Patents

Literature

42results about How to "Contact will not" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

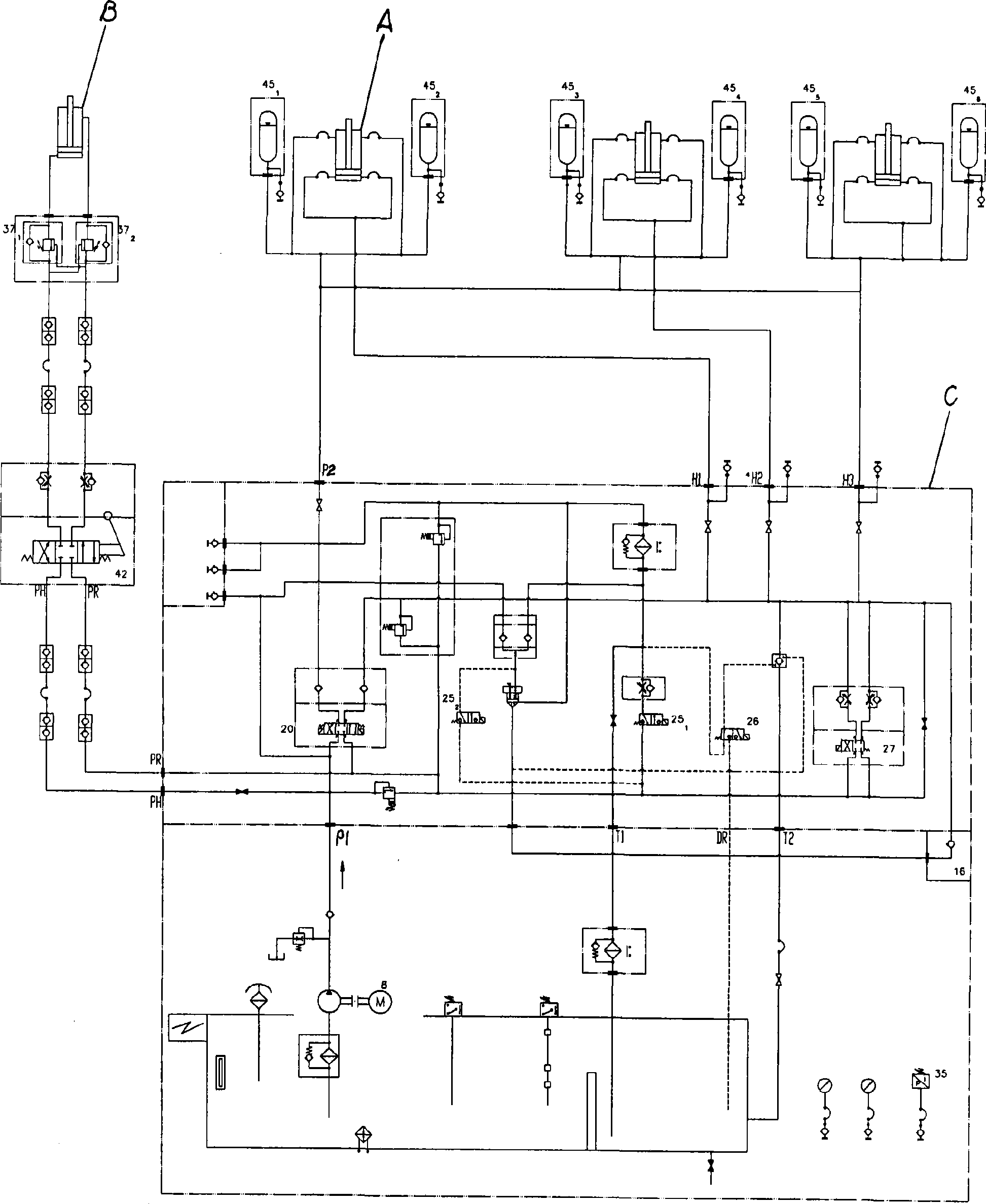

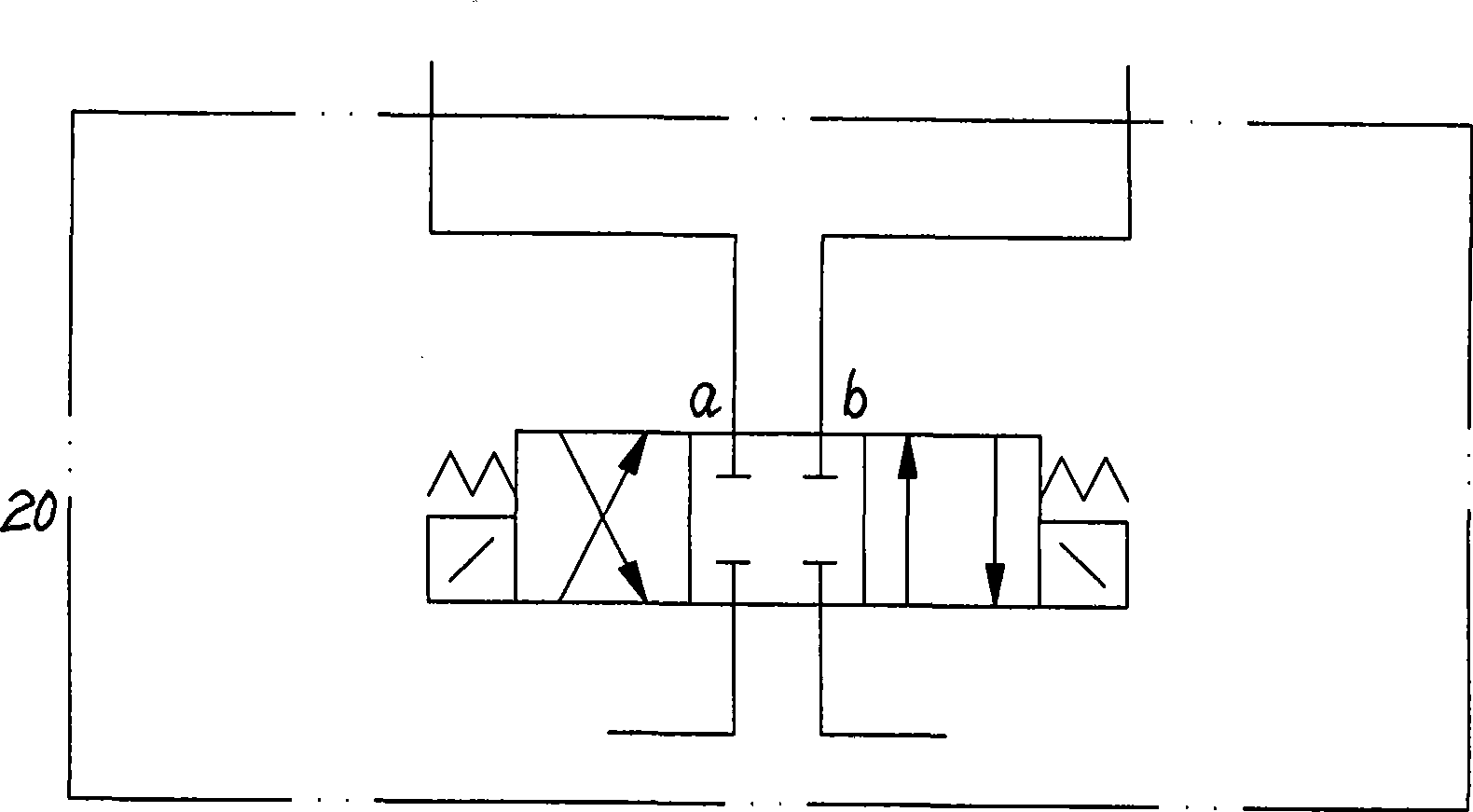

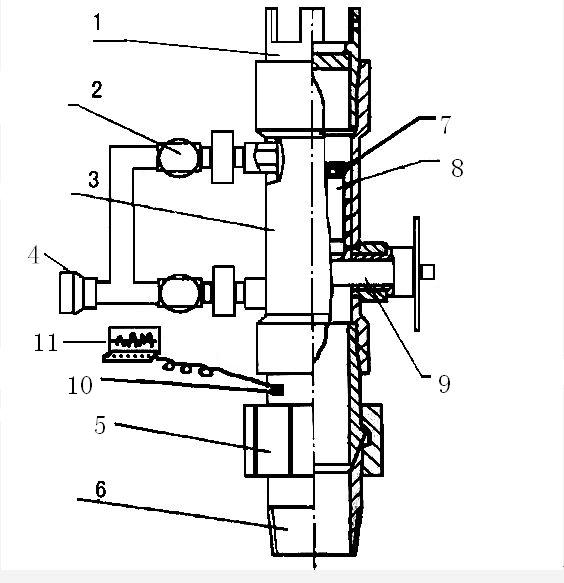

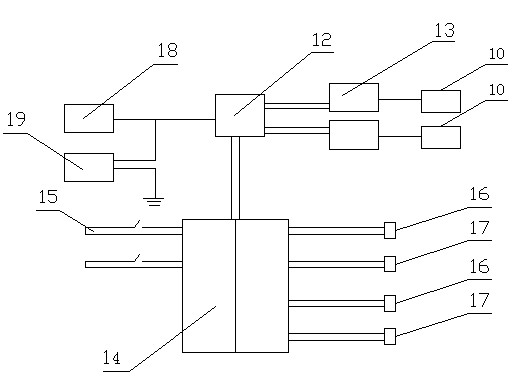

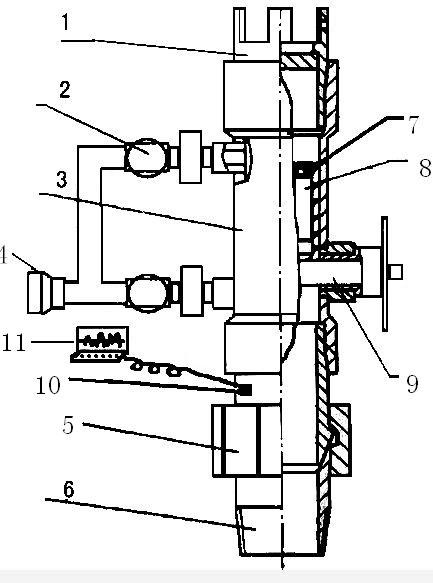

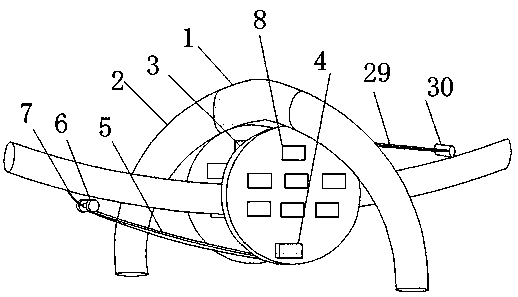

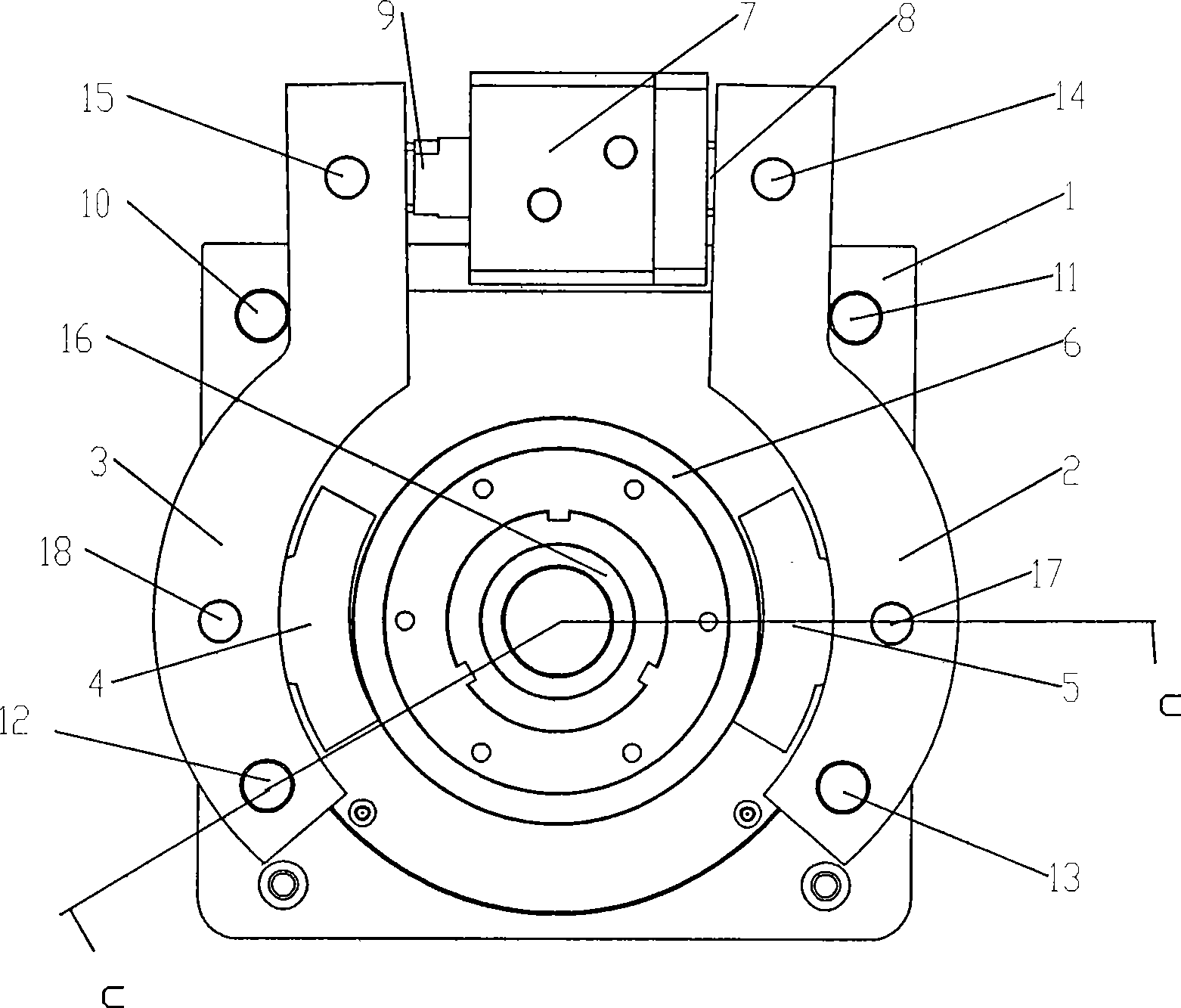

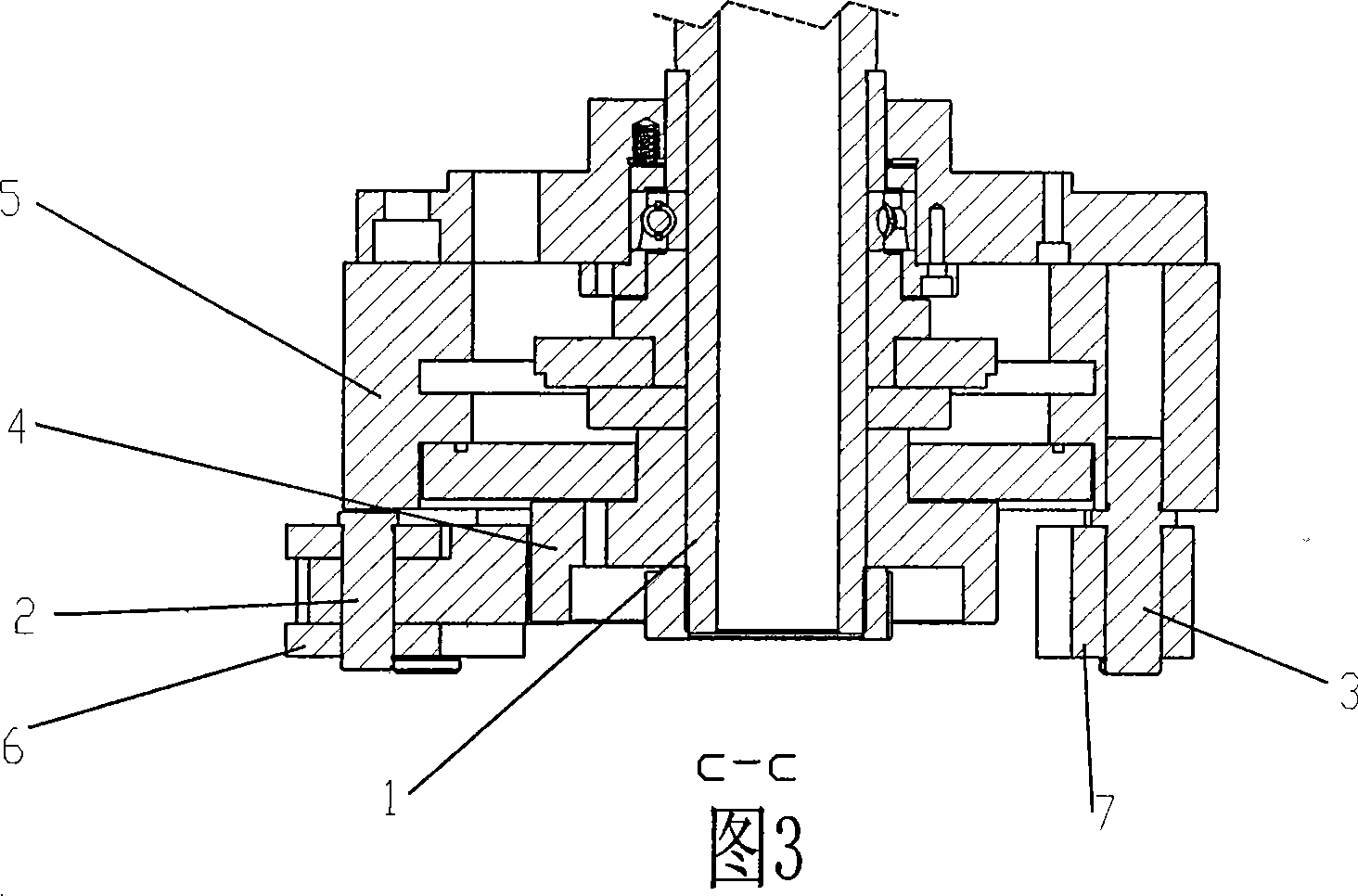

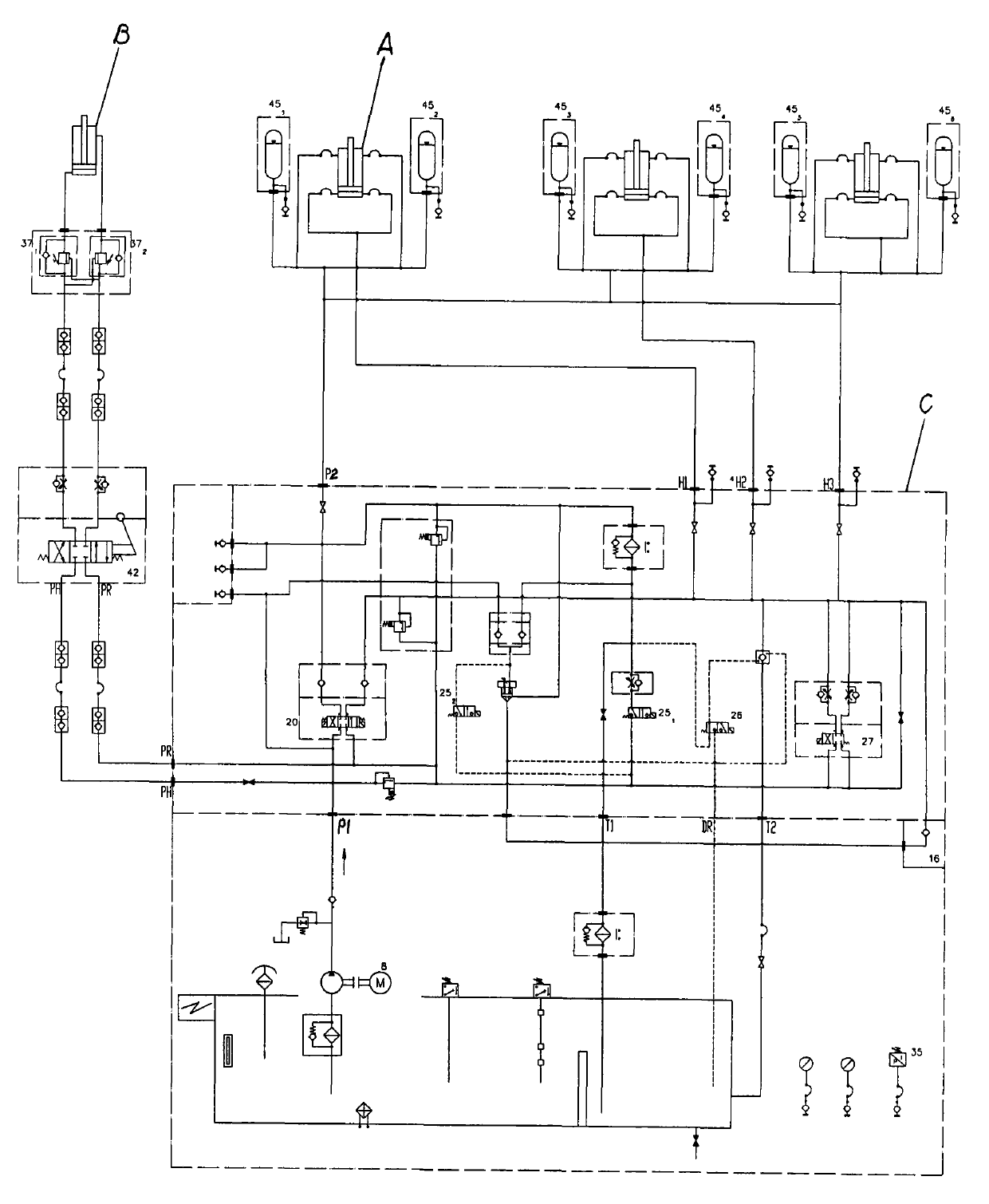

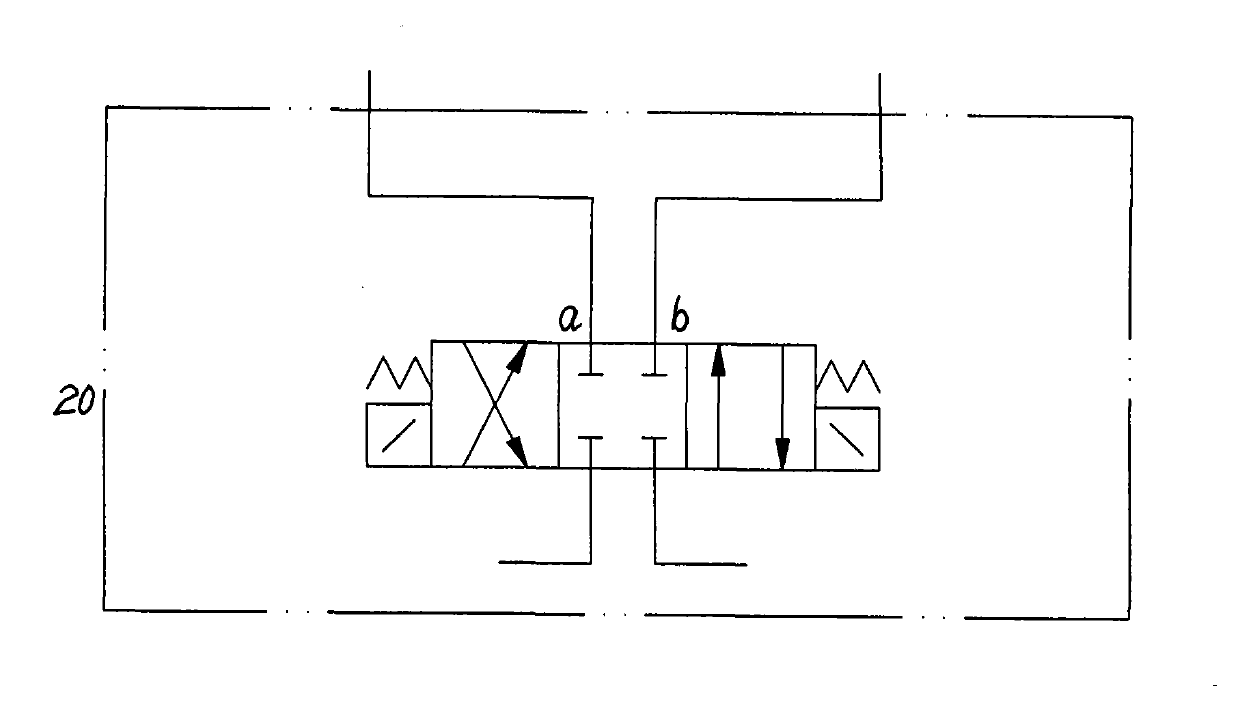

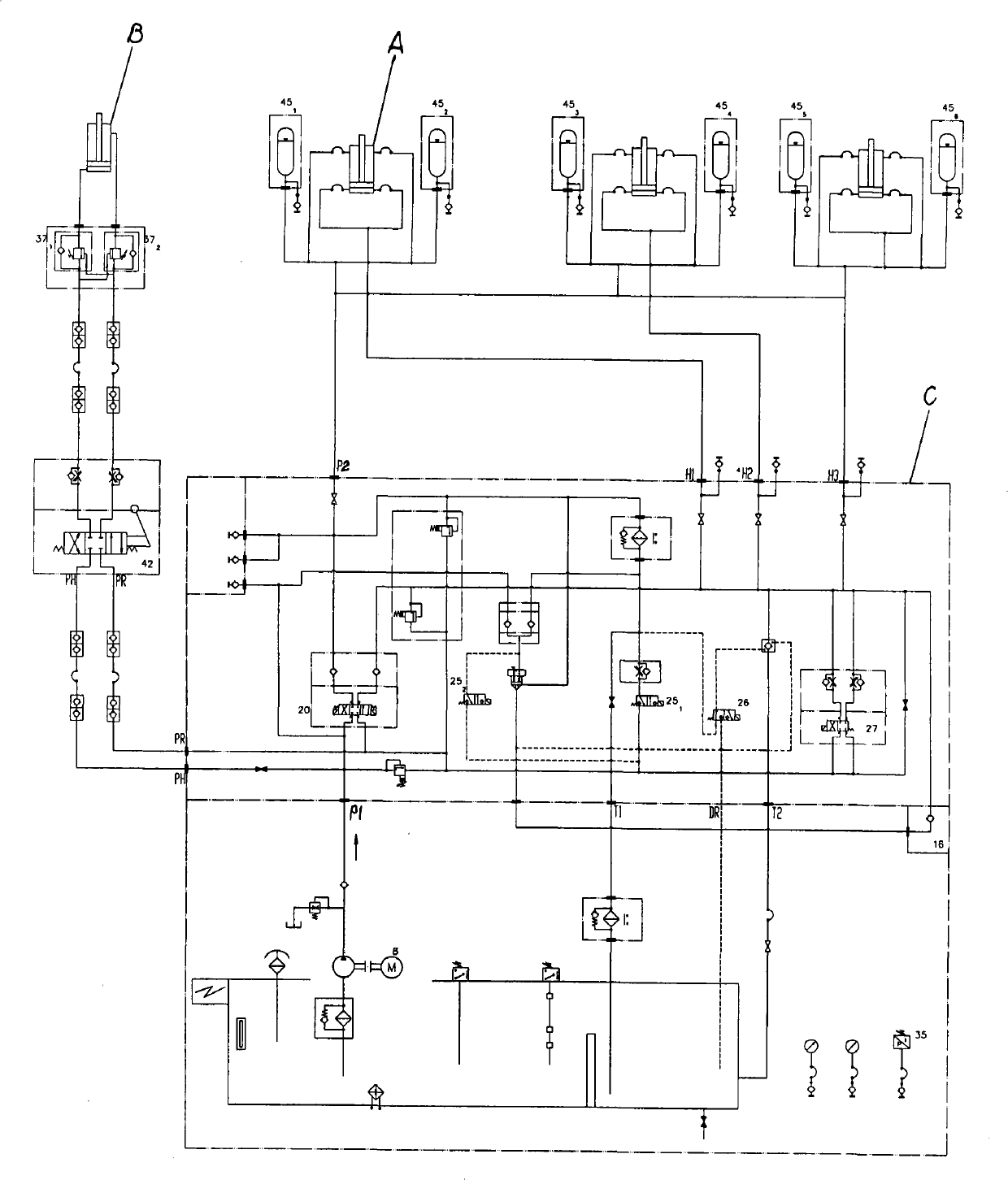

Vertical roller mill hydraulic system

ActiveCN101543797AQuick liftContact will notServomotorsGrain treatmentsHydraulic cylinderControl valves

