Protein foaming method for preparing porous ceramics composite material

A technology of porous ceramics and composite materials, used in ceramic products, applications, household appliances, etc., can solve problems such as toxic gases, endanger human health, pollute the environment, etc., to increase the strength of the green body, improve the rheological properties, foaming uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

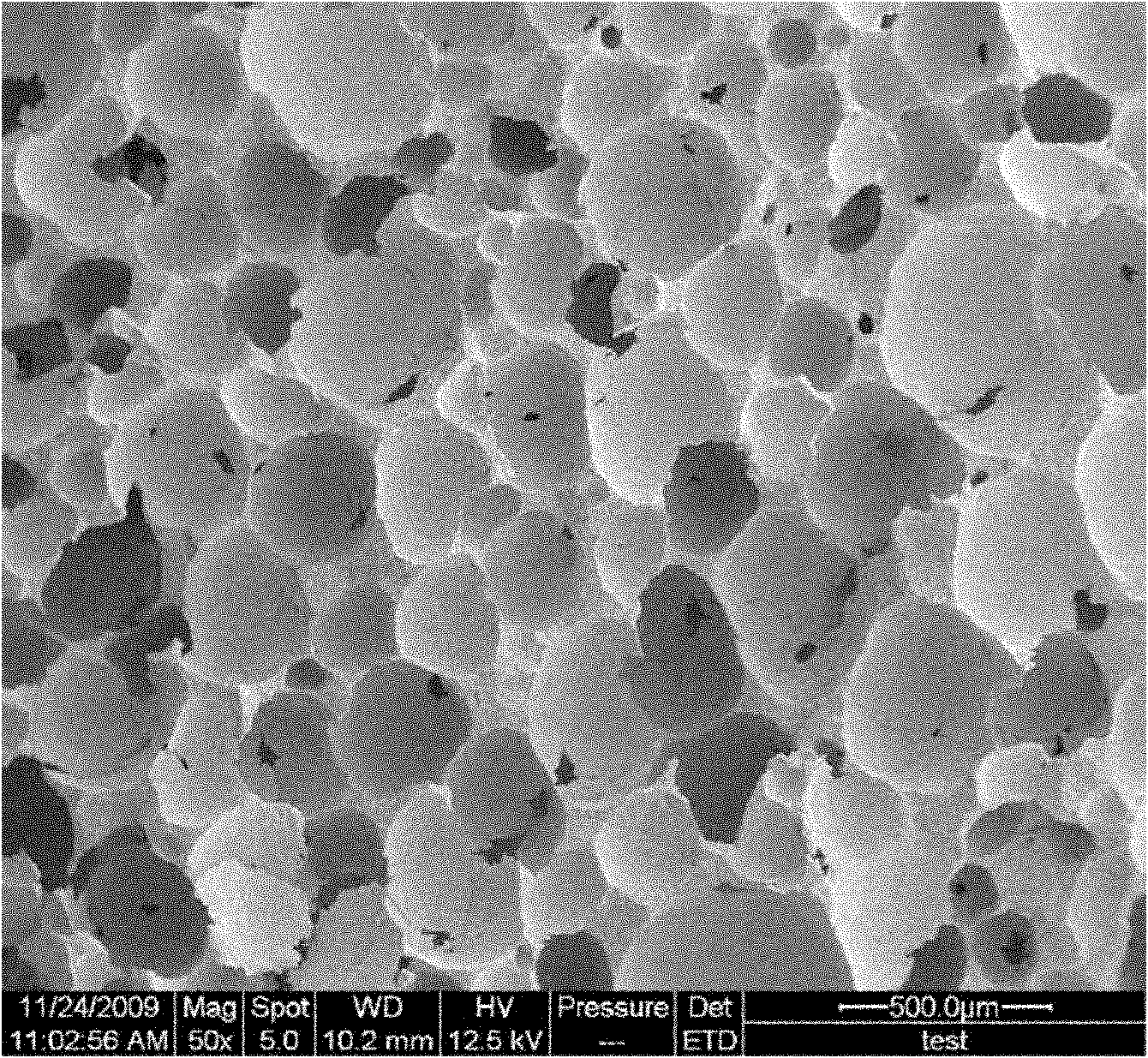

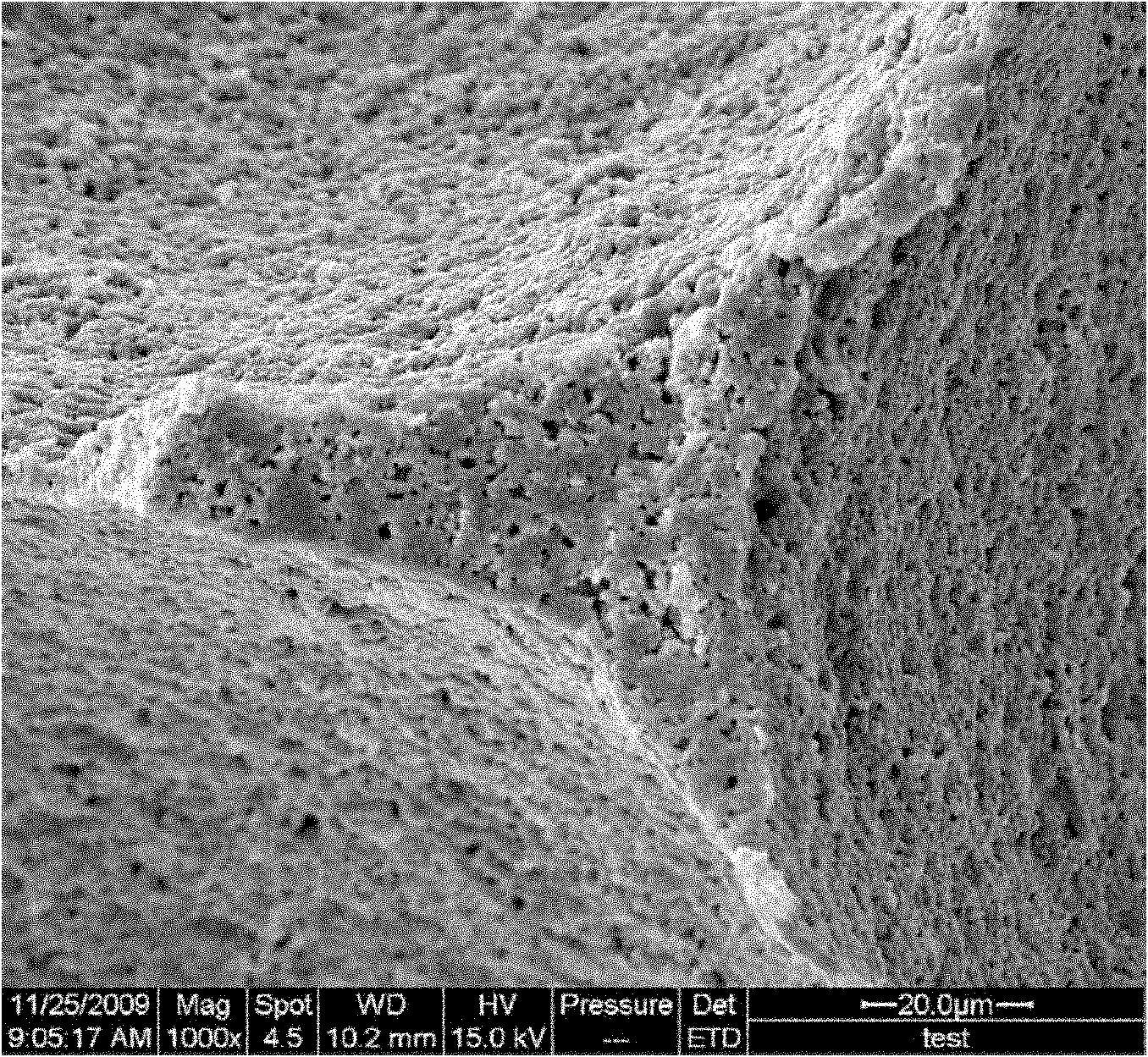

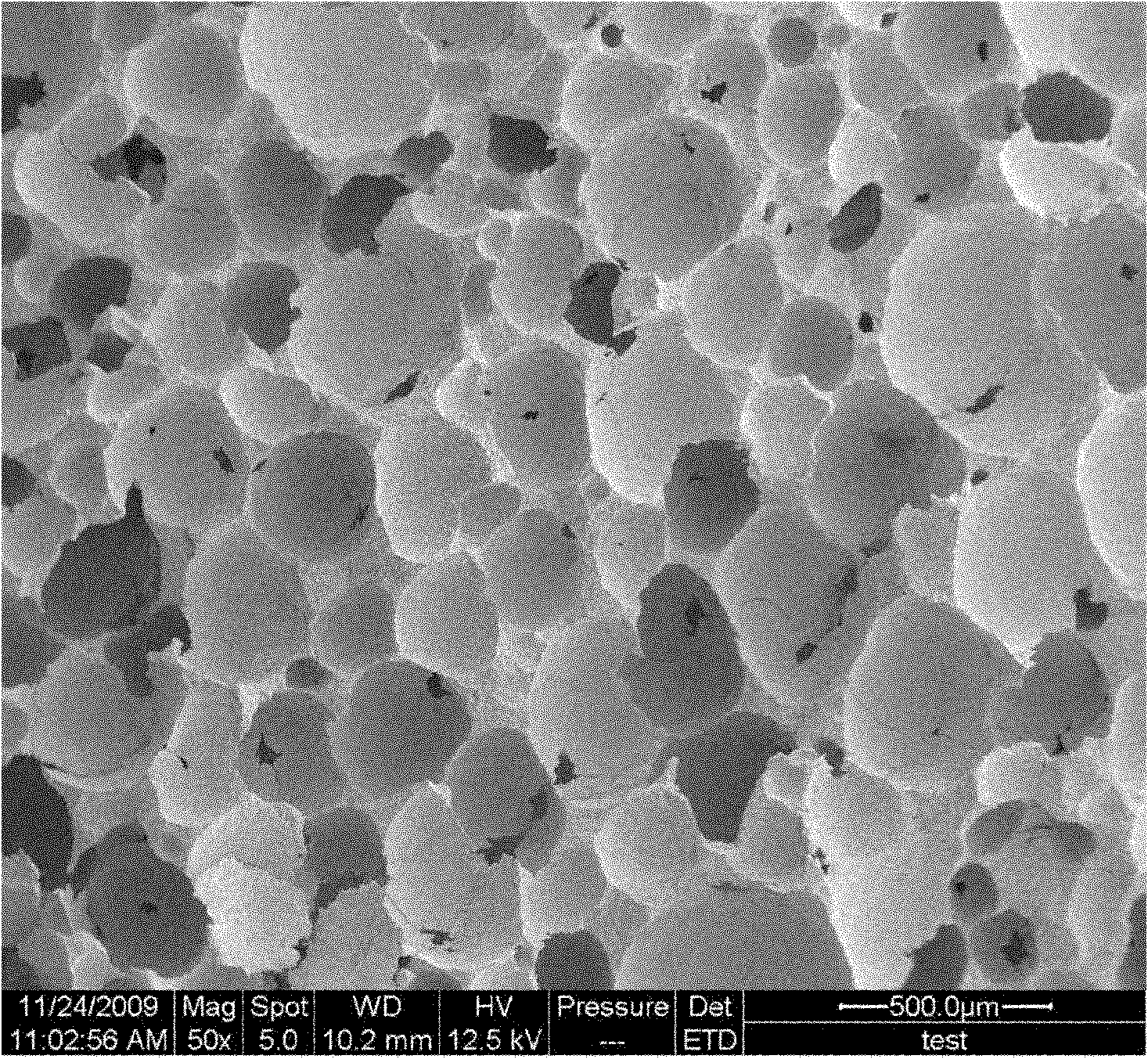

Image

Examples

specific Embodiment approach 1

[0011] Specific Embodiment 1: In this embodiment, the method for preparing porous ceramic composite materials by protein foaming