Surface coating processes and uses of same

A coating, particle technology, applied in the field of surface coating and its use, to solve the effect of health and safety problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

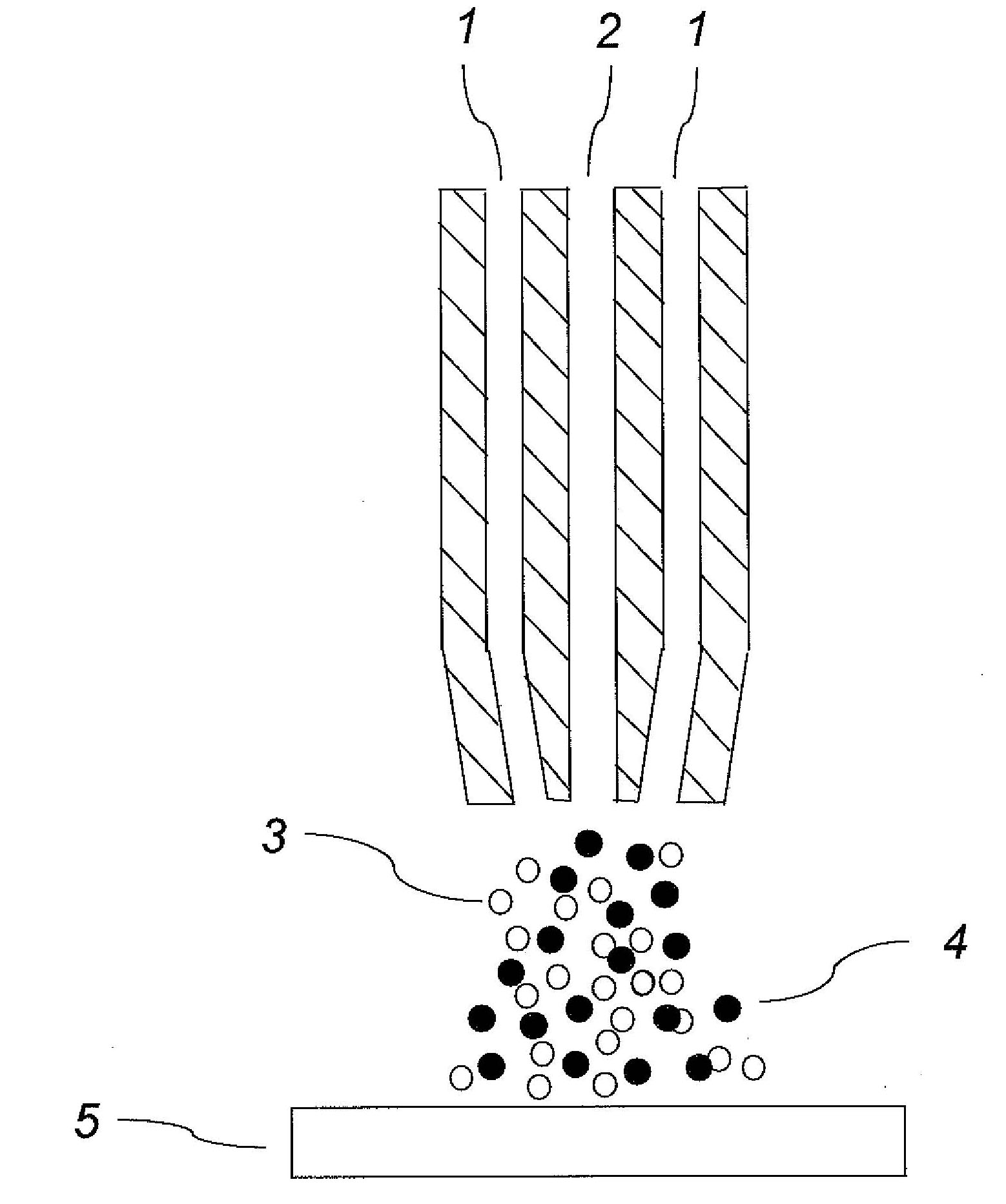

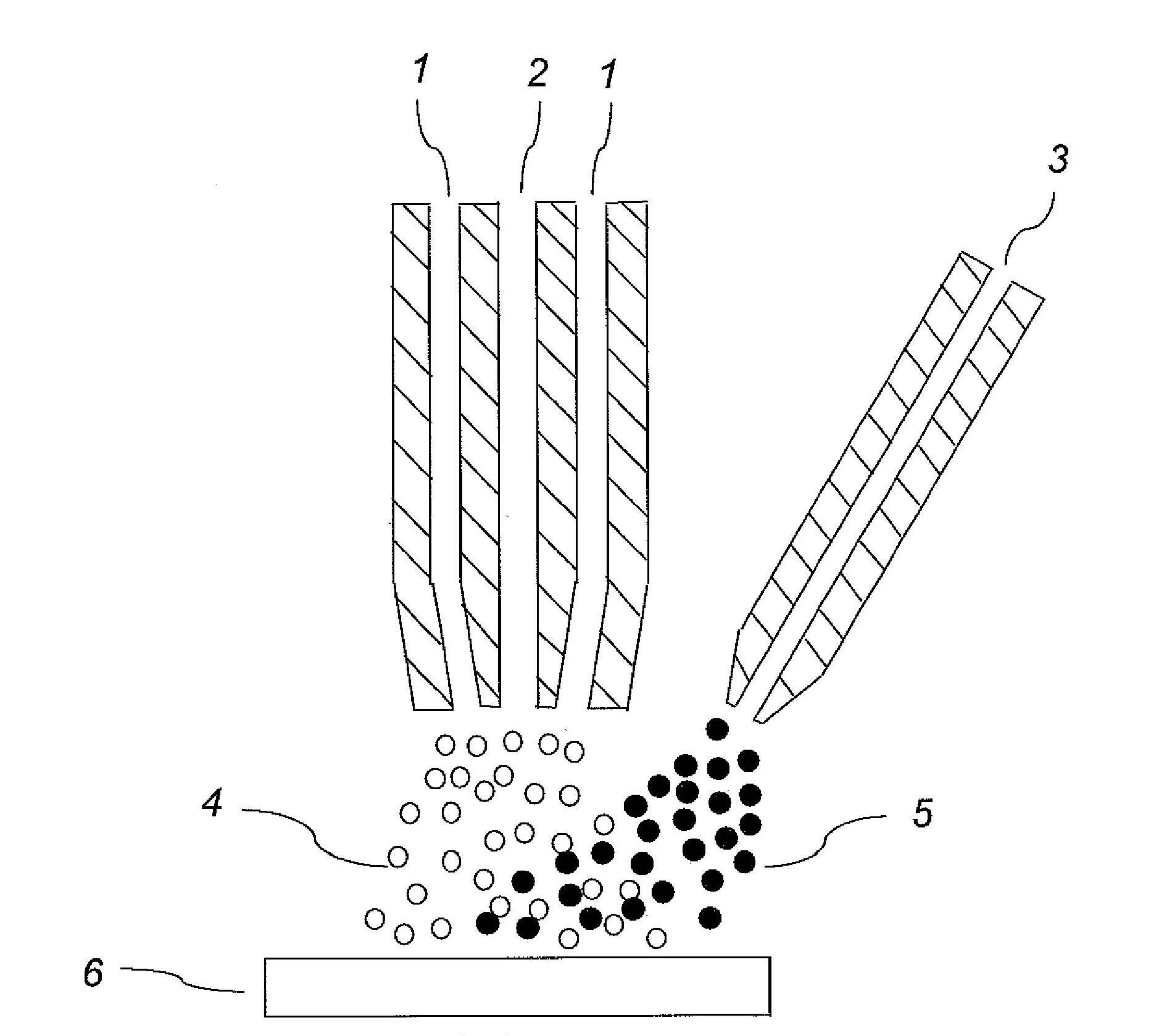

Method used

Image

Examples

example 1

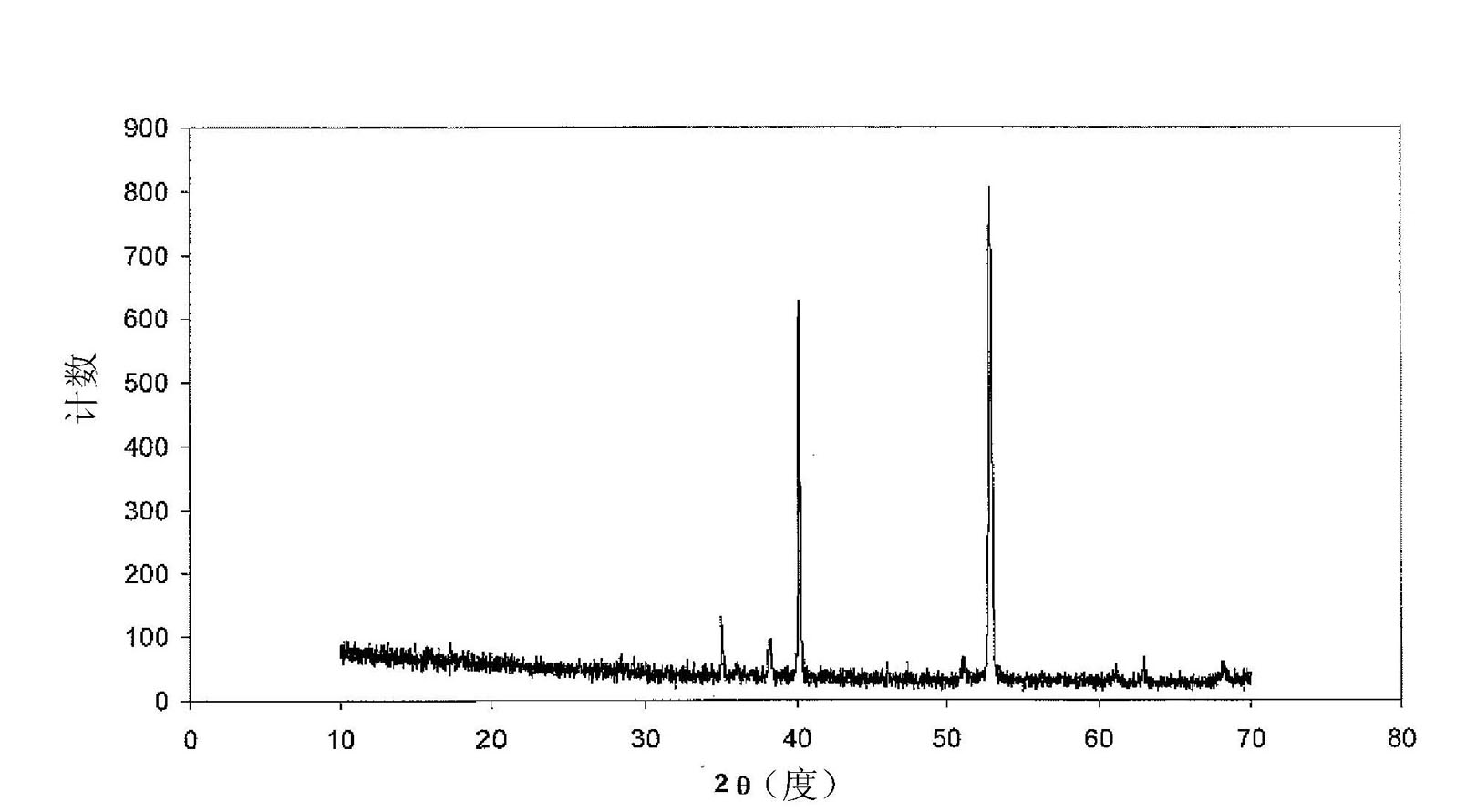

[0110] A 1 cm × 1 cm commercially pure titanium sample was subjected to steel grit blasting using a Vaniman steel grit blasting machine with alumina grit with an average particle size of 100 microns. The nozzle was kept at a distance of 20 mm from the surface and the nozzle was kept perpendicular to said surface. Substantially oxygen-free nitrogen at a pressure of 7 bar was used as carrier fluid. The silicon carbide nozzle has a bore diameter of 1 mm. 4 passes were made on the surface. Compare the XRD patterns of titanium samples ( image 3 ) with titanium specimens treated as above ( Figure 4 ), showing a peak at 43.52 in the treated titanium nitride sample feature, but not found in titanium or titanium oxide.

