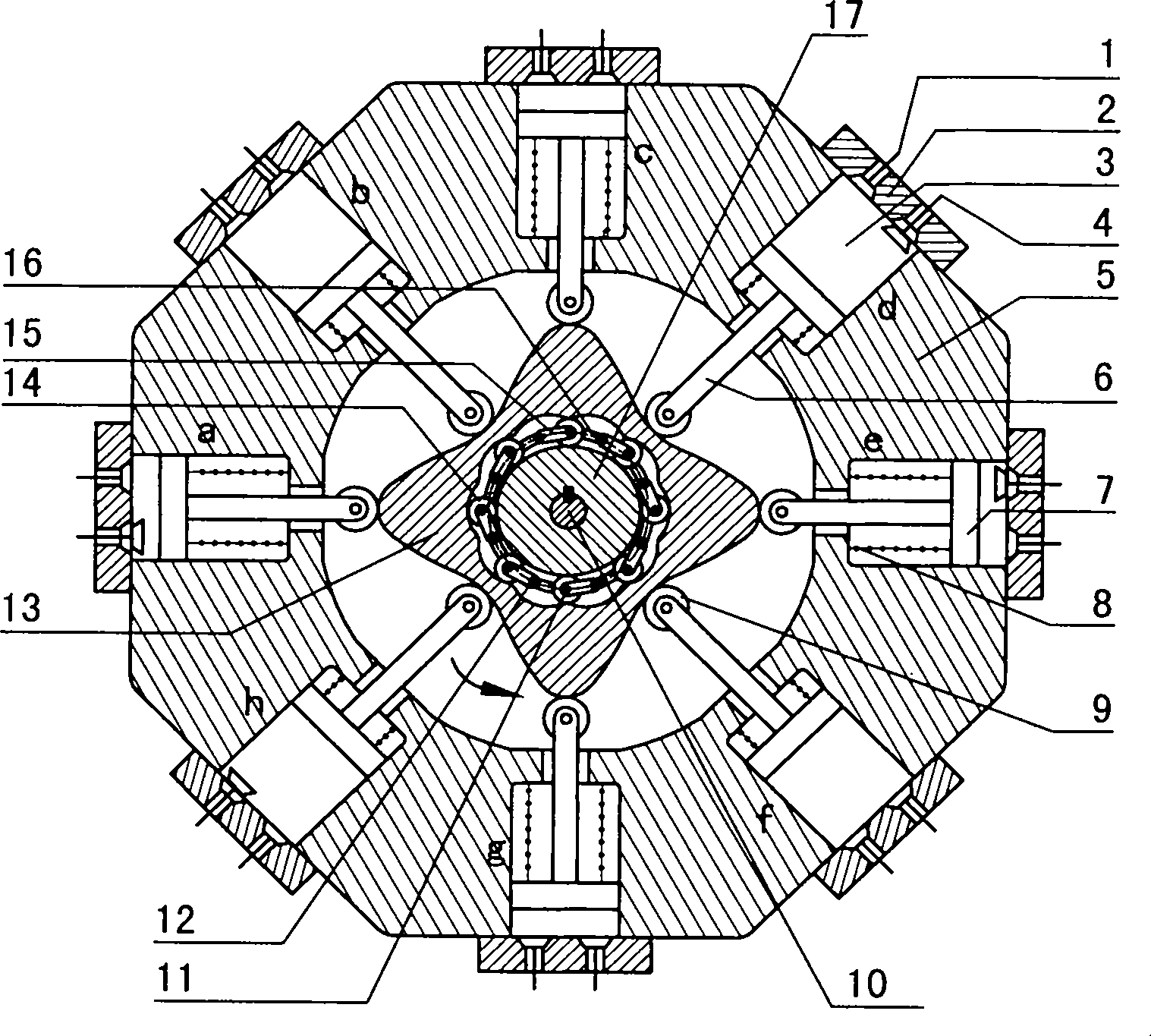

Internal dual-phase shockwave swing link transmission type internal combustion engine

InactiveCN101979853ACompact structureReduce axial sizeValve drivesMachines/enginesPistonResultant force

The invention discloses an internal dual-phase shockwave swing link transmission type internal combustion engine, relates to the field of gas power, and belongs to a multi-cylinder internal combustion engine. The invention provides a novel internal combustion engine, wherein eight cylinders are annularly, symmetrically and uniformly distributed around a convex internal dual-phase shockwave wheel, so that a resultant force stressed on the convex internal dual-phase shockwave wheel is zero; a cylinder piston directly acts on the convex internal dual-phase shockwave wheel through a push rod; and power is transferred to an output shaft which is connected with a wavelike wheel through keys from the convex internal dual-phase shockwave wheel through internal dual-phase shockwave swing link movable teeth. In the internal combustion engine, a connecting rod and a crank shaft in the conventional internal combustion engine are saved, and an external cam internal dual-phase shockwave swing link transmission mechanism of the conventional internal combustion engine does not have eccentric mass and has the advantage of self-balancing the inertial force and the working load. The rotation speed of the output shaft is determined by the transmission ratio of the transmission of the movable teeth; if a movable tooth frame is fixed, the wavelike wheel outputs low speed and large torque; and the internal combustion engine can be widely applied to the fields of military affaires and national defense needing high power, such as tanks, armored vehicles, engineering machinery and the like. The internal combustion engine has the advantages of simple and compact structure, small axial dimension and self-balanced stressing and operates stably.