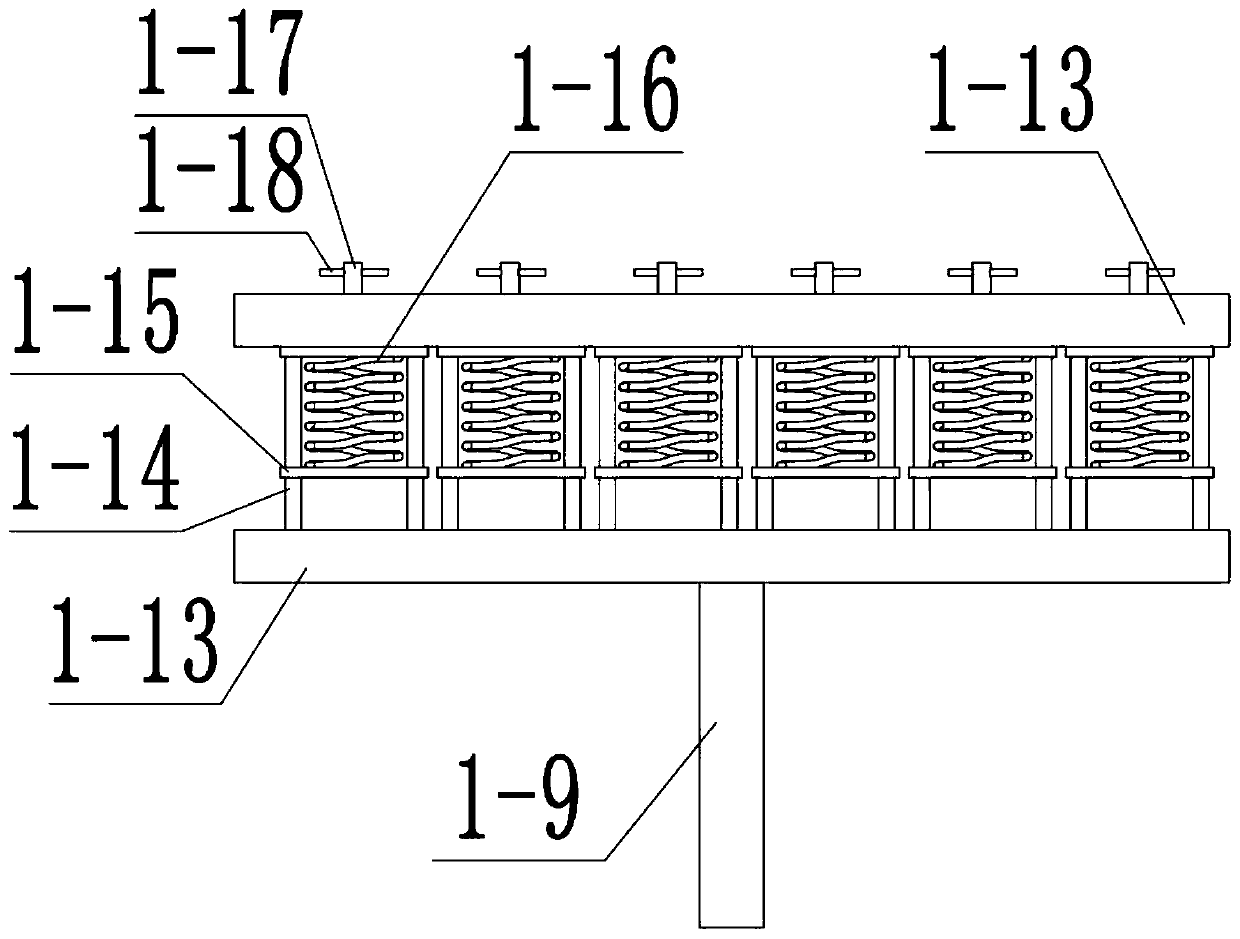

The invention relates to a vertical roller mill hydraulic system, which comprises a plurality of grinding roll clamping hydraulic cylinders, a plurality of accumulator groups, a hydraulic station and connecting pipelines among the grinding roll clamping hydraulic cylinders, the accumulator groups and the hydraulic station, wherein the hydraulic station comprises an oil tank device, an oil pump device, a grinding roll clamping control valve group and connecting pipelines among the oil tank device, the oil pump device and the grinding roll clamping control valve group; a feedline of the oil pump device is connected with an inlet of the grinding roll clamping control valve group; an oil pump motor supplies oil for the grinding roll clamping control valve group; an outlet of the grinding roll clamping control valve group is connected with piston rod cavities of the grinding roll clamping hydraulic cylinders and the accumulator groups; rodless cavities of the grinding roll clamping hydraulic cylinders are connected with the grinding roll clamping control valve group through a plurality of oil return pipes; the grinding roll clamping control valve group controls the telescoping of piston rods of the grinding roll clamping hydraulic cylinders through a plurality of electromagnetic directional valves; and the accumulator groups absorb the vibration of the grinding roll clamping hydraulic cylinders respectively. The vertical roller mill hydraulic system solves the problem of loaded pressure boost of the system and improves the service life of grinding rolls and grinding discs and the maintenance efficiency.

Owner:BAOSTEEL ENG & TECH GRP

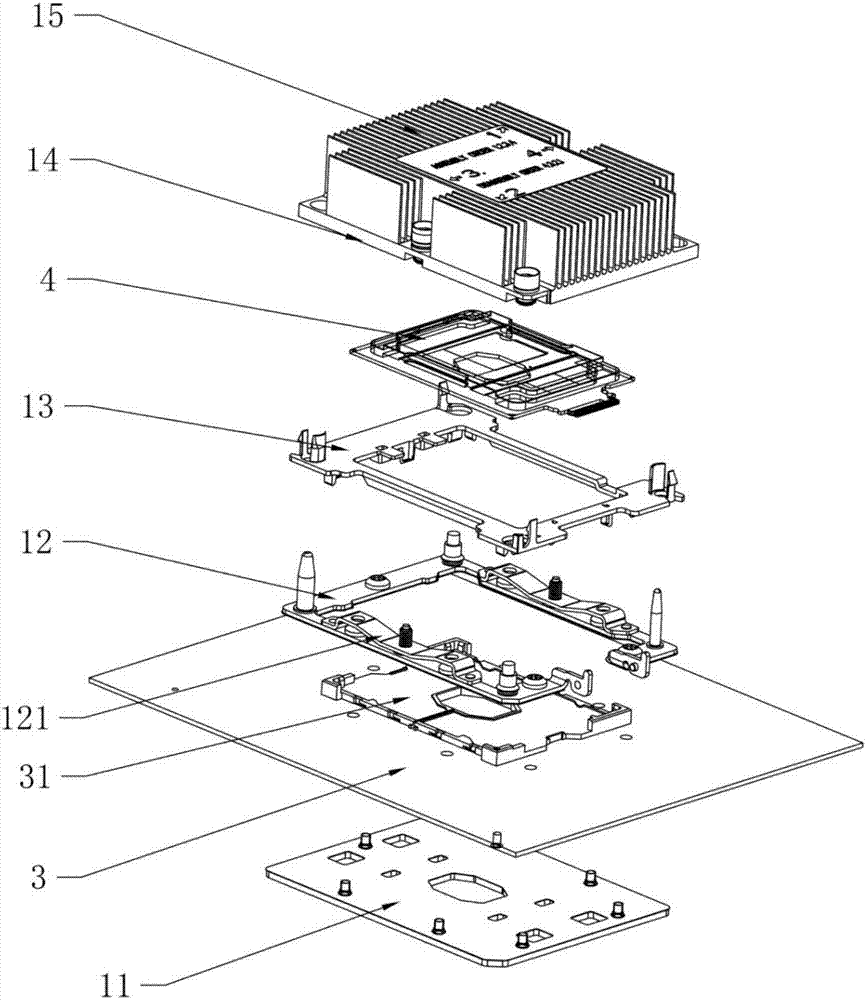

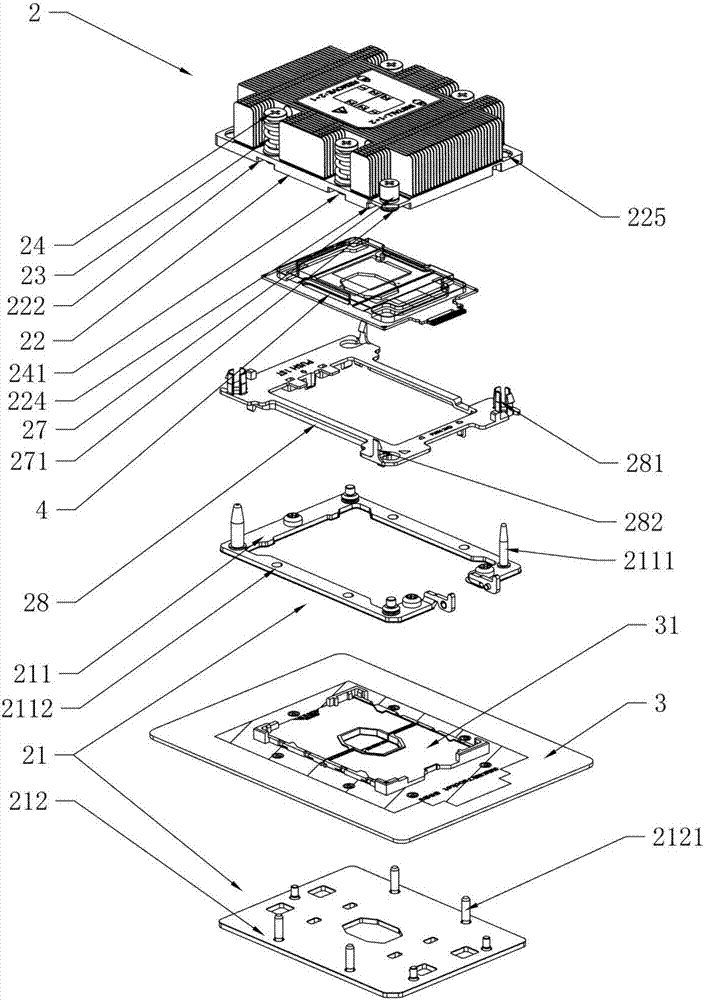

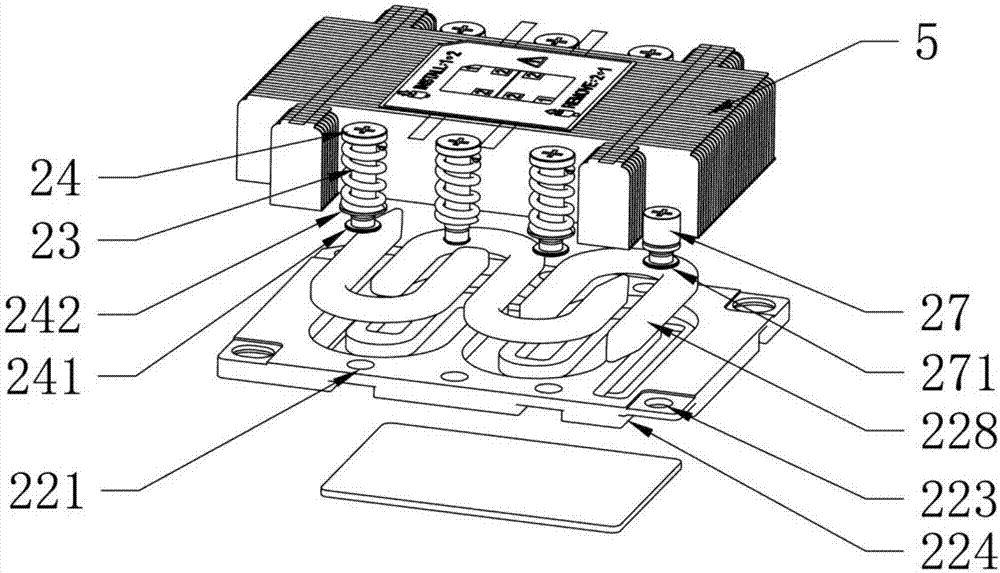

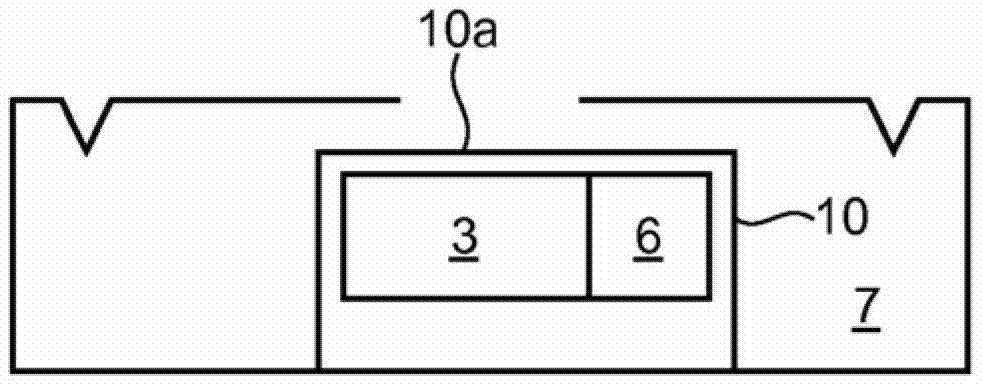

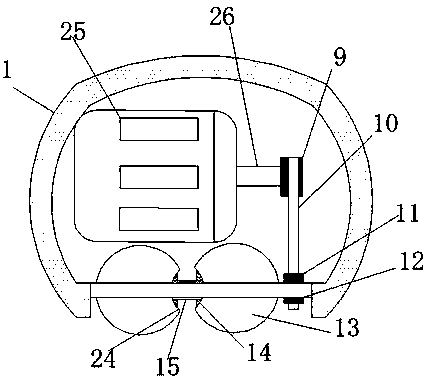

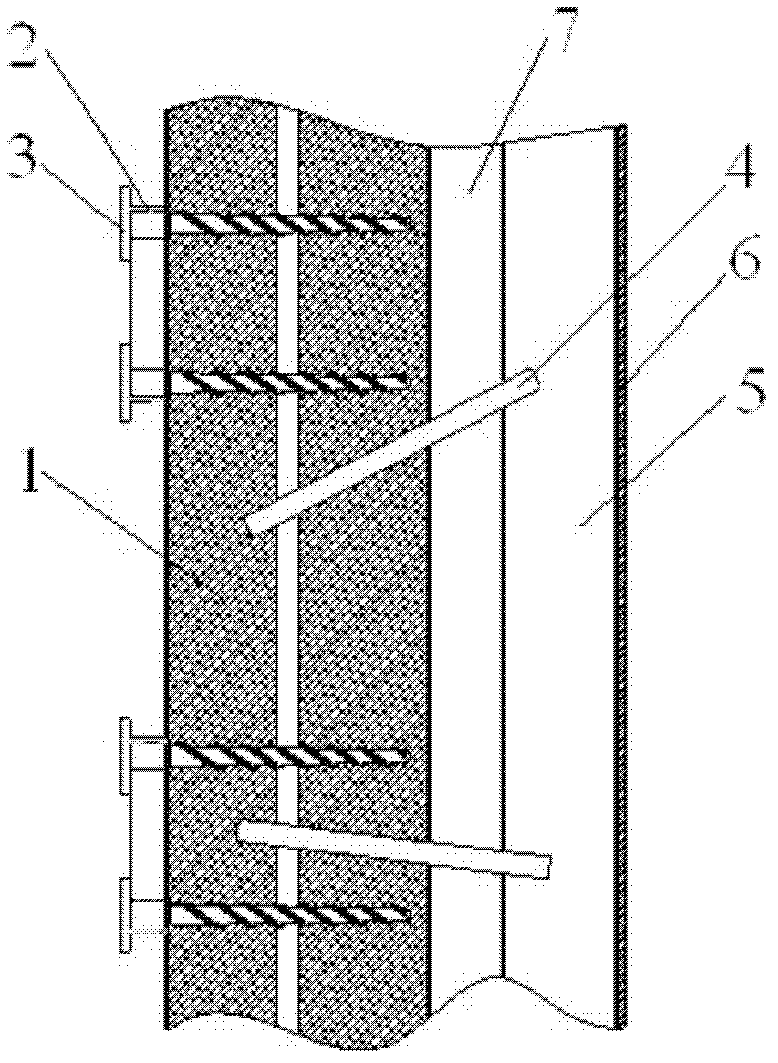

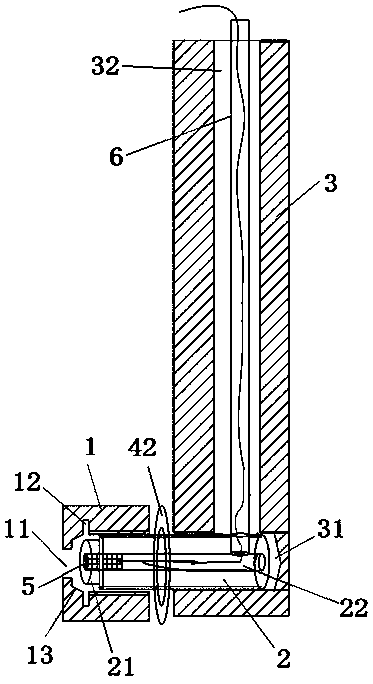

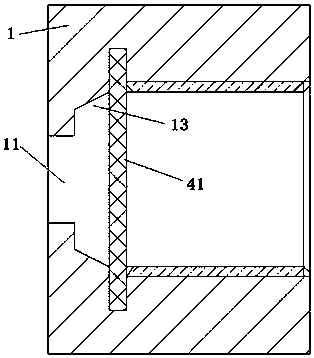

Processor fixing structure, component and computer equipment

ActiveCN107577285AEasy to hang outIncrease contact areaSemiconductor/solid-state device detailsDigital processing power distributionPrinted circuit boardBiomedical engineering

The invention relates to the technical field of computers, and in particular to a processor fixing structure. The processor fixing structure comprises a radiator substrate in contact with a processor,wherein the radiator substrate is fixed on a fixing component at a processor slot on a printed circuit board PCB; an elastic structural member and a spacing structural member for spacing the elasticstructural member are arranged on the side edge of the radiator substrate; one end of the spacing structural member penetrates the elastic structural member to be connected with the fixing component;and the elastic structural member is located between the other end of the spacing structural member and the radiator substrate. According to the processor fixing structure, the elastic structural member is compressed through shortening the distance between the other end of the spacing structural member and the radiator substrate, so that the elastic structural member gives elastic force to the spacing structural member and the radiator substrate at the same time; and the spacing structural member penetrates through the elastic structural member to be connected with the fixing component, so that the elastic force of the elastic structural member is converted into pressure from the radiator substrate to a CPU, and then the pressure to the CPU can be enhanced to satisfy an increased total pressure load.

Owner:XFUSION DIGITAL TECH CO LTD

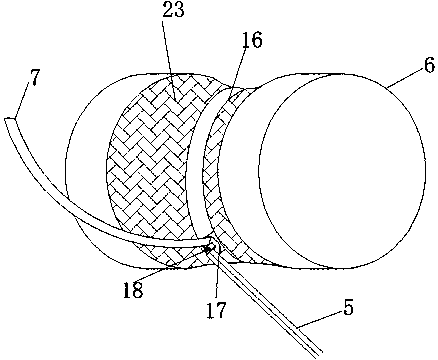

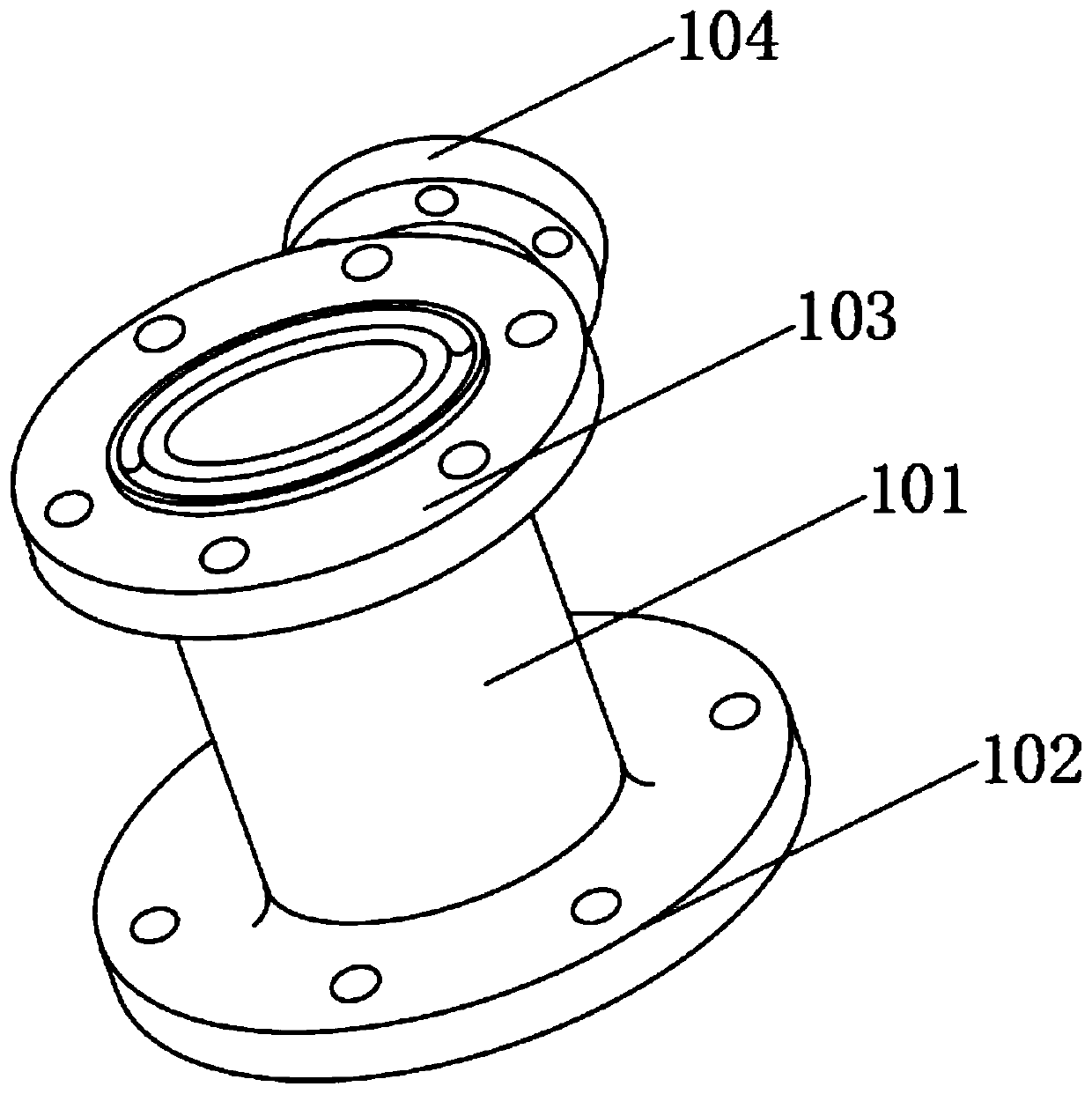

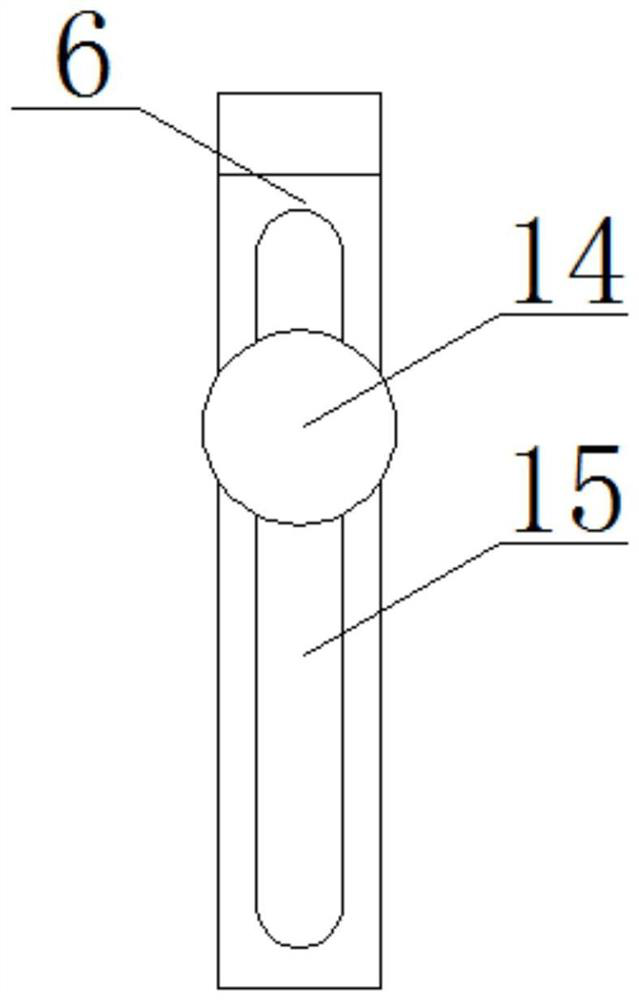

Cement head magnetic induction rubber plug indicator

The invention discloses a cement head magnetic induction rubber plug indicator, which comprises a top cover, a cement head body and a lower joint. A detection section is arranged between the cement head body and the lower joint; the cement head body is provided with a spiral stop bin which stretches into the cement head body; a well cementing rubber plug which is limited by the spiral stop bin isarranged in the cement head body; a magnet is arranged on the well cementing rubber plug; and the detection section is provided with a magnetic sensor which is connected to a secondary instrument. The rubber plug is not in mechanical hard contact with a cement head when passing through the cement head, so the rubber plug cannot be damaged; and a magnetic field is taken as a medium, the magnetic induction sensor senses the downward movement of the rubber plug, and a detection signal is contactless and has high accuracy and reliability.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

