Patents

Literature

120 results about "Grit blasting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

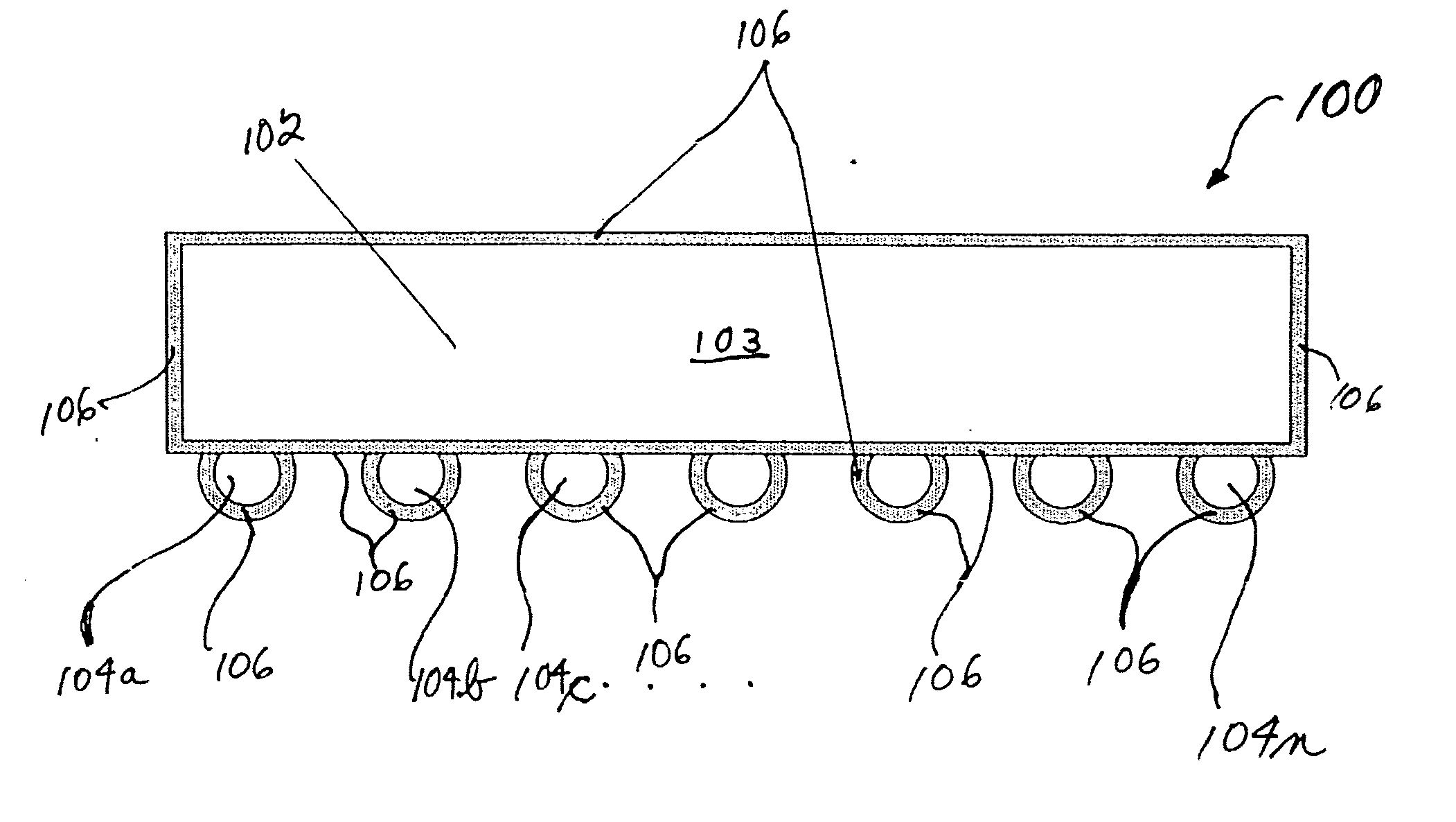

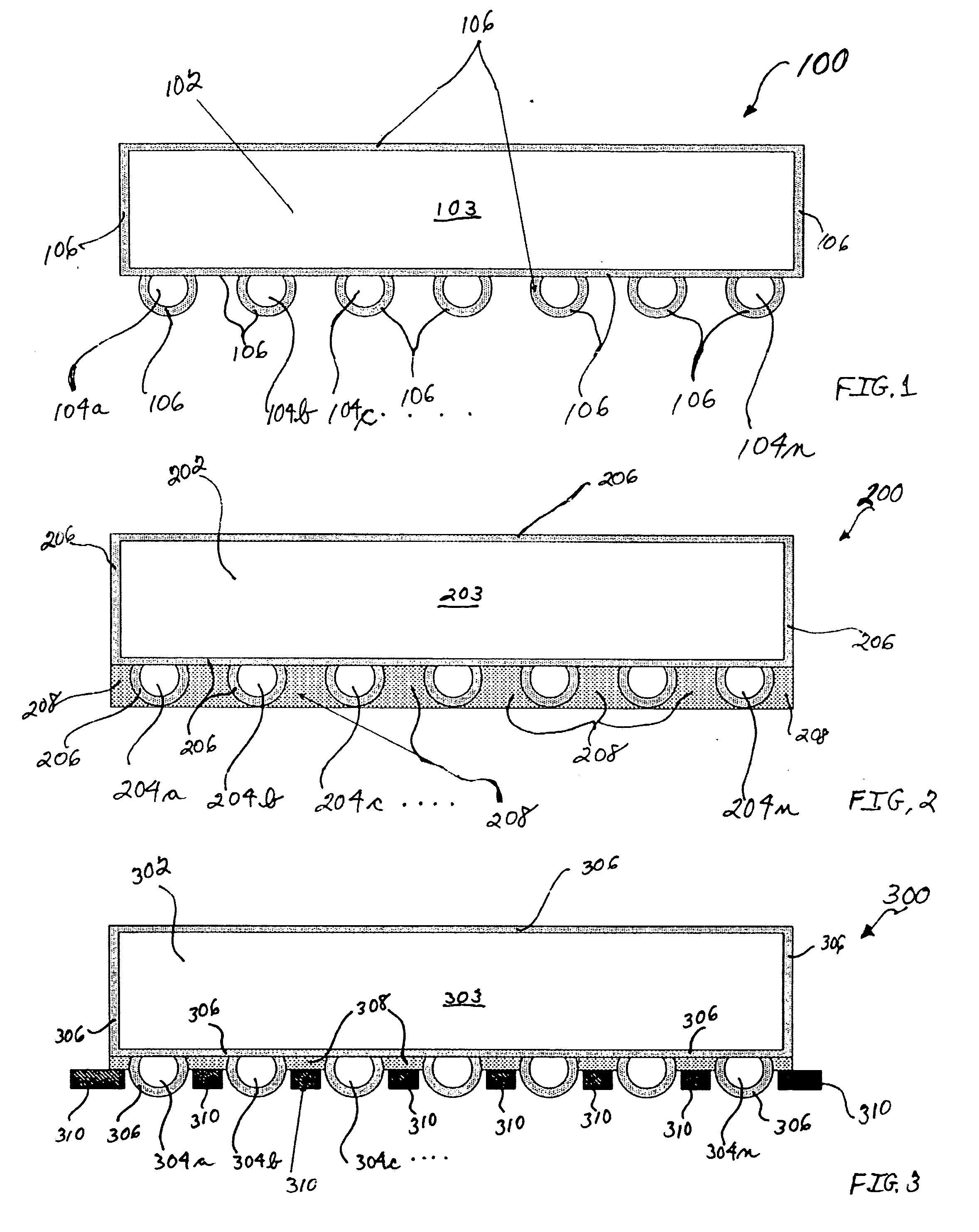

Method and apparatus for applying external coating to grid array packages for increased reliability and performance

InactiveUS20060278971A1Improve electrical performanceImprove reliabilitySemiconductor/solid-state device detailsPrinted circuit aspectsParylene coatingEngineering

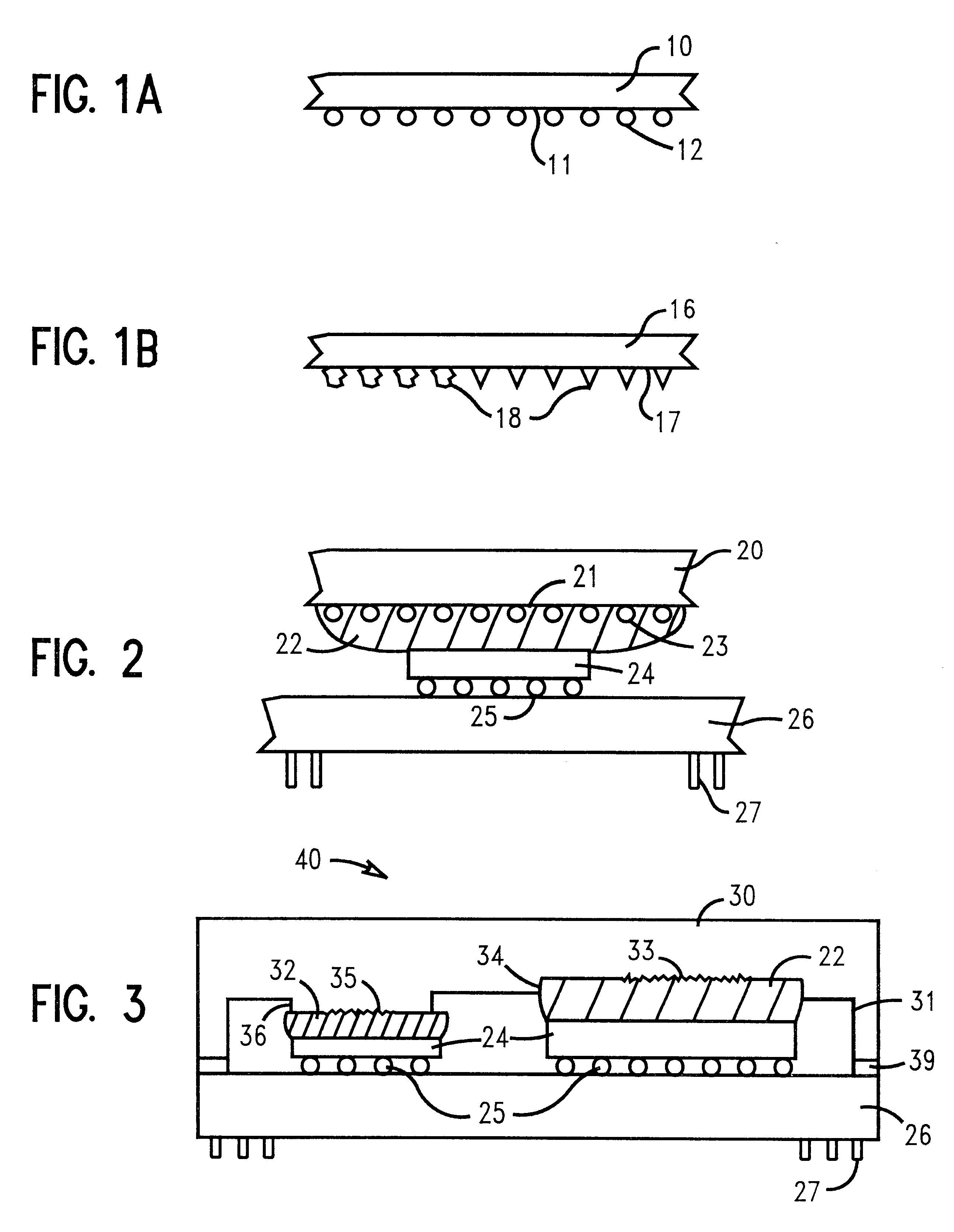

A method and apparatus are disclosed for selective removal of a conformal coating from the solder balls of grid array packages such that the benefits of the coating are realized. An ancillary benefit of the invention is improved process-ability of the grid array package by improving the mechanical containment of the solder during the reflow process and improved electrical isolation between the individual solder attachment points. For example, a method for coating a ball grid array is provided, which includes coating the ball grid array with a thin layer of parylene. Next, the solder ball side of the part is butter smeared or squeegeed with a water soluble coating and assembled wet. A mask having holes in the same pattern as the balls in the grid, and a thickness that is about 80% of the height of the balls, is applied to the solder ball side of the part. This side of the part is then butter smeared again with the water soluble coating, and the entire assembly is allowed to dry. At this point, about 20% of each parylene-coated solder ball protrudes higher than the surface of the mask. The solder ball side of the part is then grit blasted with an abrasive material. The extent that the abrasive material removes the parylene coating from the solder balls is limited by the mask and the layer of water soluble coating. Therefore, the grit blasting removes the parylene coating from only the protruding areas (e.g., about top 20%) of the solder balls. Water is then used to remove the water soluble coating, and the parylene coated part is baked to remove moisture. Thus, a parylene coated ball grid array (or column grid array) is provided that is highly impervious to moisture, has a very high dielectric strength, and thereby improves the electrical performance and reliability of the surface mounted part.