Owner:SICHUAN UNIV

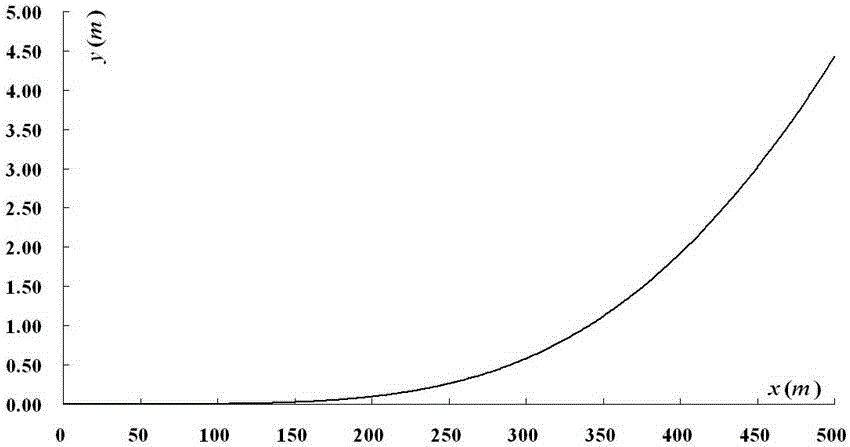

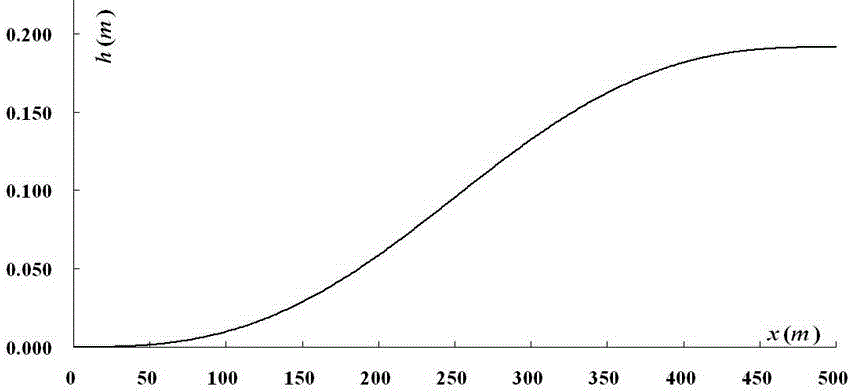

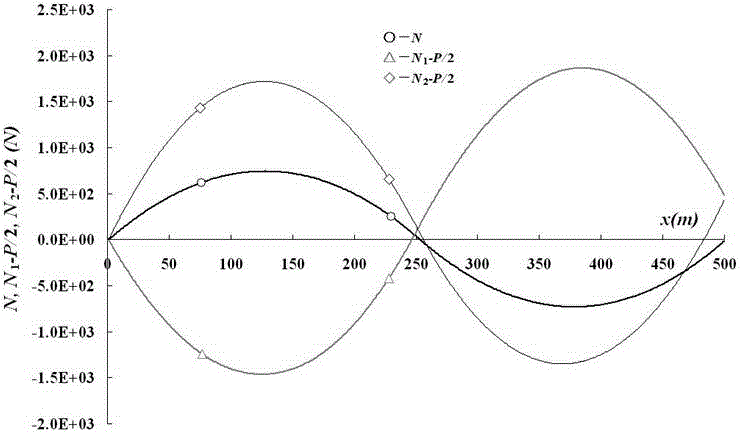

Railway curve line designing method based on "sextic two-segment transition curve"

InactiveCN104537141AImprove riding performanceEliminate vibration sourceRoadwaysSustainable transportationEngineeringCurve line

The present invention discloses a railway curve line designing method based on "sextic two-segment transition curve". The method is characterized in that a rail line of a railway is designed as the following equations: plane curve equation: y1 = 2L<2> / 15R [3(x / L)<5> - 2(x / L)<6>] [0, L / 2]; y2 = L<2> / 120R [32(x / L)<6> - 144(x / L)<5> + 240(x / L)<4> - 160(x / L)<3> + 60(x / L)<2> - 12(x / L) + 1] [L / 2, L] (1); facade ultra-high equation: h1 = 8H [(x / L)<3> - (x / L)<4>] [0, L / 2]; h2 = H [8(x / L)<4> - 24(x / L)<3> + 24(x / L)<2> - 8(x / L) + 1] [L / 2, L] (2); wherein a ZH point (a straight-spiral point) is used as the original point, the extension direction of a straight rail is used as the positive direction of the x axis, and one side of the curve is used as the positive direction of the y axis; L is the length of a transition curve; R is the radius of curvature of a circular curve; and H is the elevation of an outer rail of the circular curve in the design. Compared with existing traditional transition curves in our country, the present invention provides a curve with a higher curve continuous order, greatly improves the smoothness of the curve segment of the railway, and eliminates serious vibration source caused by unsmooth geometry of the curve segment of railway, and avoids impact between the rail of the transition curve segment and trains.

