Patents

Literature

145 results about "Enamel paint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Enamel paint is paint that air-dries to a hard, usually glossy, finish, used for coating surfaces that are outdoors or otherwise subject to hard wear or variations in temperature; it should not be confused with decorated objects in "painted enamel", where vitreous enamel is applied with brushes and fired in a kiln. The name is something of a misnomer, as in reality, most commercially available enamel paints are significantly softer than either vitreous enamel or stoved synthetic resins, and are totally different in composition; vitreous enamel is applied as a powder or paste and then fired at high temperature. There is no generally accepted definition or standard for use of the term enamel paint, and not all enamel-type paints may use it.

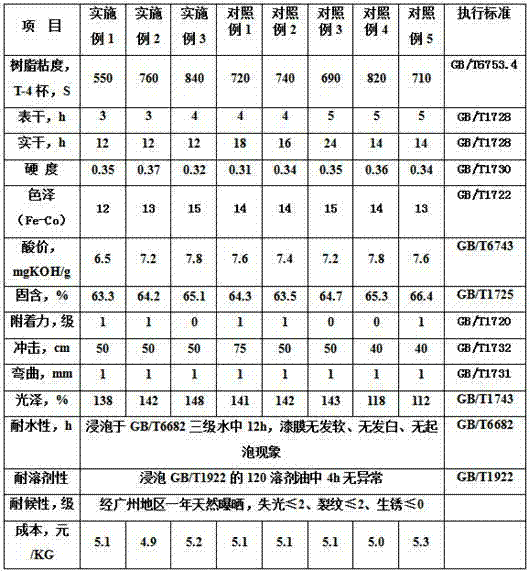

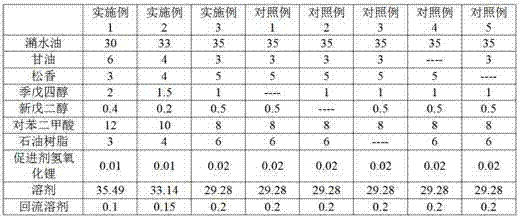

Isocyanate modified alkyd resin and preparation method thereof

The invention relates to isocyanate modified alkyd resin and a preparation method thereof. Isocyanate is utilized to modify alkyd resin, and the alkyd resin containing an ammonia ester structure is synthesized. The basic formula comprises, by weight: 20-33% of plant oil, 5-8% of polyatomic alcohol, 2-8% of organic acid anhydride, 5-10% of the isocyanate, 0.02-0.5% of catalyst, 35-50% of solvent and 3-8% of terminator. Varnish and enamel paint prepared by the isocyanate modified alkyd resin are better than ordinary middle-long-oil-degree alkyd resin paint in aspects of dryness, hardness, water resistance and the like, and are better than double-component polyurethane paint in aspects of toxicity, application property, odor and the like. The isocyanate modified alkyd resin is widely applied to the surfaces of products made of wood, metal, plastic and the like to have functions of protection and decoration. Due to the fact that the isocyanate modified alkyd resin is both hard and soft, the isocyanate modified alkyd resin has certain resistance to stone strike, can serve as primer and repair paint of agricultural vehicles and trucks, and has good market prospects accordingly.

Owner:UNION FOSHAN CHEM

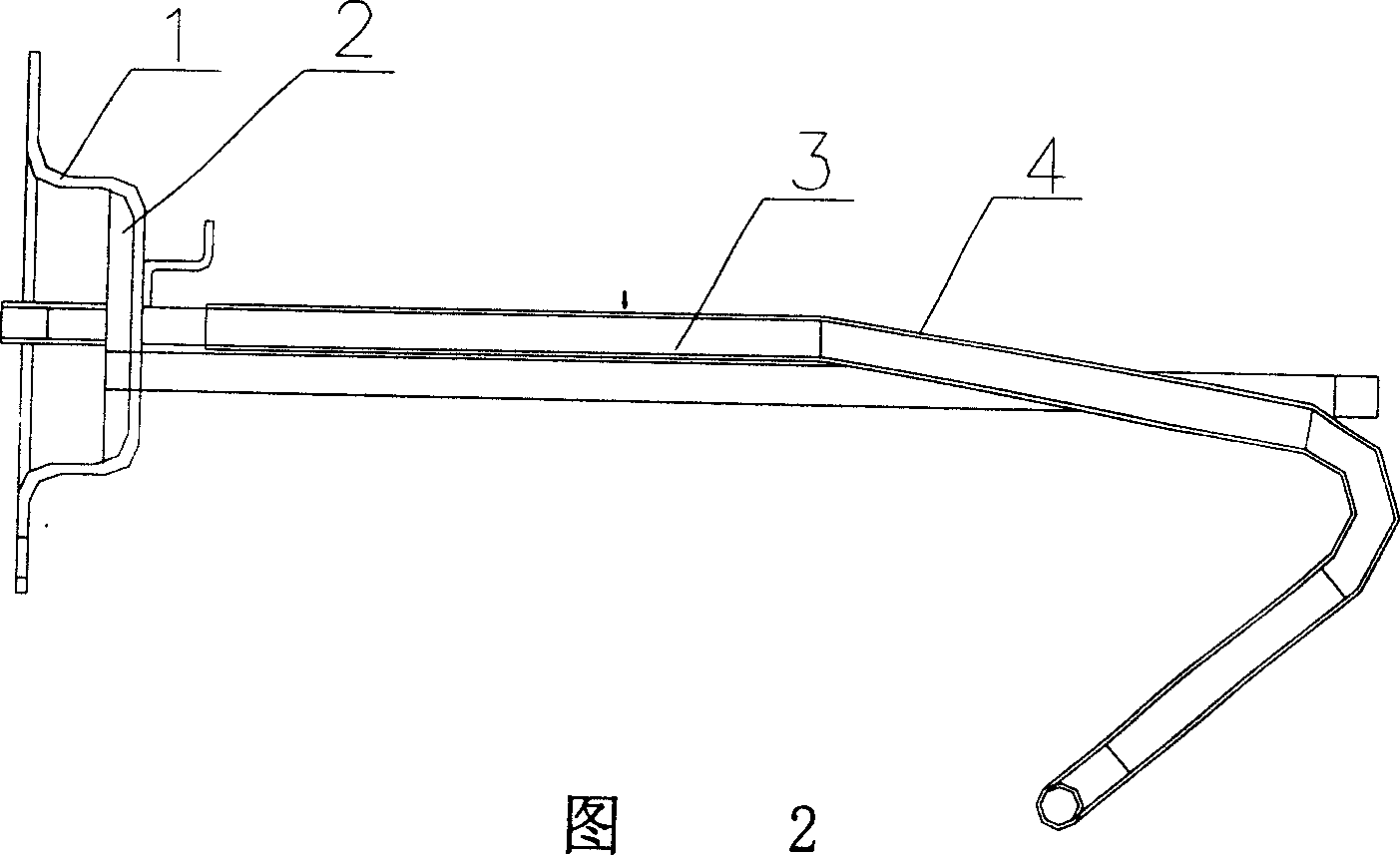

Modified asphalt hot-melt damping material for vehicles and preparation method and construction method thereof

ActiveCN101654561AHigh dampingWide temperature rangeVehicle componentsBuilding insulationsEngineeringHot melt

The invention relates to a modified asphalt hot-melt damping material for vehicles. Modified asphalt and rubber are blended; tackifying resin is added for strengthening the adhesive property of the damping material; the damping material comprises the following components in portion by weight: 100 to 200 portions of the modified asphalt, 5 to 60 portions of the rubber, 50 to 200 portions of the resin, and 250 to 800 portions of filler; and the materials are subjected to modification, rubber refining, kneading, extrusion and tabletting molding to produce the modified asphalt hot-melt damping material for the vehicles. When the modified asphalt hot-melt damping material is used on a vehicle, the modified asphalt hot-melt damping material for the vehicles is paved on a vehicle body to achievethermal lamination by only directly using the enamel paint heating process of the vehicle body. The damping material is an excellent vibration-damping noise-reduction material and has the characteristics of wide temperature range and high damping, and the damping loss factor can reach 0.8 at a temperature of between 20 and 40 DEG C.

Owner:BOGE RUBBER&PLASTICS ZHUZHOU CO LTD

Luminescent glaze for enamel painted porcelain and preparation method and application thereof

The invention discloses luminescent glaze for enamel painted porcelain and a preparation method and application thereof. The luminescent glaze for enamel painted porcelain comprises basic glaze for the enamel painted porcelain and a protective-glaze luminescent material, wherein the protective-glaze luminescent material is prepared by firstly mixing and then repeatedly braking the flux for the protective-glaze luminescent material and a luminescent material, and the flux for the protective-glaze luminescent material comprises the following components in percentage by weight: 42-48 percent of SiO2, 3-7 percent of SrO, 15-21 percent of B2O3, 0.2-1.2 percent of Al2O3, 3-7 percent of Li2O, 2-7 percent of Na2O, 1-3 percent of K2O, 0.6-3.8 percent of metal fluoride, 2-3.5 percent of P2O5, 0-0.5 percent of Ta2O3, 0-1 percent of Nb2O5, 0-0.5 percent of ZrO2, 0-3 percent of CeO2, 0-0.5 percent of La2O3, 0-2 percent of Y2O3, 5-10 percent of ZnO, and 0-5 percent of MgO. According to the luminescent glaze for the enamel painted porcelain provided by the invention, the thermal stability and luminescence properties of the luminescent material can be guaranteed so as to improve the luminance and luminous time of the prepared painted porcelain after irradiation, while the various characteristics of the traditional enamel painted porcelain can be maintained.