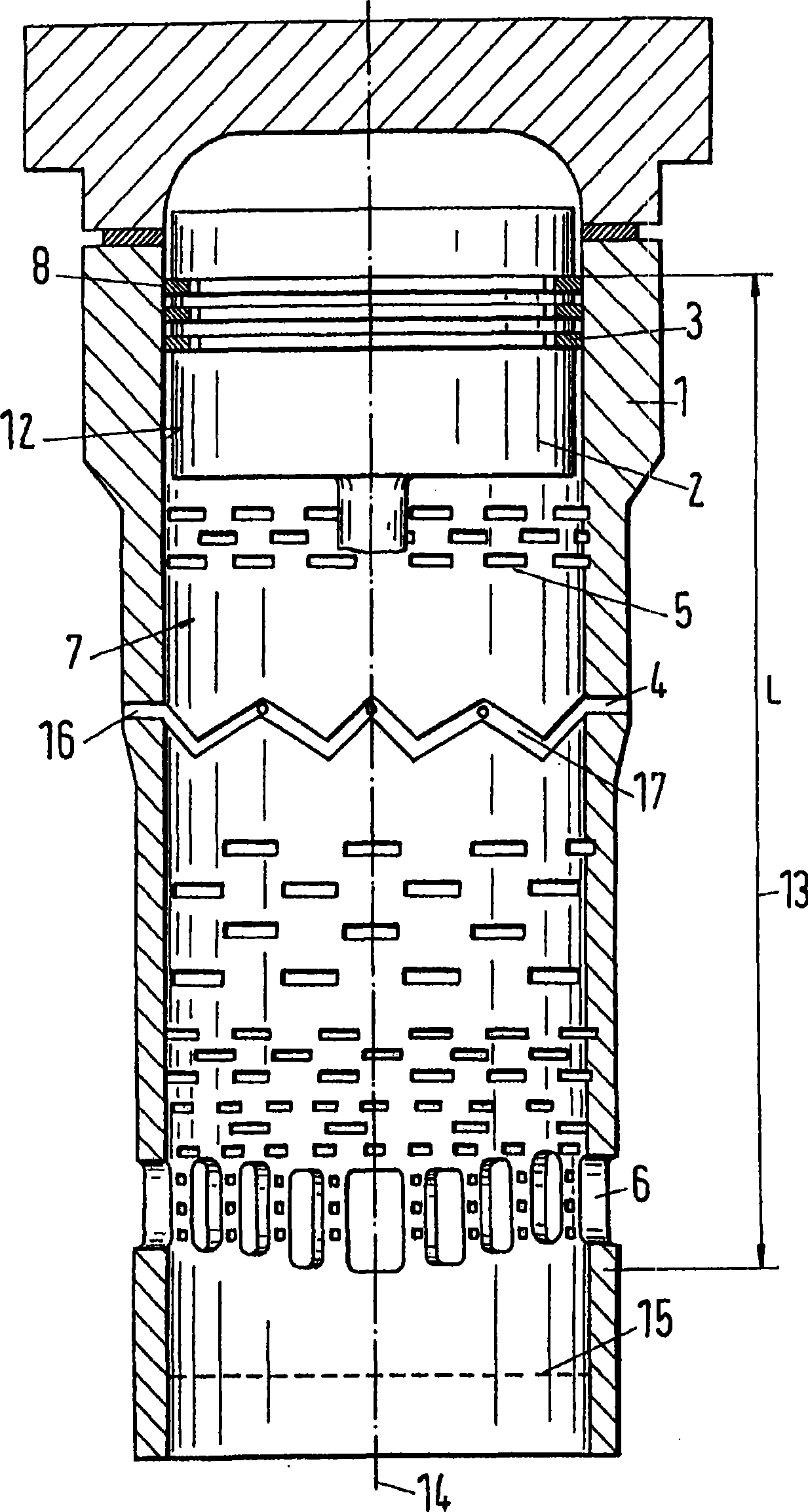

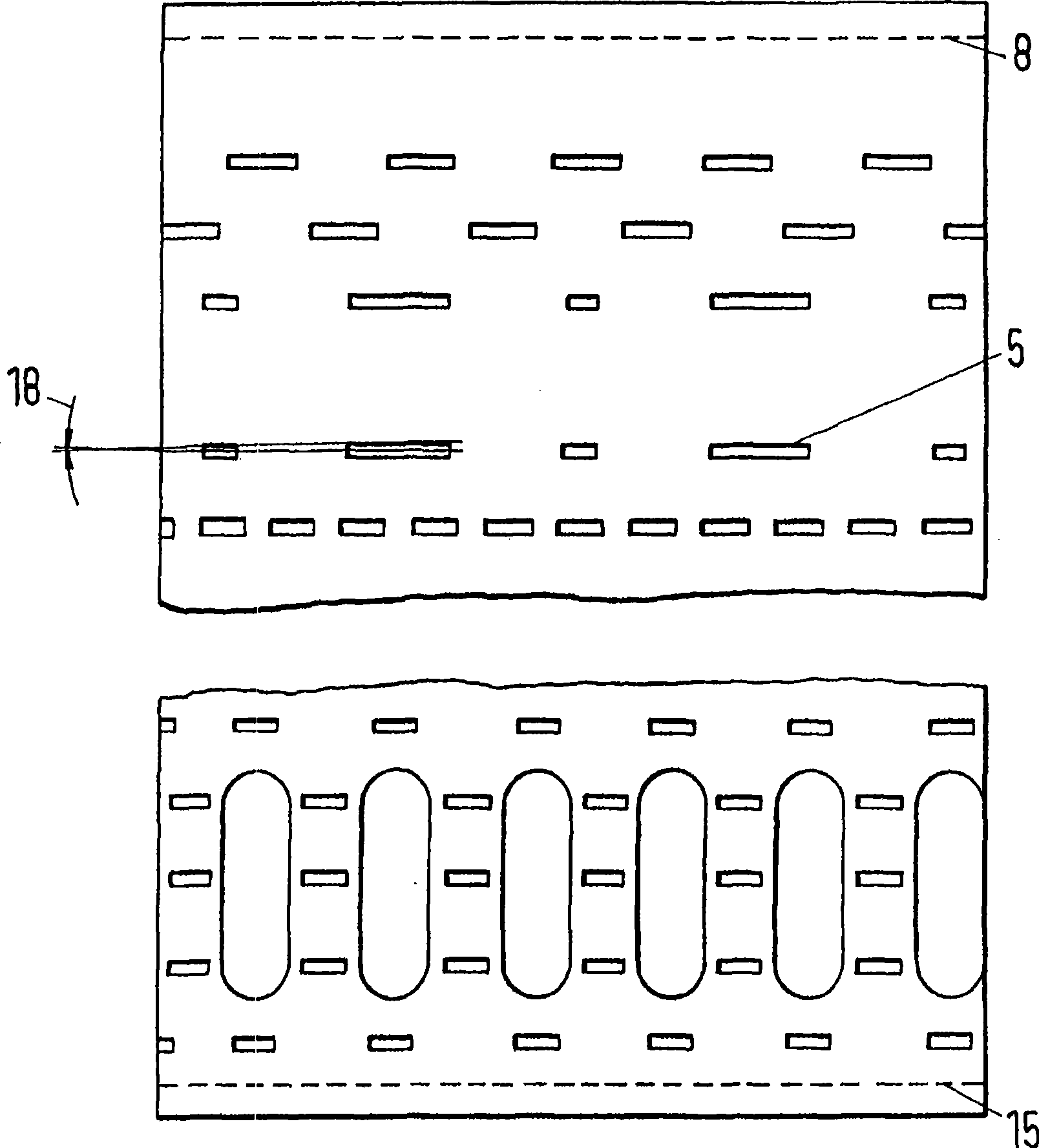

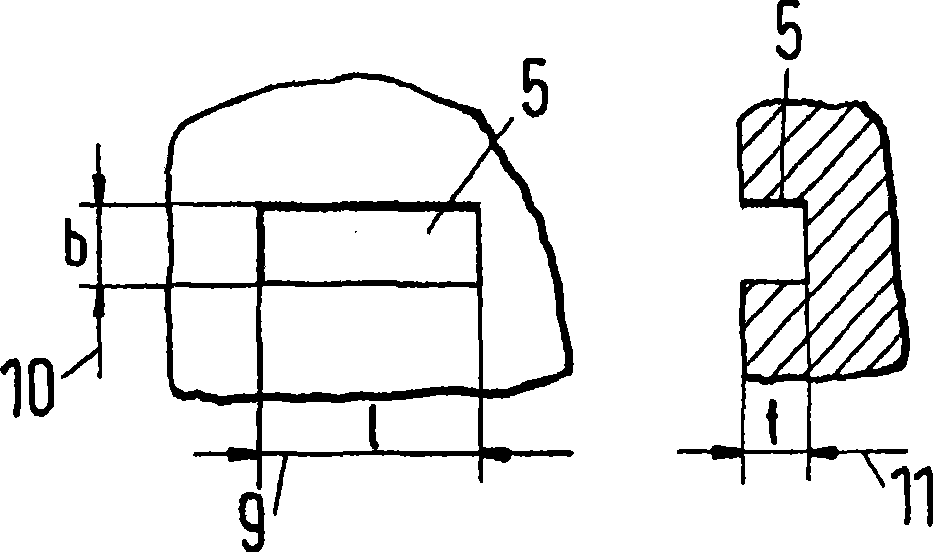

Cylinder with devices for containing lubricants

The invention relates to a cylinder with a device used to receive lubricant. A cylinder (1) comprises a device (5) used to receive lubricant. The cylinder comprises a sliding surface (7) for a piston (2) and the sliding surface has a dead point area (8) and a row of purifying grooves (6) disposed on the cylinder. The sliding surface (7) is provided with a plurality of gouge recesses (5) with length (9), width (10) and depth (11) which is over 0.4mm. The gouge recesses are disposed below an annular area of a cylinder surface (12). The annular area has length which is 15% of the length (13) of the sliding surface (7) when measured from the dead point area (8) thereon.

Owner:WAERTSILAE SCHWEIZ AG

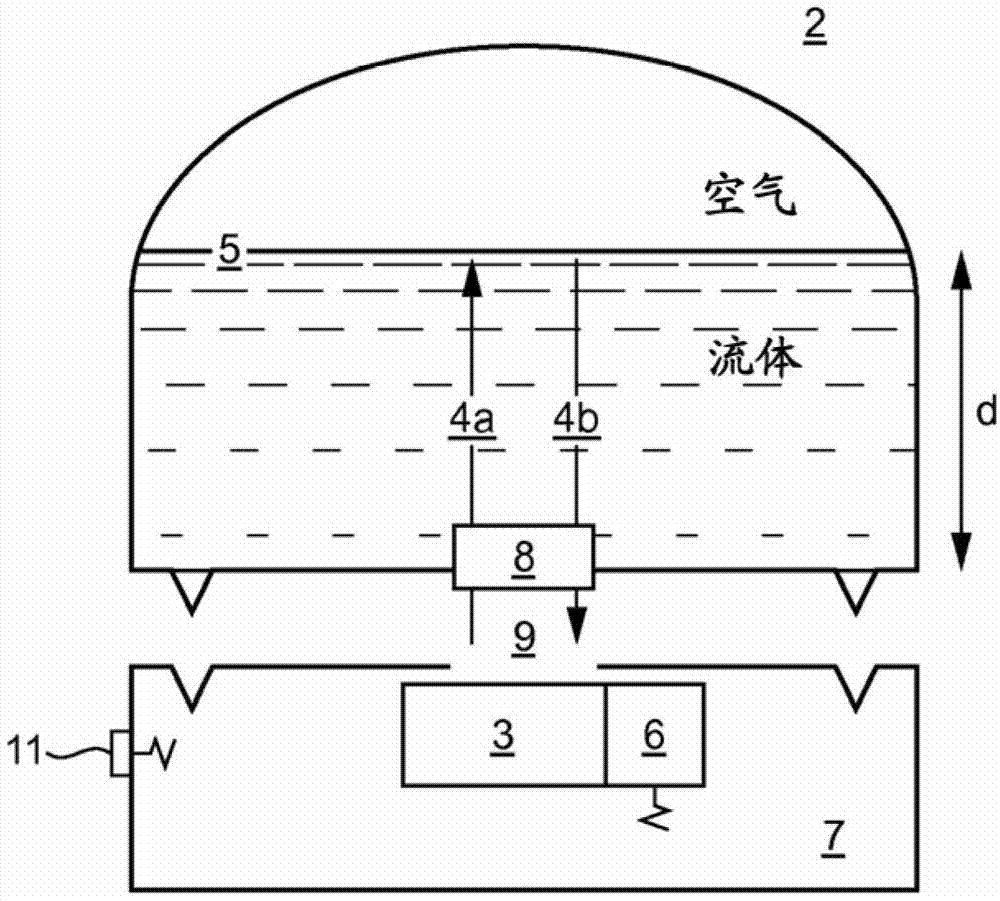

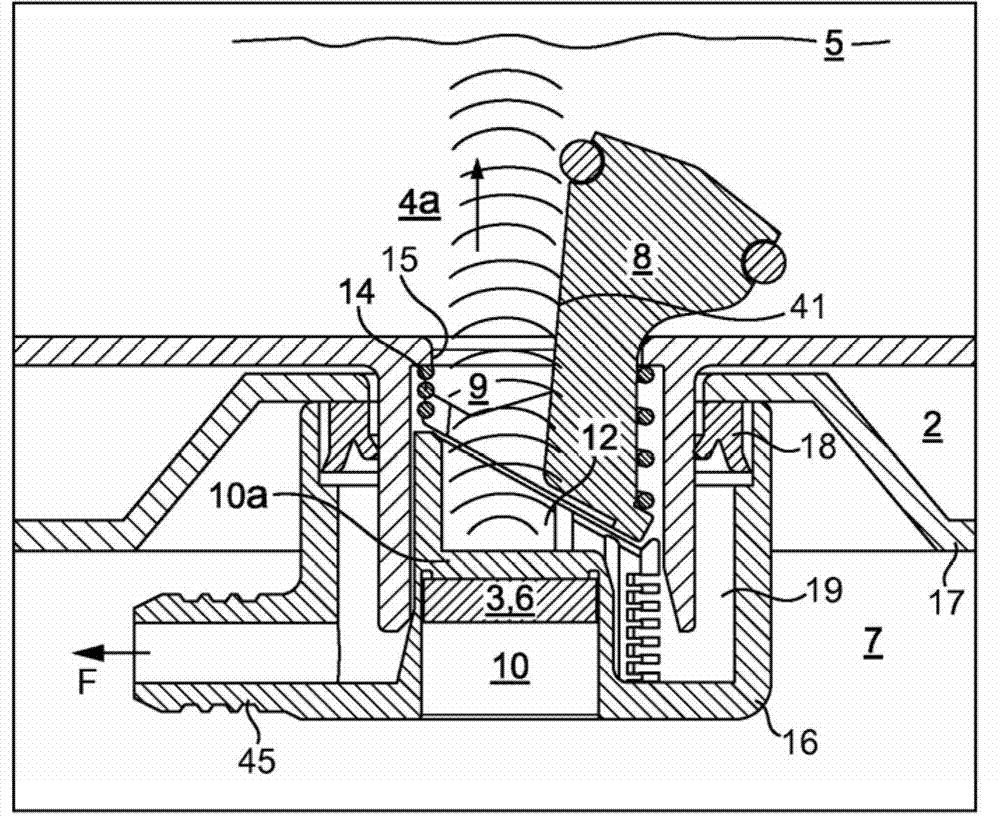

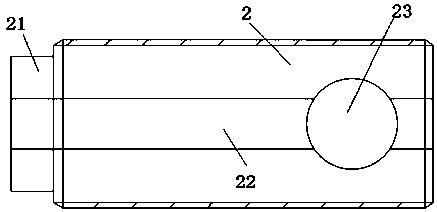

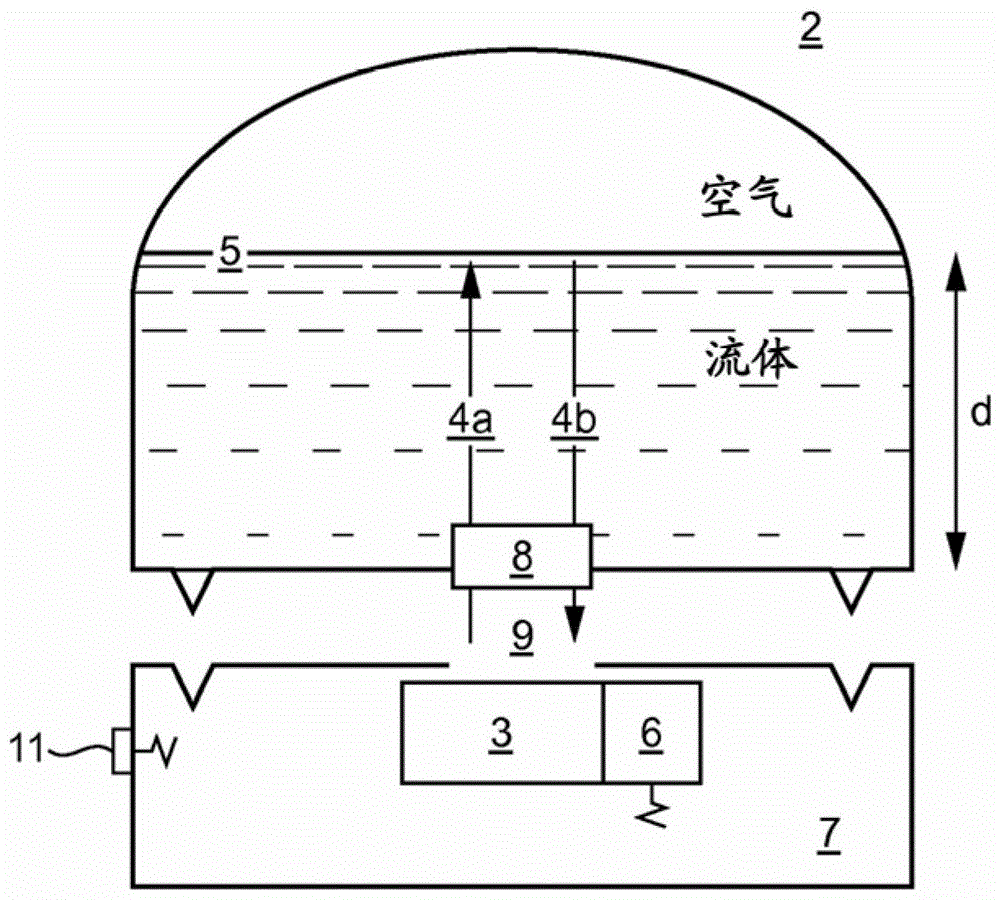

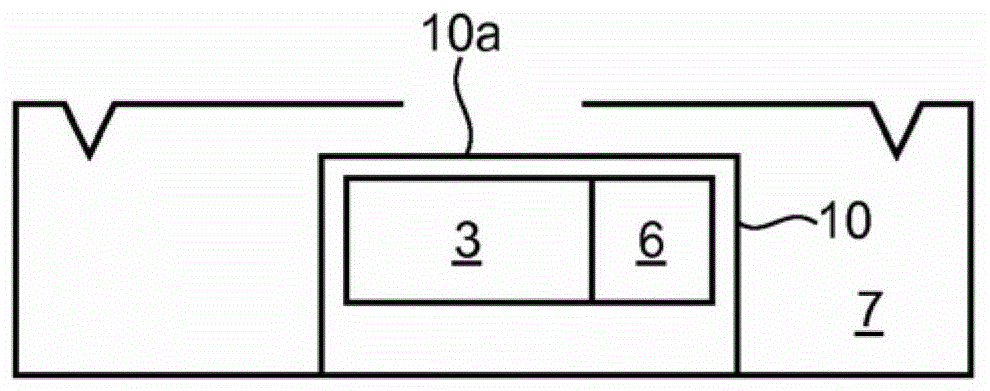

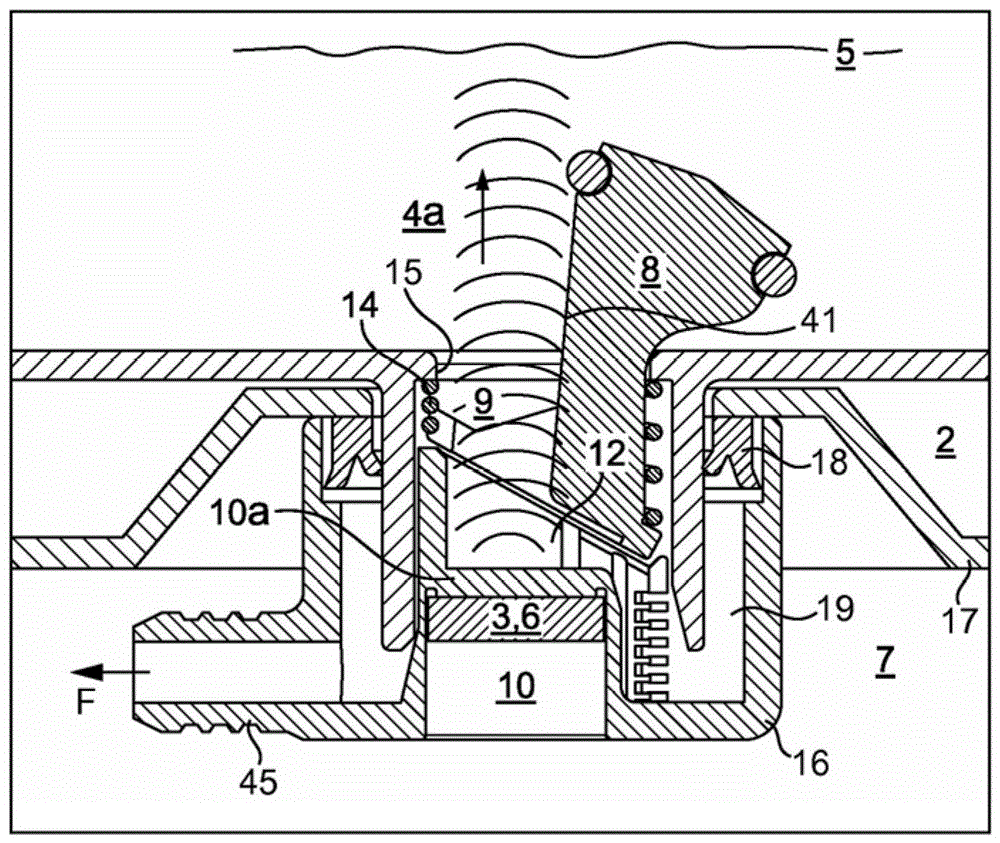

Beverage machine with integrated ultrasonic transceiver

InactiveCN102858211AHigh resolutionReliable measurement of liquid level and/or flow velocityBeverage vesselsThin material handlingTransceiverBiomedical engineering

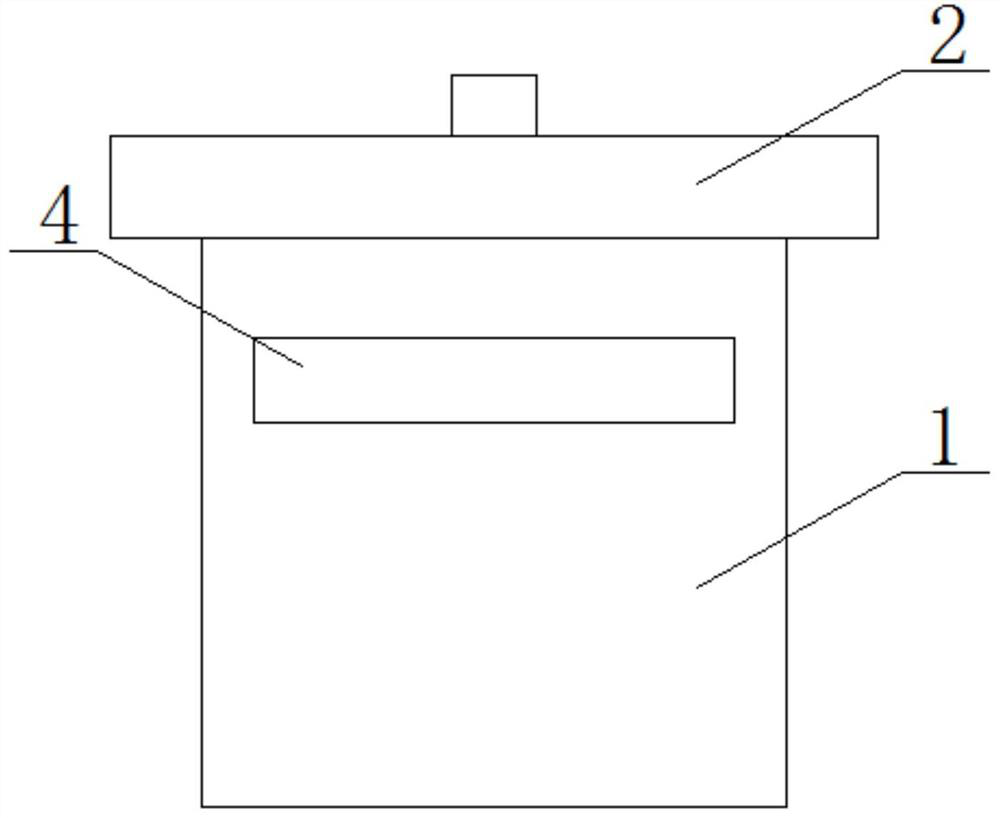

The present invention discloses a beverage machine (1) comprising a tank (2), which holds a liquid for preparing a beverage, and a dispenser (7), to which the tank is connectable, wherein the tank (2) comprises a valve (8); the dispenser comprises an opening (9) for receiving the valve in connection of the tank on the dispenser; at least one ultrasonic transceiver (3) is disposed in the dispenser (7) or tank (2), the ultrasonic transceiver being designed to emit and receive ultrasonic waves (4a, 4b) in the liquid, in order to determine the distance (d) from the transceiver to the liquid level (5), wherein it further comprises a control unit (6), which is connected to the ultrasonic transceiver (3) which is adapted to determine the distance (d) changing with time and as a result the volume (V) of the liquid flowing out of the tank.

Owner:NESTEC SA

Shell for filling gelatinized solid-liquid phase mixed fuel with stirring function

ActiveCN112414233ATotal energy guaranteeMeet PowerdesignAmmunition testingNuclear energy generationFluid phaseEngineering

The invention discloses a shell for filling gelatinized solid-liquid phase mixed fuel with a stirring function. The shell is characterized in that the lower end of an eighth outer cylindrical surfaceof an annular motion stirring disc is provided with eight eighth lower end cylindrical bosses which are uniformly distributed in the circumferential direction, the axis of each eighth lower end cylindrical boss of the annular motion stirring disc is vertical to the axis of a revolving body of the annular motion stirring disc, an eighth annular groove is formed in the middle of an eighth outer cylindrical surface of the annular motion stirring disc, and the inner side surface of the eighth annular groove of the annular motion stirring disc is an eighth middle outer cylindrical surface. The warhead shell has the function of stirring internal fuel, and solid-phase fuel, liquid-phase fuel and gel are stirred in the warhead shell until the solid-phase fuel, the liquid-phase fuel and the gel areuniformly mixed; air is prevented from being in contact with the gelatinized solid-liquid phase mixed fuel, no air exists in the fuel finally, and the power design of the warhead is met; and the riskof combustion is avoided, and the safety of the warhead is ensured.

