Follow-up stuffing adding twin-cone roller necking-in machine

A technology of closing machine and cone roller, which is applied in dough forming machinery or equipment, dough sheeting machine/rolling machine/rolling pin, baking, etc. It is not applicable to the processing of multi-layer crispy mooncakes with fillings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

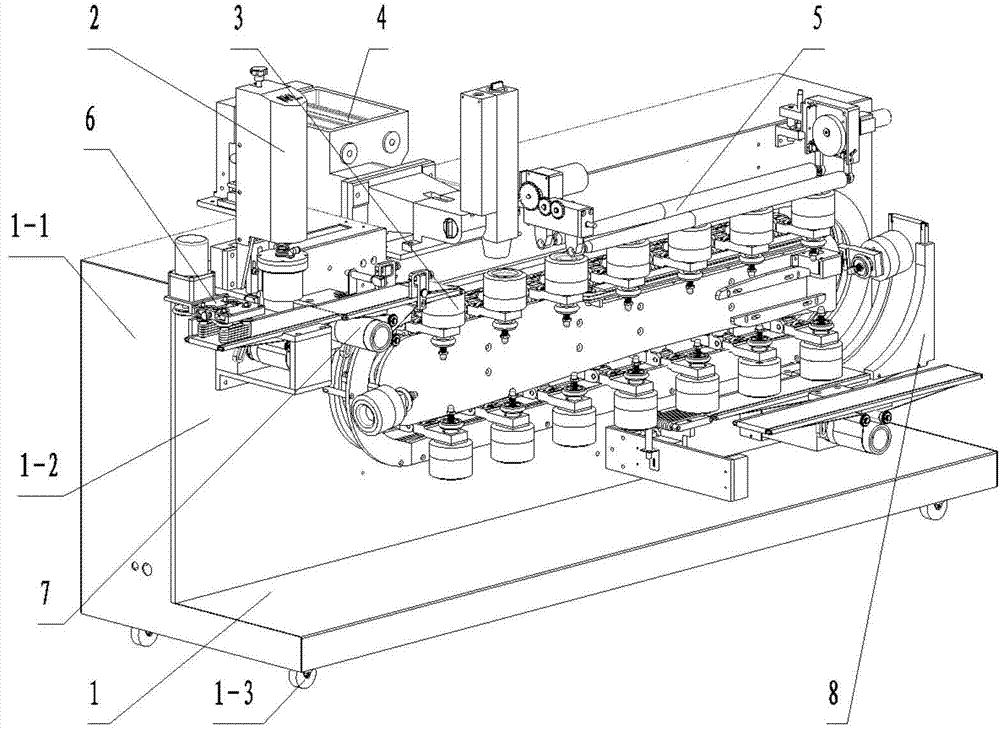

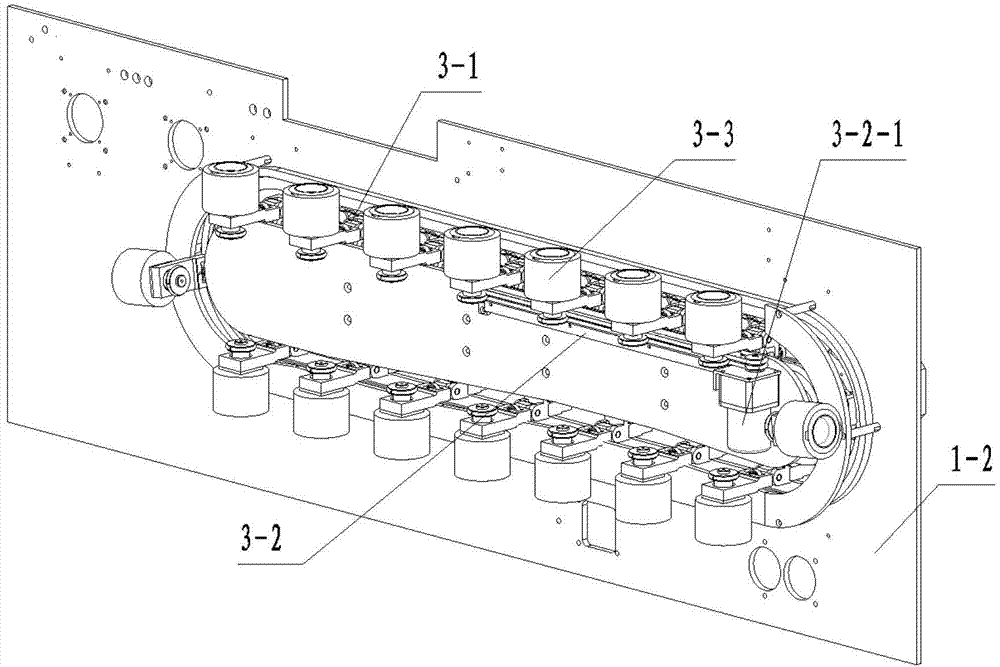

[0075] Such as figure 1 As shown, this embodiment includes: a necking machine body 1, a puff pastry blank punching device 2, a rotating mold circulation device 3, a filling device 4, and a double-cone roller necking device are sequentially arranged on the necking machine body 1 5. The rotary mold circulation revolving device 3 is arranged below the injection device 4 and the double cone roller closing device 5.