Owner:HUNAN LILING HONGYU HONGCI CERAMICS

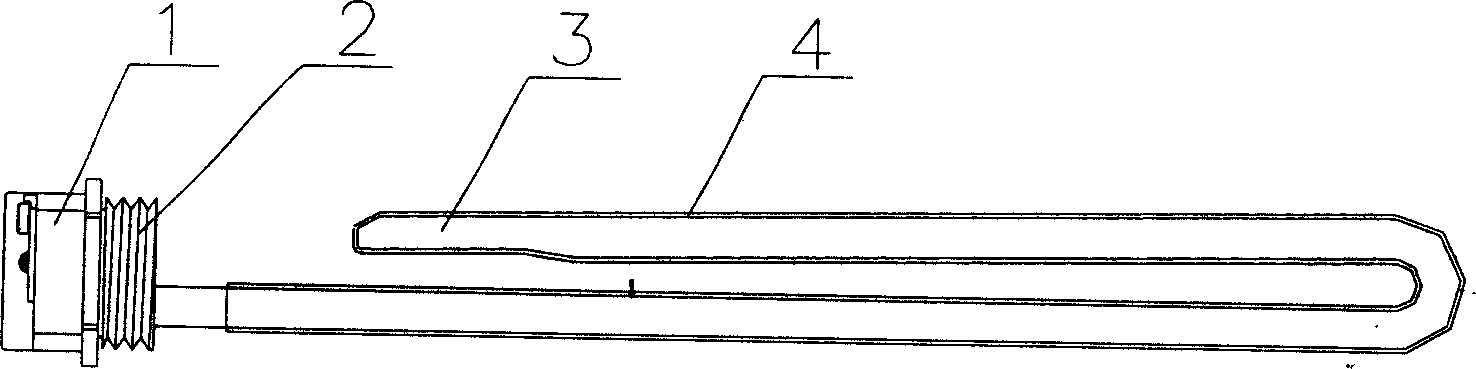

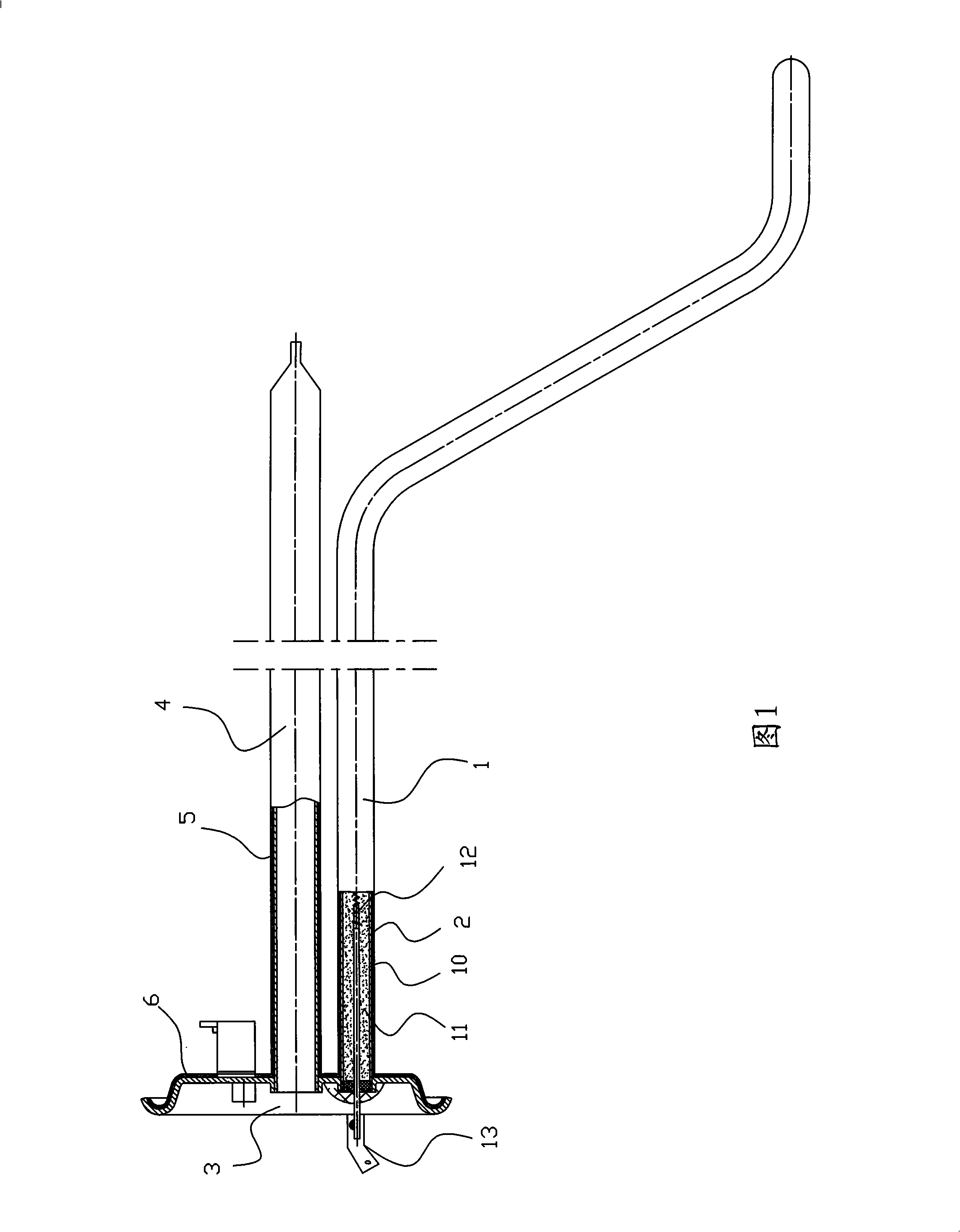

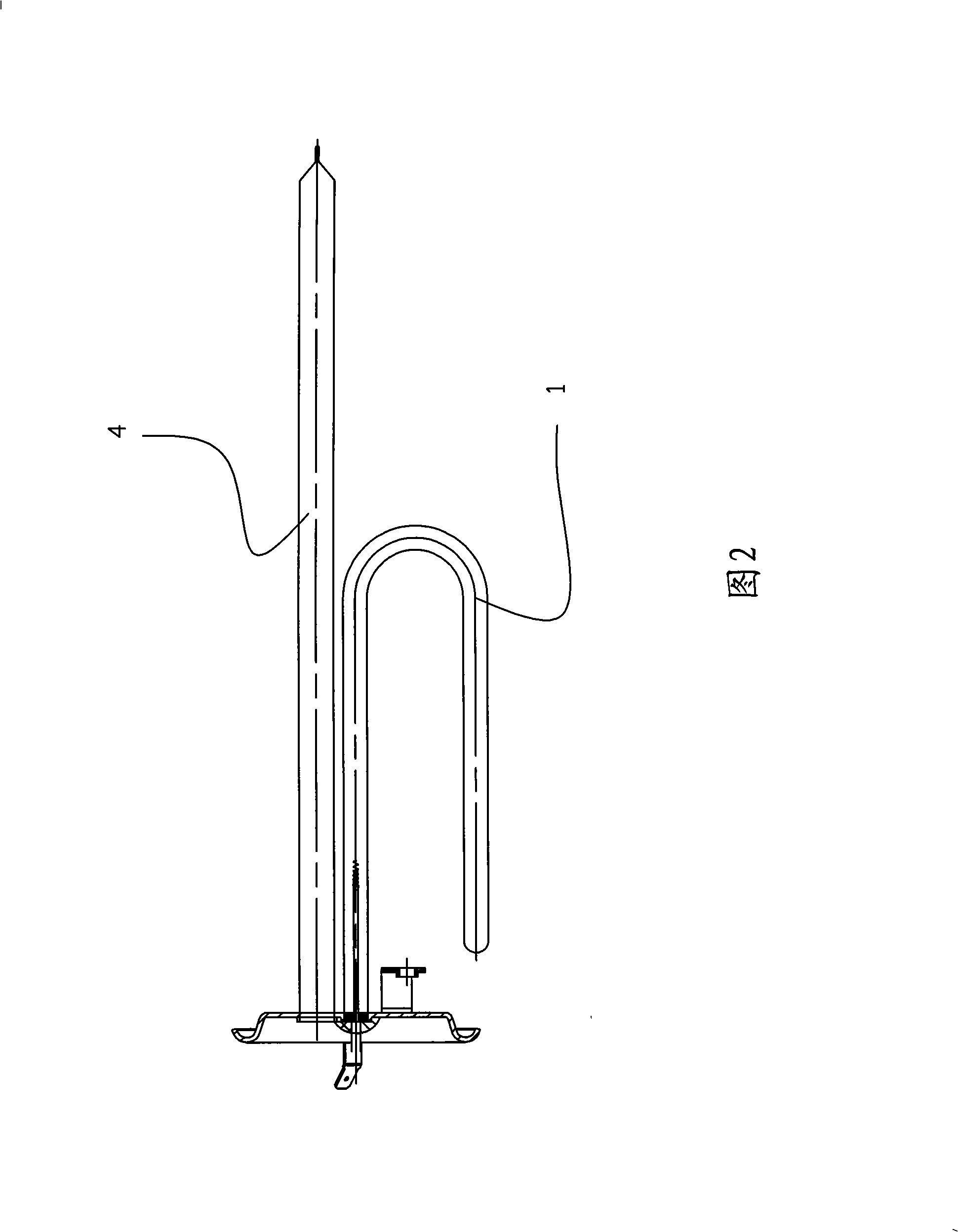

Enamel coating heating tube and manufacture for electric water heater

ActiveCN1645972ASintering method is simpleClever sintering methodHeater elementsHeating element shapesElectricityEngineering

The enamel-coated heating pipe for electric water heater is shaped into bending state. The heating wire isolating from outside casing of metal pipe by insulated terminal is installed in the pipe. The insulating heat-conductance material is filled into the space between the heating wire and outside casing of metal pipe. The key point of the invention is: after the enamel paint is coated on external surface of metal pipe, the temperature of electric heating and holding time are controlled in accordance with enamel agglomeration technology.

Owner:A O SMITH CHINA WATER HEATER CO LTD

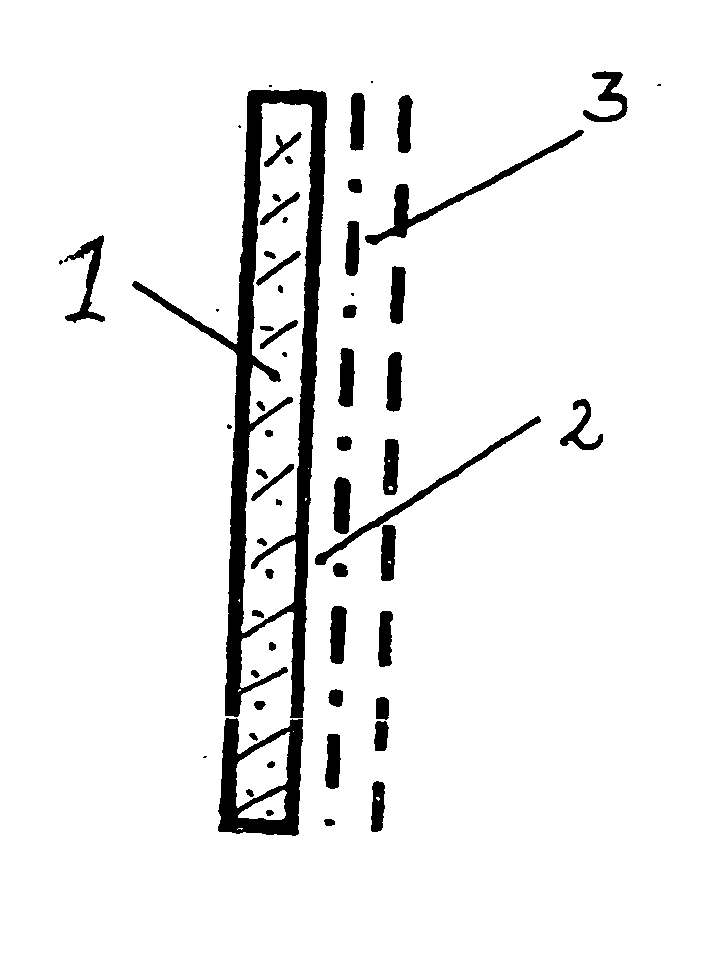

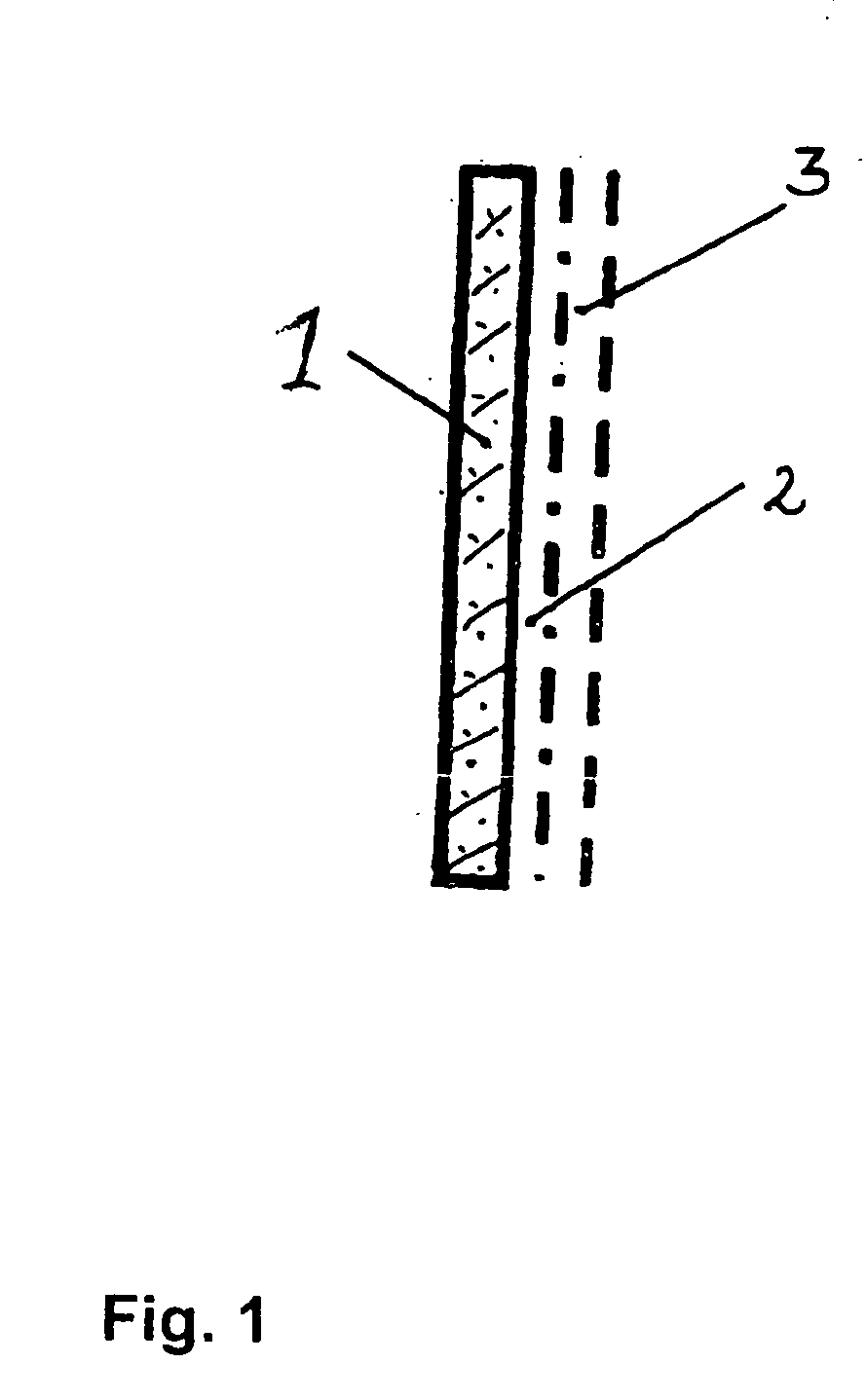

Cooking appliance door with an inner borosilicate glass window pane and cooking appliance with said door

InactiveUS20050092318A1Strong adhesionScratch resistantSelf-cleaning stoves/rangesDoors for stoves/rangesEnamel paintGlass window

The cooking appliance door has a borosilicate glass inner window pane, on which a paint layer and an infrared-reflecting layer are applied. The paint layer is high-temperature-resistant non-enamel paint with an organic or inorganic binder. In order to provide especially good adherence and high scratch resistance for the paint layer, the paint layer is applied directly on one side of the inner window pane and the infrared-reflecting layer is applied on and over this paint layer. A cooking appliance with this cooking appliance door is also part of this invention.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH +1

Method for manufacturing enamel painted porcelain

InactiveCN102602216ARich layersRich three-dimensional senseDecorative surface effectsSpecial ornamental structuresEnamel paintEngineering

The invention discloses a method for manufacturing enamel painted porcelain. The method includes steps: manufacturing ornamental patterns, color enamel ornamental portions and color enamel ornamental pattern images with golden edges, and outputting films of the ornamental patterns, the color enamel ornamental portions and the color enamel ornamental pattern images with the golden edges; printing a color enamel ornamental layer on an ornamental pattern image; covering surface sealing oil on the ornamental pattern image and a color enamel ornamental layer and manufacturing ceramic transfer paper; adhering the ceramic transfer paper on porcelain; naturally cooling the porcelain after color baking of the porcelain; and preparing color enamel ornamental pattern stained paper with golden edges, attaching the color enamel ornamental pattern stained paper with the golden edges onto the porcelain, and naturally cooling the porcelain after color baking of the porcelain. The method can be used for manufacturing the enamel painted porcelain in a batch in a standardized manner, and the manufactured color enamel porcelain is rich in layered impression, stereoscopic impression and texture, does not contain lead and cadmium heavy metal, not only can be used as display artwork, but also can be used as a practical utensil for daily life.

Owner:斯达高瓷艺发展(深圳)有限公司

Electric heating tube component and manufacturing method thereof

ActiveCN101325827AImprove corrosion resistanceCut off contactImmersion heating arrangementsEngineeringEnamel paint

The invention discloses an electric heating pipe assembly and a manufacturing method thereof. The electric heating pipe assembly comprises a heating pipe which comprises a metal tube, the metal tube is provided with heating cords made of insulated heat conduction material, and the outer surface of the metal tube of the heating pipe is covered with an enamel protective layer. The electric heating pipe is absorbed through static electricity, the outer surface of the metal tube is coated with an enamel layer, so that the coated enamel layer covers the outer surface of the metal tube completely; the electric heating pipe coated with the enamel layer is sintered at high temperature, to form a compact and firm enamel protective layer by the enamel paint coated on the surface of the metal tube. Because the outer surface of the metal tube is coated with the enamel protective layer completely, the contact of the heated pipe liquid and the metal is stopped completely, thereby improving the corrosion resistance of the surface of the metal tube and improving the service life of the electric heating pipe; moreover, the production efficiency is high, and the product quality is stable and reliable. The electric heating pipe assembly of the invention can be widely applied to the domestic and industrial fields.

Owner:法罗力热能设备(中国)有限公司

Method for preparing alkyd resin using illegal cooking oil

The invention discloses a method for preparing an alkyd resin using illegal cooking oil and belongs to the field of high polymer materials. The method includes the following steps of putting hogwash oil, rosin, glycerol, pentaerythritol, neopentyl glycol, and an accelerant into a reaction still, and performing heating and reaction; cooling acquired reactants, putting terephthalic acid in the reaction still, and performing heating and reaction; heating the reactants, adding a backflow solvent, and performing backflow heat preservation; cooling reactants, adding a petroleum resin, and performing even stirring; diluting an obtained material with a solvent. According to the method for preparing the alkyd resin using the illegal cooking oil, by means of a formulation design of the reclaimed illegal cooking oil and hogwash oil, the alkyd resin with high properties is prepared through synthetic reaction, manufactured antirust paint is excellent in antiseptic property, and ready mixed paint or enamel paint is excellent in weather fastness, glossy, bright-colored, and good in property.

