Patents

Literature

348results about How to "Solve health problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

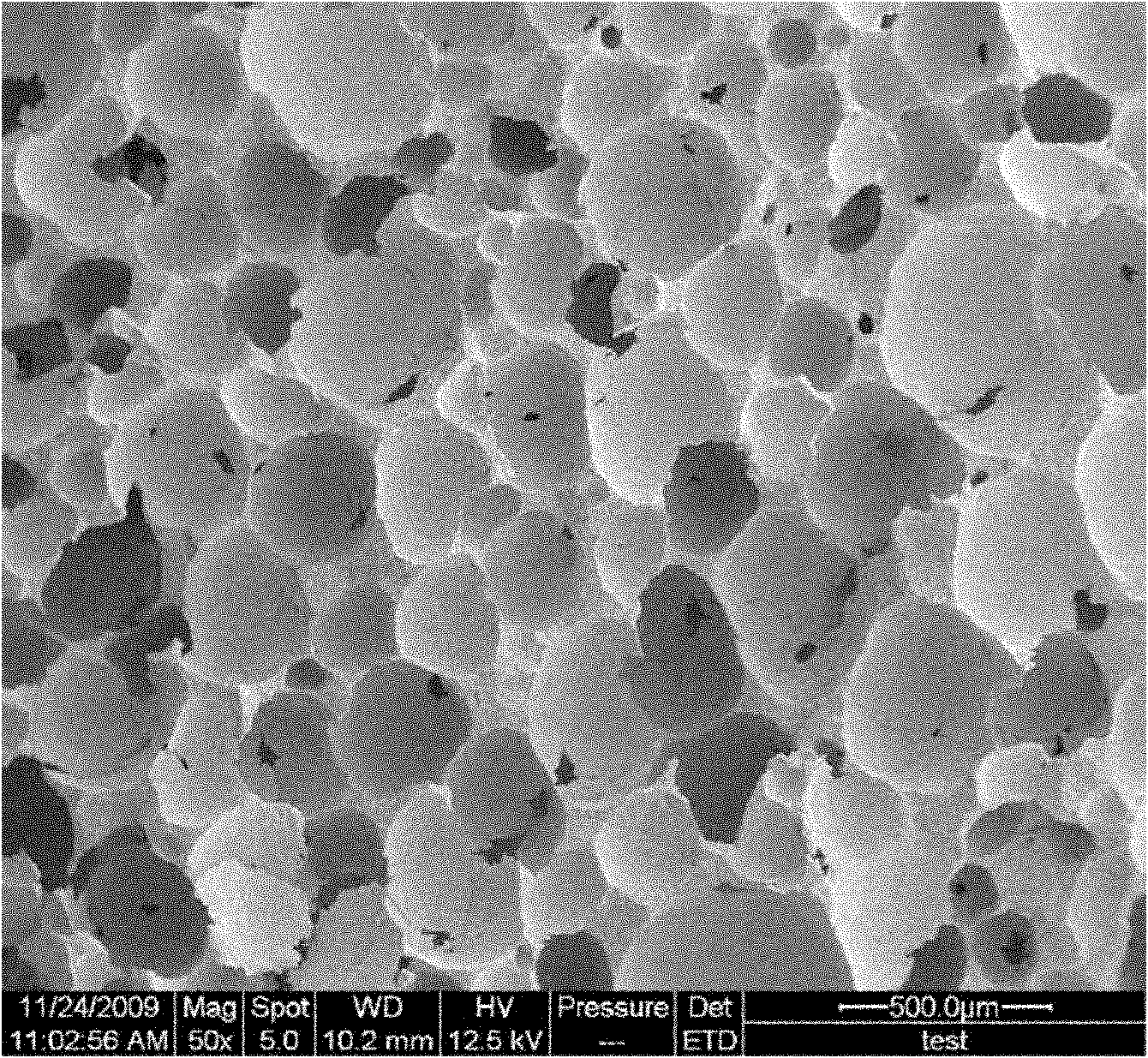

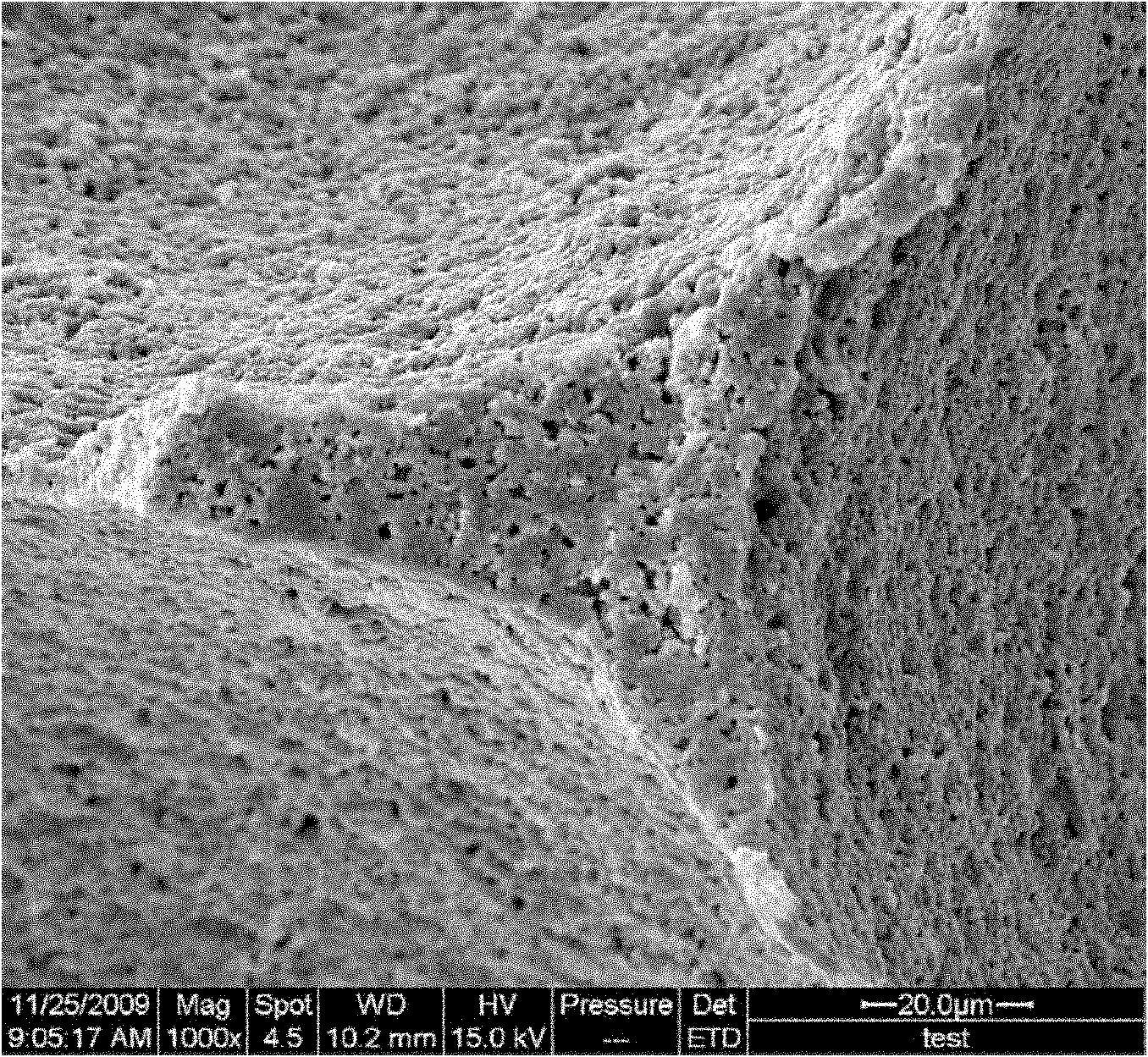

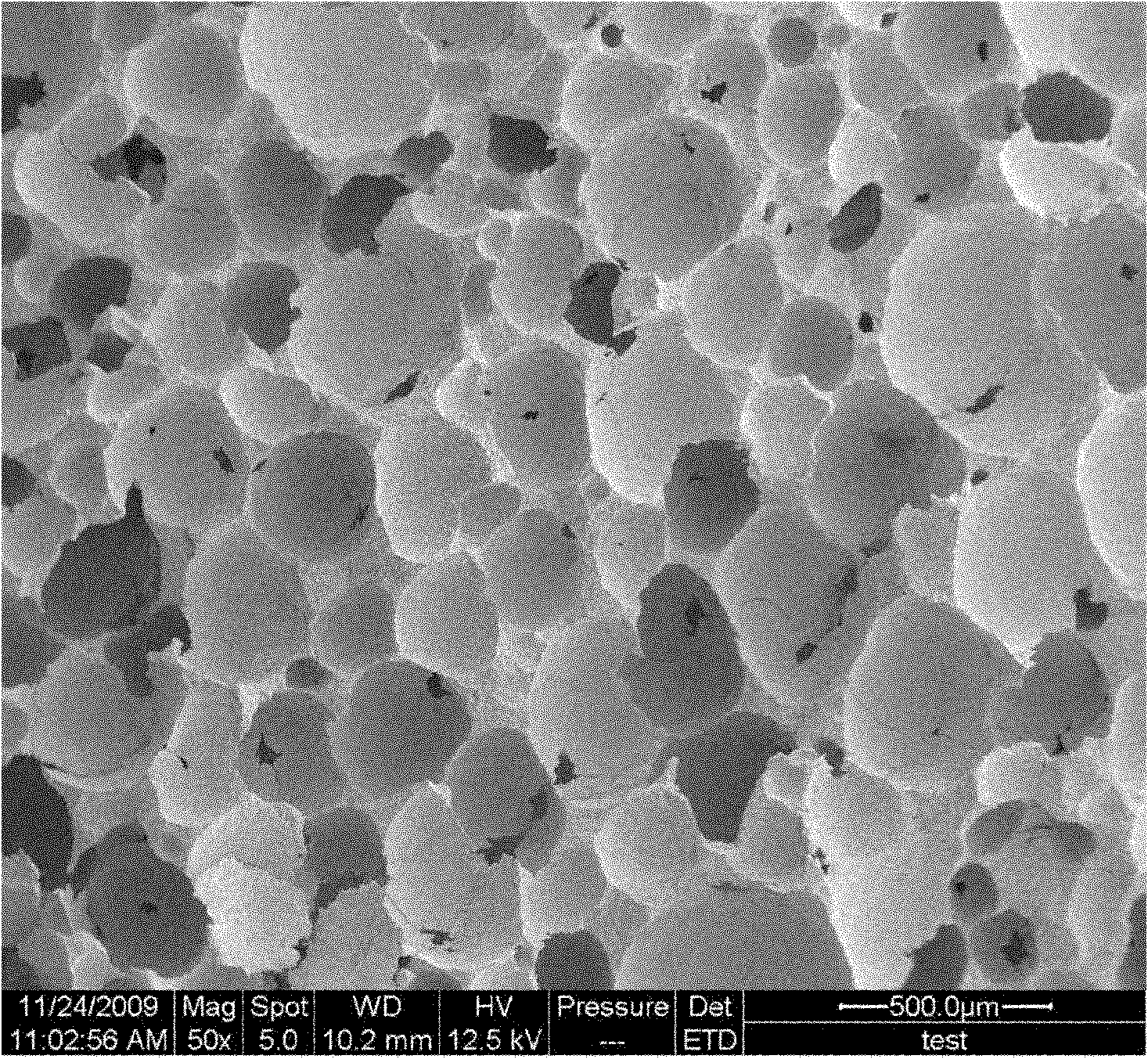

Protein foaming method for preparing porous ceramics composite material

InactiveCN101967064ASolve health problemsSolve the pollution of the environmentCeramicwareCeramic compositeHazardous substance