Owner:HONEYWELL INT INC

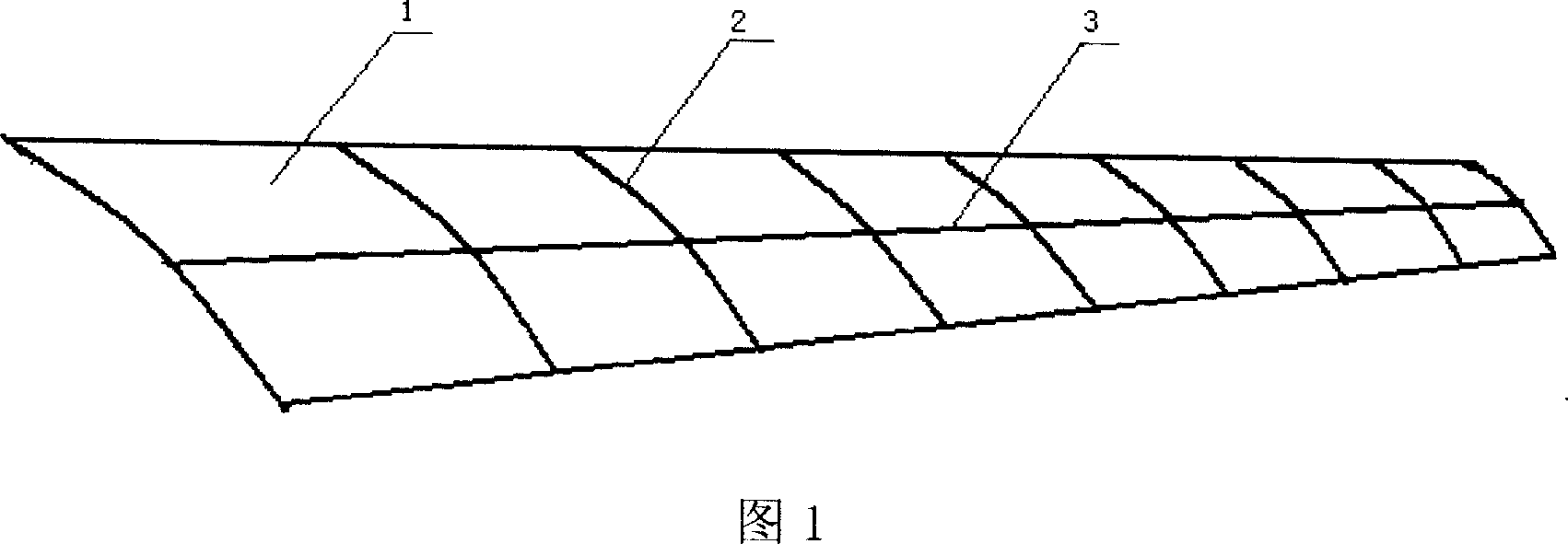

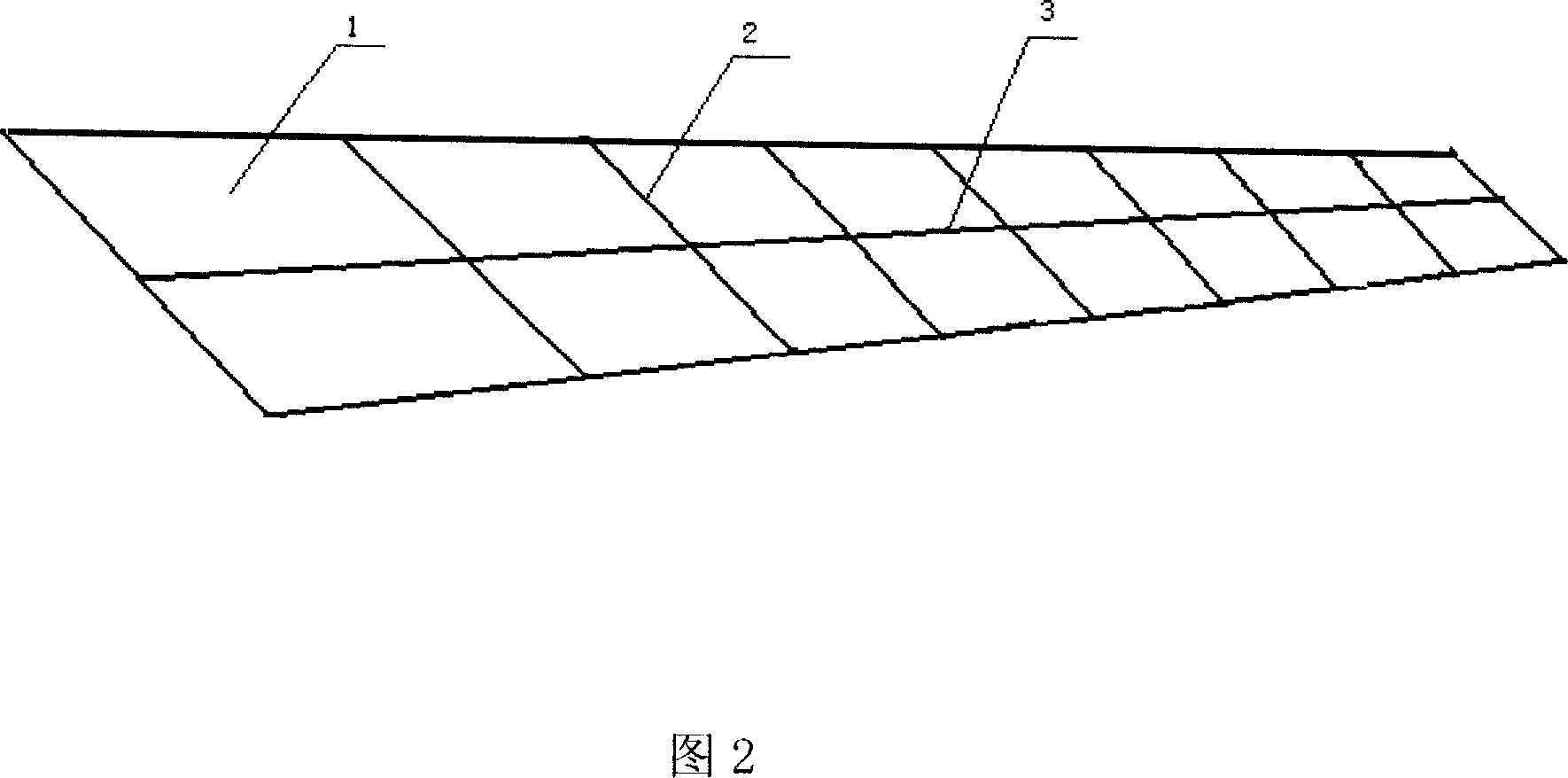

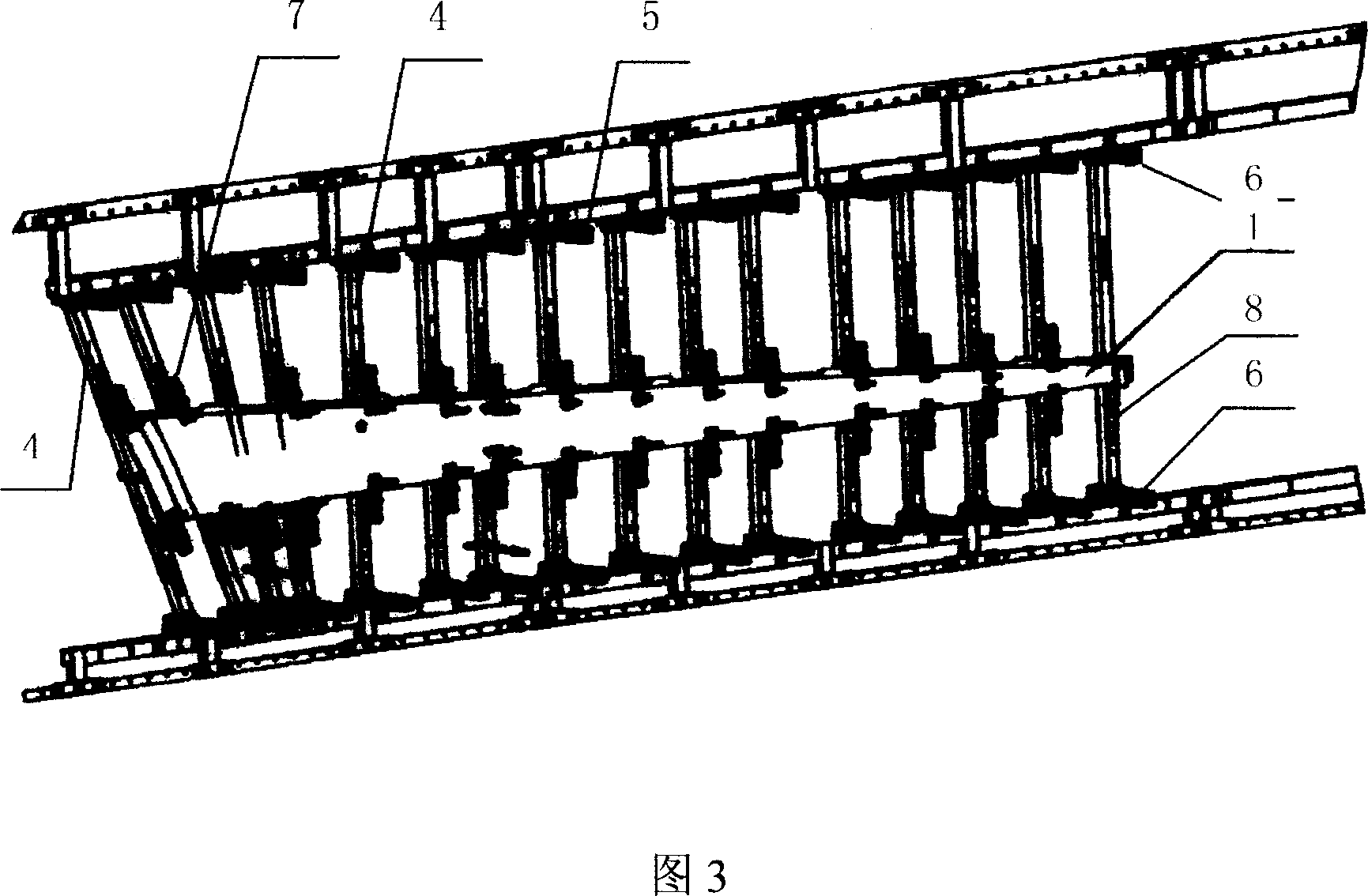

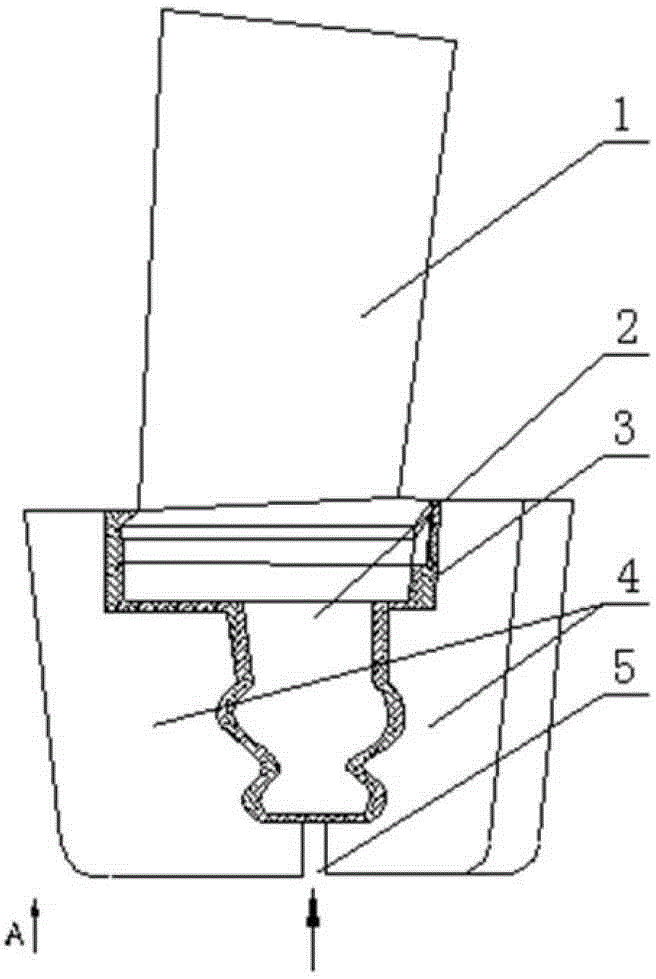

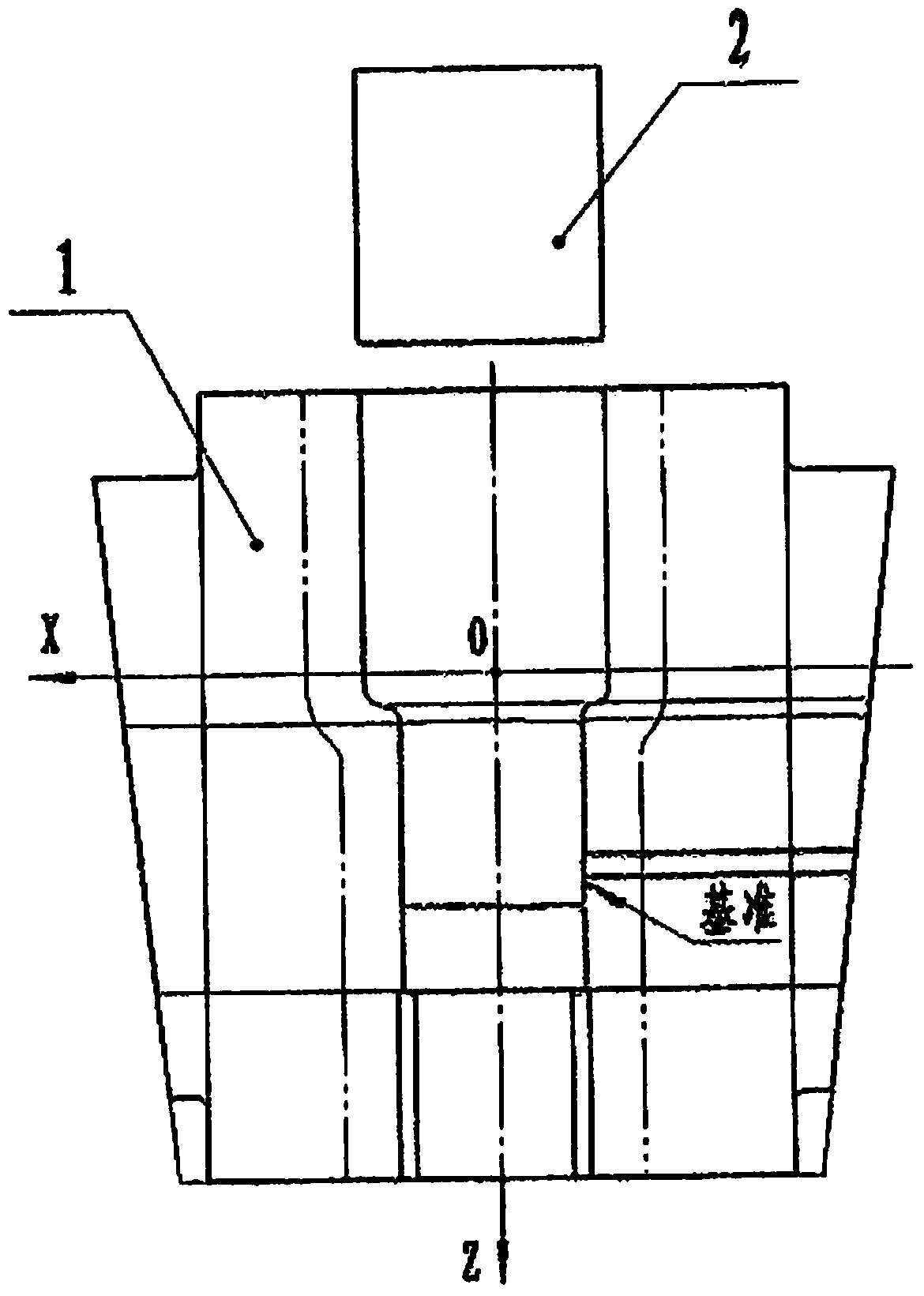

Prestressing shot-blasting formation technique for double-curved wallboard

A pre-stressing and grit-blasting technique for shaping a double-curvature plate wall used as the thick jacket of large airplane features that a pre-stressing fixture unit is used to pre-bend a plate longitudinally and transversely and fix it for applying a pre-stress to it while the grits are blasted onto said plate for obtaining a needed shape.

Owner:XIAN AIRCRAFT IND GROUP

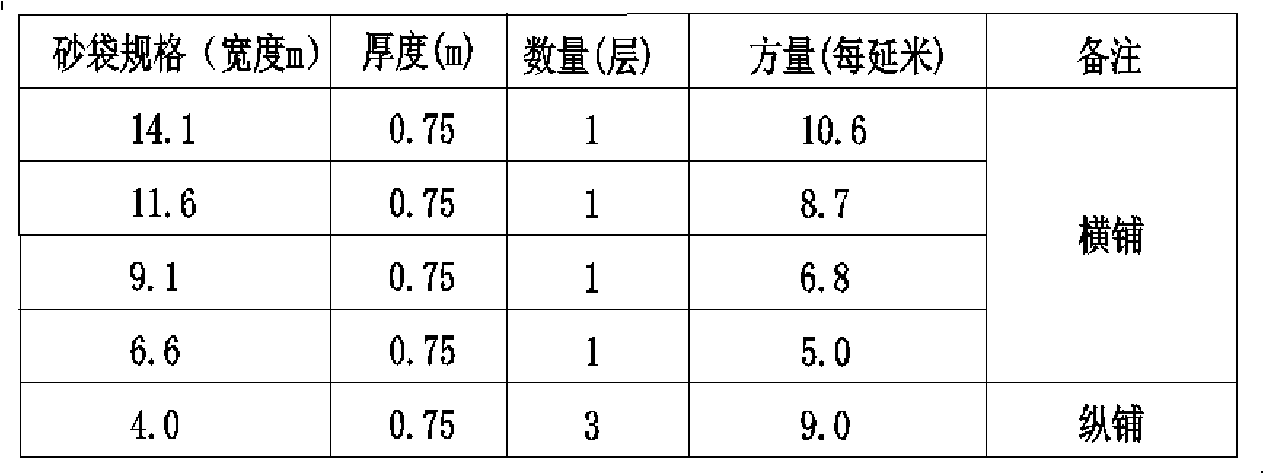

Sand dredger filling construction method of soft soil foundation embankment

InactiveCN102605697ASolve the leveling problemGuarantee the construction qualityRoadwaysFlatness problemLand resources

The invention discloses a sand dredger filling construction method of a soft soil foundation embankment. The sand dredger filling construction method comprises the steps of: (1) cleaning the surface of an embankment dredger filling field; (2) measuring and lofting, and setting an elevation mark of the dredger filling construction in a dredger filling region; (3) performing the dredger filling work in a manner of segmenting and layering, to be specific, forming a cofferdam, establishing plastic water discharge plates, building construction roads, distributing grit blasting pipe lines, dredger-filling the embankment, constructing a drain opening, and constructing water collecting wells; and (4) performing stability observation and settlement observation on the dredge-filled sand land of the embankment. The sand dredger filling construction method disclosed by the invention has the advantages of solving the flatness problem of road area at coastal tidelands, rivers, fishponds and the like, performing roadbed filling of municipal administration by fully making use of the characteristics of abundant fin sand resource in the local area, reducing exploitation usage amount of the land resource, decreasing construction cost while guaranteeing construction quality of the roadbed, being simple, convenient, feasible, efficient and practical, increasing working efficiency, saving cost and creating conditions for advanced construction of the next procedure.

Owner:TIANJIN 20 CONSTR

Thermal cap with embedded particles

InactiveUS6111314AImprove thermal reliabilityImprove adhesionSemiconductor/solid-state device detailsSolid-state devicesGrit blastingSurface modification

The present invention relates generally to a new method for improving the reliability of cooling designs using thermal paste to cool chips in semiconductor modules and structure thereof. More particularly, the invention encompasses a structure and a method that uses surface chemistry modification of the inside of the thermal cooling caps where it contacts thermal paste. The internal surface of the cap is modified by embedding particles that have the same chemical composition as one or more of the solids used in the thermal paste. The particles may be embedded in the cap by casting, grit blasting, or pressing the particles permanently into the surface.

Owner:IBM CORP

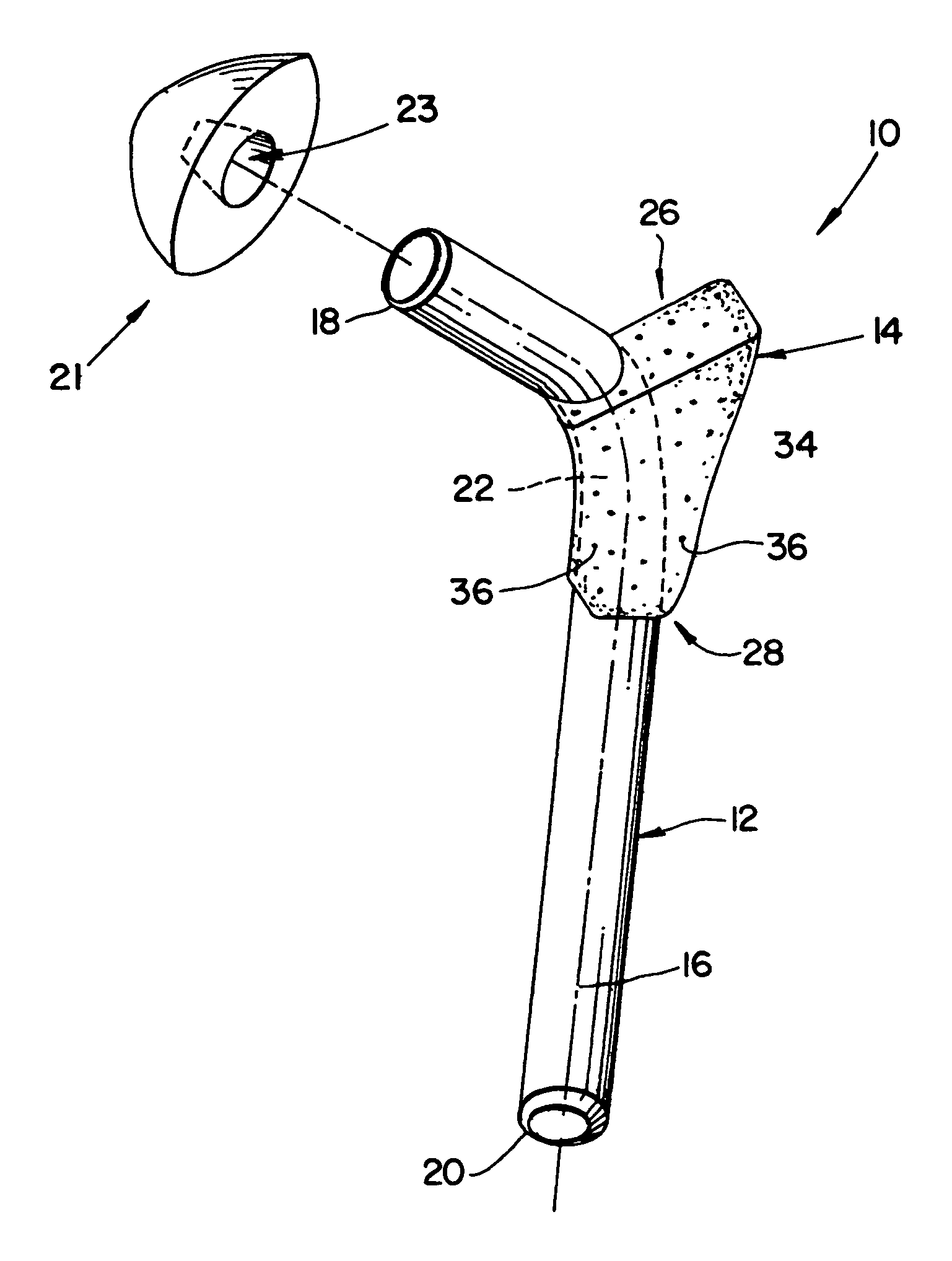

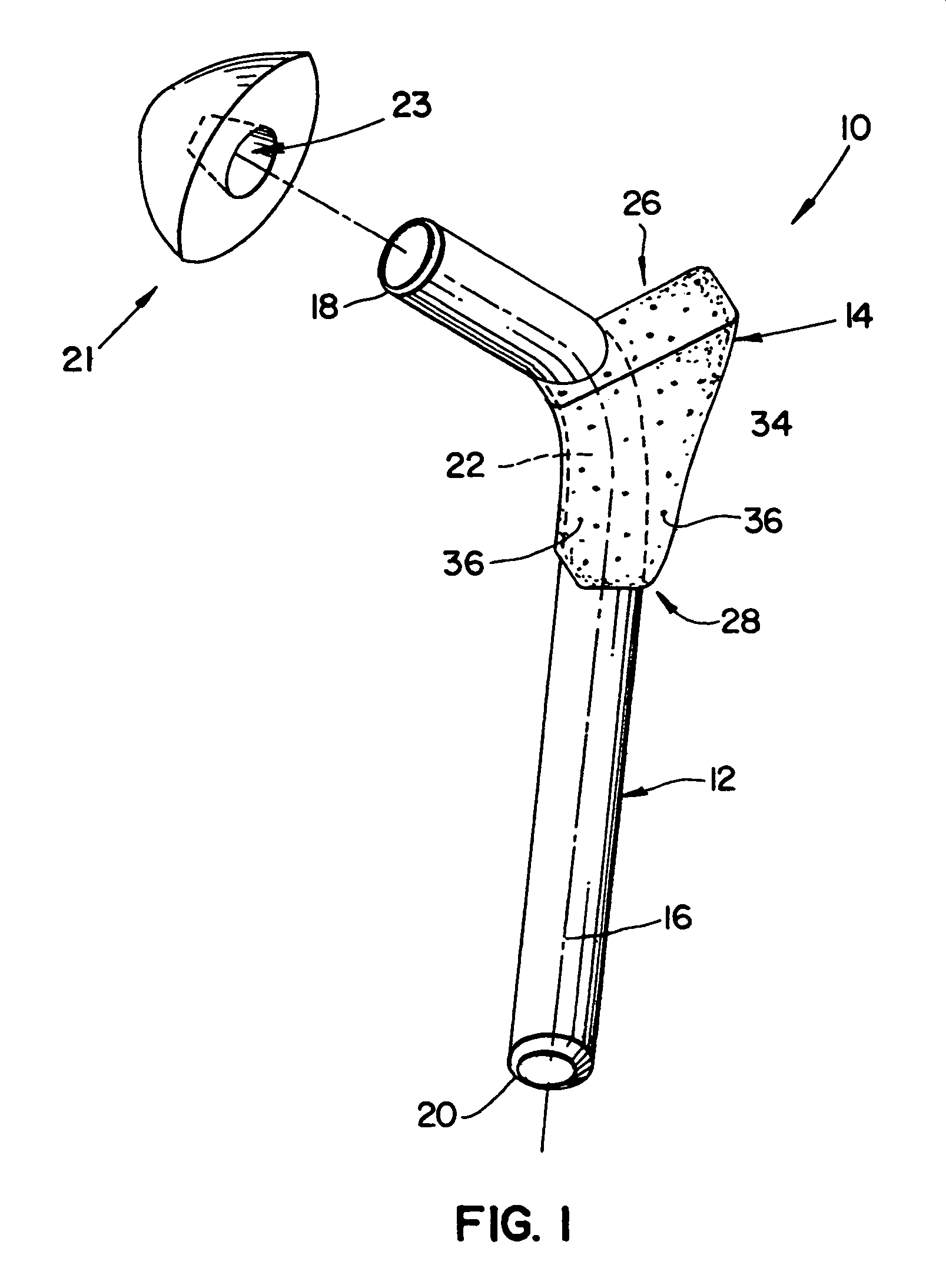

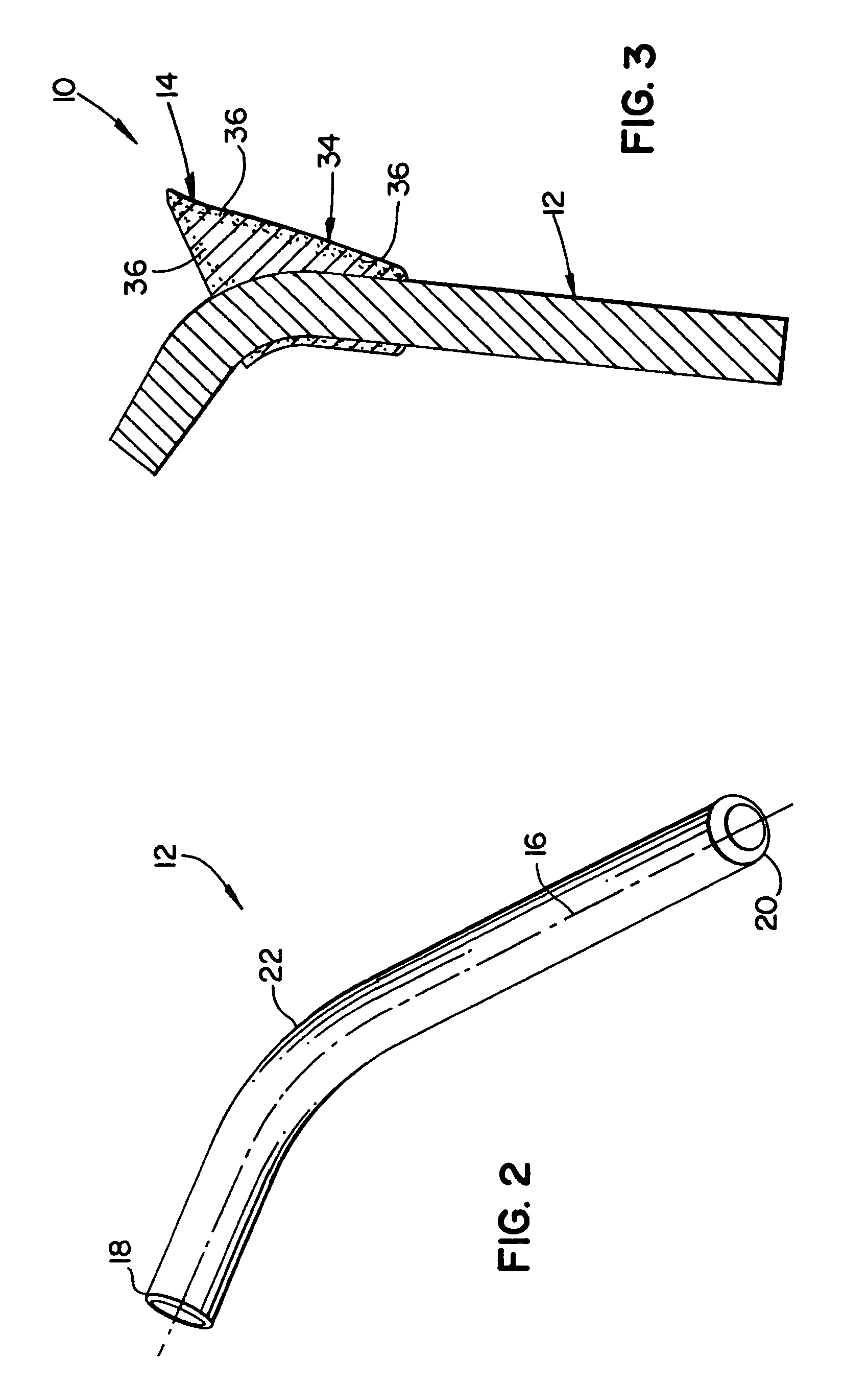

Implantable orthopedic prosthesis with textured polymeric surfaces

InactiveUS6974482B2Improve adhesionDegree of reductionJoint implantsFemoral headsPolymeric surfaceMedicine

Implantable prostheses fully or partially formed of polymer having a textured or porous outer surface. The surface permits and encourages osteogenesis into the prosthesis and enables it to become firmly and permanently anchored into surrounding bone. The prostheses include a femoral hip stem formed of a metallic core and a polymeric proximal body with a textured or porous surface formed from a laser texturing, machining, or grit blasting.

Owner:ZIMMER INC

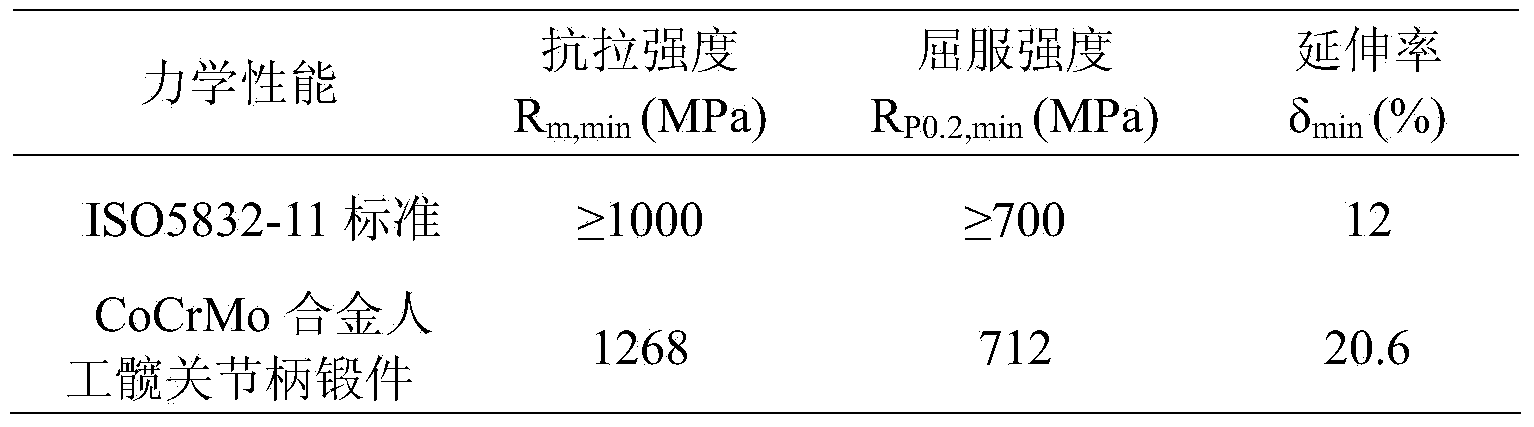

Precise forging method for CoCrMo alloy artificial joint

InactiveCN103667800AReduce deformation resistanceAvoid Forging CracksMetal-working apparatusProsthesisArtificial jointsUltimate tensile strength

The invention relates to a precise forging method for a CoCrMo alloy artificial joint. The method comprises the following steps: carrying out blanking and blank making so as to obtain a forging blank material; subjecting the blank material to forging and correction; and finally, carrying out polishing and grit blasting so as to obtain a CoCrMo alloy artificial joint forging. The invention has the following advantages: an appropriate forging temperature range for the CoCrMo alloy artificial joint is determined for the first time, remelting and heat preservation are carried out after forging and correction, so the CoCrMo alloy forging has god strength matching with plasticity.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Methods of roughening ceramic surface

InactiveCN1496343AInsulating substrate metal adhesion improvementVacuum evaporation coatingAbrasive blastingEtching

Disclosed herein is a method of roughening a ceramic surface by forming mechanical interlocks in the ceramic surface by a chemical etching process, a thermal etching process, or a laser micromachining process. Also disclosed herein are components for use in semiconductor processing chambers (in particular, a deposition ring for use in a PVD chamber) which have at least one ceramic surface having mechanical interlocks formed therein by chemical etching, thermal etching, or laser micromachining. Ceramic surfaces which have been roughened according to the chemical etching, thermal etching, or laser micromachining process of the invention are less brittle and damaged than ceramic surfaces which are roughened using conventional grit blasting techniques. The method of the invention results in a roughened ceramic surface which provides good adherence to an overlying sacrificial layer (such as aluminum).

