High voltage grounding tool for power maintenance

A power maintenance and high-voltage technology, applied in the direction of conductive connection, electrical component connection, circuit, etc., can solve the problems of equipment operation, heat generation, failure to protect the safety of maintenance personnel, loose wire connecting plates, etc., to improve work efficiency, stable and accurate rotation, Accurate effect of transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

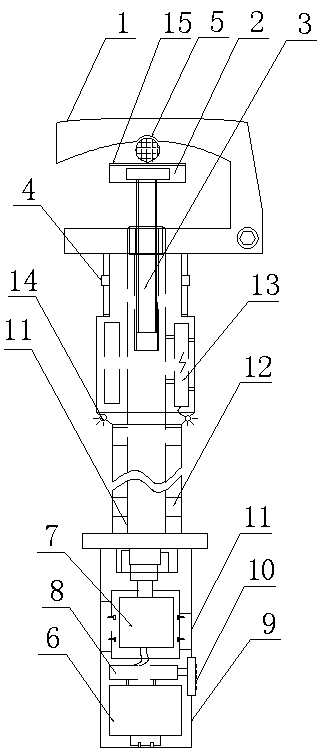

[0020] Such as figure 1 As shown, a high-voltage grounding tool for electric maintenance includes a grounding wire chuck and an operating rod 9, the wire chuck includes a C-shaped hitch 1, a wire clamping piece 2 and a lifting rod 3, and the operating rod 9 The top is provided with a joint 4 connected to the C-shaped hitch 1 , the upper end of the elevating rod 3 is connected to the wire clamping piece 2 with a protective layer 15 , and the operating rod 9 has a built-in drive mechanism connected to the elevating rod 3 .

[0021] The inner side of the upper part of the C-shaped hitch 1 is set as an upward concave arc structure, and the highest point is set with a wire clamping groove 5 .

[0022] The drive mechanism includes a power supply 6, a motor 7, a control circuit 8 and a transmission member, the motor 7 is embedded in the operating lever 9, and an operation panel 10 connected to the control circuit 8 is arranged outside the operating lever 9, and the transmission membe...

Embodiment 2

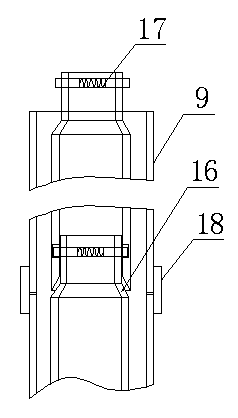

[0027] Such as figure 2 As shown, the difference from Embodiment 1 is that: the operating rod 9 is set as a multi-stage plug-in type, the locking ring 18 is arranged between the 9 segments of the operating rod, the reducing tube 16 is arranged between the segments of the movable sleeve 11, and the reducing tube 16 is arranged between the segments. An elastic pin 17 or a key structure cooperating with the movable sleeve 11 is arranged on the diameter pipe 16 .

[0028]The wire collet of the present invention includes a C-shaped hook frame, a wire clamp moving piece and a lifting rod, through which the C-shaped hitching frame is conveniently hung on the wire, and the lifting rod is used to push the wire clamping moving piece to move Realize the clamping of wires, prevent safety accidents caused by unreliable grounding, and improve the safety of operators. The lifting rod is driven by the driving mechanism built in the operating rod, which can well realize safe operation at low ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com