Extrusion forming method for blade made of GH2787 high-temperature alloy

A technology of GH2787 and high-temperature alloys, which is applied to engine components, mechanical equipment, etc., can solve the problems of high cost, large number of tooling, and long manufacturing cycle, so as to improve utilization rate, save tooling design and manufacturing, and save tooling manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

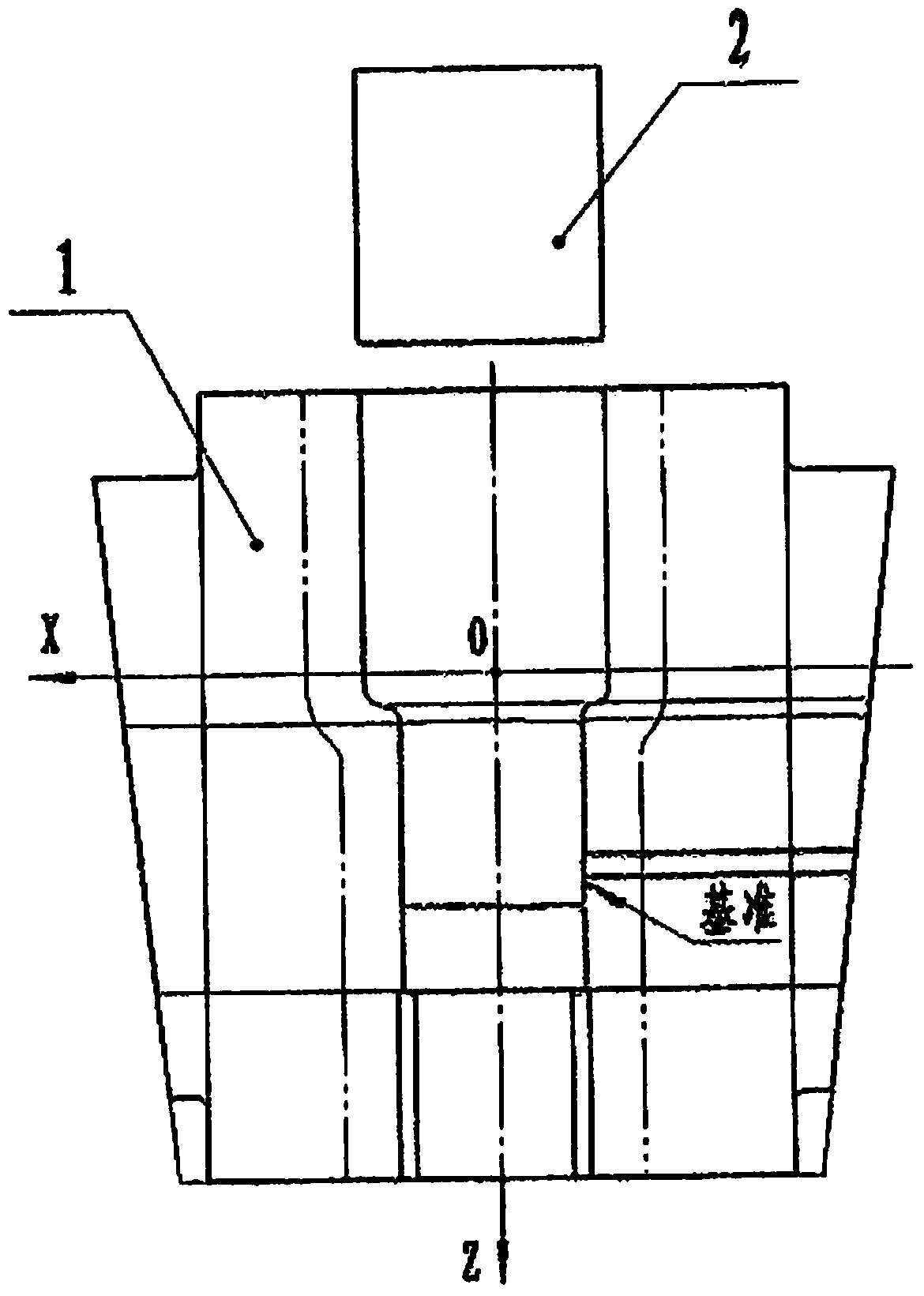

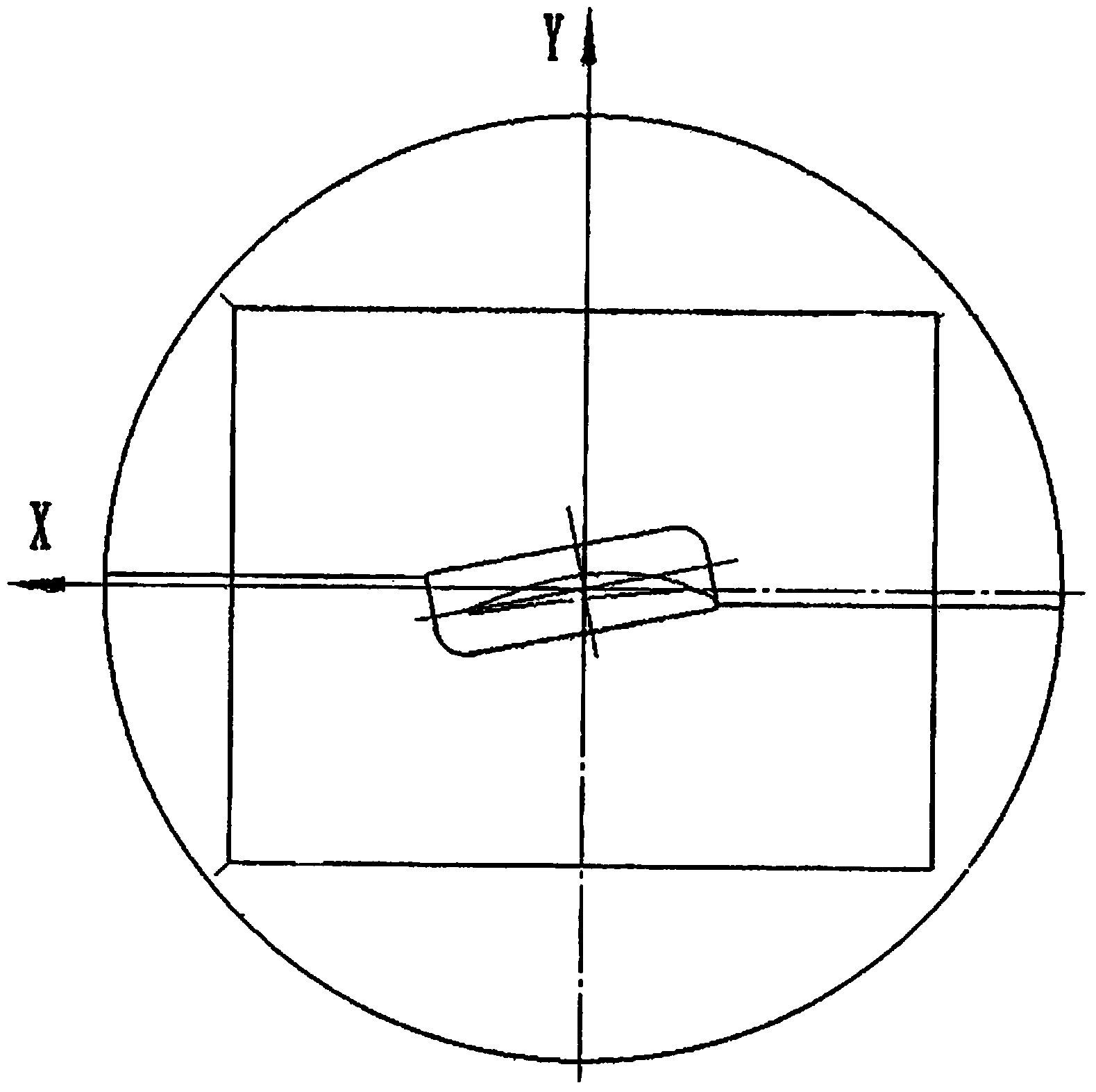

[0019] Technical scheme of the present invention comprises the following parts;

[0020] 1) Heating technology for forgings: During the heating process of superalloys for many times, the carbon, boron and other alloy elements on the surface of forgings are easily ablated and depleted, and even induce the coarsening of grains on the surface of forgings, resulting in a decrease in tensile plasticity and impact toughness , the high temperature is significantly reduced for a long time. In order to obtain the ideal microstructure and properties, and the surface oxidation and element depletion of precision forged blades must be strictly controlled due to the small margin, the heating system of the forging must be studied. Through a large number of process tests, it is determined to use electric furnace heating. Due to the thermal effect during the extrusion process of the high-speed hammer, the temperature of the parts will increase by 50-70°C. Considering that the extrusion blade b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com