Seepage prevention method and fixture for aerial engine blade rabbet

A technology of aero-engine and blade mortise, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of low production efficiency and poor anti-seepage effect, so as to improve production efficiency, save cost, prevent good penetration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0051] This embodiment is an anti-seepage method for an aero-engine blade tenon, and the specific process is:

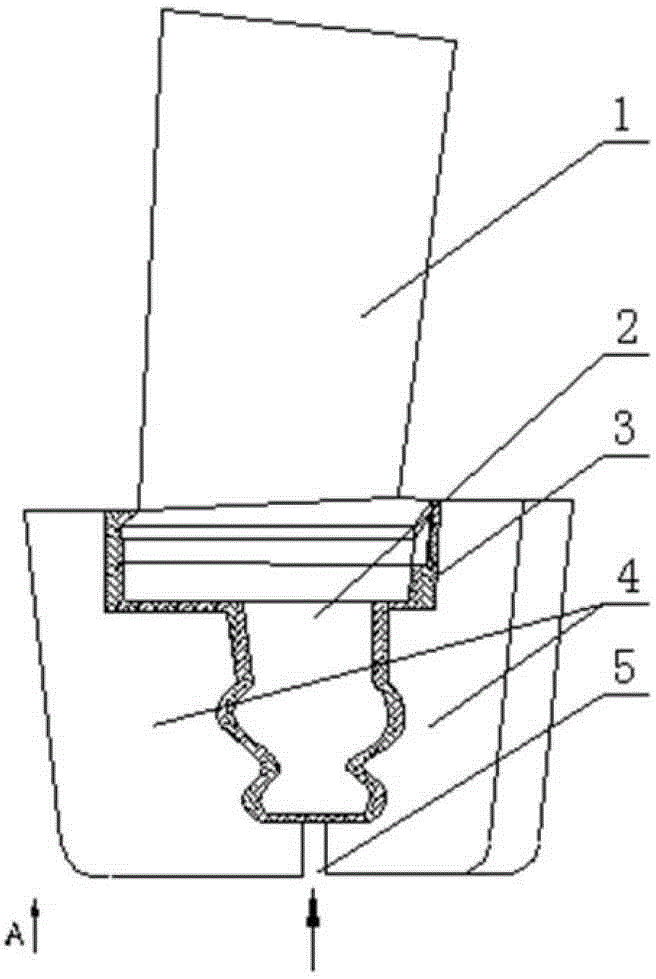

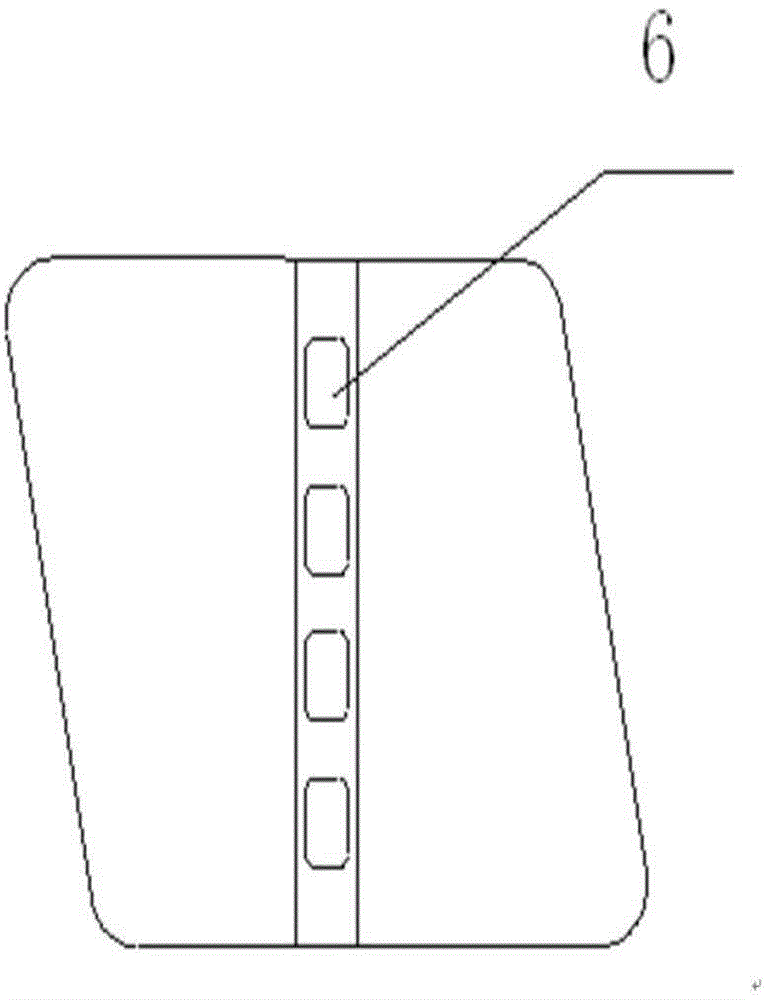

[0052] Step 1, cleaning the dirt in the blade. Align the sand outlet of the sandblasting machine with the four air inlets 6 on the top end surface of the tenon of the blade 1, and perform wet sand blowing on the inner cavity of the blade 1 to remove oil or other dirt in the inner cavity of the blade 1. The sand used in the sand blowing is 150 mesh aluminum oxide sand, the wind pressure of the sand blowing is 0.1-0.2 MPa, and the time for each blade to wet the sand blowing is 5-8 s. In this embodiment, the time for each blade to wet sand blowing is 7s, and the wind pressure of sand blowing is 0.15MPa

[0053] Step 2, cleaning the remaining sand particles in the inner cavity of the blade. Align the compressed air outlet with the four air inlets 6 on the blade 1 and blow for 15 seconds to blow out the remaining sand particles in the inner cavity of the blade.

[0054...

Embodiment 3

[0064] This embodiment is an anti-seepage method for an aero-engine blade tenon, and the specific process is:

[0065] Step 1, cleaning the dirt in the blade. Align the sand outlet of the sandblasting machine with the four air inlets 6 on the top end surface of the tenon of the blade 1, and perform wet sand blowing on the inner cavity of the blade 1 to remove oil or other dirt in the inner cavity of the blade 1. The sand used in the sand blowing is 150 mesh aluminum oxide sand, the wind pressure of the sand blowing is 0.1-0.2 MPa, and the time for each blade to wet the sand blowing is 5-8 s. In this embodiment, the time for each blade to wet sand blowing is 8s, and the wind pressure of sand blowing is 0.2MPa

[0066] Step 2, cleaning the remaining sand particles in the inner cavity of the blade. Align the compressed air outlet with the four air inlets 6 on the blade 1 and blow for 15 seconds to blow out the remaining sand particles in the inner cavity of the blade.

[0067]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com