Owner:APPLIED MATERIALS INC

Seepage prevention method and fixture for aerial engine blade rabbet

ActiveCN102978565AImprove anti-seepage effectWill not polluteSolid state diffusion coatingAviationChemical reaction

The invention relates to a seepage prevention method and a fixture for an aerial engine blade rabbet. The seepage prevention method for the aerial engine blade rabbet comprises the following steps of: after heating the cleaned blade rabbet, winding aluminum oxide cotton on the outer surface of the blade rabbet, and clamping the aluminum oxide cotton wound on the blade rabbet by two metal clamps; then putting the blade rabbet wrapped by the aluminum oxide cotton into a metal protective jacket together with the metal clamps; and taking mixtures of ferro-aluminum powders, aluminum-silicon powders and tetra-methylammonium chloride as seepage agents, and carrying out gas aluminizing in a conventional method. The aluminum oxide, used in the invention, can resist corrosive atmosphere, and can not generate any chemical reaction and further generate pollution to a blade. Due to the adoption of the seepage prevention method and the fixture for the aerial engine blade rabbet, seepage layers on the rabbet part can be completely removed by only carrying out processes of wet grit blasting and coloring for one time, the repeated processes of dry grit blasting and the coloring are avoided, the production efficiency is improved for 1-2 times, and 30-40% of cost is saved; and furthermore, the operation is simple, and the seepage prevention effect is good.

Owner:AECC AVIATION POWER CO LTD

Preparation method of high-temperature abradable sealing coating

ActiveCN102787290AImprove deposition efficiencyLow costMolten spray coatingEfficient propulsion technologiesPolyesterThermal spraying

The invention belongs to the technology of high temperature surface protection, and particularly relates to a preparation method of a high-temperature abradable sealing coating. The high-temperature abradable sealing coating comprises a bonding bottom layer, an oxygen barrier layer, a thermal insulation layer, and an abradable surface layer; the abradable surface layer comprises the following components by weight: 80%-95% of ZrO2, 5%-15% of polyester, and 0.5-5% of hBN; spraying powder is prepared by a high-energy ball milling method and is kept in reserve; before spraying of a workpiece surface, the workpiece surface is pretreated by grit blasting, and then each layer is prepared respectively by thermal spraying technology. The coating deposition efficiency is high, and the cost is low. Meanwhile, the coating has high thermal insulation performance, antioxidation performance, and abradability; the thermal cycle life of the coating at 1150 DEG C is up to more than 150 cycles, and the thermal shock life at 1150 DEG C is up to more than 1000 shocks; the structure-abradable sealing coating has a service temperature of up to 1200 DEG C.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Method for providing a thermal path through particles embedded in a thermal cap

InactiveUS6255139B1Enhanced thermal pathImprove thermal reliabilitySemiconductor/solid-state device detailsSolid-state devicesChemical compositionSolid mass

The present invention relates generally to a new method for improving the reliability of cooling designs using thermal paste to cool chips in semiconductor modules and structure thereof. More particularly, the invention encompasses a structure and a method that uses surface chemistry modification of the inside of the thermal cooling caps where it contacts thermal paste. The internal surface of the cap is modified by embedding particles that have the same chemical composition as one or more of the solids used in the thermal paste. The particles may be embedded in the cap by casting, grit blasting, or pressing the particles permanently into the surface.

Owner:INT BUSINESS MASCH CORP

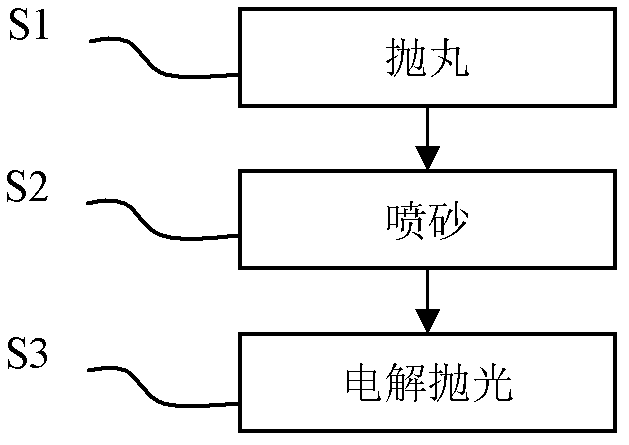

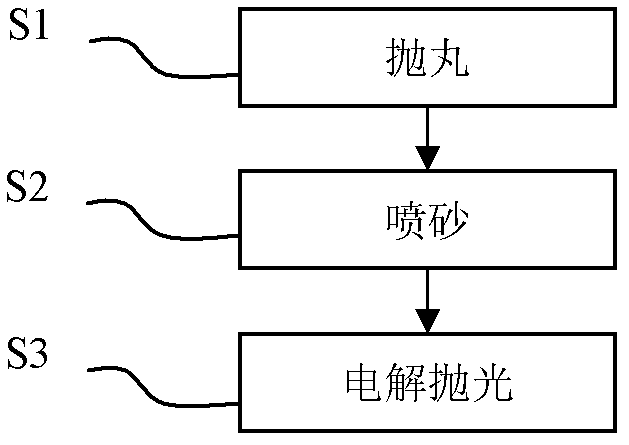

Stainless steel surface treatment method

The present invention relates to the technical field of metal surface treatment, in particular to a stainless steel surface treatment method, which includes the steps of: S1: performing shot blasting treatment on the stainless steel surface to be treated; S2: performing sandblasting treatment on the stainless steel surface after shot blasting treatment ; S3: Electrolytic polishing is performed on the surface of the stainless steel after sandblasting. The steps of shot blasting, sand blasting and electrolytic polishing are used to treat the surface of stainless steel, which can overcome the defects such as spots and cracks on the base material that are difficult to handle in the stainless steel products of the prior art section steel, and the defects such as fingerprint resistance in the prior art .

Owner:SUZHOU HUAYA TELECOMM EQUIP

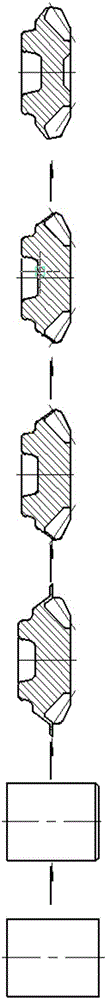

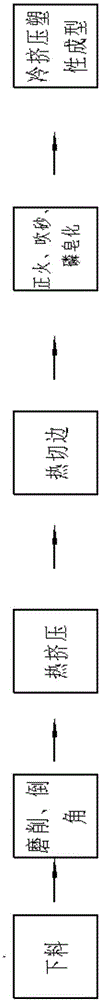

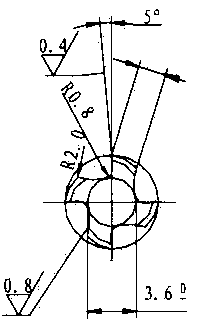

Molding process for straight bevel gear

The invention relates to a processing technique for a straight bevel gear and aims to provide a molding process for a straight bevel gear in order to improve the forging processing precision and processing efficiency of the bevel gear. The molding process comprises the following steps: (1) tooth die modeling includes rough forging tooth die modeling and finishing tooth die modeling; the pitch circle chordal tooth thickness of the rough forging tooth die is slightly smaller than that of the finishing tooth die, and the tooth whole depth of the rough forging tooth die is larger than the tooth whole depth of the finishing tooth die; the single tooth profile volume of a 0.992 rough forging tooth equals to the product of the single tooth profile volume of the finishing tooth die and 1.008; (2) the warm forging plastic forming is carried out; (3) hot forging edge cutting is carried out; (4) rough forged pieces are subjected to normalization, surface grit blasting and phosphorous saponification; (5) cold accurate alignment plastic forming is carried out. The processing technique for the straight bevel gear has the advantages that the quantity of raw materials is saved, the technological requirements on blank processing are lowered; the production cycle is reduced, and the cost is reduced; the product quality is stable, the product precision is high, the mechanical performance is good, the tonnage of required equipment is small, and the cost is low.

Owner:SICHUAN ZHONGYOU MACHINERY

Reusable ceramic-comprising component which includes a scrificial surface layer

InactiveUS6899798B2Improve adhesionMinimizing microcracking and other damageDecorative surface effectsVacuum evaporation coatingEtchingSurface layer

Disclosed herein is a method of roughening a ceramic surface by forming mechanical interlocks in the ceramic surface by a chemical etching process, a thermal etching process, or a laser micromachining process. Also disclosed herein are components for use in semiconductor processing chambers (in particular, a deposition ring for use in a PVD chamber) which have at least one ceramic surface having mechanical interlocks formed therein by chemical etching, thermal etching, or laser micromachining. Ceramic surfaces which have been roughened according to the chemical etching, thermal etching, or laser micromachining process of the invention are less brittle and damaged than ceramic surfaces which are roughened using conventional grit blasting techniques. The method of the invention results in a roughened ceramic surface which provides good adherence to an overlying sacrificial layer (such as aluminum).

Owner:APPLIED MATERIALS INC

Annular flame tube high-temperature post-enameling deformation correcting method and fixture

ActiveCN107695137ASolve the deformation processing methodIdeal size requirementsShaping toolsUltimate tensile strengthHeat treating

The invention discloses an annular flame tube high-temperature post-enameling deformation correcting method and a fixture. The high-temperature post-enameling deformation correcting method adopts hotcorrecting, the hot correcting fixture is cooperated, and a processing method comprises the steps of contacting welding sections, heat treating, grit blasting, roasting, correcting, grit blasting, coating a W300 high-temperature enamel, hot correcting and turning. The invention provides the method for treating deformation of a parts after being coated with a high-temperature enamel, and an ideal size is obtained by utilizing a hot correcting manner. With hot correcting, high-precision enamel molded surface correction is realized, the problem of enamel damage caused by mechanical correction issolved, meanwhile, the labor intensity of workers is reduced, the processing cycle of the parts is reduced, and the production efficiency of the parts is improved.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

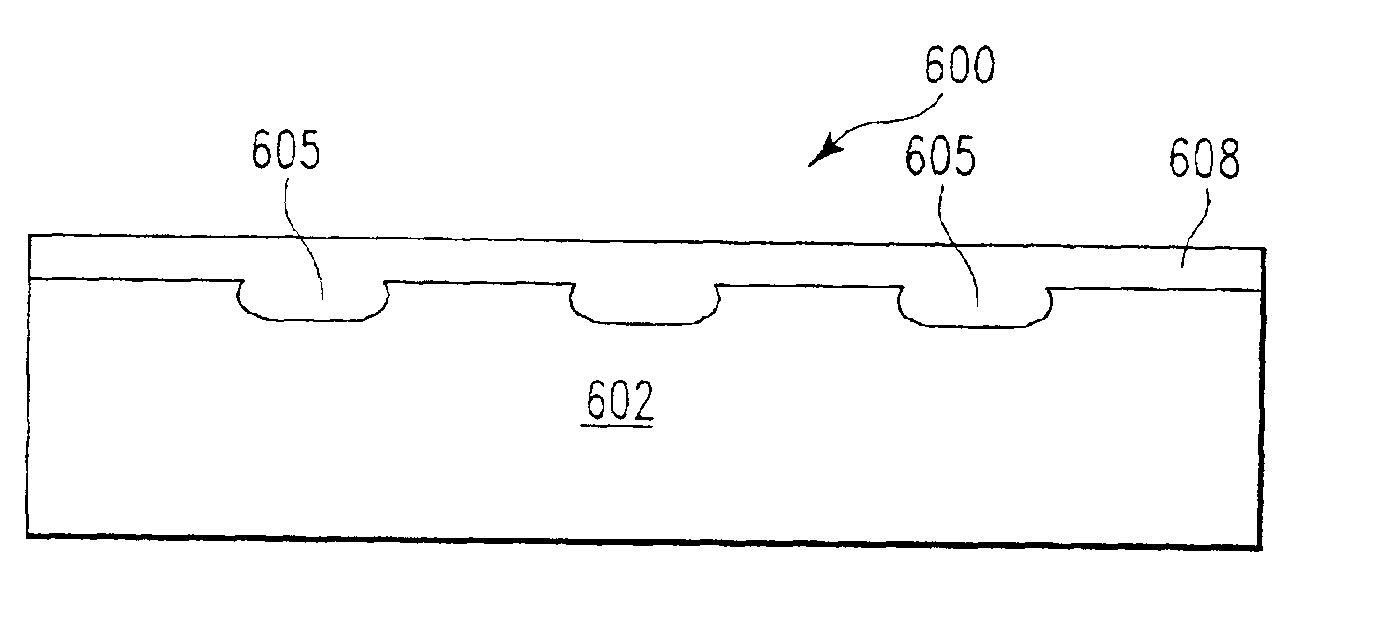

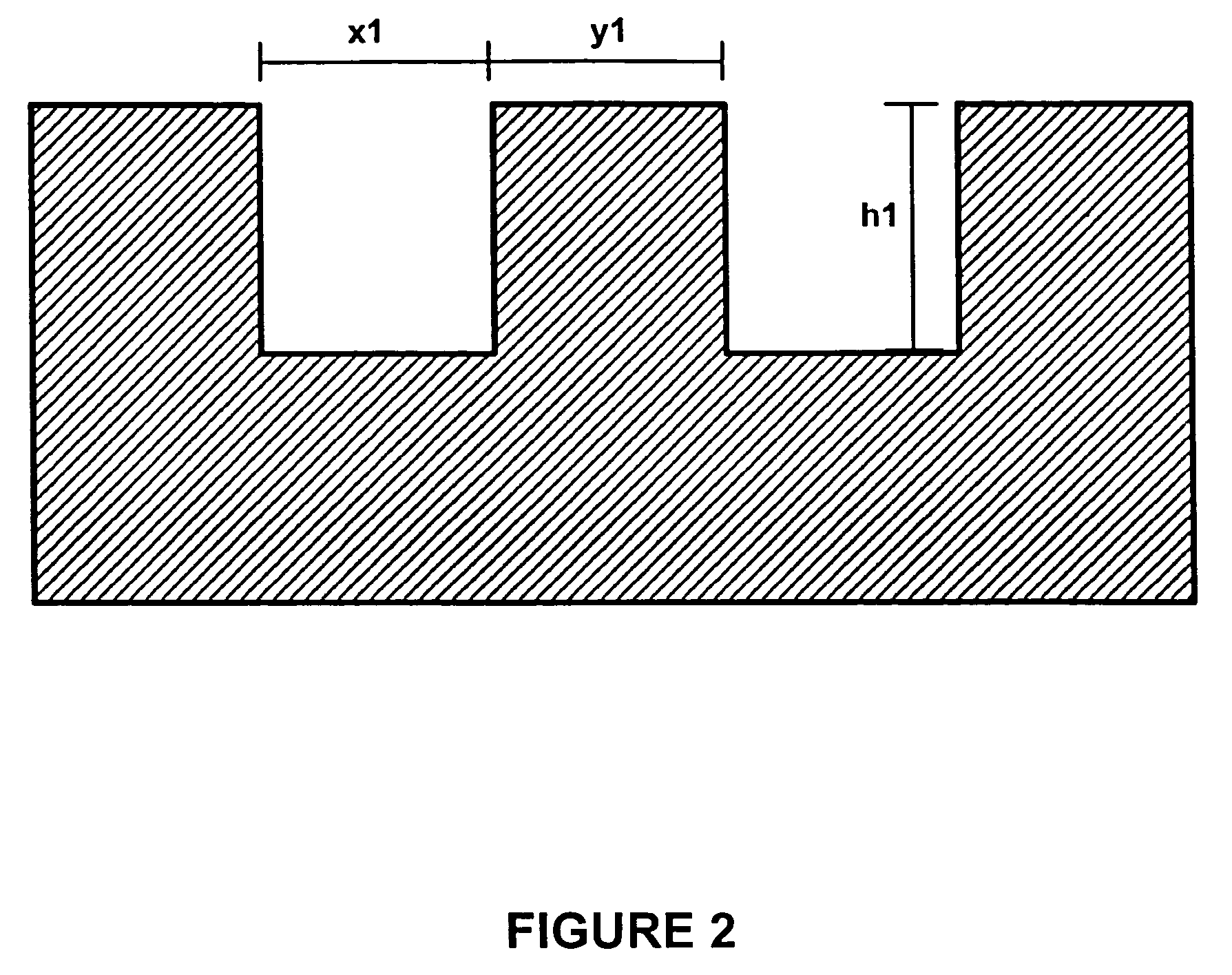

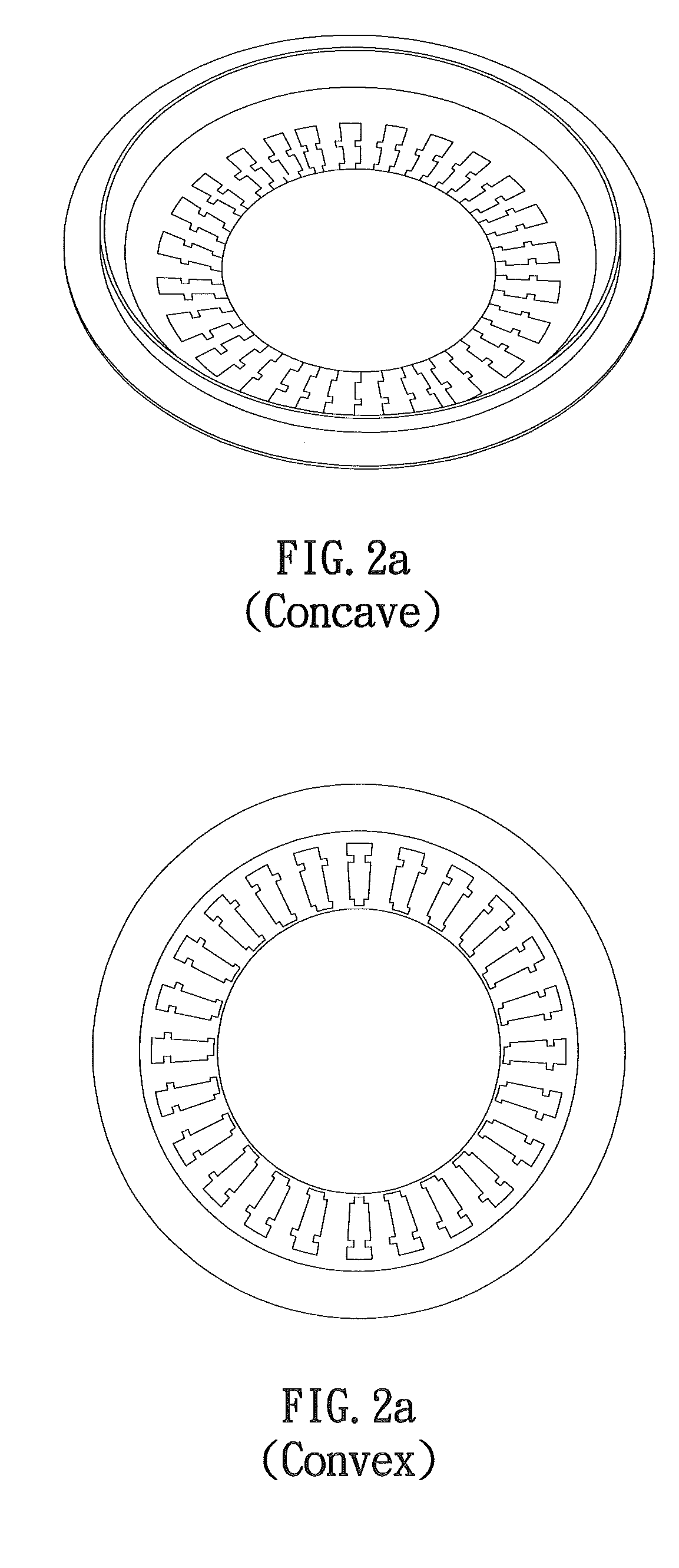

Sputter target having modified surface texture

InactiveUS20050072668A1Improve abilitiesReduce impactCellsElectric discharge tubesSputteringMaterials science

The effects of sputter re-deposition are reduced by macroscopically roughening the non-sputter areas of the sputter target. The macroscopic roughening is obtained by forming a macroscopic trough pattern in the non-sputter areas of the sputter target. A variety of patterns may be used for the trough pattern. In addition to macroscopically roughing the non-sputter areas of the sputter target, microscopic roughening of the trough patterns may be performed using conventional shot, bead or grit blasting techniques.

