Three-way valve assembly machine and assembly method thereof

A technology for assembly machines and three-way valves, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as insufficient sealing, unqualified product hygiene requirements, poor precision, etc., and achieve the effect of eliminating hygiene problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] refer to Figures 1 to 9 The embodiment of a three-way valve assembly machine of the present invention will be further described.

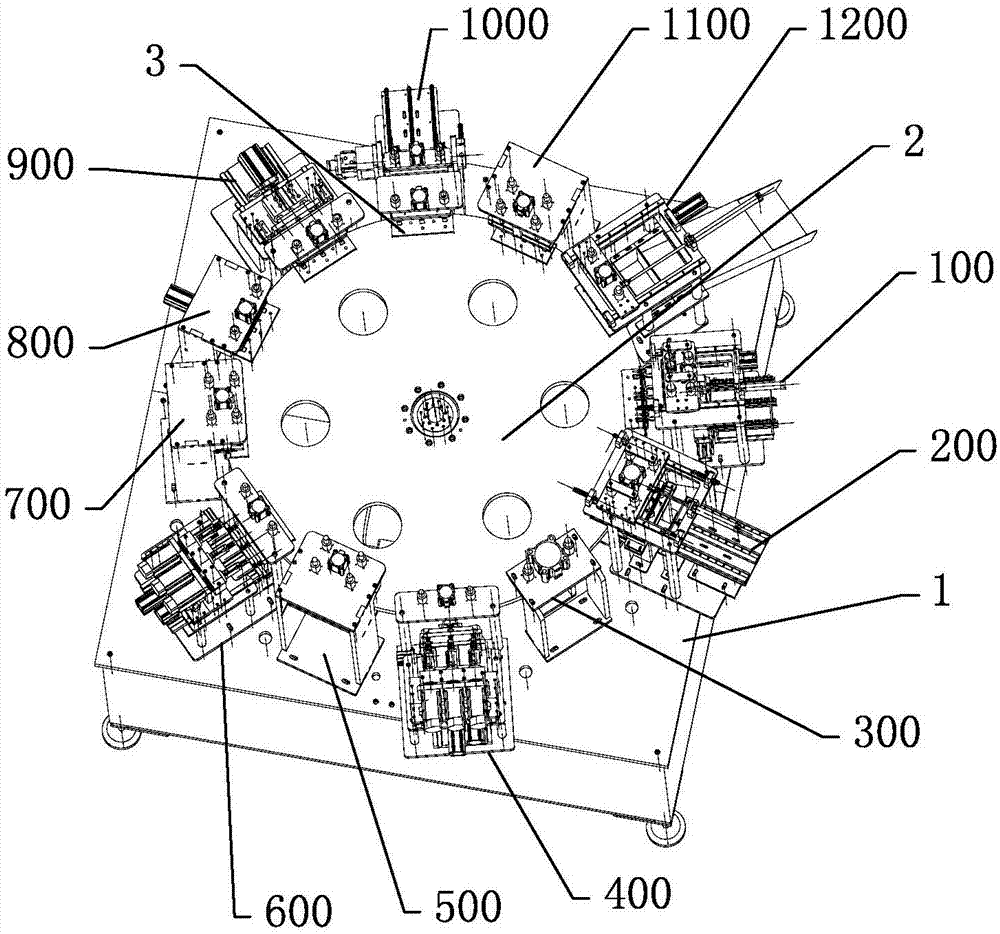

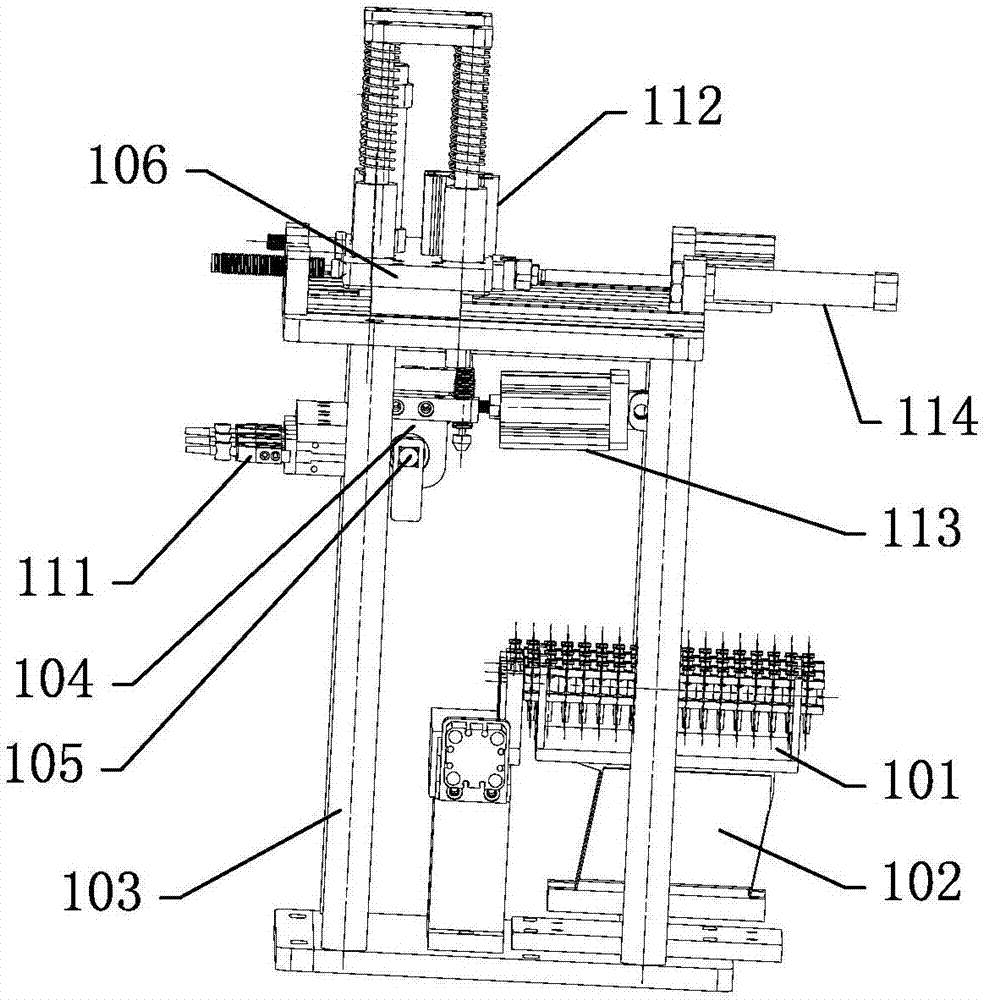

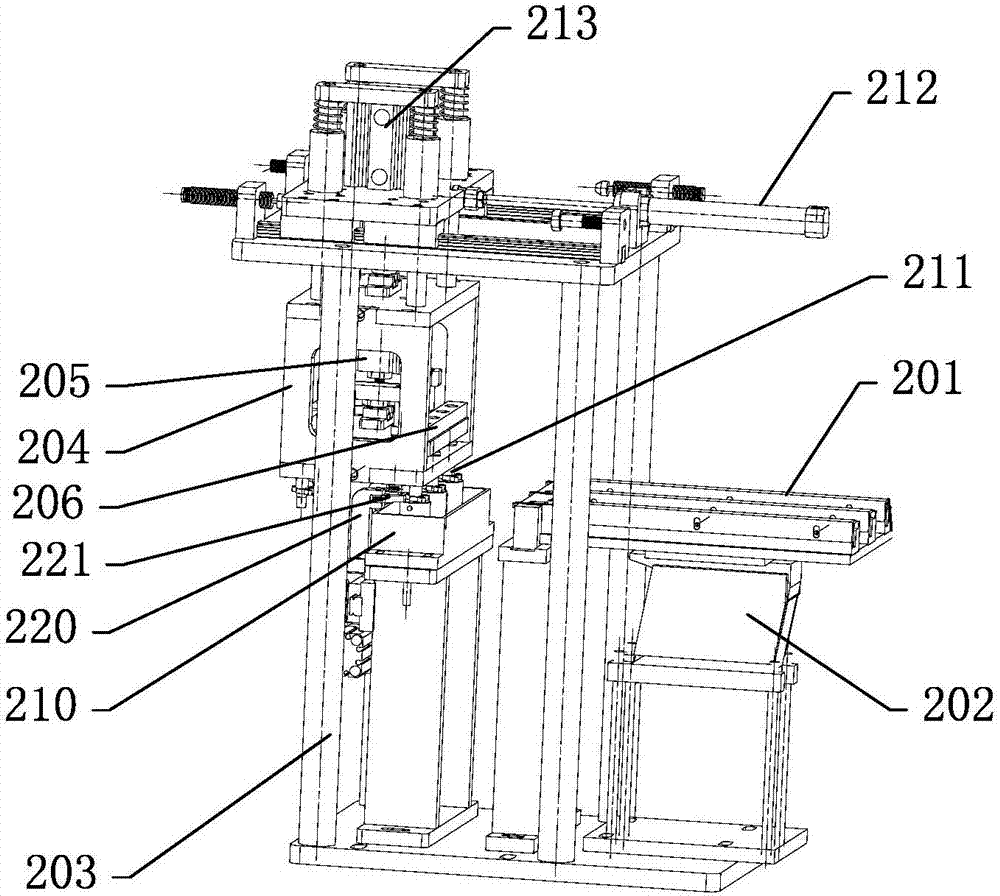

[0040] like figure 1 As shown, a three-way valve assembly machine includes a frame 1, the frame 1 is provided with a multi-station rotary table 2, and the multi-station rotary table 2 is provided with several clamps 3, for each clamp 3 and the movable path of the fixture 3, the valve body loading station 100, the valve core installation station 200, the valve core pressing station 300, the first screw cap installation station 400, the first valve Body rotation station 500, second screw cap installation station 600, second valve body rotation station 700, air tightness testing station 800, screw head installation station 900, sheath installation station 1000, valve core rotation station Bit 1100 and outfeed station 1200.

[0041]The multi-station rotary table 2 is driven by a motor, and the intermittent movement of the multi-station rotar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com