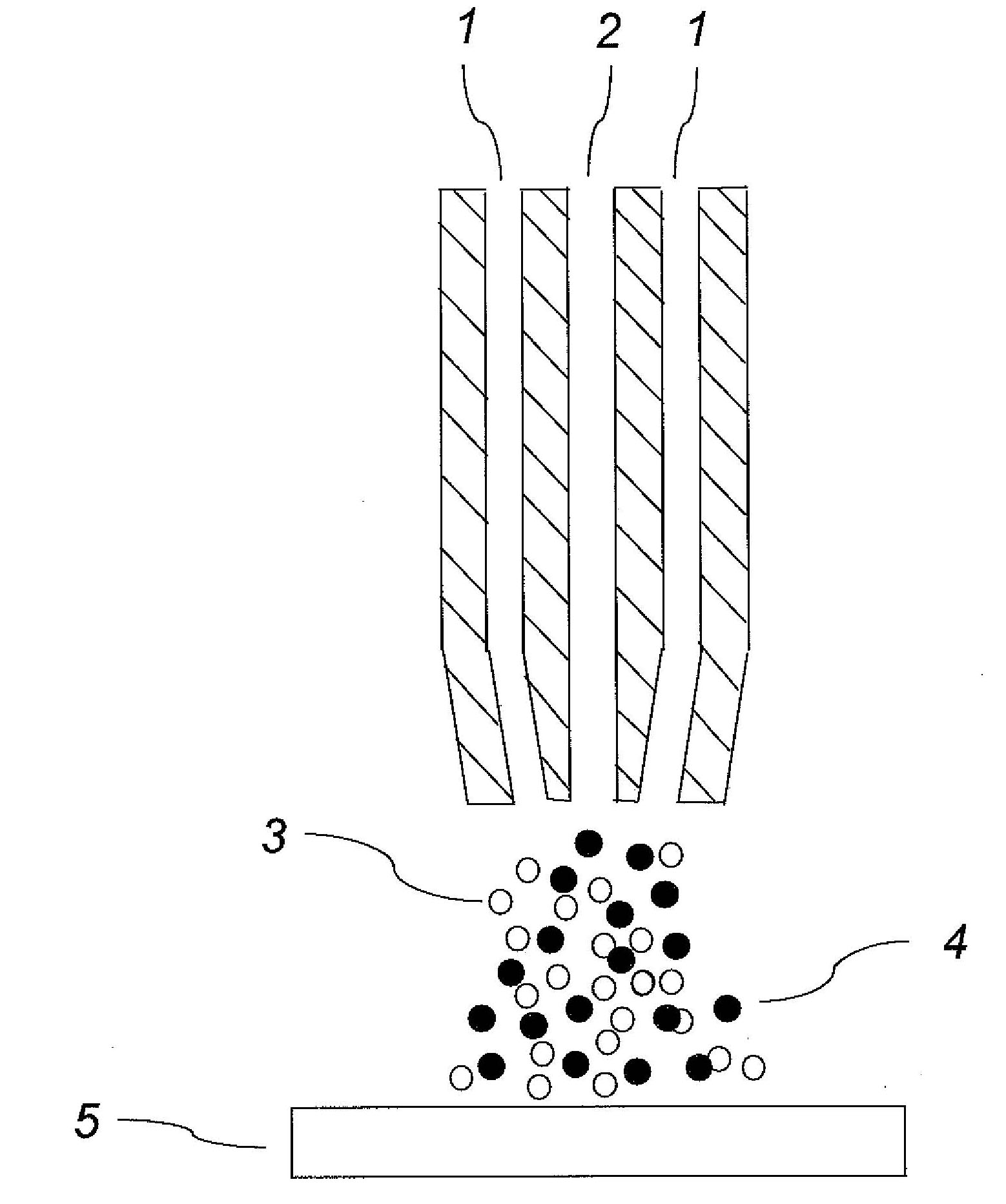

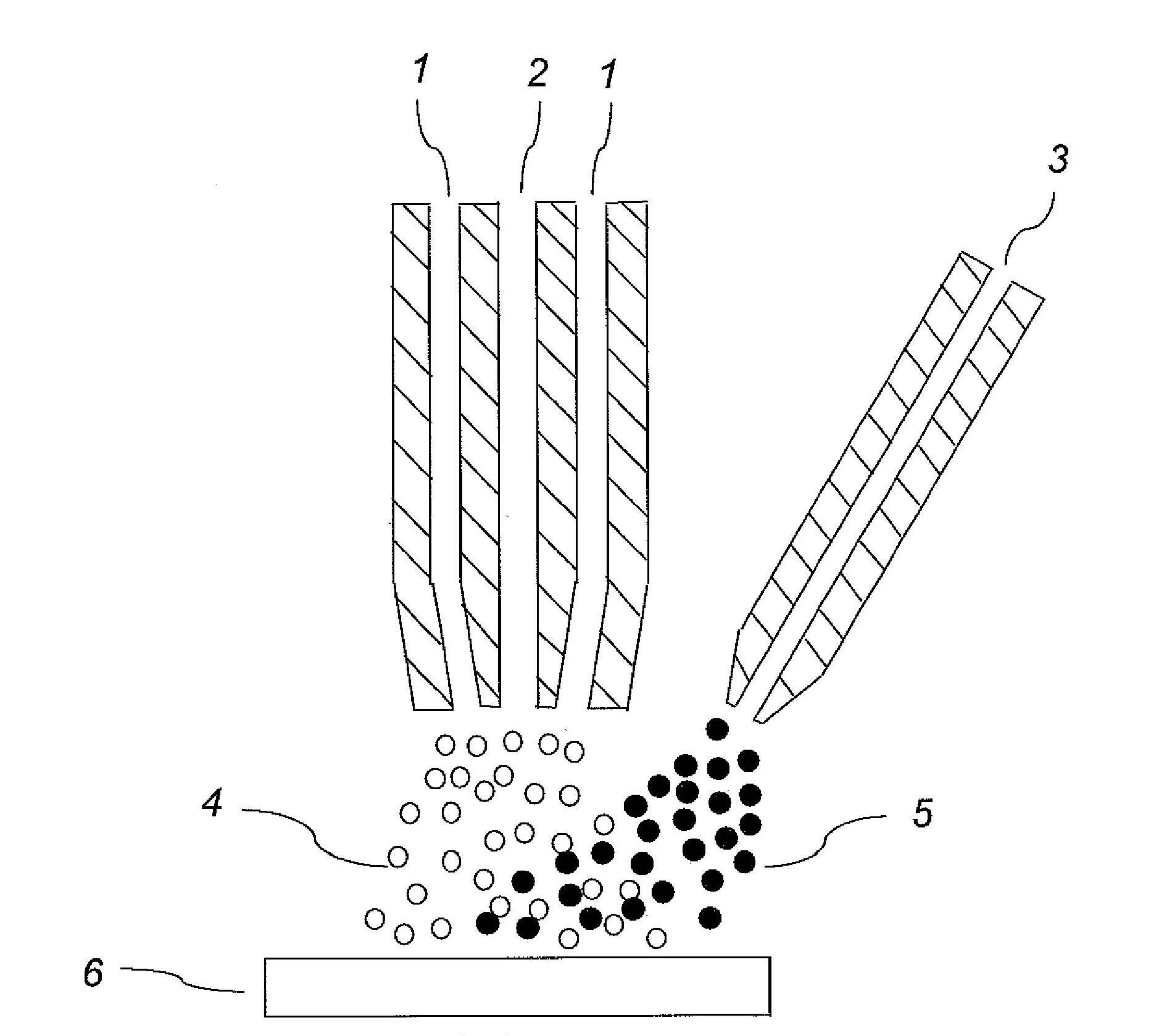

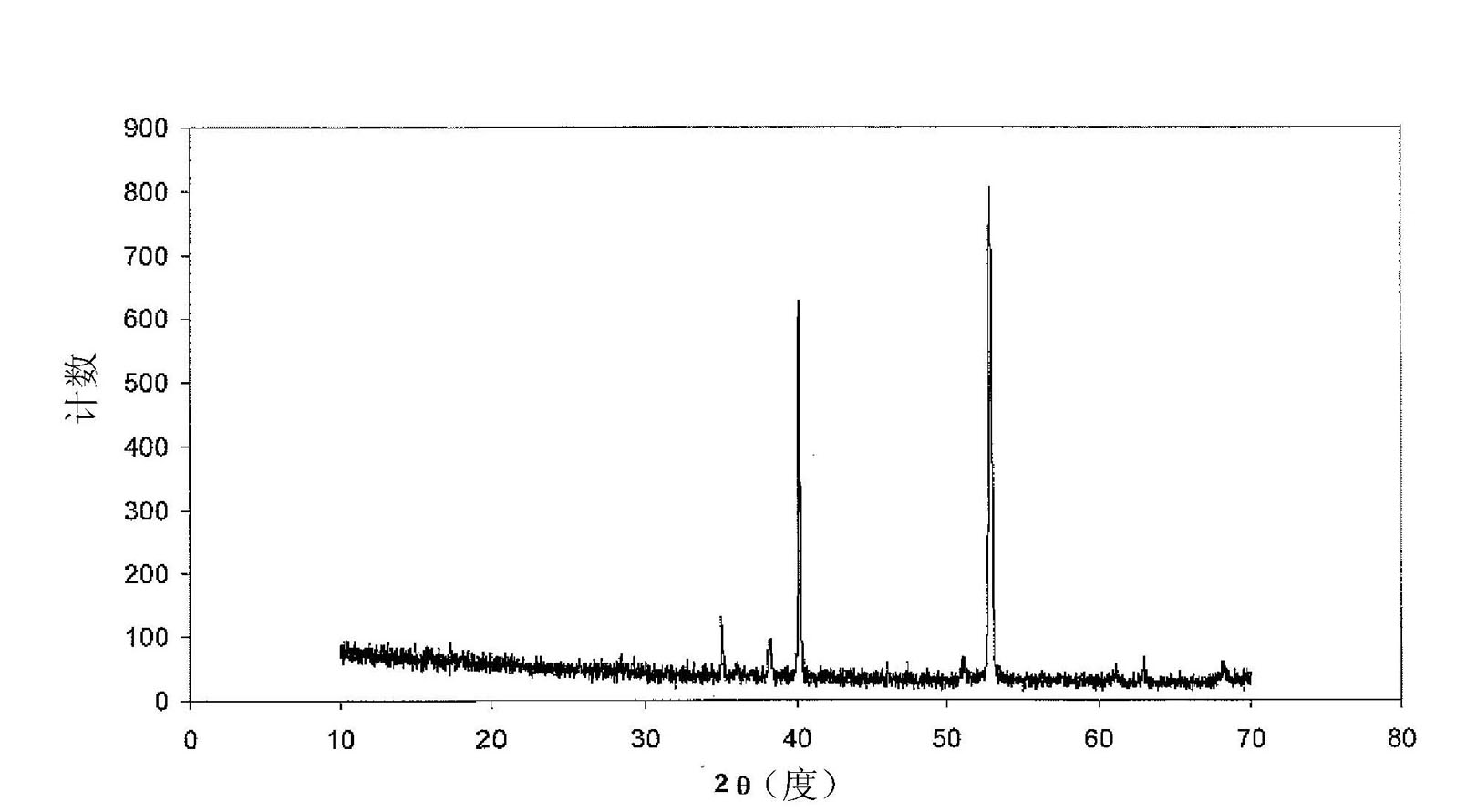

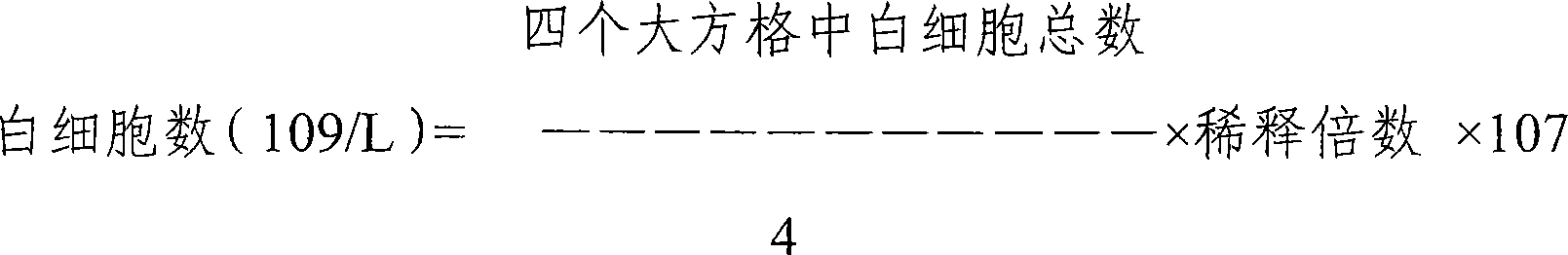

The invention discloses a protein foaming method for preparing a porous ceramics composite material, and relates to a method for preparing a composite material. The method solves the problem that toxic gas is generated to harm human health and pollute environment when a foaming agent is volatilized in a foaming method for preparing porous ceramics. The method comprises the following steps of: 1, preparing slurry; 2, preparing a sample; and 3, processing the sample into a required shape, sintering in a sintering furnace, and cooling with the furnace to room temperature to obtain the porous ceramics composite material. Compared with other methods, the method has the advantages that: a microstructure is controllable and is molded simply; and toxic gas and harmful substances polluting environment are not generated when proteins are decomposed. Polysaccharide macromolecules and water molecules form hydrogen bonds to keep the foaming stability; meanwhile, the polysaccharide macromolecules have net structures to improve the blank strength, adjust the fluidity of the slurry, improve the rheological properties of the slurry and make the foaming uniform.

Owner:HARBIN INST OF TECH

Method for making microwave vaccum frozen and dried lemon piece

InactiveCN1849921AExtended production periodSolve the problem of excessive pesticide residuesFood preservationMicrowaveFreeze-drying

The present invention relates to a production method of microwave vacuum freeze-dried lemon slices. Said method includes the following steps: (1), sorting lemon fruit; (2), storing lemon fruit under the condition of constant temperature; (3), utilizing ozone to degrade pesticide residue on the lemon fruit and make sterilization; (4), cutting head and tail of lemon fruit, cleaning the lemon fruit by using ozone water and sterilizing; (5), slicing; (6), freezing sliced lemon; (7), prefreeze-drying; (8), microwave vacuum-drying; and (9), sealing and packaging so as to obtain the invented product.

Owner:SICHUAN HUATONG LEMON

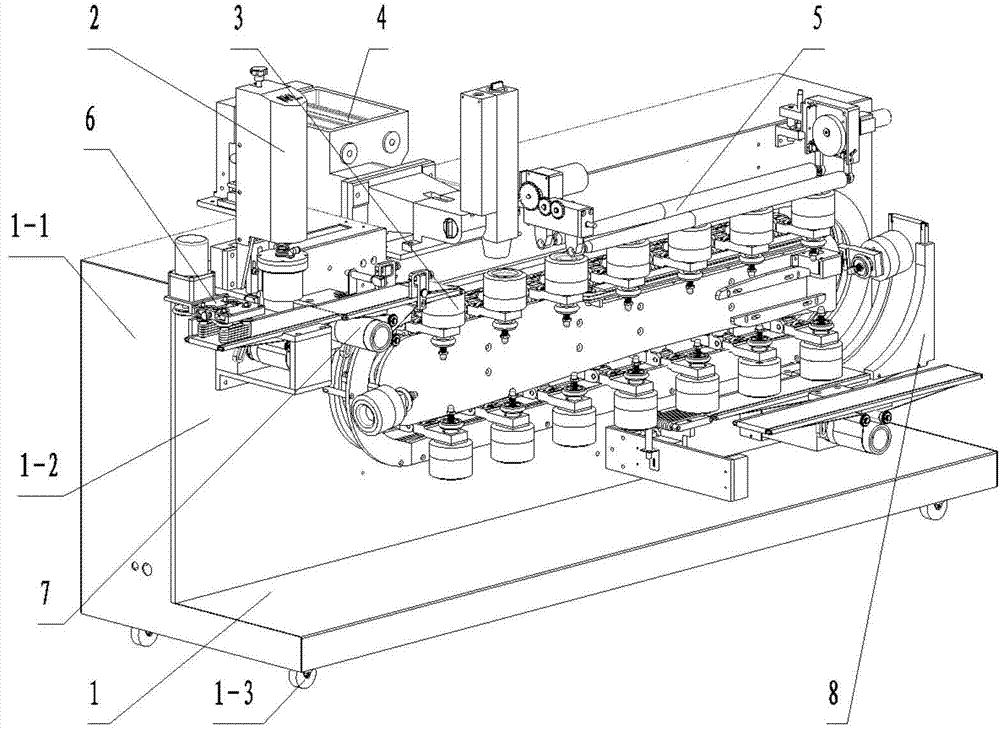

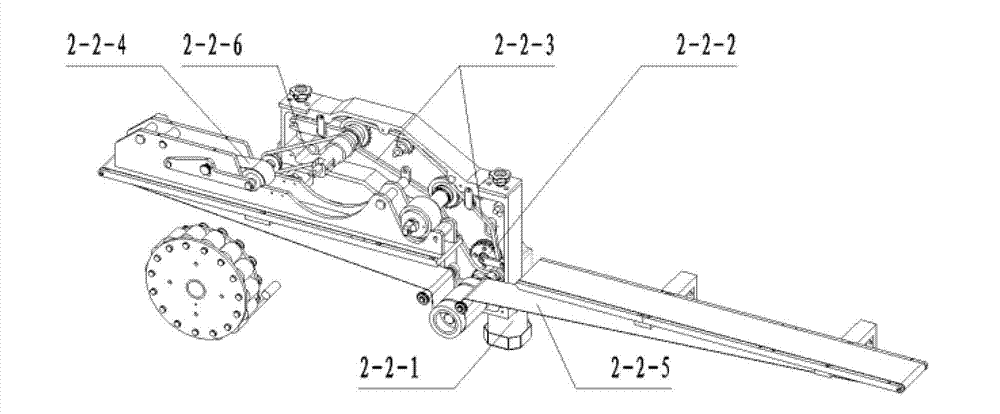

Follow-up stuffing adding twin-cone roller necking-in machine

InactiveCN102894026AOvercome technical difficulties that cannot be fully automatedChange the traditional hand-made processDough-sheeters/rolling-machines/rolling-pinsDough processingPulp and paper industryFully automatic

The invention discloses a follow-up stuffing adding twin-cone roller necking-in machine. The equipment comprises a necking-in machine body on which a crisp cake blank stamping device, a rotary mould circulation turning device, a material injection device and a twin-cone roller necking-in device are sequentially arranged, wherein the rotary mould circulation turning device is arranged below the material injection device and the twin-cone roller necking-in device. The follow-up stuffing adding twin-cone roller necking-in machine is special equipment for simultaneously finishing multiple stages before a crisp cake blank is formed and has the effects of solving the technical problem of incapability of fully-automatic production of the traditional crisp moon cake making process, firstly realizing the mechanical automation of the whole production process, reaching the yield of 40-60 / min, greatly increasing the production efficiency, completely changing the traditional manual making process for crisp refreshments and particularly for multilayer stuffed crisp moon cakes, greatly strengthening the standardization and the normalization for the production of the crisp refreshments and obtaining the optimal cost performance. The invention creates a brand new technical field for mechanically and automatically producing crisp foods.