Owner:JIANGSU HUAXIA PAINT MAKING

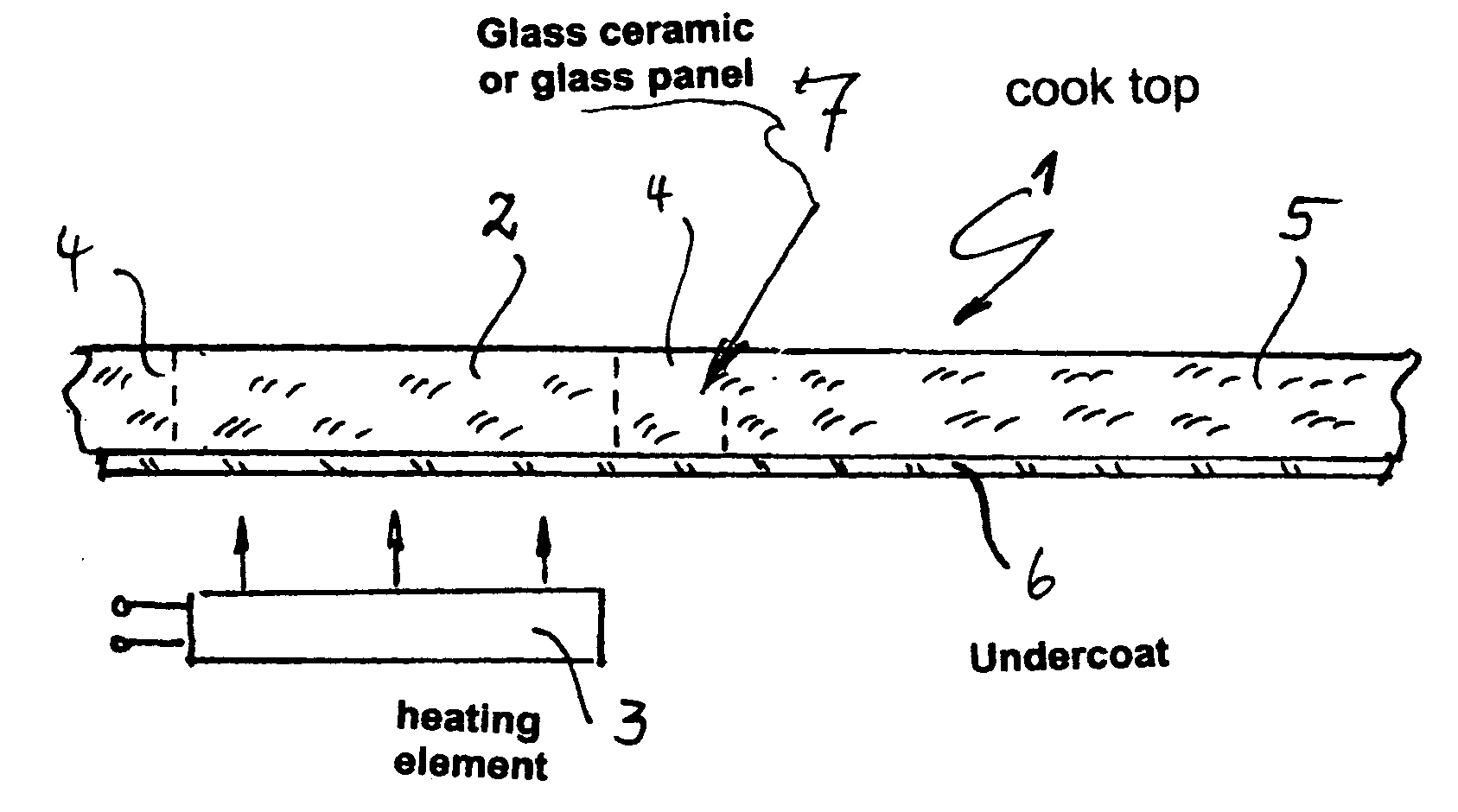

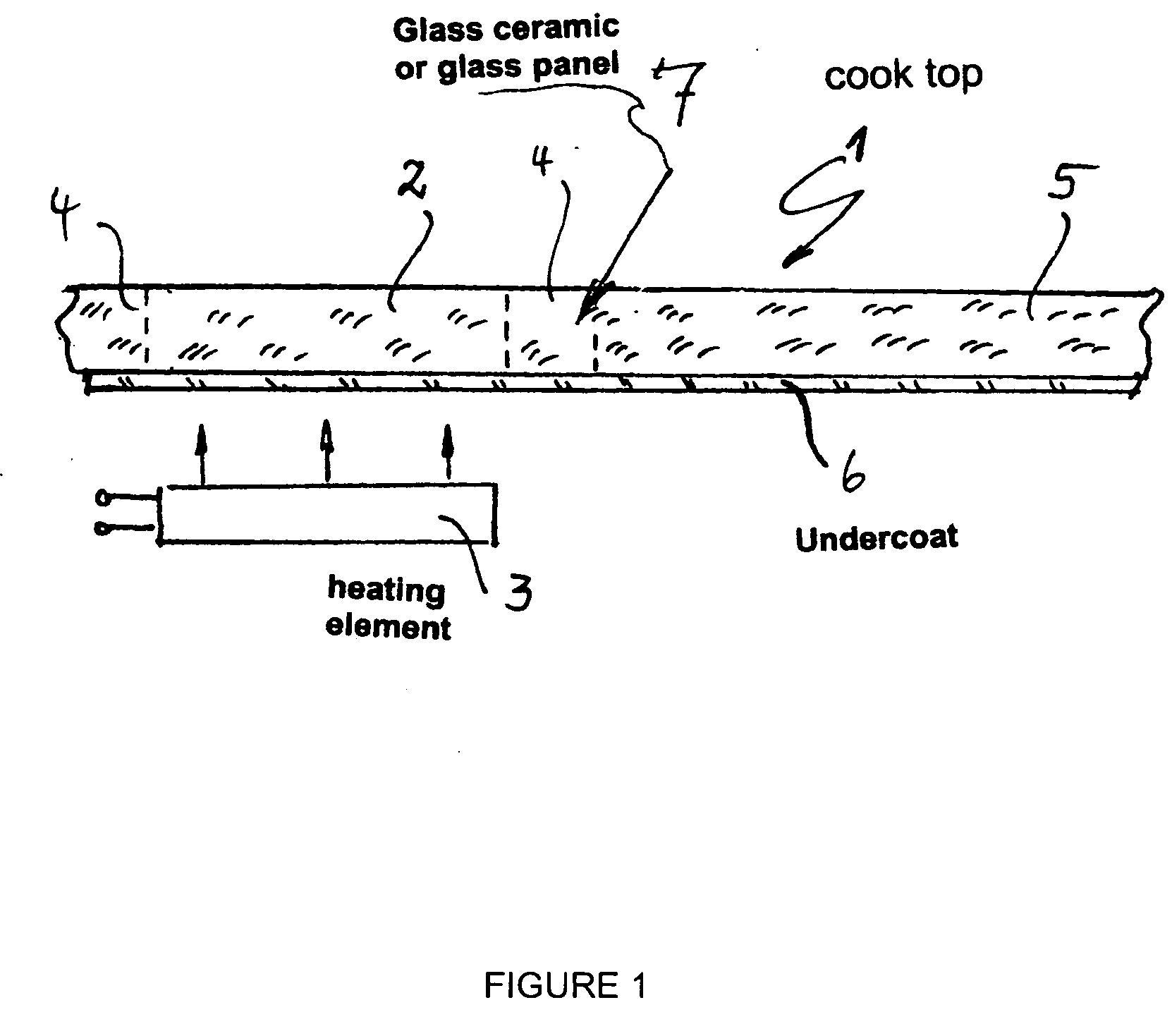

Glass ceramic or glass cook top with an IR-permeable undercoat

InactiveUS20070003769A1Reduced durabilityReduced strengthStoves/ranges topsHot plates heating arrangementsPre stressingThermal expansion

The cook top has a transparent, colorless glass ceramic or glass panel providing a cooking surface, which is made from pre-stressed special glass, and an IR-permeable undercoat on the underside of the panel, which is a heat-resistant inorganic enamel paint. In order to provide a heat-resistant cook top, through which the internal parts of the cooking unit cannot be observed, without reducing the strength of the cook top, the inorganic enamel paint includes 70 to 99, preferably 80 to 95, percent by weight of inorganic pigment and from 1 to 30, preferably 5 to 20, percent by weight of glass flux. The glass flux preferably is a borosilicate glass with a thermal expansion coefficient less than or equal to 4*10−6 K−1. The coating may be applied by screen printing techniques.

Owner:STRIEGLER HARALD

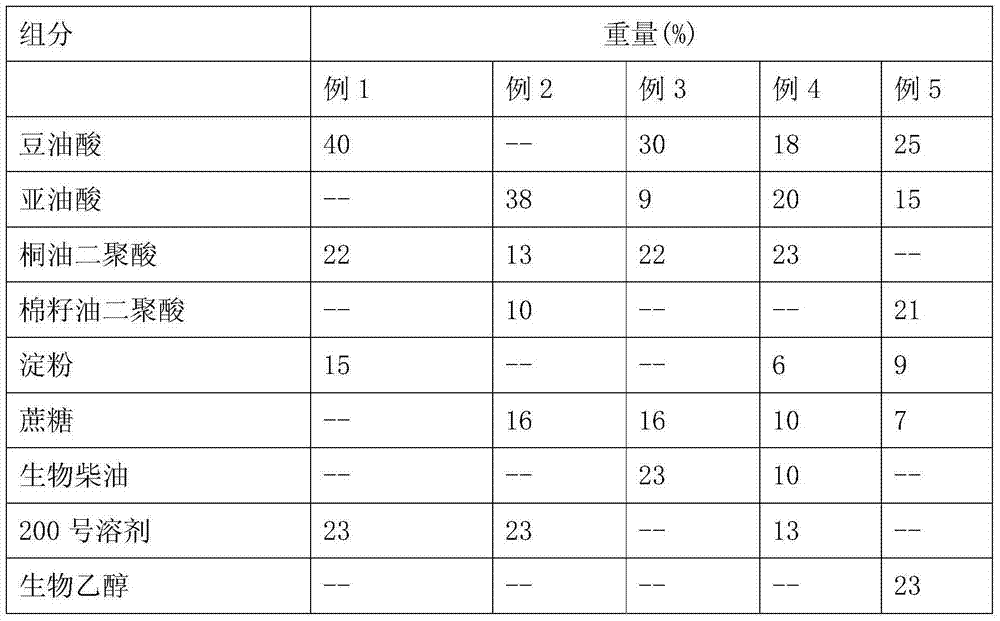

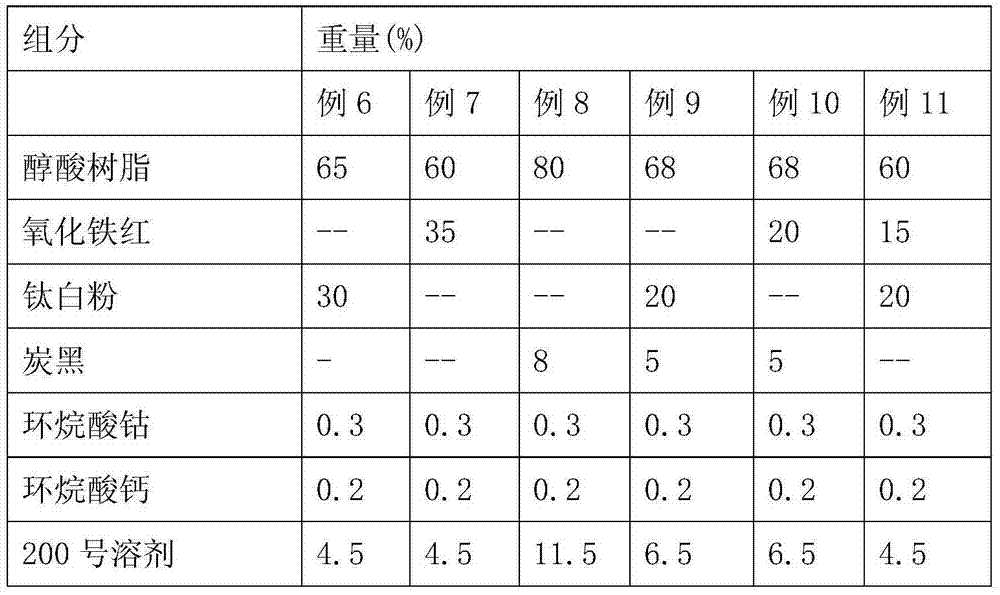

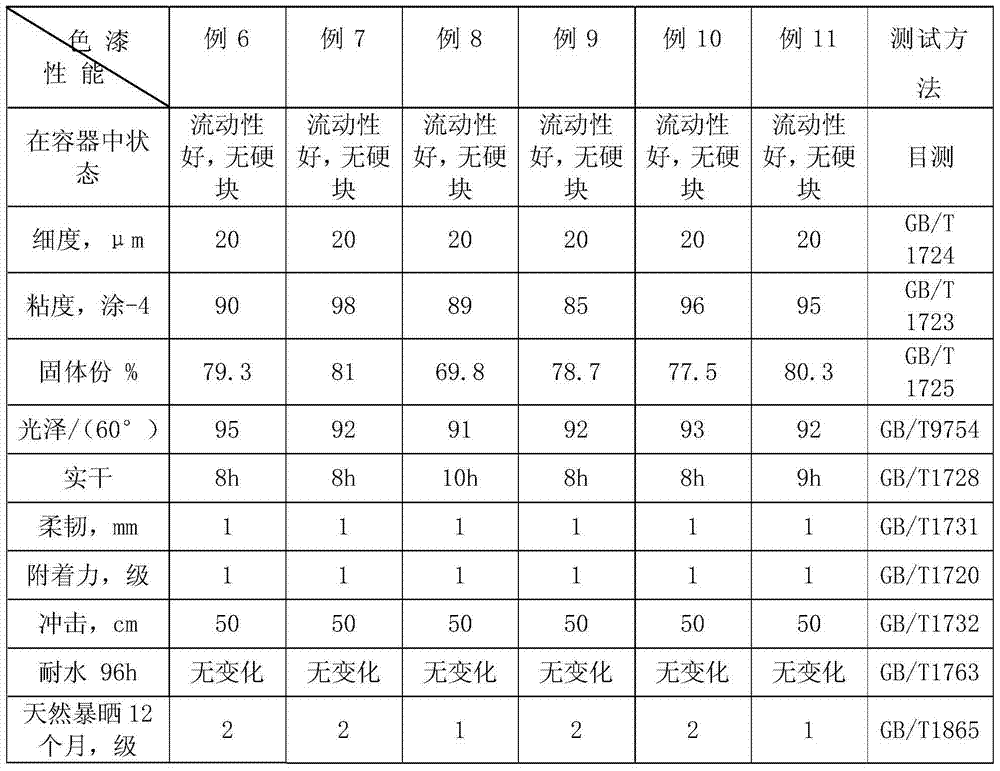

Renewable alkyd resin with high solid portion and preparation method of enamel paint

ActiveCN104497286AHigh mechanical strengthGood weather resistancePolyester coatingsAlcoholDimer acid

The invention discloses renewable alkyd resin with high solid portion and a preparation method of an enamel paint. The renewable alkyd resin comprises the following components: 30-50% of plant oleic acid, 15-35% of plant oil dimeric acid, 10-30% of polysaccharide and 20-30% of solvent. The enamel paint comprises the following components by weight: 40-80% of renewable alkyd resin with high solid portion, 8-40% of pigment, 0.1-1% of drier and 3-12% of solvent. The 100% renewable alkyd resin is prepared by renewable plant oil dimeric acid, polysaccharide, plant oleic acid and other ingredients, through elaborate preparation, the enamel paint with high mechanical strength of paint film and good weather fastness is designed, and each index can reach high solidity and low viscosity as common alcohol acid.