Owner:ZHOUKOU NORMAL UNIV

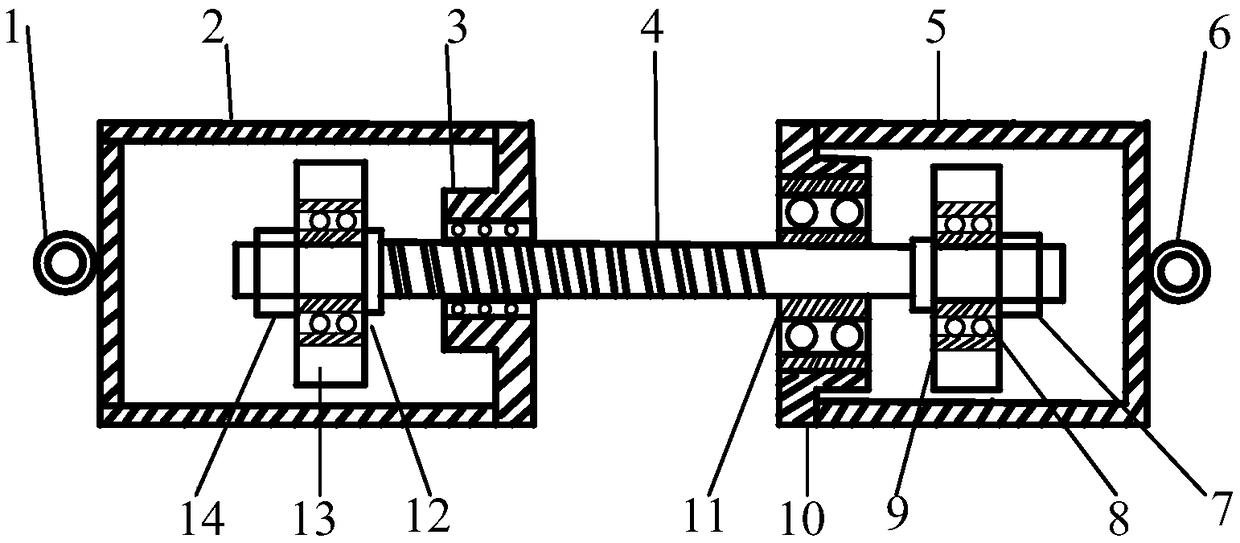

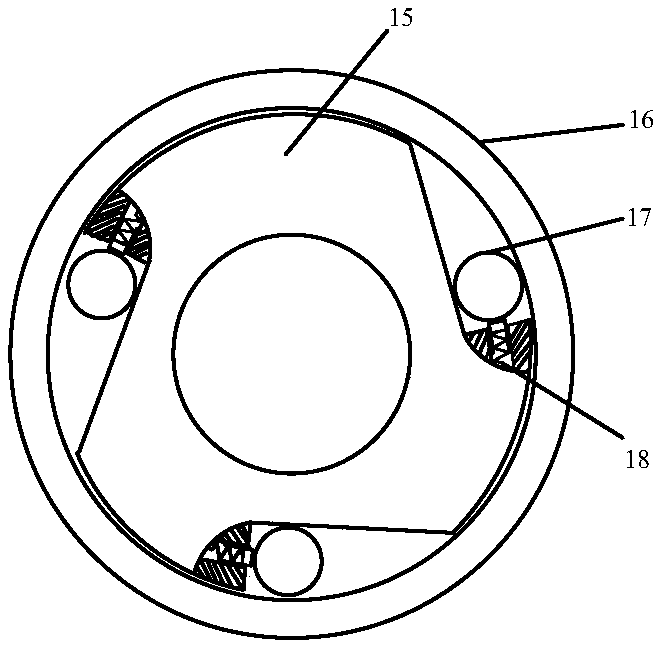

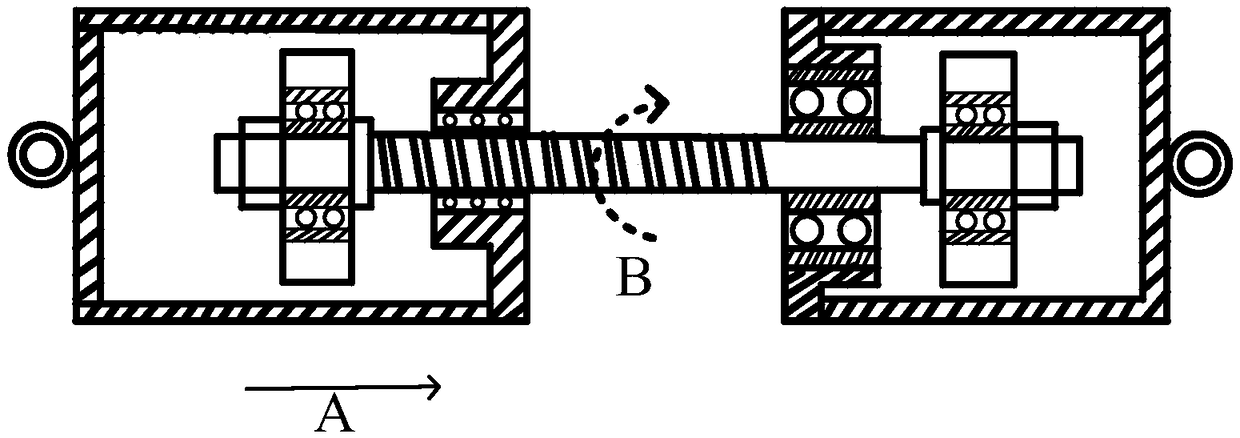

Stable-switching ball screw type inerter device

ActiveCN109253210AAchieve the desired effectReduce nonlinear factorsRotating vibration suppressionResilient suspensionsBall screwFlywheel

The invention provides a stable-switching ball screw type inerter device. The stable-switching ball screw type inerter device comprises a first mounting part, a second mounting part, a first cylinderbarrel, a second cylinder barrel, a screw nut, a screw, a flywheel A, a flywheel B, a one-way clutch A and a one-way clutch B and is characterized in that the screw is mounted between the first cylinder barrel and the second cylinder barrel in a penetrating manner, one end of the screw is rotatably mounted in the first cylinder barrel, and the other end of the screw penetrates the screw nut fixedly mounted on the second cylinder barrel and is coordinated with the screw; the first mounting part is mounted at the left end of the first cylinder barrel, and the second mounting part is fixedly mounted at the right end of the second cylinder barrel; when the motion direction of the nut instantly changes, only one of the two flywheels synchronously rotates along with the screw, flywheel impact, caused by rotation direction change, on the screw during switching is avoided effectively, stable switching is achieved, influence of nonlinear factors is small, and the performance of the inerter device is improved effectively.