method is as follows: 1. Mix 26.5g-158.8g aggregate, 40g-80g egg white, 3mL deionized water and 5g polysaccharide, add dispersing The amount of dispersant added is 0.5% of the aggregate mass, and then dispersed by a ball mill for 12 hours to obtain a slurry with an aggregate volume content of 10% to 50%; 2. Pour the slurry into a polytetrafluoroethylene mold , and then placed in a constant temperature drying oven at 75-85°C for 30-90 minutes to cure and mold. After demoulding, place it at room temperature for 12-48 hours, and then put it in an oven at 110-130°C to dry and mold to obtain samples; 3. The samples Process it into the desired shape, put it into a sintering furnace, then raise the temperature to 230°C at a heating rate of 2°C / min, keep it at 230°C for 30 minutes, raise it to 360°C at a heating rate of 2°C / min, and keep it at 360°C for 1 hou...

specific Embodiment approach 2

[0013] Embodiment 2: This embodiment is different from Embodiment 1 in that the particle size of the ceramic powder is 0.1 μm-3 μm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the ceramic powder is silicon oxide, one of alumina, zirconia, mullite, silicon carbide and silicon nitride. species or a combination of several of them. Others are the same as those in the first or second embodiment.

[0015] In this embodiment, when the ceramic powder is a composition, the ratio of each component is arbitrary.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com