Owner:XIAN MODERN CHEM RES INST

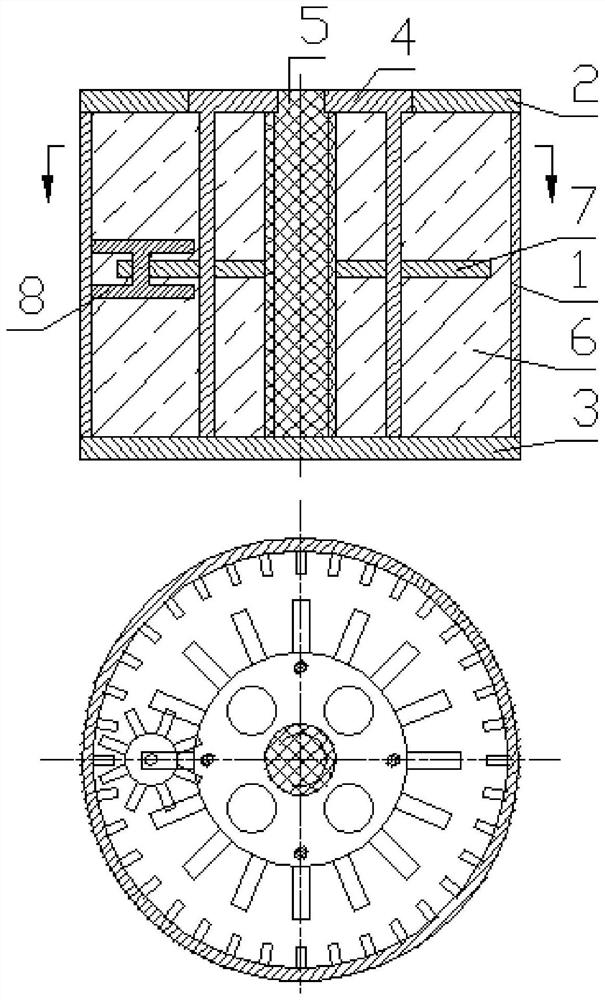

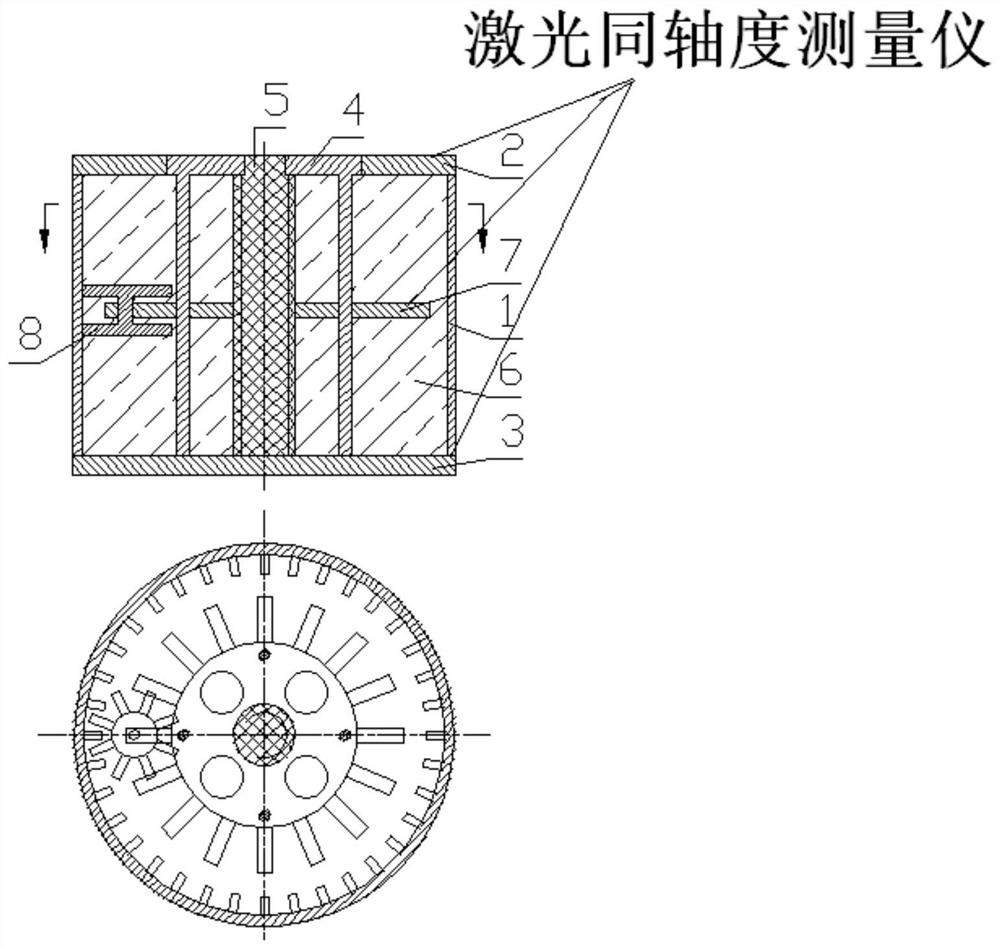

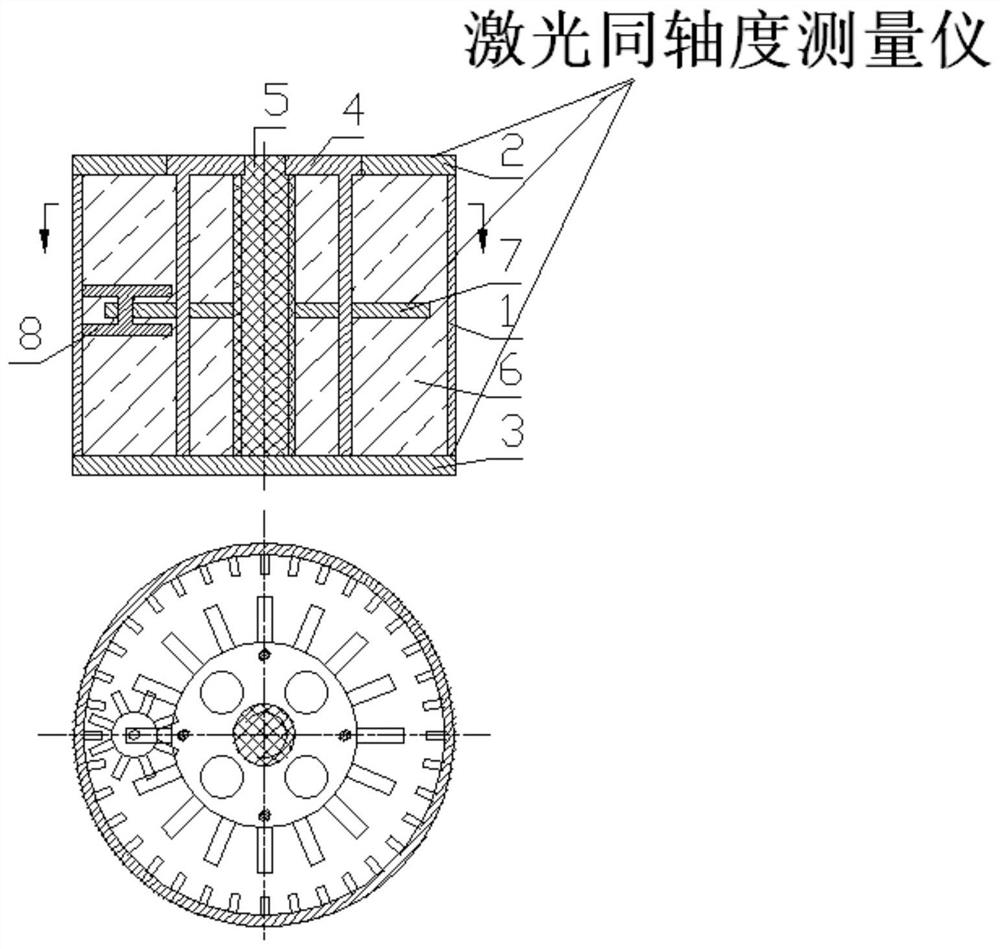

Warhead shell capable of improving filling ratio based on laser coaxiality measuring instrument

ActiveCN112390693ATotal energy guaranteeMeet PowerdesignExplosive working-up apparatusMeasuring instrumentEngineering

The invention discloses a warhead shell capable of improving the filling ratio based on a laser coaxiality measuring instrument, which is characterized in that the axis of a revolving body of a support frame 4 coincides with the axis of a revolving body of a shell 1, the support frame 4 is positioned inside the shell 1, and the fourth upper end concentric ring surface of the support frame 4 is coplanar with the second upper end concentric ring surface of an upper end cover 2; and the fourth outer cylindrical surface of the support frame 4 is in running fit contact with the second inner cylindrical surface of the upper end cover 2, and the lower ends of four fourth cylinders of the support frame 4 are in sliding fit contact with the third upper end circular plane of a lower end cover 3. Airis prevented from making contact with the gelatinized solid-liquid phase mixed fuel, no air exists in the fuel finally, and the power design of the warhead is met. The risk of combustion is avoided,and the safety of the warhead is ensured.

Owner:XIAN MODERN CHEM RES INST +1

Foreign body removal device for high voltage transmission line

InactiveCN110504639ASolve processing problemsContact will notApparatus for overhead lines/cablesHigh pressureScrub brushes

The invention belongs to the technical field of electrical equipment and in particular relates to a foreign body removal device for a high voltage transmission line. Aiming at solving the technical problems that an existing electric transmission line cleaning device is difficult to clean foreign bodies on a transmission line and especially cleaning effect is poor for wound foreign bodies such as plastic bags, the following scheme is put forward, namely the foreign body removal device for the high voltage transmission line comprises a power box, the two sides of the power box are respectively rotatably connected with an arc-shaped balance bar by virtue of a spindle, the bottom of each arc-shaped balance bar is fixedly connected with a counterweight plate, a first rotary rod is rotatably connected between the bottoms of the two counterweight plates by virtue of a spindle, one side of the first rotary rod is fixedly connected with a first cleaning rod, one end of the first cleaning rod isrotatably connected with a rotary groove by virtue of a spindle, and one end of the rotary groove is fixedly connected with a sliding column. In the foreign body removal device provided by the invention, an arc-shaped triangular knife is arranged, the plastic bags on the transmission line are cut by virtue of the arc-shaped triangular knife, and tiny foreign bodies on the transmission line are seamlessly cleaned by virtue of coordination of a ring-shaped scrubbing brush and a brush substrate, so that the cleaning effect is improved.

Owner:HUBEI UNIV

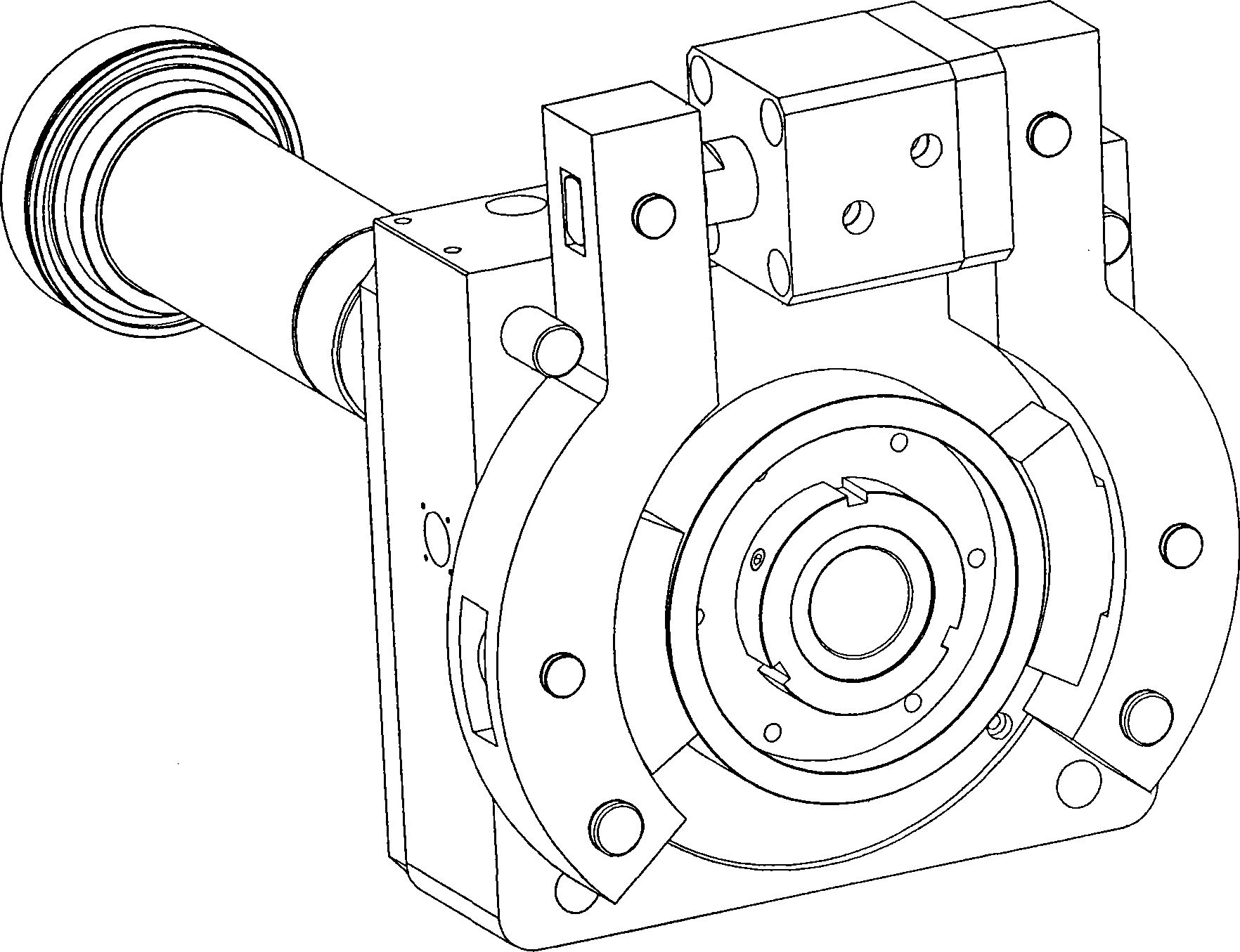

Apparatus for locking accurate main shaft

The invention provides a precise spindle locking device and relates to a locking device. The locking device consists of a fixed board, a flange, braking blocks, dowel bars and a locking oil cylinder, wherein the braking blocks and the dowel bars are arranged at two sides of the flange and are bilaterally symmetric. The flange is fixed on a spindle. The fixed board is fixed on a spindle box. The dowel bars are fixed on the fixed board. The braking blocks are fixed on the inner sides of the dowel bars. The locking oil cylinder is fixed between the left and right dowel bars. Stop pins are arranged on the outer sides of the dowel bars. The dowel bars can rotate by taking only rotating shafts as centers. Braking blocks are fixed on the dowel bars through rotating pins. Based on principles of self-centering and lever force amplification, the precise spindle locking device avoids any influence on the precision of the spindle when the spindle is locked and absolutely reliable locking is achieved, thereby ensuring the precision of processed parts, the precision of the spindle and the service life of the spindle.

Owner:GUANGZHOU CITY AGILE MFG

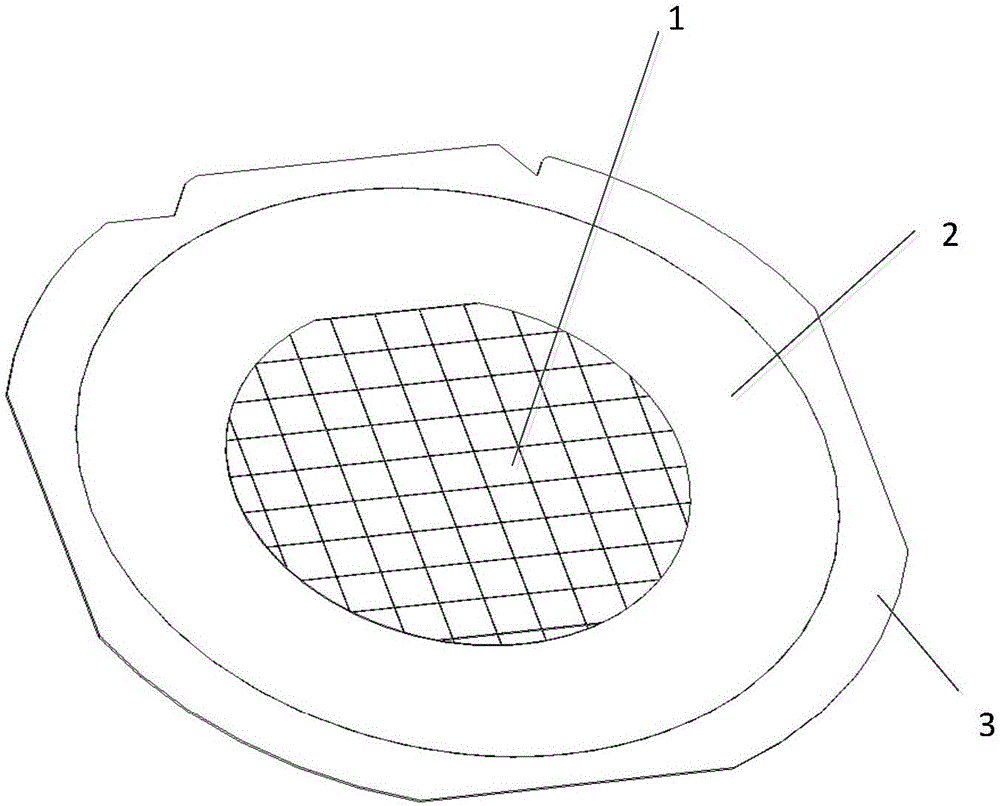

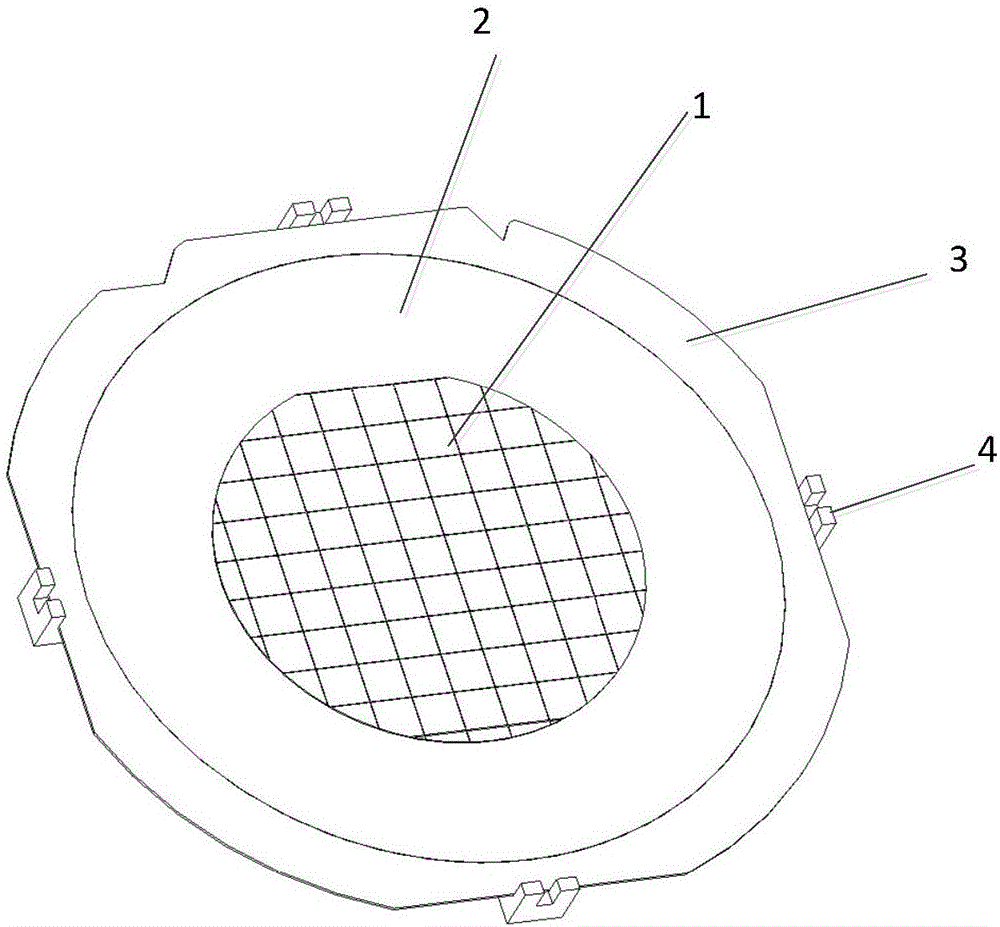

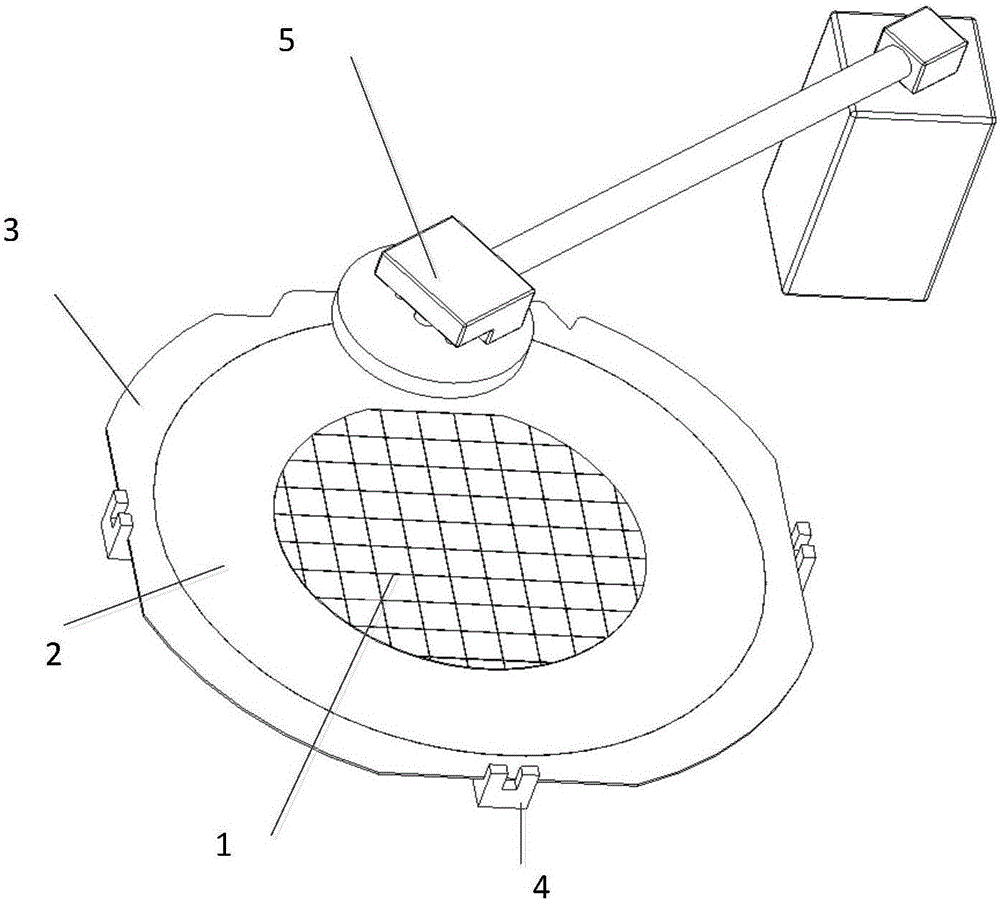

MEMS (Micro-Electro-Mechanical System) cutting and cleaning as well as releasing method of wafer

InactiveCN106629582AImprove uniformityRelease process in one stepDecorative surface effectsChemical vapor deposition coatingUltravioletBack cutting

The invention relates to an MEMS (Micro-Electro-Mechanical System) cutting and cleaning as well as releasing method of a wafer. The method comprises the following steps of pasting a UV (Ultraviolet) film, wherein the frontal surface of the wafer is put at the midpoint of a vacuum suction cup, of which the middle is suspended, of a film pasting machine; cutting, wherein a step cutting is adopted, the two-step cutting is continuously completed, the cutting thickness of a front cutting blade is 20 to 60 percent of the total thickness of the wafer, and a back cutting blade is used for thoroughly scratching the wafer; cleaning and spin-drying, wherein the wafer which is fixedly arranged on a stainless steel frame is integrally placed on a rotatable ceramic dense-hole suction cup, the ceramic dense-hole suction cup is used for fixing the periphery of the stainless steel frame, a liquid spraying system is arranged above the ceramic dense-hole suction cup, the liquid spraying system comprises a plurality of spray heads capable of leftwards and rightwards swinging to spray a solution, the spray heads spray liquid to clean the wafer, and the ceramic dense-hole suction cup is rotated at a high speed, so as to throw out waste liquid; irradiating; carrying out film expansion on the wafer; taking down a chip from the UV film by utilizing a chip pick-up device, and putting the chip into a tray; placing the tray in a degumming machine device, and carrying out structure release. The alignment for two times is not needed; the accuracy of cutting positions for the two times is guaranteed.

Owner:YANTAI RAYTRON TECH

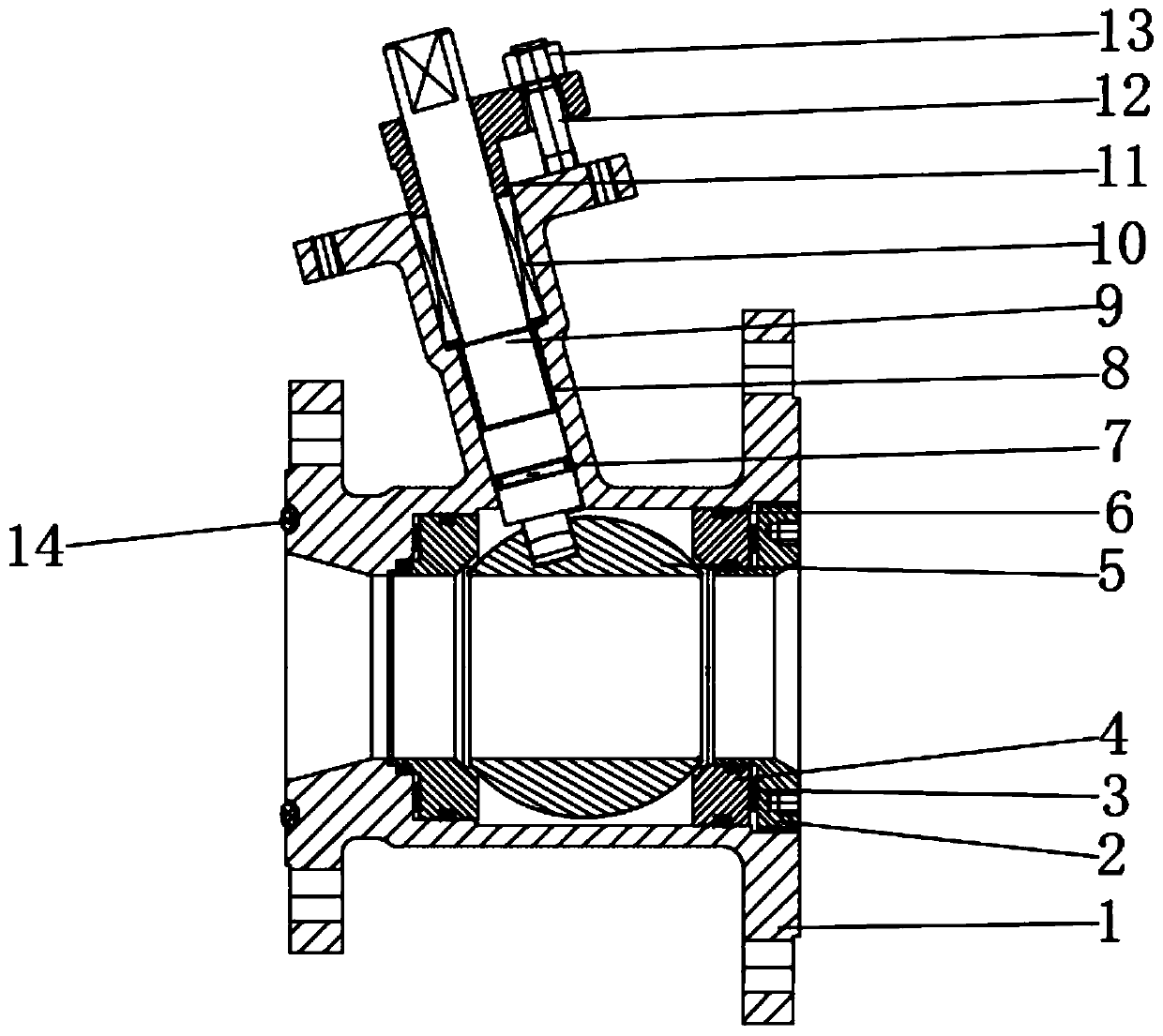

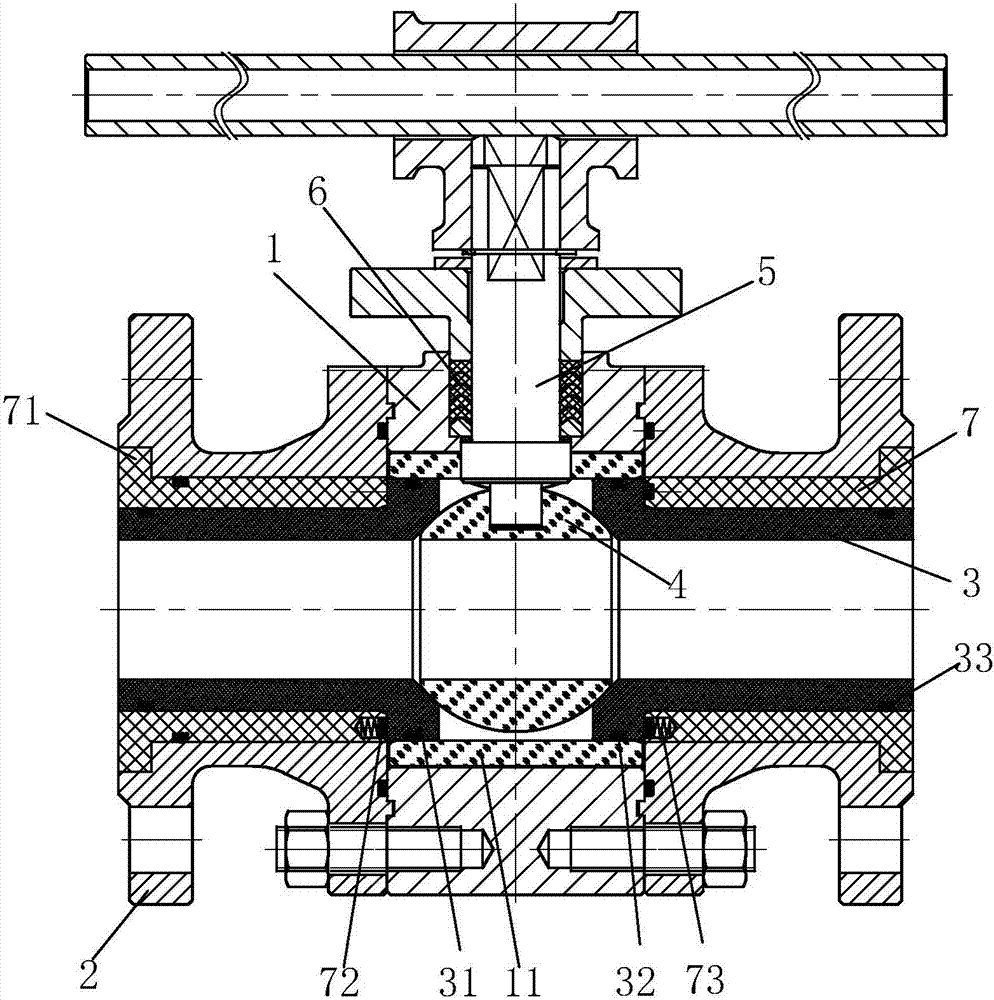

Slash kettle bottom discharging valve

PendingCN109973679AReduce rotational frictionEasy to useSpindle sealingsPlug valvesEngineeringValve seat

The invention discloses a slash kettle bottom discharging valve. The slash kettle bottom discharging valve comprises a discharging valve body, a valve body cap is arranged at one end of the discharging valve body, a discharging valve seat is embedded in the inner side, corresponding to the valve body cap, of an inner cavity of the discharging valve body, a valve body plate spring is arranged between the discharging valve seat and the valve body cap, a sphere valve element is movably embedded in an inner cavity of the discharging valve seat, the inner wall, corresponding to the discharging valve body, of the outer surface of the discharging valve seat is nested with a valve seat O-shaped ring, a discharging valve rod is embedded in the side face of the sphere valve element, the position, close to the sphere valve element, of the side face of the discharging valve rod is nested with a valve rod O-shaped ring, and the middle of the side face of the discharging valve rod is nested with a valve rod shaft sleeve. According to the slash kettle bottom discharging valve, the problem that during rotating of the sphere valve element, rotating is excessive, thus a gap is produced between the sphere valve element and the discharging valve body, and then leakage is caused can be solved, rotary frictional force of the discharging valve rod can be lowered through the valve rod shaft sleeve, thus the discharging valve rod is convenient to use, and the use time of the valve rod shaft sleeve is prolonged.