Owner:JIANGSU UNIV

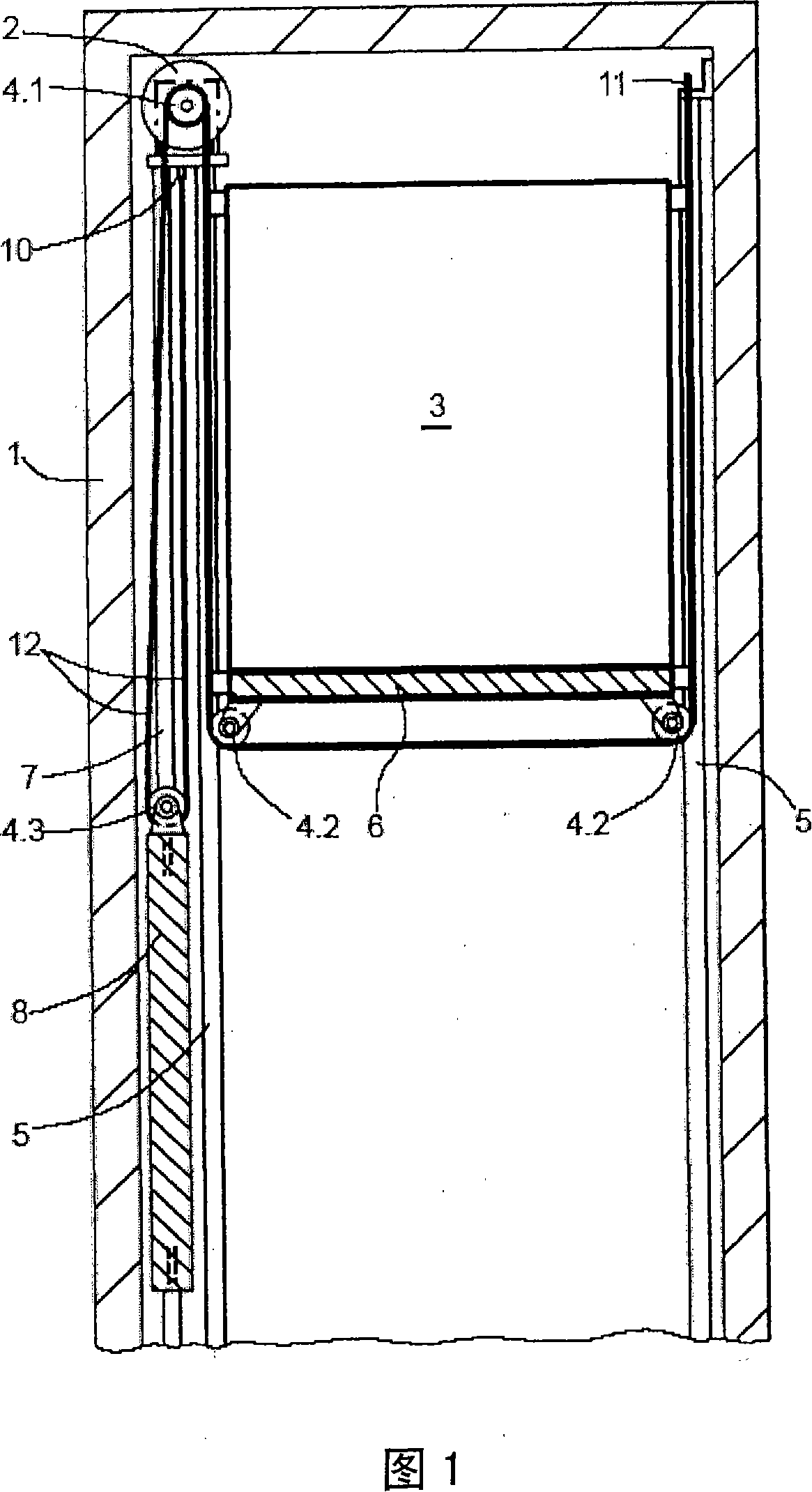

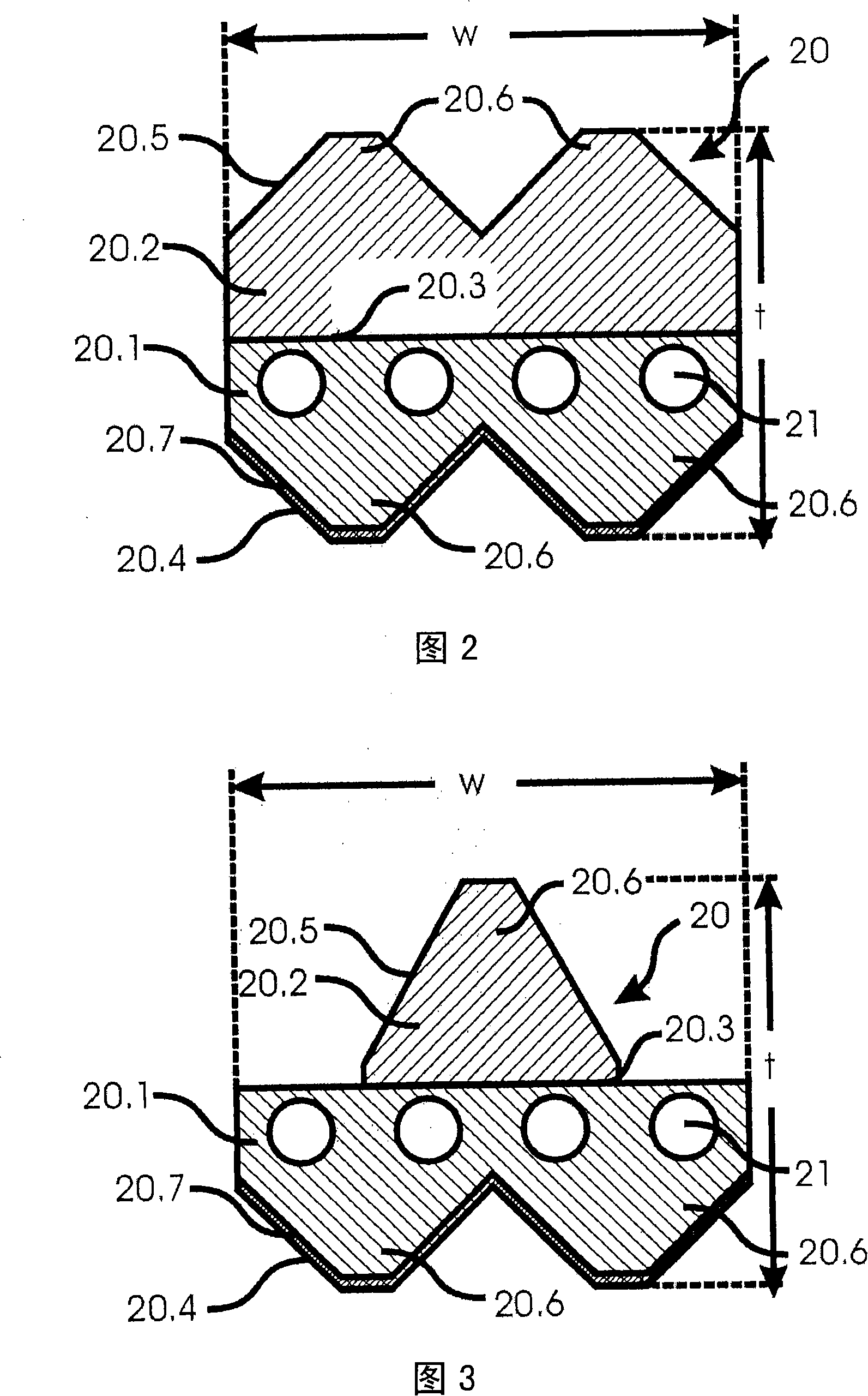

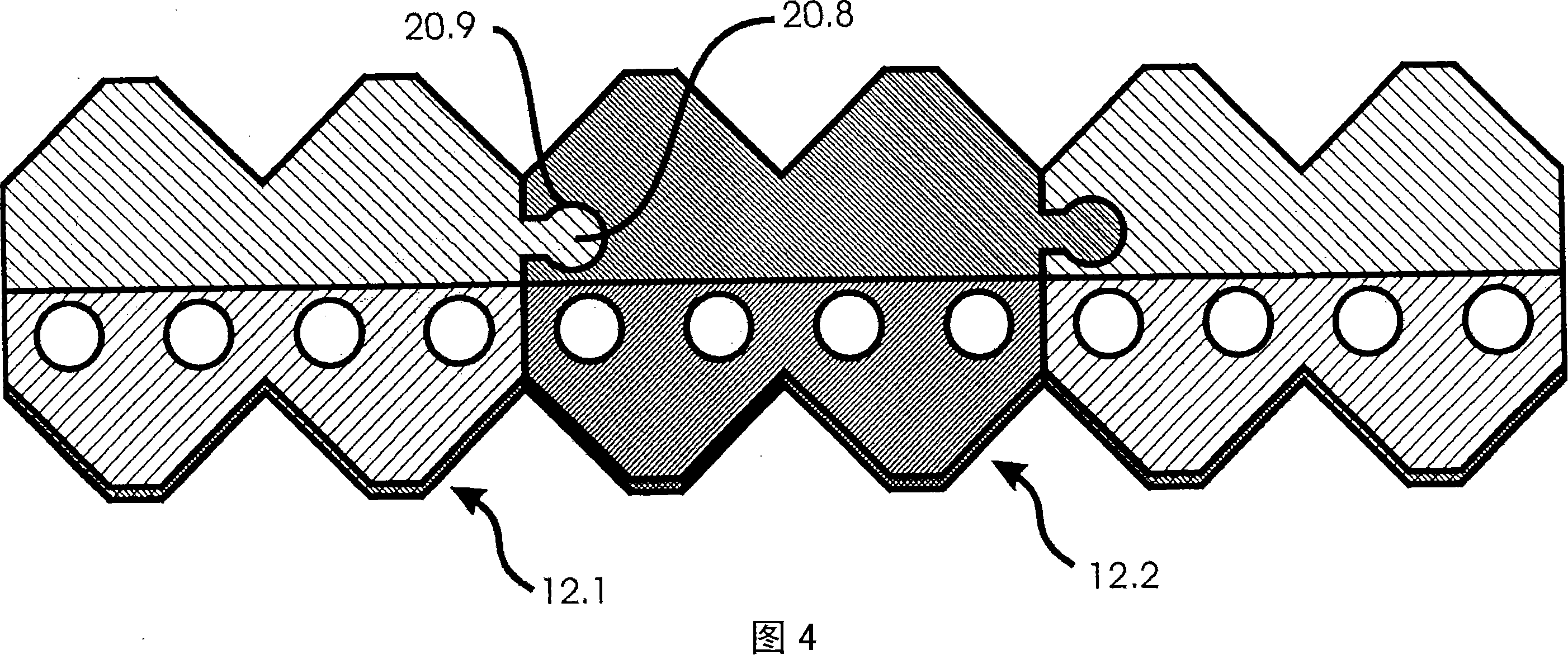

Lift facility, belt for such a lift facility, method for manufacturing such a belt, combination of such a belt and method for assembling such a combination in a lift facility

InactiveCN101121487AReduced risk of getting stuckLarge geometric moment of inertiaElevatorsBeltsEngineeringMechanical engineering

