Combination hoisting mounting method of continuous casting ladle turret

An installation method and combined hoisting technology used in transportation and packaging, load hoisting elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

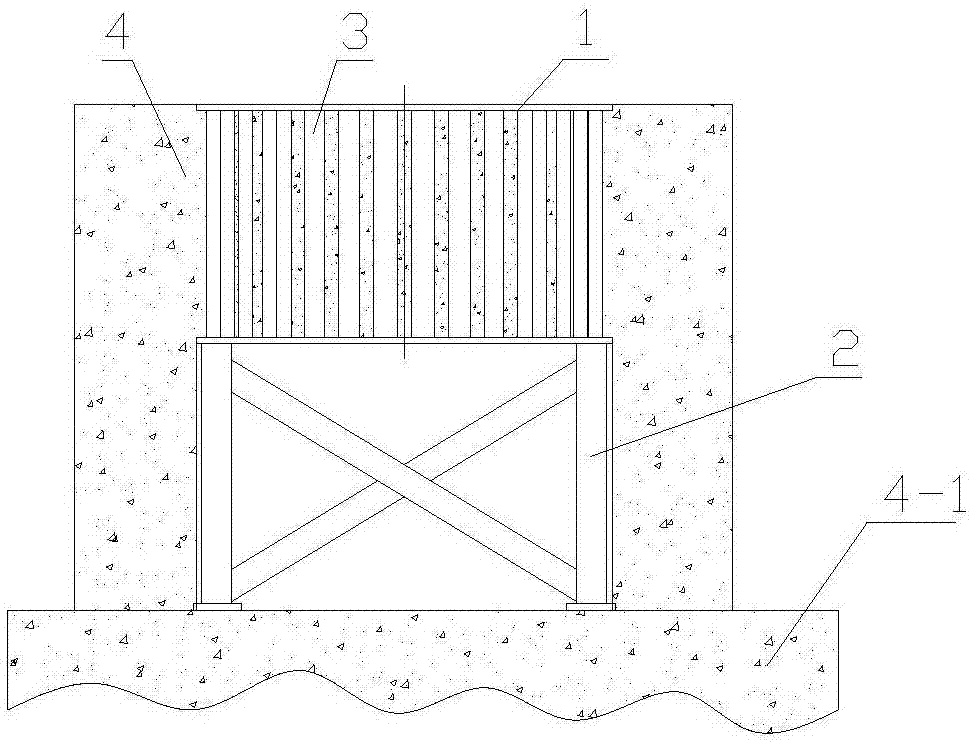

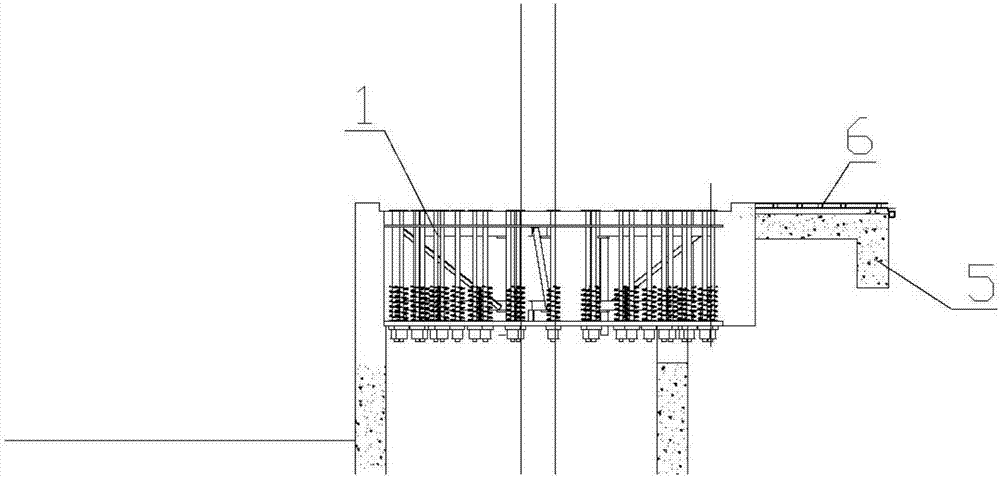

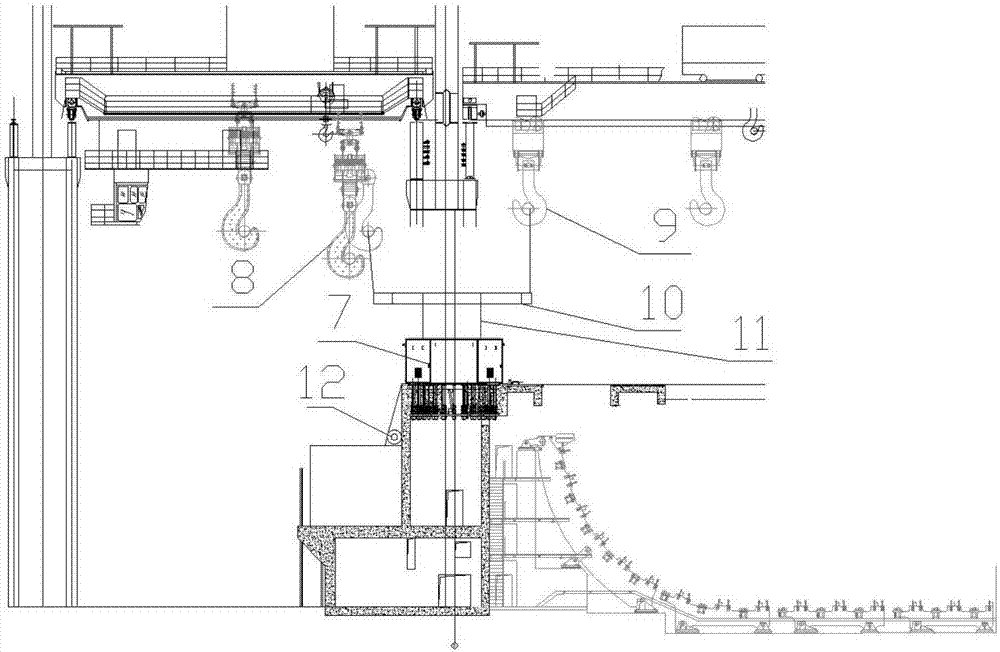

[0042] A combined hoisting and installation method for a continuous casting ladle rotary table proposed by the present invention was used in a steel mill’s four-steel rolling supporting continuous casting project in 2012 for the installation of a 300t ladle rotary table. The maximum ladle rotary table can hold up a total of 900t of heavy objects, the weight of a single piece of equipment is 334t, the receiving span of the plant is installed with a 500-ton crane, the casting span of the plant is installed with a 170-ton crane, and the construction steps for hoisting the continuous casting ladle turret into place are as follows:

[0043] Step 1. Fixture setting and anchor installation:

[0044] ①As attached figure 1 As shown in the figure, make the fixing frame (2) of the anchor first. After the production is completed, hoist the fixing frame (2) to the concrete platform (4-1), and align the upper surface of the fixing frame (2) so that it meets the requirements of the anchor. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com