Owner:浙江天天阀门有限公司

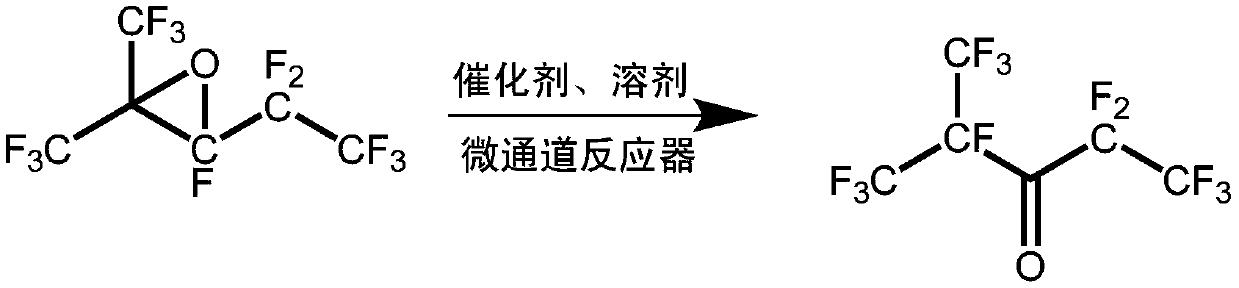

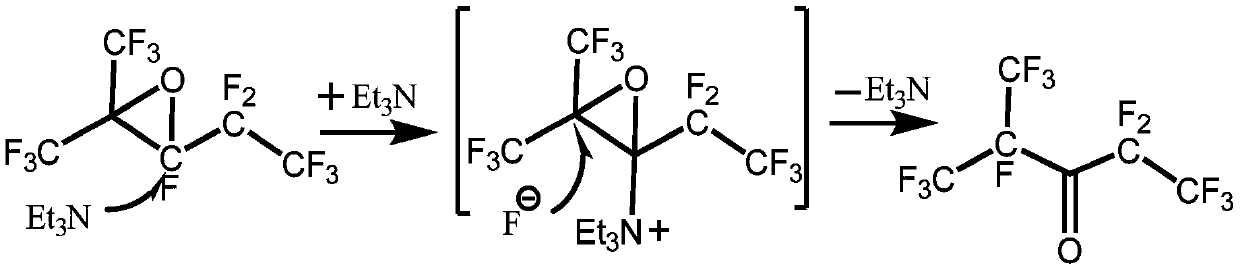

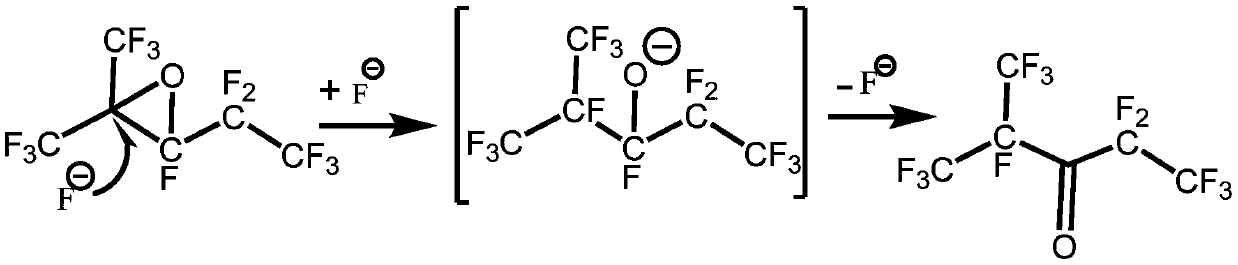

Method for synthesizing perfluoro(2-methyl-3-pentanone)

PendingCN111004100AContact will notAvoid generatingChemical/physical/physico-chemical microreactorsPreparation from heterocyclic compoundsSide productProtic solvent

The invention discloses a method for synthesizing perfluoro(2-methyl-3-pentanone). The method comprises the following steps: in the presence of a polar aprotic solvent, carrying out an isomerization synthesis reaction in a micro-channel reactor by taking perfluoro-2,3-epoxy-2-methylpentane as a raw material and using an organic amine or metal fluoride as a catalyst to obtain a reaction product, and sequentially carrying out standing separation and rectification treatment on the reaction product to obtain perfluoro(2-methyl-3-pentanone). According to the invention, a reaction is performed by using a micro-channel reactor, so that the whole isomerization synthesis reaction cannot contact water or water vapor so as to avoid the generation of by-products and improve the conversion rate and theyield of the perfluoro(2-methyl-3-pentanone); and raw materials and a catalyst are subjected to high-speed uniform mixing and heat and mass transfer in the micro-channel reactor, so that the rate ofthe synthesis reaction is increased, the continuous and efficient synthesis of perfluoro(2-methyl-3-pentanone) is realized, and the method is good in repeatability, rapid in system response, easy forautomatic control and amplified production, almost free of amplification effect, high in safety, less in three wastes and easy for industrial production.

Owner:XIAN ORIGIN CHEM TECH

Automobile heat-resistant plastic shell start-stop battery

InactiveCN112133849AExtended service lifeWon't get wetSecondary cellsCell component detailsAutomotive engineeringElectrical and Electronics engineering

The invention relates to the technical field of automobile start-stop batteries, and discloses an automobile heat-resistant plastic shell start-stop battery which comprises a battery shell, a shell top cover is fixedly mounted at the top of the battery shell, and a first rubber pad is fixedly mounted at the top of the shell top cover and located in an inner cavity of the battery shell. An air inlet strip is arranged on the left side of the battery shell, an air outlet strip is arranged on the right side of the battery shell, and a first sliding rail piece is fixedly installed in the position,close to the air inlet strip, of an inner cavity of the battery shell. According to the automobile heat-resistant plastic shell start-stop battery, a ventilation strip is arranged, and the ventilationstrip has an upward angle, so that rainwater or cleaning water cannot enter the interior of the battery shell, and therefore, the battery in the battery shell cannot be wetted, and the ventilation strip is divided into the air inlet strip and the air outlet strip; and through circulation of the two air ports, air in the battery shell can be subjected to convection in time, so that heat can be taken away in time, and waterproof and heat dissipation effects are achieved.

Owner:风帆(扬州)有限责任公司

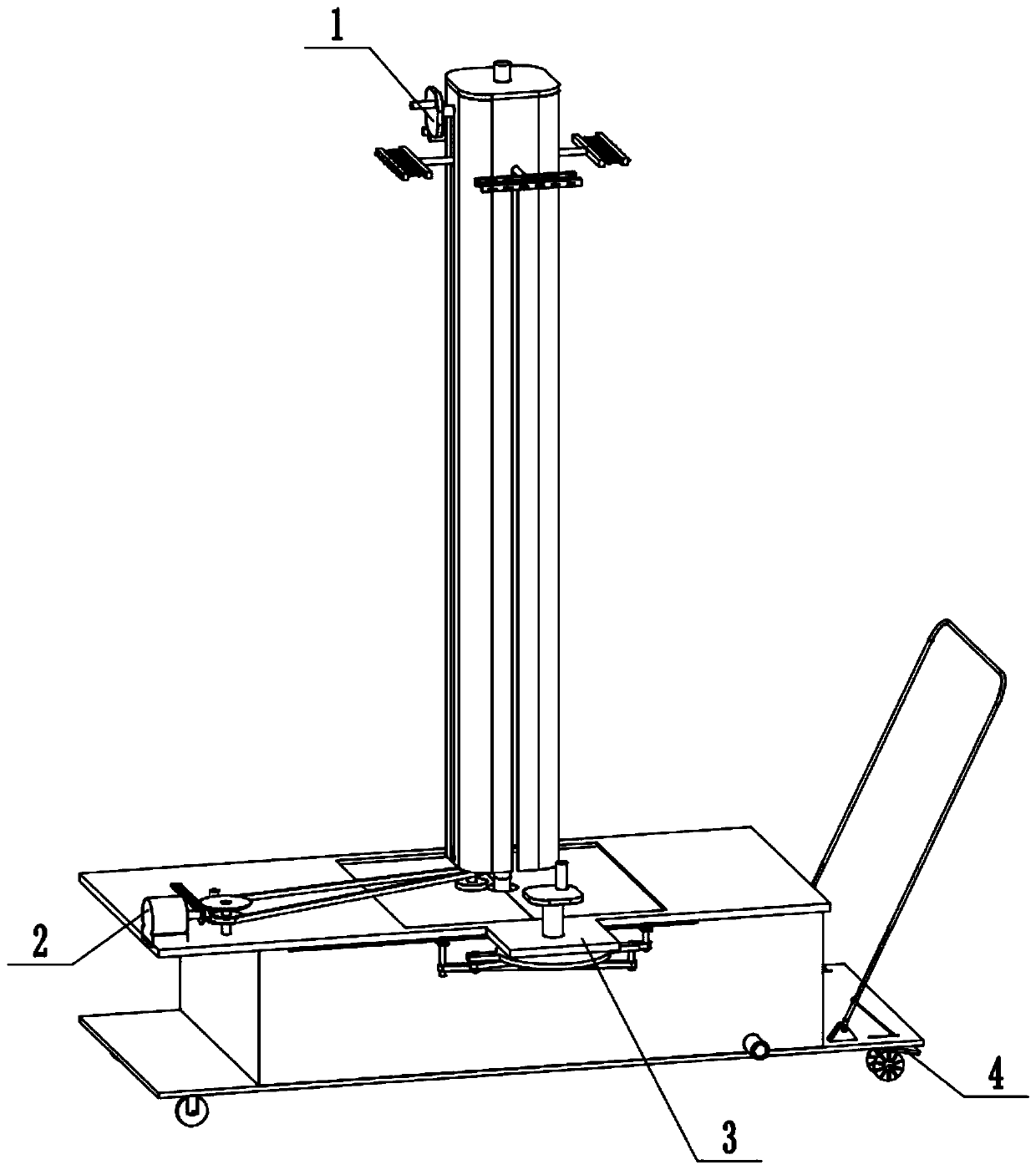

Surgical instrument disinfection equipment

The invention relates to the field of surgery, in particular to surgical instrument disinfection equipment. The surgical instrument disinfection equipment comprises an instrument fixing combination body, a power combination body, a door opening combination body and a walking combination body. In an operation, the problems that an operation instrument is not convenient to take and inconvenient to find, or the disinfection treatment of postoperative instruments can be prevented from colliding with a new pollution source after being disinfected, the sterilized bacteria are polluted is solved. Thesurgical instrument disinfection equipment solves the above problem. The surgical instrument can be inserted into a clamp and is convenient to take, a surgical instrument rack can be lifted and can be adjusted to the height which can be conveniently taken by a user, a square spring is adjusted, the surgical instrument can be clamped by the clamp, the surgical instrument rack is descended to the lowest point, a power device drives the surgical instrument rack to rotate in the disinfectant, dirt on the surface of the instrument is scoured, and meanwhile, the disinfectant is fully contacted anddisinfected with the surface of the instrument.

Owner:马雪

Antipruritic and mosquito-repelling and itch-relieving patch

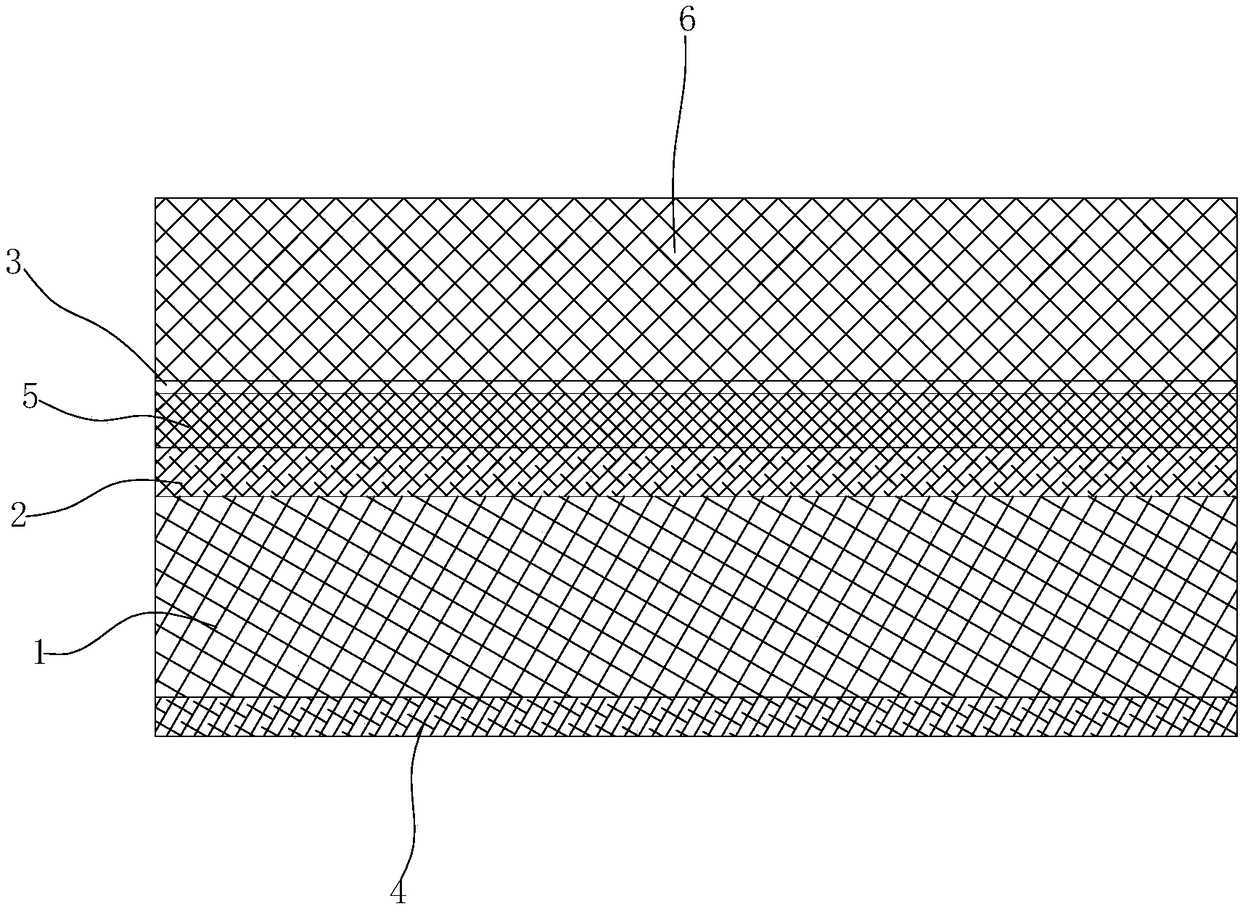

PendingCN108498572AAnti-itchGood anti-itch effectCosmetic preparationsToilet preparationsOrganic acidAntipruritic agents

The invention relates to an antipruritic agent and a mosquito-repelling and itch-relieving patch. The antipruritic agent comprises, by weight, 1-10% of sodium polyacrylate, 0.05-2% of a crosslinking agent, 0.01-5% of an organic acid, 1-30% of a filler, 15-70% of a humectant, 1-30% of a solubilizer, 0.5-8% of an adhesive, 20-80% of water and 1-30% of plant essential oil. The antipruritic agent is applied to the first surface of a separation film (2), and is cured to form an antipruritic layer (1); a protective film (4) is pasted on the surface of the antipruritic layer (1); and a mosquito repelling drug is attached to the second surface of the separation film (2) to obtain the mosquito-repelling and itch-relieving patch.