Owner:INVENTIO AG

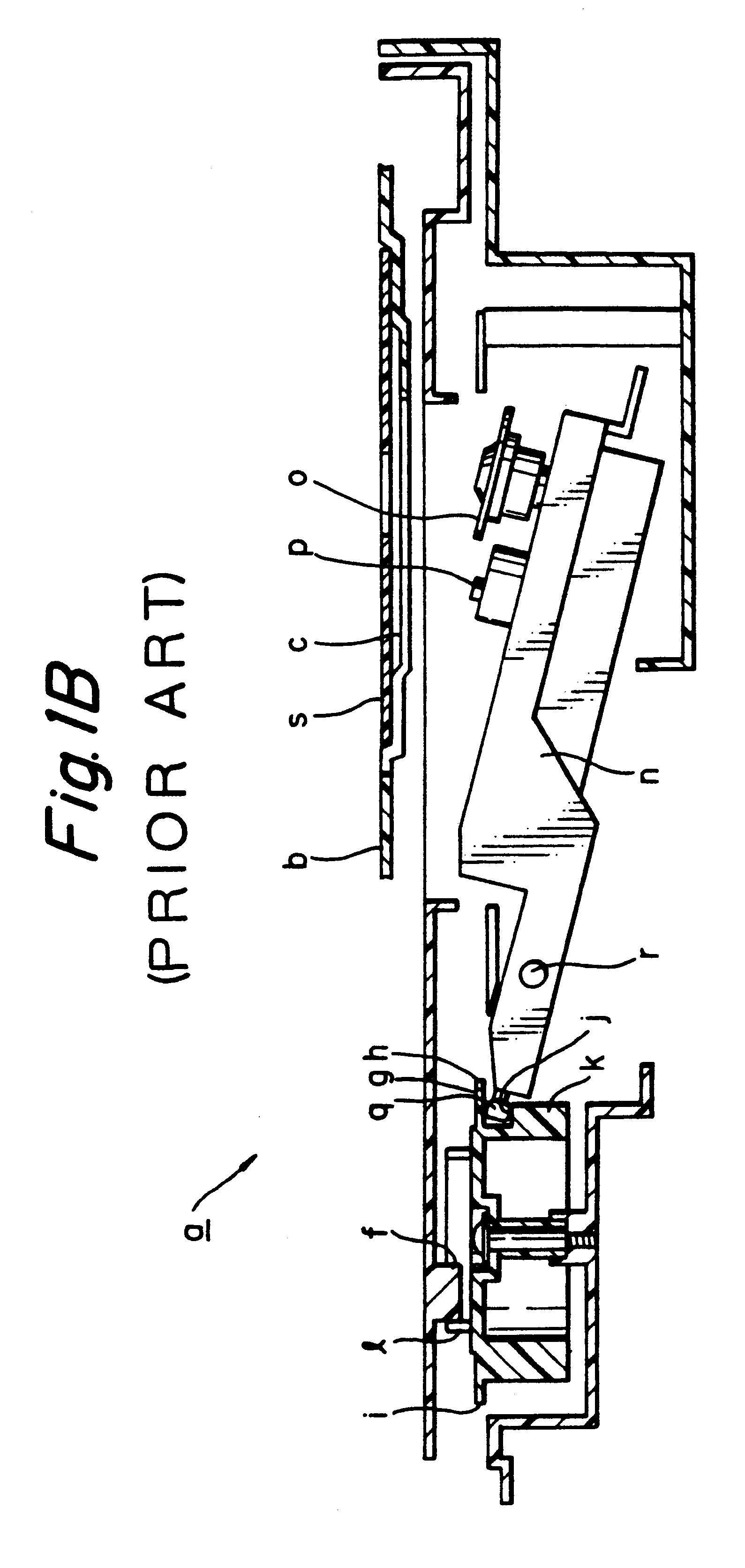

Disc loading mechanism in a disc player for positioning a disc and an optical pickup while reducing mechanical shocks to the disc tray

InactiveUSRE37170E1Easy loadingEliminate crashApparatus modification to store record carriersUndesired vibrations/sounds insulation/absorptionCompact discOptical pickup

A loading mechanism of a disc tray onto which recording medium discs such as compact discs, laser discs, or the like are set and which moves between a pull-out position at which the disc tray was pulled out of an outer casing and a pull-in position at which the disc tray was pulled into the outer casing. The engagement between the loading gear and the rack of the disc tray is released just before the pull-in operation of the disc tray is completed and, at the same time, a cam portion formed on the loading gear comes into engagement with the abutted portion of the disc tray, thereby allowing the disc tray to be subsequently pulled in by the pressing motion of the cam portion to the abutted portion. Thus, the pull-in speed of the disc tray can be reduced just before the completion of the pull-in operation of the disc tray and a shock which occurs upon completion of the pull-in operation of the disc tray can be reduced. Due to this, a shock sound by the collision of the disc tray and the member on the casing side for restricting the pull-in position of the disc tray and the shock to the disc player by such a collision are eliminated, thereby raising the quality of the disc player.