Owner:HERAEUS INC

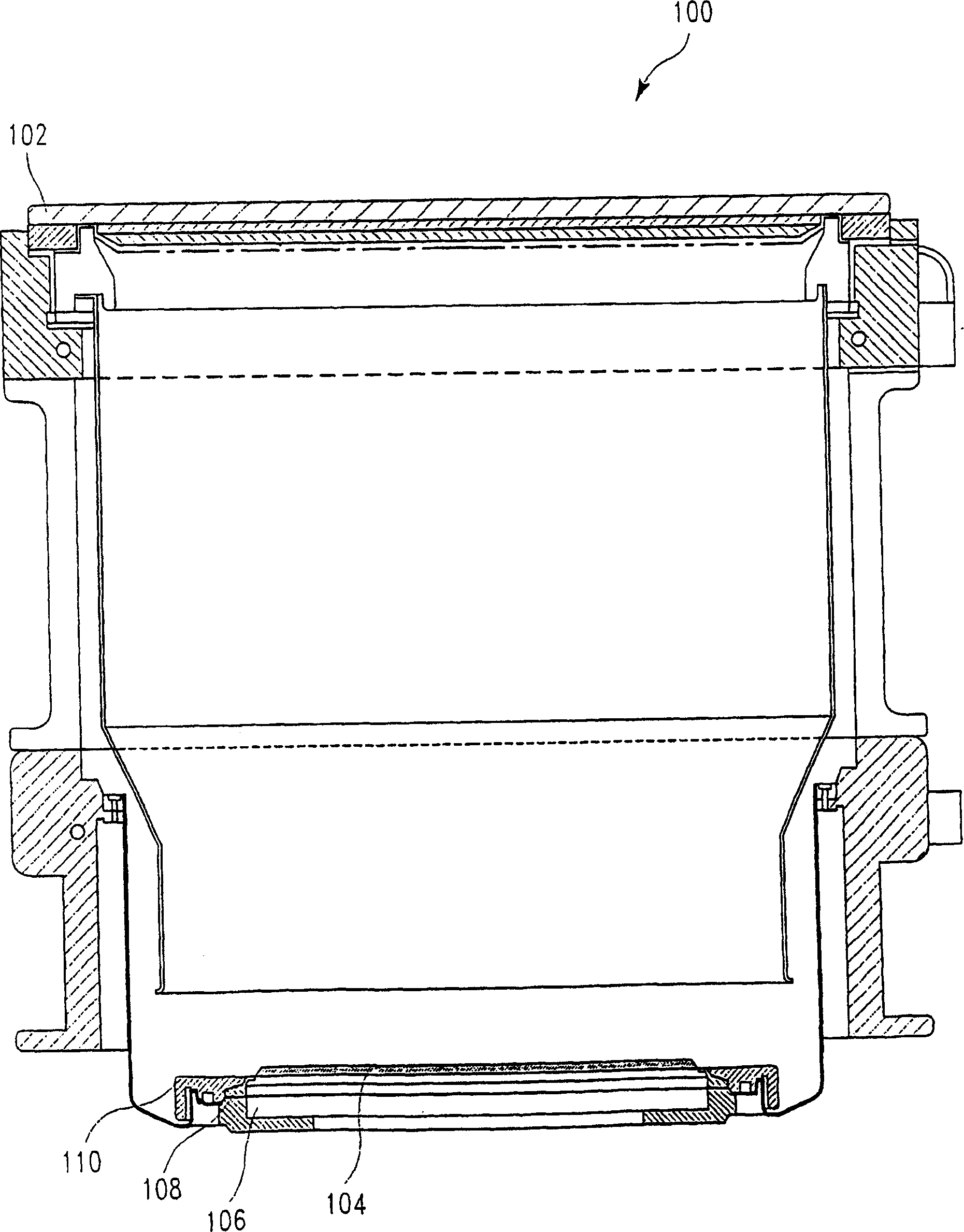

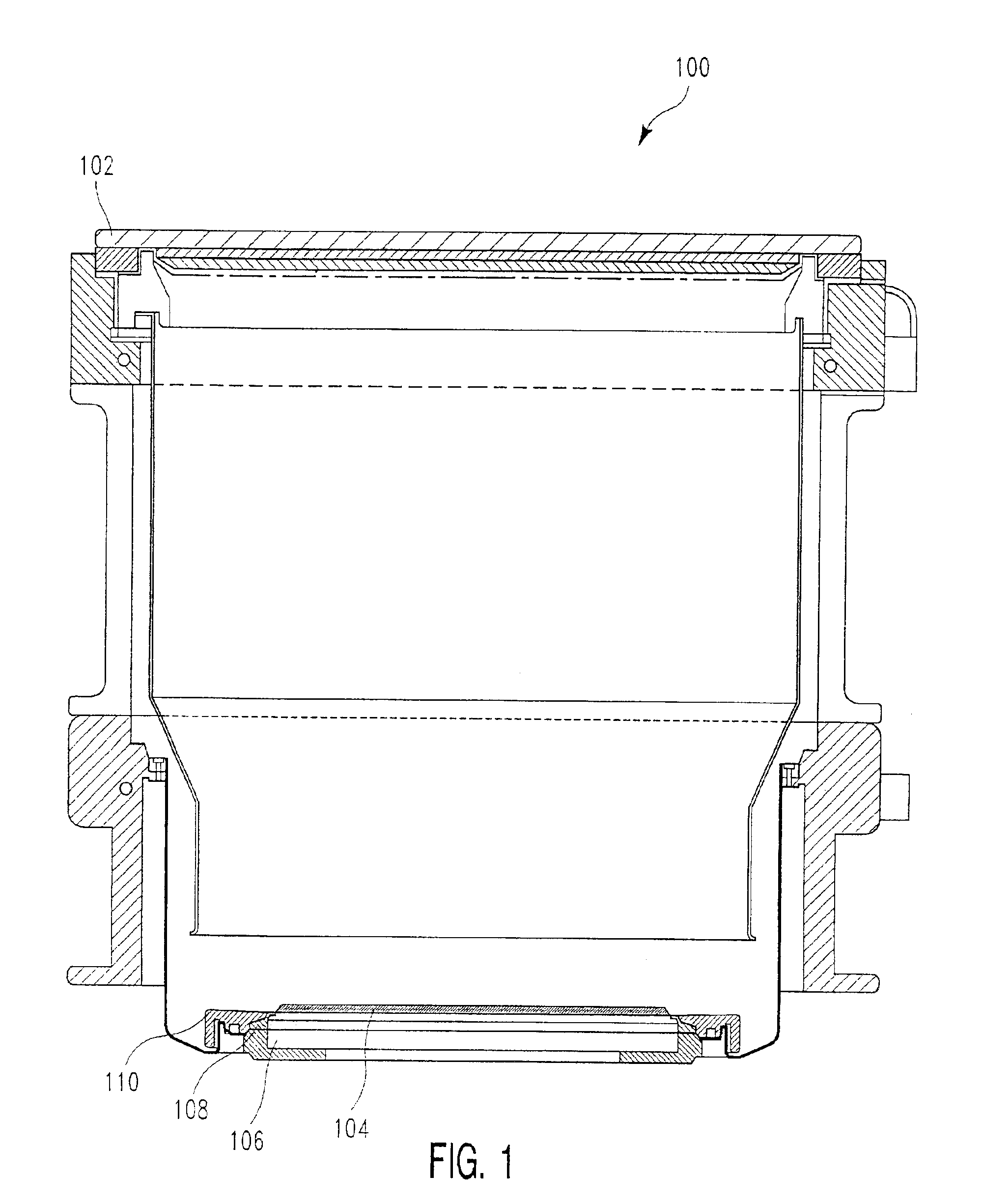

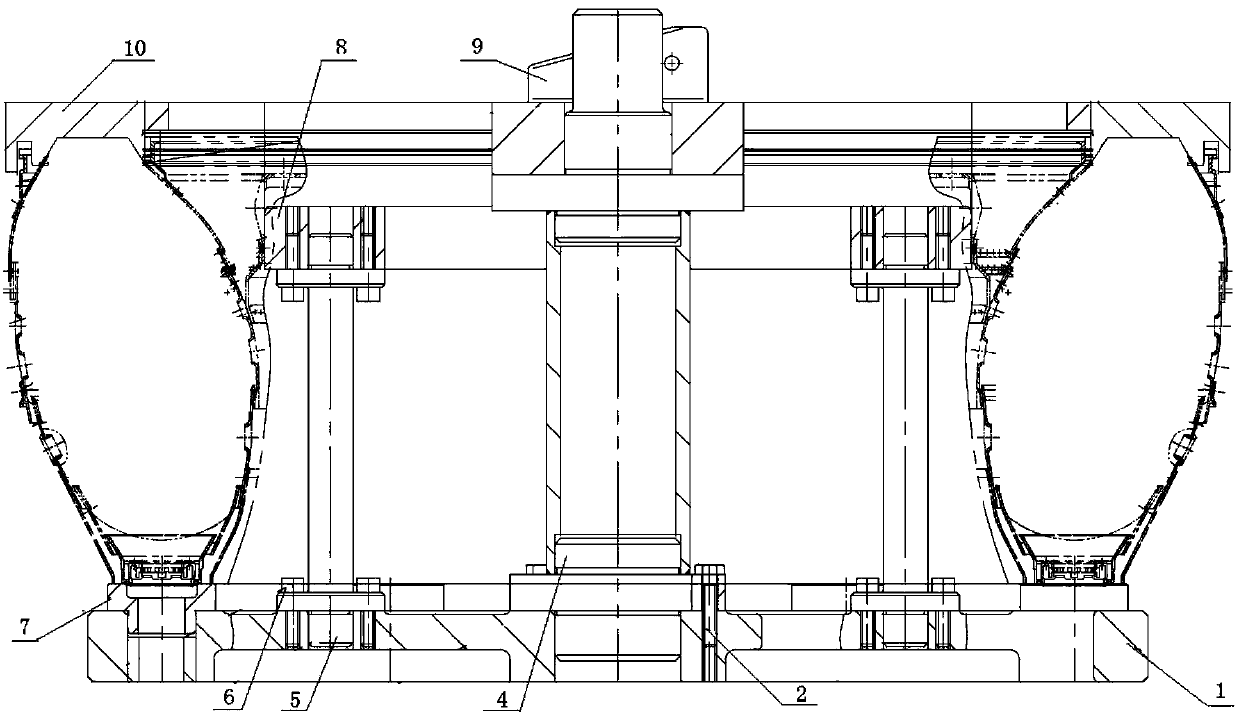

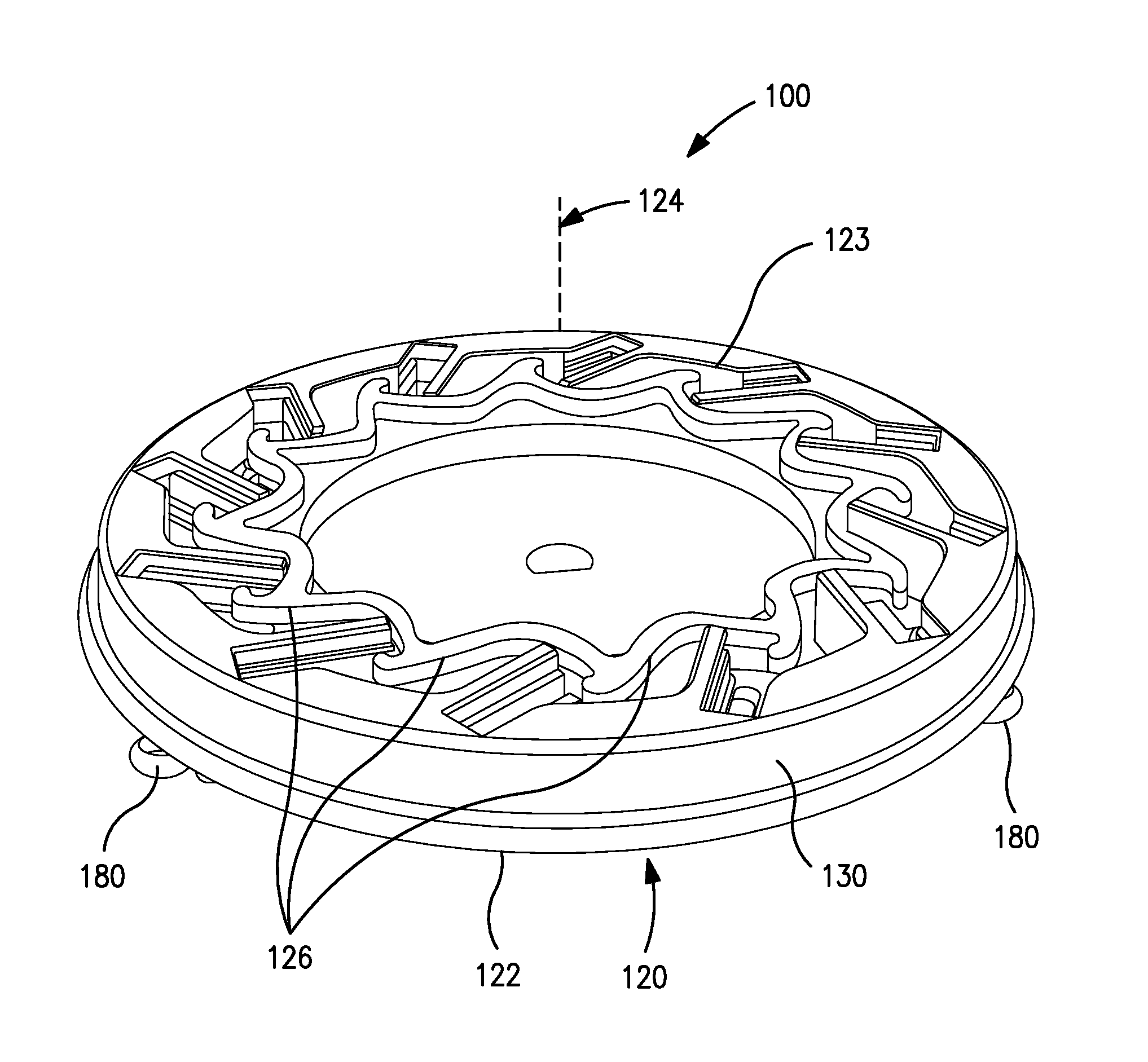

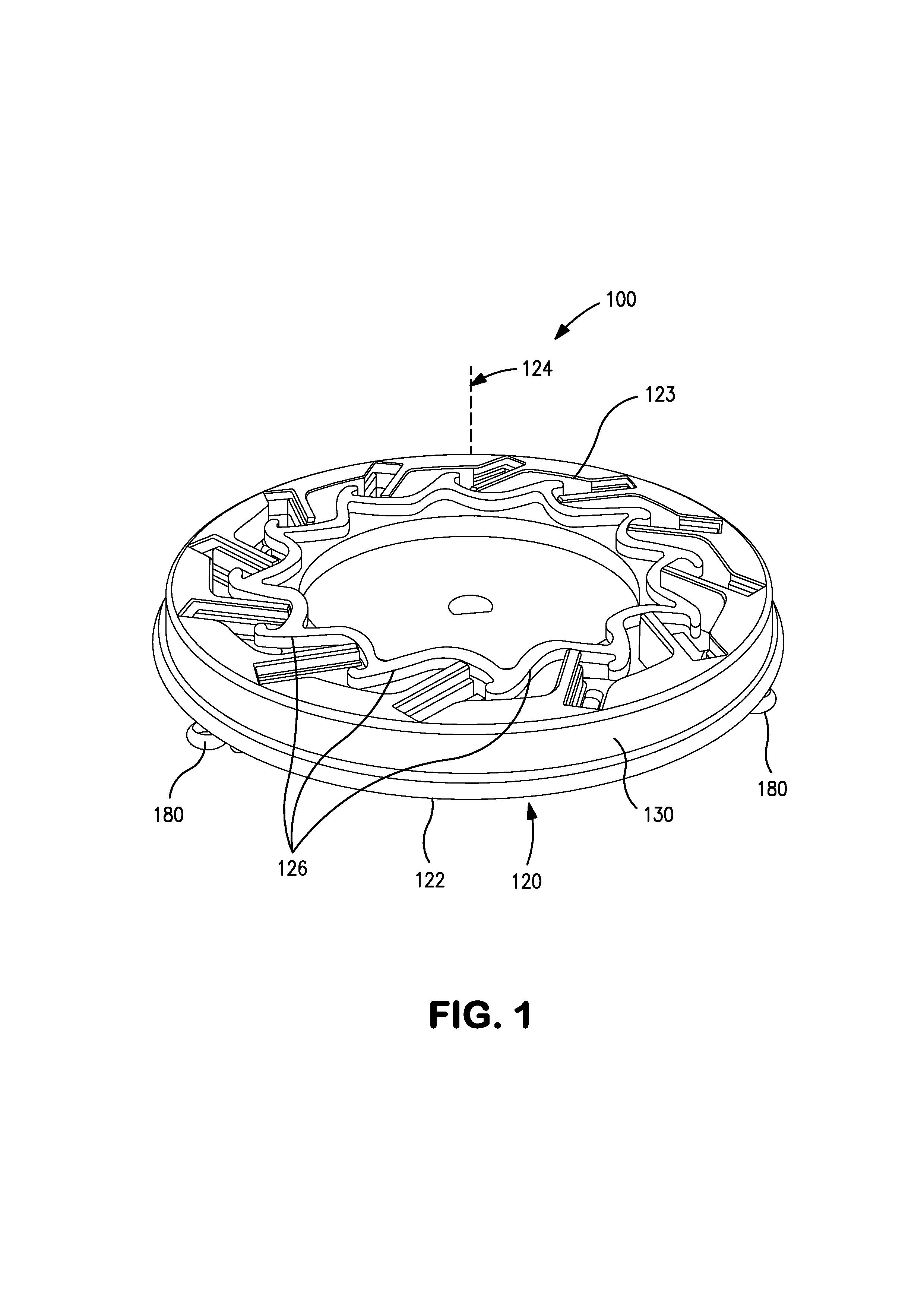

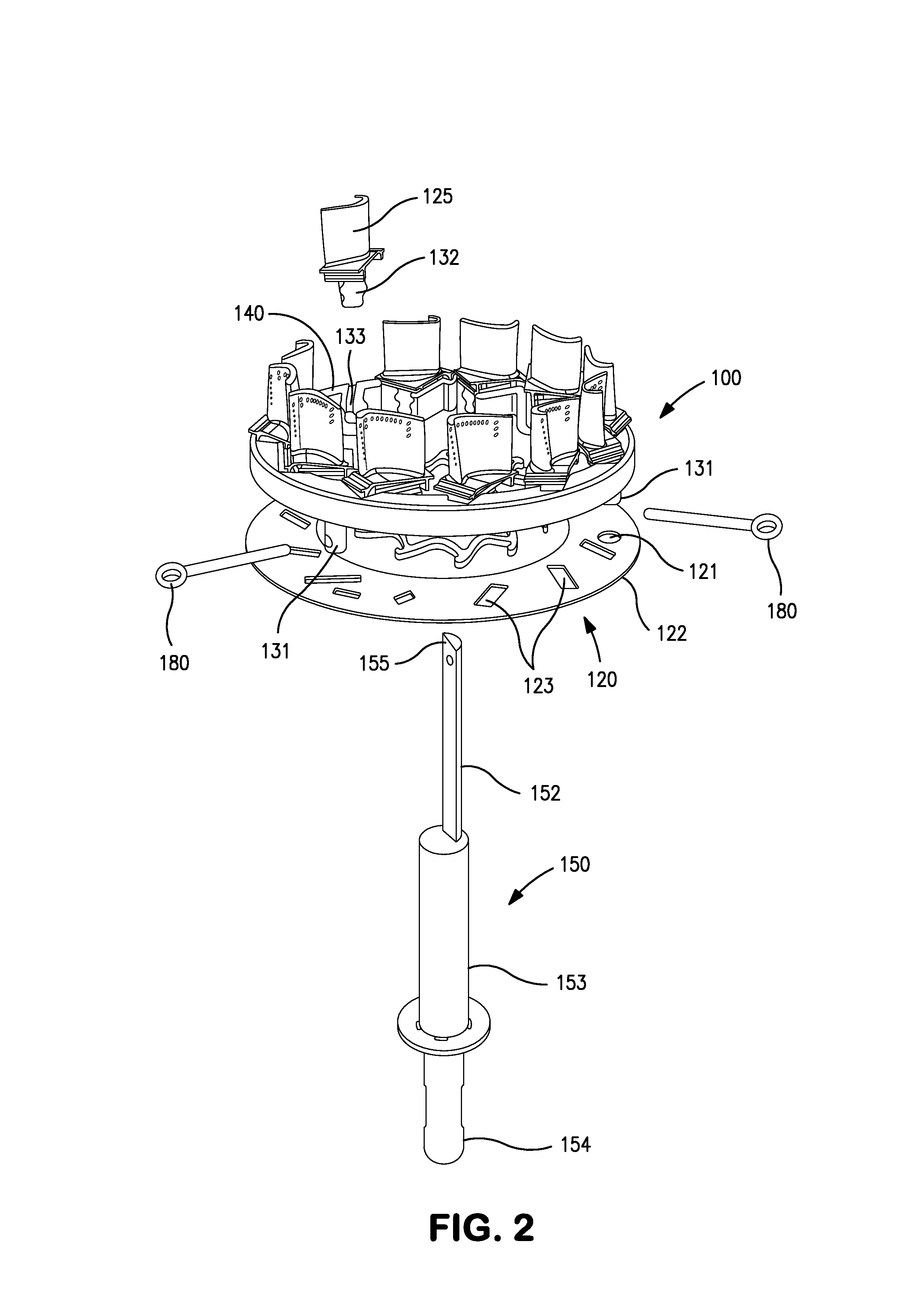

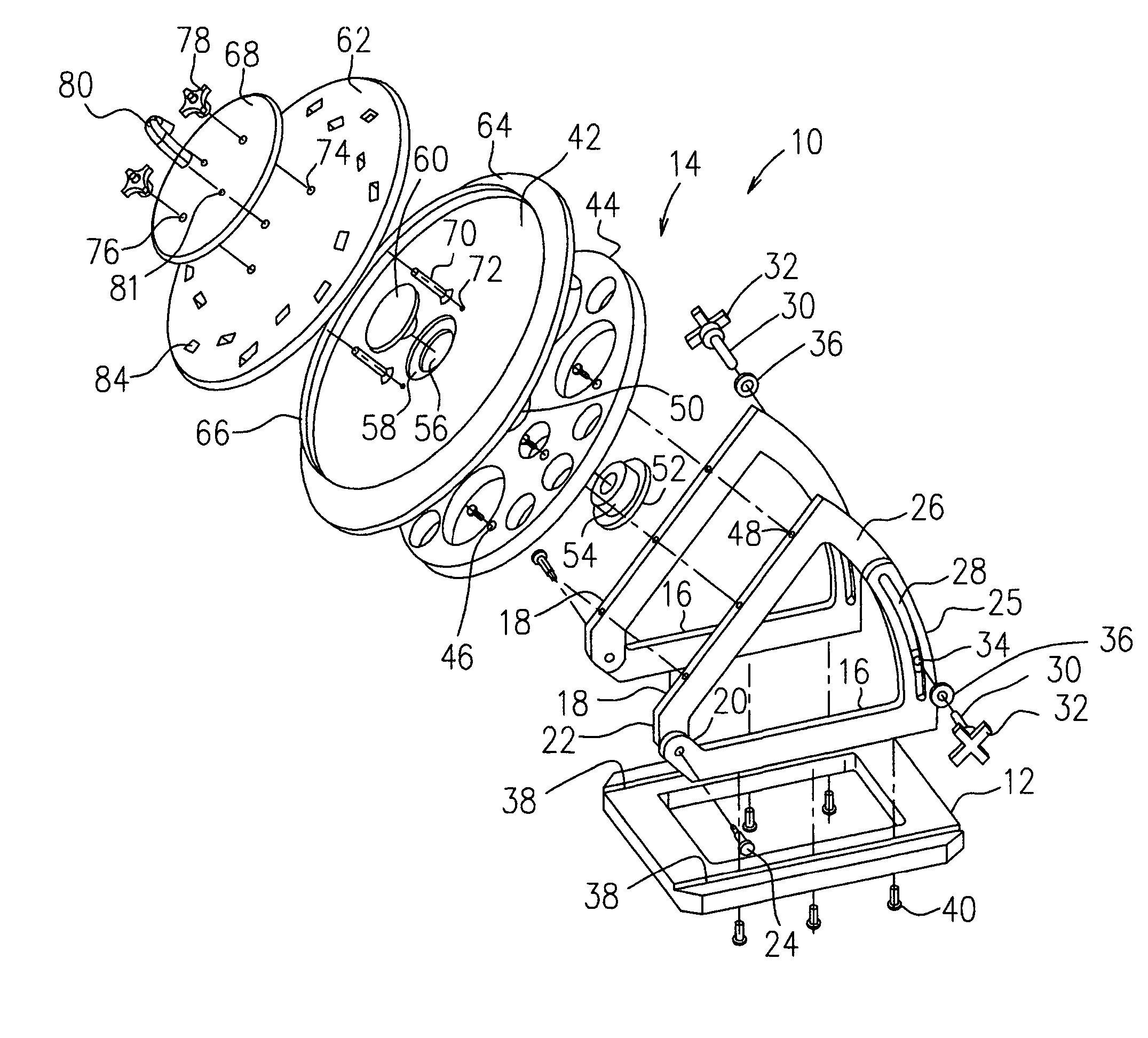

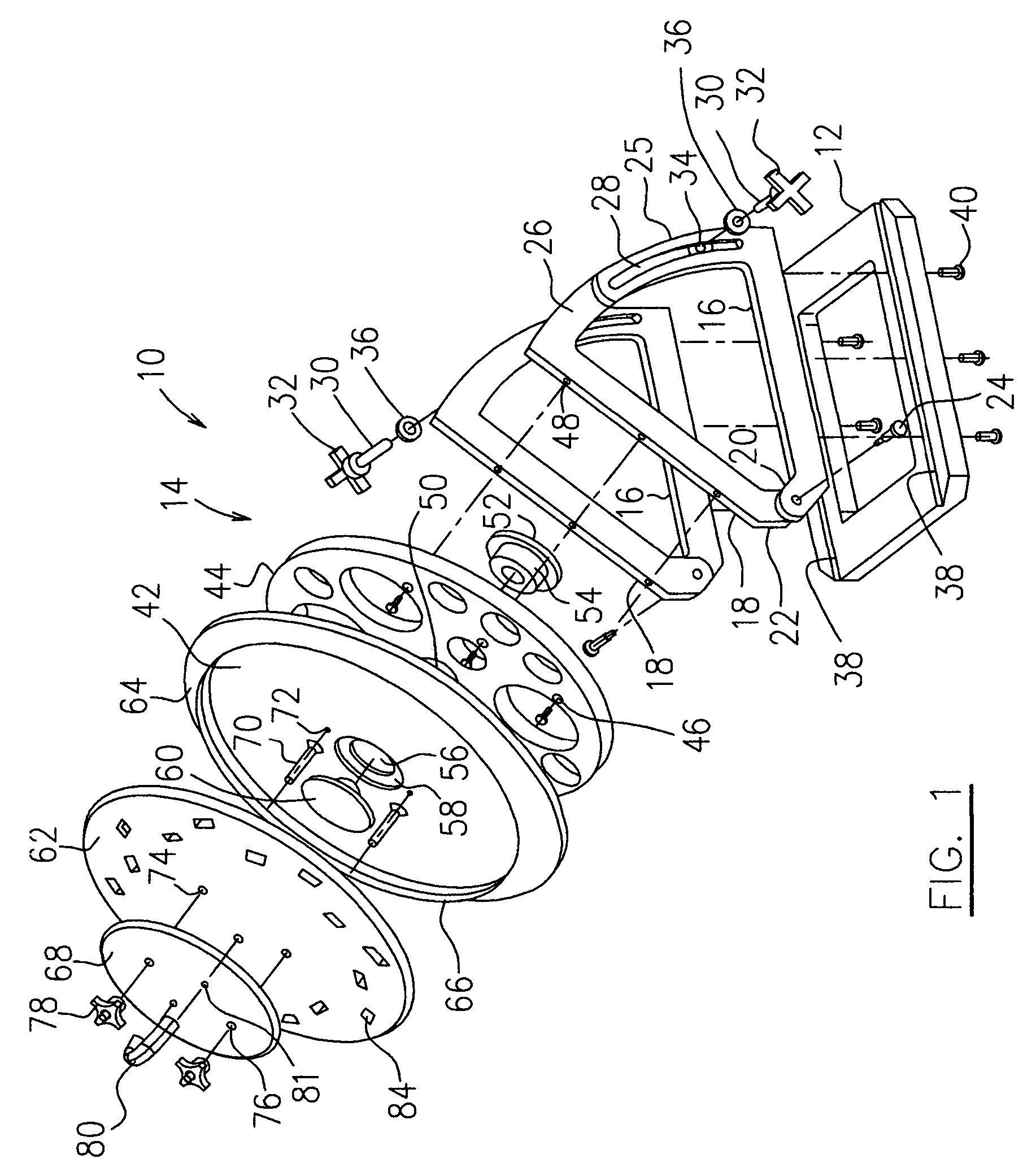

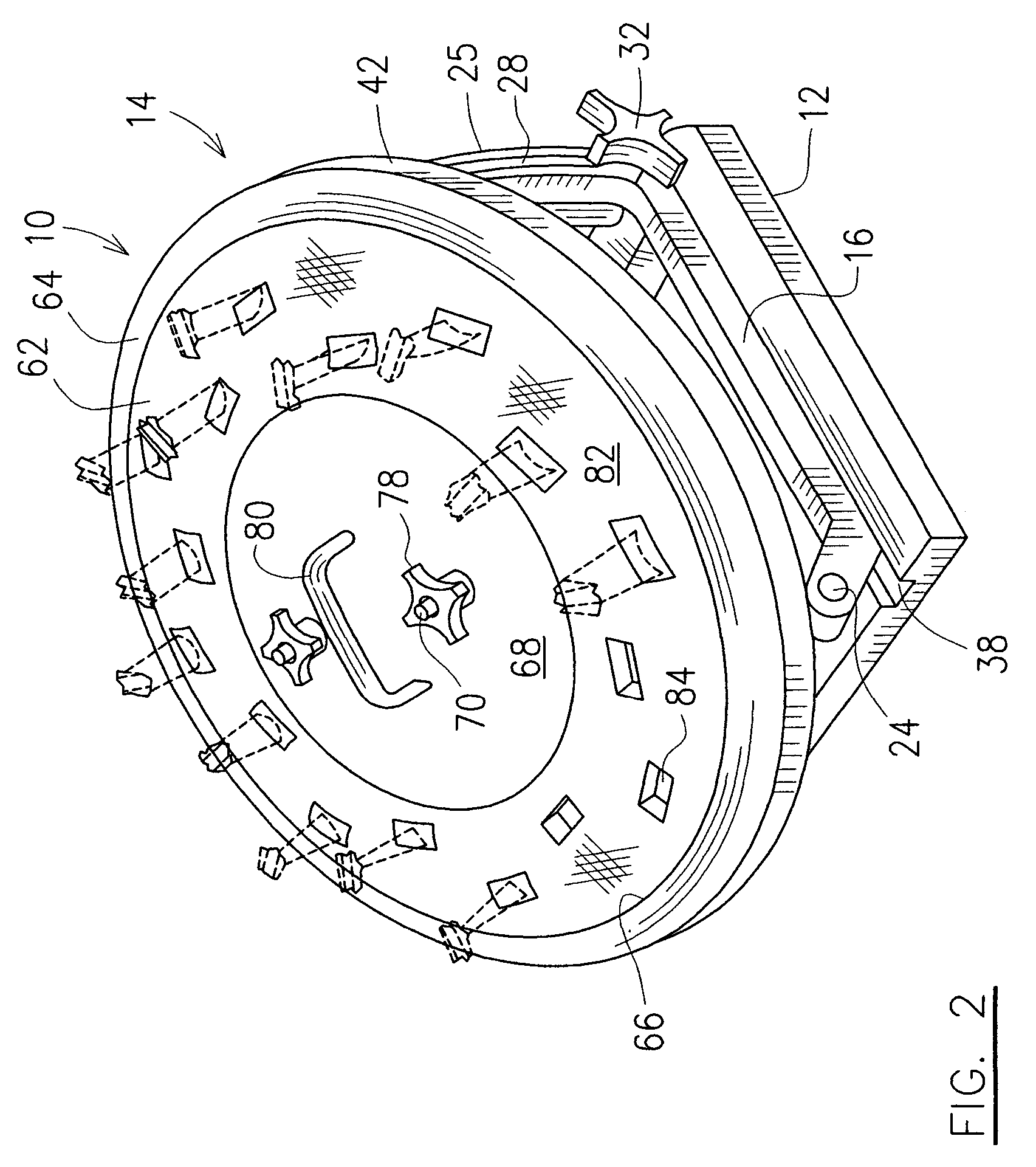

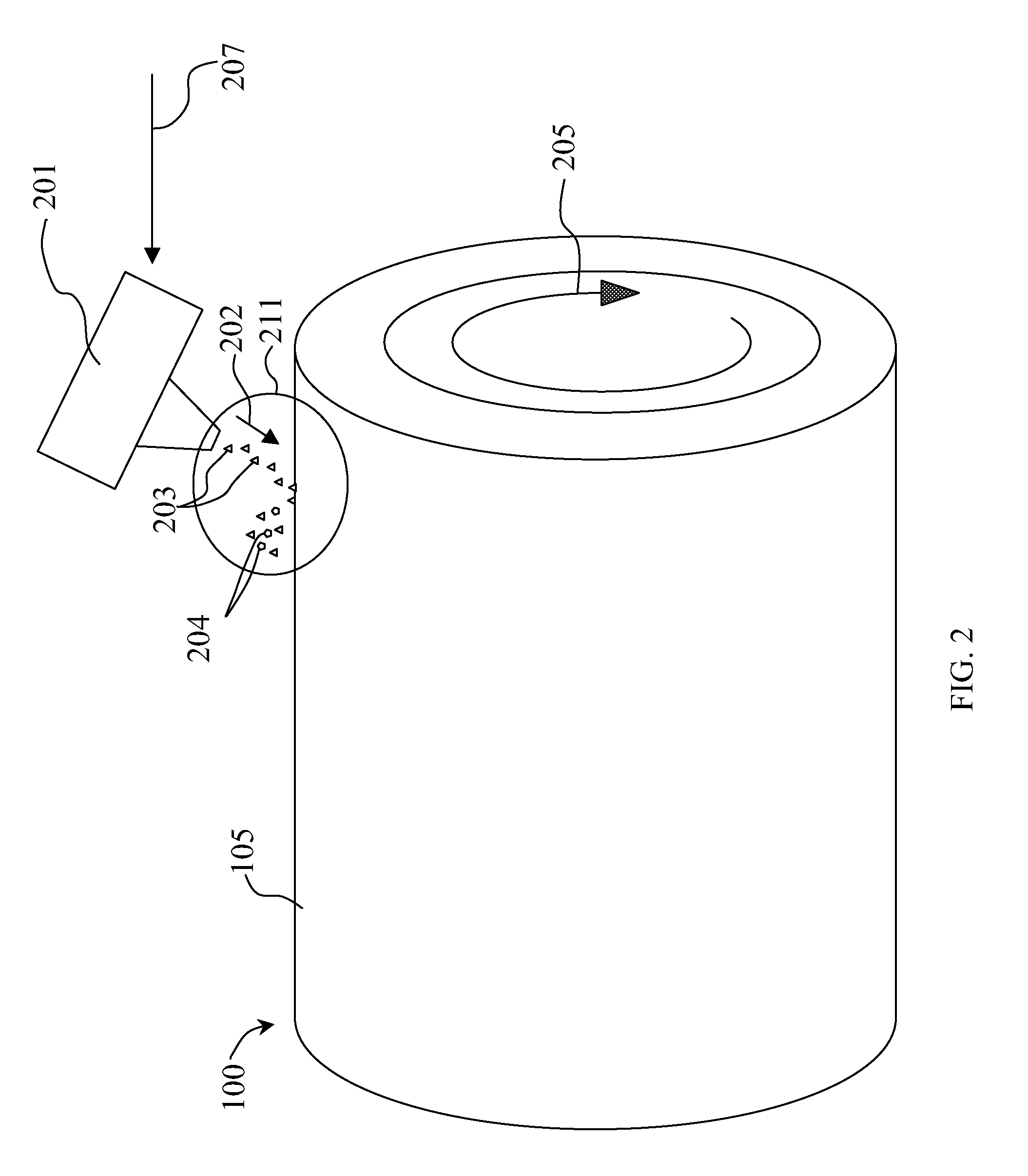

Multifunction tooling fixture assembly for use in a coating related operations

ActiveUS20130177707A1Vacuum evaporation coatingSputtering coatingMechanical engineeringGrit blasting

A modular, rotisserie type multifunctional tooling fixture assembly is disclosed. The disclosed tooling fixture assembly comprises a positioning ring having a plurality of anchor members configured or adapted to retain a plurality of workpieces to be processed, and a retaining base defining a plurality of retaining members configured to be in locking engagement with the anchor members of the positioning ring and retain a plurality of workpieces in a fixed orientation. The tooling fixture assembly has utility in various coating related processes, including coating and grit blasting operations.

Owner:PRAXAIR ST TECH INC

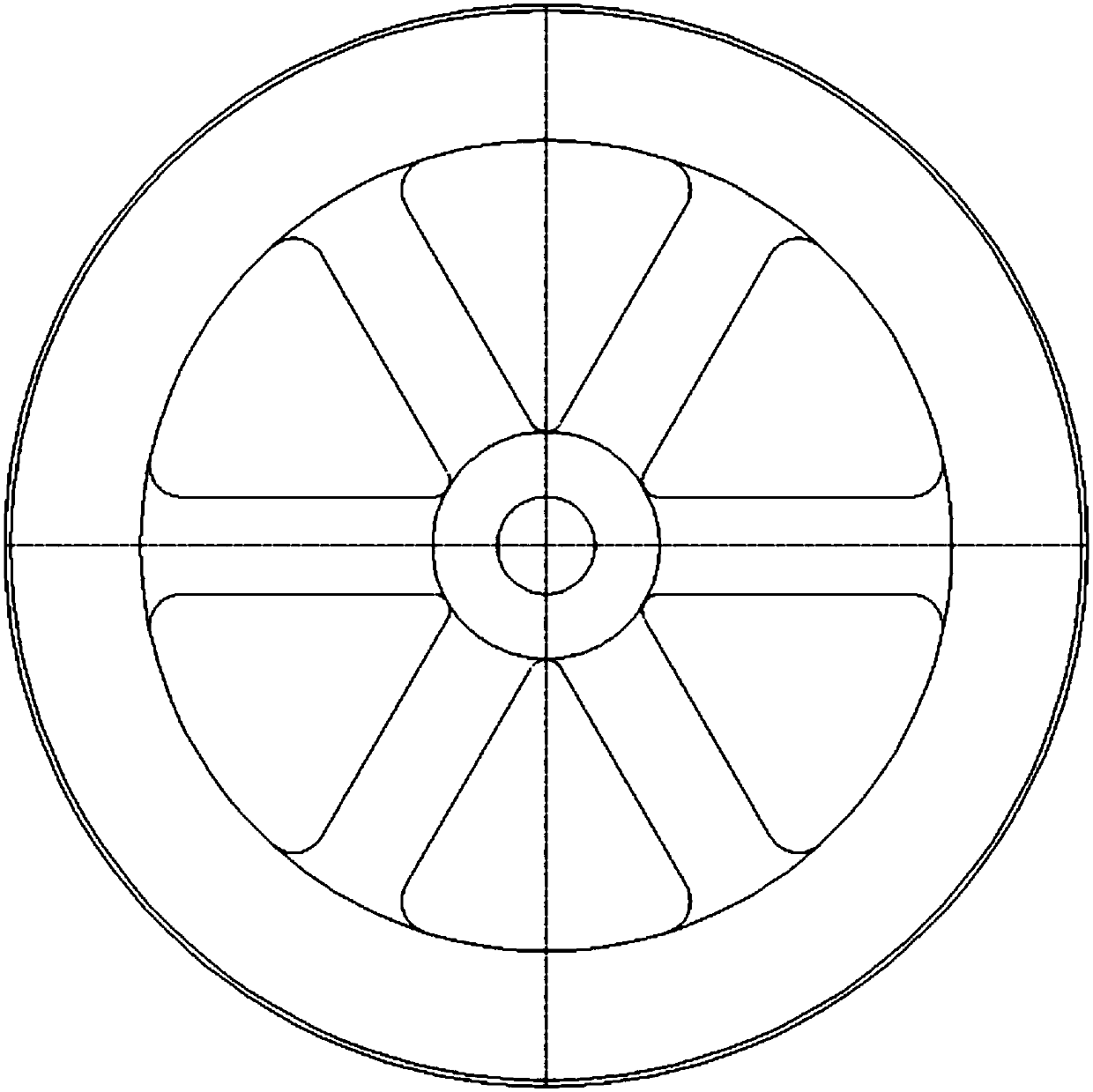

Bidirectional injection moulding method of stator rubber of screw drilling tools

The invention discloses a bidirectional injection moulding method of stator rubber of screw drilling tools, which belongs to the technical field of stator rubber injection of screw drilling tools andcomprises the following steps: grit-blasting; washing and drying; brushing adhesive; assembling a mould core into an internal hole of a steel pipe; putting a stator and an injection moulding mould inan oven and heating; carrying out vacuum negative-pressure rubber injection from two ends to the center of the stator; sealing the stator and putting the stator in a vulcanizing boiler to carry out vulcanization; taking out the stator and cooling; disassembling screw nuts, end caps and shims used for positioning on two ends of the stator, and pushing the mould core out of the rubber layer of the internal hole of the stator so as to be disengaged. The rubber injection method from two ends to the center of the stator prevents rubber from pressing the mould core to cause linear deformation of themould core, fundamentally eliminates the wrapping extent and the core shift of the rubber layer hole in the internal hole of the stator, greatly prolongs the service life of the stator, reduces air bubbles in the rubber layer of the stator and defects on the surface, such as pits, flow marks and the like and increases the qualification rate. The method overcomes the defects of low speed and longtime of rubber injection.

Owner:南京金三力橡塑有限公司

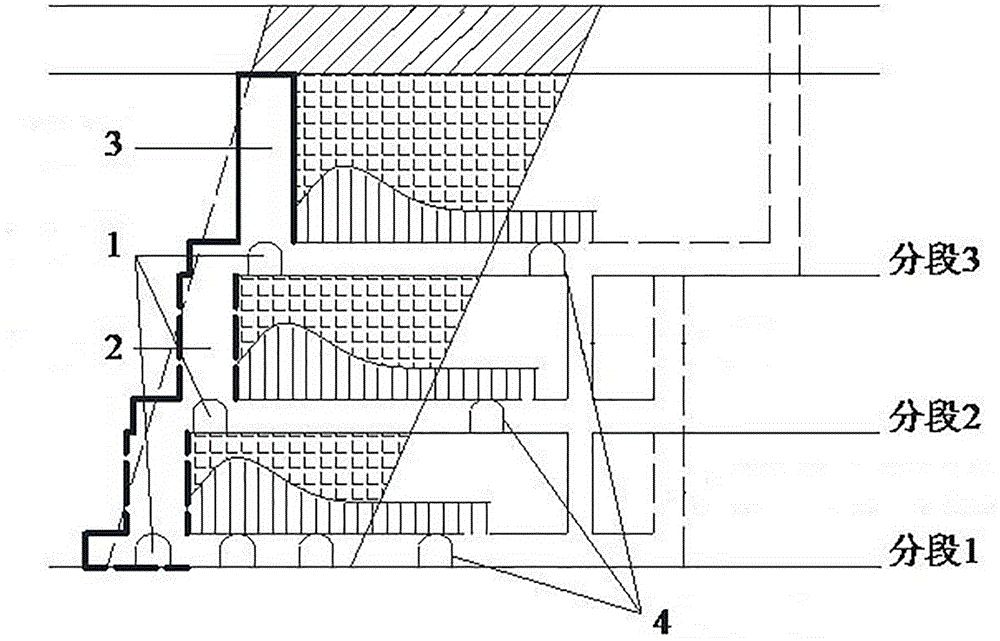

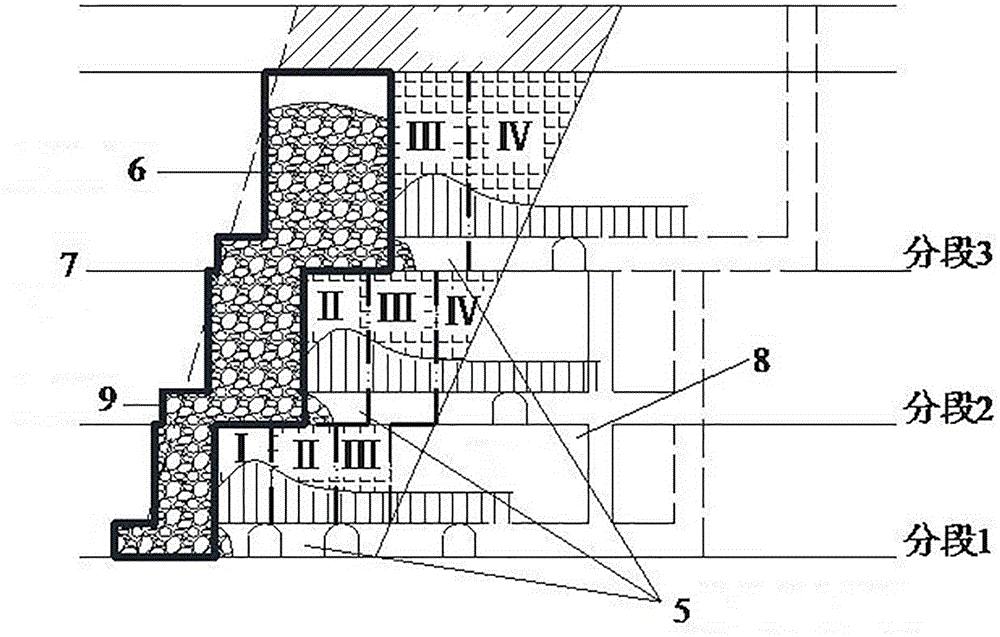

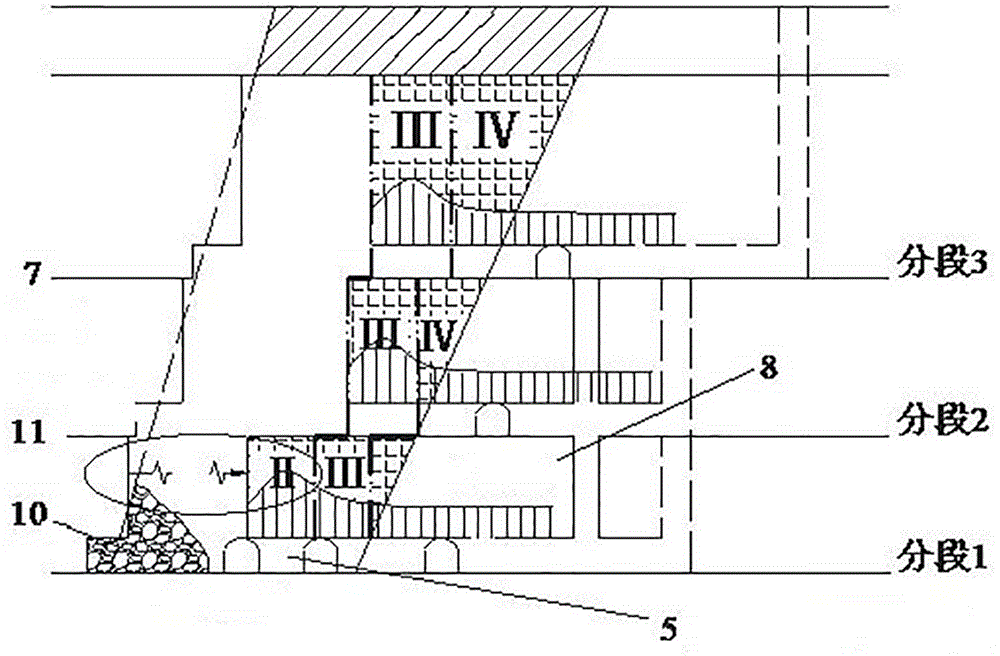

Sublevel-open-stoping-method pressure-relief stoping method for high-dipping medium-thick ore body