Owner:浙江小正科技有限公司

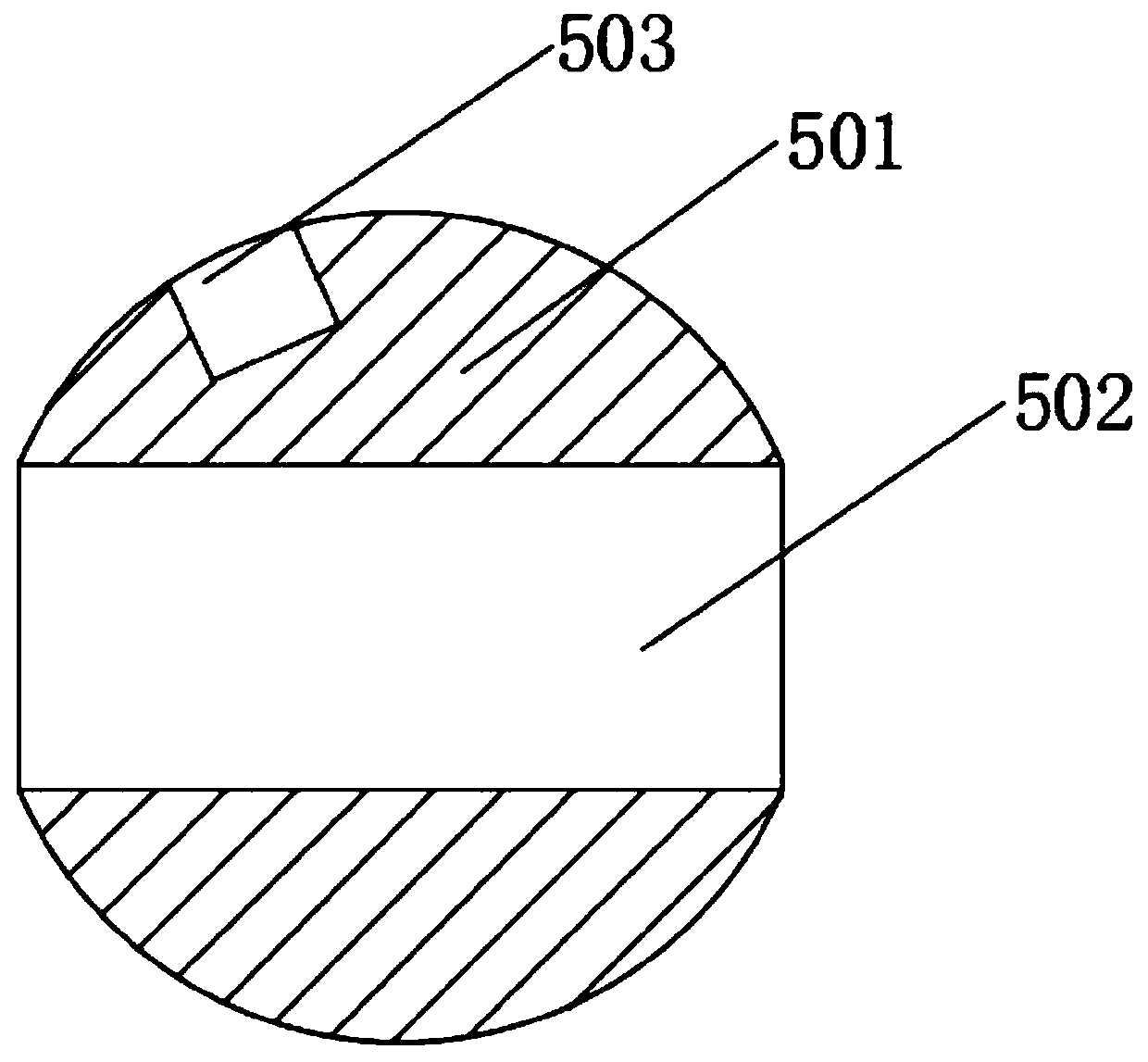

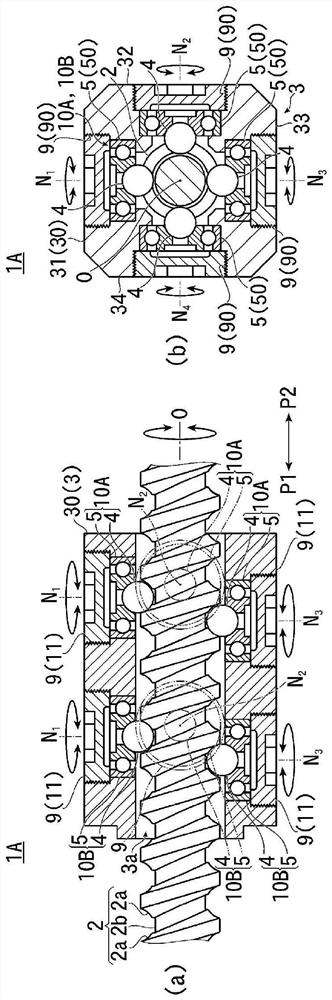

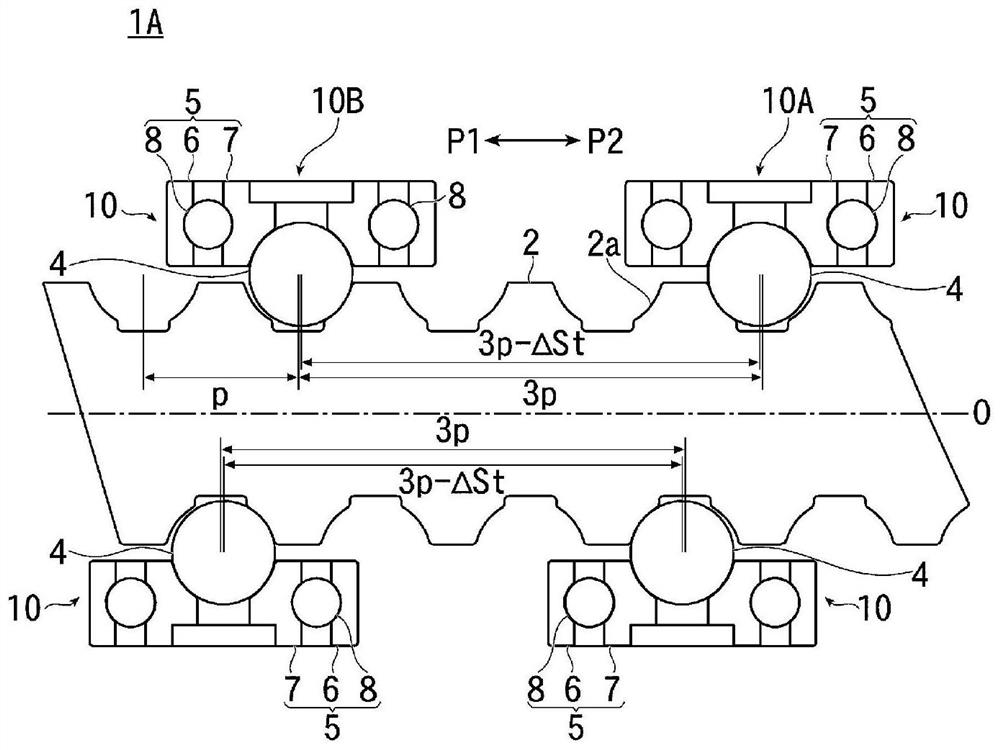

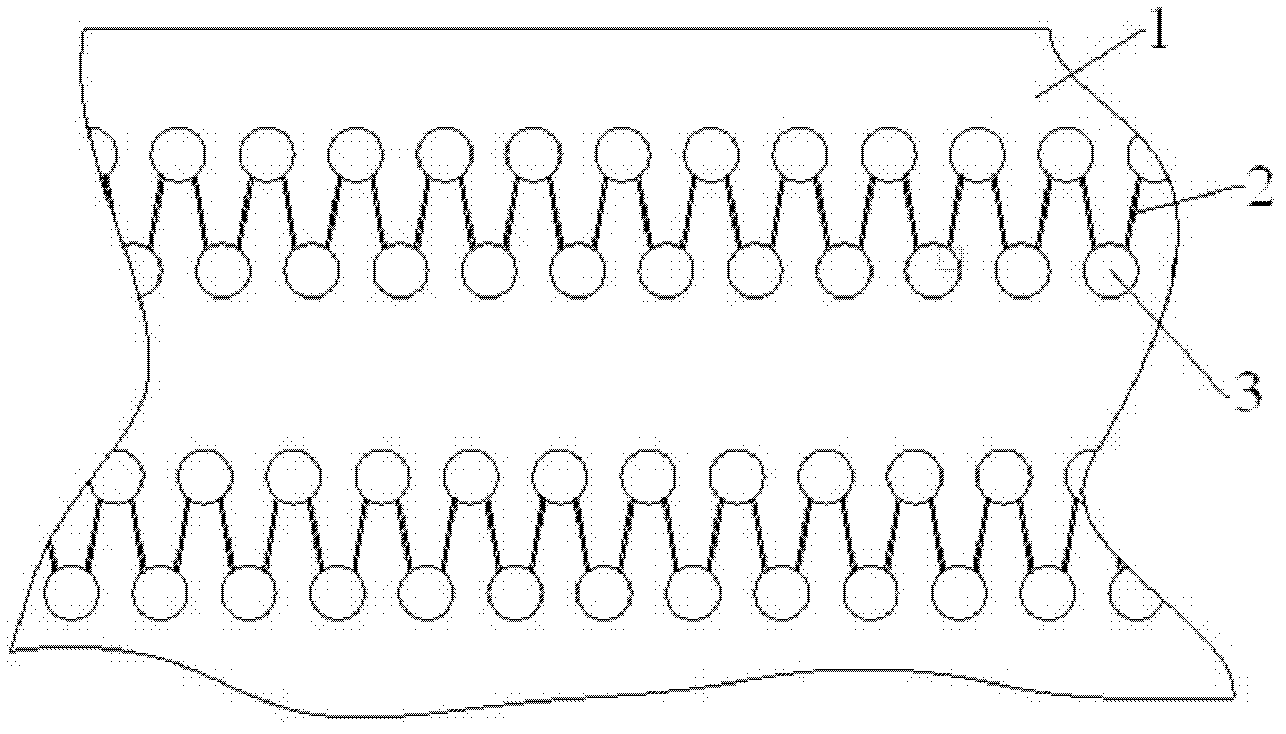

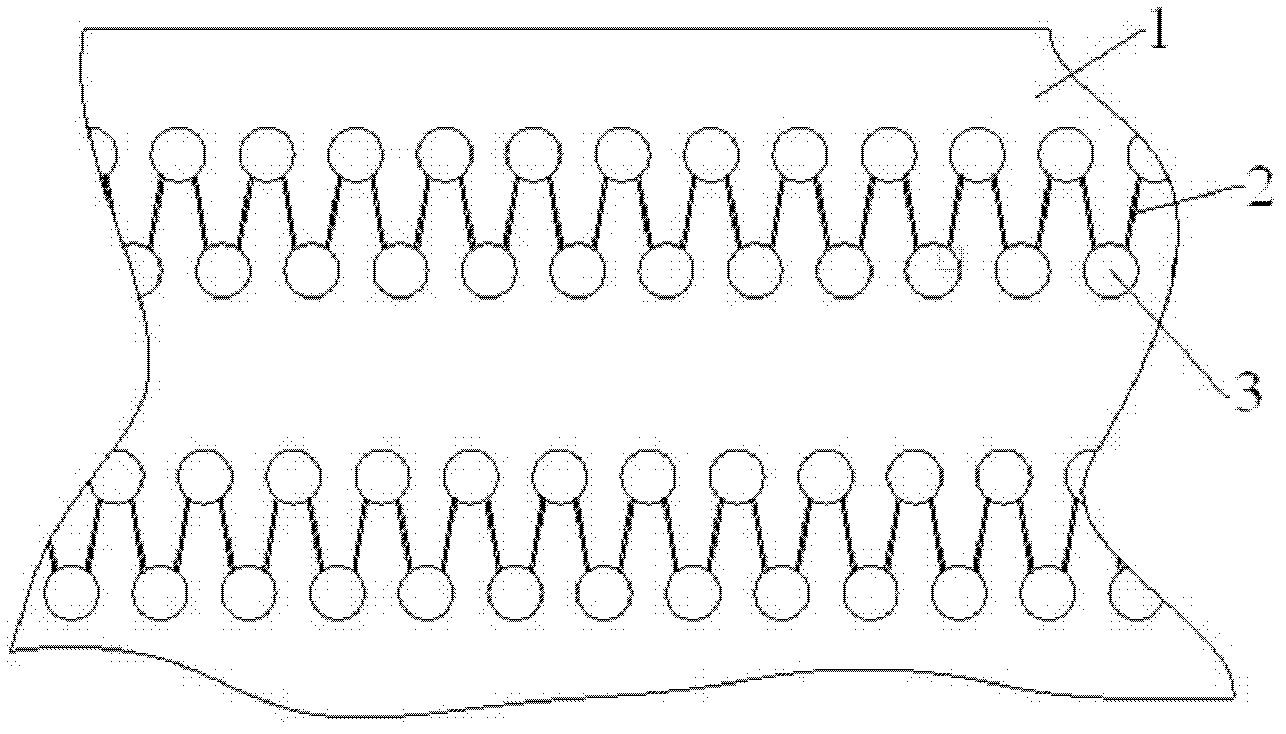

Ball screw mechanism and linear motion device

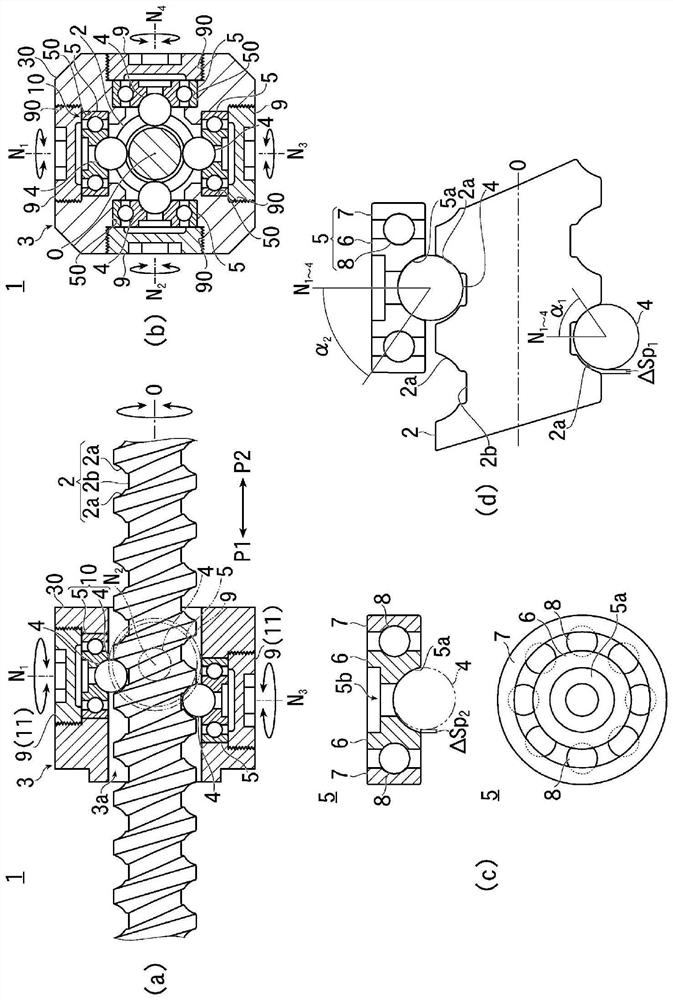

Provided is a ball screw mechanism that can prevent vibration and noise and avoid an increase in heat by ensuring smooth movements of balls without the occurrence of obstructions or the like of the balls on a screw shaft, and without the need to consider the return of the balls as in a conventional circulation-type ball screw. The present invention is provided with a screw shaft 2 that has a spiral groove 2a and extends linearly; a housing 30 that surrounds the circumference of the screw shaft 2; and a plurality of balls 4 and ball bearings 5 that transmit the thrust of the screw shaft 2 to the housing 30. The ball bearings 5 each have outer rings 7 that are attached and fixed to the housing 30 at predetermined intervals along the spiral groove 2a of the screw shaft 2, and inner rings 6 provided with a concave spherical contact surface 5a, which is in contact with the balls 4, on the side surface facing the screw shaft 2. The inner rings 6 are installed so as to be rotatable about rotation axes N1-N4 that cross the rotation axis O of the screw shaft 2. The balls 4 are disposed adjacent to the inside of the spiral groove 2a of the screw shaft 2 at predetermined intervals while in contact with the contact surfaces 5a of the ball bearings 5.

Owner:水野逸人

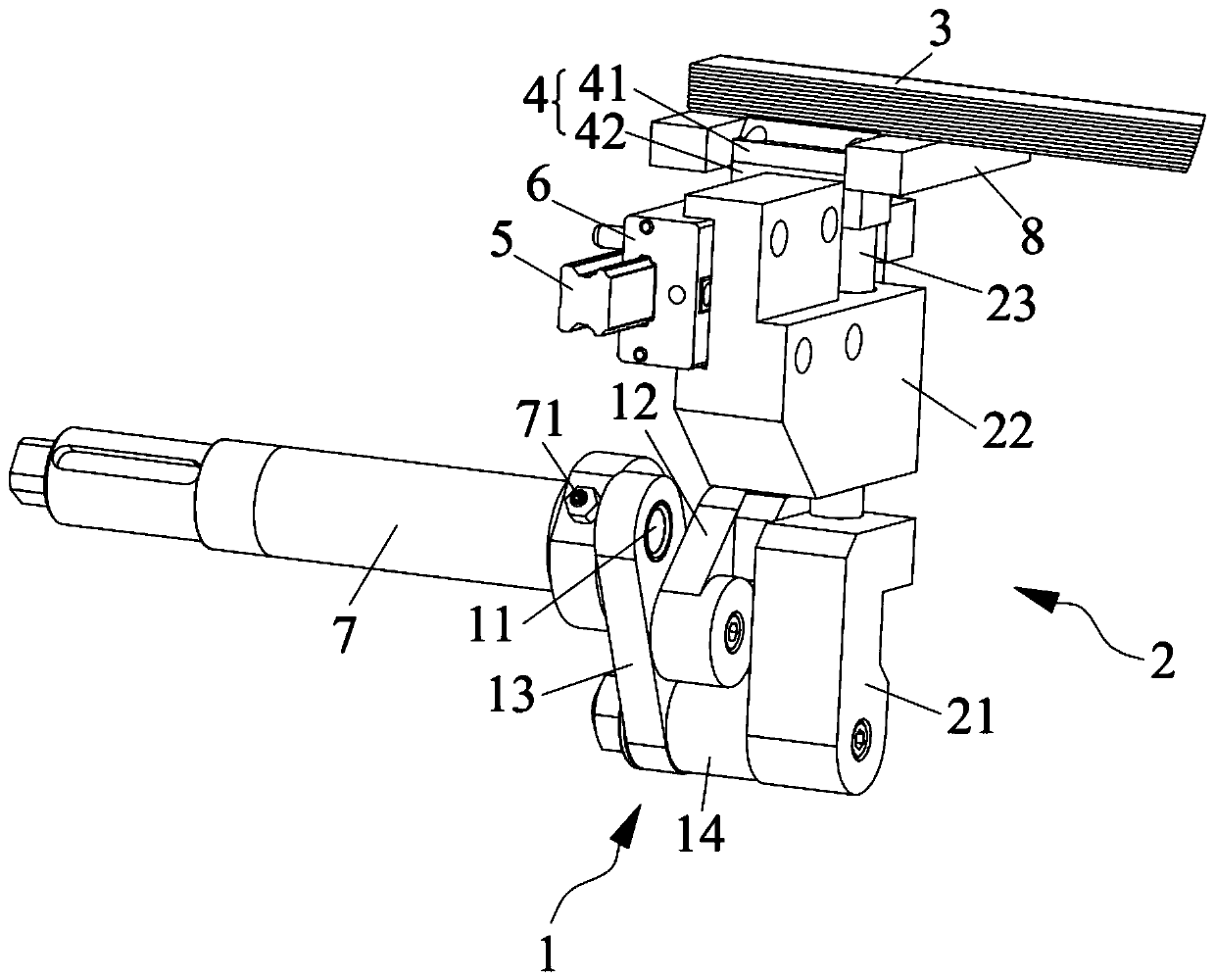

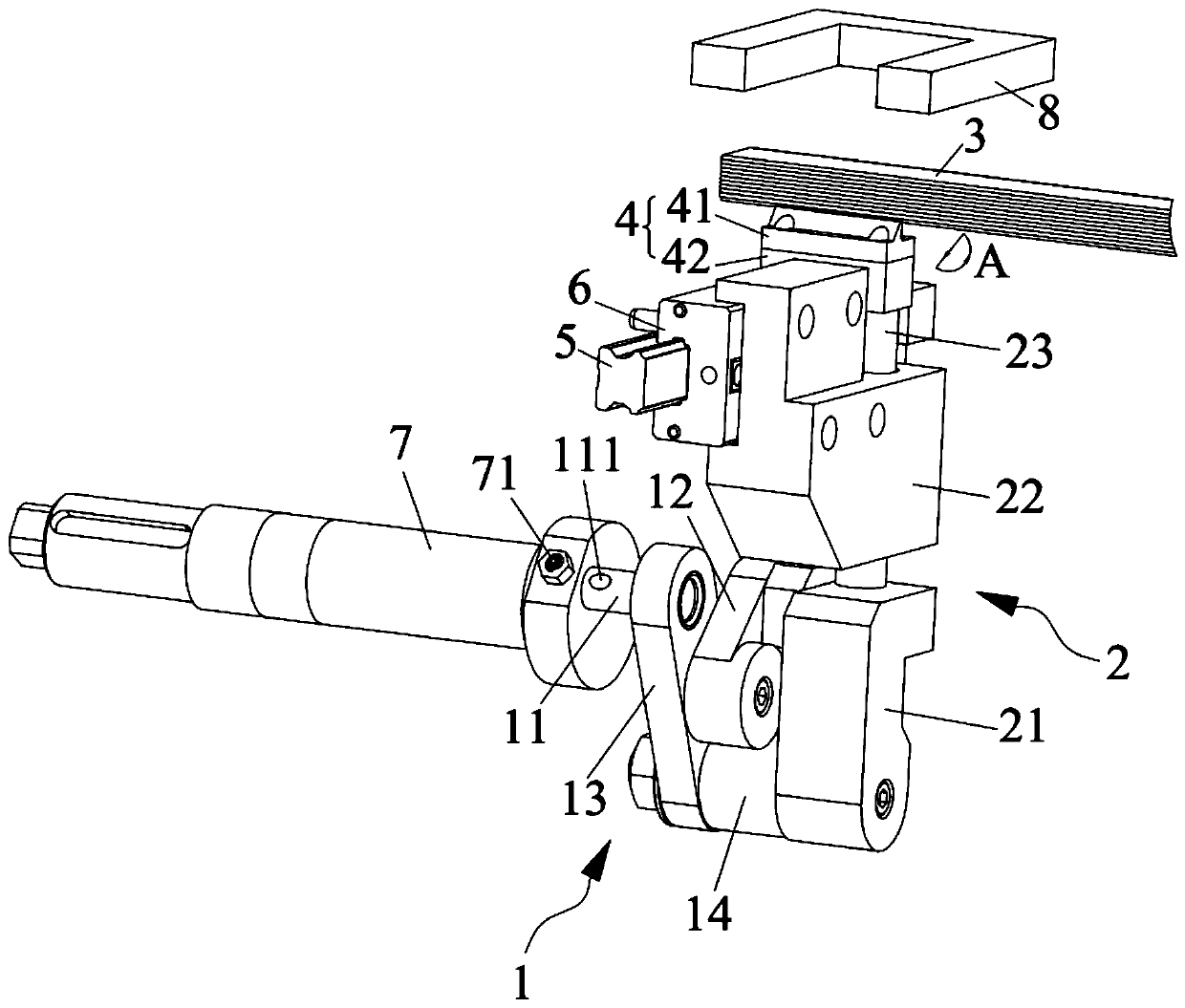

Flat tube discharging device

PendingCN110654894AFast dischargeAvoid frictional damageConveyorsDe-stacking articlesMechanical engineeringHeat exchanger

The invention discloses a flat tube discharging device and belongs to the technical field of heat exchanger flat tube production equipment. The flat tube discharging device comprises a driving part, aknockout assembly and a middle connecting rod mechanism. The material beating assembly abuts against a flat tube to discharge the flat tube; one end of the middle connecting rod mechanism is in driving connection with the driving part, the other end of the middle connecting rod mechanism is connected with the knockout assembly, and the driving part drives the middle connecting rod mechanism to move so as to drive the knockout assembly to not make contact with the next flat tube after the knockout assembly discharges the flat tube and returns back to the original point. The flat tube discharging device has the beneficial effects that the middle connecting rod mechanism can drive the knockout assembly to move, so that the knockout assembly can be prevented from making contact with the nextflat tube in the process of returning to the original point, friction between the knockout assembly and the flat tube is avoided, and friction damage of the flat tube which is not discharged and the knockout assembly can be avoided at the same time.

Owner:SHANGHAI HEKE EQUIP MFG

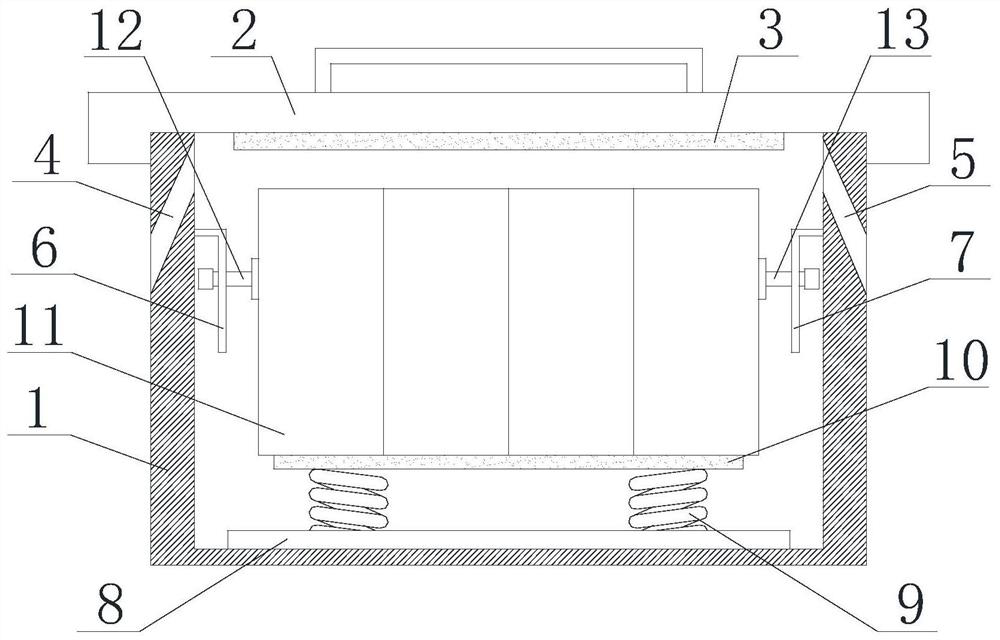

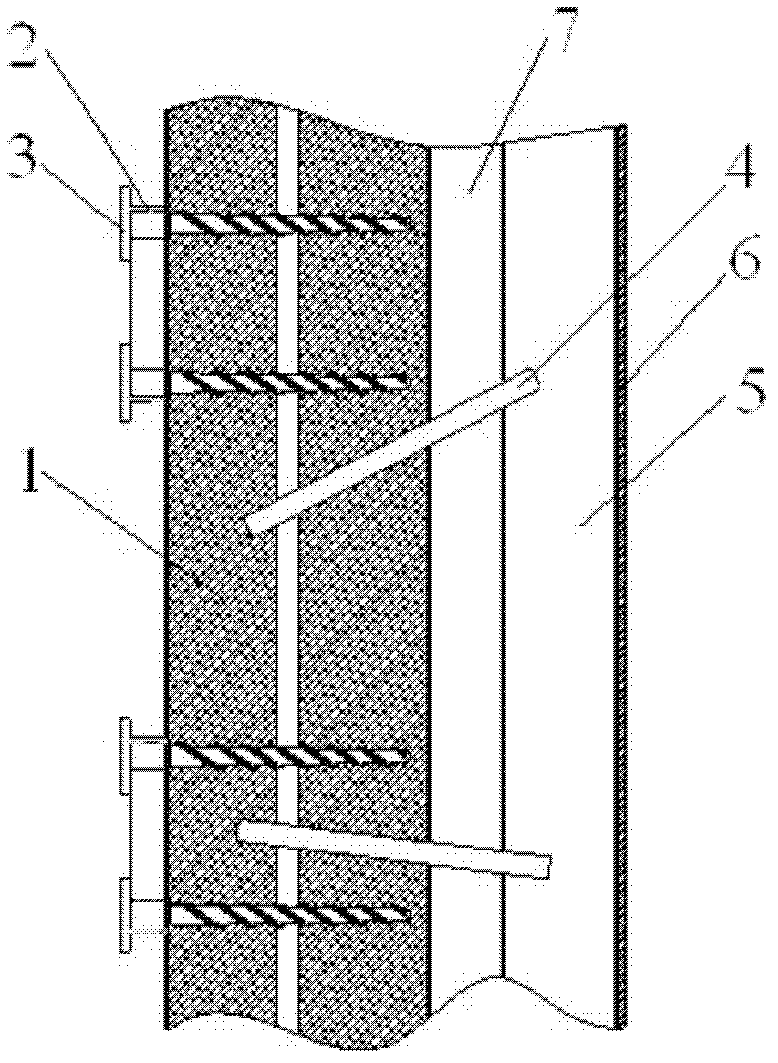

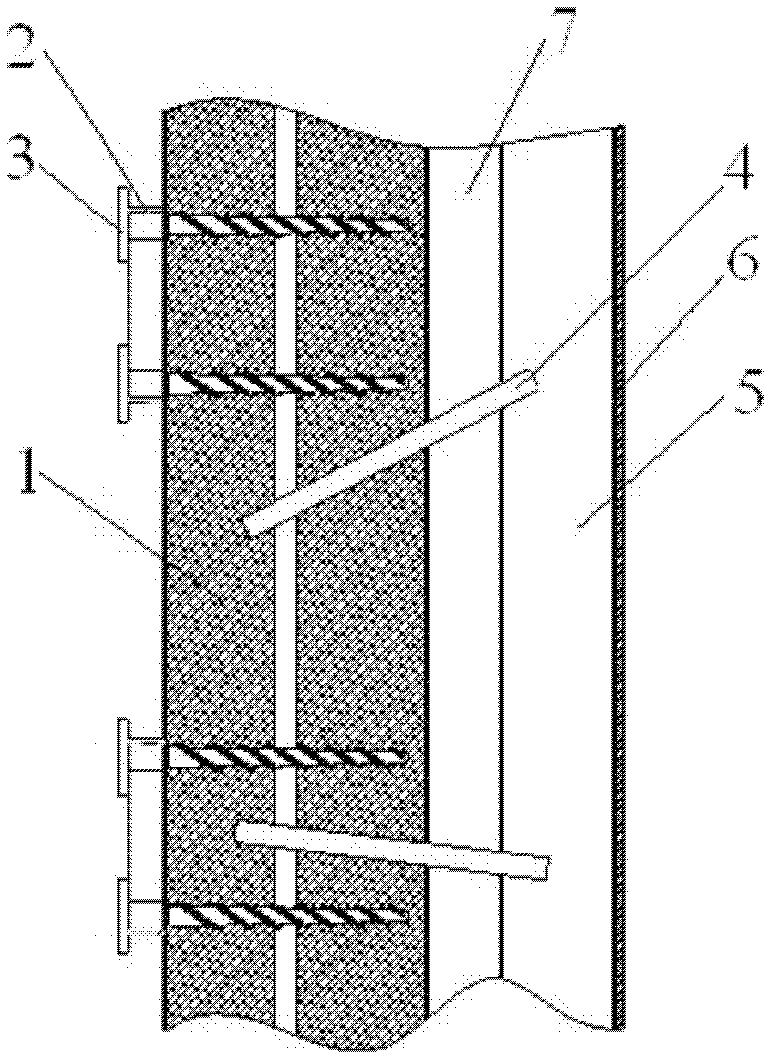

Box type heat treatment device

ActiveCN102560012AShorten heating timeSave heatFurnace typesElectric heating for furnacesThermal insulationElectric heating

The invention discloses a box type heat treatment device, which comprises a furnace body (5), a furnace body panel (6) and an electric heating wire belt (2). The inner side surface of the furnace body (5) is provided with a furnace lining (1), wherein the gap is arranged between the furnace lining (1) and the furnace body (5), and the material of the furnace lining (1) is high temperature resistant fiber cotton. The electric heating wire belt (2) is fixed on the furnace lining (1). With the technical scheme of the present invention, the furnace wall heat storage is reduced, such that the heating time of the blank furnace is shortened, the heat energy is saved, and the thermal insulation effect of the heat treatment furnace is improved; the phenomena similar to refractory brick structure oxidizing, re-qualitation, and the like are overcome, the performance of the device is stabilized, the service life of the device is prolonged, and the production cost is saved.

Owner:ANHUI NINGGUO XINNING IND

A warhead shell with improved filling ratio based on laser coaxiality measuring instrument

ActiveCN112390693BTotal energy guaranteeMeet PowerdesignExplosive working-up apparatusMeasuring instrumentEngineering

The invention discloses a warhead casing with improved filling ratio based on a laser coaxiality measuring instrument. The axis of the rotating body of the supporting frame 4 coincides with the axis of the rotating body of the casing 1. The supporting frame 4 is located inside the casing 1 and supports the The fourth upper end concentric annular surface of the frame 4 is coplanar with the second upper end concentric annular surface of the upper end cover 2, and the fourth outer cylindrical surface of the support frame 4 is in contact with the second inner cylindrical surface of the upper end cover 2. The support frame The lower ends of the four fourth cylindrical bodies of 4 are in sliding fit contact with the third upper end circular plane of the lower end cover 3 . The contact between air and gelled solid-liquid mixed fuel is avoided, and finally there is no air inside the fuel, which satisfies the power design of the warhead. The risk of burning is avoided and the safety of the warhead is guaranteed.

Owner:XIAN MODERN CHEM RES INST +1

Vertical roller mill hydraulic system

ActiveCN101543797BQuick liftContact will notServomotorsGrain treatmentsHydraulic cylinderEngineering

The invention relates to a vertical roller mill hydraulic system, which comprises a plurality of grinding roll clamping hydraulic cylinders, a plurality of accumulator groups, a hydraulic station and connecting pipelines among the grinding roll clamping hydraulic cylinders, the accumulator groups and the hydraulic station, wherein the hydraulic station comprises an oil tank device, an oil pump device, a grinding roll clamping control valve group and connecting pipelines among the oil tank device, the oil pump device and the grinding roll clamping control valve group; a feedline of the oil pump device is connected with an inlet of the grinding roll clamping control valve group; an oil pump motor supplies oil for the grinding roll clamping control valve group; an outlet of the grinding rollclamping control valve group is connected with piston rod cavities of the grinding roll clamping hydraulic cylinders and the accumulator groups; rodless cavities of the grinding roll clamping hydraulic cylinders are connected with the grinding roll clamping control valve group through a plurality of oil return pipes; the grinding roll clamping control valve group controls the telescoping of piston rods of the grinding roll clamping hydraulic cylinders through a plurality of electromagnetic directional valves; and the accumulator groups absorb the vibration of the grinding roll clamping hydraulic cylinders respectively. The vertical roller mill hydraulic system solves the problem of loaded pressure boost of the system and improves the service life of grinding rolls and grinding discs and the maintenance efficiency.

Owner:BAOSTEEL ENG & TECH GRP

Box type heat treatment device

ActiveCN102560012BLess heat storageShorten heating timeFurnace typesElectric heating for furnacesFiberHeating time

The invention discloses a box type heat treatment device, which comprises a furnace body (5), a furnace body panel (6) and an electric heating wire belt (2). The inner side surface of the furnace body (5) is provided with a furnace lining (1), wherein the gap is arranged between the furnace lining (1) and the furnace body (5), and the material of the furnace lining (1) is high temperature resistant fiber cotton. The electric heating wire belt (2) is fixed on the furnace lining (1). With the technical scheme of the present invention, the furnace wall heat storage is reduced, such that the heating time of the blank furnace is shortened, the heat energy is saved, and the thermal insulation effect of the heat treatment furnace is improved; the phenomena similar to refractory brick structure oxidizing, re-qualitation, and the like are overcome, the performance of the device is stabilized, the service life of the device is prolonged, and the production cost is saved.