Owner:SONY CORP

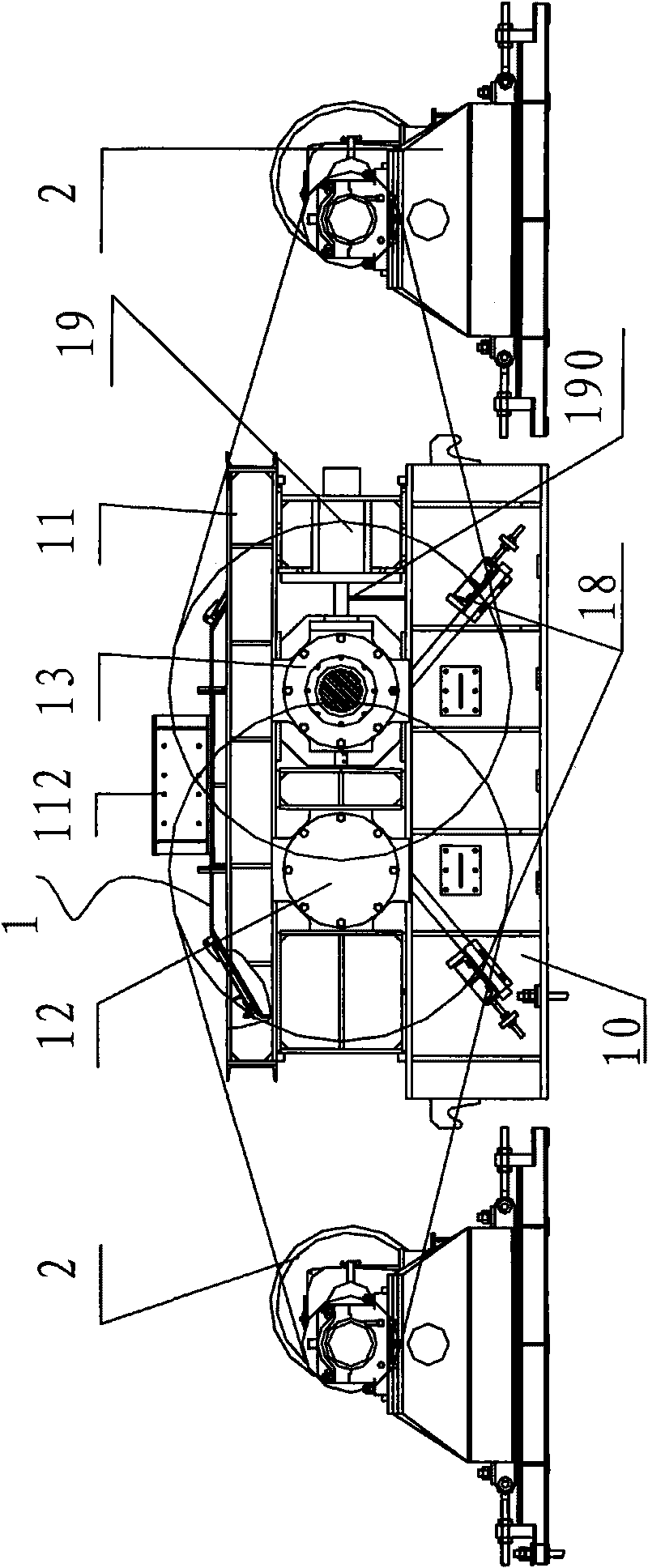

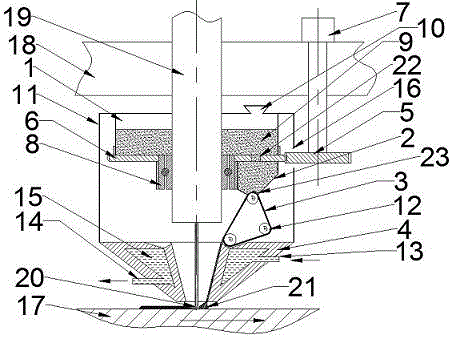

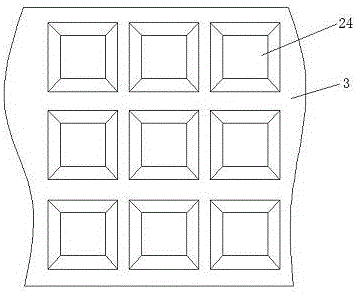

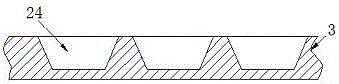

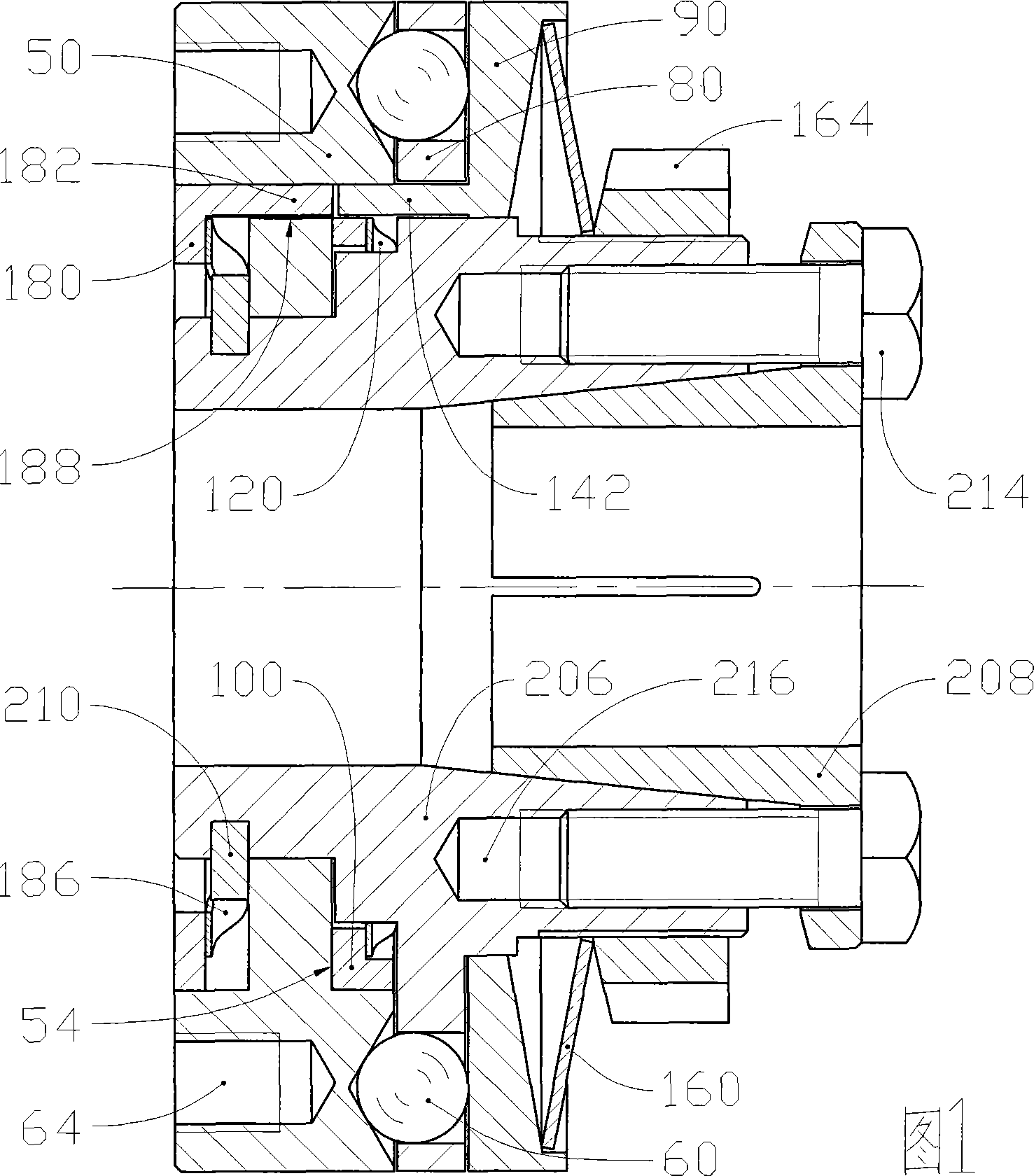

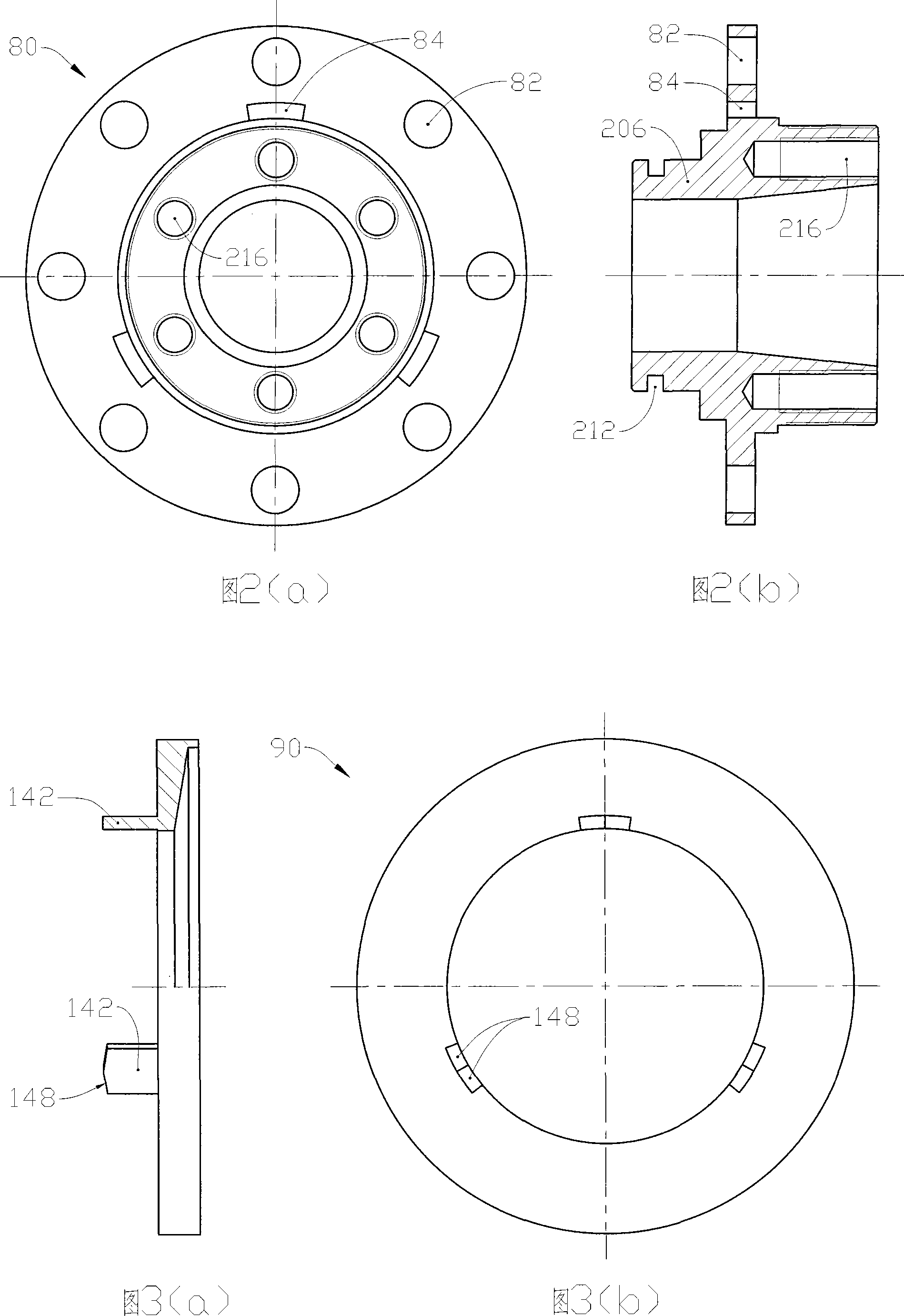

Synchronous powder spreading type metal laser 3D printing powder feeding device

ActiveCN106694883AReduce flow velocityReduce shockAdditive manufacturing apparatusIncreasing energy efficiencyElectric machinerySynchronous motor

A synchronous powder spreading type metal laser 3D printing powder feeding device comprises a powder storage bin (1), a powder feeding bin (2), a powder feeding belt (3), a powder spreading head (4), a driving transmission gear (5), a driven transmission gear (6), a driving motor (7), a cross beam (18), a cladding head (19) and a shell (11). The powder feeding bin is fixed to the cladding head through a rolling bearing and rotates freely. A transmission gear is installed on the upper portion of the powder feeding bin and meshes with the other transmission gear to form a transmission gear pair, and preset movement is achieved under driving of the motor. The powder storage bin stays still but keeps sliding relative to the powder feeding bin. Powder enters the powder feeding belt from a bottom outlet of the powder feeding bin, is fed to the powder spreading head under driving of a driving wheel and is evenly spread on a base plate under the action of gravity to form a powder layer. The powder spreading head and the shell are together fixed to the cladding head. The powder feeding bin and the cladding head move coordinately through procedure setting, the effect that the powder layer is always directly in front of a laser spot is ensured, and circulating water is adopted for cooling in the powder spreading head.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