InactiveCN107178367AExtend recovery timeAccelerate recovery cycleDisloding machinesUnderground miningDetonationRock blasting

The invention belongs to the technical field of mining, and particularly relates to a sublevel-open-stoping-method pressure-relief stoping method for a high-dipping medium-thick ore body. The method achieves pressure-relief type stoping by means of the steps that a cut parvis is formed through blasting in groups, and then the ore body is divided into three subsections in the vertical direction of the ore body; the ore body is divided into a plurality of stopes in each subsection, and each stope is divided into I-VI rows of grouped concentrated blasting subareas to conduct blasting in groups; broken ores are formed after blasting is conducted, a route for transmitting hanging wall stress to heading wall through the ore body is cut off, and pressure-relief grooves in stair shapes are formed in the vertical direction of the ore body. In addition, through multi-group concentrated blasting, a hole-by-hole millisecond blasting detonation technology is adopted, disturbance and damage to rock mass caused by multi-group blasting of traditional operation are reduced, the blasting efficiency is enhanced, the stope room stoping period is shortened, and the ore production efficiency is enhanced.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Metal tube taking plastic tube as liner and manufacturing method of metal tube

ActiveCN106907530AImprove water flow capacityImprove water delivery efficiencyCoatingsRigid pipesCooking & bakingHeating time

The invention provides a metal tube taking a plastic tube as a liner and a manufacturing method of the metal tube. The metal tube taking a plastic tube as a liner comprises a metal tube and a plastic composite tube stock; the plastic composite tube stock is formed by an outer layer hot melting adhesive layer and an inner layer plastic tube; plastic composite tube stock is manufactured online, the inner wall of the metal tube is subjected to sand blasting and shot blasting or grit blasting after being polished, the plastic composite tube stock is pulled into the well-processed metal tube, and the two ends of the plastic composite tube stock are sealed and inflated and are placed in a sealed steam room or baking room to be heated, such that the metal tube and the plastic composite tube stock are adhered fixedly, and trimming and spraying are performed. The invention further comprises a manufacturing method of the metal tube taking a plastic tube as a liner. The sealed steam room or baking room is adopted for heating, the product quality is stable, and percent of pass is high; a plurality of or even different models and types of tube stocks can be heated simultaneously, the total heating time is less, the production efficiency is high, the energy consumption cost for product heating can be saved, plants and production devices for production can be saved more, and investment cost is reduced.