Owner:ANHUI NINGGUO XINNING IND

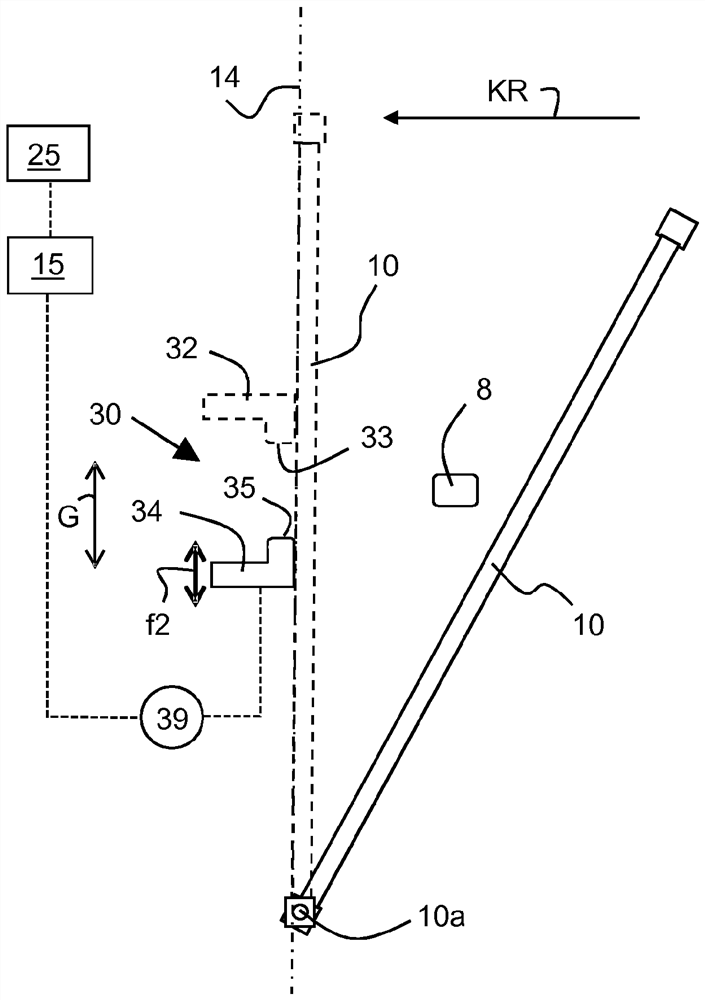

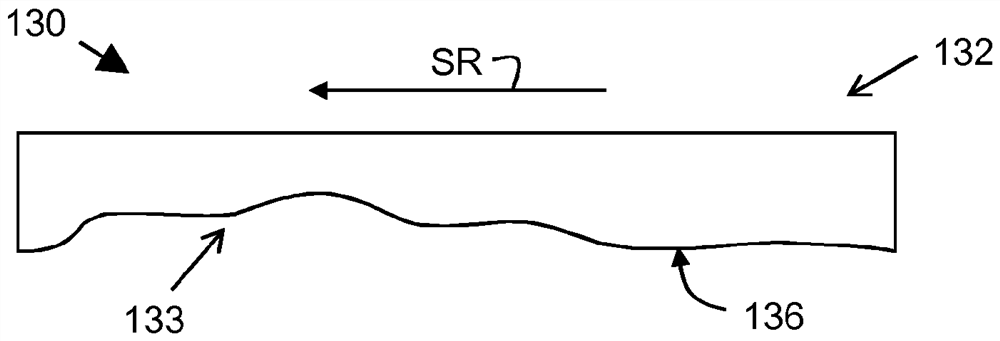

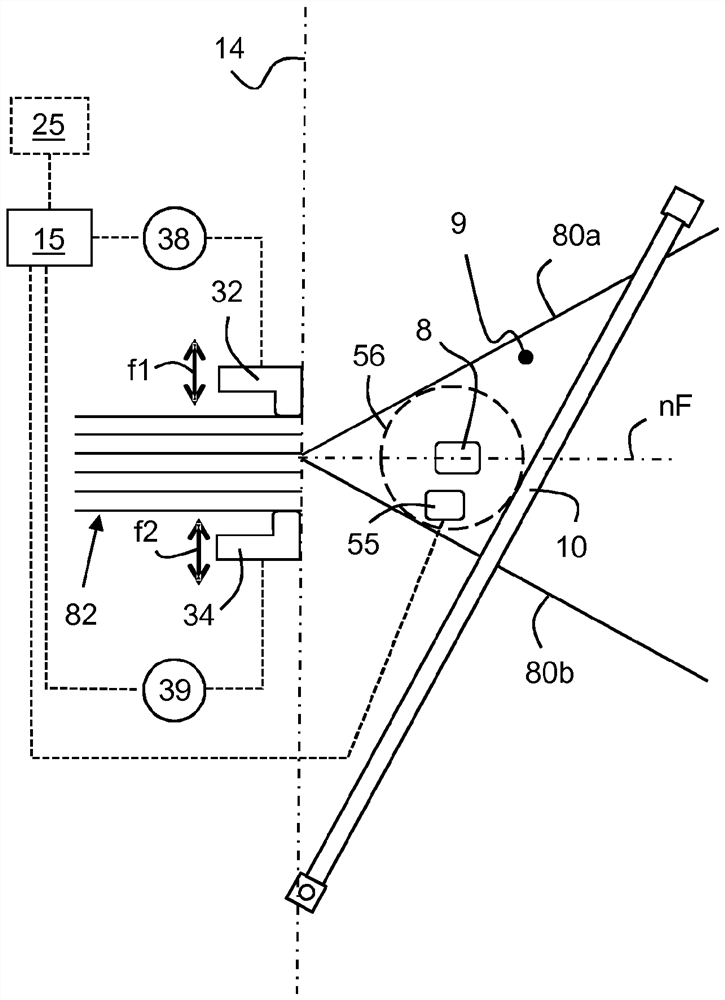

Loom and method for guiding a woven fabric in a loom

PendingCN112352071AEasy to guideAvoid collisionPile-fabric loomsAuxillary apparatusControl cellStructural engineering

The invention relates to various designs of a loom, which designs can be combined with one another, said loom comprising at least one guiding device having at least one guiding unit (32, 34) for the contacting guidance of a woven fabric (82) in the region of the reed beat-up plane (14). According to one embodiment, a control unit (15) is provided, which is designed to control at least one drive (38, 39) for the at least one guiding unit (32, 34). For the actuation, the control unit (15) processes information related to the woven-fabric structure in the region of the reed beat-up plane (14) and / or information regarding the position of the warp threads (80a, 80b) in the open shed. The invention further relates to methods for guiding a woven fabric in the region of the reed beat-up plane (14).

Owner:LINDAUER DORNIER GMBH

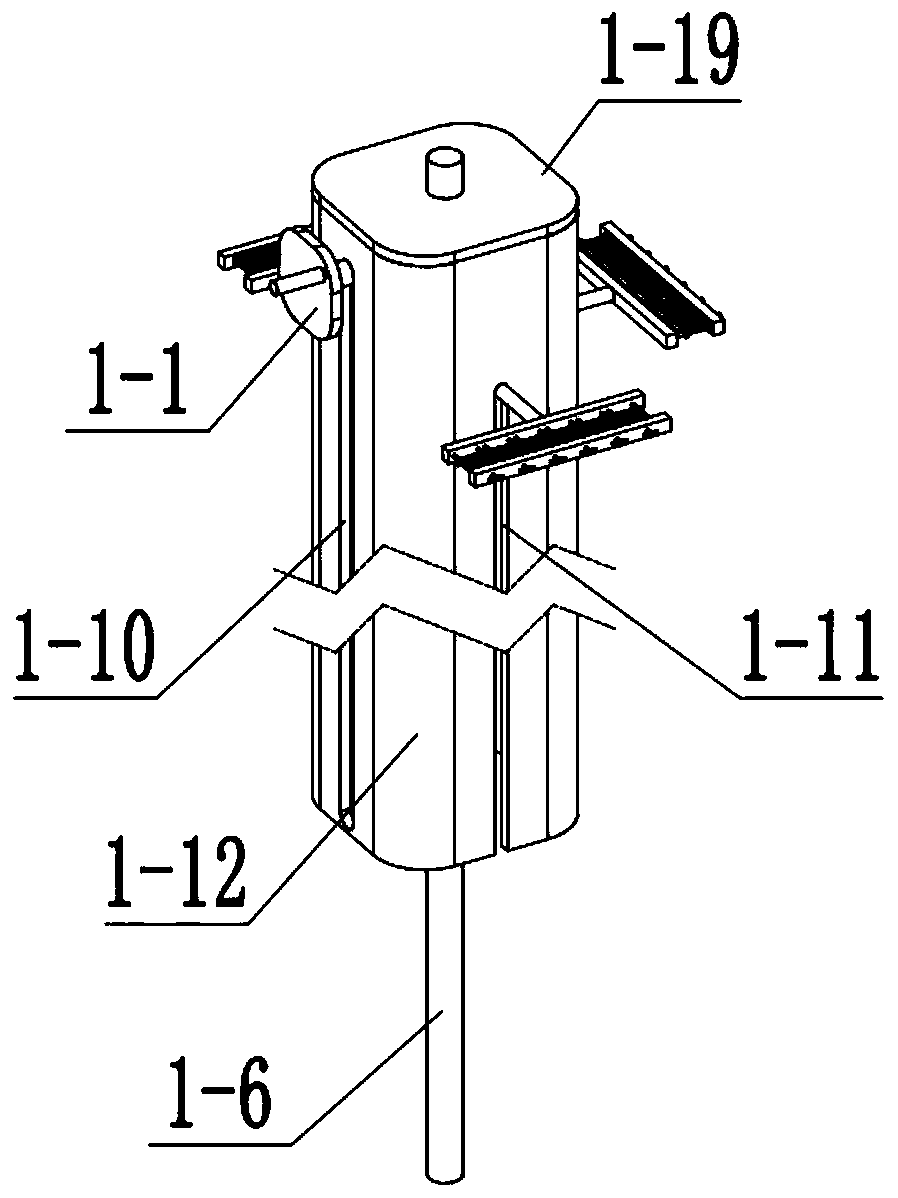

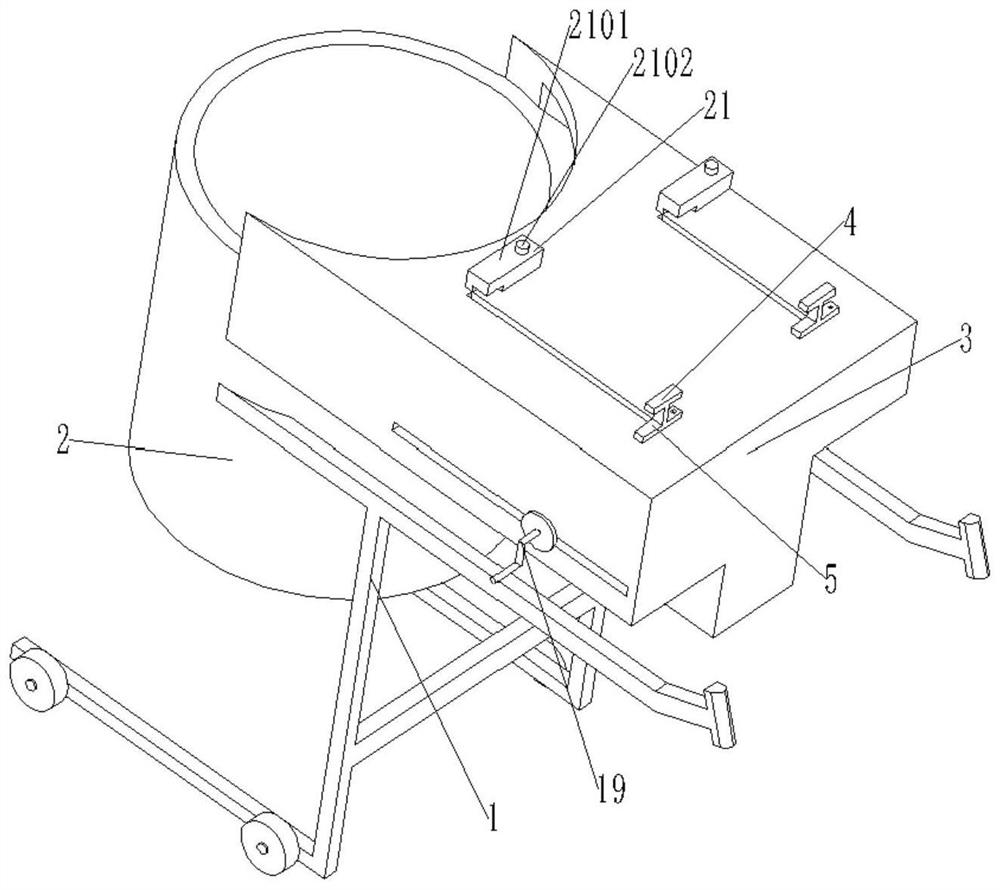

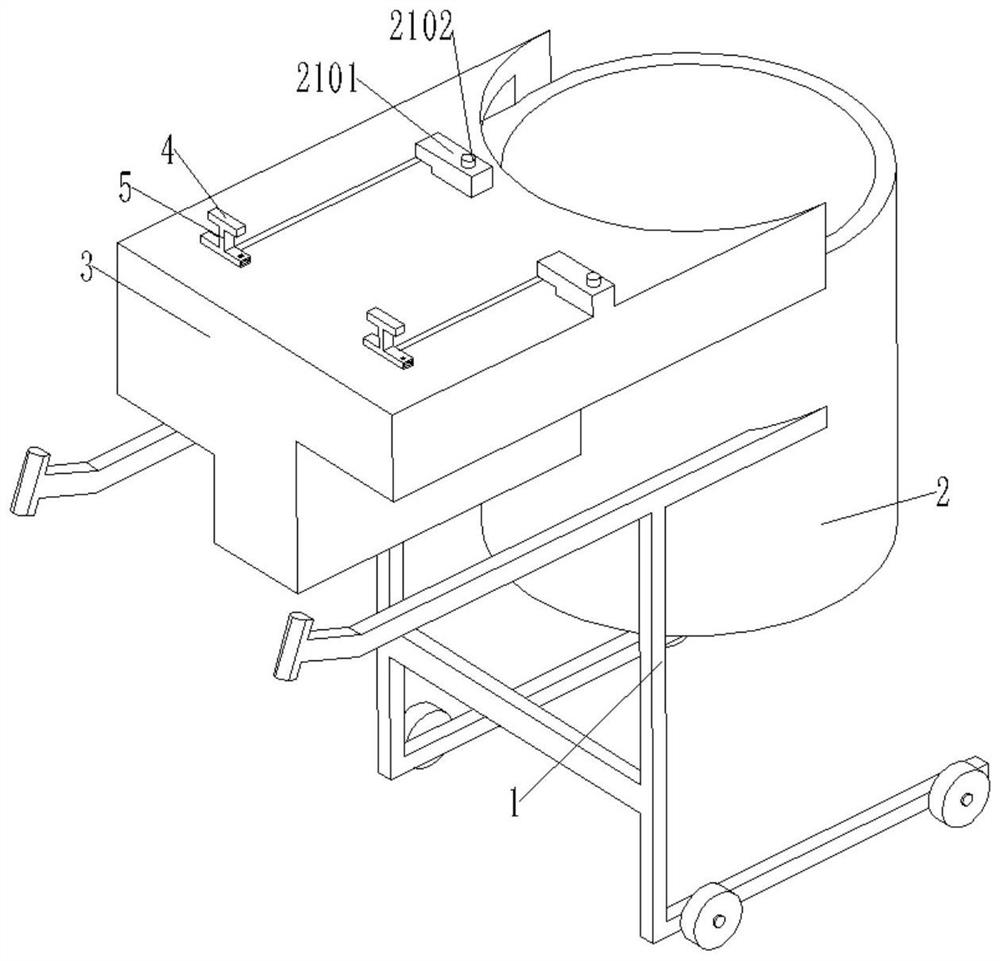

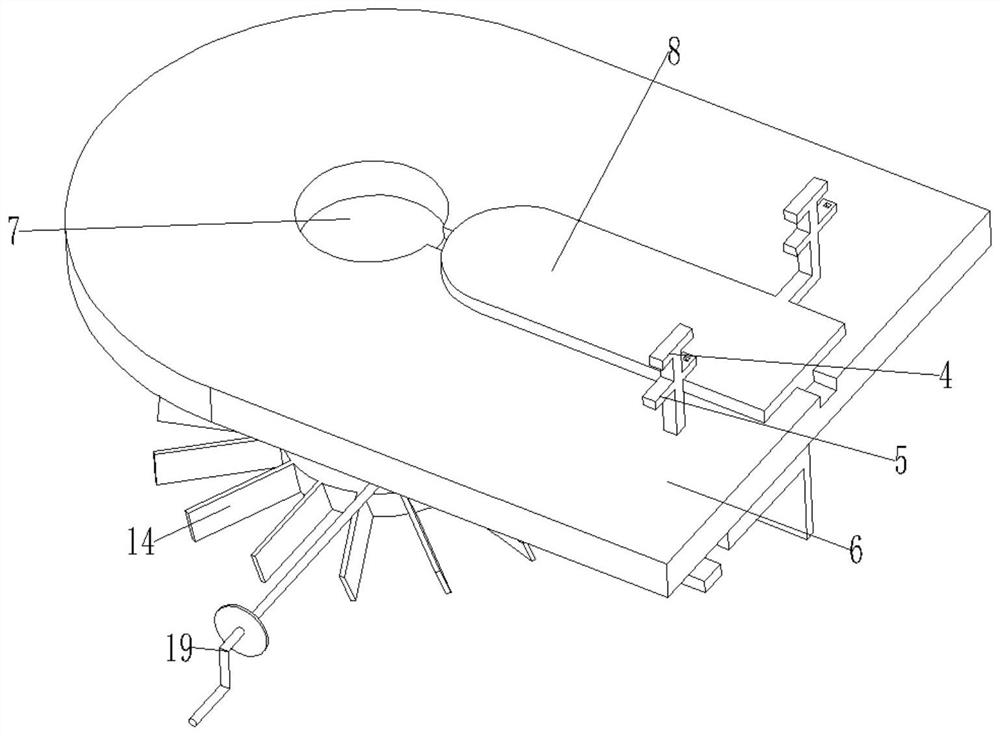

A material transfer device used in the capsule preparation process

ActiveCN112046995BGuarantee product qualityAvoid contactLarge containersManual conveyance devicesVehicle frameEconomic benefits

The invention discloses a material transfer device used in the capsule preparation process, which includes a vehicle frame main body, a storage cylinder, a storage box, a first sealing plate, a second sealing plate and a sealing plate positioning mechanism. The first sealing plate and the feed round hole ensure that when the material is transported into the storage tube, the material is prevented from contacting with the air, thereby preventing the impurities and dust in the air from polluting the material, and the material in the storage tube is filled. Finally, when it is necessary to transfer the materials in the storage tube, the feed circular hole on the first sealing plate is blocked by the second sealing plate, so that the material will not be mixed with the air in the process of transportation. Impurities and dust are in contact with each other, so as to ensure that the material will not cause quality damage during transshipment, thereby ensuring the production quality of the capsules and ensuring the economic benefits of production.

Owner:林保玲

An electrode device for detecting the electrochemical performance of porous coating materials

ActiveCN105928866BPrevent penetrationImprove sealingWeather/light/corrosion resistanceMaterial electrochemical variablesPorous coatingEngineering

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

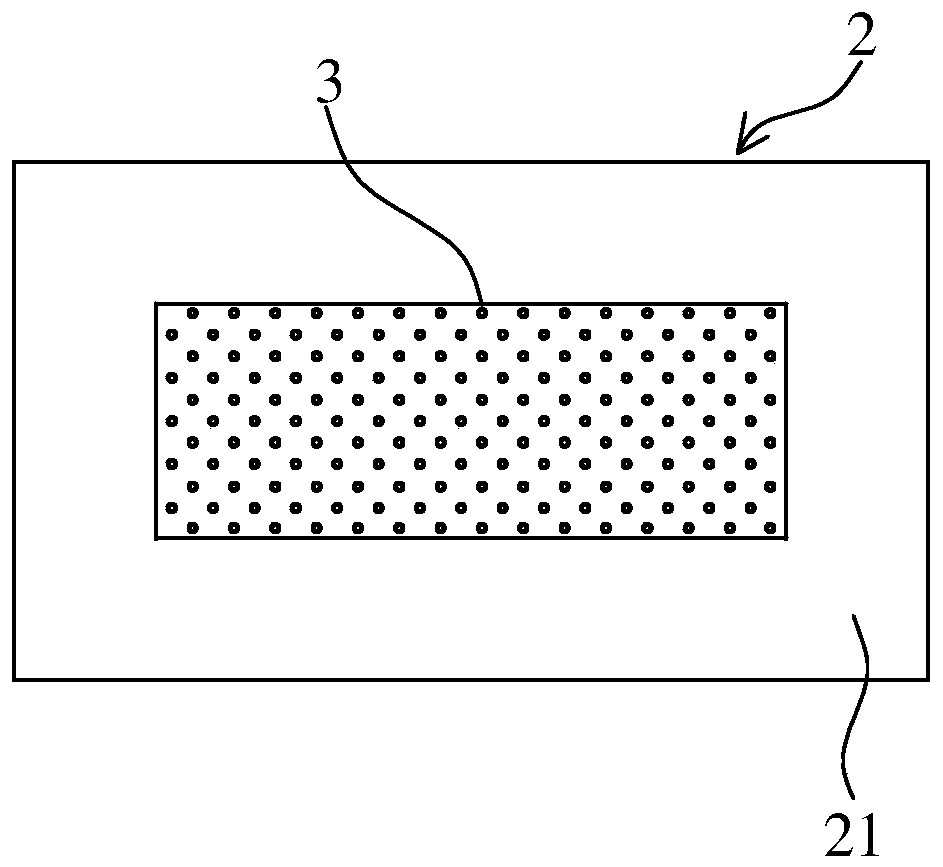

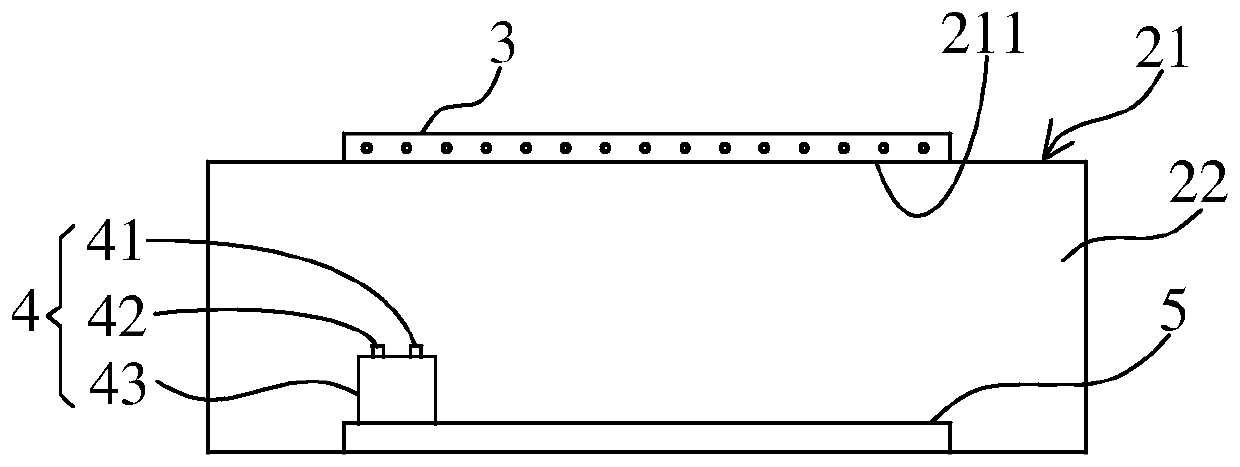

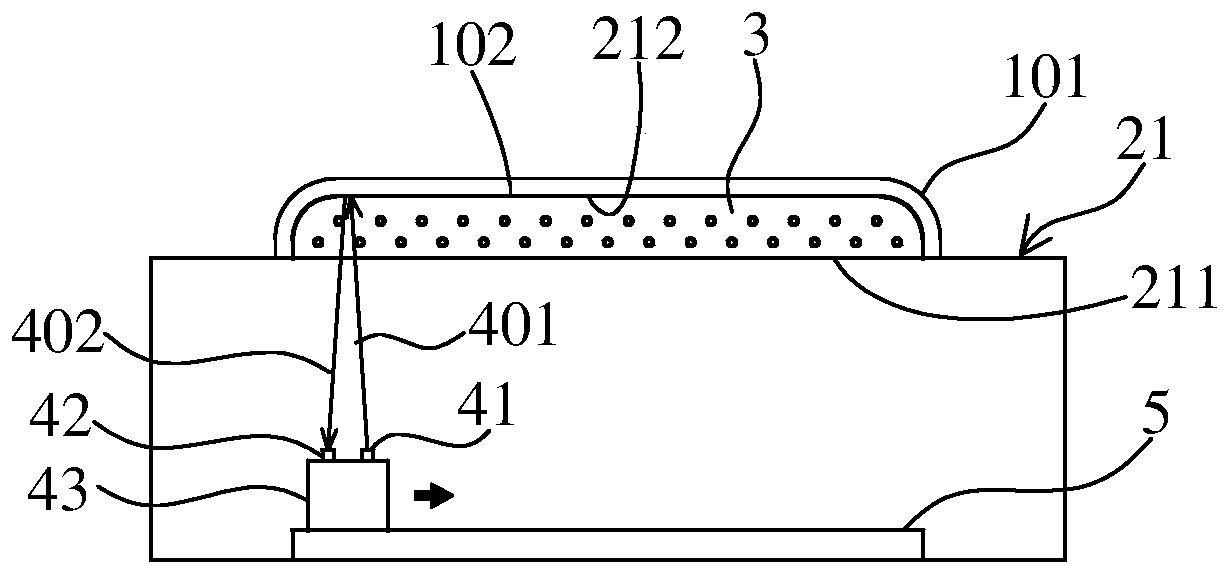

Beverage machine with integrated ultrasonic transceiver

InactiveCN102858211BContact will notSolve health problemsBeverage vesselsThin material handlingTransceiverBiomedical engineering

The present invention discloses a beverage machine (1) comprising a tank (2), which holds a liquid for preparing a beverage, and a dispenser (7), to which the tank is connectable, wherein the tank (2) comprises a valve (8); the dispenser comprises an opening (9) for receiving the valve in connection of the tank on the dispenser; at least one ultrasonic transceiver (3) is disposed in the dispenser (7) or tank (2), the ultrasonic transceiver being designed to emit and receive ultrasonic waves (4a, 4b) in the liquid, in order to determine the distance (d) from the transceiver to the liquid level (5), wherein it further comprises a control unit (6), which is connected to the ultrasonic transceiver (3) which is adapted to determine the distance (d) changing with time and as a result the volume (V) of the liquid flowing out of the tank.

Owner:NESTEC SA

Efficient anti-corrosion ceramic ball valve

PendingCN107228205AHigh temperature resistantAnti-acid and anti-alkaliPlug valvesMetallic materialsPolytetrafluoroethylene

The invention discloses an efficient anti-corrosion ceramic ball valve. The efficient anti-corrosion ceramic ball valve comprises a valve body, a valve cover, a valve seat, a valve ball and a valve rod; the valve body and the valve cover are made of metal materials; the valve seat and the valve ball are made of ceramic; the valve cover is assembled on the valve body; the valve seat is arranged in the valve body and the valve cover in a sleeving way; the valve rod is in tight fit with the valve body through fillers; one end of the valve rod is connected with the valve ball arranged in the valve body; a valve cover lining made of polytetrafluoroethylene is lined between the valve seat and the valve cover; the valve cover lining adopts a cylindrical structure; and the valve cover lining is arranged outside the valve seat in a sleeving way and is arranged in the valve cover in a sleeving way. The valve cover lining isolates contact of a medium, the metal valve cover and the valve body, the sealing effect is guaranteed through tight contact of the valve cover lining, the valve seat and the valve cover, leakage is avoided, corrosion is avoided efficiently, the efficient anti-corrosion ceramic ball valve can be applied to the environment of high-corrosivity fluid mediums, the service life is prolonged, and extremely high corrosion resistance is achieved.