Owner:NANJING CHANGJIANG PAINT

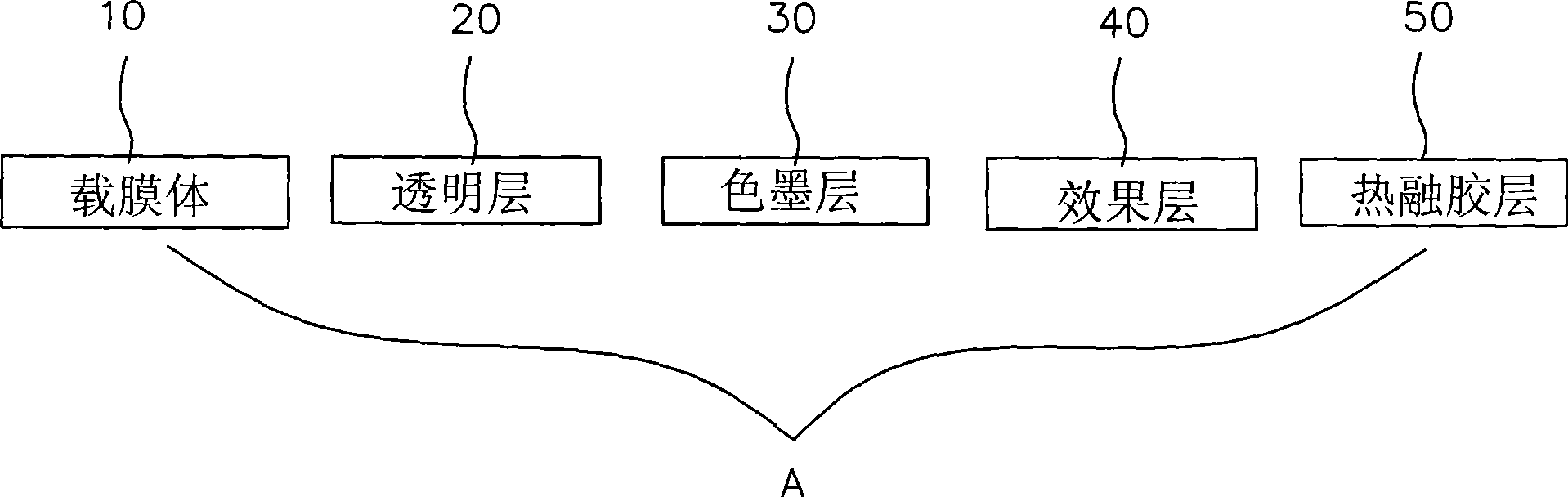

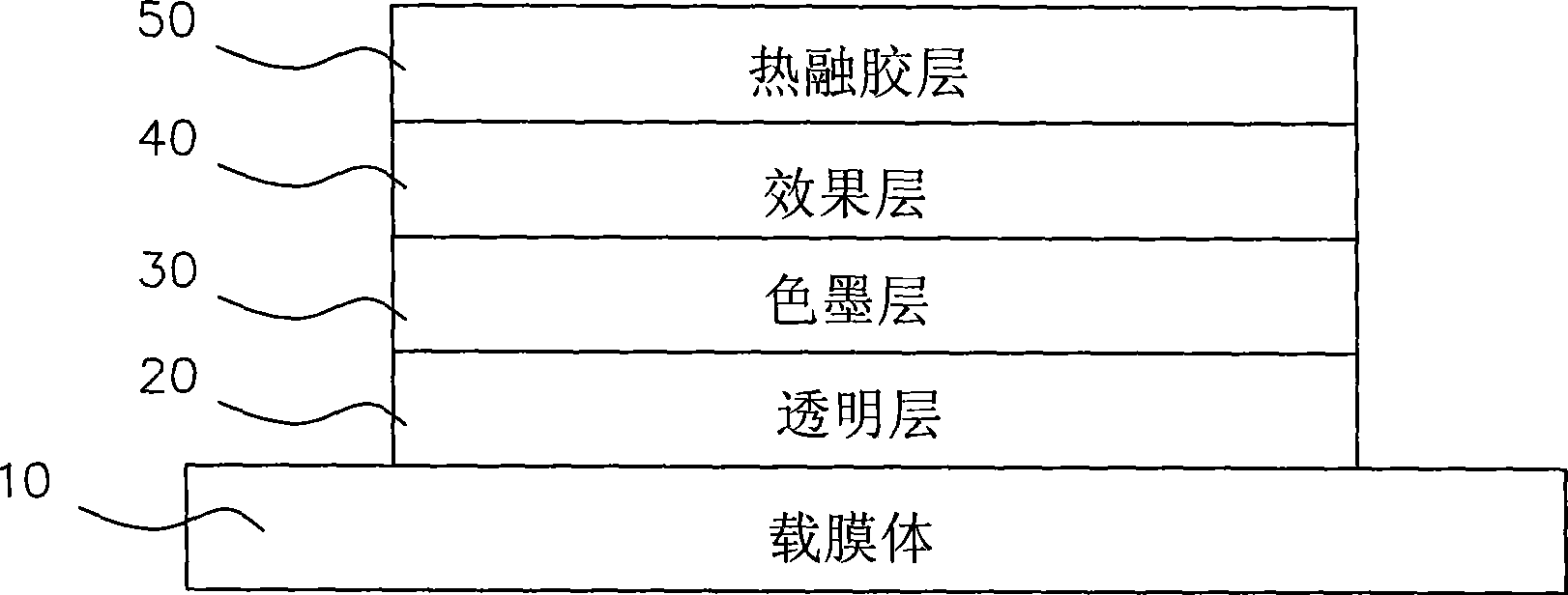

Method for preparing coating-proof 3D printing transfer paper

InactiveCN101367299AIncrease productivityLow costDecorative surface effectsPattern printingEnamel paintPrinting ink

The invention relates to a method for manufacturing a painting-free three-dimensional transfer paper for transcription of colored drawing on a curved surface. The method comprises the following steps: a film carrying body is provided; a required pattern is printed by stencil on the film carrying body to form a transparent layer; a color ink layer is formed on the transparent layer; an effect layer is manufactured on the surface of the color ink layer by utilization of the thickness of printing ink; and a thermal thawing rubber layer is printed on the effect layer, and a finished product is obtained. By adoption of the method for manufacturing the painting-free three-dimensional transfer paper, the colored drawing on the curved surface can be transcribed on magnesium aluminum alloy, aluminum alloy or metalwork products such as notebook computers, mobile phones, MP3 and so on; the effects of high light, extinction, local solid emboss and so on can be revealed and simultaneously enamel paint is not required to be painted; and the environmental pollution is reduced.

Owner:王淑满

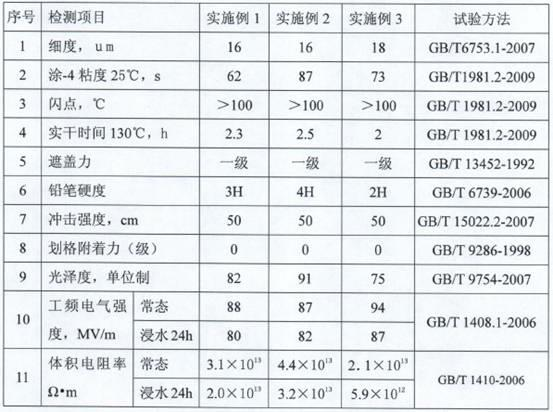

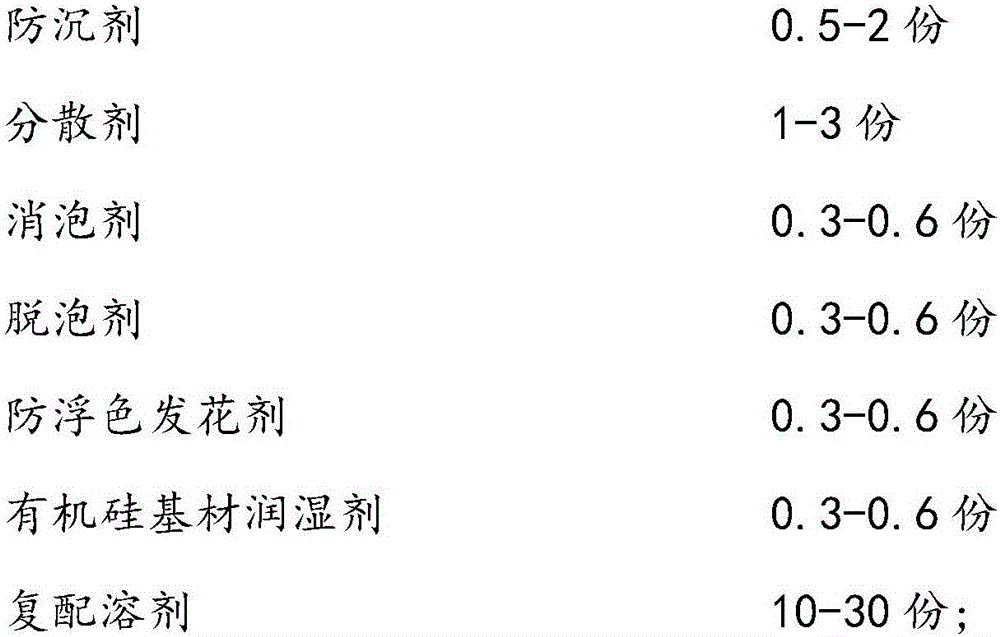

Single-component water-soluble insulated enamel paint and preparation method thereof

The invention relates to single-component water-soluble insulated enamel paint and a preparation method thereof. The single-component water-soluble insulated enamel paint is characterized by consisting of the following components in part by weight: 26 to 33 parts of water-soluble acrylic resin, 6.5 to 11 parts of amino resin curing agent, 28 to 36 parts of water, 1.7 to 2.4 parts of neutralizing agent, 2.5 to 5 parts of latent solvent, 31 to 37 parts of pigment and filler, 0.1 to 0.3 part of wetting agent, 0.1 to 0.3 part of dispersing agent, 0.1 to 0.3 part of defoaming agent and 0.1 to 0.3 part of flatting agent. The single-component water-soluble insulated enamel paint of the invention has the advantages that: the enamel paint does not need preparing during use and is rapid and convenient to use; paint liquid has high storage stability; combustion and explosion dangers are avoided; exhaust emission pollution is avoided, air environments of a workshop and a plant can be improved andharm to human body is reduced; and a paint film is yellowing-resistant at a high temperature and has large hiding power and good decorating and beautifying effects.

