Stretching and roll forming machine of multi-layer puff pastry sheet

A forming machine and puff pastry technology, applied in the direction of rolling dough sheet machine, dough sheeting machine/rolling machine/rolling pin, baking, etc., can solve the problem of complex mechanical action, no discovery, high production process and requirements problems, to achieve the effect of improving production efficiency, avoiding hygiene problems, and strengthening standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

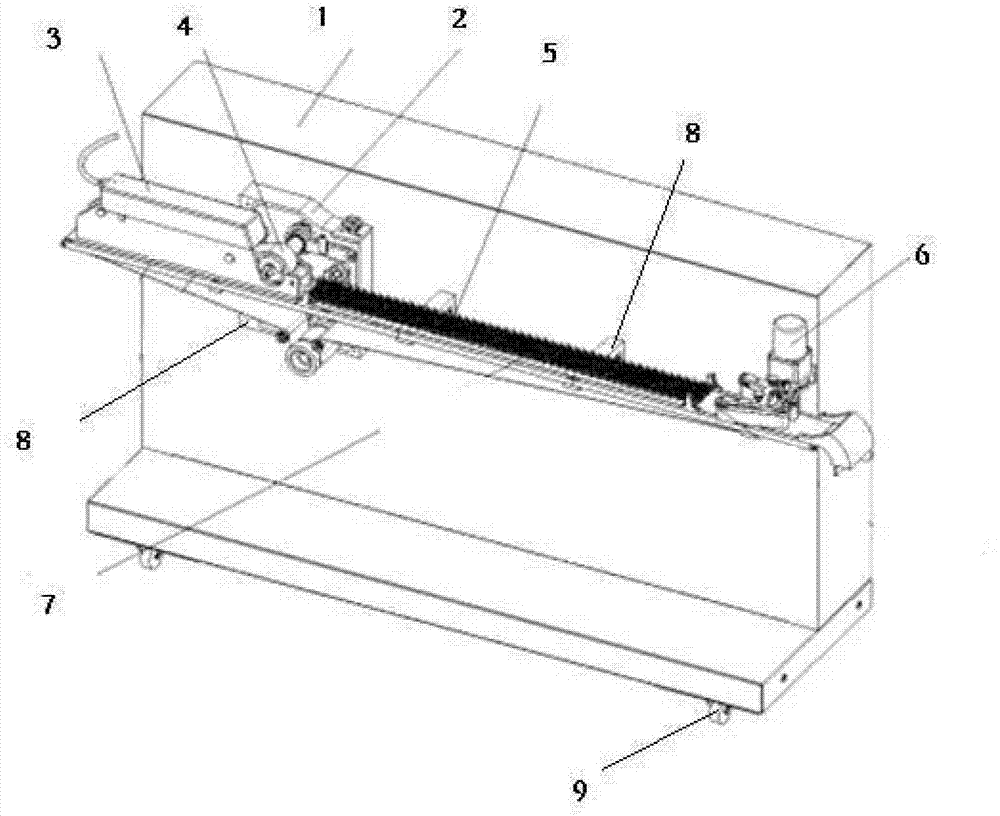

[0042] like figure 1 As shown, this embodiment includes: a fuselage 1, a transmission device 2 arranged on the fuselage 1, a powder spraying device 3, a non-rigid rolling device 4, a puff pastry roll forming device 5 and Puff pastry material guiding device 6.

[0043] The fuselage 1 described in this embodiment includes: a frame 7 , an installation panel 8 and casters 9 , where the frame 7 is provided with casters 9 on the ground part, and the installation panel 8 is arranged on the frame 7 .

[0044] Frame 7 described in the present embodiment adopts welding frame.

[0045] The transmission device 2 is arranged on the above-mentioned installation panel 8 .

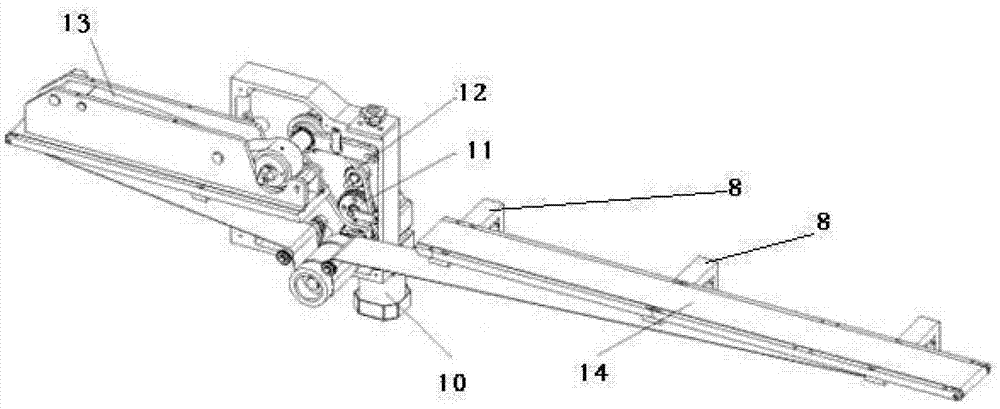

[0046] like figure 2 Shown: the transmission device 2 described in this embodiment includes: a transmission device motor 10, a transmission device gear 11, a multi-layer calender roll conveyor chain 12 and a multi-layer calender roll conveyor belt 14, and the transmission device motor 10 is directly connected to the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com