Vertical roller mill hydraulic system

A technology of vertical roller mill and hydraulic system, applied in the direction of mechanical equipment, fluid pressure actuating device, grain processing, etc., to achieve the effect of fast lifting and falling speed, stable and reliable requirements, and elimination of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A preferred embodiment of the present invention will be specifically introduced below in conjunction with the accompanying drawings.

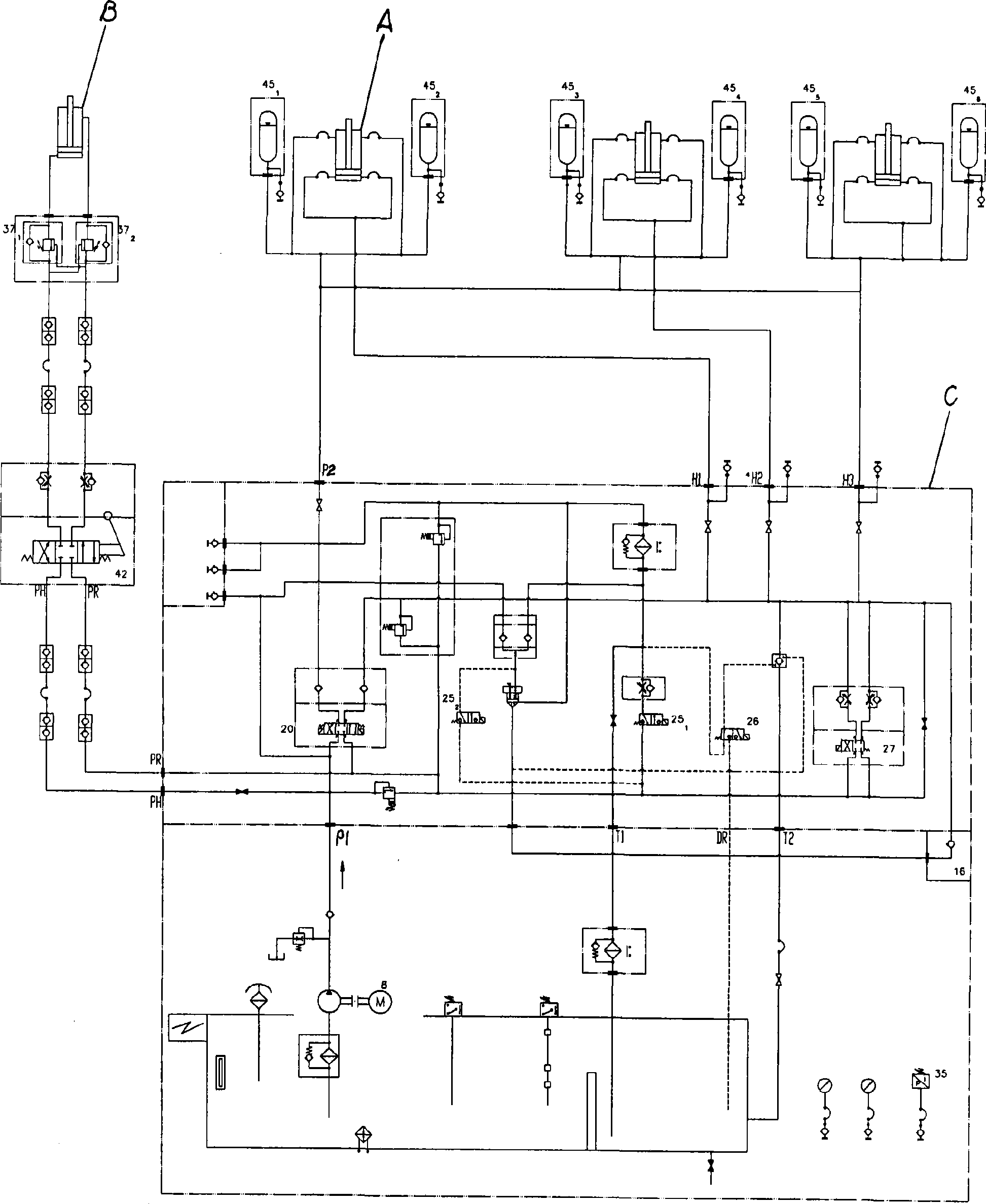

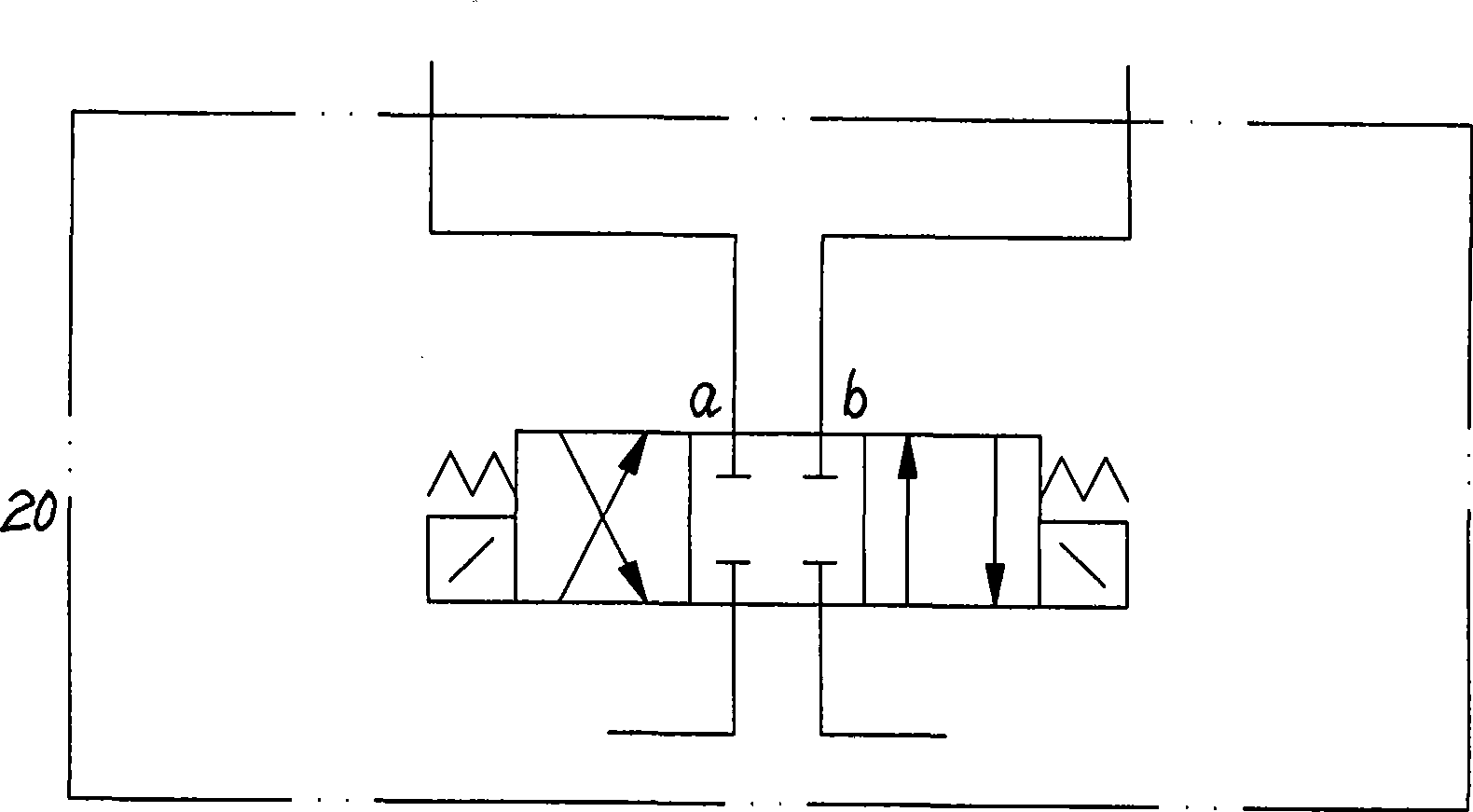

[0028] see figure 1 , the present invention is a vertical roller mill hydraulic system, which consists of three roller clamping hydraulic cylinders A, six accumulator groups 45, a hydraulic station and the connecting pipelines between them, and the hydraulic station It is composed of an oil tank device, an oil pump device, a grinding roller clamping control valve group C and connecting pipelines between them. Every two accumulator groups are correspondingly connected to the piston rod cavity of the grinding roller clamping hydraulic cylinder A. In this embodiment, a bladder type accumulator is selected as the accumulator group 45 to eliminate the impact vibration of the vertical roller mill And the pressure pulsation of the vertical roller mill hydraulic system itself.

[0029] The oil supply pipeline of the oil pump device in the hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com