Owner:上海电动工具研究所(集团)有限公司

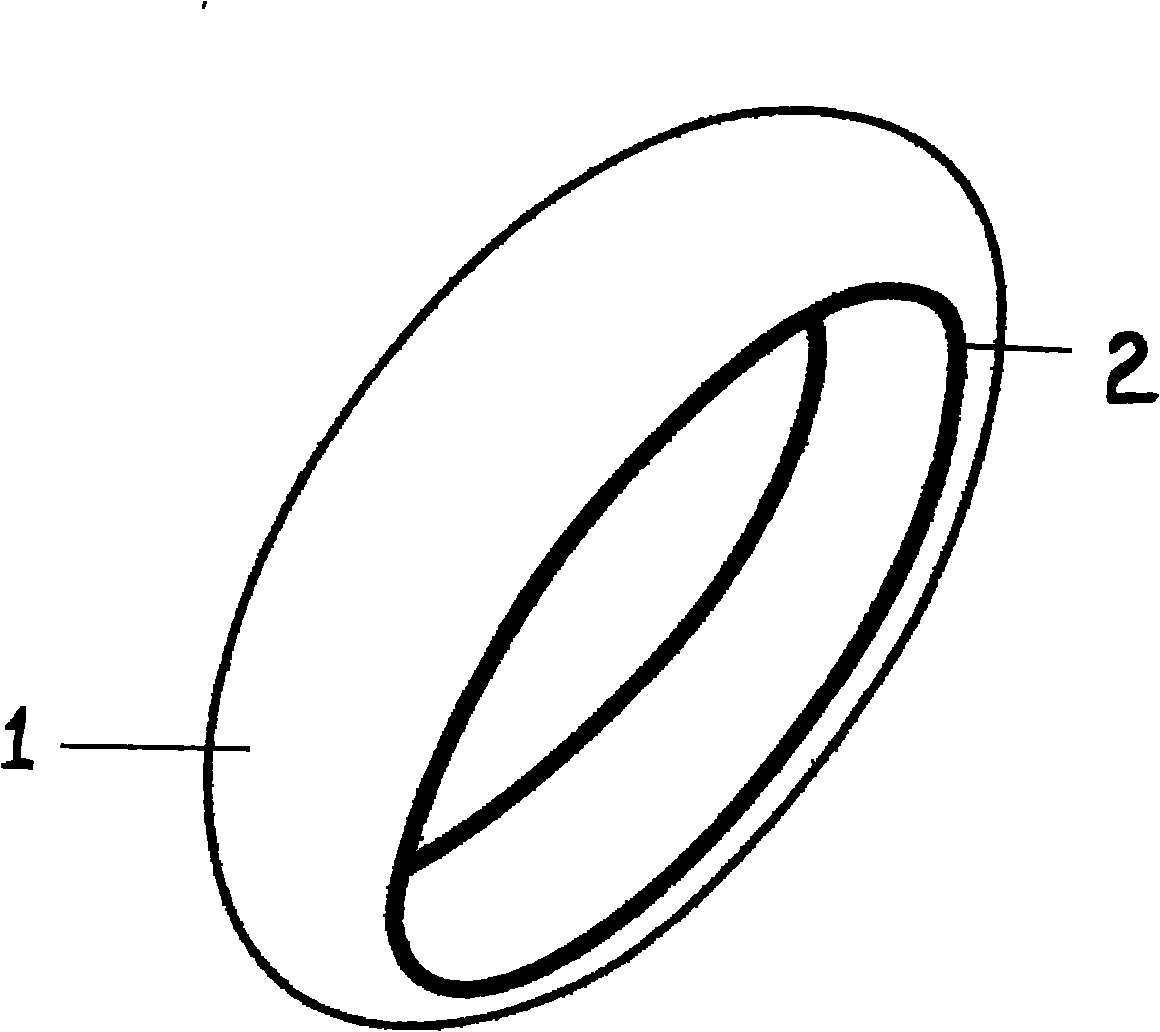

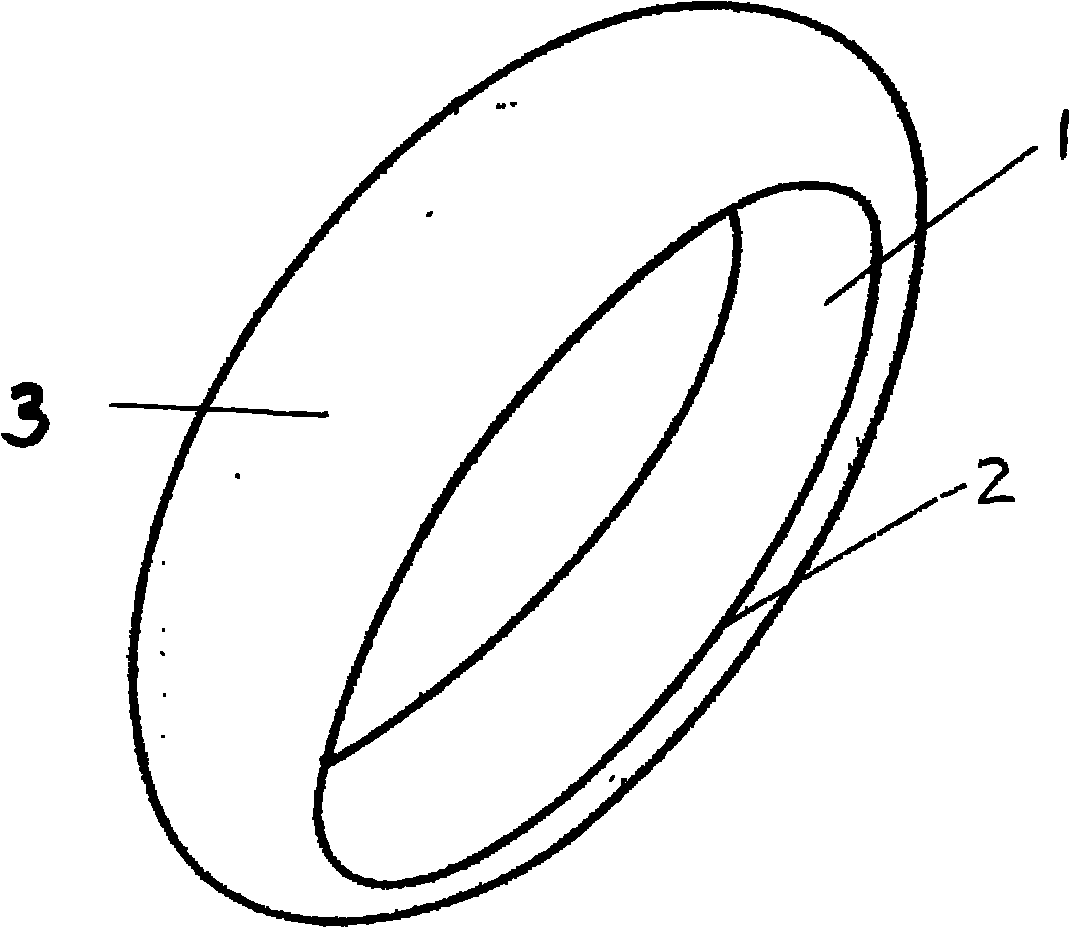

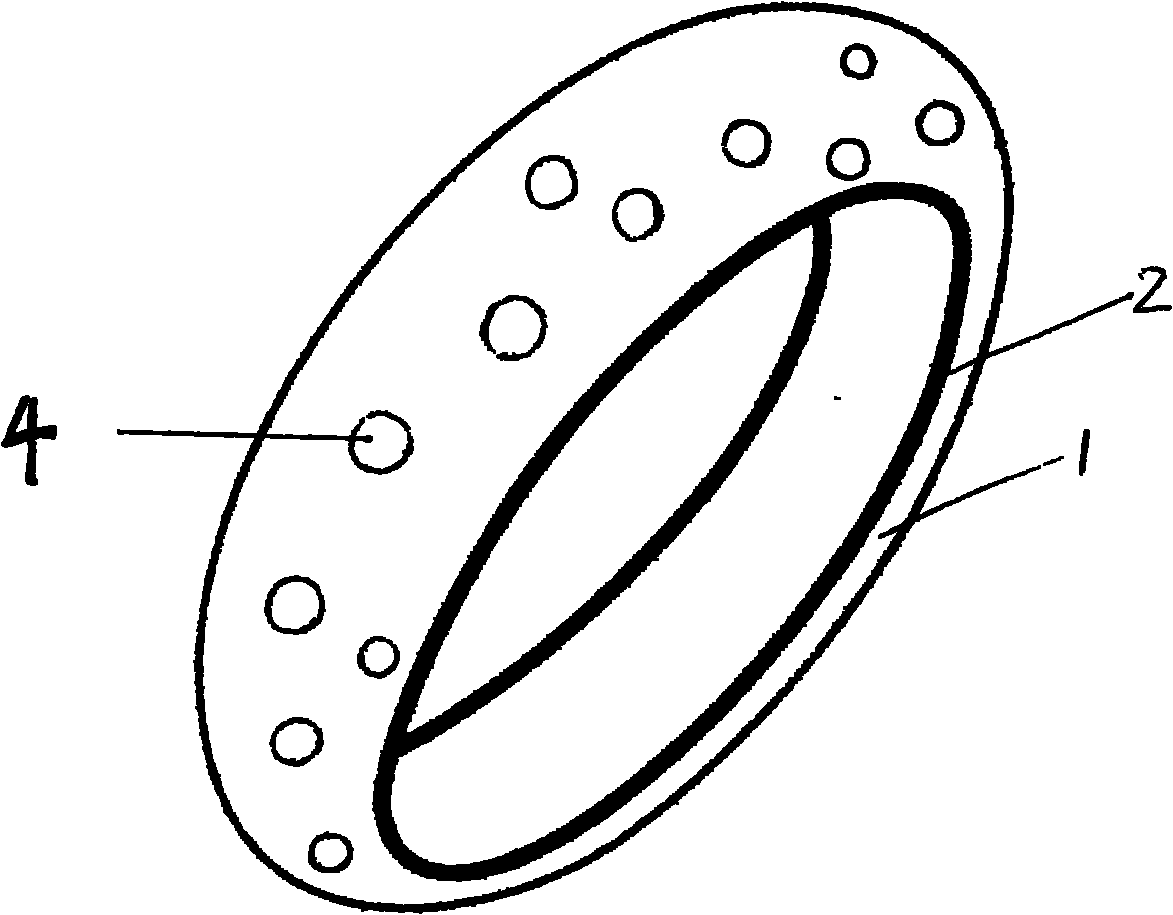

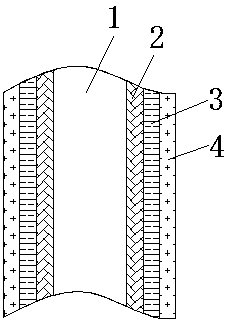

Bracelet with enamel painted on material mold

InactiveCN101779848AEasy to viewHigh collection valueBraceletsWrist-watch strapsEnamel paintMaterials science

The invention discloses a bracelet with enamel painted on a material mold. A glass mold is taken as a bracelet body, and patterns are drawn on the glass mold bracelet body, and the bracelet with the enamel painted on the material mold is prepared by sintering. The bracelet body (1) with the enamel painted on the material mold is embedded with a metal edge (2) / layer (3) and / or jewelry (4). The bracket is prepared by painting the enamel on the material mold, so the application field of the enamel painted on the material mold is expanded. By embedding metal, jewelry and the like, the enjoyment and collect value of the bracelet are improved.

Owner:翟皓月

Color-matching method of paint having brilliant feeling

To provide a method for color-matching a paint having brilliant feeling whose reference blend is already known and which contains a brilliant material, comprising (1) a step of obtaining the liquid color measurement data for an enamel paint not containing a brilliant material in accordance with a paint blend excluding the brilliant material and if necessary, a paint additive from a reference paint blend of a paint having brilliant feeling whose reference paint blend is already known, (2) a step of obtaining a toned enamel paint adjusted to the liquid color measurement data for the enamel paint by blending and toning a paint material such as an elementary color paint excluding a brilliant material and if necessary, a paint additive on the basis of the liquid color measurement data for the enamel paint, and (3) a step of color-matching a paint having brilliant feeling by adding a brilliant material and if necessary, a paint additive to the toned enamel paint.

