Annular flame tube high-temperature post-enameling deformation correcting method and fixture

A flame tube, high temperature technology, applied in the fields of welding, heat treatment, machining, and spraying, can solve problems such as deformation, reduce processing cycle, reduce labor intensity, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

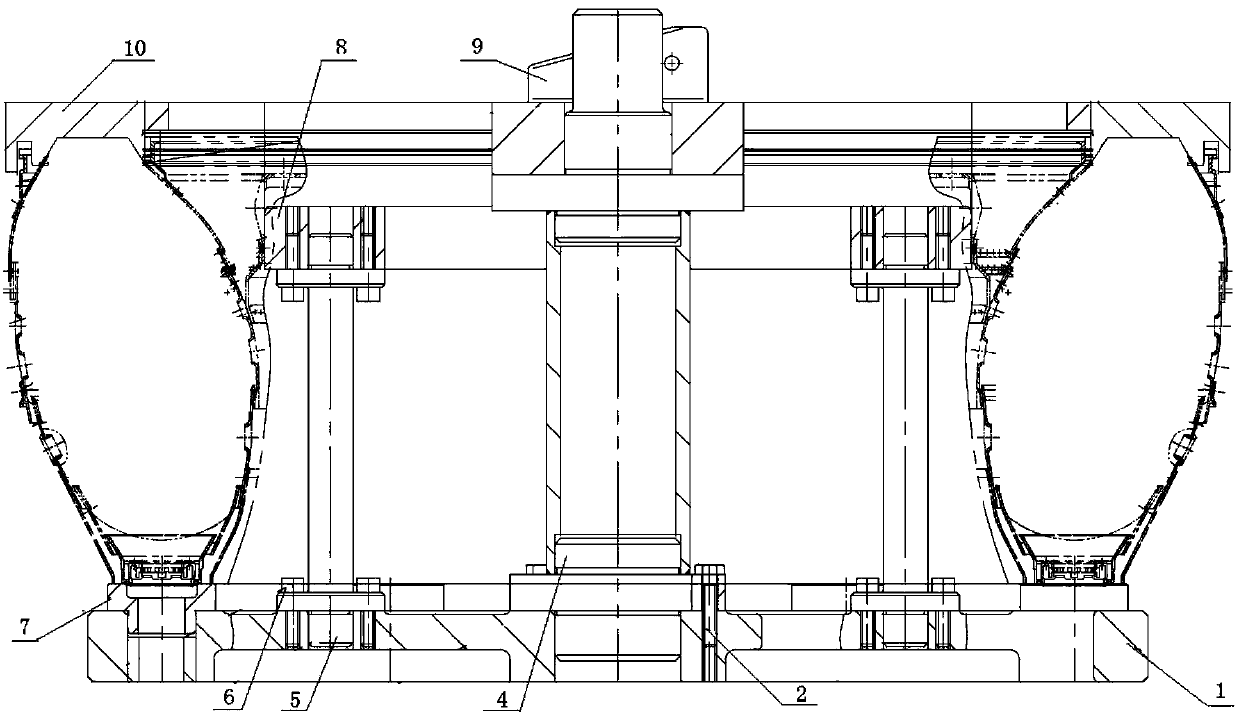

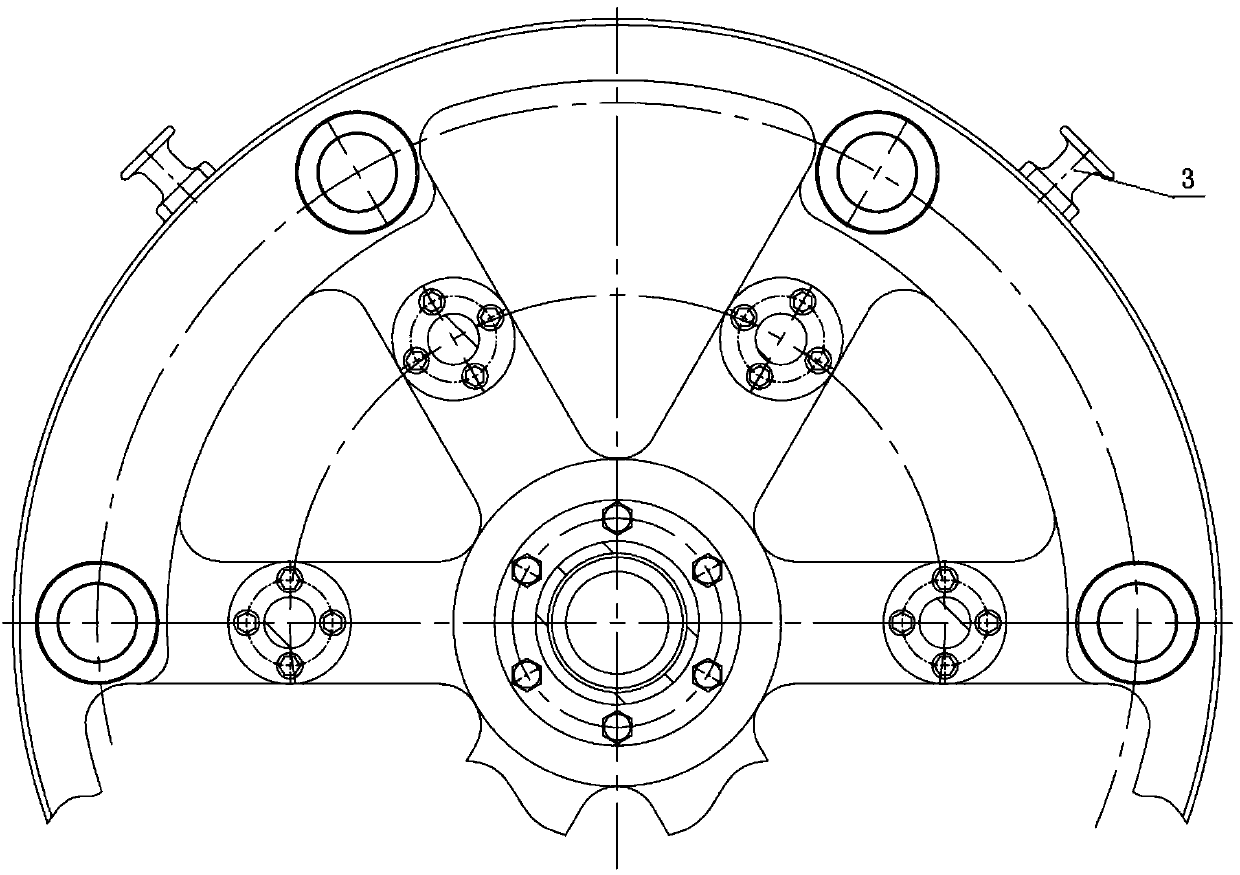

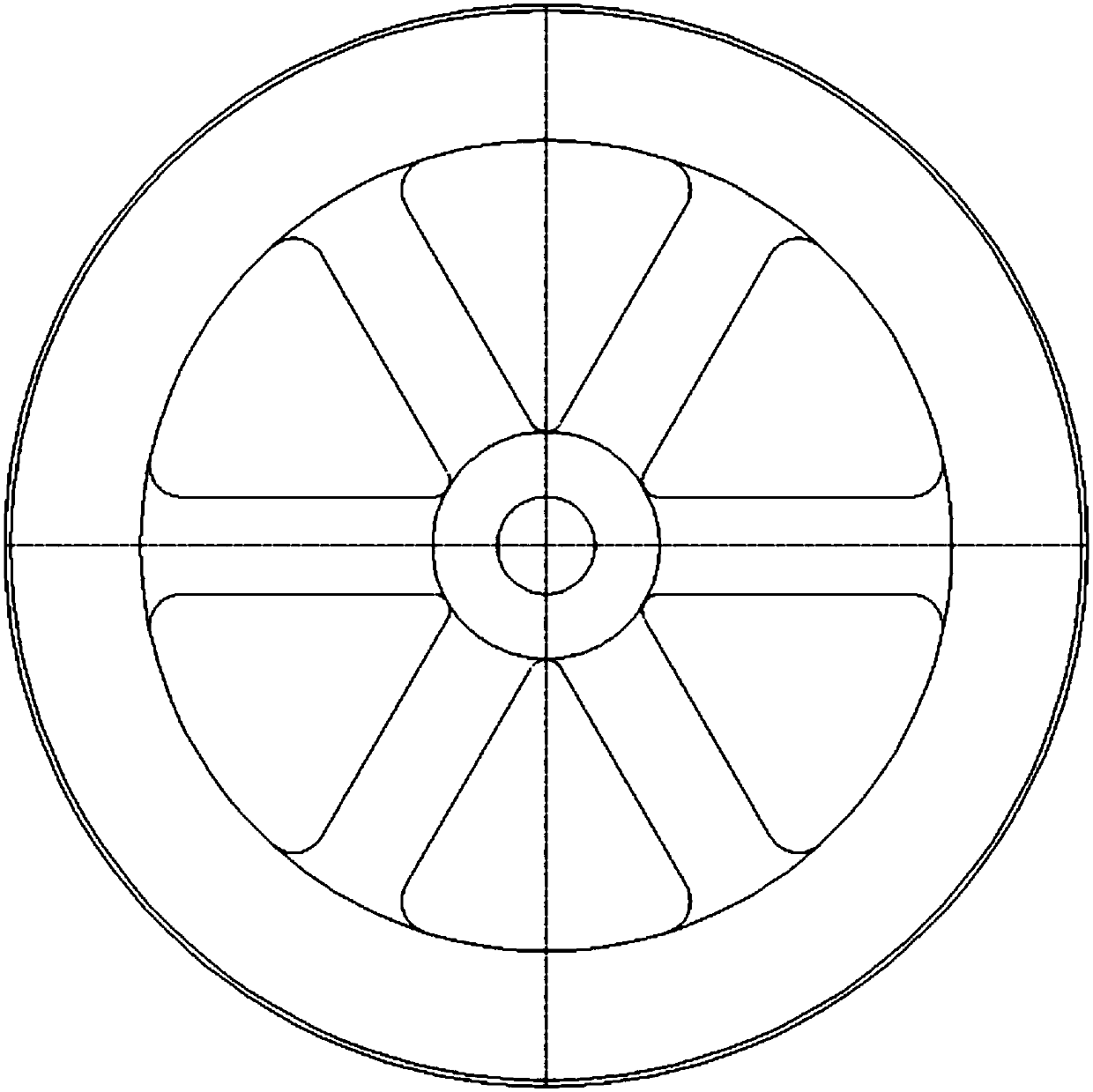

[0026] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

[0027] A method for deforming and correcting the shape of an annular flame cylinder after high-temperature enamel paint includes the following technological process: sand blowing—roasting—correction—sand blowing—coating with W300 high temperature enamel paint—heat correction—turning. After coating with high-temperature enamel, put the parts into the heat-shaping fixture and put them into the furnace together for heat-shaping process. The furnace temperature rises with the furnace temperature, and the heating time is 30-40min. The final temperature is 800±10℃, and the duration is 2.5-3.5h. Cool down with the furnace to below 500°C and leave the furnace for air cooling. After the thermal adjustment of the part is completed, it directly meets the requirements of subsequent turning processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com