Beverage machine with integrated ultrasonic transceiver

An ultrasonic and beverage machine technology, applied in the field of beverage machines, can solve problems such as fragility, inaccuracy, and blocking, and achieve the effect of improving resolution, measuring reliable liquid level and/or flow velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

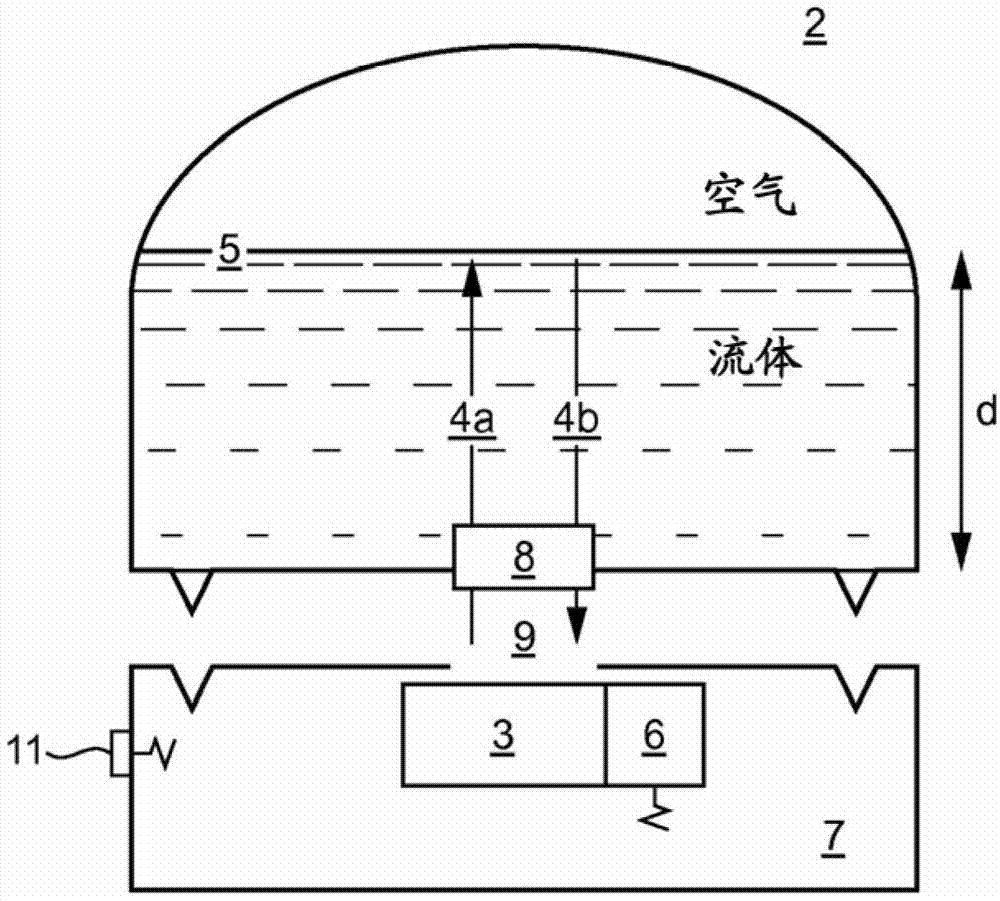

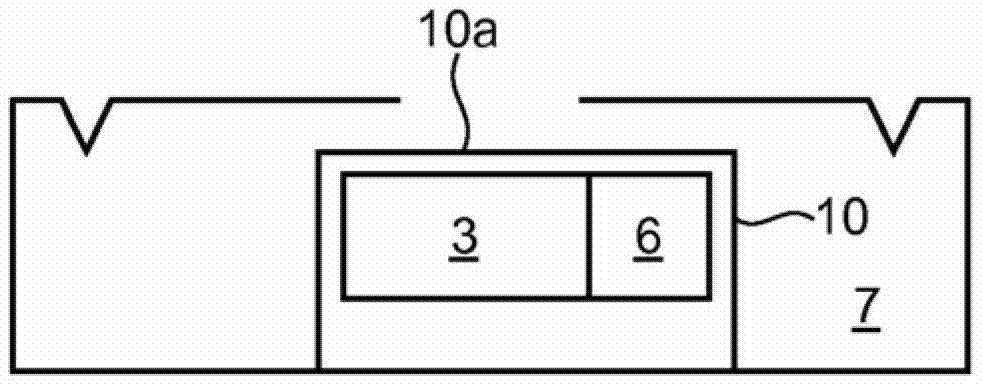

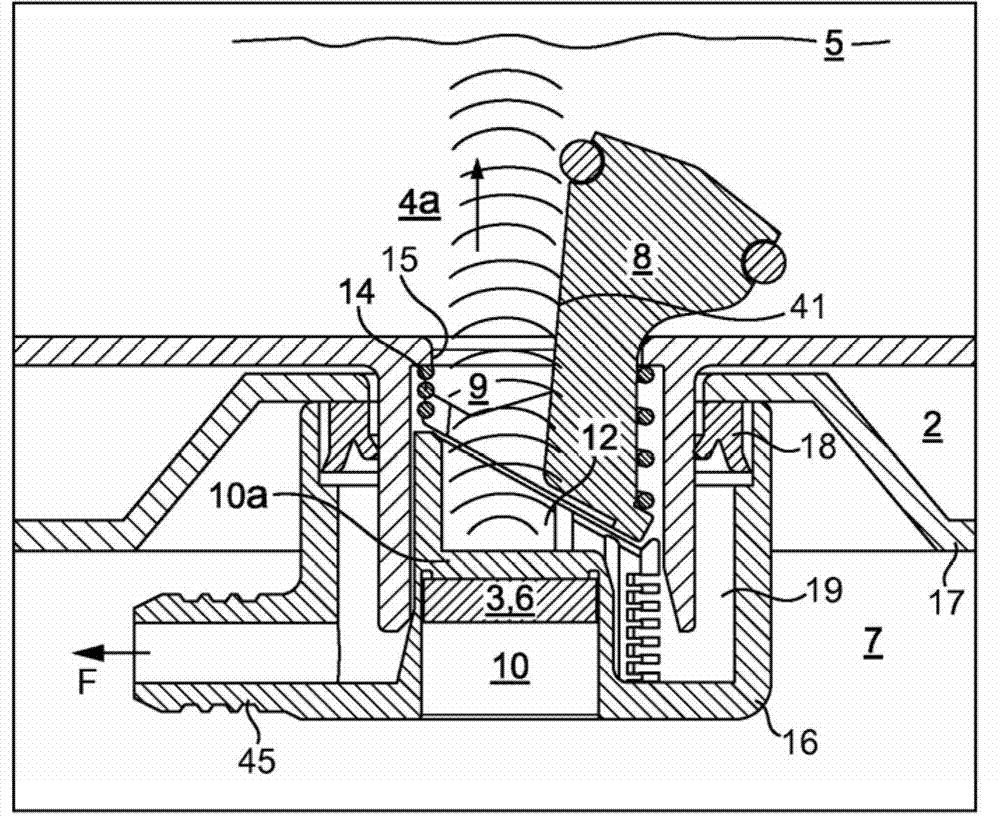

[0067] figure 1 The tank 2 and the dispenser 7 of the beverage machine of the invention are shown. Tank 2 holds liquid (indicated by the shaded area) which is used by the beverage machine to prepare hot or cold beverages. As a preferred but non-limiting example, the machine is designed for the preparation of nutritional liquids such as infant formula. For simplicity, well-known components of the beverage, such as pumps, heaters or brewing (or dilution) units, are not shown. Typically, the liquid in the tank is water. However, the invention is not limited to tanks holding water, and the tanks may hold different liquids, such as milk. For example, the liquid may then be mixed with a serving of an ingredient such as infant formula powder or liquid concentrate contained in a packaging container such as a portioning capsule or pod.

[0068] The interface between the liquid in the tank and the air is the liquid level 5. The distance from the bottom of the tank to the liquid lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com