A method of post-deformation correction of high-temperature enamel in an annular flame cylinder

A flame cylinder and high-temperature technology, which is applied in the fields of welding, heat treatment, machining, and spraying, can solve problems such as deformation, achieve the effects of reducing processing cycles, reducing labor intensity, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

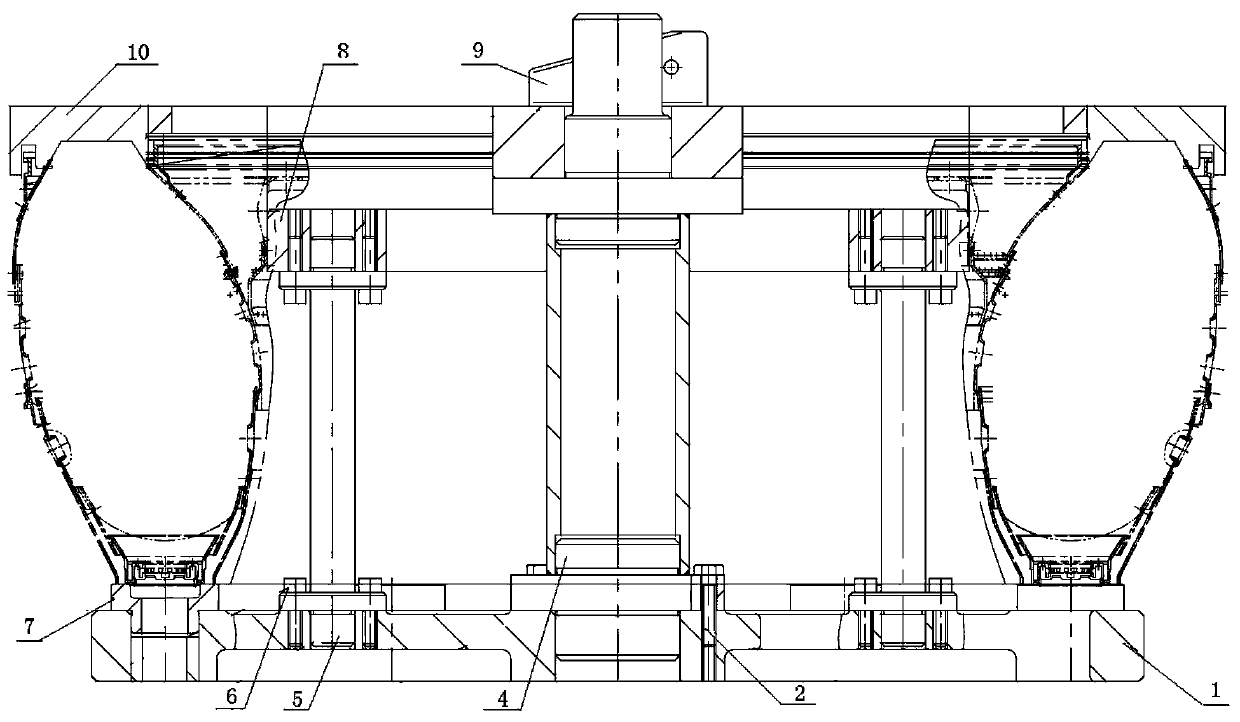

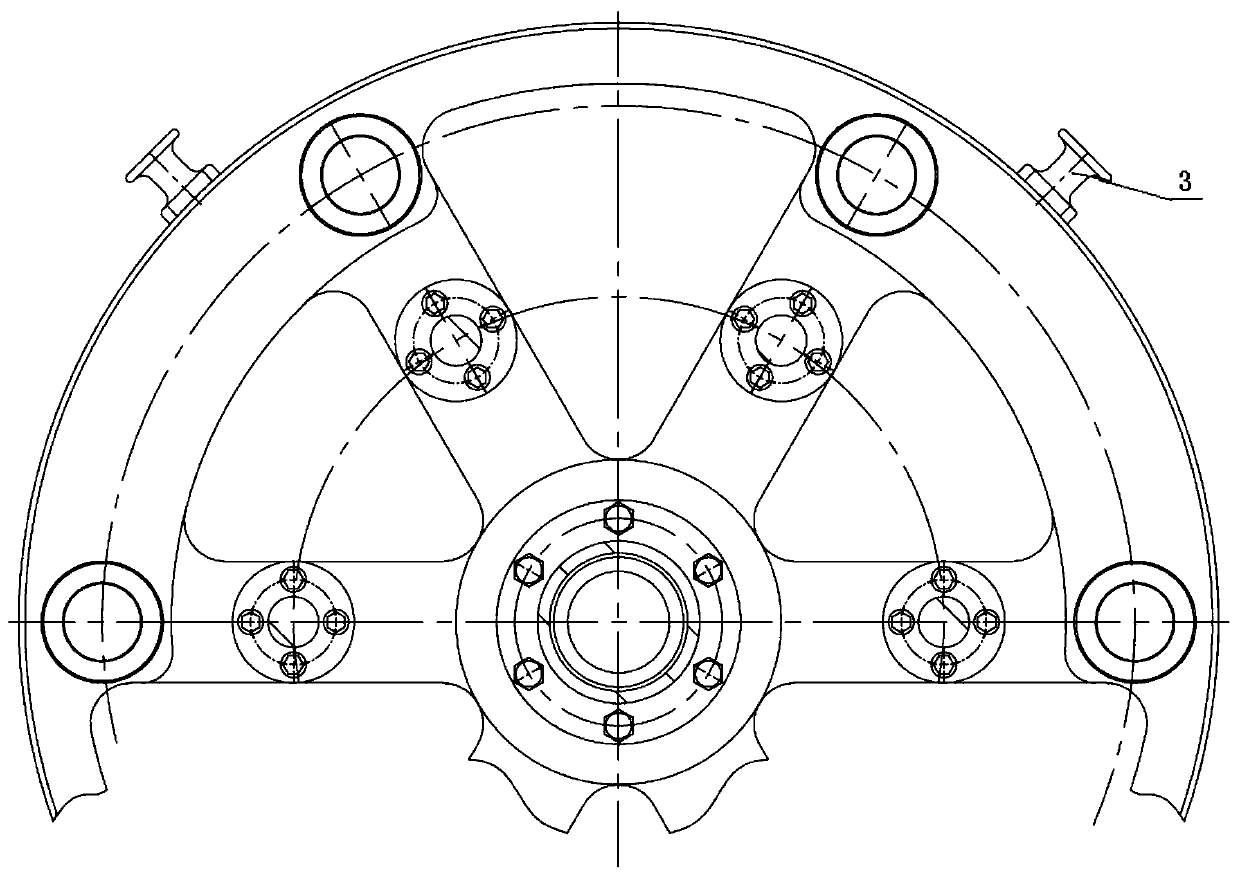

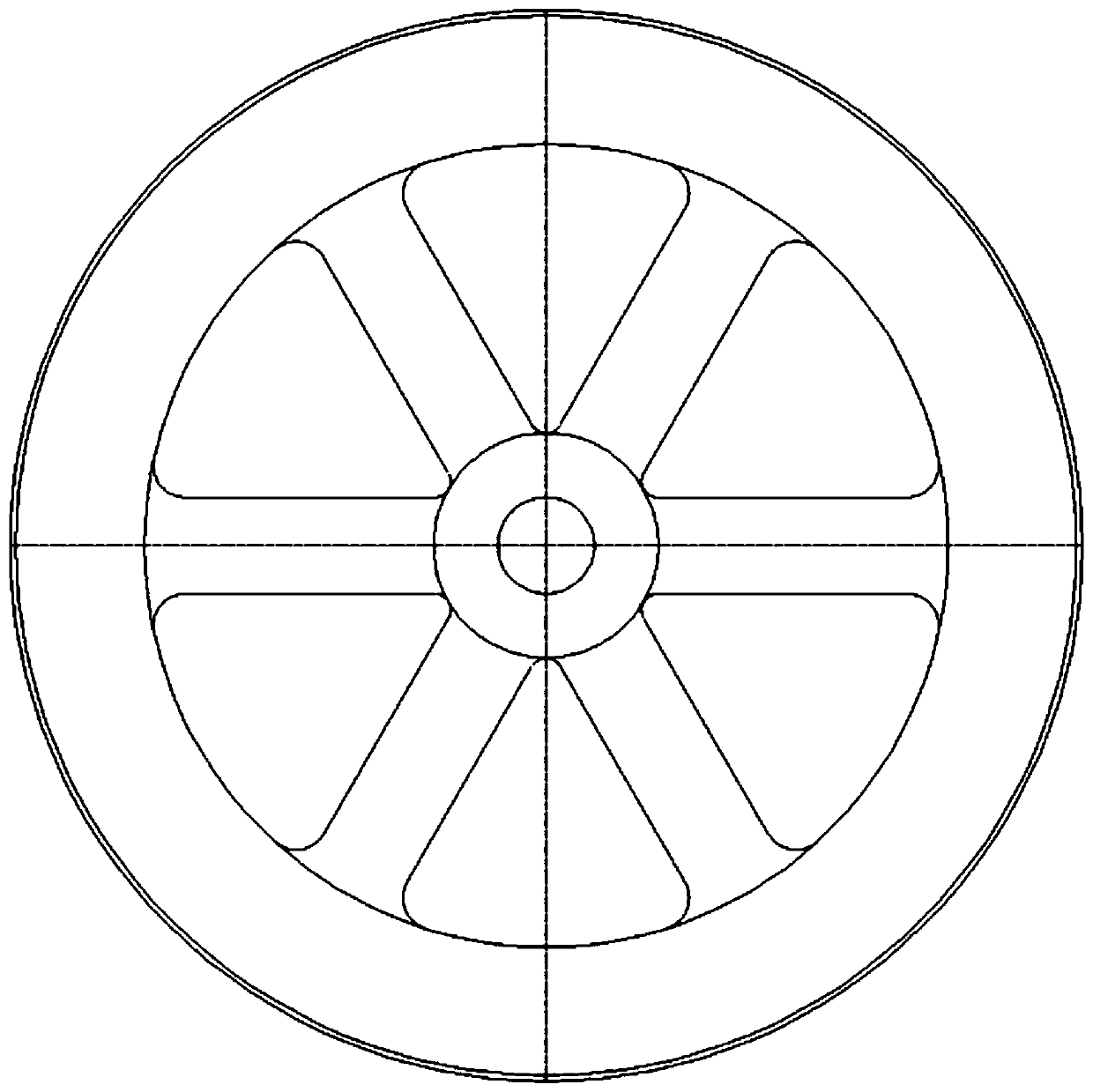

[0026] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the above.

[0027] A method for deforming and shaping an annular flame tube after high temperature enamel, including the following process flow: sand blowing-roasting-correction-sand blowing-W300 high temperature enamel coating-thermal shaping-turning processing. After applying the high-temperature enamel, put the parts into the hot-calibration fixture and enter the furnace together for the hot-calibration process. The furnace temperature rises with the furnace, the heating time is 30-40min, the final temperature is 800±10℃, and the duration is 2.5~3.5h. Cooling with the furnace cooling to below 500 ℃, out of the furnace air cooling. After the part thermal calibration is completed, it directly meets the requirements of subsequent turning processing.

[0028] Such as Figure 1~7 As shown, in order to coopera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com