Zero-impact spring steel ball safety clutch

The present invention discloses a no-collision spring steel ball safety clutch, which has the characteristics of no overload impact or no collision, high rotating speed, simplicity and reliability, easy manufacture, and long service life. The present invention is characterized in that the no-collision spring steel ball safety clutch is provided with a blocking embedding mechanism preventing a steel ball embedding mechanism from being embedded under the overload condition, the mechanism on the axial direction is positioned in the steel ball embedding mechanism, and the mechanism on the radial direction is positioned in the steel ball embedding mechanism or outside the steel ball embedding mechanism; a lift angle of both sides blocking the working surface is formed to enough ensure the friction self-locking collided on the both sides and the stability of the blocking operating condition, in order that the lift angle has the capabilities that the adaptive axle base is changed and the abrasion is automatically compensated; no collision characteristic of the overrunning operating condition of the two embedding mechanisms, and the separating block of the blocking embedding mechanism and the absolute reliability of the embedding return process are maintained for a long time. After the overload separation, the positive rotation or negative rotation which is simple and convenient can evenly realize the embedment replacement of the clutch automatically.

Owner:洪涛

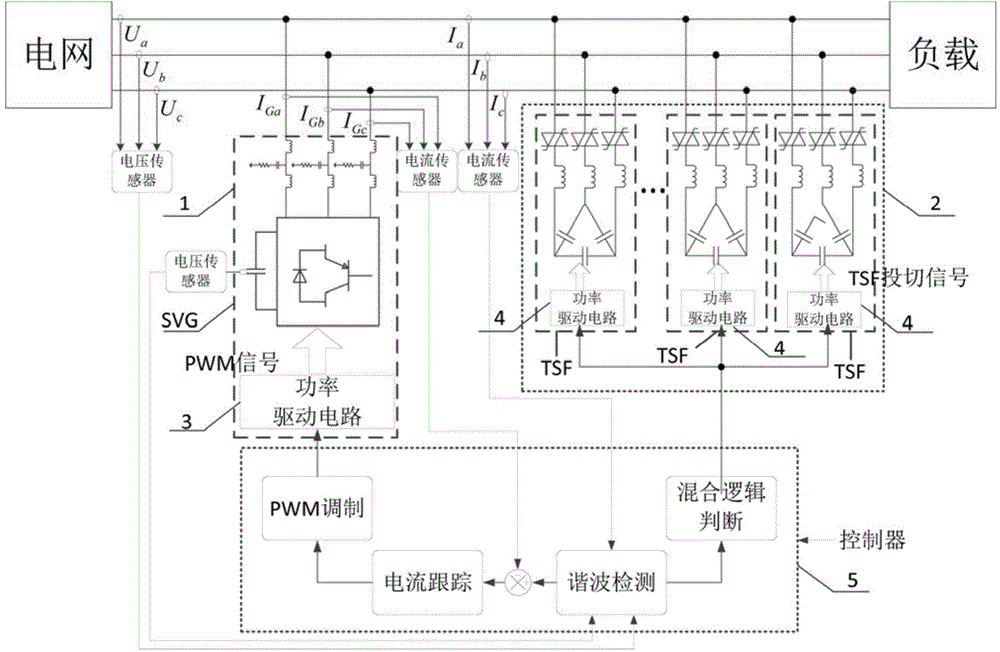

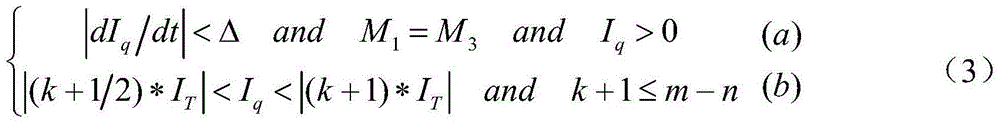

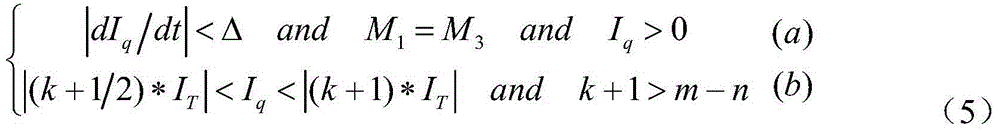

Control method for high-power reactive and harmonic dynamic hybrid compensation system