Owner:上海伟隆机械设备股份有限公司

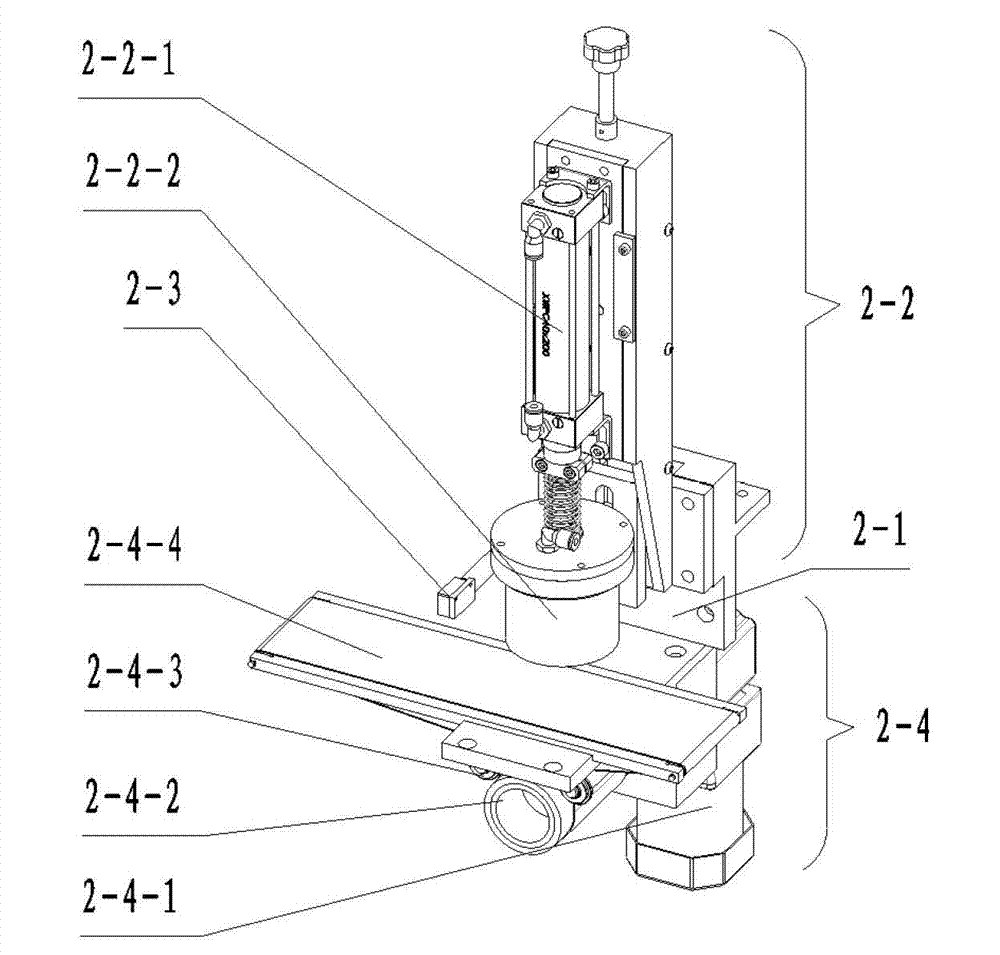

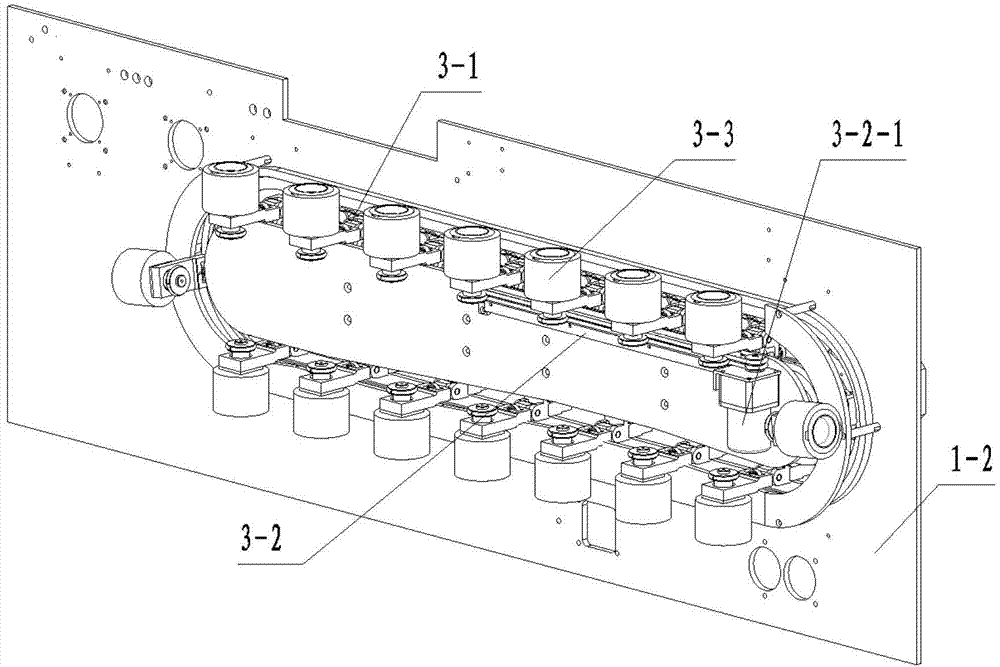

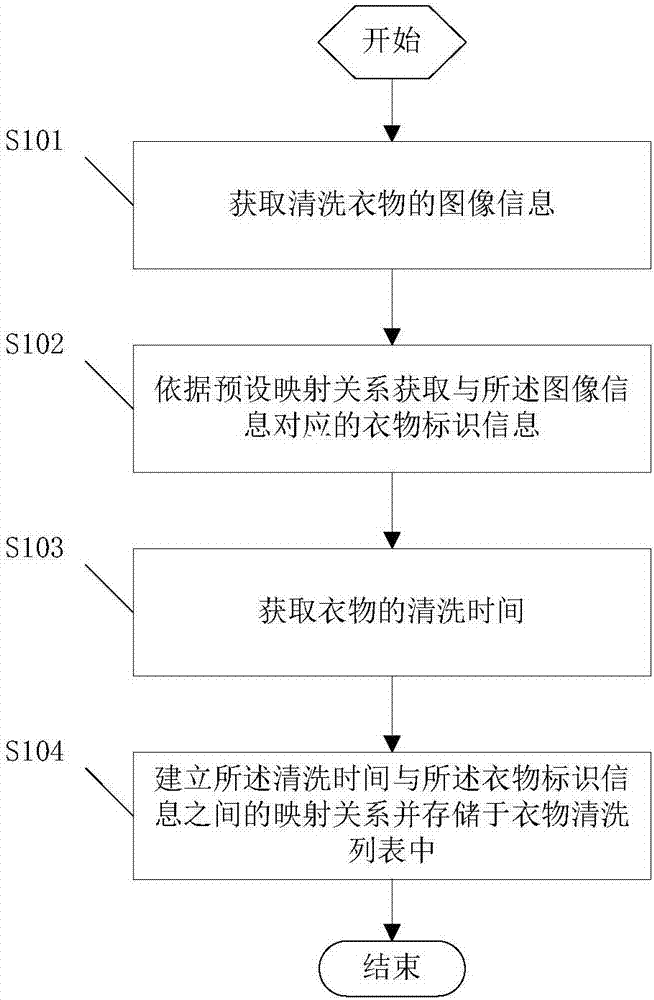

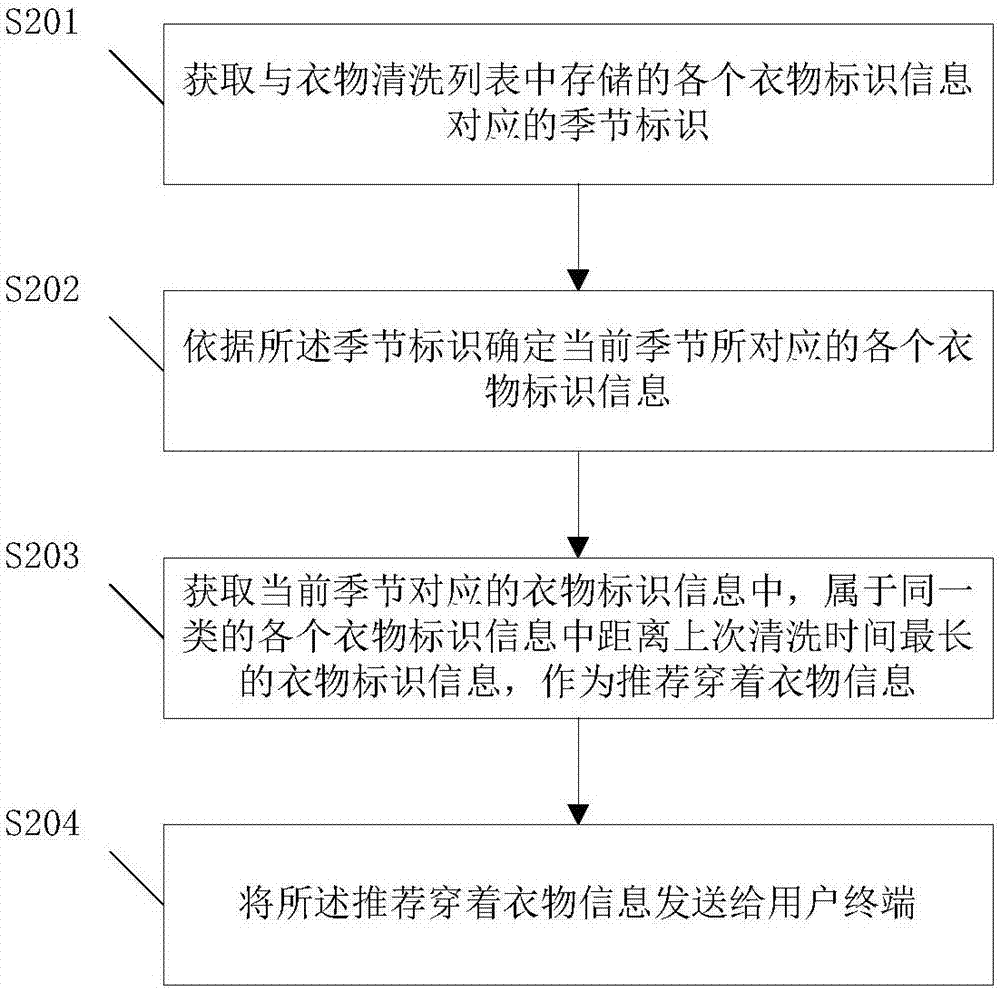

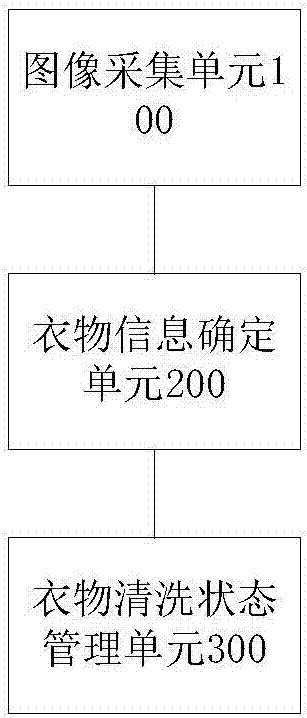

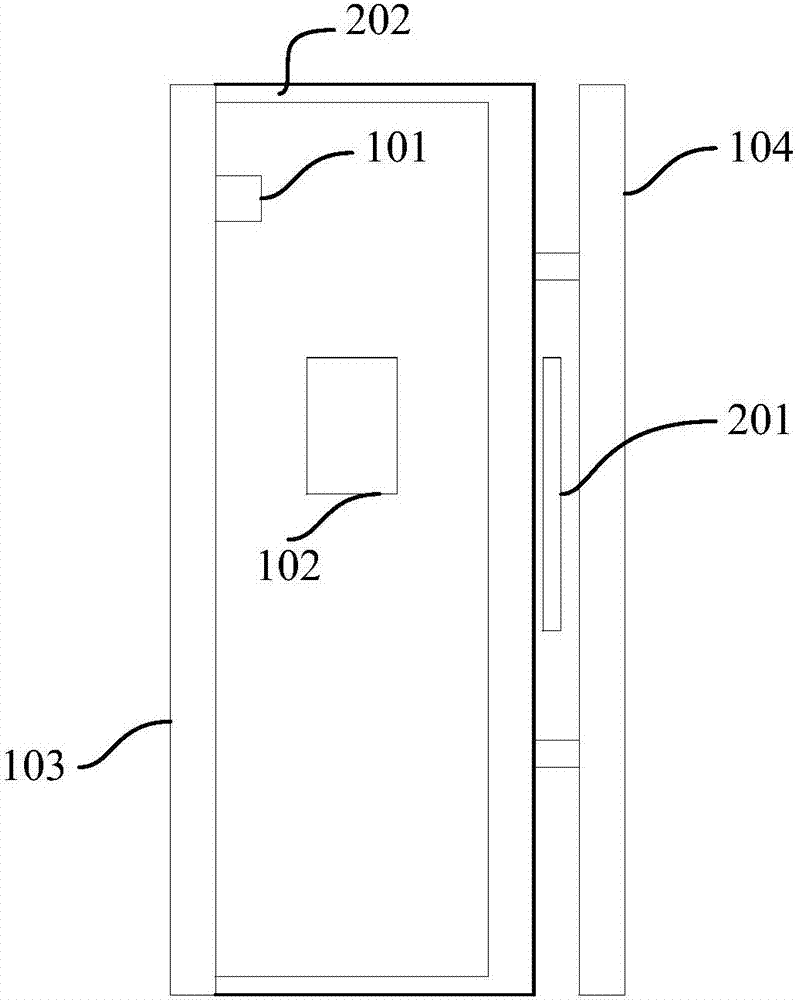

Clothes management method and system, washing machine and server

ActiveCN107090693ASolve health problemsOther washing machinesControl devices for washing apparatusData mining

The invention provides a clothes management method and system, a washing machine and a server. The method comprises steps as follows: acquiring image information of cleaned clothes; acquiring clothes identification information corresponding to the image information according to a preset mapping relation; acquiring clothes cleaning time; establishing a mapping relation between the cleaning time and the clothes identification information and storing the mapping relation to a clothes cleaning list. A user can check the latest cleaning time of the clothes by checking the clothes cleaning list, so that the hygienic problem caused by the fact that the user wears clothes which are not cleaned for a long time is solved.

Owner:GREE ELECTRIC APPLIANCES INC

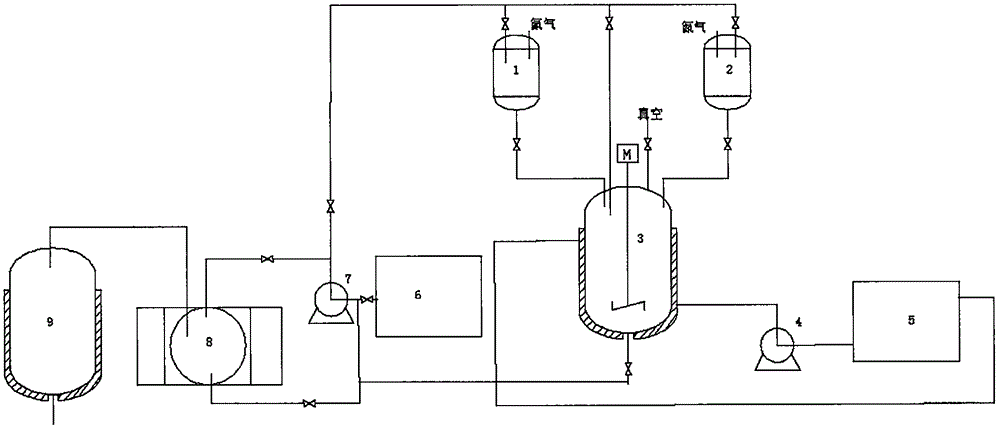

Atmosphere-controlling preservation method for meat

InactiveCN101356935ASolve bacterial residueGreat tasteMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsVacuum coolingChemistry

The invention discloses an air-regulating preservation method of meat, which belongs to the technical field of meat preservation. The technical points of the method comprises the following steps that: (1) selected fresh meat materials are washed cleanly, cut well and put in a pot for cooking; (2) the cooked meat materials are packed in a vessel and covered, and then are sent to a clean-room; a vacuum cooling machine is used for reducing the surface temperature of the meat materials to 5 - 10 DEG C and the internal temperature to 8 - 12 DEG C; (3) the cooled meat materials in the clean-room are put in a food plastic box; which, after being vacuumized, is filled with the mixed gas of CO<2> and N<2> for fresh-keeping packaging; and (4) the packed meat materials are stored in an environment of 4 to 8 DEG C. The method has the advantages of good fresh-keeping effect and is used for keeping fresh the cooked meat food.

Owner:杨声盛

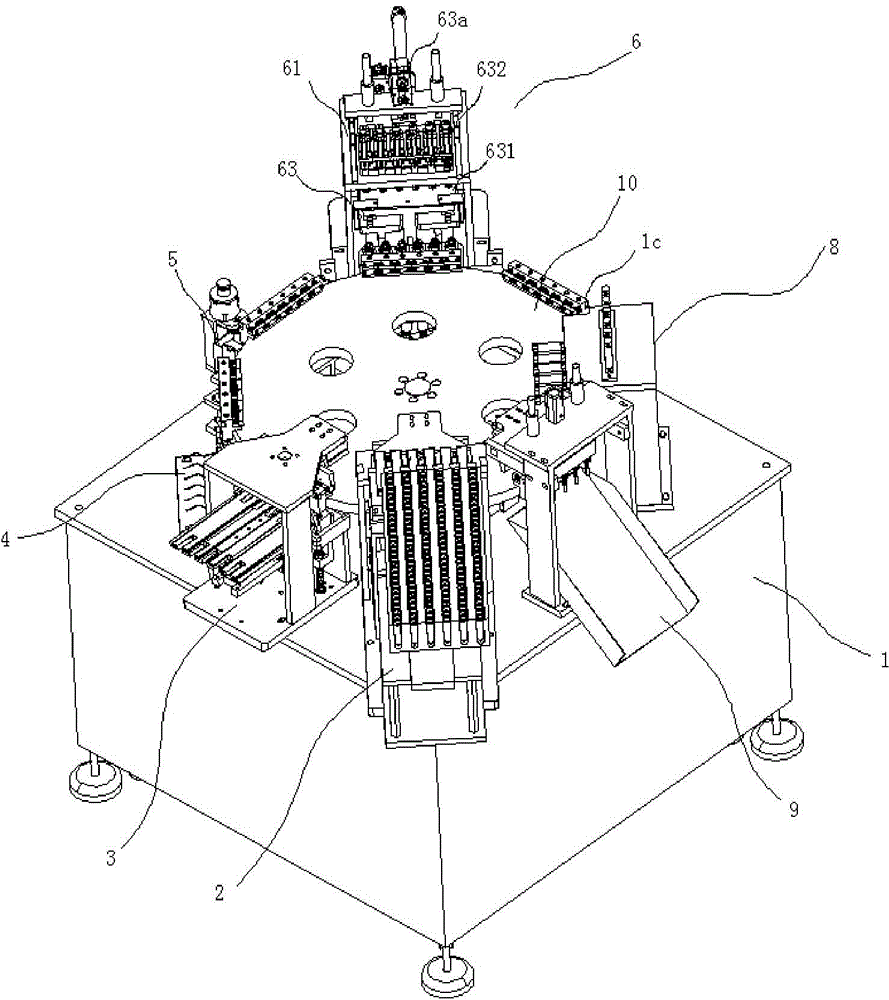

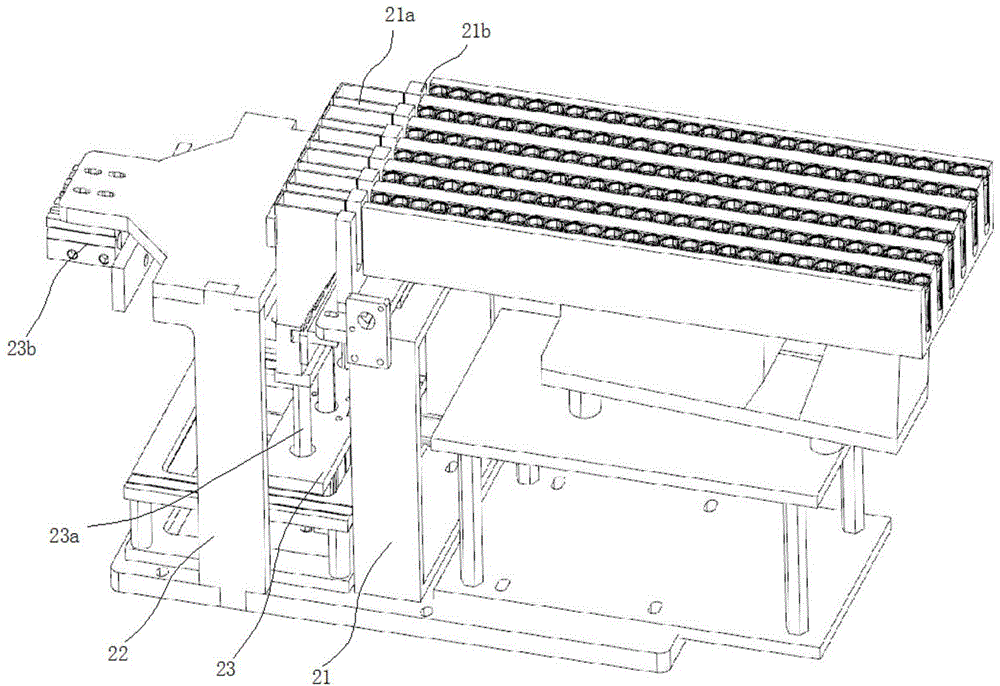

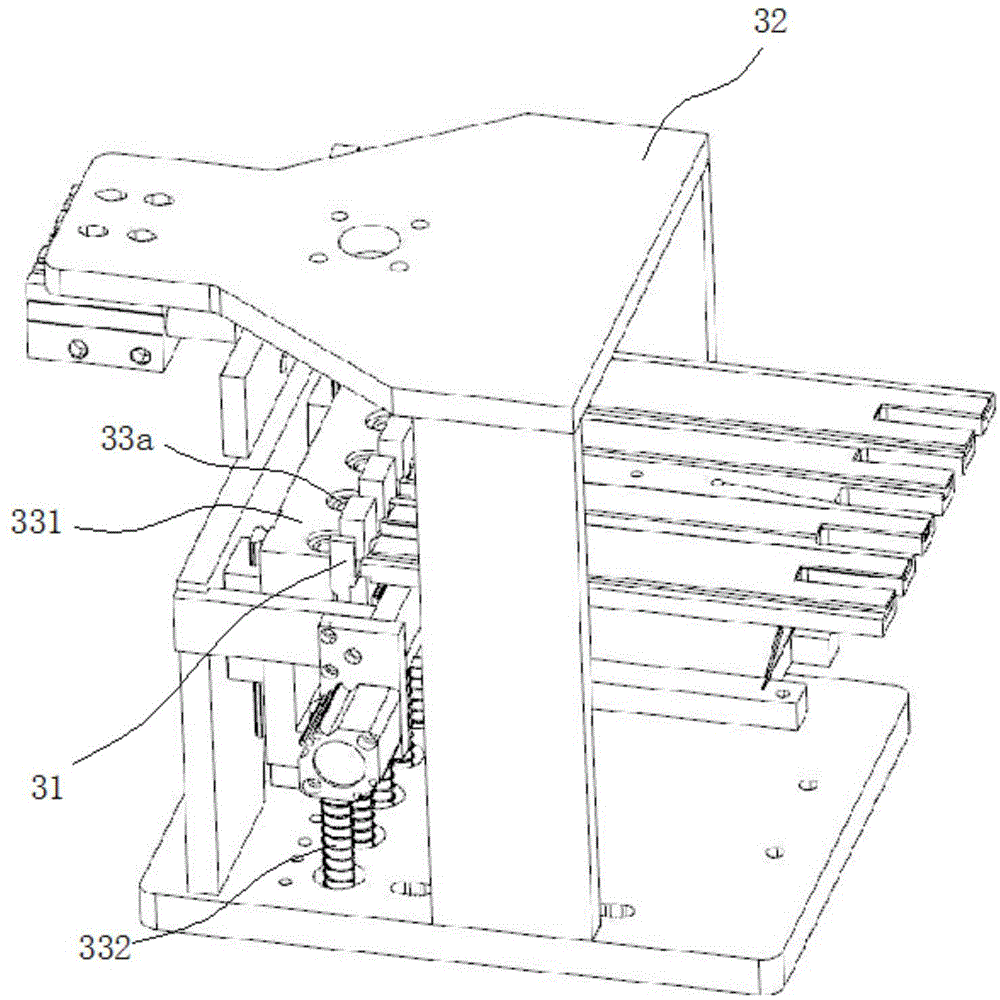

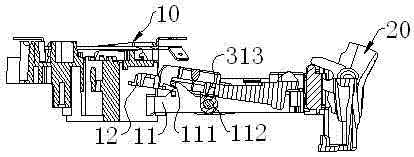

Full-automatic drip chamber assembly machine

ActiveCN104827282AExtended service lifeImprove assembly efficiencyAssembly machinesEngineeringAssembly machine

The invention relates to the technical field of the assembly of piercing needles among medical instruments, and more specifically, the invention relates to a full-automatic drip chamber assembly machine, which comprises a working table, wherein a large turnplate which can rotate is arranged on the working table, and a plurality of clamps for clamping and arranging workpieces are arranged on the large turnplate; for each clamp and the movement path of each clamp, a drip chamber mounting station, a filter screen mounting station, a filter screen detection station, a glue application station, a piercing needle mounting station, a piercing needle detection station, a discharge station and a rejecting station are respectively arranged on the working table, the drip chamber mounting stations are used for mounting drip chambers, the filter screen mounting stations are used for mounting filter screens on the drip chambers, the filter screen detection stations are used for detecting whether the filter screens and the drip chambers are assembled in place, the glue application stations are used for applying glue on the inner edges of the drip chambers, the piercing needle mounting stations are used for mounting piercing needles on the drip chambers, the piercing needle detection stations are used for detecting whether the piercing needles and the drip chambers are assembled in place, the discharge stations are used for outputting qualified finished products, and the rejecting stations are used for rejecting unqualified finished products. The full-automatic drip chamber assembly machine is structurally reasonable, operation is stable, and the efficiency of piercing needle and drip chamber assembly is high.