Owner:肖和飞

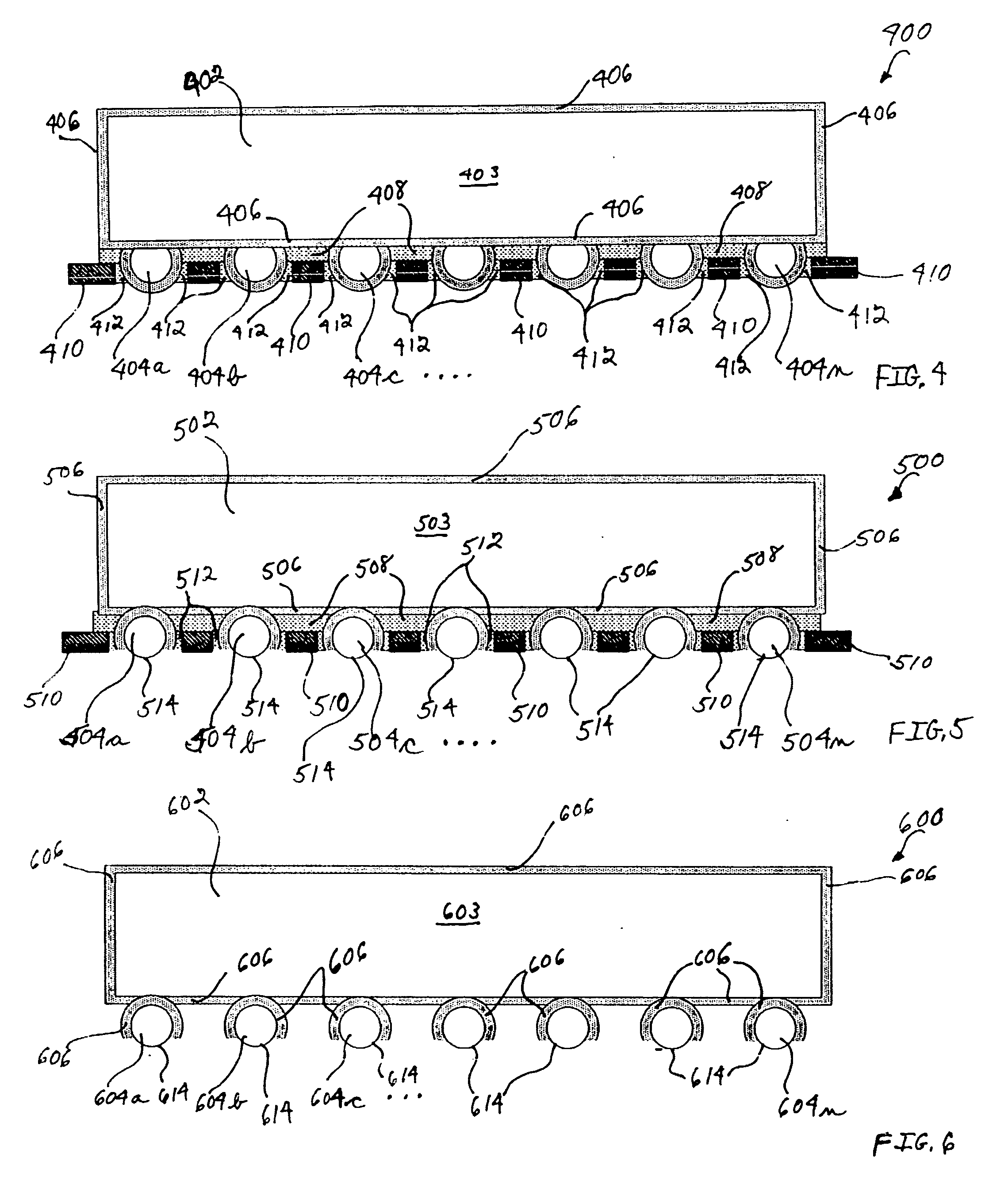

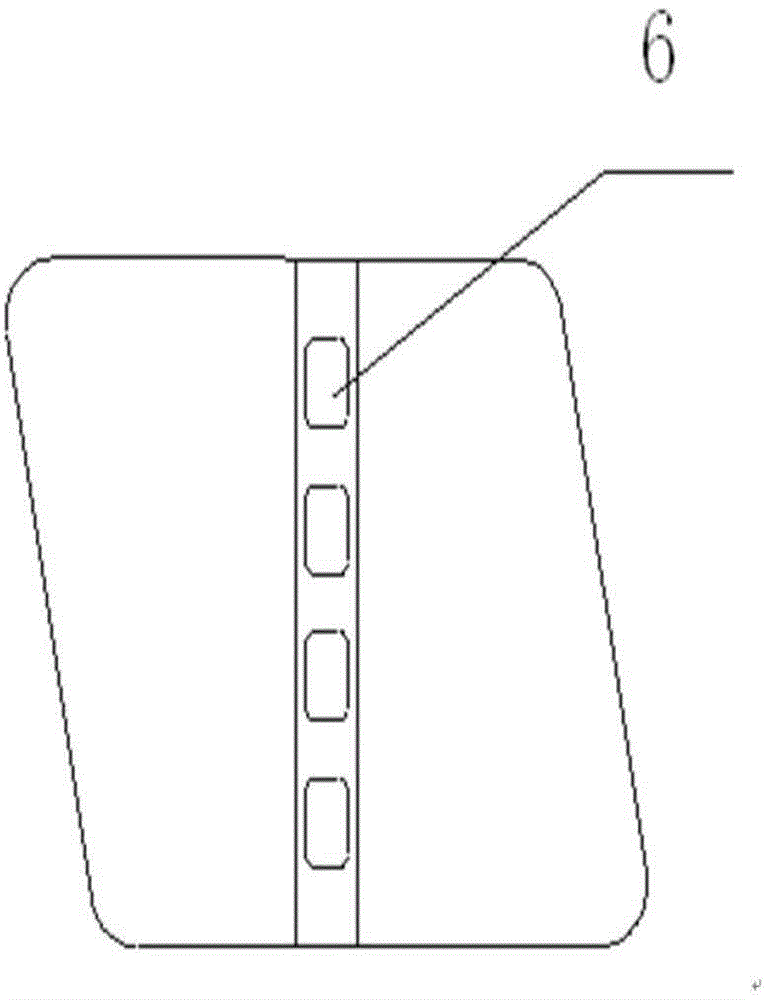

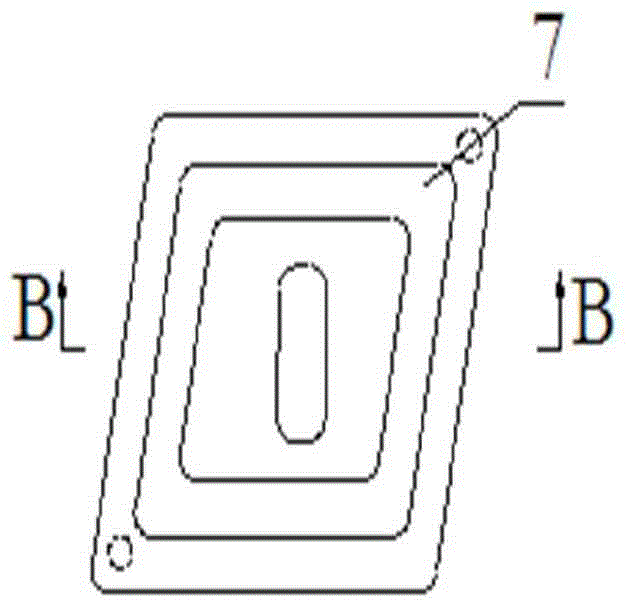

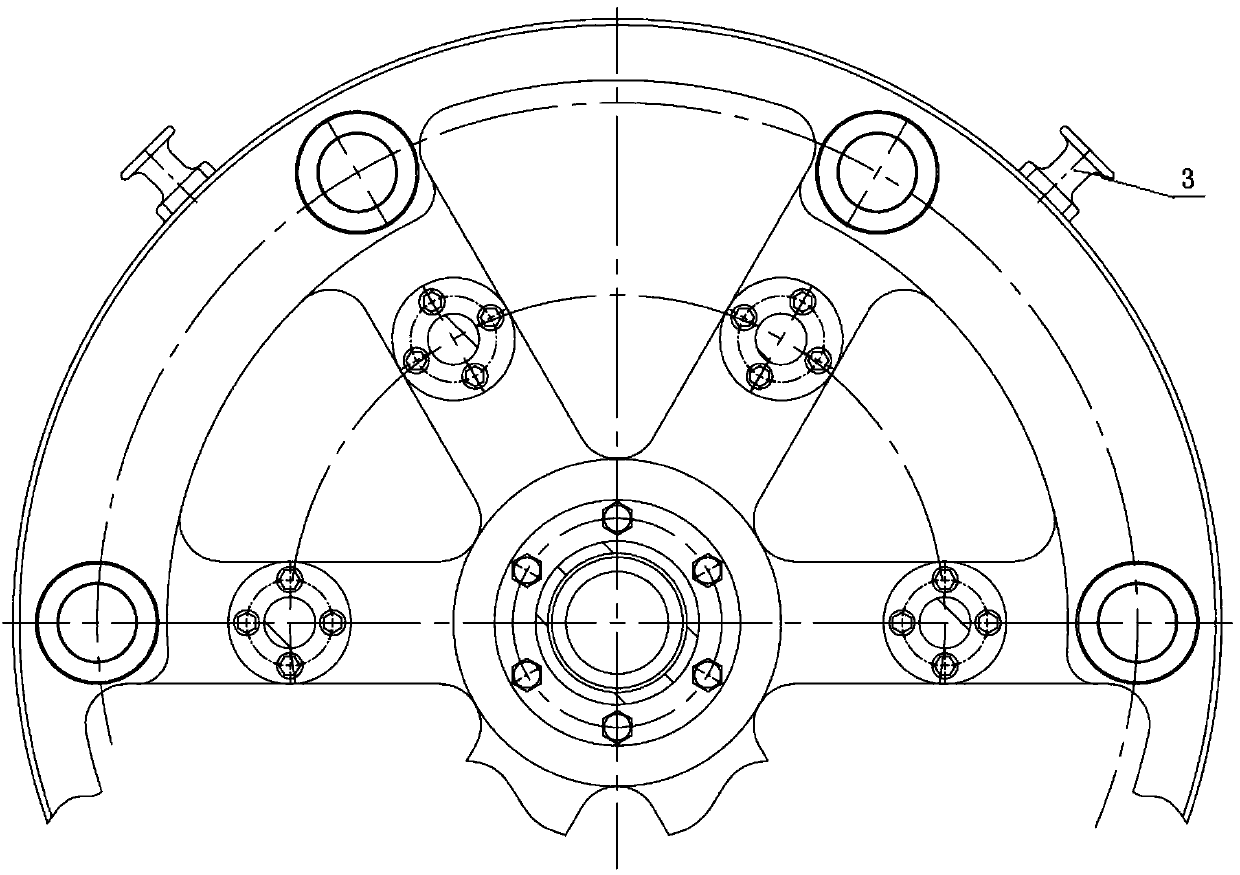

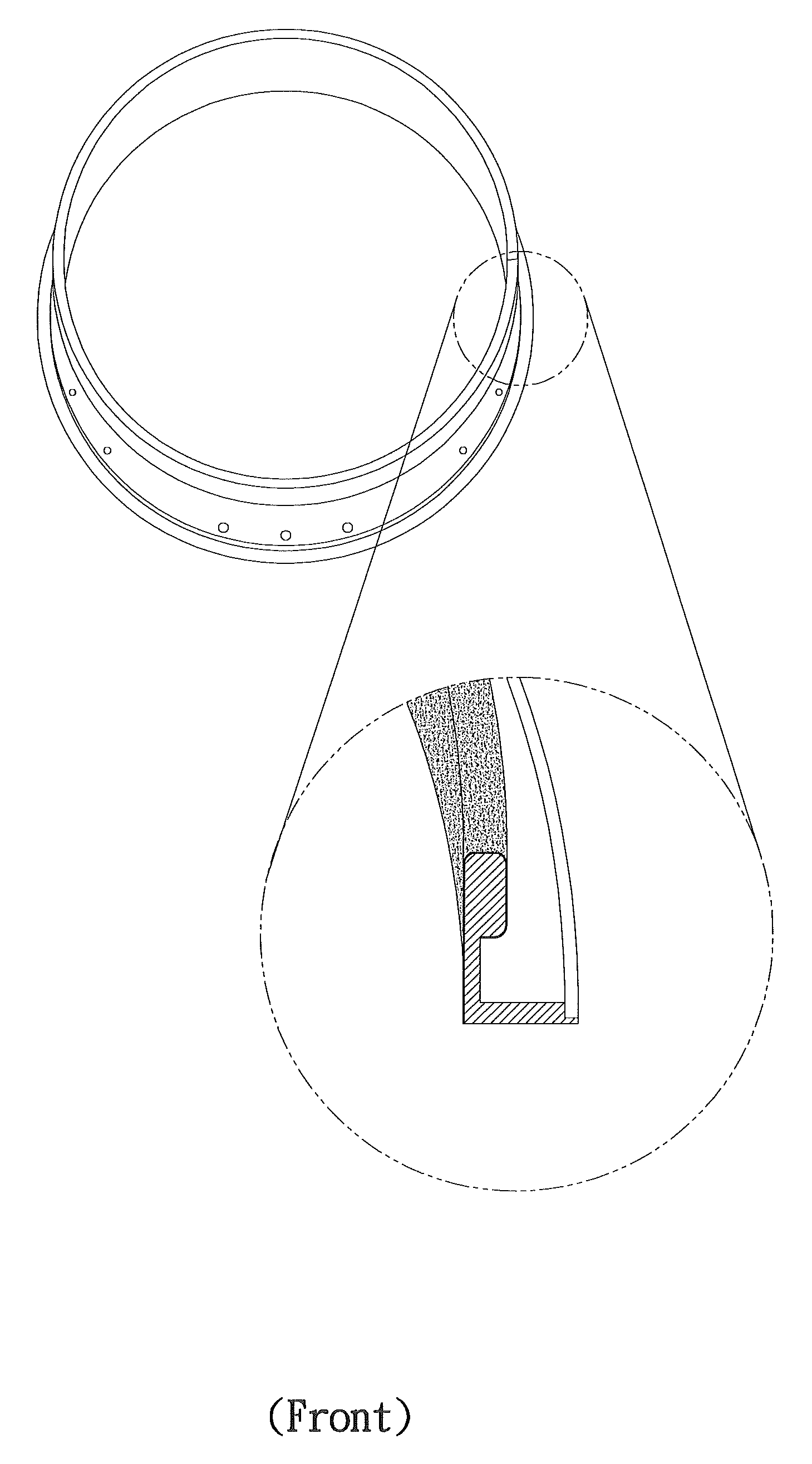

Apparatus for supporting airfoils in a grit blasting process

ActiveUS7207869B2Low costLoading and unloadingAbrasive blasting machinesGrinding work supportsSand blastingGrit blasting

Owner:PRATT & WHITNEY CANADA CORP

Extrusion forming method for blade made of GH2787 high-temperature alloy

ActiveCN103586391AReduce manufacturing costsShorten the development cycleEngine componentsSolution treatmentSuperalloy

The invention discloses an extrusion forming method for a blade made of GH2787 high-temperature alloy. The extrusion forming method comprises the first step of heating a billet electric furnace to 1000-1050 DEG C, keeping the temperature for 3 minutes and performing direct extrusion forming on the blade, wherein according to the deformation amount of the blade, the head of the blade is 20%-30%, and the extrusion ratio of the body of the blade is 5-7; the second step of clearing the surface of a forge piece in a grit-blasting mode, the third step of performing vibrating finishing, clearing the surface of the forge piece and improving the roughness and light integrity of the surface of the forge piece, and the fourth step of performing solution treatment and aging treatment on the forge piece, wherein the temperature of the solution treatment is 940+ / -10 DEG C and is kept for 1-2 hours, then air cooling is performed on the forge piece, the temperature of the aging treatment is 780+ / -10 DEG C and is kept for 16 hours, and finally air cooling is performed on the forge piece. Compared with a traditional precision forging forming technology, the extrusion forming method has the advantages that four sets of tool design and manufacture are saved, the costs of the tool manufacture are saved by close to RMB 80,000 yuan, and meanwhile the preparation time of the blade is shortened; due to the facts that the forge piece of the blade is designed by adopting the method of adding allowance in equal proportion, and the allowance for machining the single surface of the blade is only 0.3+ / -0.2mm, the use rate of the material is enhanced.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