ActiveCN104362631AImprove robustnessHigh control precisionReactive power adjustment/elimination/compensationReactive power compensationEnvironmental resistanceHybrid logic

The invention discloses a control method for high-power reactive and harmonic dynamic hybrid compensation method. The hybrid compensation system comprises an SVG (static var generator), a TSF (thyristor switched filter) group and a controller, and the SVG and TSFs are parallelly connected to a grid. The three-phase current of the grid between the SVG and the TSFs is taken as a detection object, voltage and current values collected by sensors are processed through the controller, switching signals of the TSFs are acquired according to hybrid logic judgment, most of the reactive power of loads is compensated in a graded manner, and specific subharmonic is filtered out; control parameters of the SVG are acquired according to an instantaneous-power theory, and the surplus reactive power and harmonic of the loads are continuously compensated. A cost-effective scheme for rapid continuous compensation of the high-power reactive and harmonic is provided, impact of switching of passive equipment on the grid can be completely avoided, and harmonic current is avoided flowing to the grid, so that the control method is energy saving, emission reducing, green, environment friendly, good in social and economical effectiveness, wide in application range and especially applicable to the field of oil drilling.

Owner:江苏辰午节能科技股份有限公司

Double-phase shock wave swing rod type high-speed internal combustion engine

InactiveCN102094710ASmall shock and vibrationReduce noiseValve drivesMachines/enginesShock waveDouble phase

The invention discloses a double-phase shock wave swing rod type high-speed internal combustion engine, and relates to the field of fuel gas power. The invention provides a novel internal combustion engine, wherein eight cylinders are annularly, symmetrically and uniformly distributed around a convex inner central wheel, so that the resultant force borne by the convex inner central wheel is zero; cylinder pistons directly act on the convex inner central wheel through push rods; and the power is transmitted to an output shaft connected with a double-phase shock wave wheel key from the convex inner central wheel through a movable tooth transmission of a double-phase shock wave swing rod. In the internal combustion engine, a connecting rod and a crankshaft in the traditional internal combustion engine are omitted; and a double-phase shock wave swing rod transmission mechanism in the convex wheel has no eccentric mass and has the advantage of automatic balance of inertia force and working load. The revolution speed of the output shaft depends on the transmission rate of the movable tooth transmission; if a movable tooth rack is fixed, the double-phase shock wave wheel outputs power at a high speed; the internal combustion engine can be widely applied to the fields in need of high revolution speed, such as small generators, helicopter engines and the like; and when the output revolution speed is regular, the emission of harmful gases can be reduced. The internal combustion engine has the advantages of simple and compact structure, small axial size, automatic stress balance and stability in operation.

Owner:SICHUAN UNIV

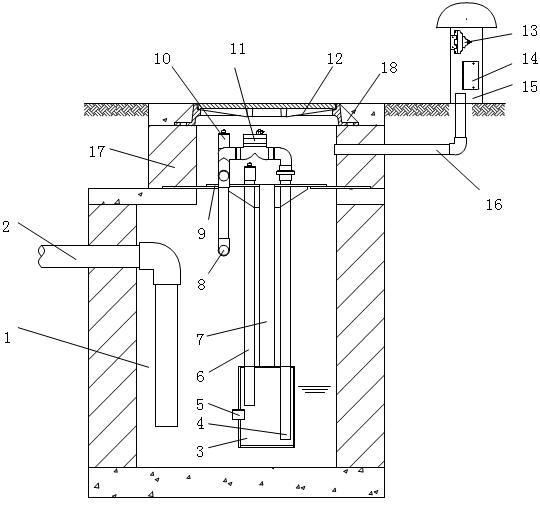

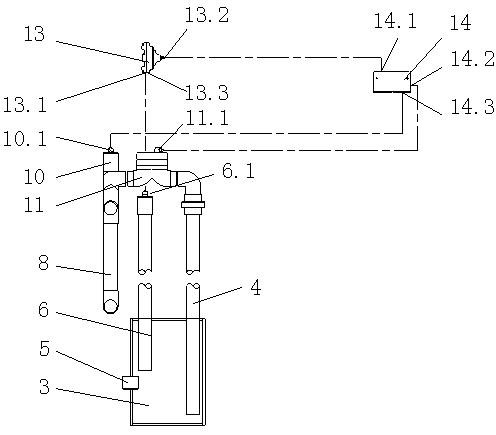

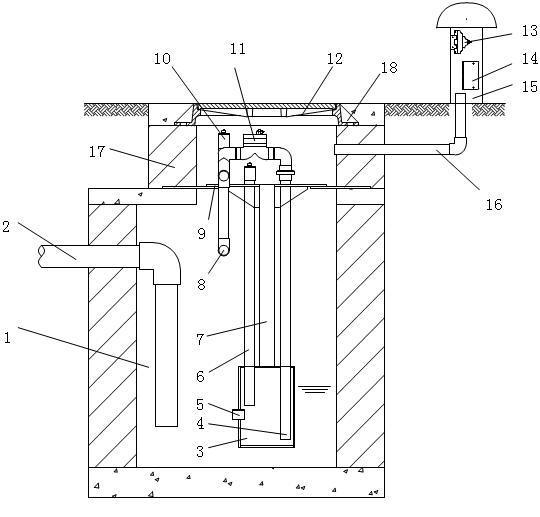

Sump well for vacuum drainage system

ActiveCN102121271ARemove balanceEliminate shockCesspoolsSewerage structuresEngineeringMultiple point

The invention relates to a sump well for a vacuum drainage system. The sump well comprises a collection well, a sewage pumping pipe, a drainage pipe, a vacuum valve, a controller for controlling connection and disconnection of the vacuum valve and a water level sensor for collecting water level information, wherein the outlet of the drainage pipe is connected into a vacuum pipeline, and the inletof the drainage pipe is connected with the outlet of the sewage pumping pipe through the vacuum valve; the inlet of the sewage pumping pipe extends into a sewage pumping level in the collection well;and a signal output end of the water level sensor is connected with a signal input end of the controller. Along with sewage collection in the well, the sump well drains automatically and intermittently to the vacuum drainage system, has a simple structure, and does not require a lift pump, so that the problems of being low in safety, easy in blockage, difficult in cleaning, high in power consumption and the like caused by assembling the lift pumps on multiple points can be avoided, and sewage collected by gravity flow can be lifted to the vacuum drainage system without extra additional power,and the sump well is convenient to check and maintain.

Owner:ENVIROSYST BEIJING ENVIRONMENTAL ENG & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com