Owner:KANSAI PAINT CO LTD

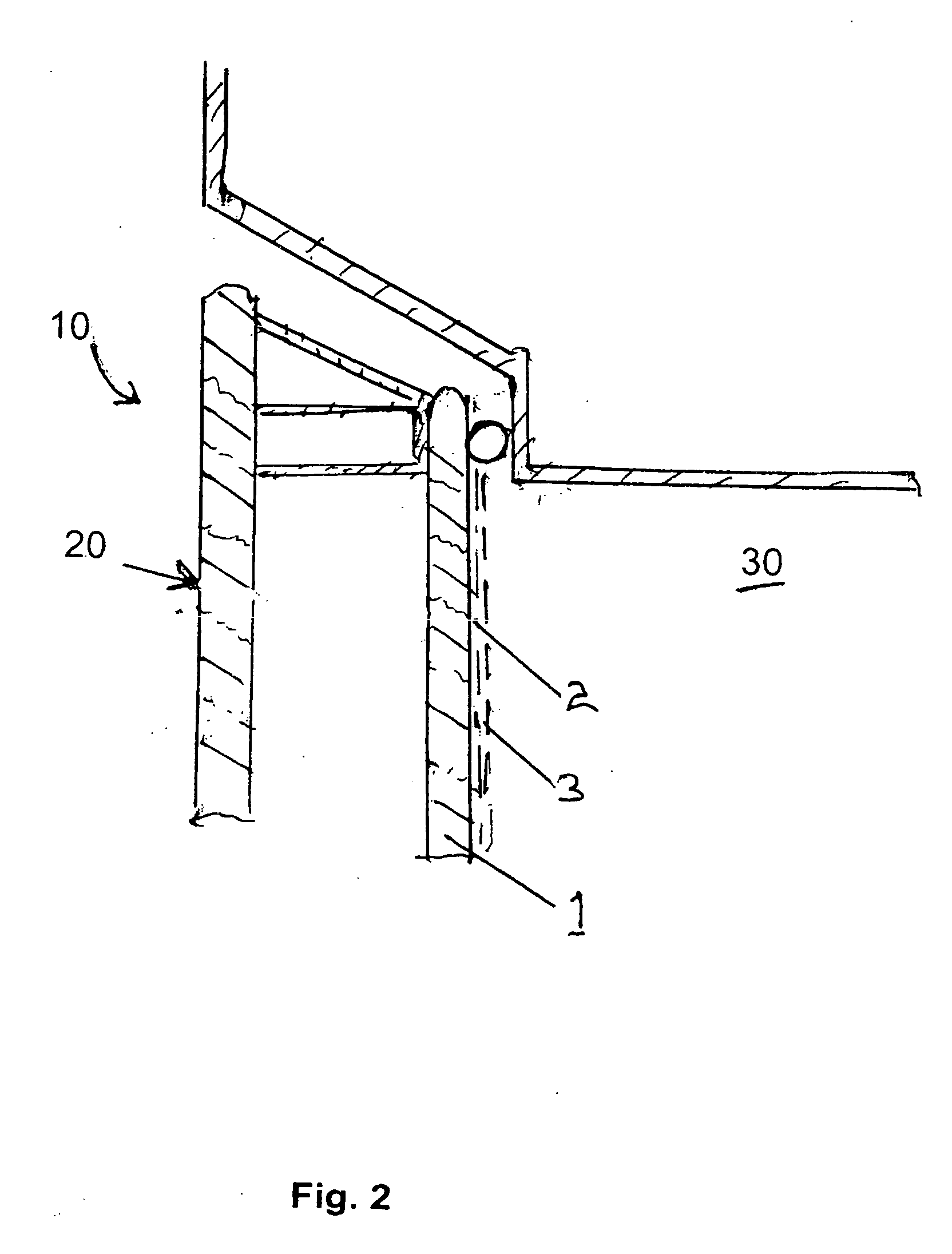

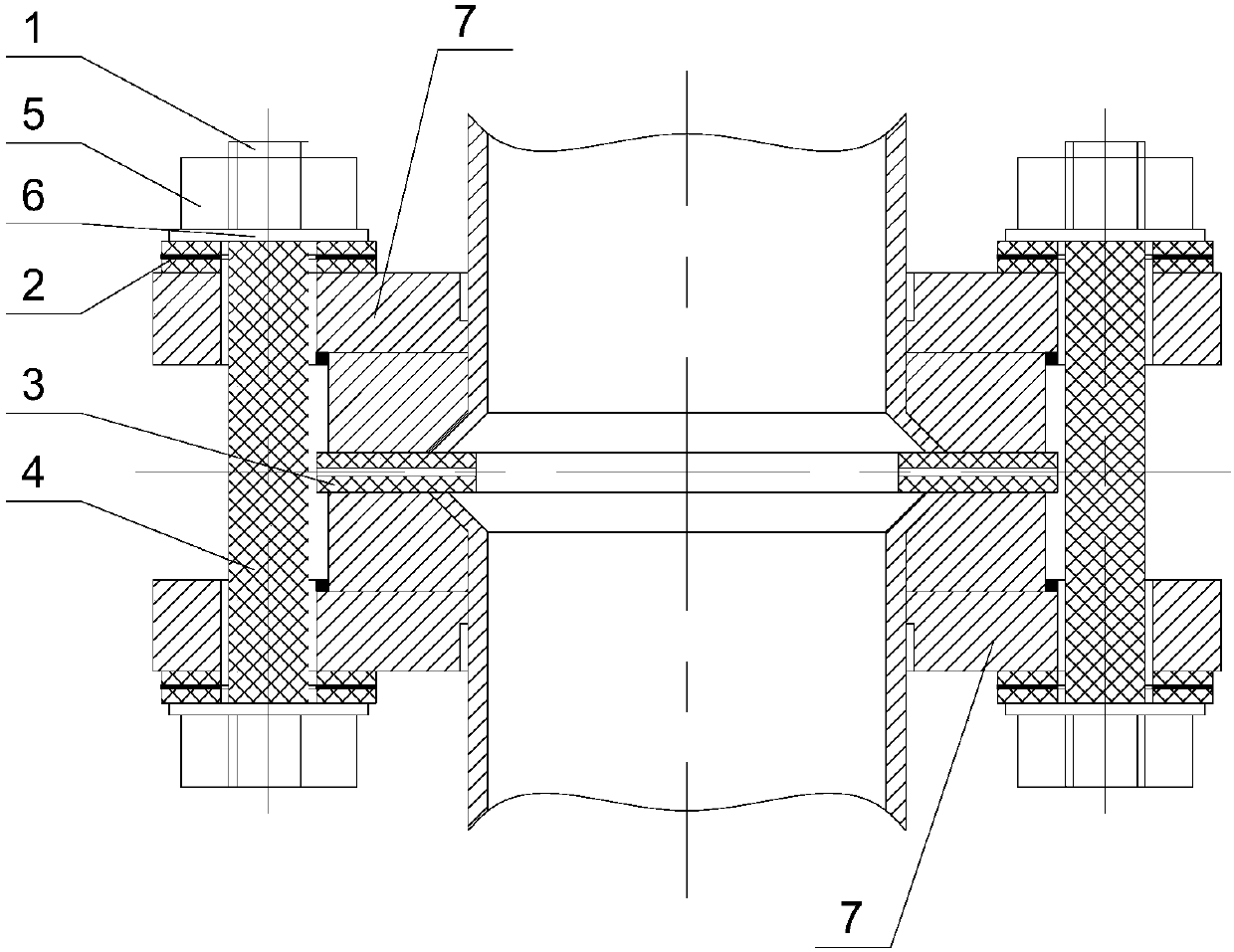

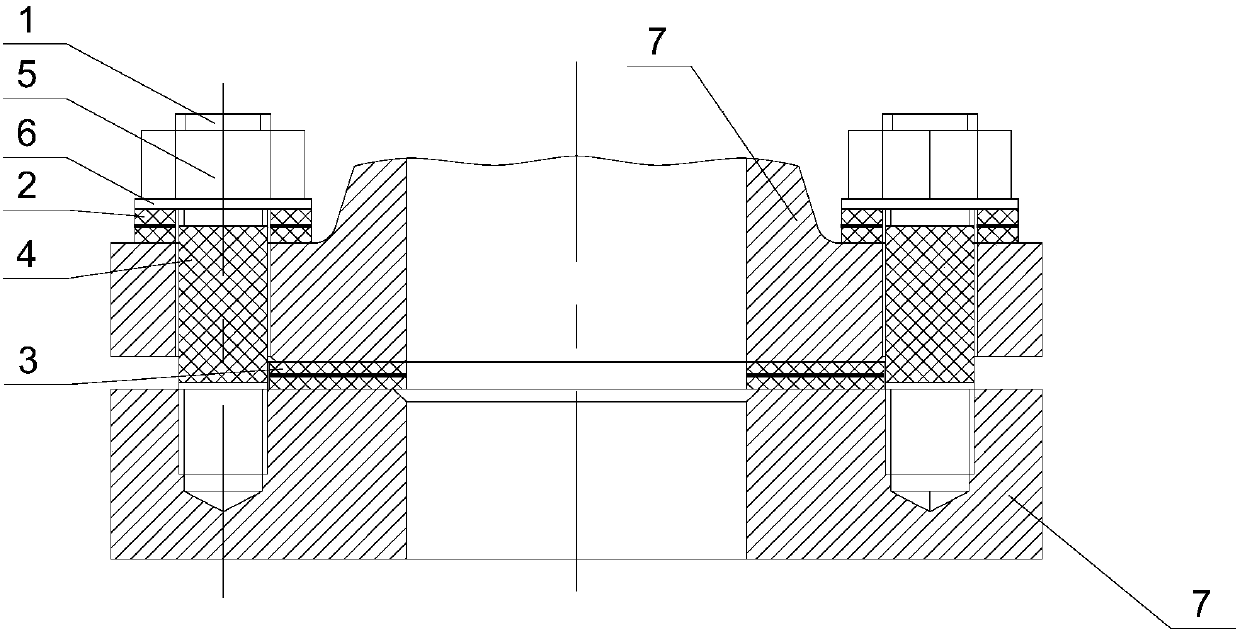

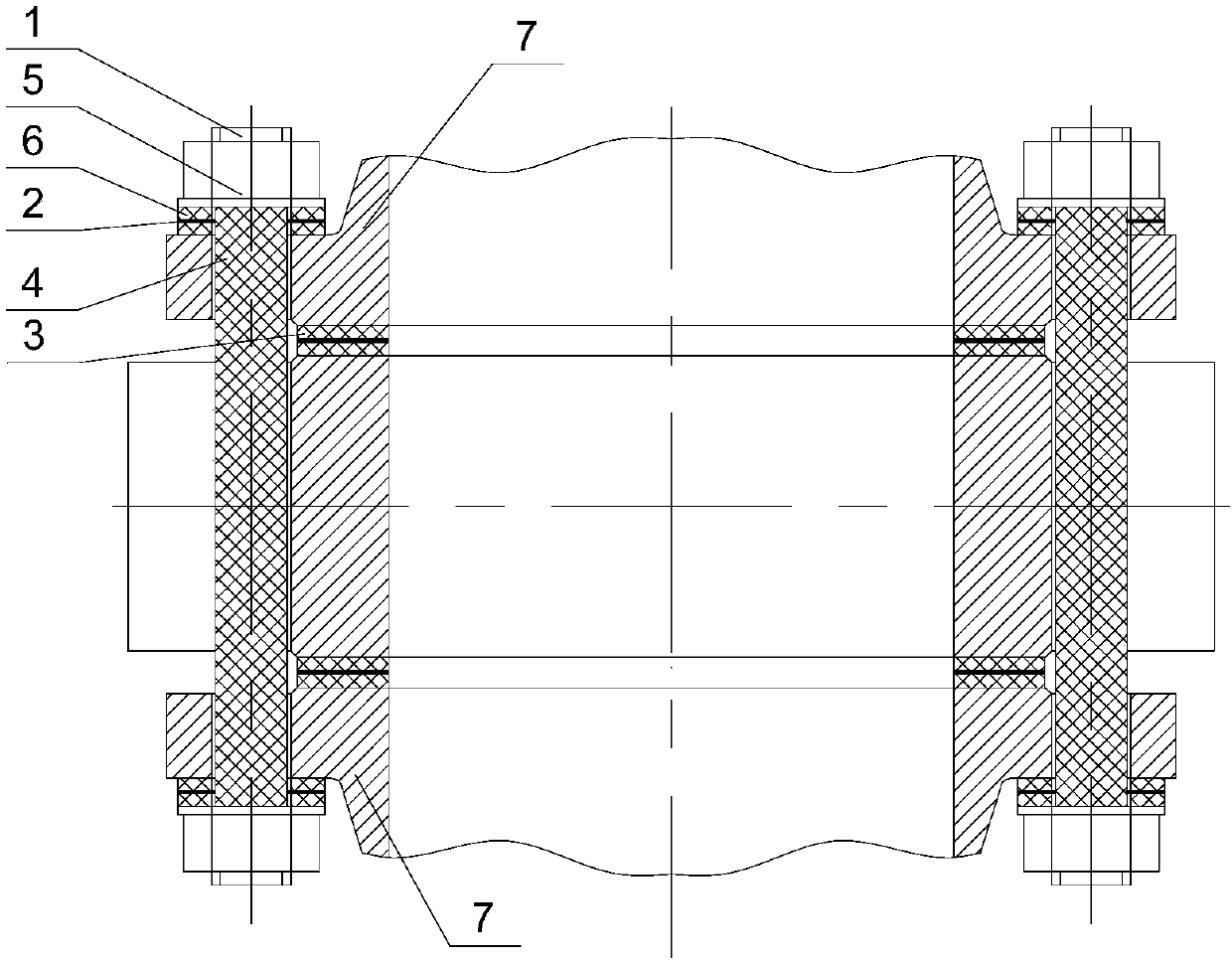

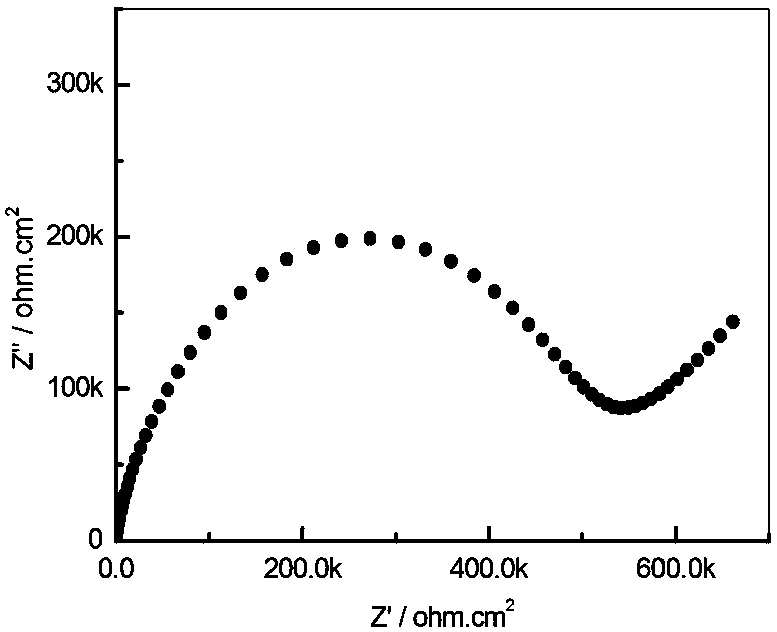

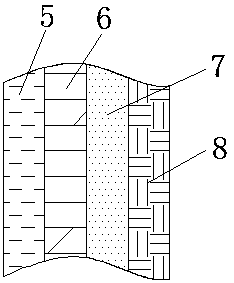

Special-shaped ship metal pipe system connecting corrosion prevention structure and construction method

PendingCN107795774AIncrease resistanceImprove insulation performanceFlanged jointsCorrosion preventionElectricityElectrical resistance and conductance

The invention discloses a special-shaped ship metal pipe system connecting corrosion prevention structure. The structure comprises bolts (1) which are arranged on the peripheries of connectors of special-shaped metal pipe system flanges (7) and nuts (5) which are matched with the bolts (1). Composite electric insulation spacers (3) are arranged between the connectors of the flanges (7). The periphery of each bolt (1) is sleeved with a protective tube (4). Composite electric insulation washers (2) are arranged between the flanges (7) and the nuts (2). The invention further discloses a construction method of the prevention structure. By adoption of the special-shaped ship metal pipe system connecting corrosion prevention structure, the composite electric insulation spacers are used for isolating the pipe system butt flange face from fasteners, electronic channels generated through special-shaped metal contact are cut off, the inner walls and the outer walls of pipelines within a certainrange of a connecting structure and the two ends of the structure are coated with insulation enameled paint, the resistance of seawater in pipe systems at the two ends of a special-shaped metal jointis increased, ion channels in the seawater are cut off, and a good electric insulation effect can be achieved.

Owner:NAVAL UNIV OF ENG PLA +1

Bottom-surface-in-one fluorocarbon enamelled paint and its preparing method

InactiveCN1935911AMeet the requirements of long-term anti-corrosionEnsure vividnessAnti-corrosive paintsElectrical resistance and conductanceLacquer

The invention relates to back plane unity new type fluorine carbon lacquer enamel used in corrosion protection. Its component mass shares are as follows: fluoro resin 20-70, polyaniline 1-25, dispersant 0.1-5, and wetting agent 0.1-5. The invention can ensure coating anti-corrosive property, stability, brilliancy, doesn't add other conducting filling while making static conducting anti corrosive paint, will not cause the organic carbon black or graphite granule pollution for the medium to keep conducting resistance stable.

Owner:查培法

Mica-titanium pearlescent glaze for enamel painted porcelain, preparation method of glaze slip and application of mica-titanium pearlescent glaze

InactiveCN108298818AImprove high temperature resistanceSolving Thermal Stability ChallengesTalcMaterials science

The invention discloses a mica-titanium pearlescent glaze for enamel painted porcelain, a preparation method of glaze slip and an application of the mica-titanium pearlescent glaze. The mica-titaniumpearlescent glaze for the enamel painted porcelain comprises an enamel painted porcelain base glaze and a mica-titanium pearlescent pigment protective glaze in a weight ratio being 4:(1-8), wherein the enamel painted porcelain base glaze is prepared from components in percentage by weight as follows: 22%-40% of quartz, 12%-20% of lepidolite, 6%-10% of feldspar, 2%-3% of talc, 10%-23% of borax, 6%-11% of boric acid, 3%-9% of strontium carbonate, 1%-3% of zinc oxide, 0%-3% of zirconium silicate, 0.1%-3% of cerium oxide, 0.5%-3% of aluminium oxide and 0%-5% of fluorite, and the sum is 100%. High-temperature stability of mica-titanium pearlescent pigment can be improved, the pearlescent characteristic of a ceramic product can be guaranteed, various features of the traditional enamel painted porcelain can be kept, then the enamel painted porcelain product can display extremely beautiful interference effect (metal gloss and color), and the pearlescent effect is added to the enamel painted porcelain.

Owner:HUNAN LILING HONGYU HONGCI CERAMICS

Method for producing enamel covered aluminum flat wire

InactiveCN1988061ALightweight unitReduce manufacturing costFlat/ribbon cablesBase-materialsMaterials scienceEnamel paint

This invention discloses a manufacturing method for enamel insulated Al flat wires, which manufactures an Al lead with round section shape to an Al flat lead with rectangular section by extrusion and drawing and uses drawing lubricant when drawing, cleans the flat Al lead in alkali solution to remove oil dirt on the surface then to remove the oxidation layer on the surface with organic solution then coats the lead with enamel paint to finish the process.

Owner:先登高科电气有限公司

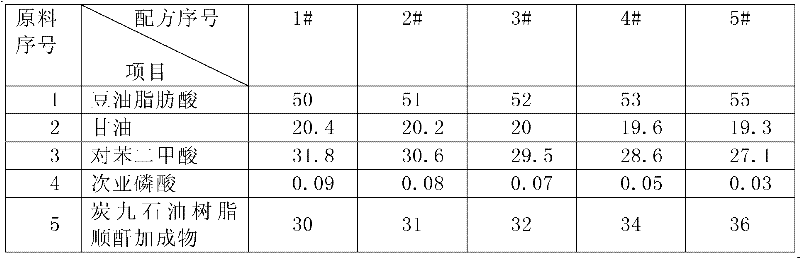

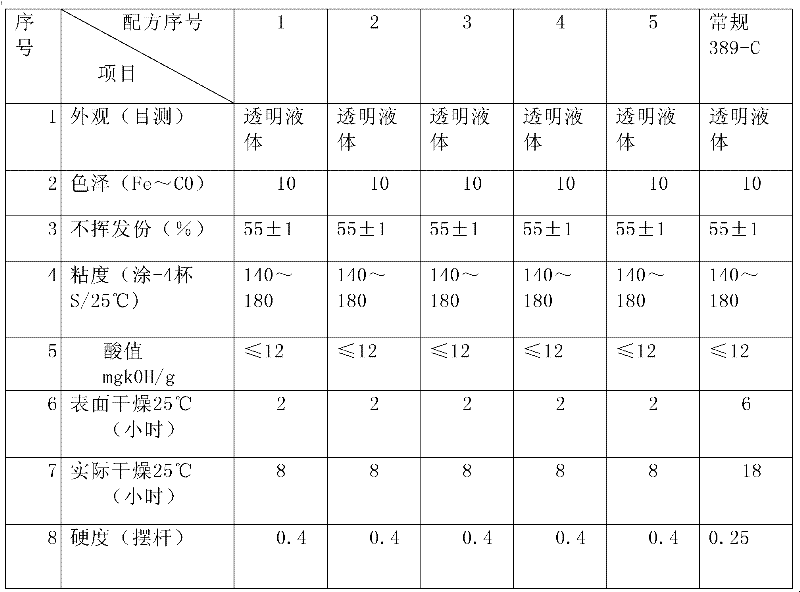

Alkyd resin for quickly drying alkyd enamel paint and preparation method thereof

ActiveCN102336897AIncrease unsaturationHigh hardnessMagnetic paintsPolyester coatingsGlycerolDrying time

The invention discloses alkyd resin for quickly drying alkyd enamel paint and a preparation method thereof. The alkyd resin for quickly drying alkyd enamel paint is prepared by twice esterification from the raw materials and an auxiliary material, wherein the raw materials comprise the following components in parts by weight: 50-55 parts of soybean oil fatty acid, 19.3-20.4 parts of glycerol, 27.1-31.8 parts of terephthalic acid, 30-36 parts of petroleum resin maleic anhydride addition compound and 0.03-0.09 part of hypophosphorous acid; and the auxiliary material comprises 2 parts by weight of xylene. The alkyd resin for quickly drying alkyd enamel paint has the advantages that: the drying time is shortened to 1 hour or below from original 4-5 hours on the premise of not increasing the resin cost, and the hardness is increased to more than 0.4 from 0.25, thereby meeting the normal-temperature quick drying requirement of customers.