Owner:WENLING DEGUANG AUTOMATION EQUIP

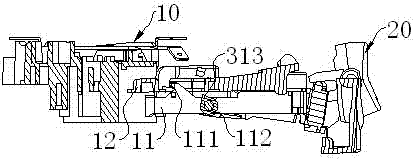

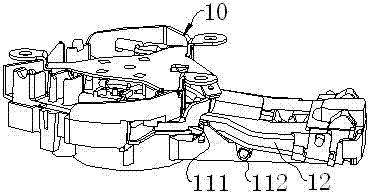

Three-way valve assembly machine and assembly method thereof

PendingCN107263092AEliminate Hygiene ProblemsRealize fully automatic assemblyAssembly machinesPhysicsEngineering

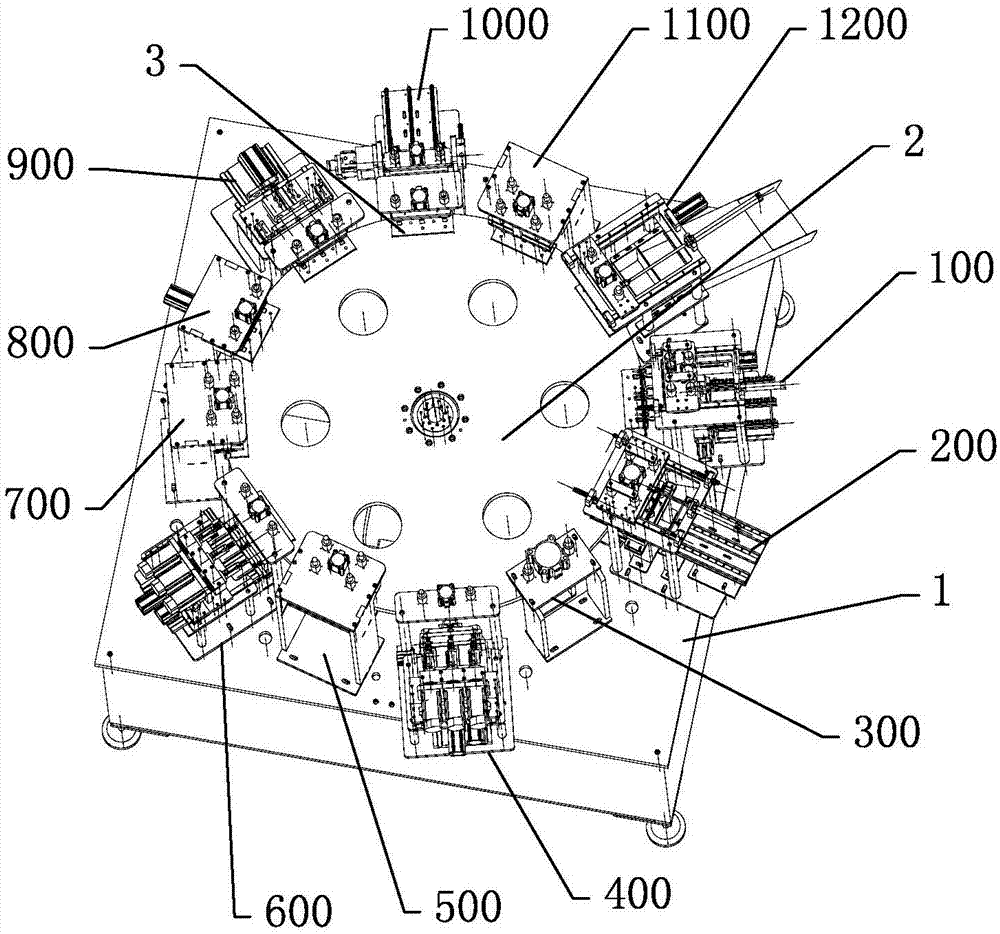

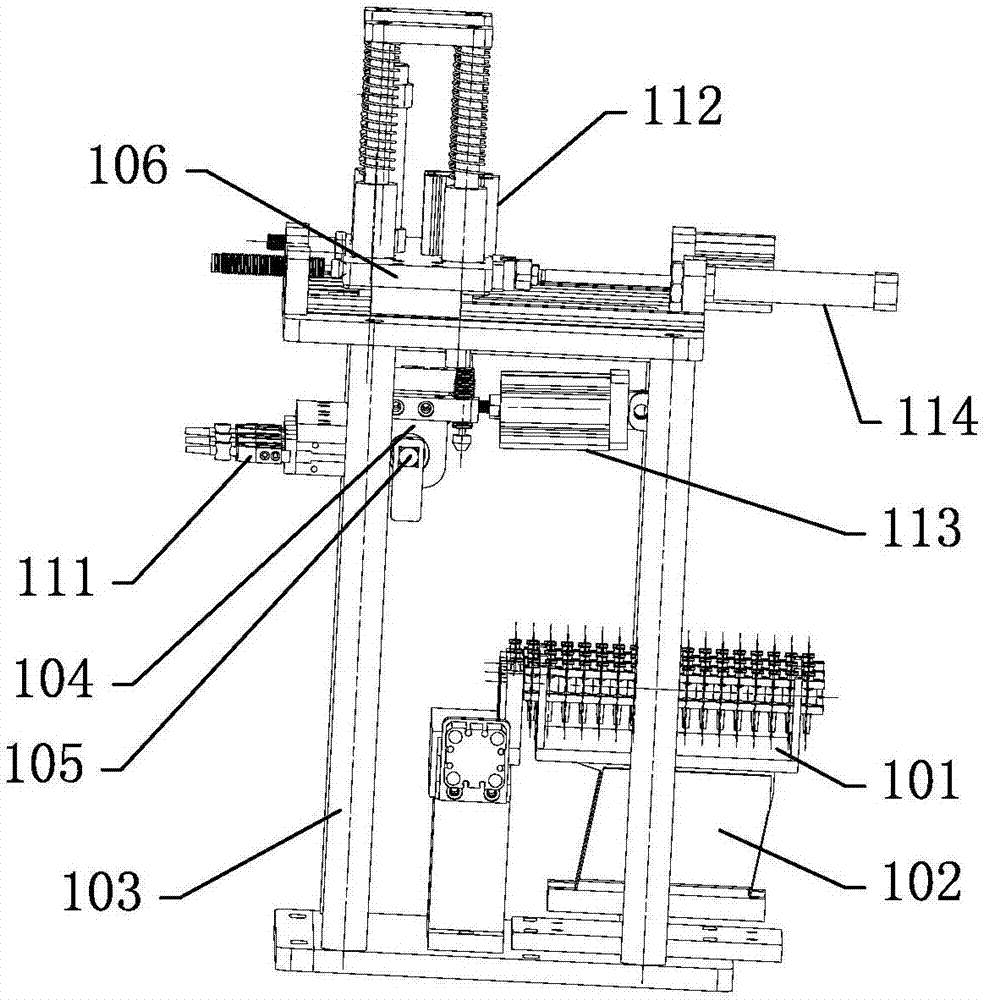

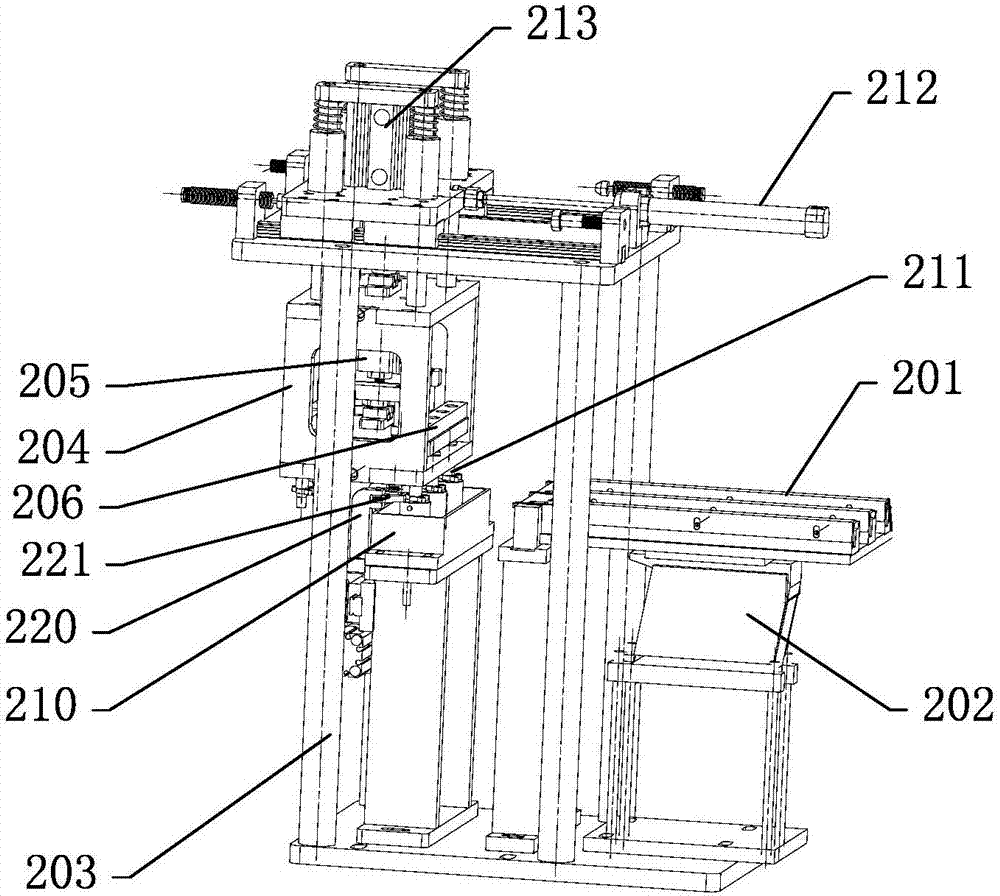

The invention discloses a three-way valve assembly machine and an assembly method thereof, and aims to provide the high-efficiency and high high-precision three-way valve assembly machine and the assembly method thereof. According to the technical scheme, the three-way valve assembly machine comprises a machine frame (1); a multi-station rotary workbench (2) is arranged on the machine frame (1); a plurality of clamps (3) are arranged on the machine frame (1); and aiming at the clamps and movable paths of all the clamps, a valve body feeding station (100), a valve element mounting station (200), a valve element compressing station (300), a first screw top mounting station (400), a first valve body rotating station (500), a second screw top mounting station (600), a second valve body rotating station (700), a gas tightness detection station (800), a spiral head mounting station (900), a sheath mounting station (1000), a valve element rotating station (1100) and a discharging station (1200) are sequentially arranged on the machine frame (1). The three-way valve assembly machine and the assembly method thereof are applicable to the field of assembly.

Owner:WENLING DEGUANG AUTOMATION EQUIP

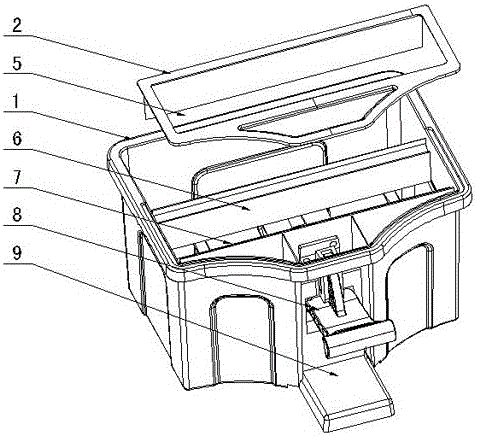

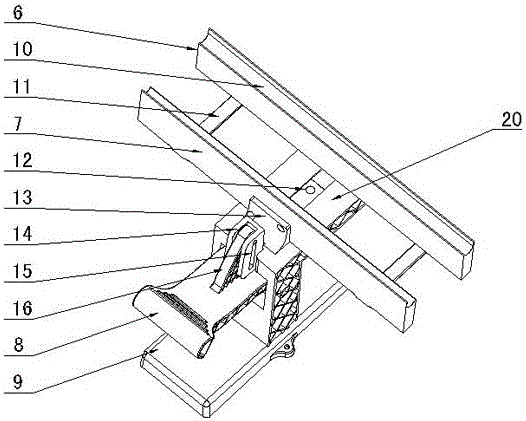

Mopping and sweeping integrated sweeping machine with self-cleaning function and sewage recovery function

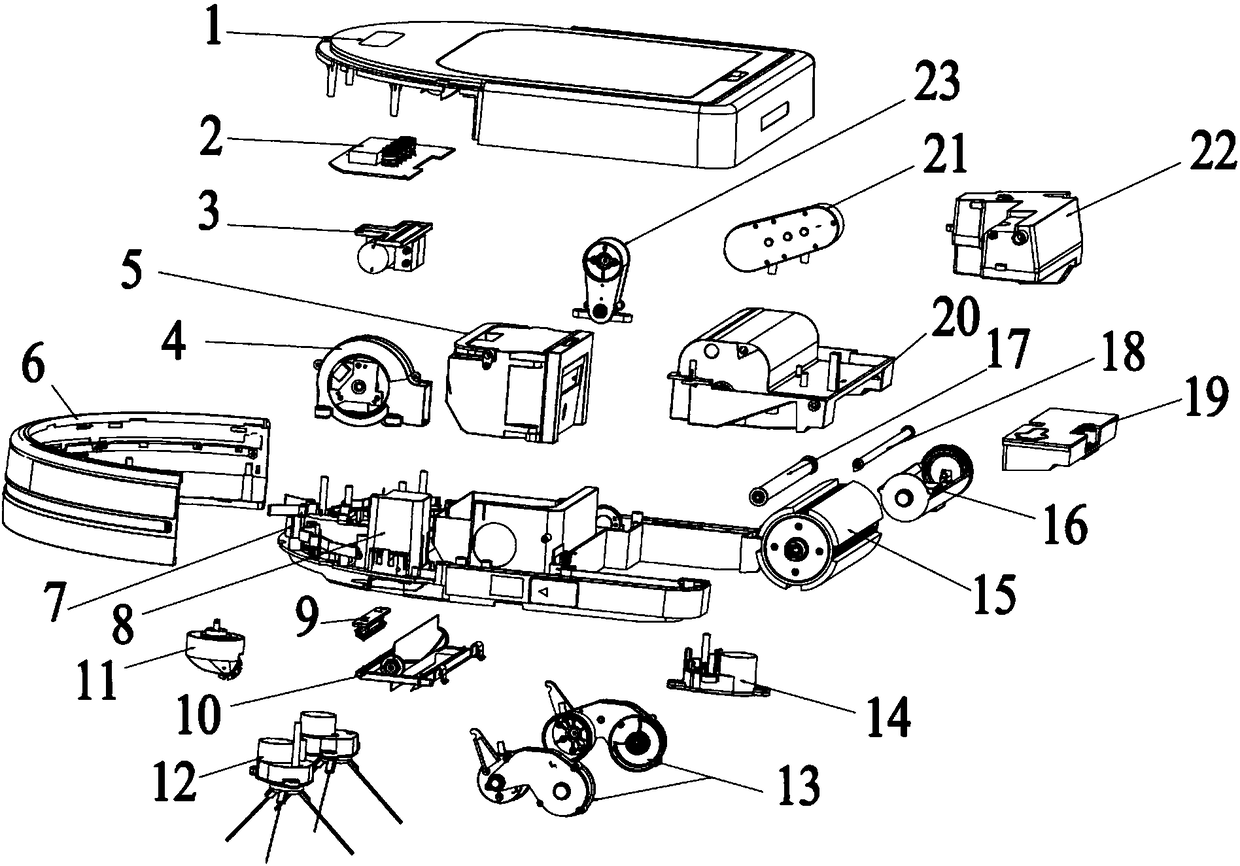

PendingCN109316126AAffect performanceEnsure suction effectAutomatic obstacle detectionTravelling automatic controlPulp and paper industrySewage

The invention relates to the technical field of an intelligent sweeping machine, in particular to a mopping and sweeping integrated sweeping machine with a self-cleaning function and a sewage recoveryfunction. Th machine comprises an upper cover, a water pump, a printed circuit board, a display screen, a fan, a dust box, a front touch mechanism, a lower cover base, a battery, a UV lamp assembly,a middle sweep brush assembly, a universal wheel, a side brush, left and right wheel assemblies, a lifting gear box, a roller, a sewage recovery tank, a roller bracket, a roller gear box, a water purifying tank and a medium sweep gear box; the water pump, the fan, the dust box, the battery and the UV lamp assembly are mounted on the base of the lower cover, the universal wheel is installed in front of the lower cover base, the left and right wheel assemblies are respectively mounted on the left and right sides of the lower cover base of the sweeping machine, and the roller is mounted on the roller bracket. The machine solves granular waste, hair, dust and sewage generated by sweeping and mopping the ground at one time, recycles the garbage, the hair, the dust and the sewage into the relevant dust box and a sewage recycle tank, and improves the product practicality.