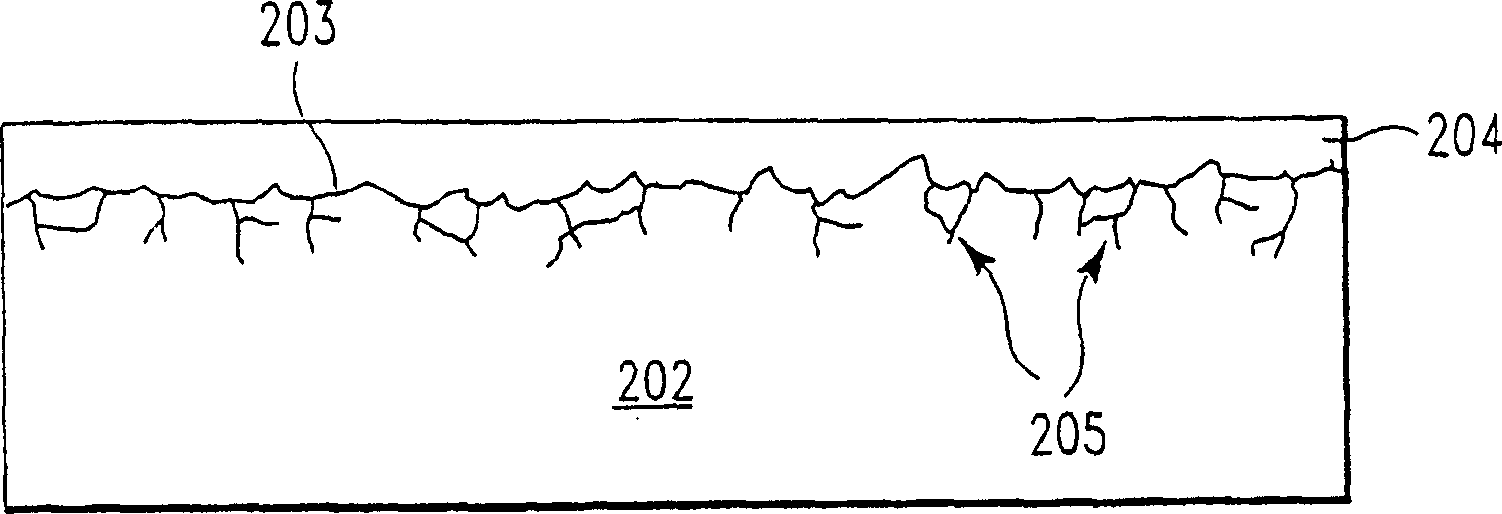

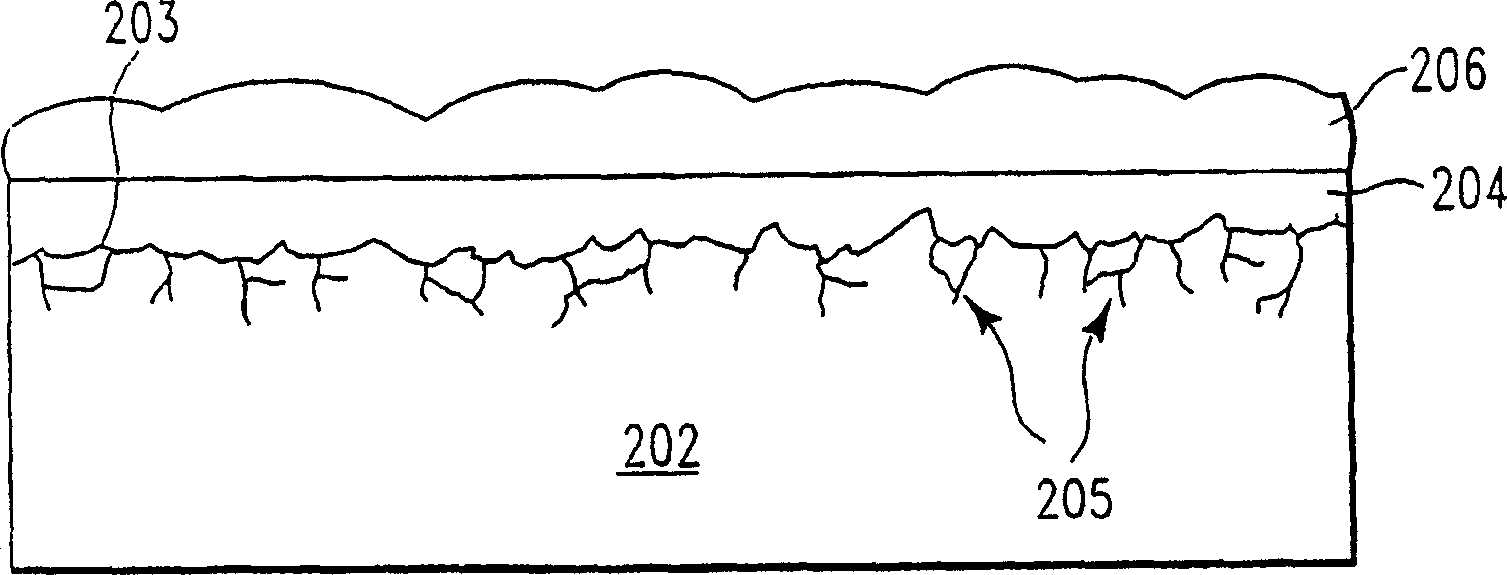

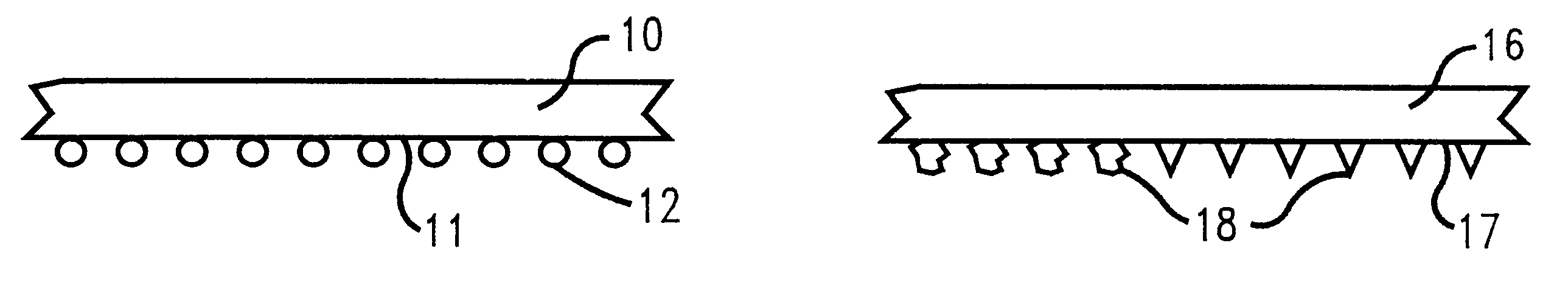

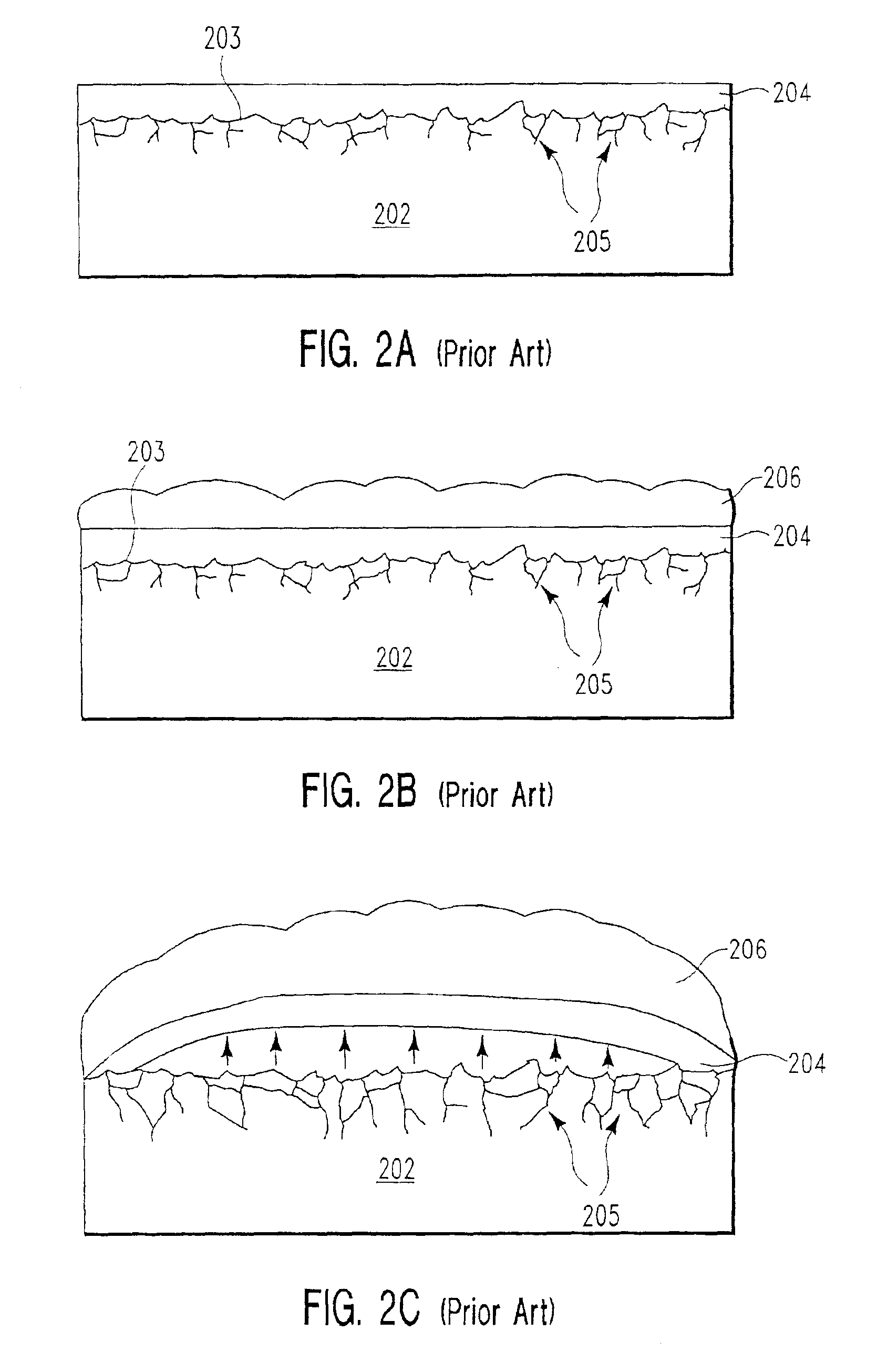

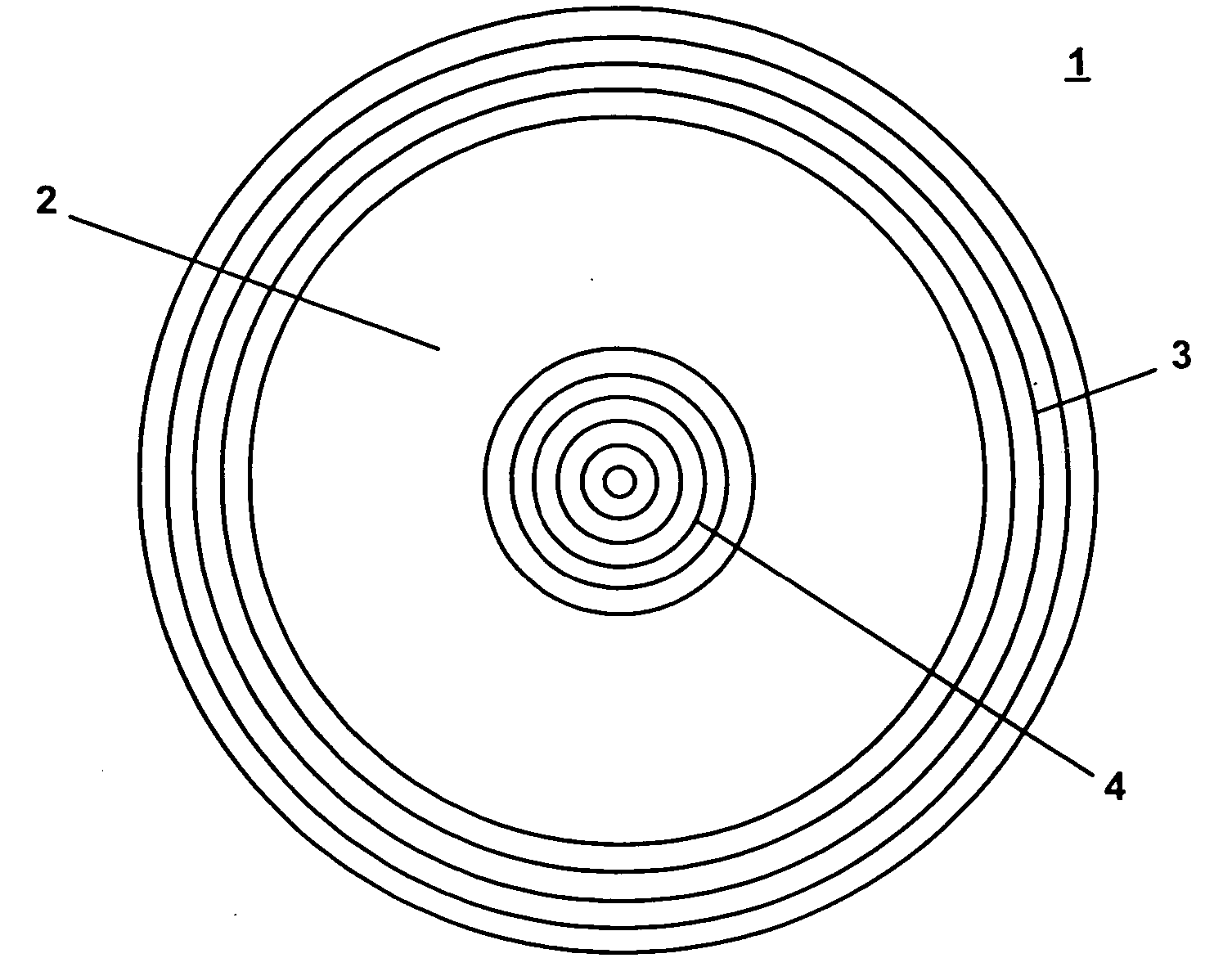

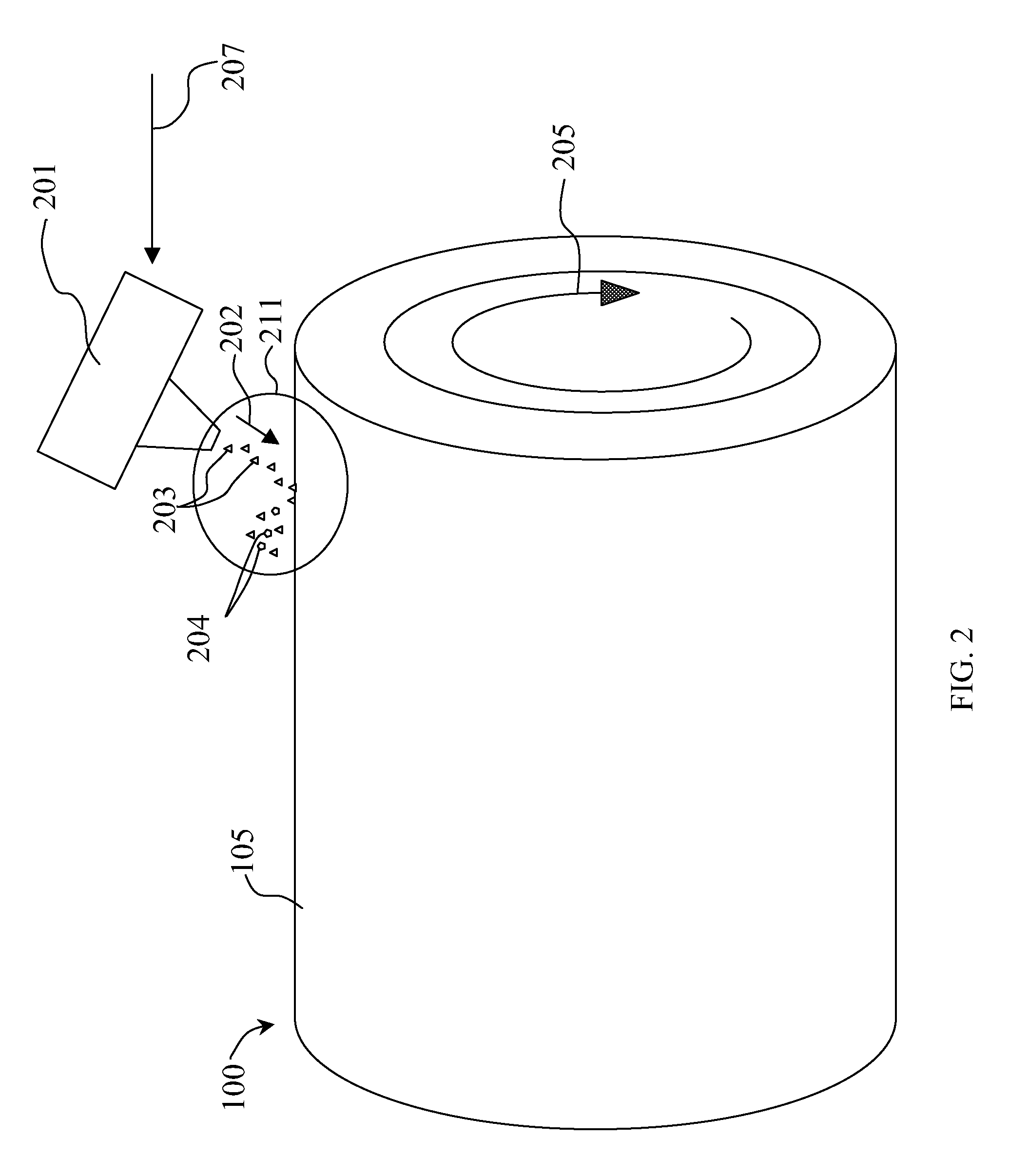

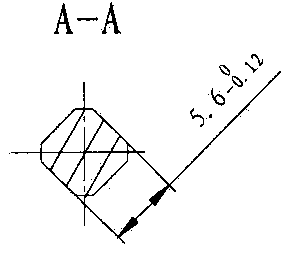

Cylinder liners and methods for making cylinder liners

InactiveUS20070277771A1Remove undesirable surface effect surfaceEliminate surface defectsCylinder headsCylindersMechanical bondCylinder block

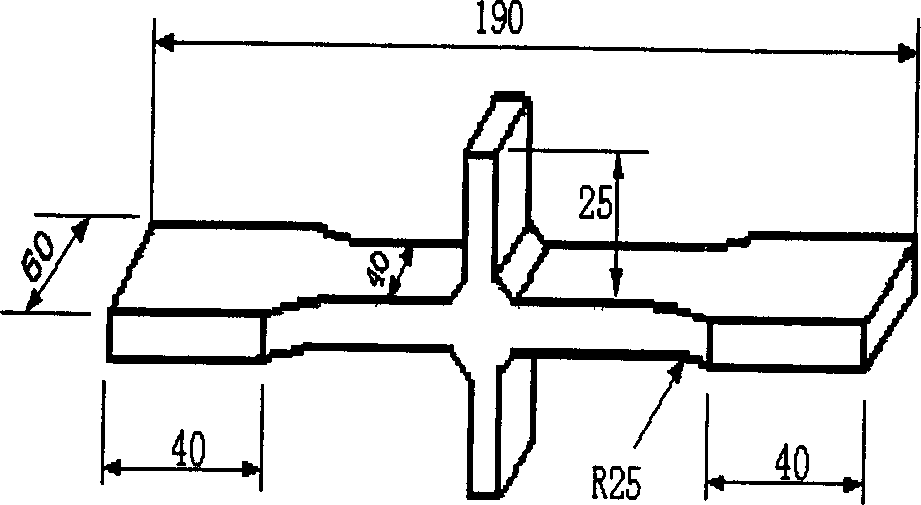

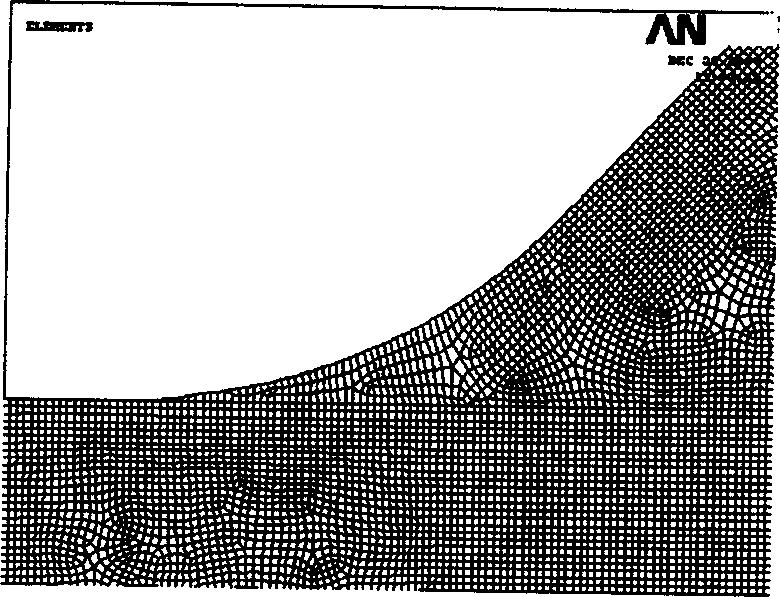

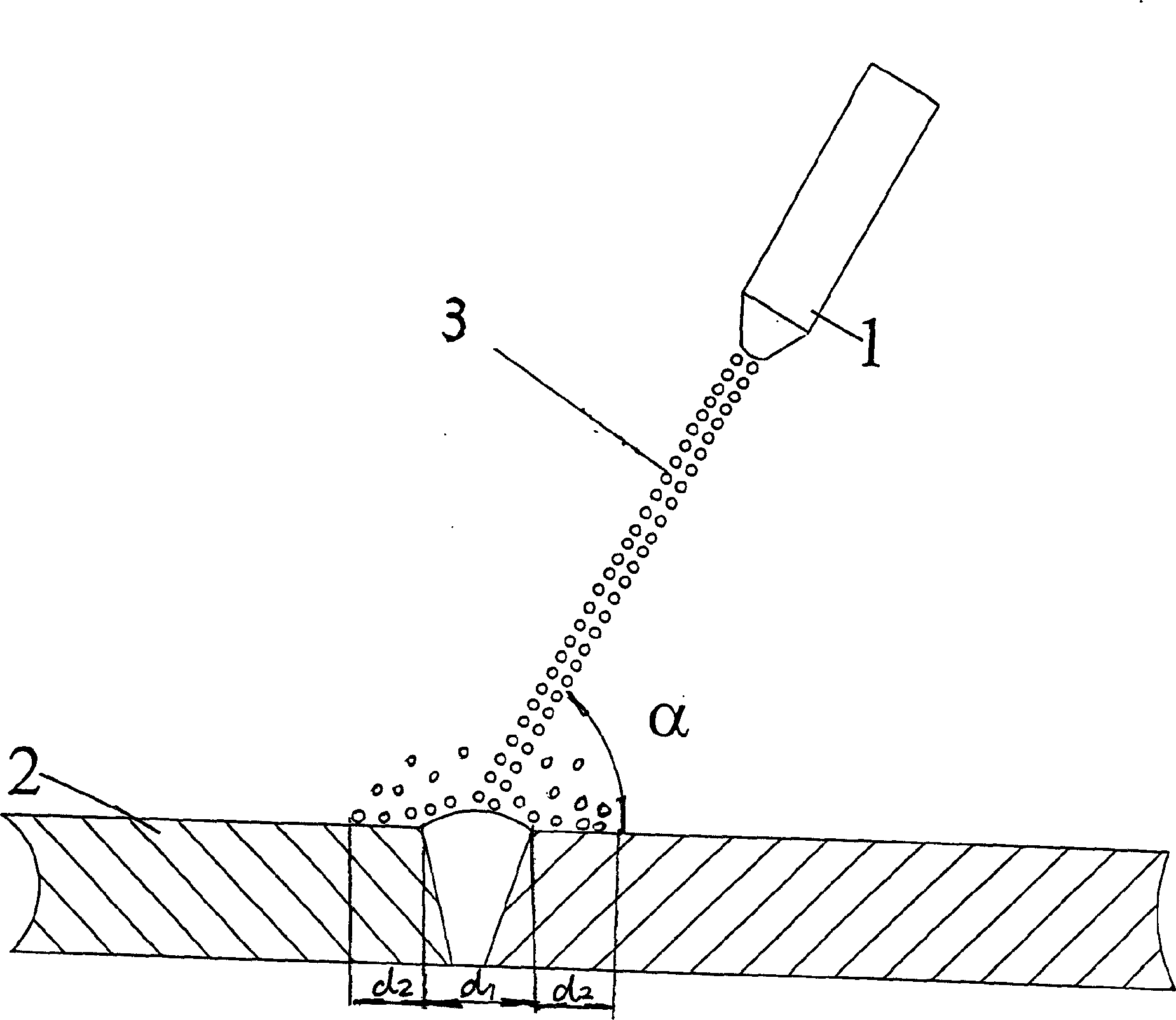

A method for making cylinder liners and cast engine blocks having cylinder liners having a strong mechanical bond with the engine block. The method includes providing a cast metallic cylinder liner having an outer surface of the cylinder liner. The surface of the cylinder liner is preferably machined to remove surface effects or defects present from the casting process. Grit particles are directed at the outer surface of the cylinder liner with a grit blasting device at a predetermined angle of contact at a sufficient velocity to form cavities on the outer surface. The cavities that are formed have a geometry capable of forming a mechanical bond with the casting material of the engine block.

Owner:SLINGER MFG

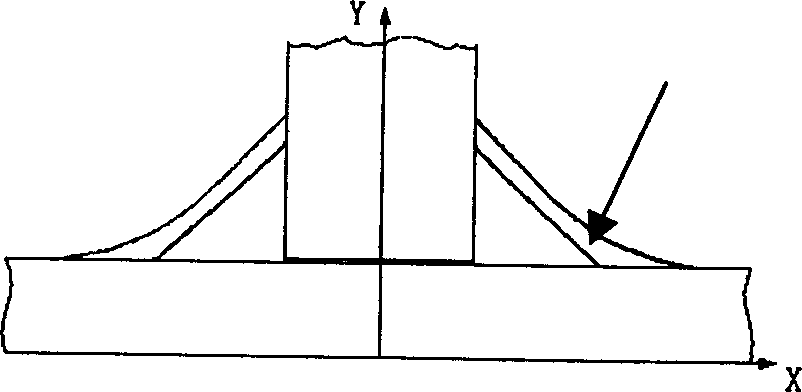

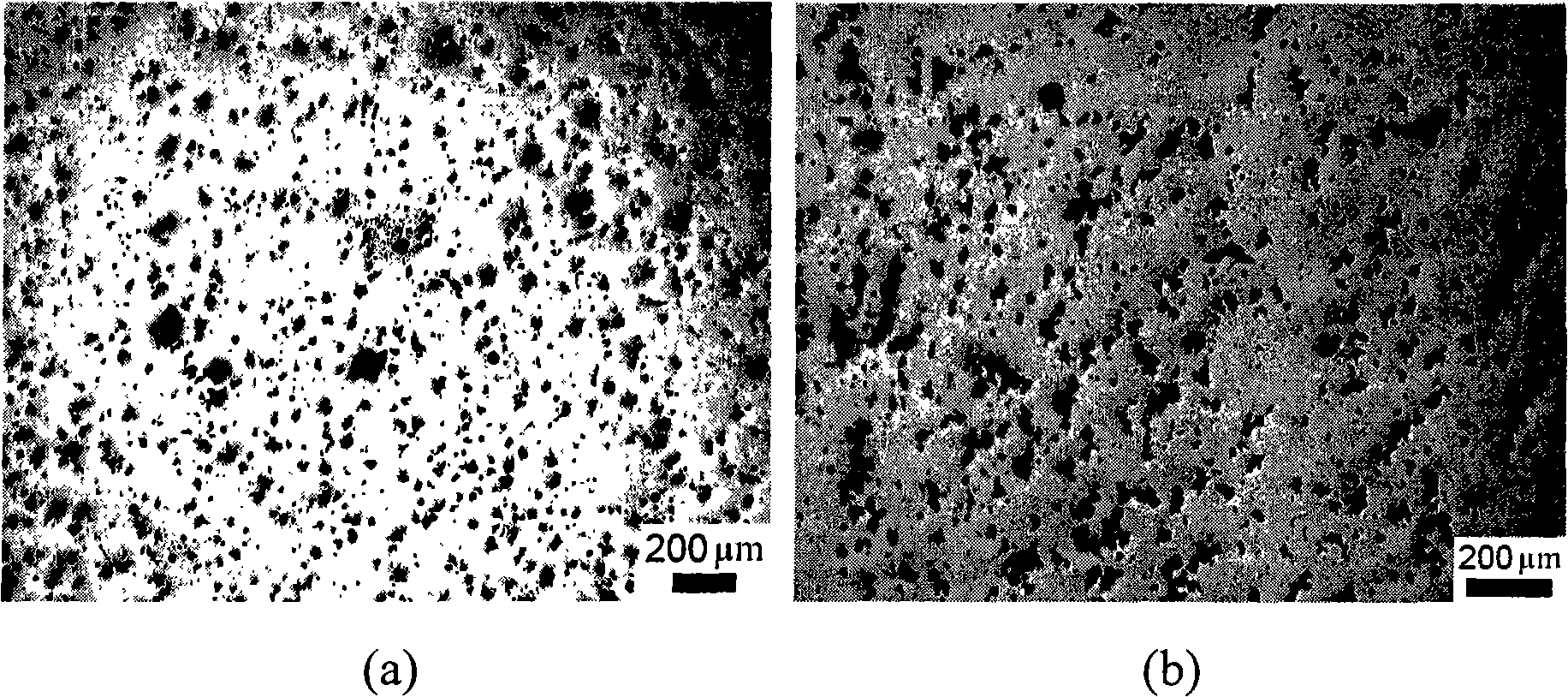

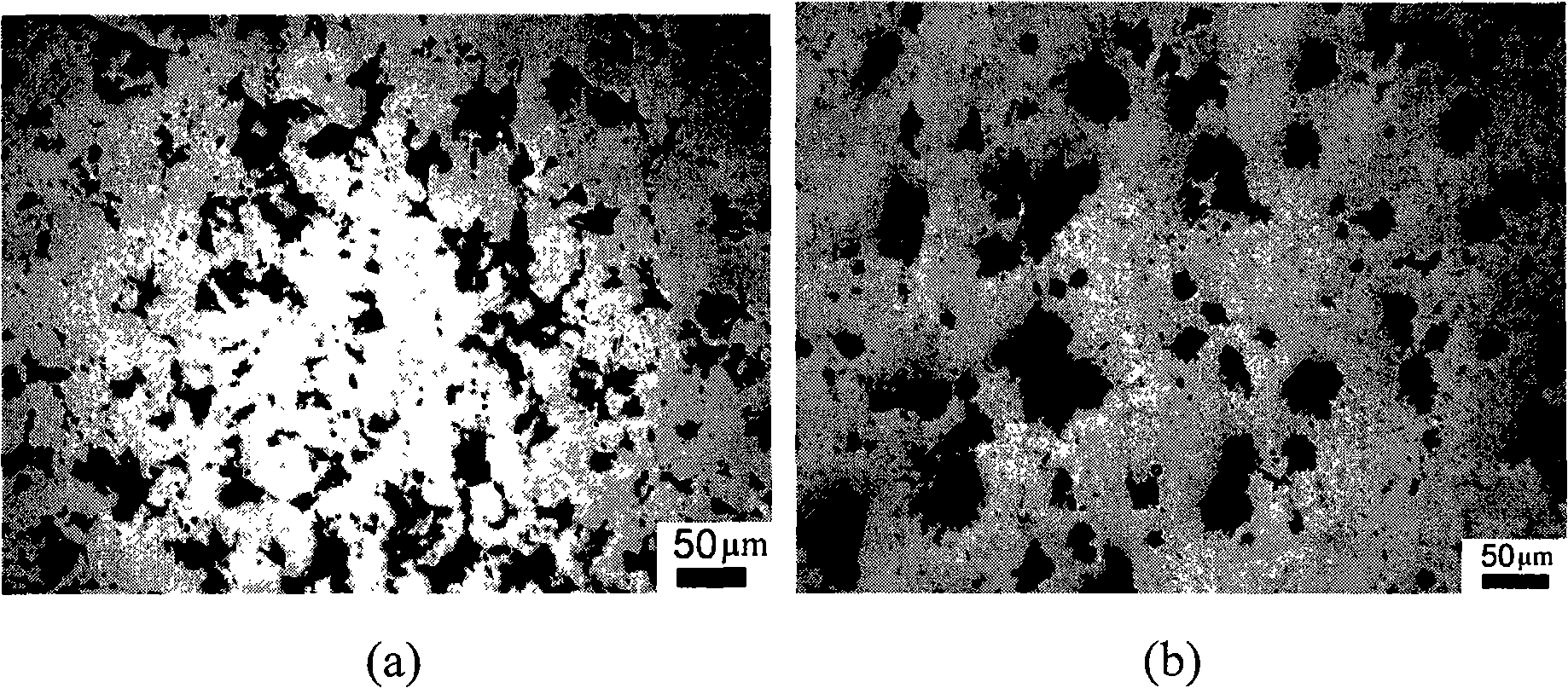

Plasma spraying method for improving fatigue performance of welded structure

InactiveCN1670237AImprove fatigue performanceImprove fatigue strengthMolten spray coatingStress concentrationUltimate tensile strength

The invention discloses a plasma spraying method for improving the endurance feature of welded structures in the invention, applied to a plasma spraying process in spraying coat on the surface of brazing seam, which is comprised the following steps: a. gritting blasting in the brazing seam of specimen; b. plasma spraying bound substratum on the surface of the brazing seam for 0.03mm to 0.07mm in thickness, the materials of which is selected form Ni / AL, Ni / Cr or McrALY, wherein the M is a transient metal as Fe, Ni, Co or NiCo; c. spraying plasma powder on the brazing seam surface as face coat for 0.8mm to 1.2mm in thickness. The invention improves the endurance feature of the welded structure in such a way of plasma spraying coats of a low elasticity modulus in the weld joint, with which the shape of the cross section can be improved, the stress concentration there can be lower and the endurance strength of the welded structure can be advanced; (b) comparing to the welding specimen, the endurance strength of the invented plasma spraying specimen increases 25.9 percent, while flame spraying specimen increases only 9.7 percent.