Owner:山东奔腾漆业股份有限公司

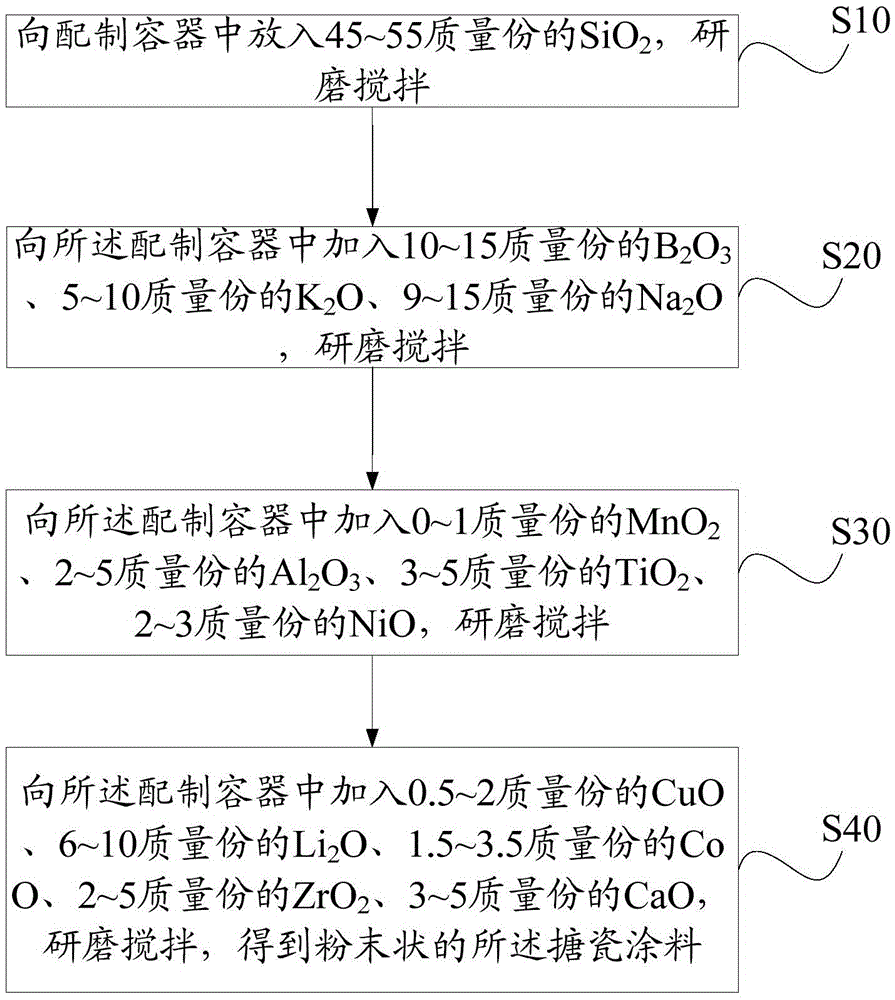

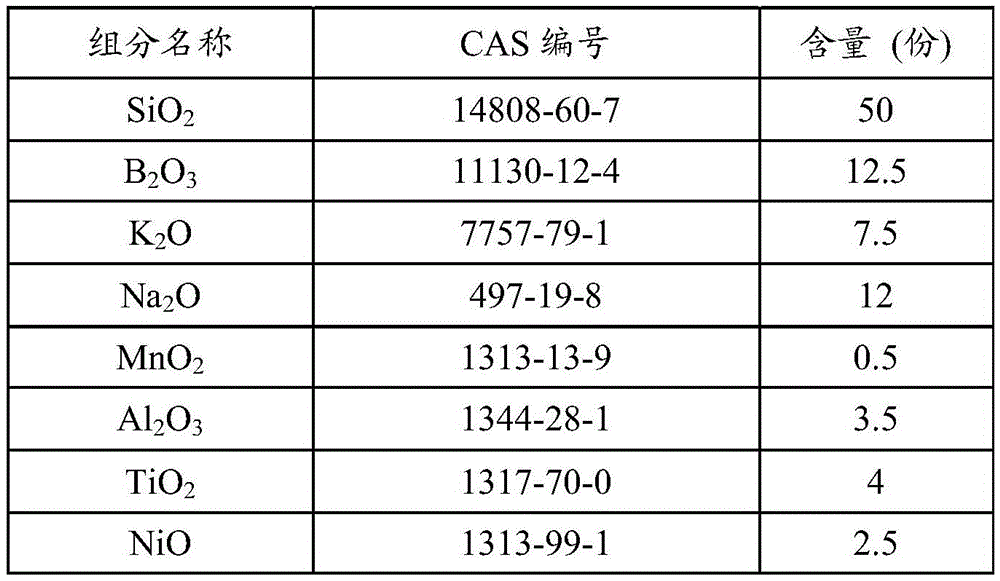

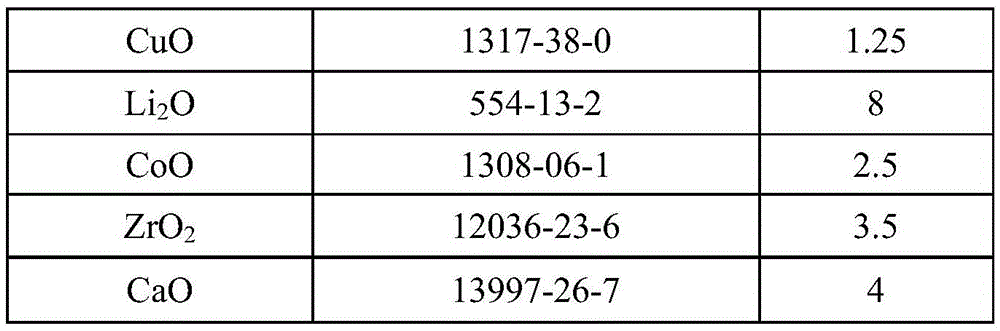

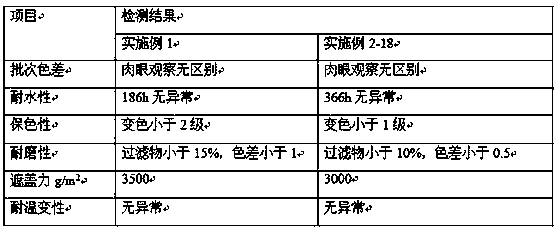

Enamel paint, preparation method thereof, and enamel product

The invention provides an enamel paint, a preparation method thereof, and an enamel product. The enamel paint comprises the following components in parts by weight: 45 to 55 parts of SiO2, 10 to 15 parts of B2O3, 5 to 10 parts of K2O, 9 to 15 parts of Na2O, 0 to 1 part of MnO2, 2 to 5 parts of Al2O3, 3 to 5 parts of TiO2, 2 to 3 parts of NiO, 0.5 to 2 parts of CuO, 6 to 10 parts of Li2O, 1.5 to 3.5 parts of CoO, 2 to 5 parts of ZrO2, and 3 to 5 parts of CaO. By optimizing the components and component contents of enamel paint, the adhesive force and adherence of the enamel paint are effectively improved; the bonding strength between enamel layer and product matrix is enhanced; the possibility of cracking and bursting of enamel is prominently reduced, the yield of enamel products is increased; moreover, during the preparation and application process, the coating performance is improved without using any other adhesive, auxiliary material, or other chemical component, thus the preparation technology and construction technology are simple, at the same time, the development period is not prolonged, and the cost is not increased.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Waterborne polyurethane enamel paint and preparation method and application method thereof

ActiveCN105504941AImprove wear resistanceGood color retentionMagnetic paintsPolyurea/polyurethane coatingsDefoaming AgentsEnamel paint

The invention relates to the technical field of real stone paint, in particular to waterborne polyurethane enamel paint and a preparation method and application method thereof. Raw materials of the waterborne polyurethane enamel paint comprise polyurethane emulsion, hydroxypropyl methyl cellulose, AMP-95, a dispersing agent, a wetting agent, a defoaming agent, a packing material, a coalescing agent, a levelling agent, a rheological agent, a thickening agent, a coupling agent and water. The excellent abrasion resistance and adhesiveness are achieved, and therefore the fading phenomenon is prevented from occurring; artificial colored sand prepared from the waterborne polyurethane enamel paint has the good weather resistance, water resistance, washing resistance and the like and is little in batch color difference, and ordinary white sand can be adopted, so that exhaustive exploitation on natural resources is avoided.

Owner:广东施彩新材料科技有限公司

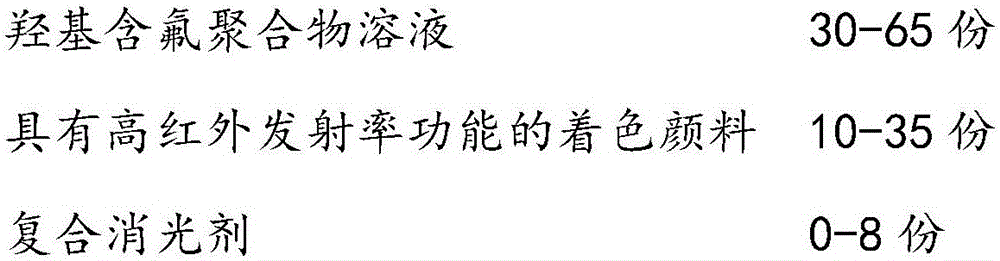

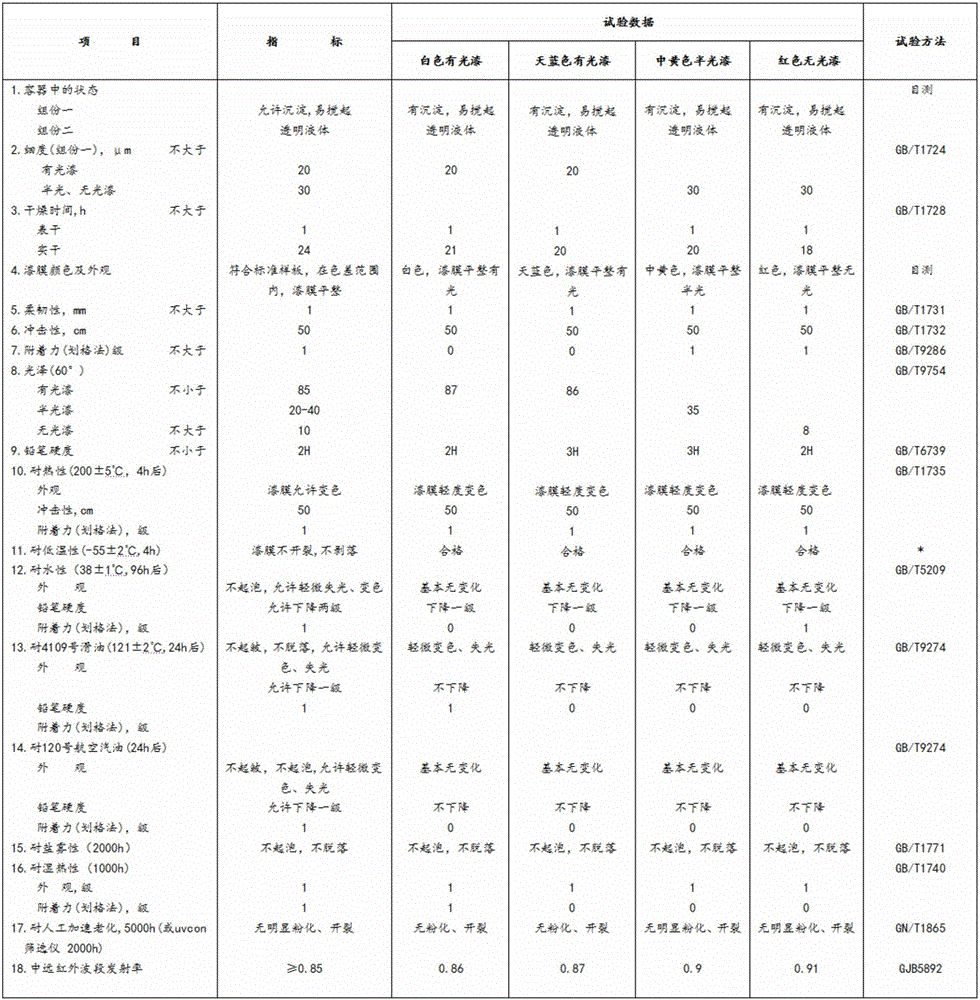

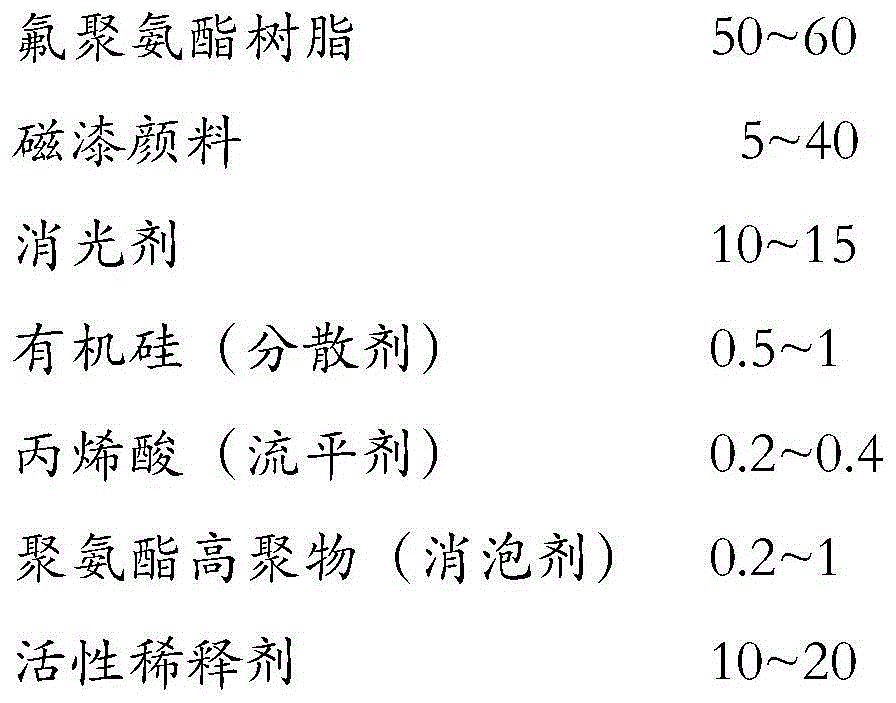

Bi-component fluorinated polyurethane enamel paint with high emissivity and preparation method thereof

InactiveCN106752826AEasy to prepareSuitable for the needs of large-scale industrial productionFireproof paintsMagnetic paintsFar infraredLubrication

The invention provides a bi-component fluorinated polyurethane enamel paint with high emissivity and a preparation method thereof. The bi-component fluorinated polyurethane enamel paint is formed by a component A and a component B at weight ratio of 100:(20-45); except a high infrared emitting function, the paint still has super weather fastness of the fluorinated polyurethane enamel paint; the artificial aging resistance can reach 5000 hours; the corrosion resistance is ultrahigh; the paint can resist against water for 96 hours at 38 DEG C and can resist against high-temperature lubrication oil for 24 hours; the adhesive force is excellent; the paint can resist against humidity and heat for 1000 hours and salt mist for 2000 hours; the paint is mainly applied to outdoor severe environments, such as, high-temperature high-humidity strong ultraviolet irradiation areas, seaborne and near coast areas and military or civil use fields with high demand on emissivity in medium far infrared wave band, such as airplane, equipment, facilities and vehicles; and the preparation method is simple and can meet the requirement of large-scale industrial production.