Owner:勤耕云智能科技(深圳)有限公司

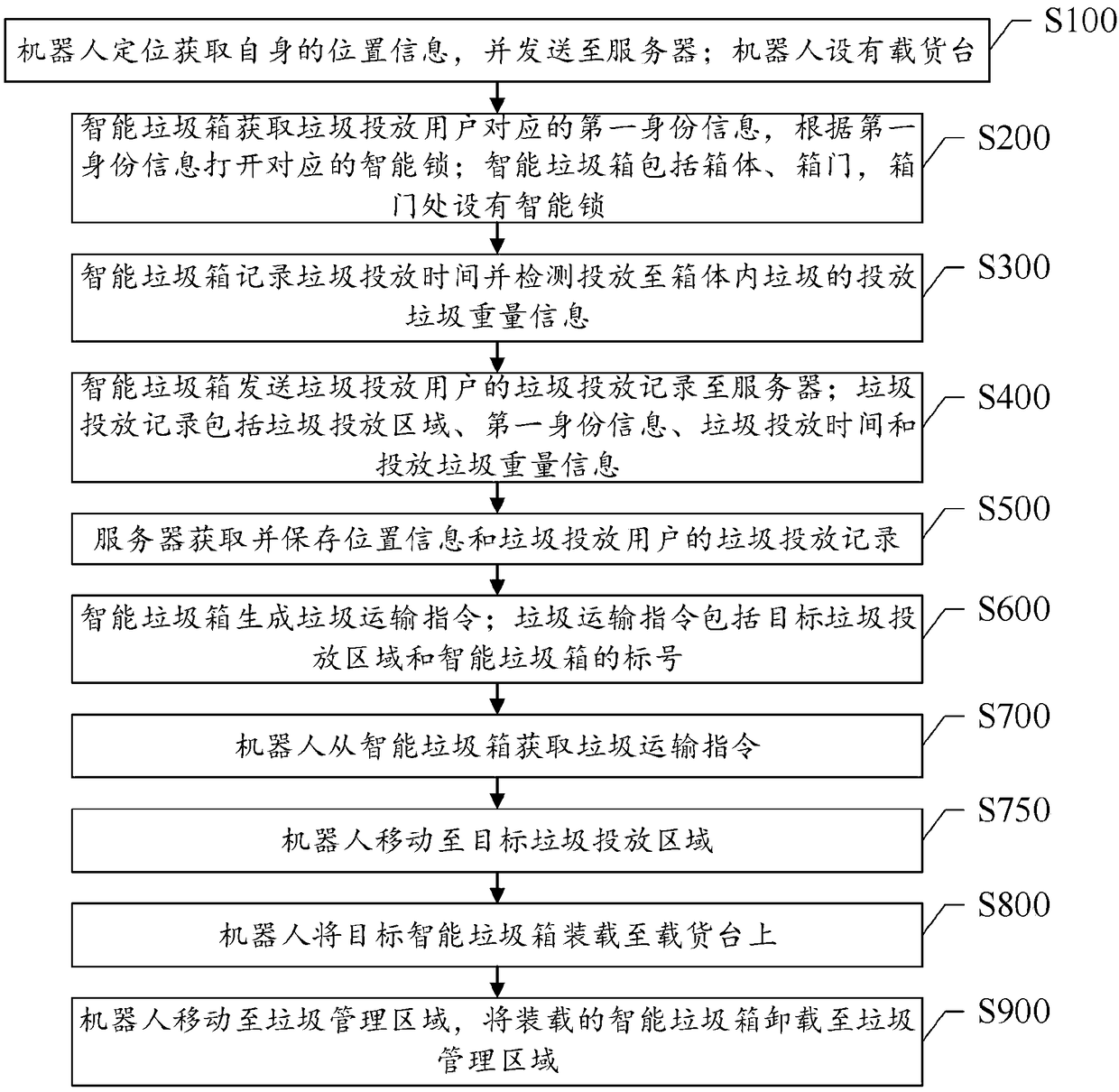

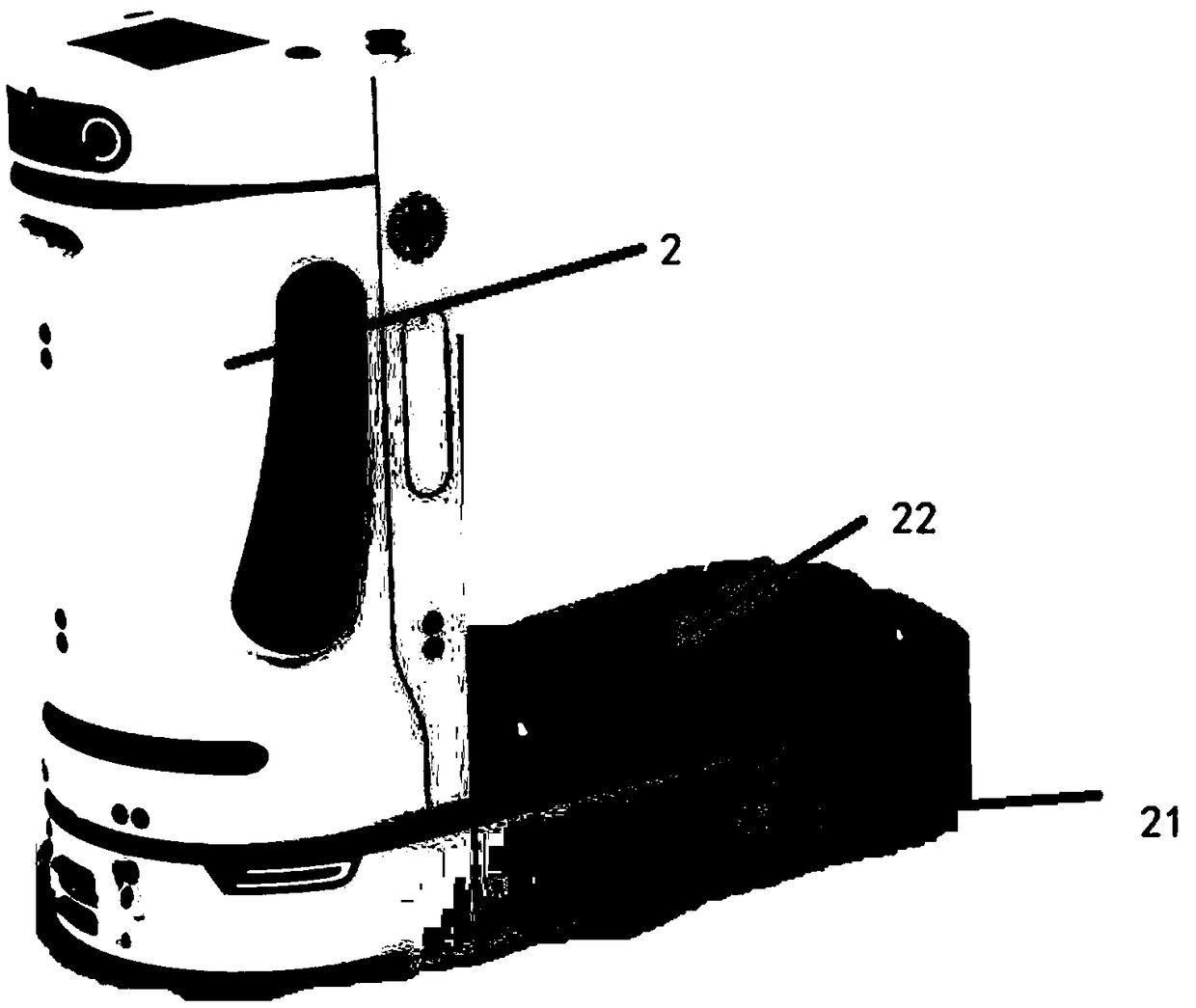

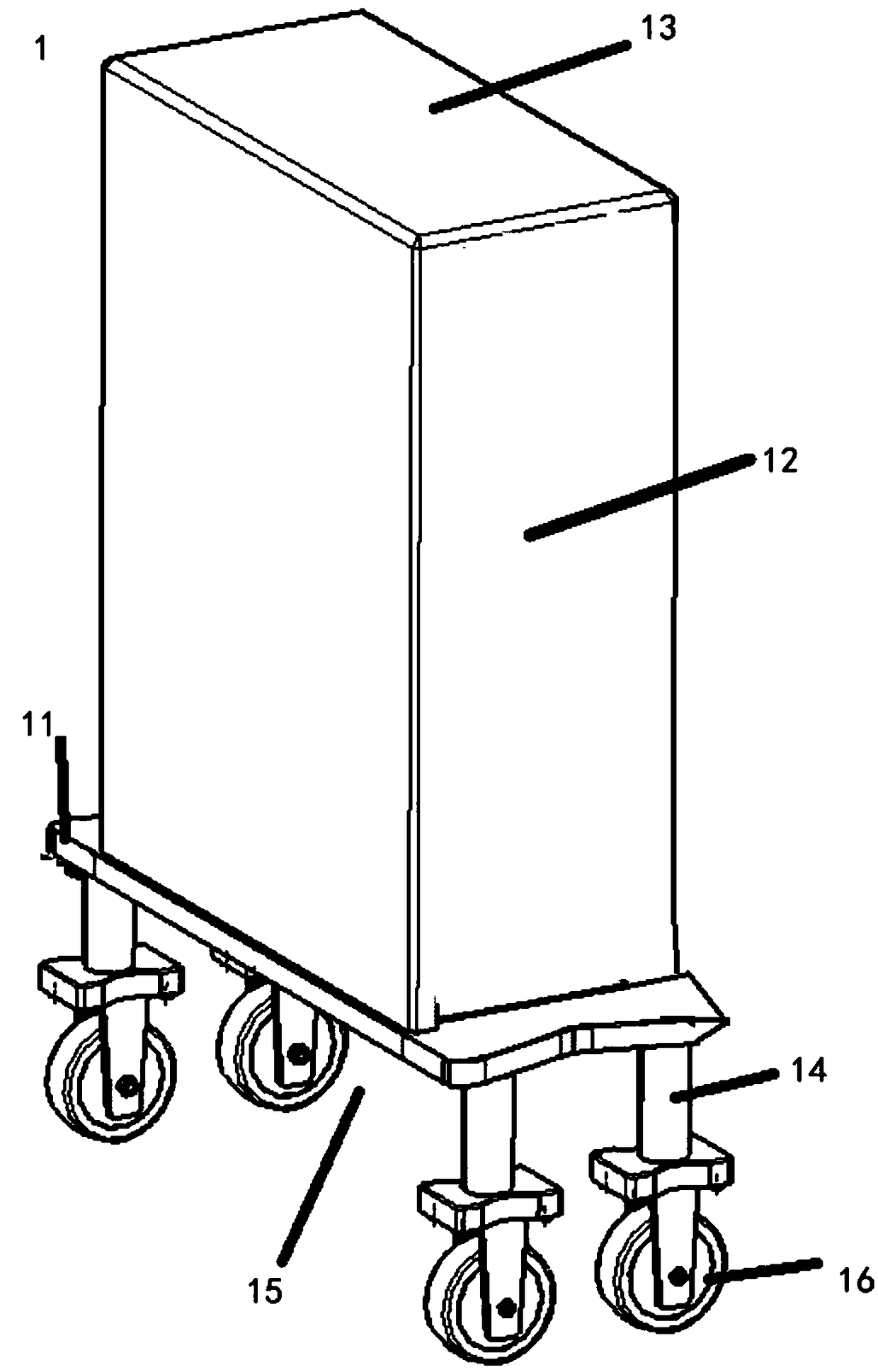

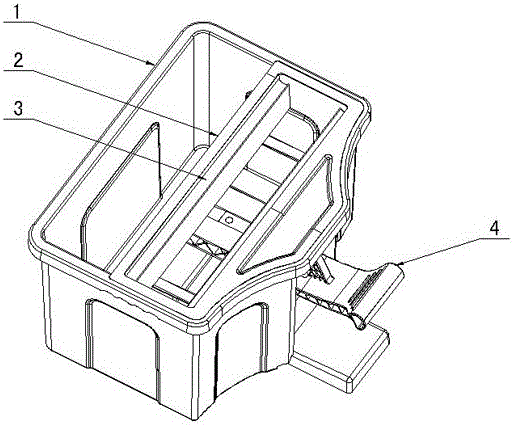

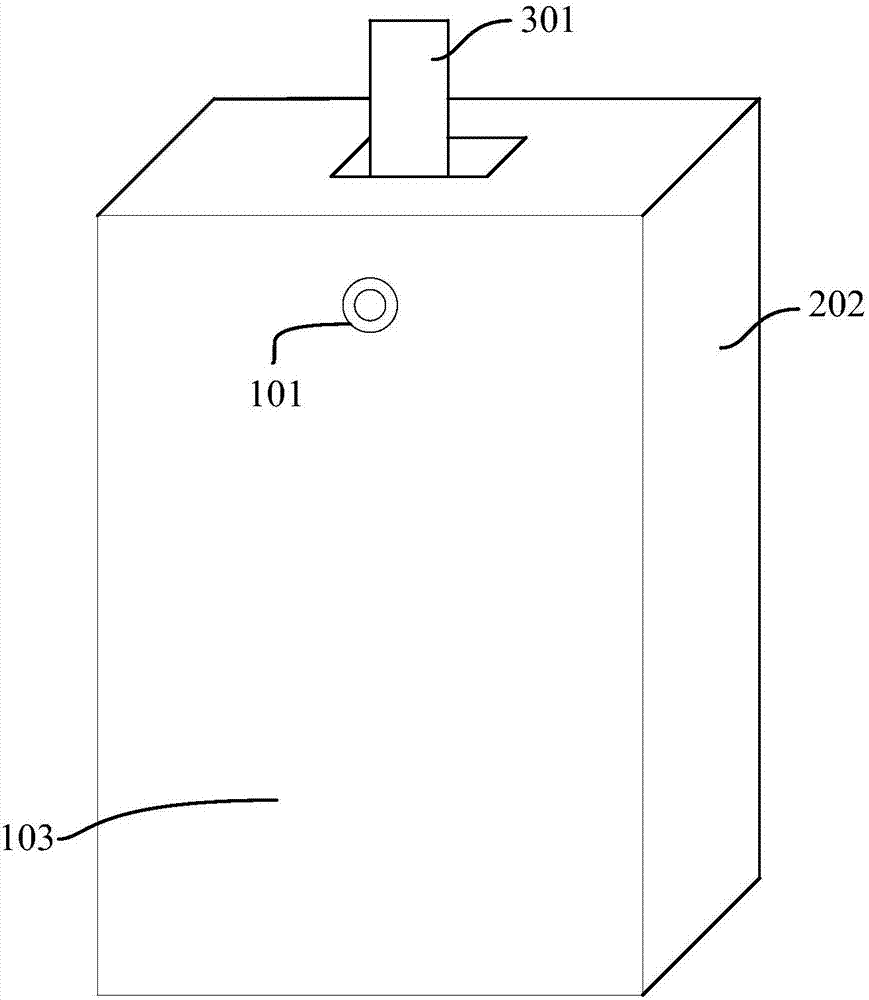

Trash management method and system based on robot

ActiveCN109230081ASolve health problemsReduce labor costsRefuse receptaclesEngineeringManagement area

The invention discloses a trash management method and system based on a robot. The method includes the steps of positioning the robot to obtain position information, arranging a carrying table on therobot, obtaining first identity information corresponding to a trash throwing user by an intelligent trash can, opening a corresponding intelligent lock according to the first identity information, recording trash throwing time by the intelligent trash can and detecting the thrown trash weight information of trash thrown in a can body, obtaining and storing the position information and the trash throwing record of the trash throwing user by a server, generating a trash conveying instruction by the intelligent trash can, moving the robot to a target trash throwing area, loading the target intelligent trash can onto the carrying table by the robot, moving the robot to a trash management area, and unloading the loaded intelligent trash can to the trash management area. By means of the methodand system, the sanitation problem in the trash conveying process is solved. The trash delivery link is monitored and controlled, and subsequent tracing and responsibility investigating are facilitated. Trash does not need to be conveyed manually, and labor cost is reduced.

Owner:JIANGSU MUMENG INTELLIGENT TECH

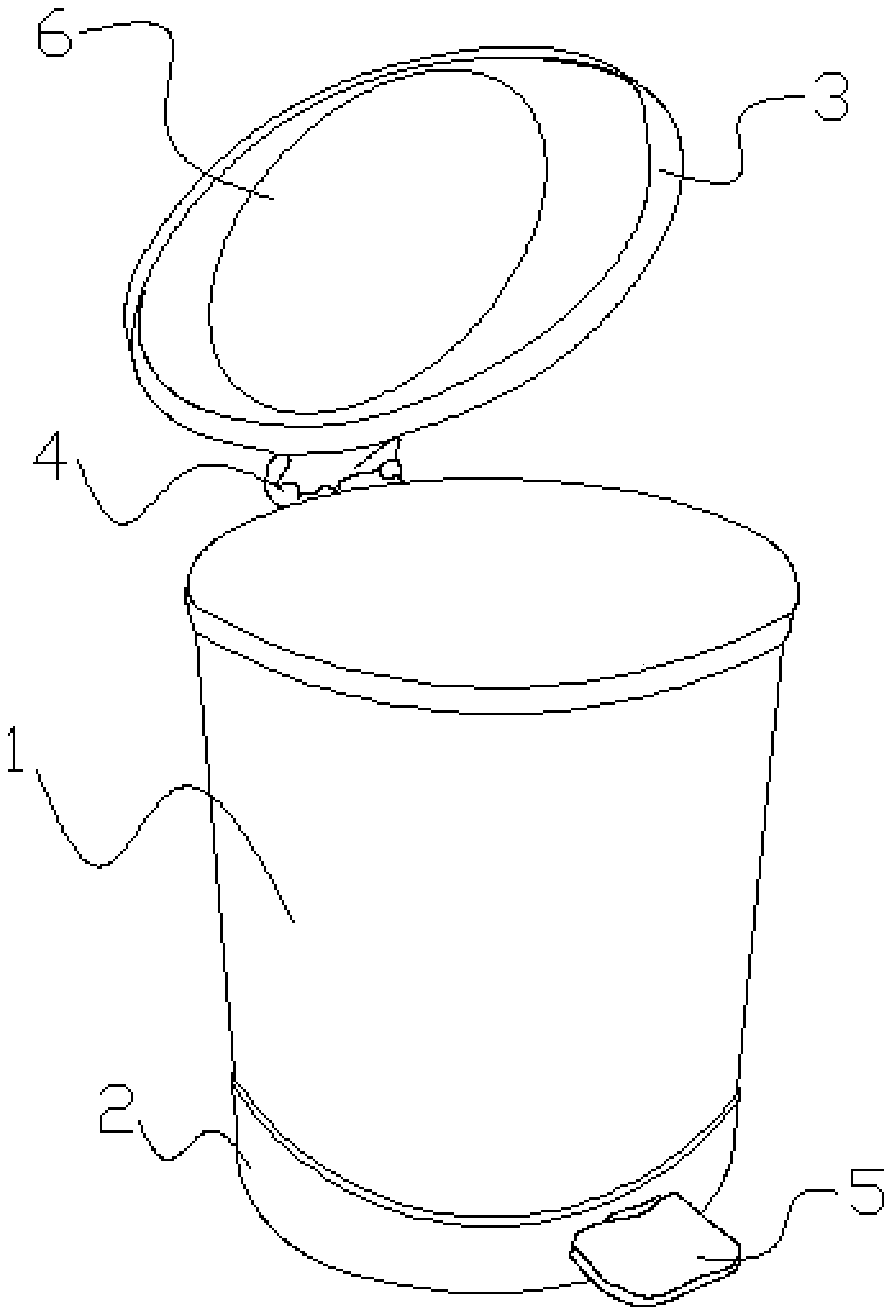

Collodion mop cleaning barrel

InactiveCN105769083ASolve health problemsSolve usabilityCarpet cleanersFloor cleanersMechanical engineeringExtrusion

The invention discloses a collodion mop cleaning barrel, which comprises a barrel body (1) and a base (9), wherein the base is fixed on the barrel body (1); a water extruding device (3) and a driving device (4) are arranged on the base (9); the water extruding device (3) comprises a water extruding fixing plate (7), a water extruding moving plate (6) and a guide rail connecting rod (12); the upper part of the base (9) is provided with an expanding part (20); a guide rail groove (19) is formed in the expanding part (20); a guide rail connecting rod (12) is arranged on the guide rail groove (19); the water extruding fixing plate (7) is fixed on the expanding part (20) through a fixing plate seat (13); the water extruding moving plate (6) is fixed on the guide rail connecting rod (12) through a moving plate seat (18); a collodion head is put between the water extruding fixing plate (7) and the water extruding moving plate (6) during dewatering; the driving device (4) drives the water extruding moving plate (6) to move in the direction towards the water extruding fixing plate (7) through the guide rail connecting rod (12) so that the collodion head is tightly clamped for water extrusion. After the structure is used, the collodion mop cleaning barrel has the advantages that the structure is simple and reasonable; the operation and the use are convenient; the water extruding effect is good; the work efficiency is high, and the like.

Owner:应高安

Early-strength sprayed concrete

The invention discloses early-strength sprayed concrete and belongs to the technical field of concrete. The early-strength sprayed concrete is prepared from, by weight, 400-450 parts of sulphate aluminium cement, 20-50 parts of silicon powder, 800-1000 parts of medium sand, 800-1000 parts of crushed stone, 1-2.5 parts of a water reducer, 0.03-0.09 part of lithium carbonate and 180-225 parts of water. The concrete is particularly suitable for quick repairing, emergency maintenance and supporting engineering of weak surrounding rock, and has the advantages of being quick in setting and early in strength, high in hour strength, high in resilience and low in production cost.

Owner:JIAHUA SPECIAL CEMENT

Aqueous formaldehyde-free glass wool binder and preparation method thereof

ActiveCN102533168AEnhanced bubble forming abilityImproved thermal and acoustic insulationNon-macromolecular adhesive additivesAcid polymer adhesivesOXALIC ACID DIHYDRATEPolymer science

The invention discloses an aqueous formaldehyde-free glass wool binder and a preparation method of the binder. The solid content of the binder is 35-40%, the curing temperature is 150-250 DEG C, and the curing time is 5 minutes. The preparation method of the invention comprises the following steps (by mass parts): adding 10-16.5 parts of polyols, 0.5-2 parts of catalyst containing phosphorus and 0.1-2 parts of foaming agent into 4-42 parts of water, stirring and mixing; adding 0.5-1.5 parts of silicane coupling agent, 35-80 parts of polyacrylic acid oligomer or polyacrylic acid copolymer and 0.1-1 part of strong acid into the above liquid mixture in order, and regulating pH to 1-3. The preparation method of the invention does not release free formaldehyde or organic solvent, and has the advantages of being healthy and environmentally friendly. In addition, the preparation method of the invention efficiently improves the capacity of the binder for producing bubbles in the curing process and the heat insulation and sound insulation effects of glass wool products by adding oxalic acid or oxalate as the foaming agent.

