Multi-station automatic forming system device for multilayer crisp stuffed moon cakes

An automatic forming and system device technology, applied in dough forming and cutting combination, dough forming machinery or equipment, dough sheeting machine/rolling machine/rolling pin, etc., can solve the problems of low efficiency, complicated mechanical action, Unhygienic and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

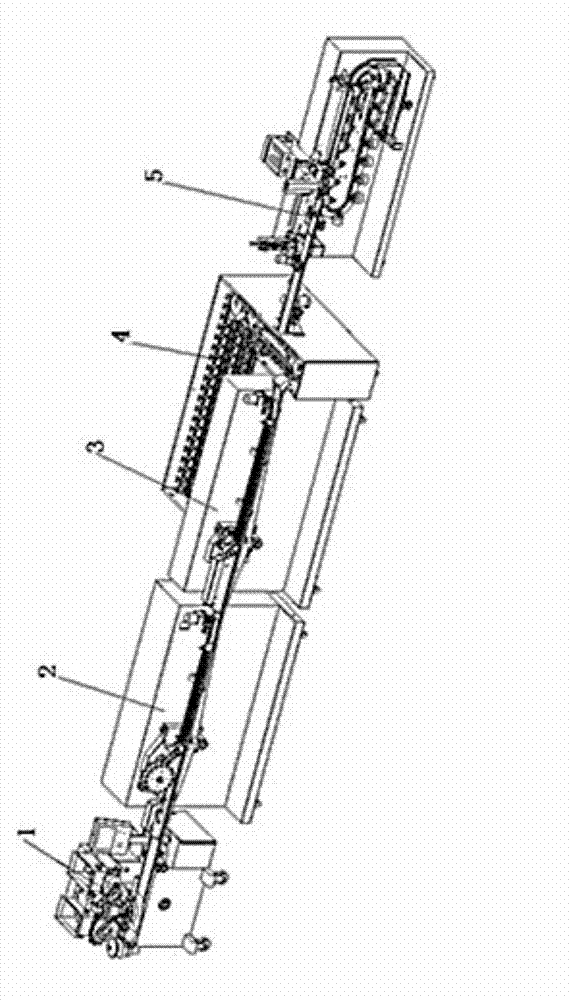

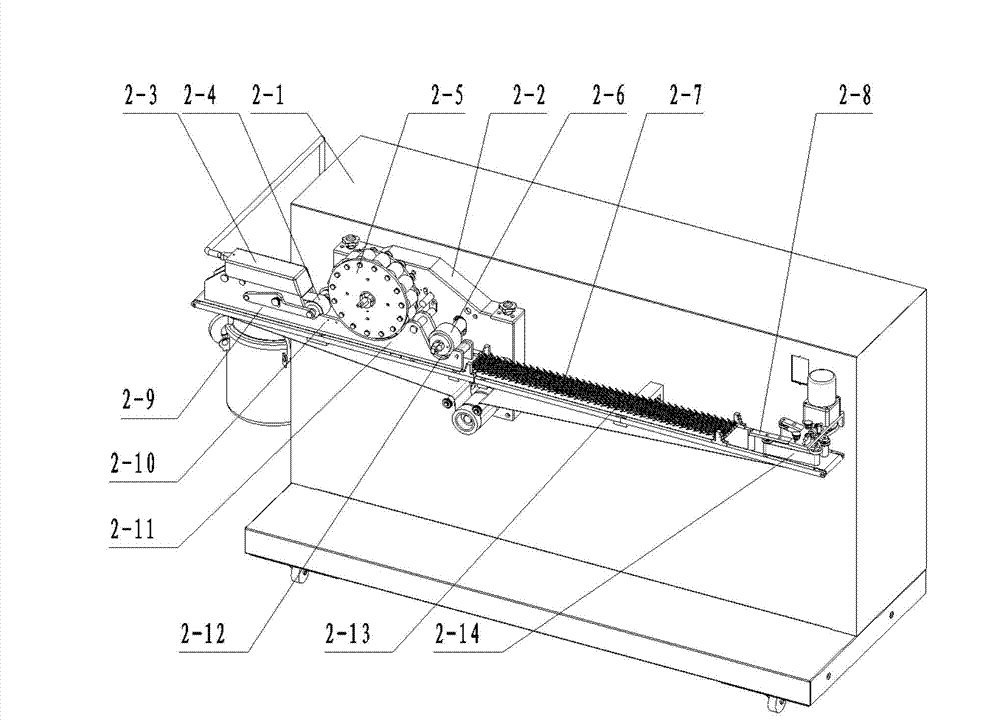

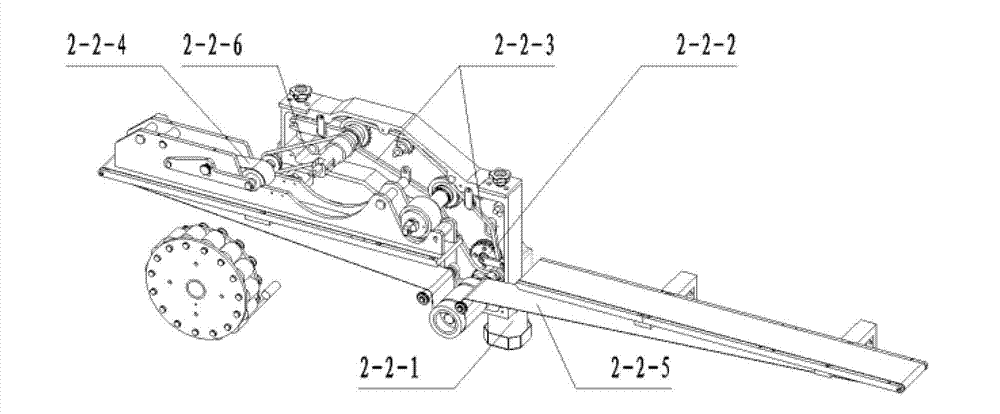

[0099] Such as figure 1 As shown, this embodiment includes: noodle-crispy wrapping cutting machine 1, first calendering roll forming machine 2, second calendering roll forming machine 3, puff pastry soothing proofing machine 4 and follow-up filling closing Machine 5 and the program controller are respectively connected and controlled by the surface-crispy wrapping machine 1, the first calender roll forming machine 2, the second calender roll forming machine 3, puff pastry soothing proofing machine 4 and follow-up heating Stuffing closing machine5.

[0100] The program controller described in this embodiment adopts the disclosed prior art, and can also adopt commercially available program controller products. The program controller connects each machine and issues instructions to control the execution of each process of each machine. The machines in the process are connected to each other through transmission parts, and the embryos or multi-layer cake embryos are transferred. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com