Cylinder with devices for containing lubricants

A technology for lubricants and cylinders, applied in the directions of cylinders, cylinder heads, engine components, etc., can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

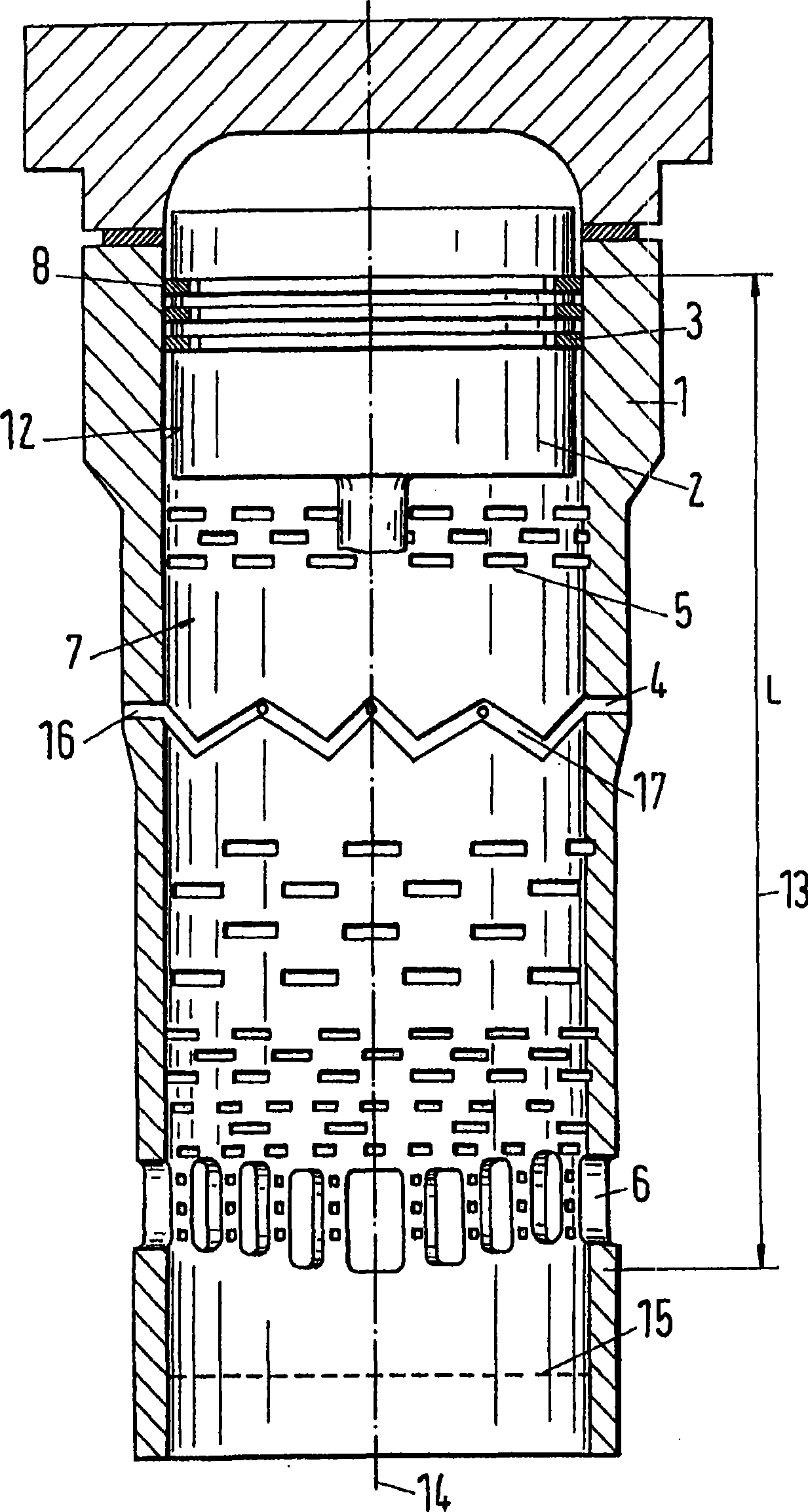

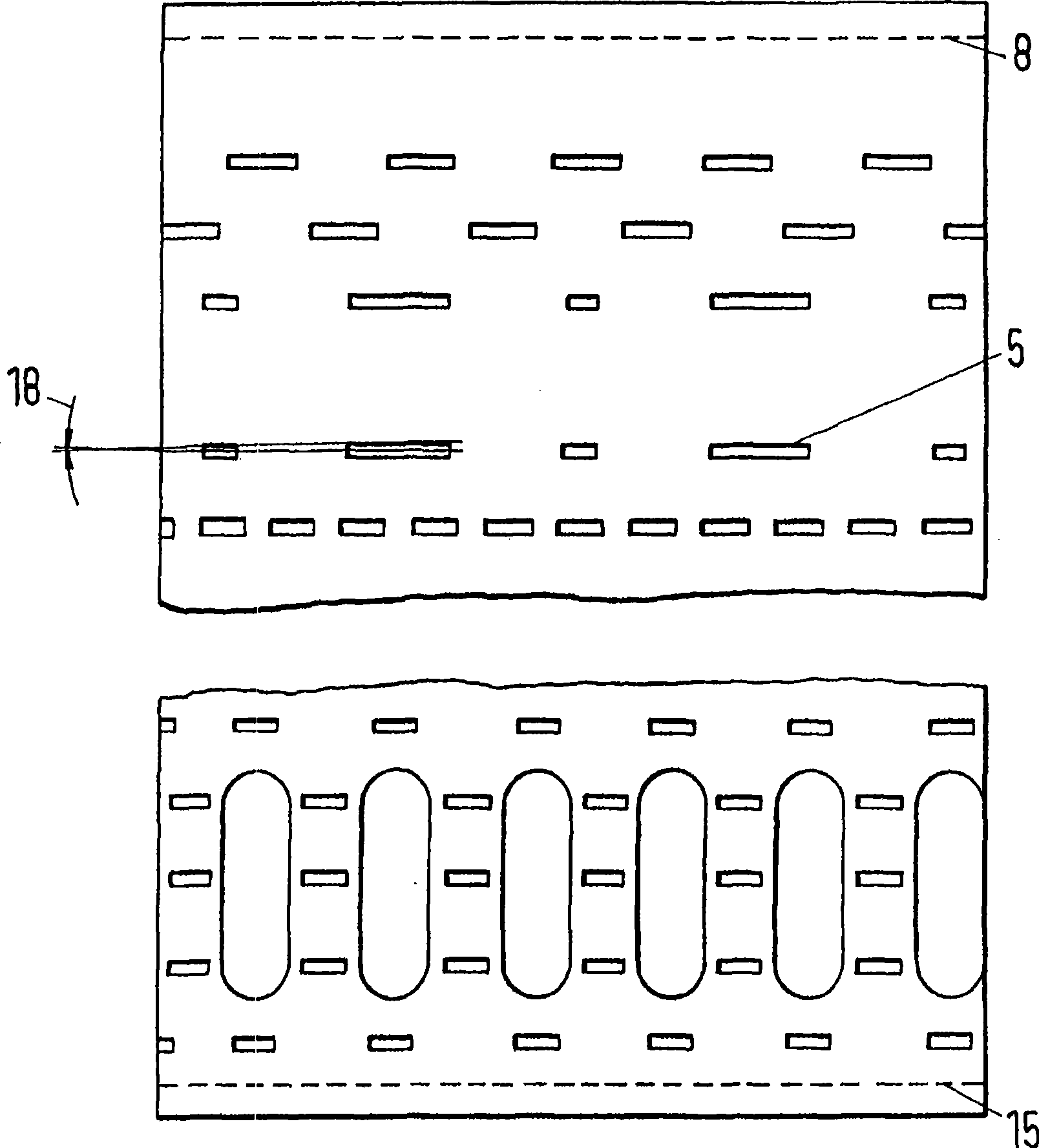

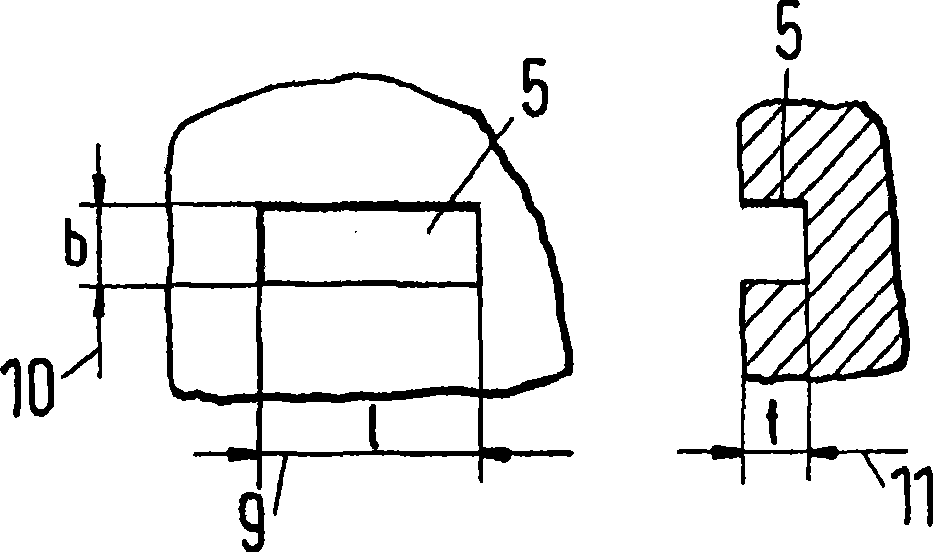

[0022] figure 1 A section through a cylinder 1 provided in a piston engine is shown. The piston engine is a two-stroke or four-stroke engine, especially a large diesel engine. This large diesel engine is generally equipped with a cylinder, and the inner diameter of this cylinder is mostly greater than 190mm. Typical diameters are between 250 and 1000mm. A piston reciprocates inside the cylinder and is connected to a rotatable drive shaft via a connecting rod. This reciprocating movement of the piston occurs between top dead center and bottom dead center. figure 1 The piston is shown in the top dead center position. If a section perpendicular to the axis of the cylinder is placed through the top dead center of the uppermost piston ring, the plane will intersect the inner wall of the cylinder along a line which is hereinafter referred to as the top dead center zone 8. With the vertical arrangement of the cylinders, the top dead center zone 8 forms the uppermost boundary of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com