Owner:SOUTH CHINA UNIV OF TECH

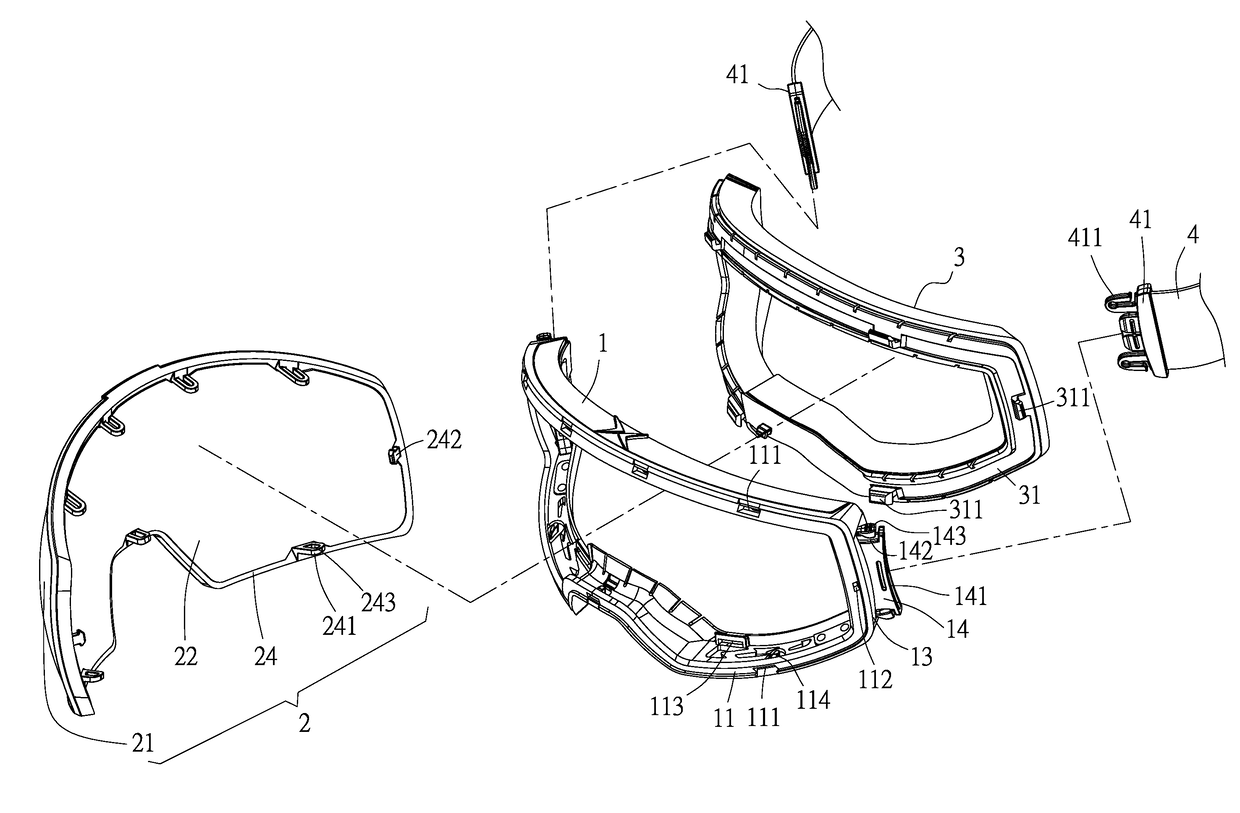

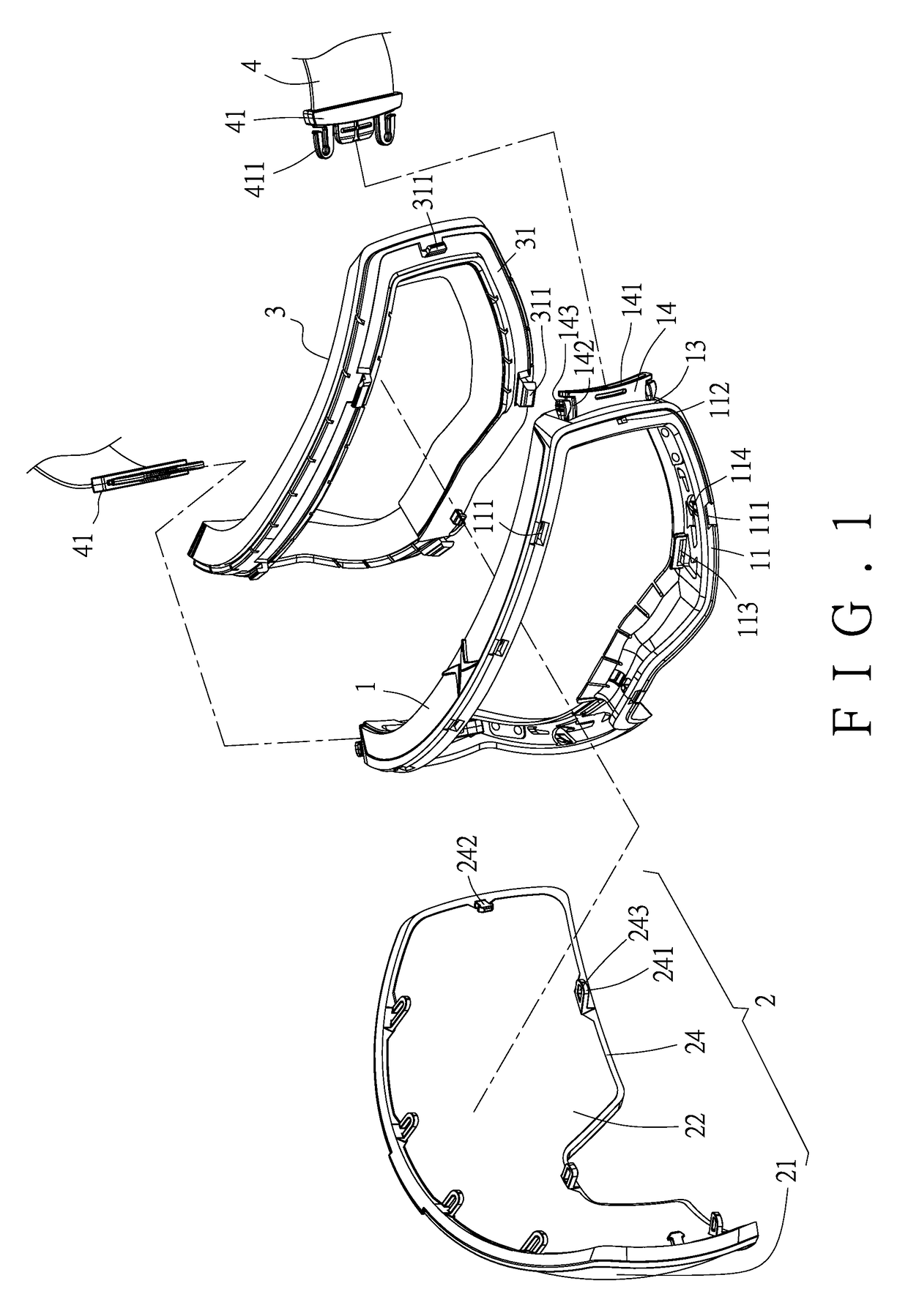

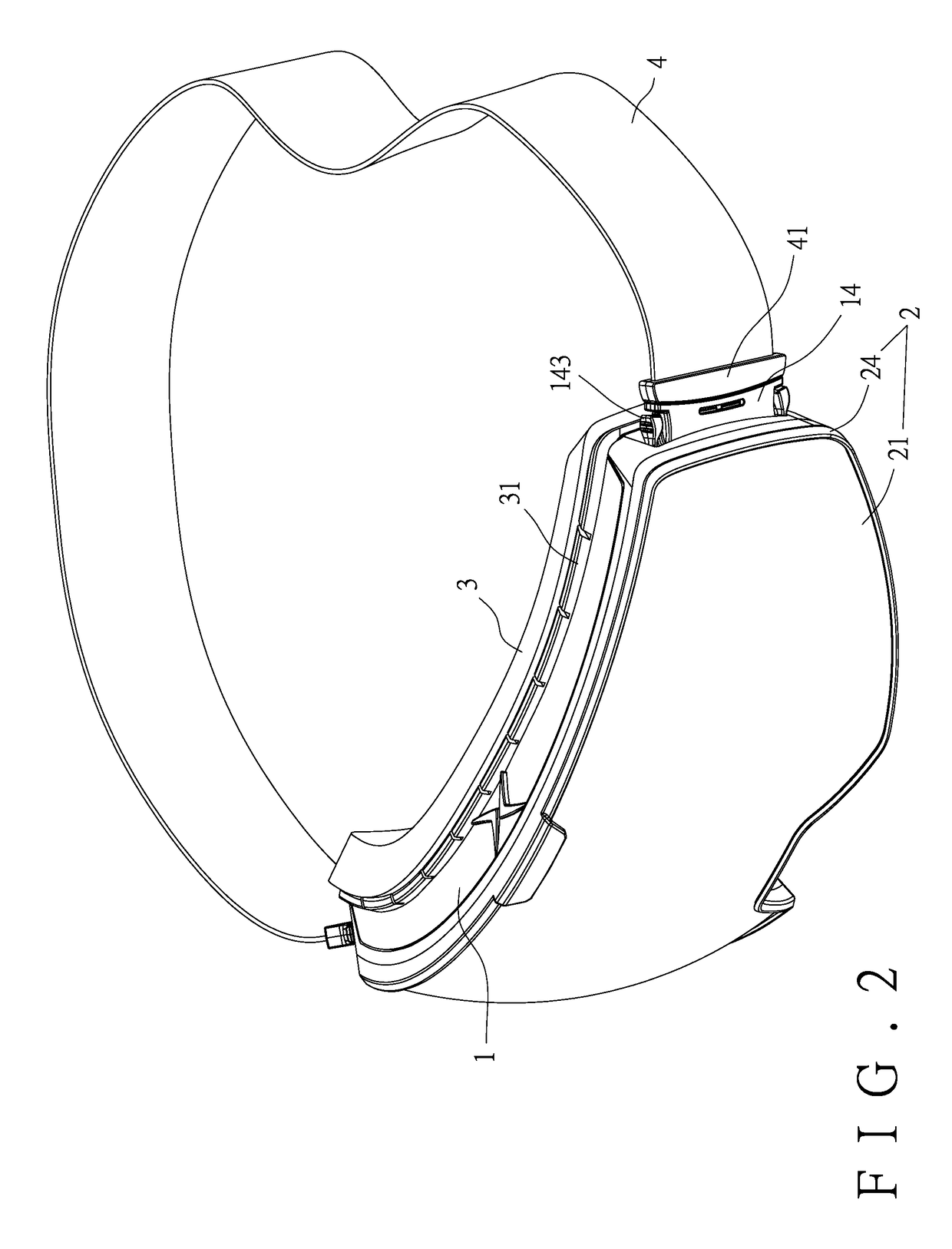

Snow goggles allowing disassembly

InactiveUS20170216098A1Easy to separateSolve health problemsGogglesProtective garmentCouplingEngineering

Snow goggles allowing disassembly include a goggle frame, a lens set, a protective pad, and a strap, each rapidly detachable for replacement or cleaning. The goggle frame has a first coupling side with first and second engaging portions, a second coupling side with a third engaging portion, and a peripheral portion with two first fastening units. The lens set includes first and second lenses, a connecting member, and a lens mount with fourth and fifth engaging portions for engagement with the goggle frame. The protective pad has a pad mount with a sixth engaging portion for engagement with the goggle frame. The strap has two ends each with a second fastening unit for engagement with the corresponding first fastening unit.

Owner:BORRION ENTERPRISE +1

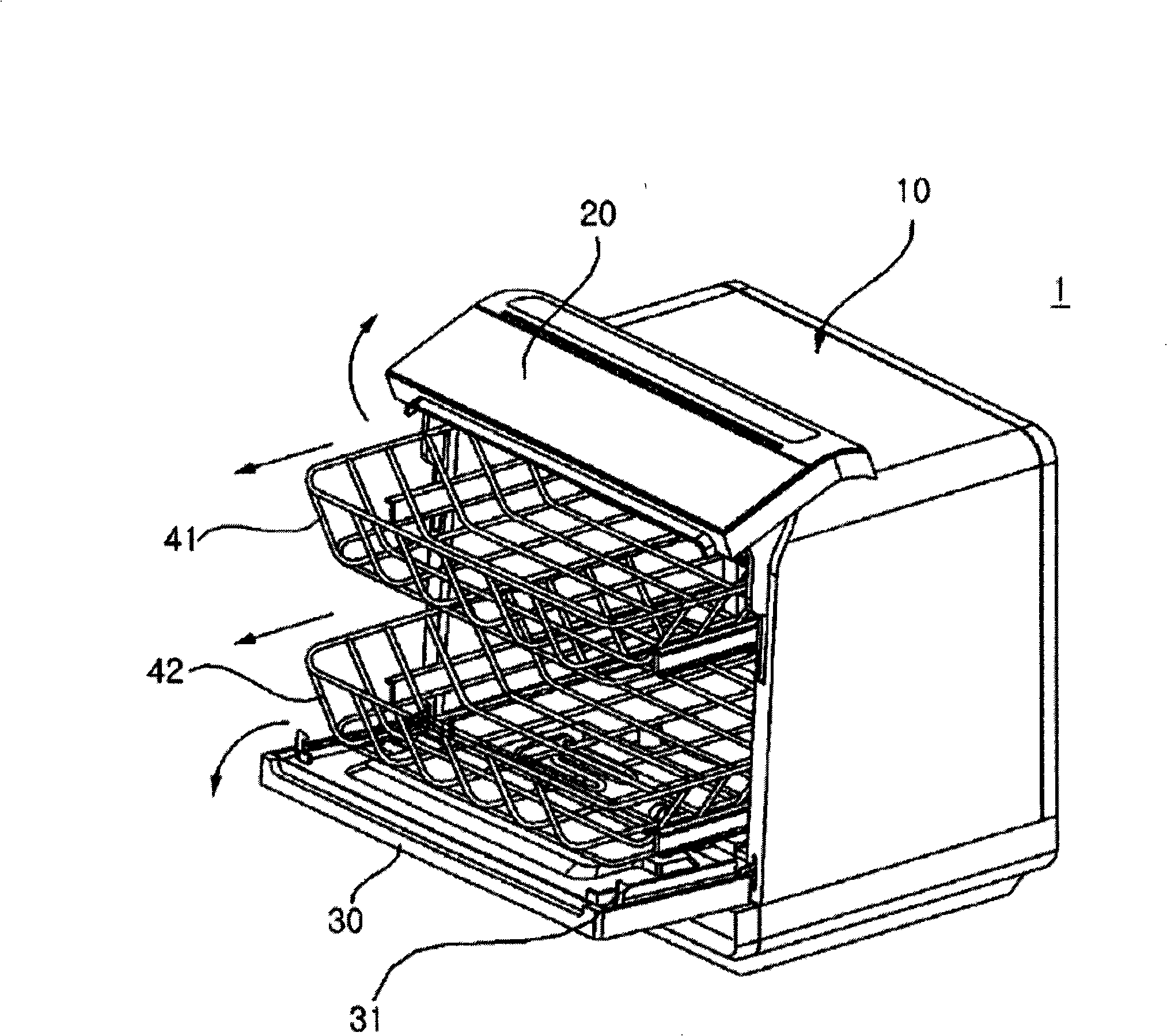

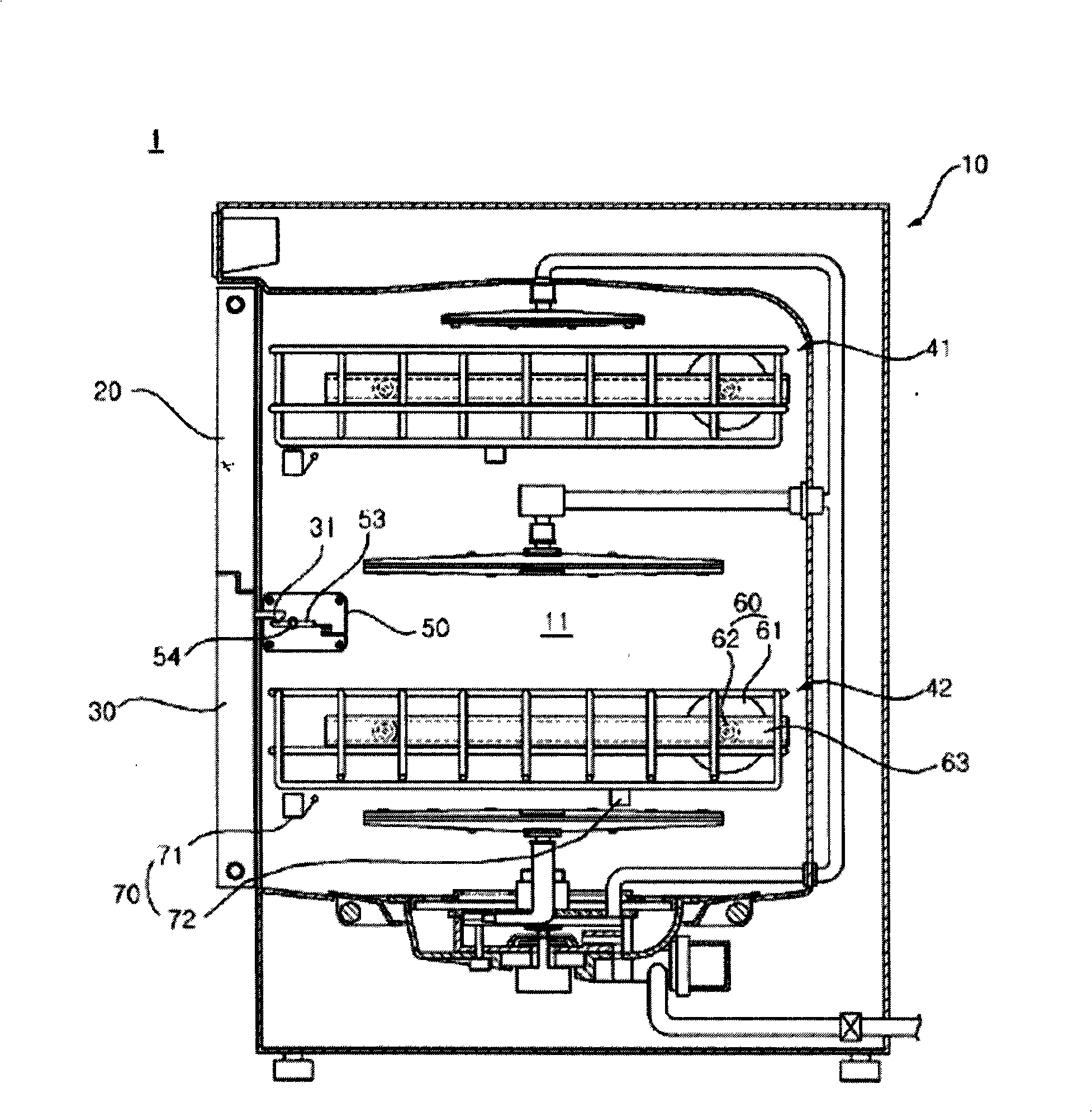

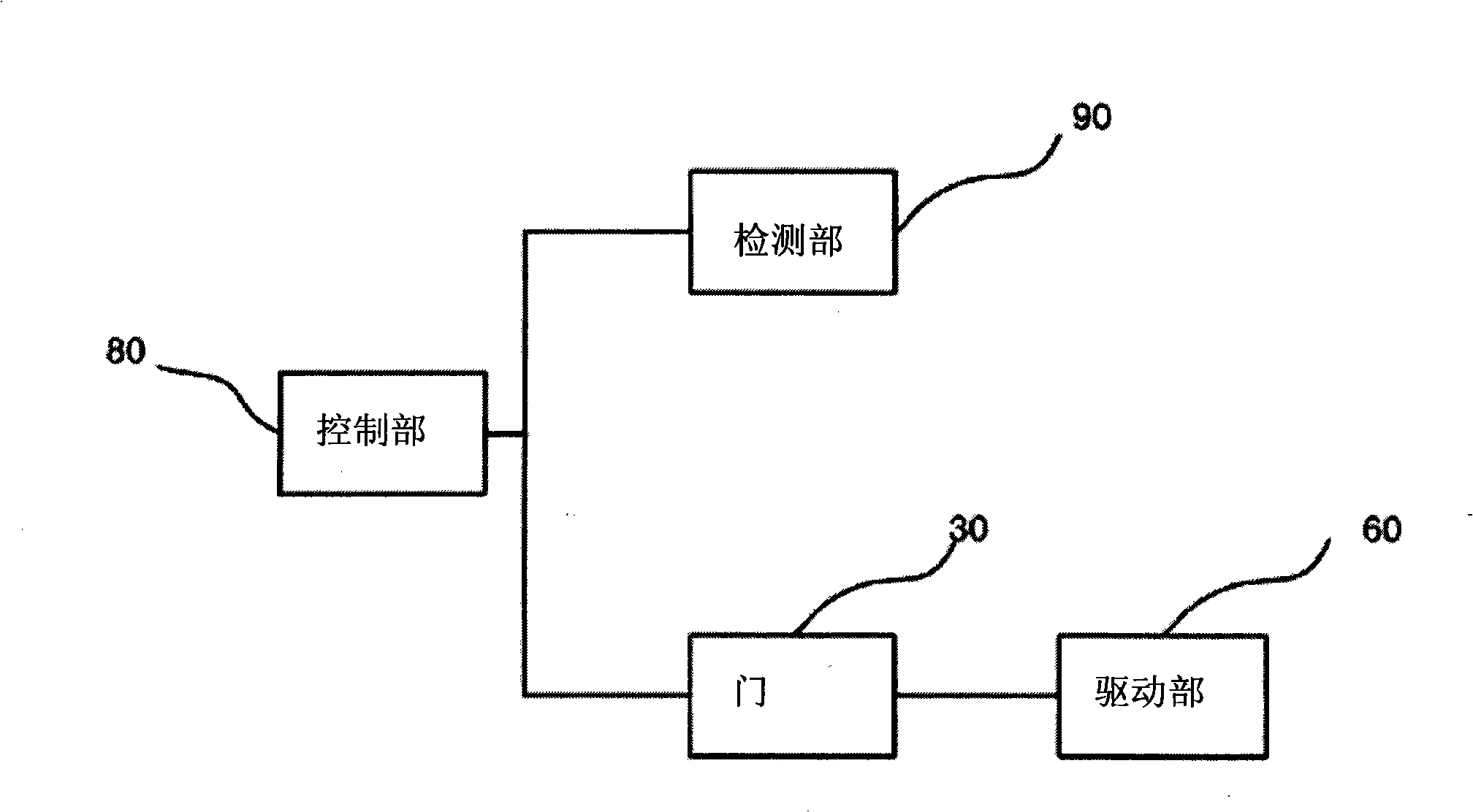

Dish washer and dish washer control method

InactiveCN101347320ASolve health problemsAvoid dangerTableware washing/rinsing machine detailsKitchenware cleanersEngineeringMechanical engineering

The invention discloses a bowl washing machine and the control method thereof. The bowl washing machine comprises: a shell of bowl washing chamber, a door for closing the washing chamber, a rack for containing the bowls disposed in the washing chamber, a driving component for driving the rack and making part of that extended out and a control component for opening the door and controlling the driving component to make the rack extended out after the washing and drying is finished. The machine in the invention can solves the sanitation problem caused by the residual water in bowls, can prevent the danger to users caused by the residual vapor after the drying process is finished, and can control the bowl containing rack to extend out of the shell after the user indication process is finished, consequently, improves the using convenience for user.