[0111] The samples were further grit blasted with alumina using a Vaniman grit blaster. During grit blasting, an atomized dispersion of polytetrafluoroethylene (PTFE) nanoparticles in ethanol was directed to the same point on the surface. The alumina has an ave...

example 2

[0114] A 1 cm × 1 cm commercially pure titanium sample was bombarded with alumina grit and a dispersion of atomized PTFE powder in ethanol. The alumina has an average particle size of 100 microns, while the PTFE particles have an average particle size of 200 nm. Using a Vaniman steel blasting machine, alumina grit was delivered to the surface through a silicon carbide nozzle with a 1 mm hole diameter. The carrier gas was air at a pressure of 5 bar. An aerosol of PTFE in ethanol was generated using a spray gun. An air flow at a pressure of 5 bar was passed through the venturi across a second venturi connected to a reservoir of ethanol containing PTFE nanoparticles, generating an aerosol via the Bernoulli effect. Both the air flow carrying the alumina grit and the air flow carrying the aerosol were focused on the titanium specimen. The distance between the titanium sample and the nozzle was kept within 60 mm. A titanium sample is placed at this point. 4 passes were performe...

example 3

[0117] A 1 cm × 1 cm commercially pure titanium sample was bombarded with alumina grit and a dispersion of atomized hydroxyapatite nanocrystals in ethanol. The average particle size of alumina is 100 microns. Using a Vaniman steel blasting machine, alumina grit was delivered to the surface through a silicon carbide nozzle with a 1 mm hole diameter. The carrier gas was air at a pressure of 5 bar. A spray gun was used to create a dispersion of atomized hydroxyapatite in ethanol. An air flow at a pressure of 5 bar was passed through the venturi across a second venturi connected to the hydroxyapatite-containing ethanol reservoir, generating an aerosol via the Bernoulli effect. Both the air flow carrying the alumina grit and the air flow carrying the aerosol were focused on the titanium specimen. The distance between the titanium sample and the nozzle was kept within 60 mm. 4 passes were performed on the surface.

[0118] Subsequently, the samples were cleaned by ultrasonic wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com