Owner:YONGJIA COUNTY DATANG VALVE

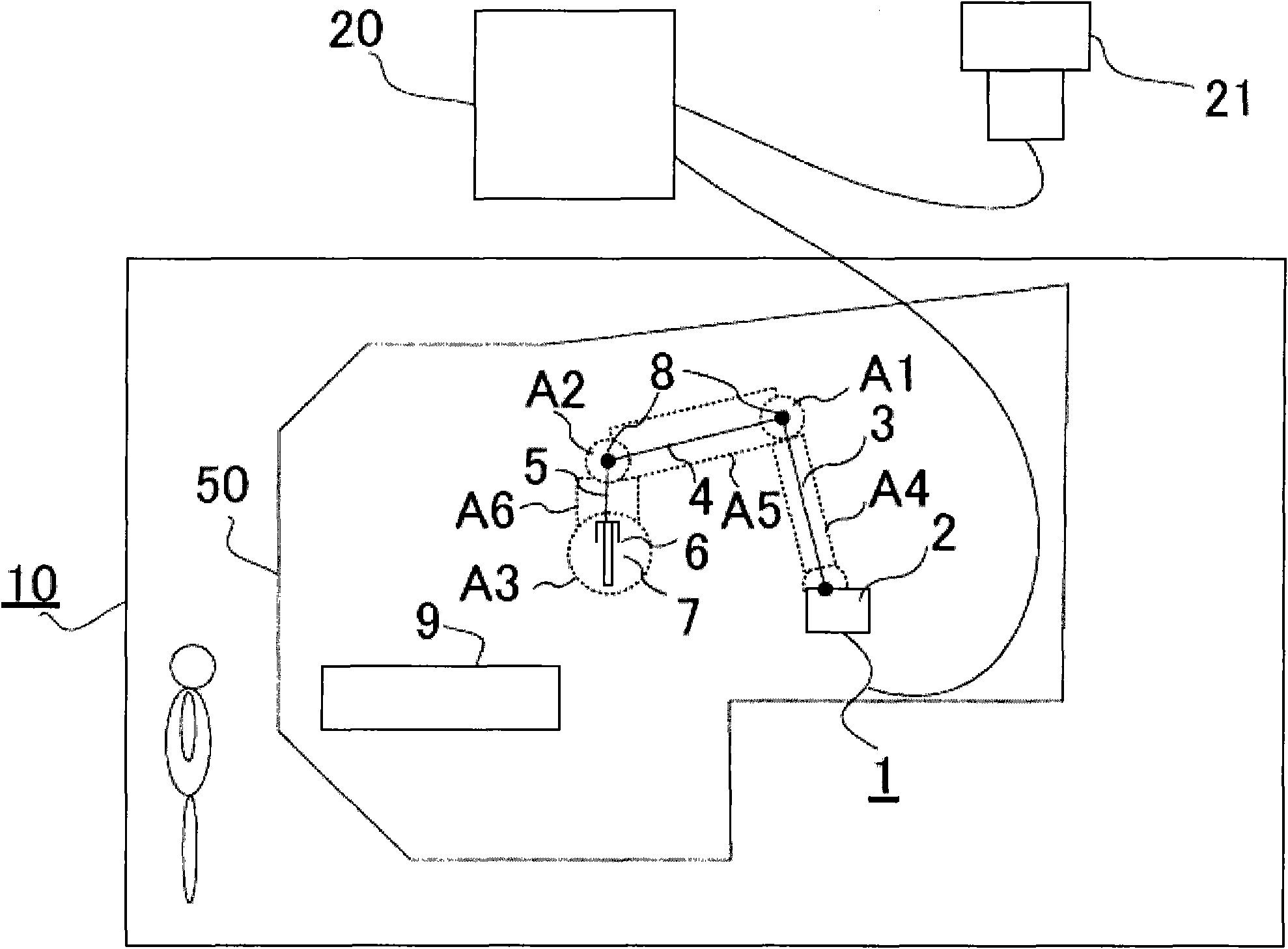

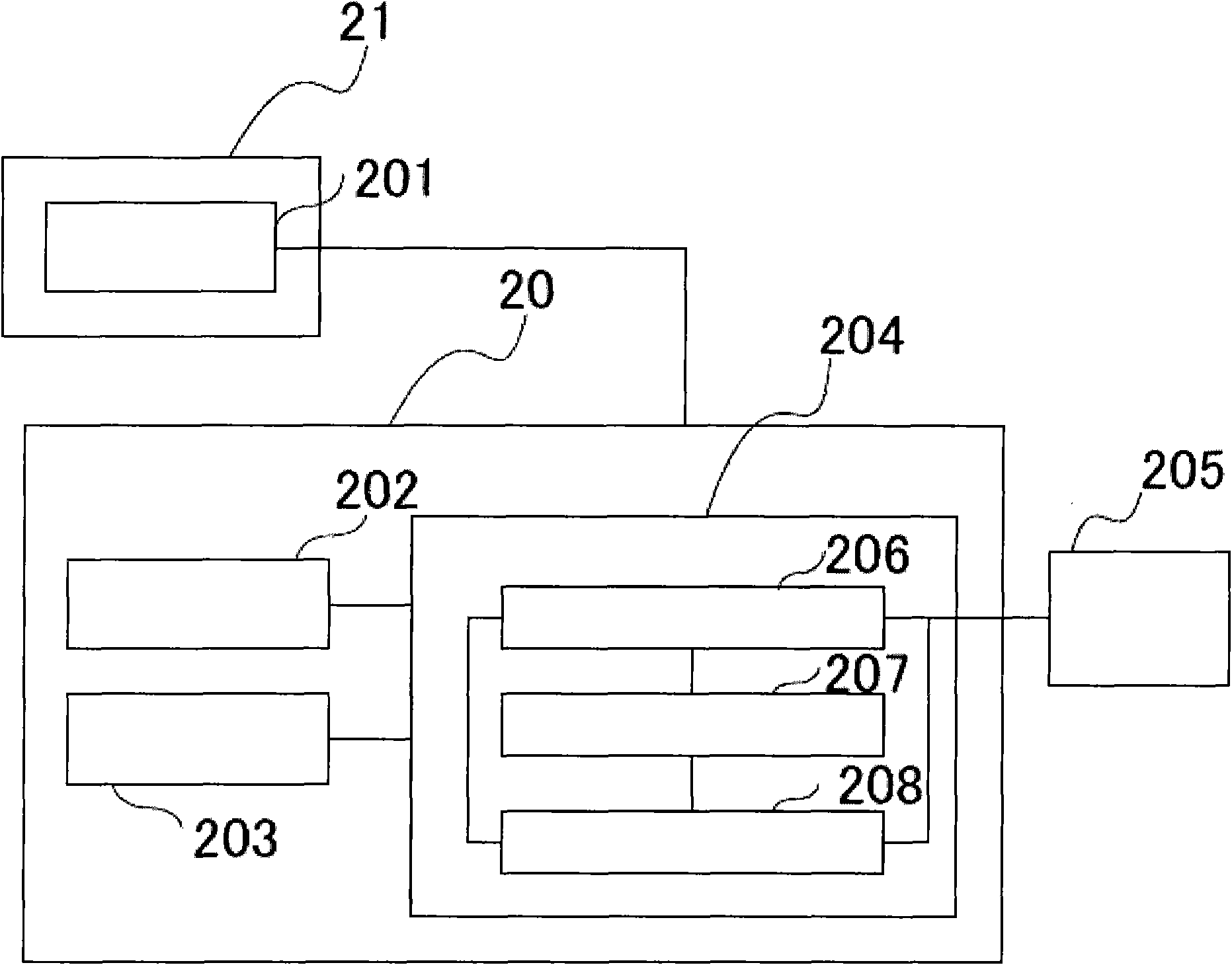

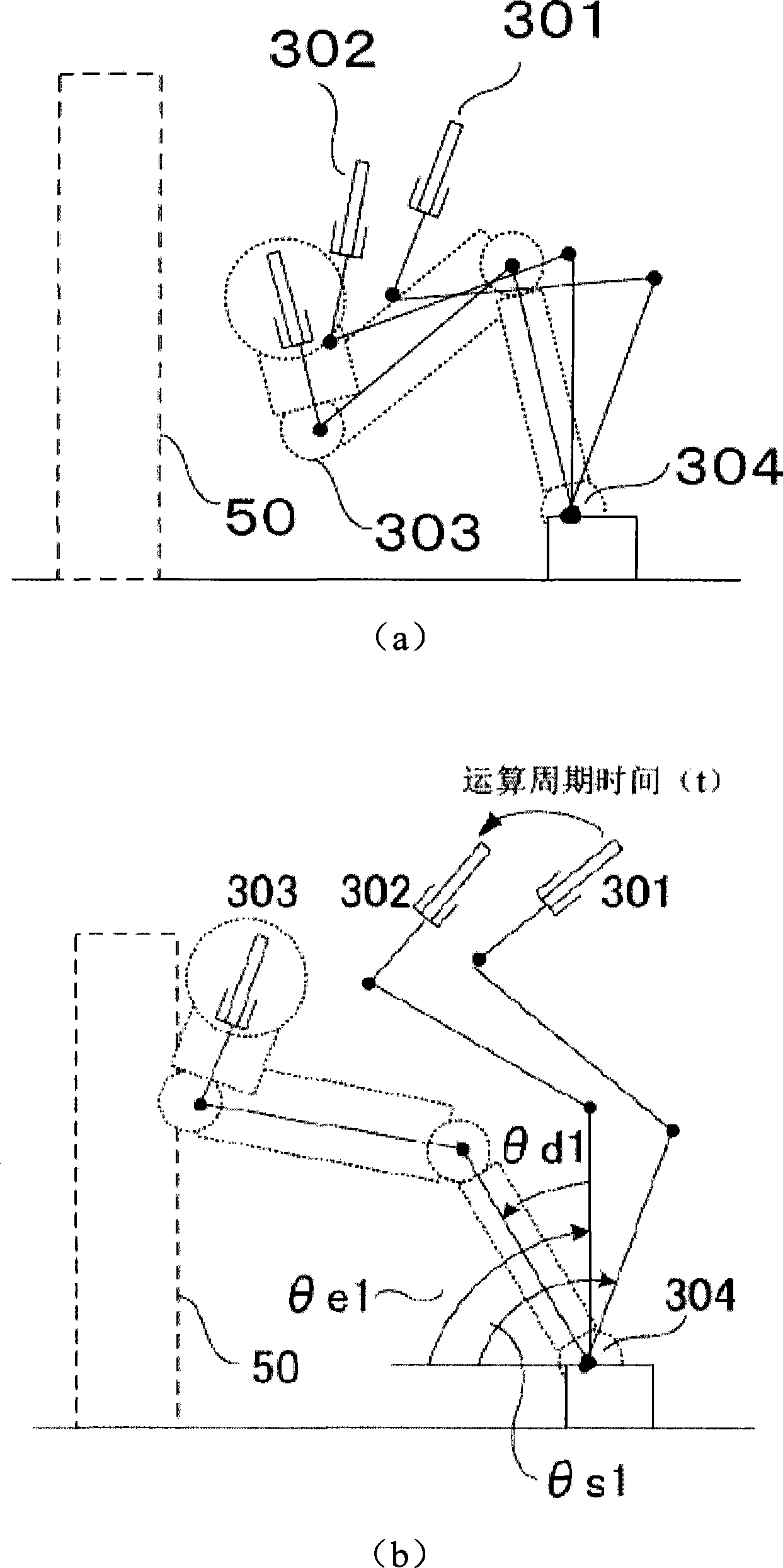

Robot system

ActiveCN102189552BContact will notEfficient use ofProgramme controlProgramme-controlled manipulatorRobotic systemsSimulation

The present invention can effectively utilize the ground space of factories and the like while improving the safety of robot operation, and can simplify equipment. It is processed in the following order and defined on the memory: the arm occupation area including the workpiece and tool of the arm and wrist of the robot; the virtual safety fence that the arm cannot touch; and the movable range of each axis, based on the inertia measured actually Estimate the inertial movement angle of each axis of the robot when the robot is suddenly stopped during the execution of the motion command to the next target position, and calculate the predicted inertial movement position of the robot by adding it to the next target position. Control to stop the robot immediately when abnormality is confirmed whether the arm occupied area at the movement prediction position is in contact with the virtual safety fence or whether the position of each axis of the robot is within the operable range.

Owner:YASKAWA DENKI KK

Glass profile measuring device and its measuring method

ActiveCN108895993BAvoid contactAccurate measurement dataUsing optical meansUsing fluid meansEngineeringMechanical engineering

The invention discloses a glass contour measuring device and a measurement method thereof. The glass contour measuring device comprises a measurement platform, an air bag and a sensing operation unit,the measuring device uses the air bag to completely fill an accommodation space, formed by curved-surface coverage glass, in the measurement platform, and changes a movement manner of the sensing operation unit to measure the deformation amount of the air bag after inflation, and thus, the glass contour of the curved-surface coverage glass is reckoned.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

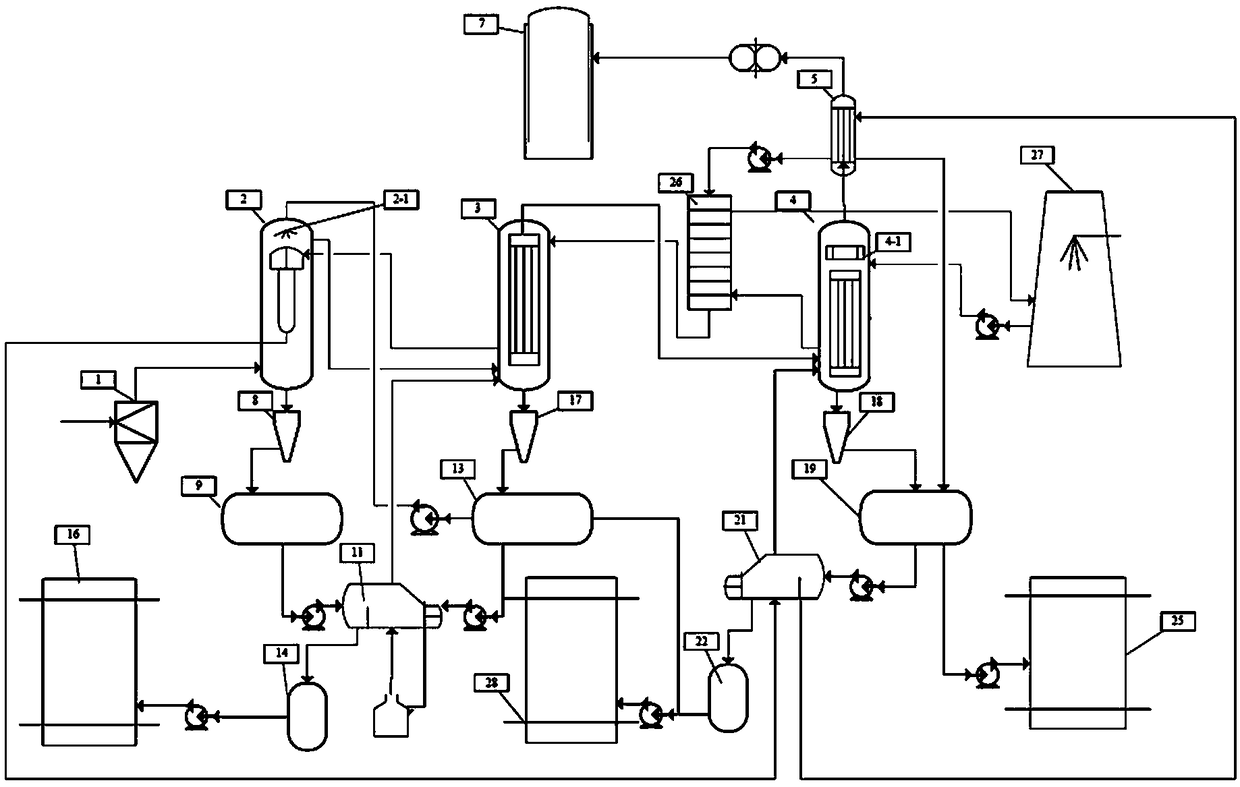

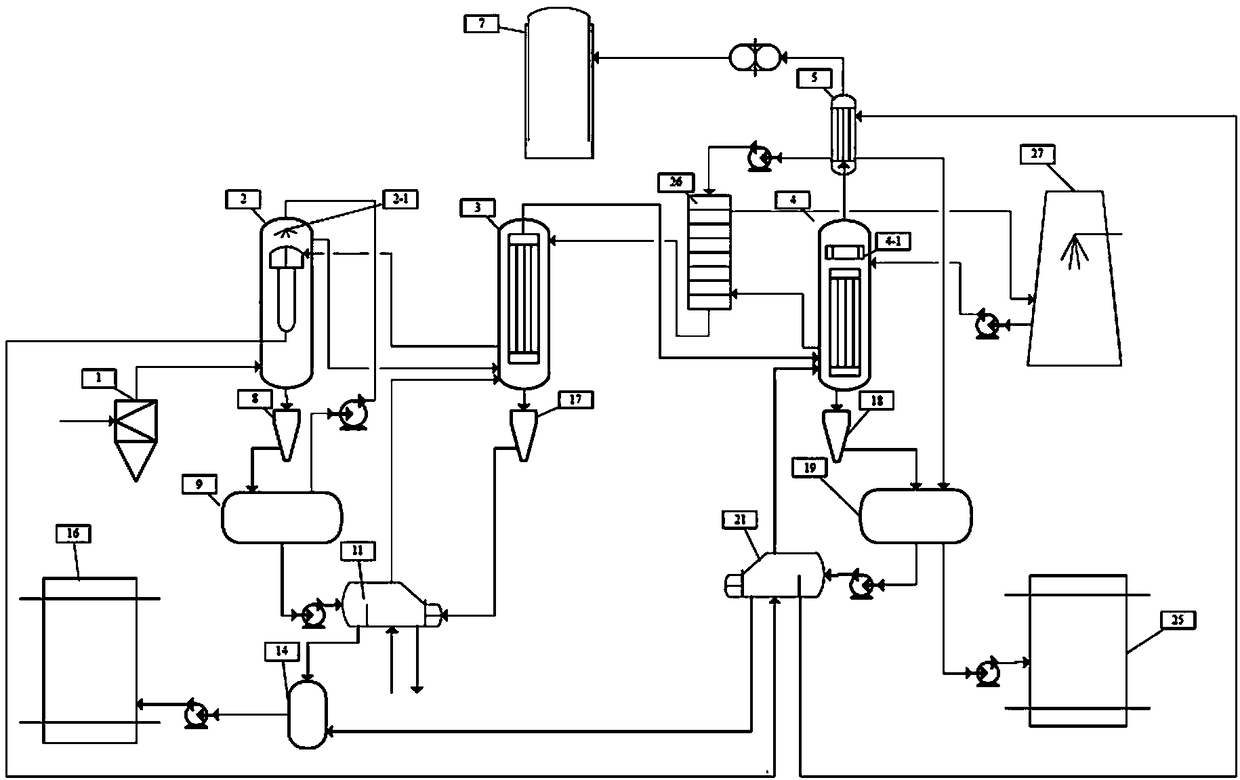

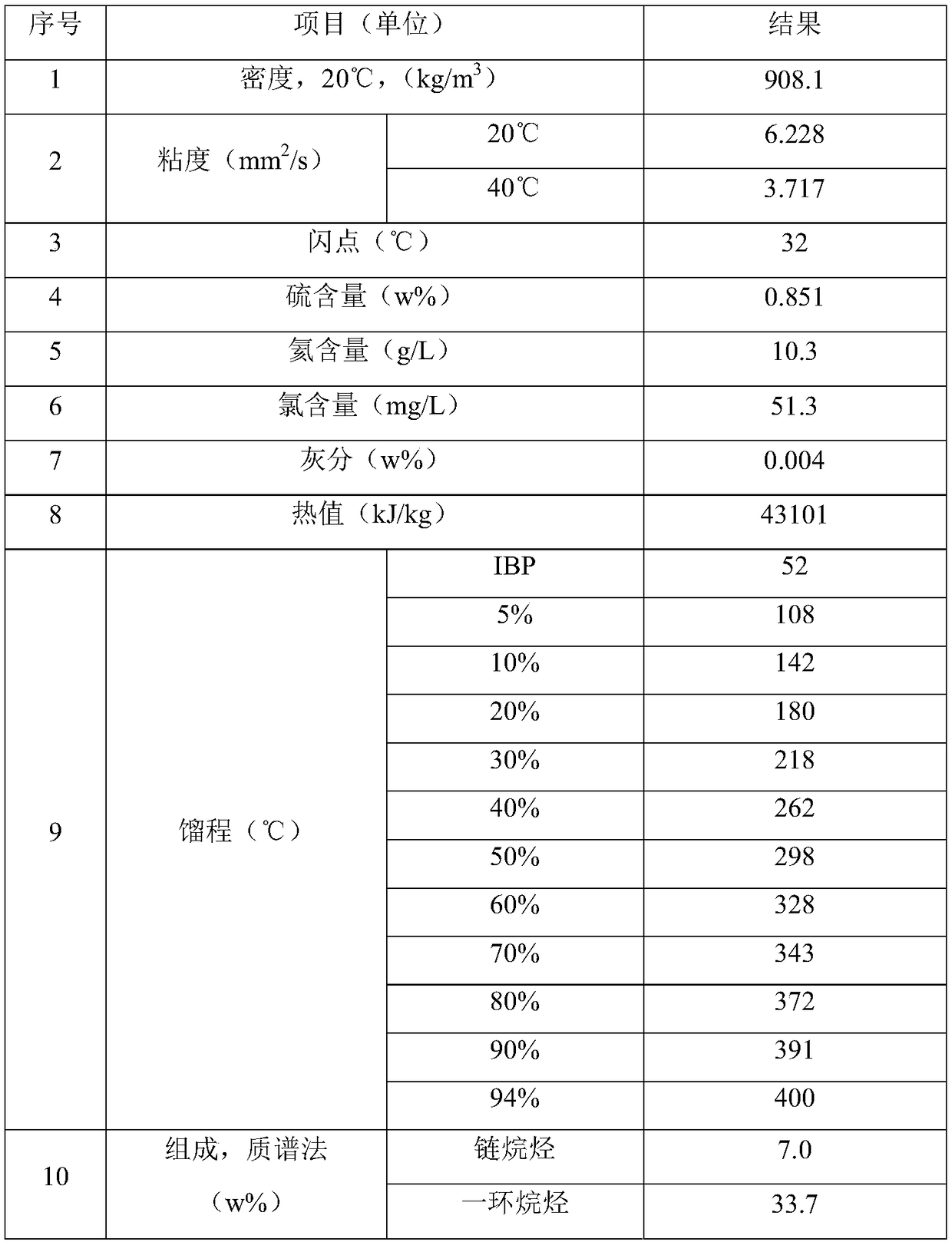

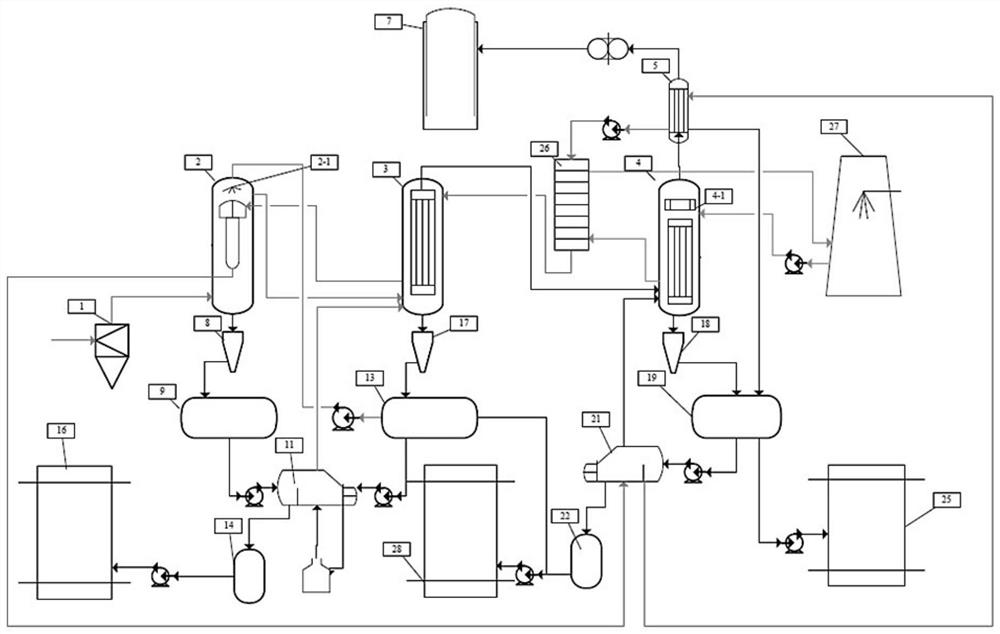

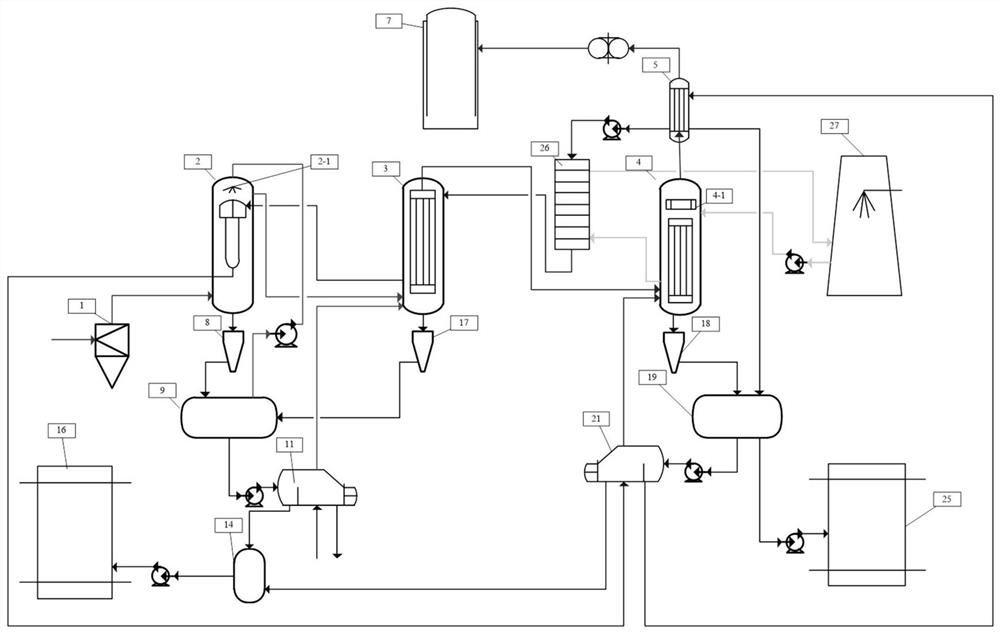

Device for condensing and recovering pyrolysis gas, method and application thereof

ActiveCN109289225ARealize condensation purificationAvoid contactVapor condensationPlate heat exchangerReboiler

The invention relates to the field of recycling solid waste and hazardous waste by a pyrolysis method, and discloses a device for condensing and recovering pyrolysis gas. The device comprises a pre-separator, a falling film mixed-cold heat exchanger, a first dividing wall-type heat exchanger, a second dividing wall-type heat exchanger, a reheater and a gas cabinet connected in sequence; the bottomof the falling film mixed-cold heat exchanger is connected with a first separator, a first oil tank and a first reboiler; the bottom of the first dividing wall-type heat exchanger is connected with asecond separator and a second oil tank in turn, and the second oil tank is further connected to the first reboiler, the falling film mixed-cold heat exchanger and a second tank respectively; the bottom of the second dividing wall-type heat exchanger is sequentially connected with a third separator, a third oil tank and a third reboiler; the reheater is further connected with the third oil tank; and the device further comprises a third heat exchanger. The device can comprehensively solve the problems of solid particle separation, heat exchange tube wall hanging or tube blocking phenomena, andpoor heat transfer performance on the oil and gas side, and realizes efficient condensation and classification condensation recovery of the pyrolysis gas.

Owner:国宏中晶集团有限公司

A device, method and application for condensing and recovering pyrolysis gas

ActiveCN109289225BRealize condensation purificationAvoid contactVapor condensationReboilerSolid particle

The invention relates to the field of pyrolysis solid waste and hazardous waste recycling, and discloses a device for condensing and recovering pyrolysis gas. The device includes a pre-separator connected in sequence, a falling film mixed cooling heat heat exchanger, second partition wall heat exchanger, reheater and gas cabinet; the bottom of the falling film mixed cooling heat exchanger is connected with the first separator, the first oil tank and the first reboiler; the first partition wall exchanger The bottom of the heater is connected with a second separator and a second oil tank in turn, and the second oil tank is further connected with the first reboiler, the falling film mixed cooling heat exchanger and the second oil tank respectively; The bottom of the heater is sequentially connected with a third separator, a third oil tank and a third reboiler; the reheater is further connected with the third oil tank; and the device also includes a third heat exchanger. The use of this device can comprehensively and effectively solve the problems of solid particle separation, wall hanging or plugging of heat exchange tubes, and poor heat transfer performance on the oil and gas side, and realize efficient condensation of cracked gas and classified condensation recovery.

Owner:国宏中晶集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com