Owner:NANJING LG PANDA APPLIANCES

Water wash cotton for bedding and clothing and production technology thereof

The invention discloses a bedding-clothing water washed cotton and its producing process, and its characteristic: it contains the components in weight percent: cotton and hair fibers 20%-80% and other fibers 80%-20%. It includes the working procedures made in sequence: screening, degreasing, bleaching, high-temperature sterilizing, UV sterilizing, mixing, combing, paving net, and thermal-setting. The beneficial effects: it is a novel heat-preserving material developed by using cotton, hair, and other fibers; it has the functions: heath, moth prevention, moisture transmission, waste wash resistance, good model maintenance, comfort, etc. The product has wide application range, the thin-type low-g weight material can be used to make air-conditioner water-wash bedding for the summer, and fashionable dresses and overskirts, etc; the thick-type high-g weight material can be used to make heat-preserving bedding for the winter, heat-preserving cotton-padded clothes, sleeping bags, cushions, etc.

Owner:王洪云

Surface coating processes and uses of same

InactiveCN101883663ASolve health problemsFix security issuesLiquid surface applicatorsMolten spray coatingAerosol sprayMaterials science

The present application relates to processes for coating surfaces and provides a method of forming a coating on a surface. The method involves bombarding a surface with particles having sufficient energy to remove surface material. At the same time an aerosol is delivered to the surface. The cooperative action of the particles impinging on the surface and the presence of the aerosol contribute to the formation of a coating on the surface.

Owner:HKPB科技有限公司

Health care food having an auxiliary protection function from radiating harm

InactiveCN101095515ASolve health problemsSolve the root problem of the body's weaknessAntinoxious agentsCapsule deliveryMedicineAdditive ingredient

The invention discloses a health food having the effect of resisting radiation, which is a capsule prepared from the following active Chinese medicinal constituents (by weight portions): acanthopanax root parts, rhodiola root 1-10 parts, Chinese angelica root 1-10 parts, lucid asparagus root 1-10 parts. Each 100g of the food contains salidroside 0.1g, acanthopanax root glycoside 0.03g.

Owner:王奉友

Production technology of sweet potato vermicelli

ActiveCN103734580AGuaranteed colorIntrinsic Quality GuaranteeFood freezingFood shearingWarm waterInternal quality

The invention relates to a production technology of sweet potato vermicelli, which comprises the processes of starchy sauce preparation, dough preparation, vermicelli preparation, cooling and drying, wherein the processes of starchy sauce preparation and dough preparation comprise the following steps: 1) starchy sauce preparation: pouring a fixed quantity of starch into a starchy sauce jar, adding 35-45 DEG C warm water of which the weight is 1.5-2 times the weight of the starch, and stirring uniformly; and adding 94-97 DEG C hot water of which the weigh is 4.5-5.5 times the weight of the starch in weight, stirring uniformly into a paste, and cooling to 68-70 DEG C; and 2) dough preparation: based on 100kg of starch with over 99% of fineness, adding 20-24kg of prepared starchy sauce paste and 52-55kg of 35-45 DEG C warm water, and stirring for 10-12 minutes while ensuring that the temperature in dough preparation is 40-45 DEG C; and pouring the prepared dough into a vacuum machine, and performing vacuumizing treatment through a vacuumizing machine to finish the dough preparation process. In the production technology of sweet potato vermicelli provided by the invention, no additive is added in the starchy sauce preparation process, the color and internal quality of the vermicelli are guaranteed, and the mouthfeel and toughness of the vermicelli are increased by the vacuumizing treatment.

Owner:河南新天豫食品有限公司

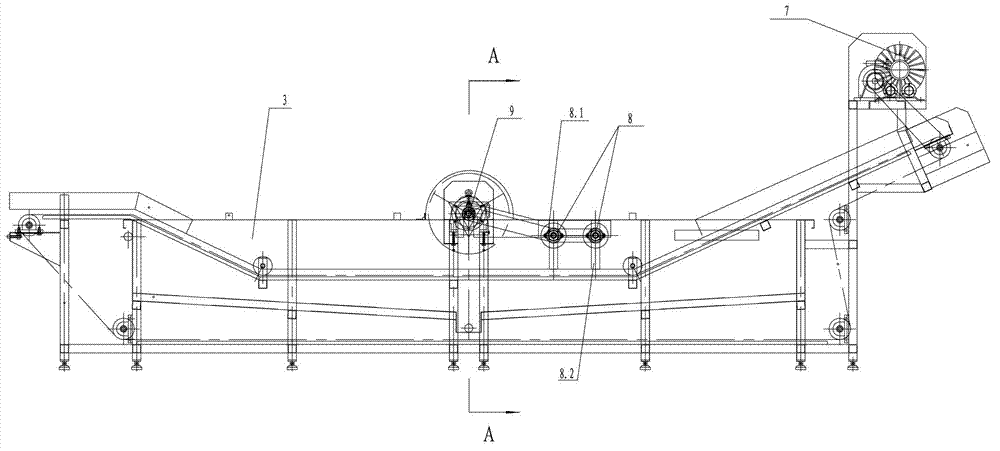

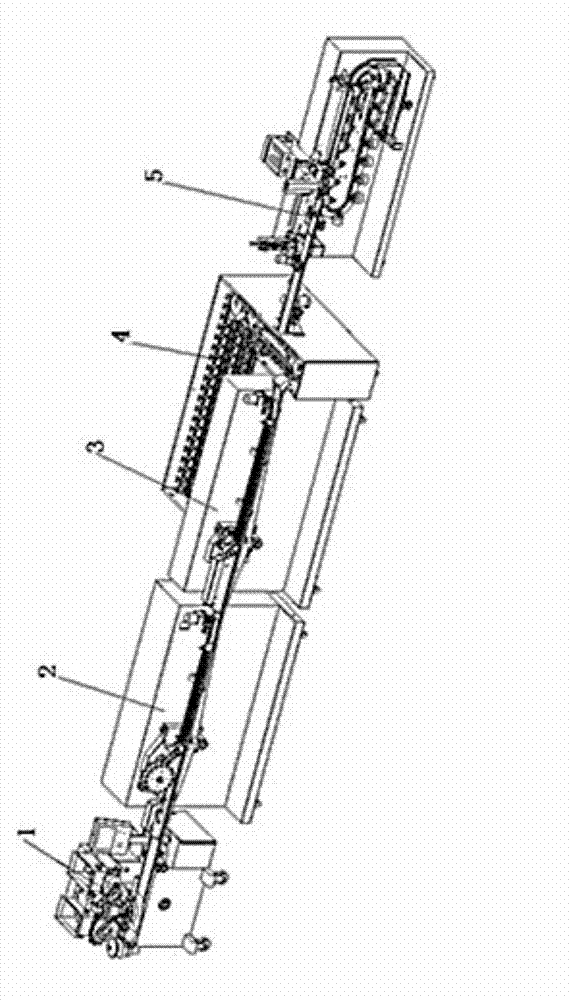

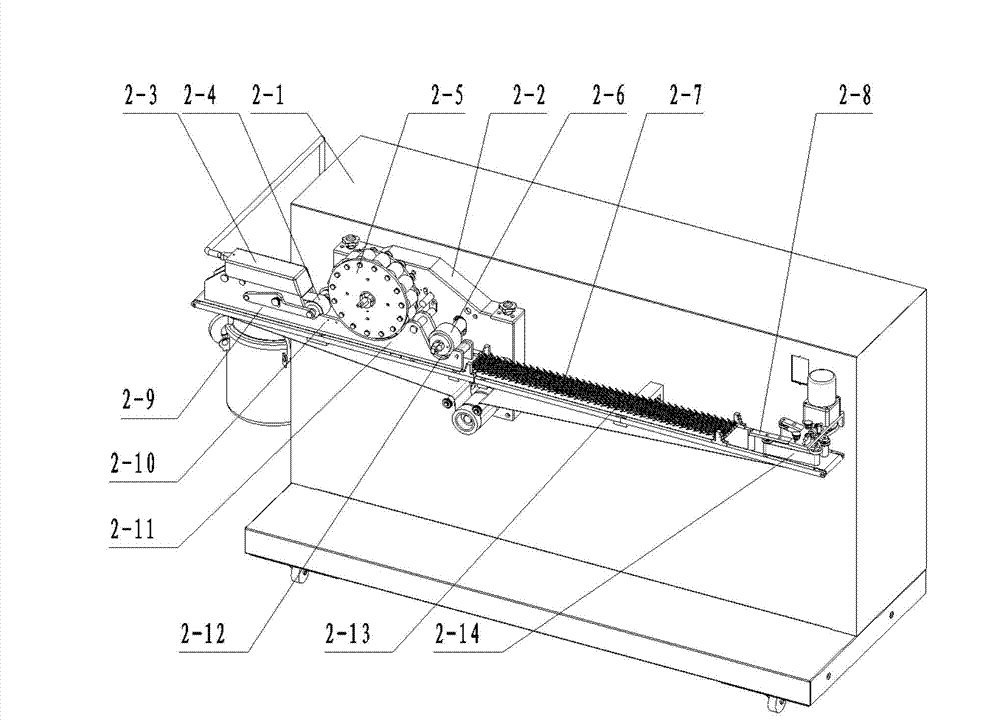

Leaf vegetable washing line

InactiveCN102948917ACleaning saves timeEasy to cleanFood treatmentAgricultural scienceAgricultural engineering

The invention discloses a leaf vegetable washing line. The leaf vegetable washing line comprises a vegetable cutting device (1), a vegetable washing machine and a drying device (5). Conveying belts are arranged on the vegetable cutting device (1), the vegetable washing machine and the drying device (5). The vegetable washing machine comprises a first vegetable washing machine (3) and a second vegetable washing machine (4), and the second vegetable washing machine (4) is connected with an ice water storage device. One end of the first vegetable washing machine (3) is connected with an output end of the vegetable cutting device (1) while the other end of the first vegetable washing machine (3) is connected with one end of the second vegetable washing machine (4); and the other end of the second vegetable washing machine (4) is connected with the drying device (5). Hair removing mechanisms (8), stirring mechanisms (9), bubbling mechanisms (10) and flushing mechanisms (11) are arranged in washing tanks of both the first vegetable washing machine (3) and the second vegetable washing machine (4). The leaf vegetable washing line saves time and labor, washes more cleanly and can satisfy the requirement on retaining the freshness of the leaf vegetable.

Owner:ZHEJIANG XIANGYING KITCHEN EQUIP

Method and device for pushing processing information

InactiveCN105512482ASolve health problemsImprove experienceComputer-assisted medical data acquisitionSpecial data processing applicationsOral problemsComputer science

The invention provides a method and device for pushing processing information so as to increase the function of a toothbrush and meet the demand of people for increasing emphasis on oral health. The method includes the steps that oral condition parameters of a current user are acquired; the processing information matched with the oral condition parameters is pushed to the current user. By means of the method for pushing the processing information, the processing information can be pushed for the oral problem of the current user with more pertinence while the function of the toothbrush is increased, the user can solve the oral problem in time easily, and the user experience can be improved.

Owner:XIAOMI INC

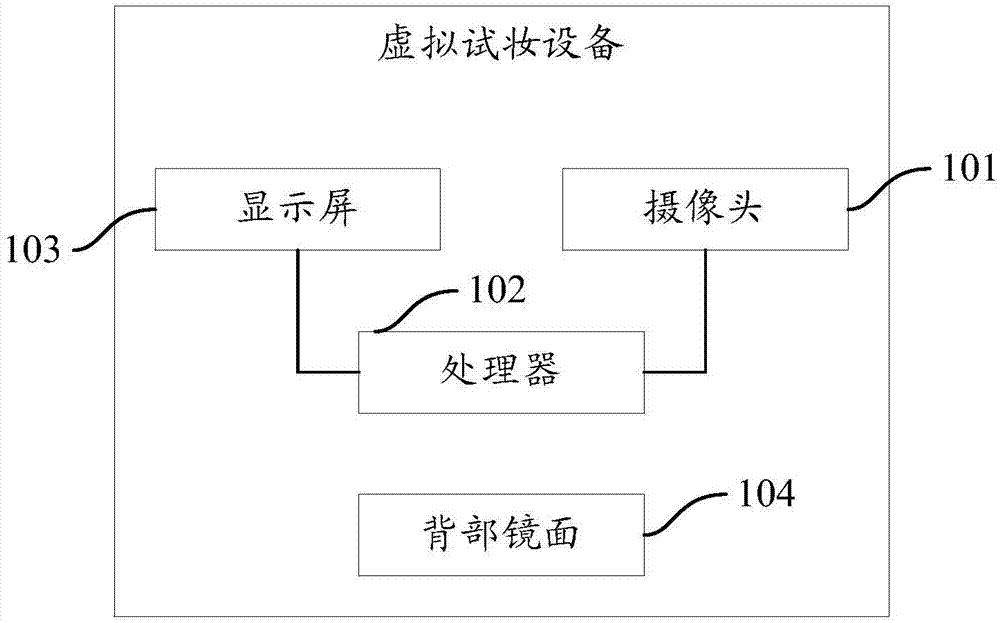

Virtual makeup trying device

PendingCN107392713AImprove experienceShorten the timeBuying/selling/leasing transactionsComputer hardwareComputer graphics (images)

Te present invention provides a virtual makeup trying device. The device comprises a camera, a processor, a display screen and a back mirror surface. A camera is connected with a processor; the processor is connected with a display screen; the back mirror surface is located at the back side of the display screen; the display screen is a minute surface screen, and when the display screen is a turn-off screen, the display screen is a minute surface state; the camera is configured to collect face images of makeup trying users and send the face images to the processor; the display screen is configured to display at least one cosmetic, receive a selection instruction of the makeup trying users selecting target cosmetics from at least one cosmetic, send the selection instruction to the processor and display the makeup face images sent by the processor; the processor configured to determine the target cosmetics according to the selection instruction sent from the display screen and employ the target cosmetics to perform makeup processing of the face images sent by the camera and generate the makeup face images which are sent to the display screen. The virtual makeup trying device can improve the user experience.

Owner:汕头市智美科技有限公司

Preparation method for sodium fatty acyl methyl taurate

InactiveCN106588709ASolve environmental problems of emissionsSolve environmental problemsOrganic compound preparationSulfonic acids salts preparationSolubilityAcyl group

The invention discloses a preparation method for sodium fatty acyl methyl taurate. According to the method, an organic solvent is not used for performing crystallization and re-crystallization, and a byproduct-centrifugal filter liquor in a reaction process is recycled, so that the environment and health problems caused by use of the solvent and the environmental protection problem of salt-containing and acid-containing wastewater discharge in a purification process in the past are solved. A frozen recovered filter liquor is added in a freezing crystallization process, so that the temperature is reduced; and sodium chloride in the filter liquor is used for performing seeding, and the effects of crystal seeds and crystal nucleuses are achieved, so that the graining in the process is quick, wrapped impurities due to non-crystal agglomeration are reduced, and the prepared product is higher in purity and higher in content. The freezing crystallization is combined with the freezing centrifugation, so that the crystal solubility is reduced and the product yield is increased. Through optimized selection of a process route, the process is advanced and rational, can be realized by using a general device, and is simple in operation, relatively high in economic benefit and relatively low in environmental pollution.

Owner:ZHANGJIAGANG GREAT CHEM

Temperature controller switching component

InactiveCN102376492ASimple structureSolve health problemsBoiling over preventionThermal switch detailsControl theoryWater bottle

The invention relates to the technical field of switching mechanisms, in particular to a temperature controller switching component which can be used for an electric kettle. The component comprises a temperature controller and a switching button, wherein the temperature controller comprises a main body component and a moving component; the moving component is arranged on the main body component and can rotate around a rotating shaft; the moving component rotates to close or open a circuit contact of the main body component; the component also comprises a bracket; the bracket is provided with a connecting rod capable of driving the moving component to act and is clamped with the main body component through the connecting rod; the switching button is clamped on the bracket; and through mutual linkage action between the switching button and the bracket and between the bracket and the temperature controller, the switching button drives the bracket to move, the connecting rod of the bracket pushes the moving component of the temperature controller to realize on and off of the temperature controller circuit when the switching button acts. Through the temperature controller switching component, the problems of sanitation and beautification finally caused by over-large holes due to a large switching path on a kettle body are solved, and meanwhile, the technical problems of large space occupied by the switch and limitation in size design of the kettle body are solved.

