Full-automatic drip chamber assembly machine

An assembly machine, fully automatic technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as damage to patients' health, cross-infection, and weakened drug efficacy, to eliminate sanitation problems, improve efficiency, and improve usage. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Reference Figure 1 to Figure 10 The embodiments of the present invention are further described.

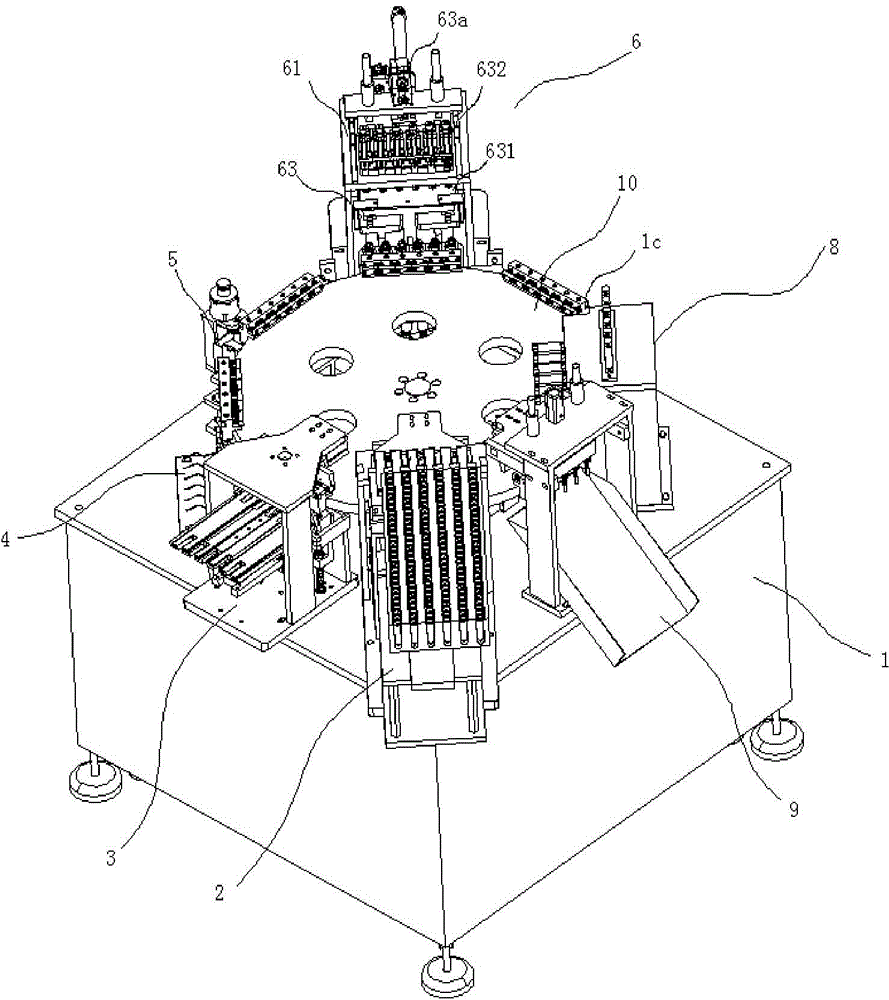

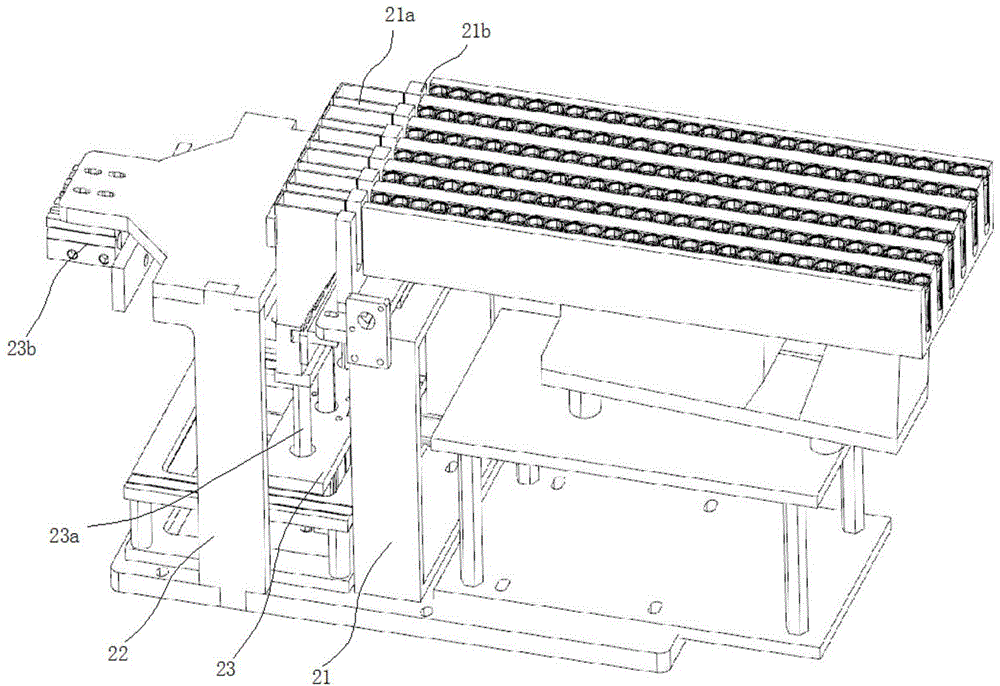

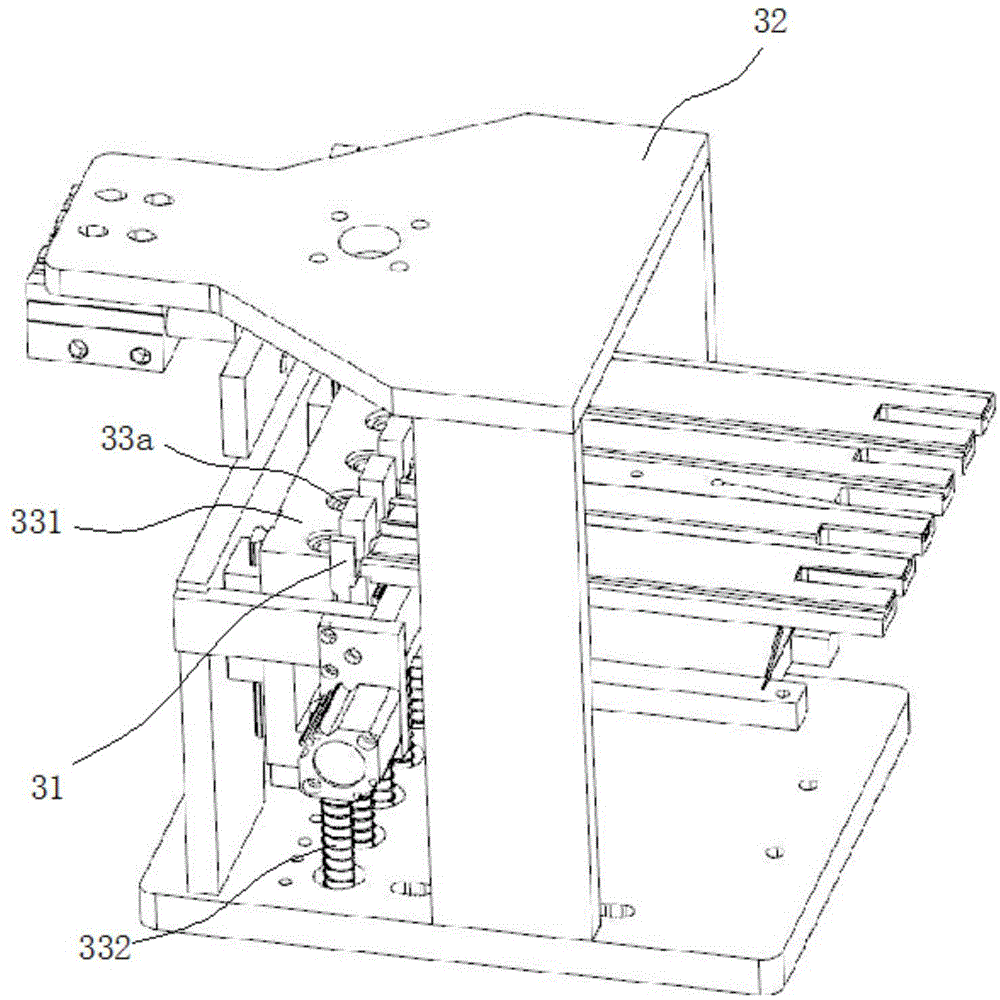

[0038] A full-automatic assembling machine for a dripping bucket includes a worktable 1 on which a large rotatable turntable 10 is provided. The large turntable 10 is provided with a plurality of clamps 1c for clamping and placing workpieces. 1c and the movement path of the clamp 1c, on the workbench 1, there are respectively an upper drip hopper station for filling the drip hopper, an upper filter station for installing a filter screen for the drip hopper, and an inspection filter between the drip hopper The installation of the filter screen station 4, the glue-dipping station for applying glue to the inner edge of the drip bucket 5, the upper bottle needle station for filling the bottle needle for the drip bucket 6, the detection of the bottle needle and the drip bucket Whether it is installed in place between the test bottle needle station 7, the discharging station 8 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com