[0076] The body 1 of the closing machine includes: a closing machine frame 1-1, a number of closing machine mounting panels 1-2 and closing machine casters 1-3. The landing part of the closing machine frame 1-1 is provided with closing machine casters 1 -1, the closing machine installation panel 1-1 is installed on the closing machine frame 1-1.

[0077] The retractor frame 1-1 is a welding frame.

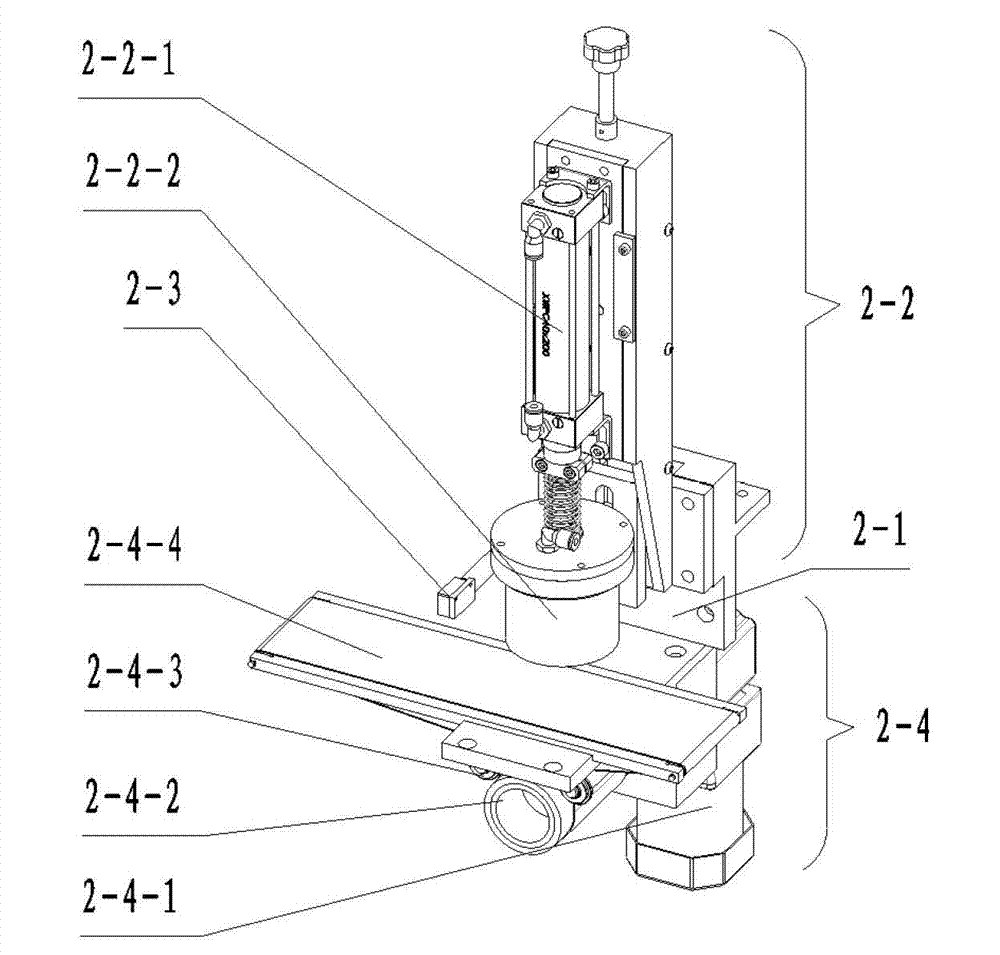

[0078] Such as figure 2 As shown, the puff pastry blank stamping device 2 includes: stamping device frame 2-1, single-stroke double-action stamping machine 2-2, stamping device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com