Owner:MIDEA GRP CO LTD

Multi-station automatic forming system device for multilayer crisp stuffed moon cakes

InactiveCN102885100AIncrease productivityAvoid congestionDough sheet coiling machinesDough-sheeters/rolling-machines/rolling-pinsFood flavorMultiple layer

The invention relates to a multi-station automatic forming system device for multilayer crisp stuffed moon cakes. The multi-station automatic forming system device comprises a dough and crisp packing and discharging machine, a first-time flattening and coiling forming machine, a second-time flattening and coiling forming machine, a crisp layer leavening machine and a follow-up stuffing supplying and sealing machine, wherein a programming controller is connected with the dough and crisp packing and discharging machine, the first-time flattening and coiling forming machine, the second-time flattening and coiling forming machine, the crisp layer leavening machine and the follow-up stuffing supplying and sealing machine respectively to control the five machines. The programming controller is connected with the five machines respectively, and sends out commands to control the five machines to execute processes on line. The five machines are connected by transmission devices on the five machines, and blank or multiple layers of cake blanks are transmitted from an inlet of the multiple players of cake blank to an outlet by the transmission devices after the mechanical action is accomplished. The multi-station automatic forming system device can ensure traditional flavor and taste of the crisp dessert, and realizes the output at the speed of 40-60 desserts per minute. The multi-station automatic forming system device opens up a new technical field of producing the multilayer crisp stuffed moon cakes through mechanical automation.

Owner:上海伟隆机械设备股份有限公司

Special slow-release fertilizer for flowers

InactiveCN104892228AProlong flowering periodSolve pollutionFertilizer mixturesFlowering seasonAmmonium nitrate

The invention relates to the technical field of compound fertilizers, in particular to a special slow-release fertilizer for flowers. The special slow-release fertilizer comprises raw materials in parts by mass as follows: 20-40 parts of ammonium nitrate, 3-8 parts of manganese sulfate, 2-6 parts of zinc sulfate, 1-5 parts of ferric citrate, 5-10 parts of diammonium phosphate, 2-6 parts of magnesium sulfate, 2-6 parts of borax, 2-7 parts of ammonium molybdate, 2-8 parts of sodium alginate and 0.8-2.4 parts of potassium humate. Compared with commercially available ordinary fertilizers for the flowers, the special slow-release fertilizer for the flowers has the advantages that the highest peak of nutrient releasing of N, P and K is postponed by 5 days, the nutrient releasing amount of N, P and K is reduced by 125 mg / kg, 35 mg / kg and 80 mg / kg in 30 days respectively, so that the flower season of the potted flowering-ornamental flowers is prolonged by 7-12 days, leaves of the foliage-ornamental flowers are deep green, the slow-release fertilizer is safe, hygienic and free of odor and has a long-lasting effect in the use process, and the holding time lasts for 3-4 months.

Owner:ZHANGJIAGANG WUHU NEW MATERIAL TECH DEV

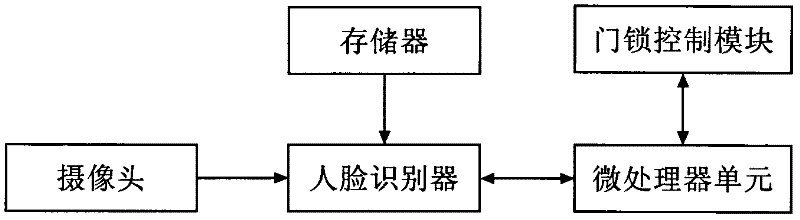

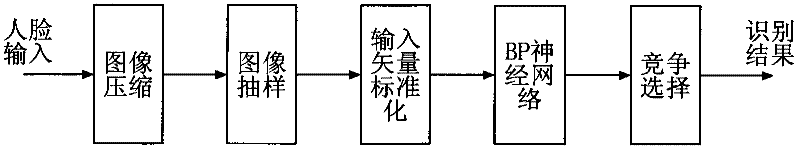

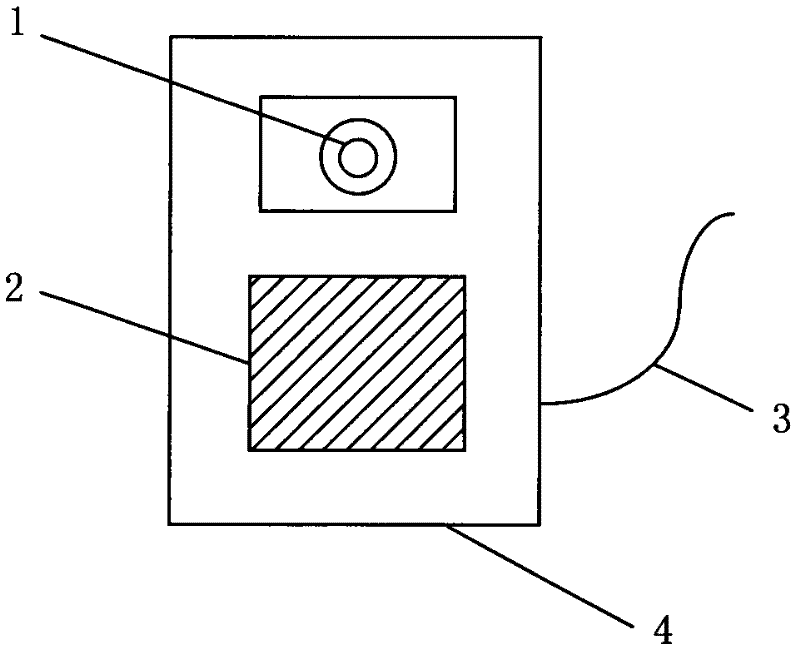

Face recognition device applied to entrance guard

InactiveCN102651067AImprove securityAvoid misjudgmentCharacter and pattern recognitionIndividual entry/exit registersInformation processingPattern recognition

The invention belongs to the technical field of image recognition and information processing, and discloses a face recognition device applied to an entrance guard. The face recognition device applied to the entrance guard mainly comprises a camera, a face recognizer, a memorizer, a door lock control module and a microprocessor unit, wherein the camera is connected with the face recognizer, the memorizer is connected with the face recognizer, the microprocessor unit is connected with the door lock control module, and the face recognizer is connected with the microprocessor unit. The face recognizer is used for receiving and recognizing the face information obtained by the camera and comparing the face information with data memorized in the memorizer, the compared result can be output to the microprocessor unit and can be judged by the microprocessor unit, and a door lock is unlocked by the door lock control module which is controlled by the microprocessor unit if the comparison is succeeded. By adopting the face recognition mode based on a video, the security of an entrance guard system is increased, and the misjudgment as an identity card is stolen by others can be avoided; and by adopting the non-contact type face recognition mode, the sanitation problem due to the adoption of contact-type fingerprint recognition can be avoided.

Owner:CHANGSHU RES INSTITUE OF NANJING UNIV OF SCI & TECH

Intelligent garbage can

The invention relates to an intelligent garbage can. The can is characterized by comprising a can body, a base, a can cover, a connecting device, a pedal and a link mechanism, wherein the bottom end of the can body is fixed on the base, and the can cover is connected with the can body through the connecting device; the pedal is movably arranged on the side surface of the base, the pedal is connected with the can cover through the link mechanism, and a permanent magnet is arranged on the upper surface of the pedal; and a pressure sensor, a control unit and a power supply which are sequentiallyand electrically connected are arranged on the inner surface of the can cover, and an electromagnet electrically connected with the control unit is arranged at the interface between the can body and the upper surface of the pedal. According to the intelligent garbage can, the characteristic that garbage is contacted with the inner surface of the can cover when the garbage is fully loaded is ingeniously utilized, a pressure sensing system is arranged to automatically identify the fully loaded condition of the garbage can, the pedal is automatically locked magnetically, and the situation that aperson still forcibly opens the garbage can under the condition that the person knows that the garbage can is fully loaded is prevented.

Owner:台山市金誉创展投资有限公司

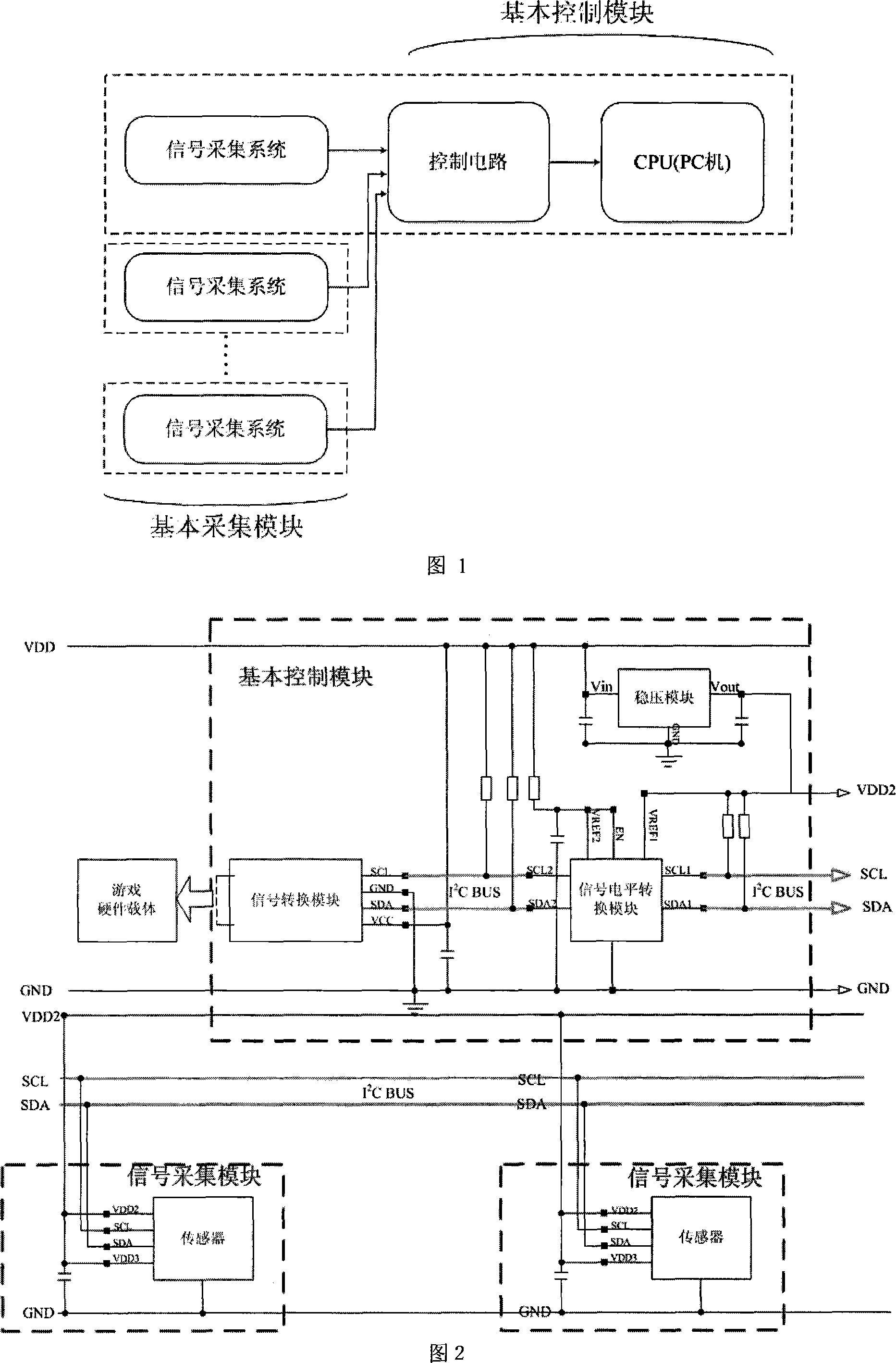

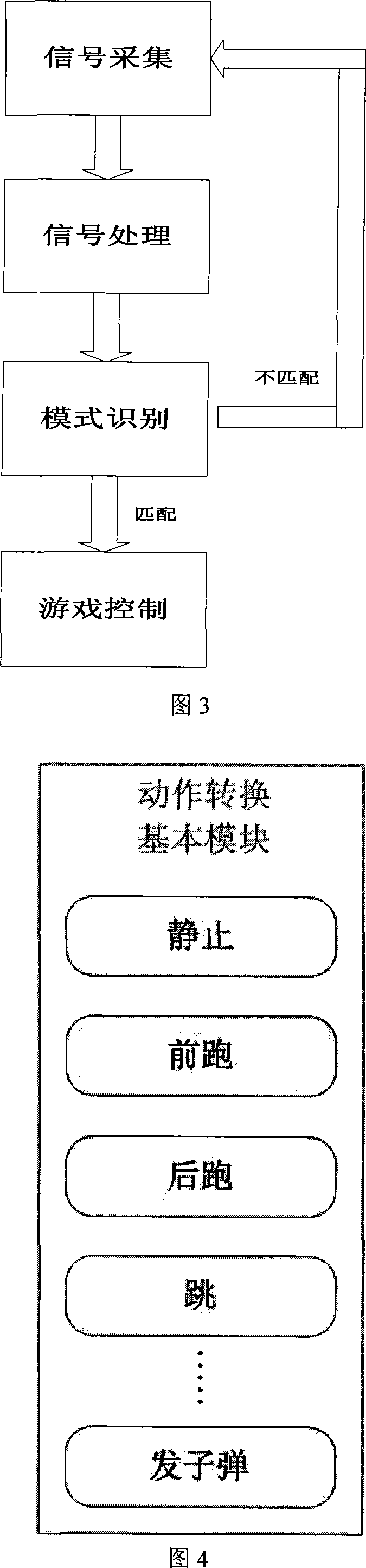

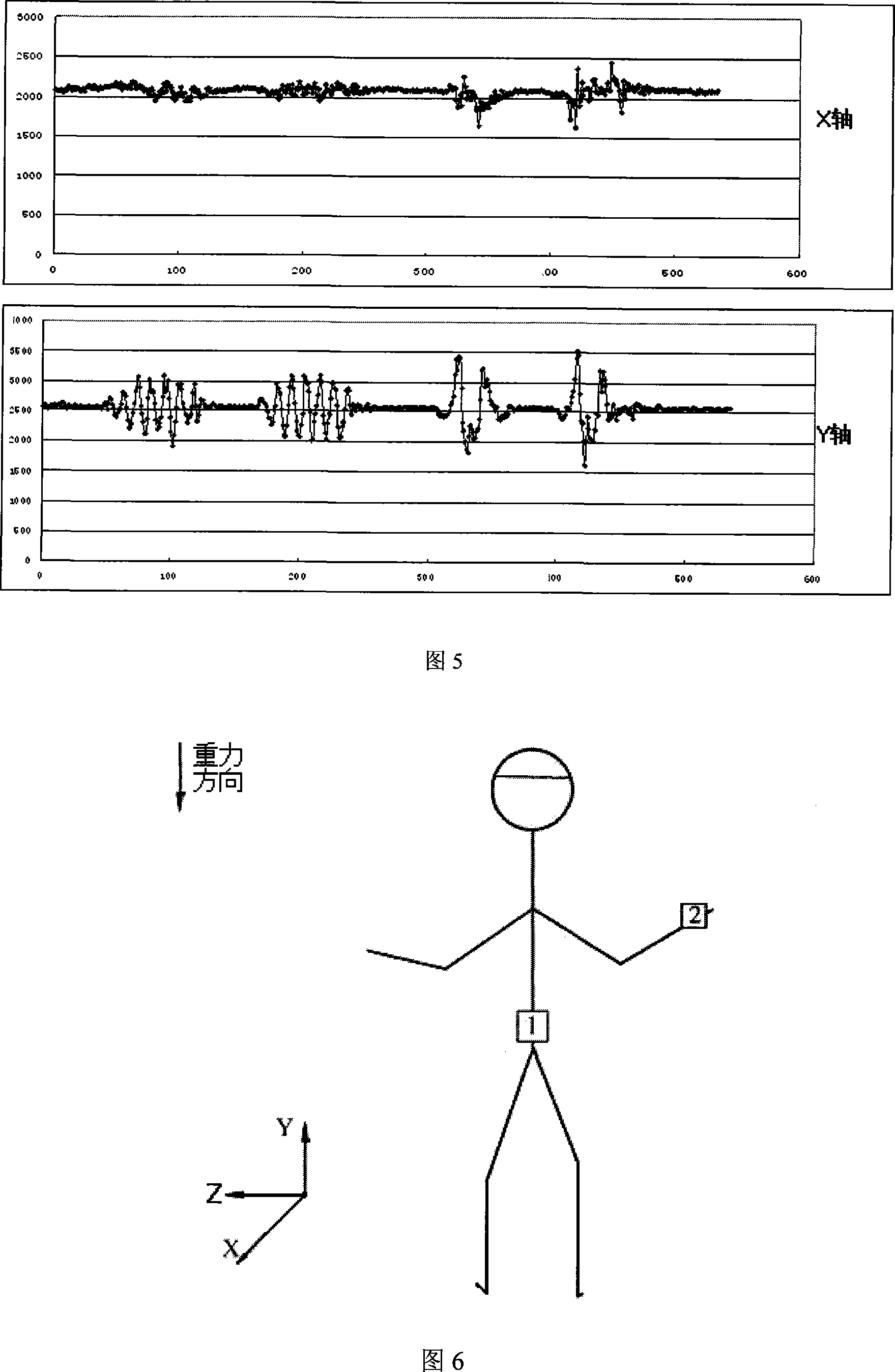

Method of controlling action emulation and system thereof

InactiveCN101229432AAvoid restrictionsSolve health problemsInput/output for user-computer interactionVideo gamesGraphicsSoftware system

The invention discloses a motion simulation control method and a system thereof. The method utilizes a signal collector to collect the motion information of a motion object and transform the motion information into motion images for matching with defined motion images; control instruction corresponding to the motion images after matching successfully is sent to control the motion of characters in games and simulation is realized; the motion simulation control system comprises a hardware system used for collecting and transferring the motion information and a software system used for processing the motion information. The simulation system of the invention not only has high reliability and low cost but also has small volume and flexible design.

Owner:PEKING UNIV

Natural toxin-expelling young-keeping herbal tea and preparation method thereof

The invention discloses a natural toxin-expelling young-keeping herbal tea. The herbal tea uses honey and 8 purely natural flowers and plants consisting of ginseng flower, trollflower, carnation, rose, roselle, shaddock flower, red date and wolfberry as raw materials and does not contain any artificial auxin component. The plurality of effective flower and plant components of the herbal tea can adjust endocrine, eliminate toxins in the body, regulate the exterior by tonifying the interior, remove foreign substances which are not inherent in the skin, purify the body and the heart, maintain beauty and keep young, and the herbal tea is convenient to drink and especially caters for taste of females. A great number of people taste the herbal tea by themselves, and the herbal tea wins public praise. The herbal tea has the advantages of scientific and reasonable compatibility, simple preparation, low cost and convenience in drinking.

Owner:廖少波

Preparation process for wild stem-less post-fermented vine tea

The invention discloses a preparation process for wild stem-less post-fermented vine tea. The preparation process comprises the following steps: completely manually picking annual tender wild vine tea buds and leaves growing in a mountainous area of southwestern Hunan at an elevation of 500 meters or higher 10 days before and after the tomb sweeping day, wherein the diameters of the leaves are less than or equal to 1cm, and the lengths of leafstalks are less than or equal to 3cm; cleaning the fresh leaves, withering the cleaned leaves, and performing fixation, rolling, loosening, pile fermentation, drying and aroma extraction to obtain a finished product, wherein a completely manual manner is adopted for raw material picking, loosening and pile fermentation, and a mechanical manner is adopted for cleaning of the fresh leaves, withering treatment, fixation, rolling, drying and aroma extraction. According to the preparation process, the cold and cool characters of vine tea are improved; a post fermentation process is adopted, so that the content of active ingredients is higher, the cold and cool characters of the vine tea are reduced, and adapted populations are widened; the active ingredients of the vine tea are improved, dry tea is silver and high in dihydromyricetin content, the active ingredients and quality of the vine tea are completely improved, the form of the dry tea is unified, and the dry tea can be sold more easily; the preparation process is safe and sanitary, large-scale stable production can be realized, and market requirements can be met.

Owner:绥宁县神农金康药用植物科技开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com