Owner:TIANJIN UNIV

Glass cloudburst treatment art for improving anti-stress corrosion performance of welding joint of stainless steel

ActiveCN1757484AImprove stress corrosion resistanceStress Corrosion Resistant StrengtheningAnti stressCloudburst

A glass grit blasting technology for increasing the stress corrosion resistance of the welded seam between stainless steels includes such steps as cleaning the surface of the welded seam, blasting the glass grits onto the welded seam by a blasting gun driven by compressed air and with an inclination by 70-100 deg.C, cleaning the surface of welded workpiece, and detecting the residual stress by X-ray diffractometer.

Owner:NANJING UNIV OF TECH

Plastic surface treatment technique

InactiveCN104017231AMaintain glossImprove appearance gradeMolten spray coatingGrit blastingSurface finishing

The invention relates to a plastic surface treatment technique which comprises the following steps: plastic degreasing, plastic swelling, plastic surface coarsening, primary grit blasting, spraying treatment, hole sealing treatment, secondary grit blasting (carrying out grit blasting on the plastic surface by using a high-pressure spray gun and a sand material), and water washing and drying. The treatment technique is simple, shortens the treatment time, and enhances the high-temperature oxidation resistance and corrosion resistance of the plastic; and the plastic has higher surface smoothness and is beautiful.

Owner:CHUZHOU HONGYUAN SPRAYING

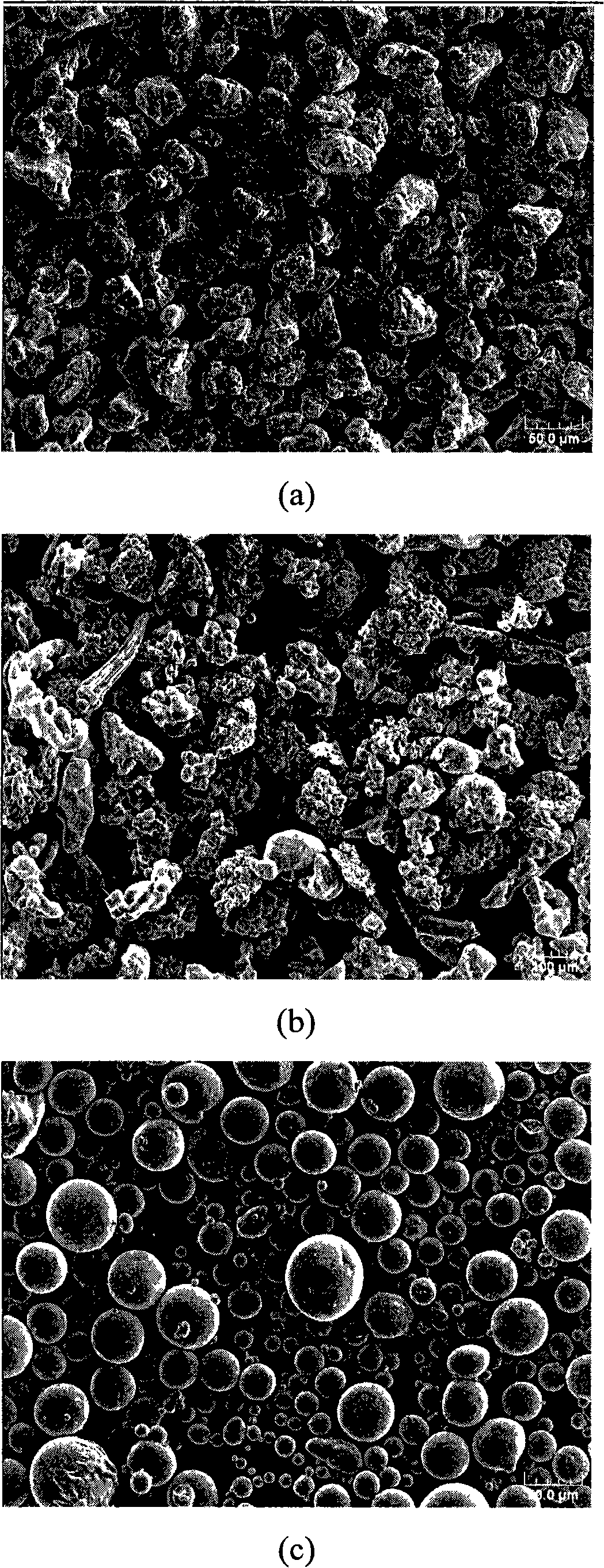

Preparation method for porous titanium and porous titanium alloy

The invention relates to a method for preparing porous titanium and tporous titanium alloy, which is characterized in that the preparing steps are as follows: Ti powder or Ti alloy powder is baked in an oven; grit-blasting coursing pretreatment is performed on the surface of a flat shape matrix or the surface of a club-shaped matrix; the cold spraying method is used to spray the prepared Ti powder or the Ti alloy powder on the matrix; and then a coating layer gained in step three is put in a vacuum heat treatment furnace for heat treatment. The invention has the characteristics of simple technology, short production cycle and low cost. The porosity of the porous titanium and the porous titanium alloy prepared by the method is distributed evenly with good controllability. The porosity of the porous titanium and the porous titanium alloy prepared by the method can be changed in the range of between 5 and 50 percent, and the intensity can be changed in the range between 30 and 75 MPa according to the porosity. The controllability of the method is good and the production efficiency is high, which is favorable for industrialization.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

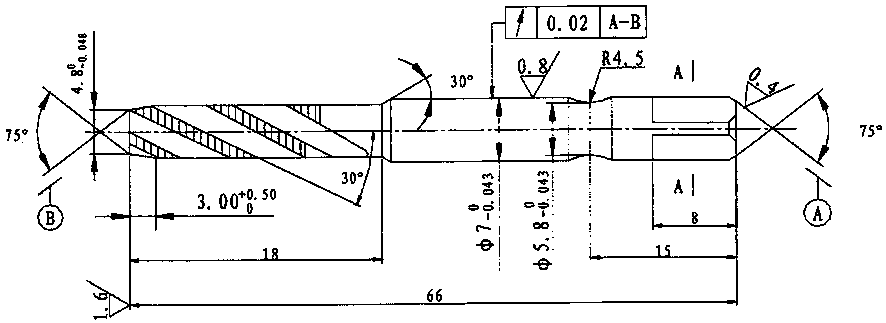

Processing method for TC4 titanium alloy spiral groove screw tap

The invention provides a processing method for a TC4 titanium alloy spiral groove screw tap. The method comprises the working procedures of blanking, rough turning, finish turning, milling, benching, heat treatment, grit blasting, surface treatment, external grinding working procedure, thread grinding, cutter grinding, relief grinding, laser carving, and the like. In the thread grinding working procedure, a tail of a spiral groove is used as a grinding benchmark, threads are at least fed for three times to grinding and processing, the threads are relief grinded to meet the requirement, and annealing is strictly prevented; in the relief grinding working procedure, different relief grinding manners are adopted according to the actual demands of the production, one manner is that a 0.5-1mm of allowance is kept during relief grinding of a dorsal horn, and another manner is that only the about 0.1mm of allowance is kept during relief grinding of the dorsal horn. Through the adoption of the method disclosed by the invention, the accuracy requirement of the spiral groove screw tap based on the TC4 titanium alloy materials can be effectively ensured, the production efficiency is greatly improved, and even more, the processing problem that a spiral tooth back is a curve tooth surface is perfectly solved.

Owner:SHENYANG AIRCRAFT CORP

Cylinder liners and methods for making cylinder liners

InactiveUS7665440B2Easy to processEliminate the effects ofCylinder headsCylindersMechanical bondEngineering

Owner:SLINGER MFG

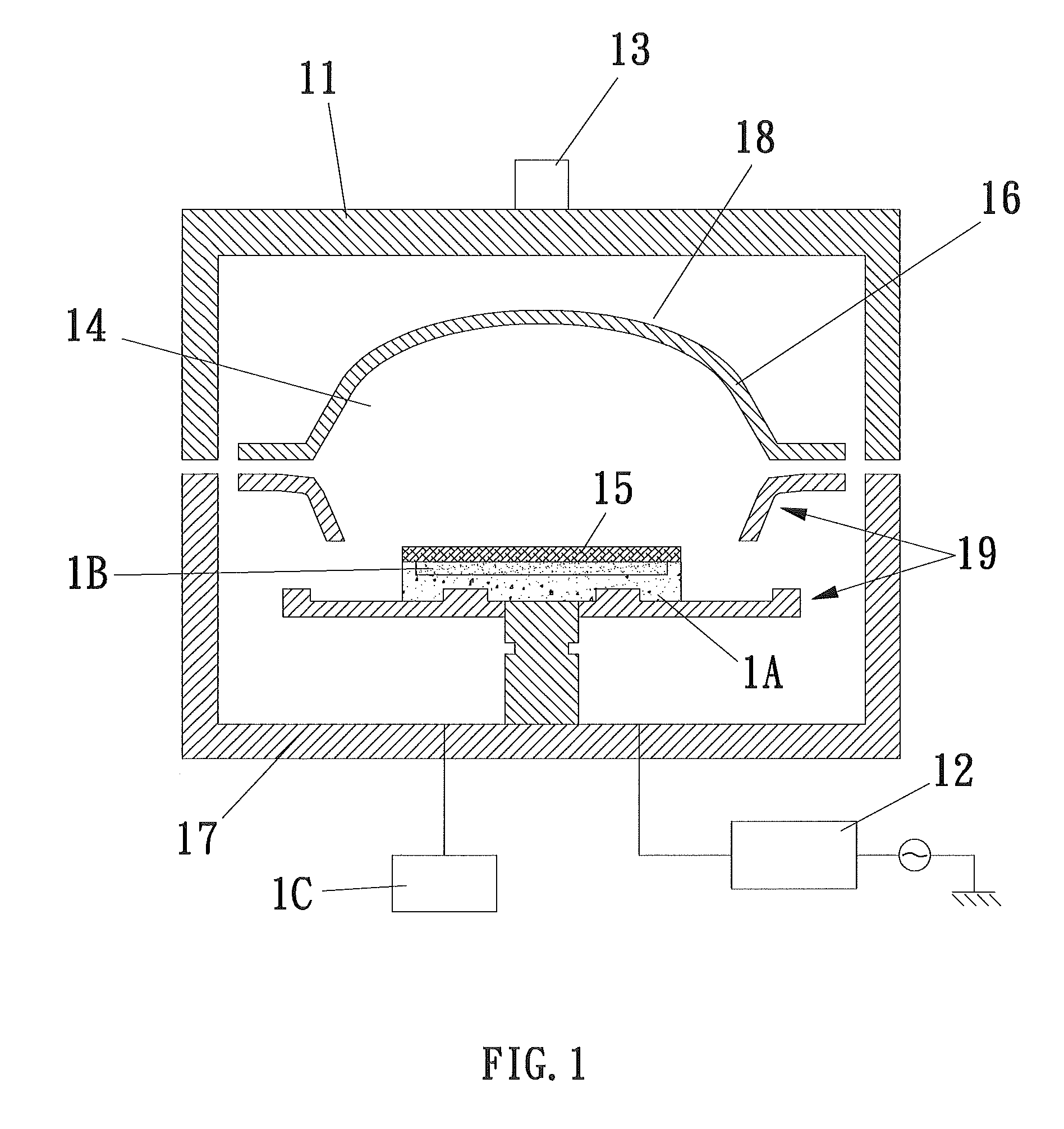

Reaction chamber structural parts with thermal spray ceramic coating and method for forming the ceramic coating thereof

InactiveUS20090311145A1Effectively minimizing uneven distribution of plasmaExtended service lifeGaseous chemical processesLiquid surface applicatorsThermal sprayingMetallurgy

In a reaction chamber for manufacturing semiconductor devices, flat displays, solar panels, a thermal spray ceramic coating with special geometric patterns is provided on structural parts in the reaction chamber. The geometric patterns of the ceramic coating are designed according to operating conditions in the reaction chamber, such as the energy source and the plasma producing gases being used, the intended plasma distribution and subsequent reactions in the reaction chamber, and compositions of the ceramic coating. To form the ceramic coating with special geometric patterns, a special masking process is adopted, and, after the forming of the ceramic coating with desired geometric patterns, a post grit blasting treatment is conducted to obtain a desired surface coarseness for the ceramic coating.

Owner:SHIH HER TECH

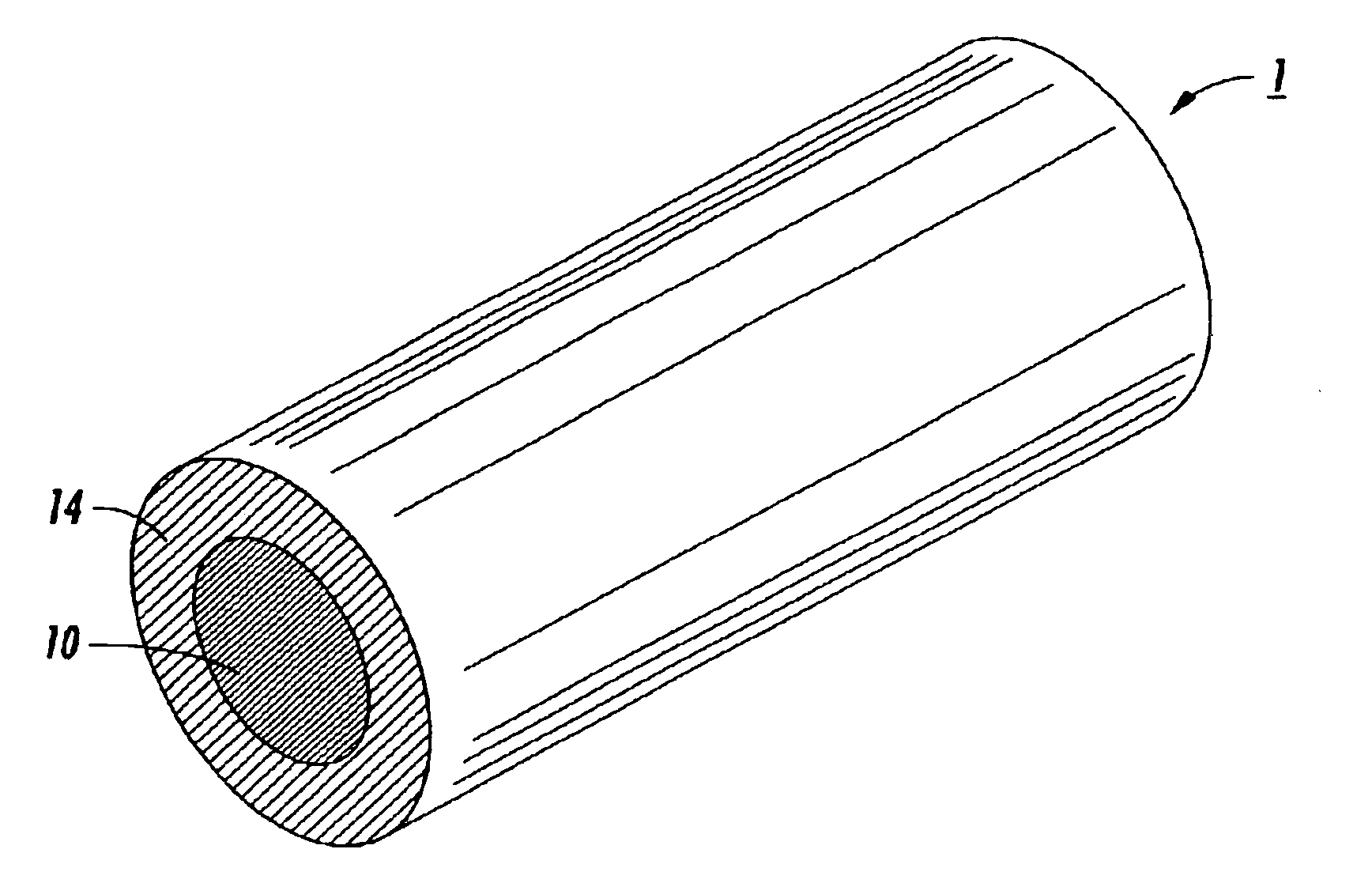

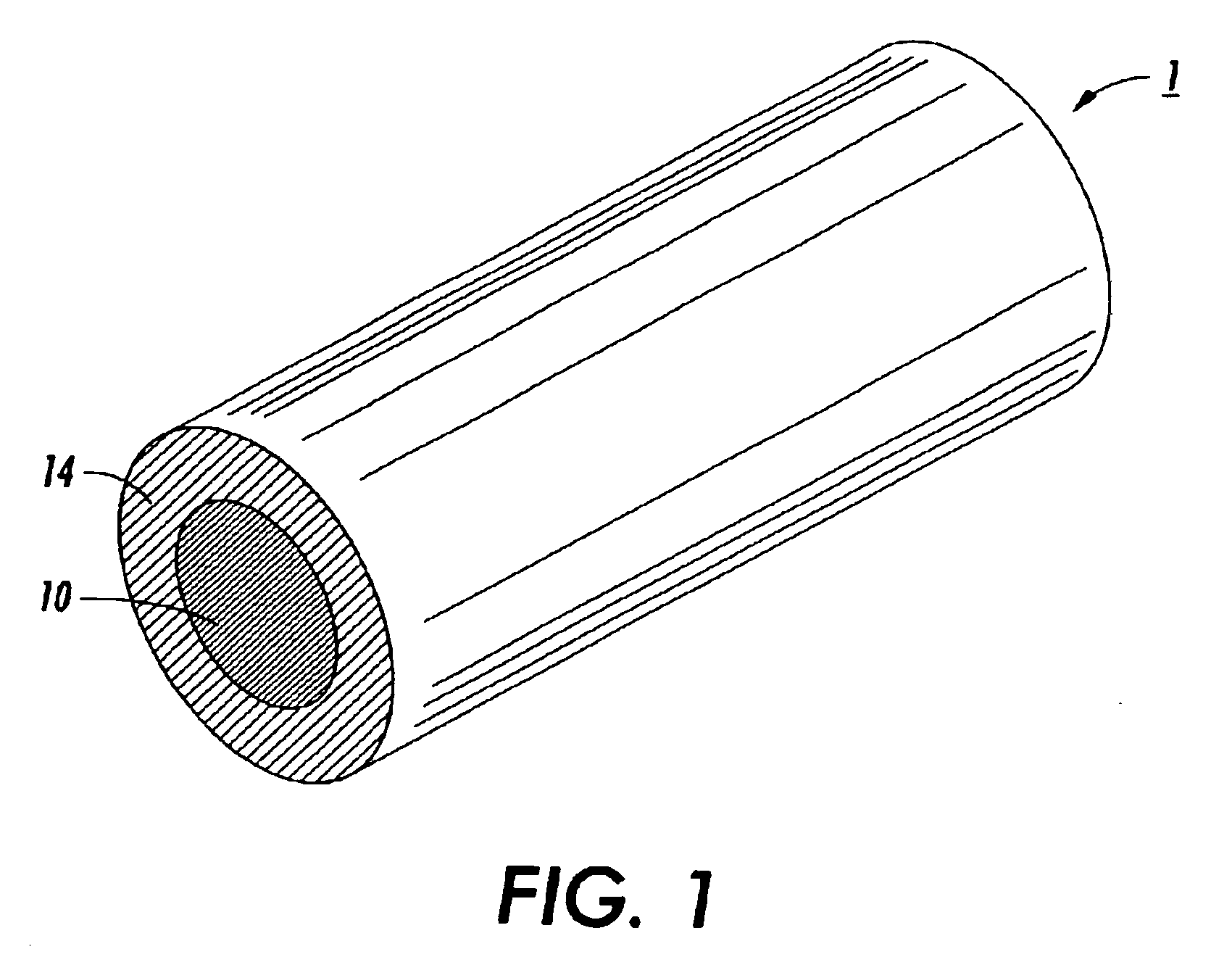

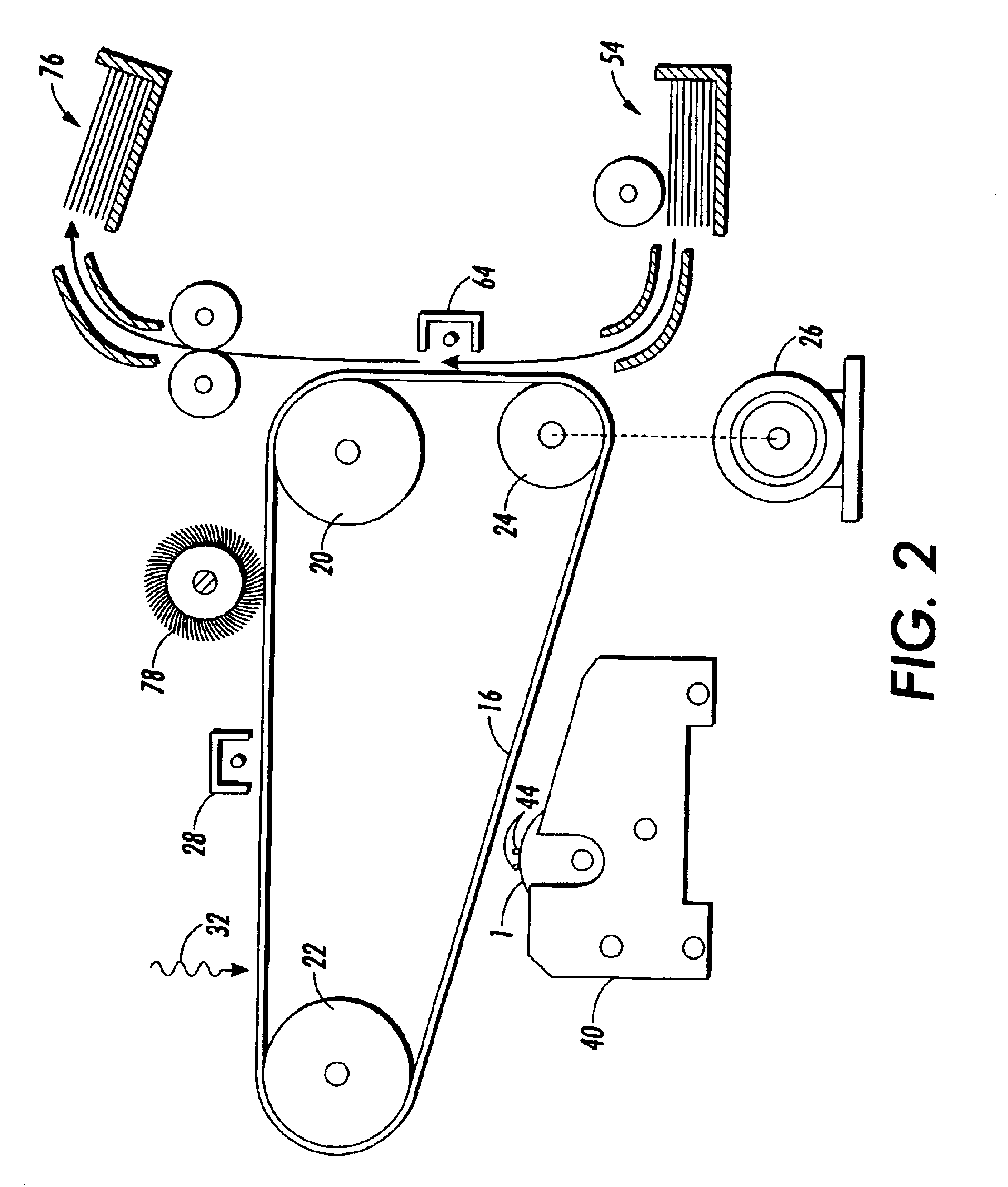

Charging member having titanium oxide outer coating on grit blasted substrate

A process for producing a charging member by grit blasting a charging member substrate, plasma spraying a single component outer coating consisting essentially of titanium dioxide powder directly to the grit blasted stainless steel substrate, and the outer coating has a resistivity of from about 10−10 to about 10−3 ohms-cm.

Owner:XEROX CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com