Owner:天津灯塔涂料工业发展有限公司

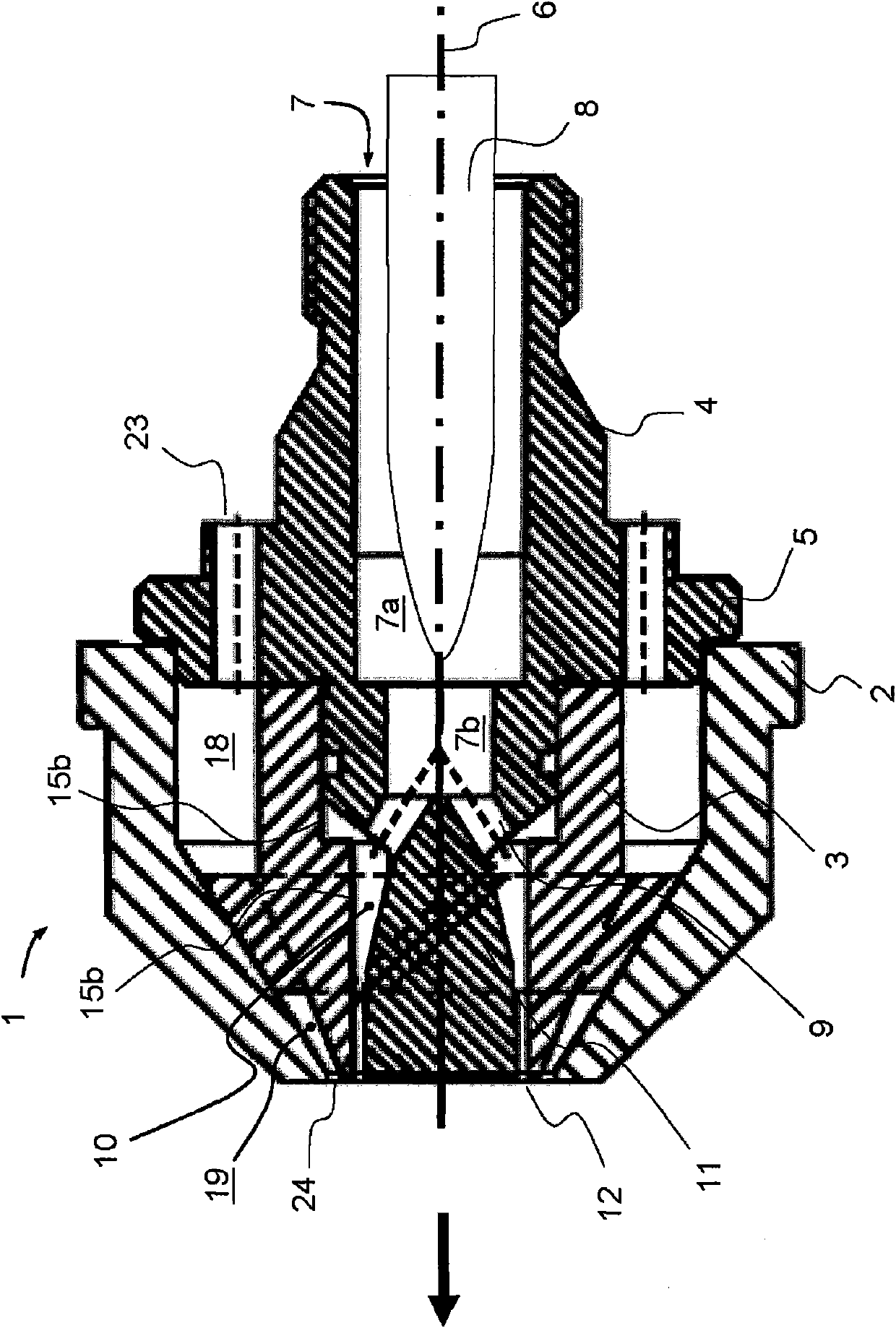

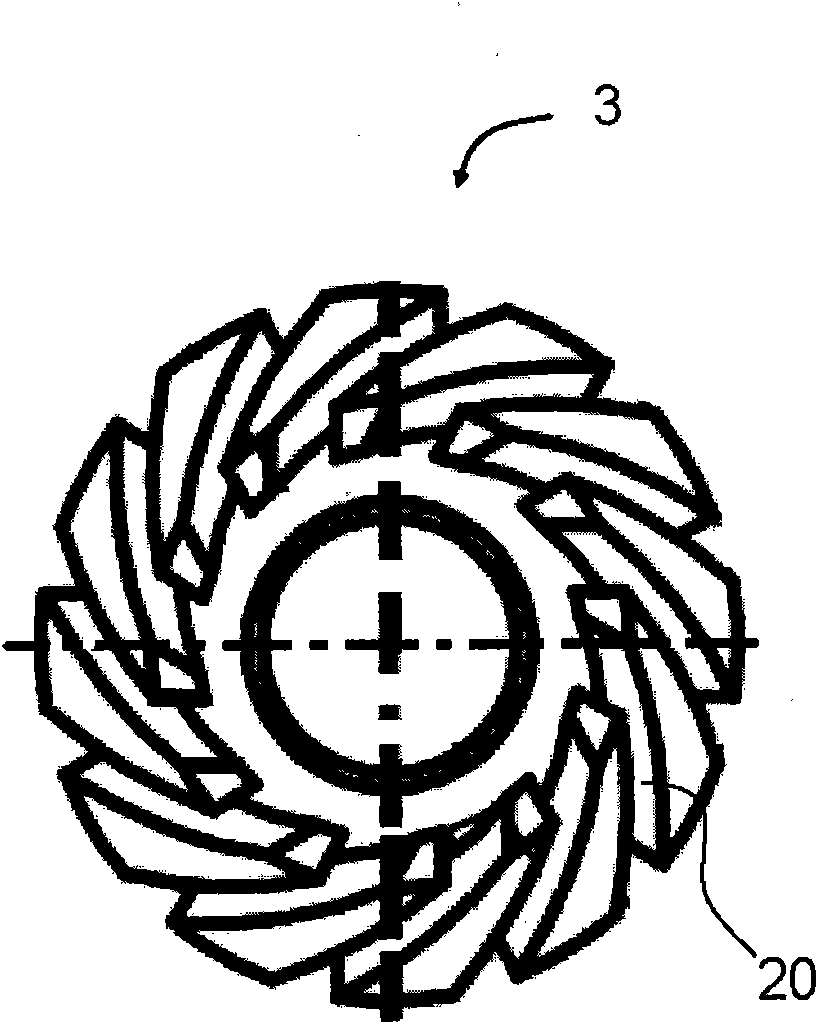

Device and method used for spraying liquid

InactiveCN102114441AHigh coating efficiencyEfficient sprayingLiquid spraying apparatusEngineeringWhirlwind

The invention relates to a method used for pneumatically spraying liquid especially such as colourant, enamel paint, paint, and the like and generating spray that is applied to an object, wherein the method is characterized in that a spraying device (1) is utilized. In the method, liquid basically departs from the spraying device (1) under zero pressure. Spraying air in the spraying device is formed through rotation at a first angle (14) relative to a longitudinal axis (6) of the spraying device and at a second angle (21) relative to an axes (22) perpendicular to the longitudinal axis (6) of the spraying device, so that spraying air can depart from the spraying device in a whirlwind manner. The first angle (14) ranges from 25 to 40 degrees, and the second angle (21) ranges from 35 to 55 degrees. Liquid is sprayed by spraying air after departing from the spraying device.

Owner:EIC GRP GMBH (DE)

Preparation method for efficient alkyd resin anti-corrosion enamel paint

InactiveCN107603439AEasy to manufactureMagnetic paintsAnti-corrosive paintsSodium BentonitePolyethylene glycol

The invention discloses a preparation method for efficient alkyd resin anti-corrosion enamel paint. The method comprises the following steps: by taking dry long-oil-length alkyd resin, dry short-oil-length alkyd resin and 20(s)-O-androstane-4-terpene-17beta-acyl camptothecin as film-forming materials, and taking a mixture of p-xylene and butyl acetate at a volume ratio as a solvent, adding talcumpowder, bentonite, a dispersing agent polyethylene glycol 200, a leveling agent polyether modified dimethyl silicone polymer and a drier manganese naphthenate; and quickly stirring, thereby acquiringthe efficient alkyd resin anti-corrosion enamel paint. The enamel paint has higher corrosion resistance and ageing resistance and can be applied to the heavy corrosion protection engineering in the fields of petrochemical equipment, pipelines, offshore oil platforms, wharf facilities and ships.

Owner:GUANGXI UNIV FOR NATITIES

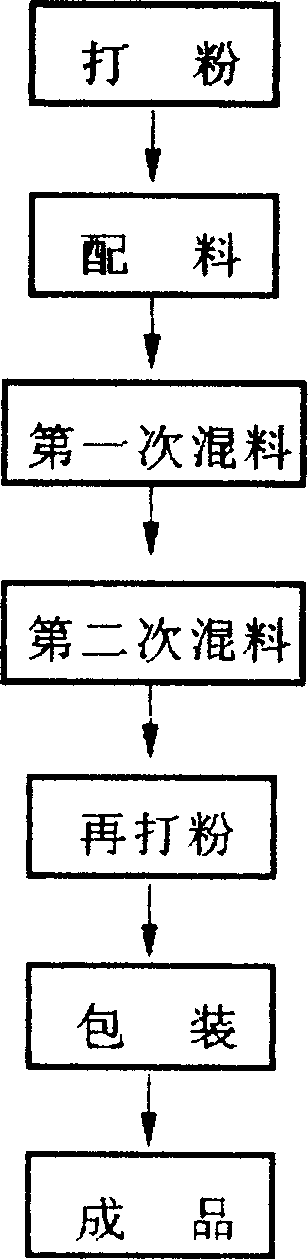

Novel environment protection ceramic interior wall paint and method for preparing the same

An environment protection type enamel paint for internal wall is prepared from French blue, lime powder, sodium carbonate, borax, magnesium oxide, magnesium sulfate (or chloride), plaster powder, sulfurized alkali, paper pulp and bleaching powder through pulverizing, proportioning, mixing twice and pulverizing. Its advantages are hard painted surface with high resistance to wriping and moisture, no poison, flame retarding, low cost and high whiteness.

Owner:苏幸全

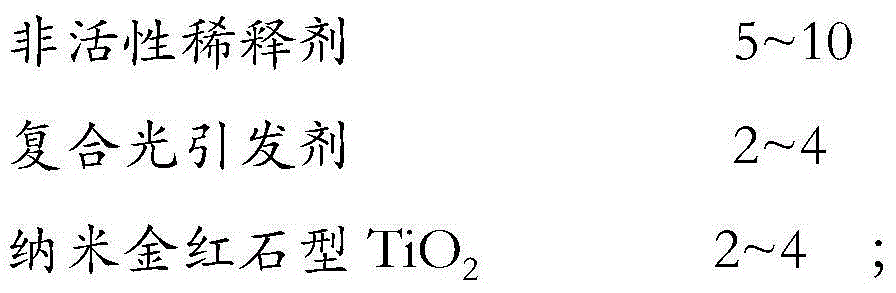

Primer matched paint and preparation method thereof

ActiveCN104387824AGood weather resistanceImprove mold resistanceMagnetic paintsSynthetic resin layered productsWeather resistanceElectron microscope

The invention provides a primer matched paint and a preparation method thereof. The primer matched paint is composed of a photocuring fluorine-containing aircraft skin enamel paint and an ultraviolet-curing polyurethane acrylate primer. The preparation method comprises the following steps: mixing the components, dispersing by sanding, processing by an ultrasonic dispersion technique for 40-120 minutes until the fineness reaches 10 mu m and the observation by an electron microscope shows that the nano TiO2 is uniformly dispersed in the paint solution, storing at 50 DEG C for 28 days, and slightly precipitating the paint. The VOC (volatile organic compound) of the primer matched paint can be lowered to 10% below. The weather resistance, mold resistance, salt spray resistance and damp-heat resistance of the paint are greatly enhanced, thereby ensuring that the formed cured paint film has excellent protective actions.

Owner:天津灯塔涂料工业发展有限公司

GIS enamel technology

ActiveCN107876353ASimple processWorkmanship is feasiblePretreated surfacesSpecial surfacesSand blastingSurface roughness

The invention belongs to the field of GISs, and particularly relates to a GIS enamel technology. The GIS enamel technology comprises the steps of roughening treatment, coating pretreatment, coating treatment and coating post-treatment which are sequentially conducted on a GIS shell part. Roughening treatment comprises that after the GIS shell part is subjected to sand blasting or shot blasting treatment, a Ra value of the surface roughness of the GIS shell part reaches 11-13, coating pretreatment comprises that the GIS shell part which is subjected to roughening treatment is sequentially subjected to degreasing, bright dipping, passivating, rinsing, water blowing and drying, coating treatment comprises that the GIS shell part which is subjected to coating pretreatment is sequentially coated with primer, putty, intermediate coat and enamel paint, and coating post-treatment comprises that polishing treatment is conducted on the GIS shell part which is subjected to coating treatment. According to the GIS enamel technology, a prepared GIS shell is bright in surface gloss, full and attractive, and has no particle or impurity, and the production cost is reduced while the quality of a GISmodel machine is improved.

Owner:SHANGHAI SIEYUAN HIGH VOLTAGE SWITCHGEAR

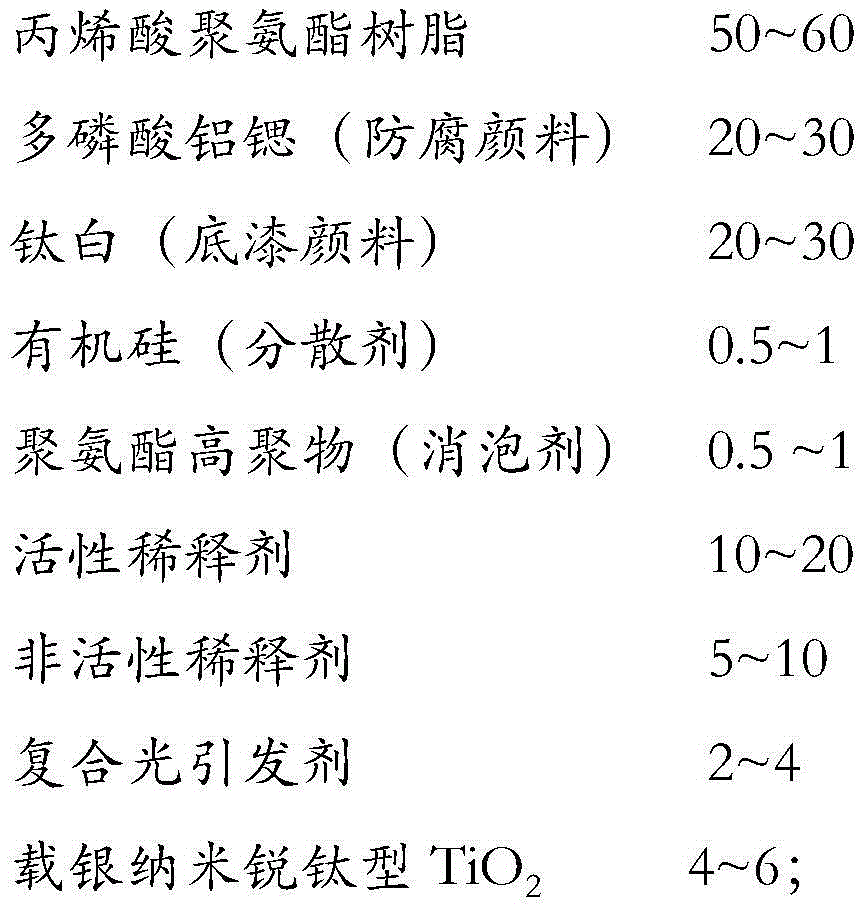

Drill bit with long service life

InactiveCN108526553ASolve the problem of insufficient service lifeExtended service lifeTwist drillsEpoxyWear resistant

The invention discloses a drill bit with long service life. The drill bit comprises a drill bit body; a wear-resistant layer is arranged on the surface of the drill bit body; a corrosion-resistant layer is arranged on the side, far away from the drill bit body, of the wear-resistant layer; a high-temperature-resistant layer is arranged on the side, far away from the wear-resistant layer, of the corrosion-resistant layer; the wear-resistant layer comprises wear-resistant pimpled rubber, a ceramic polymer coating layer body, a high-temperature coating layer body and a crystal nucleus new material layer body; and the ceramic polymer coating layer body is located on the outer side of the wear-resistant pimpled rubber. The drill bit with long service life has the advantages that the wear-resistant layer, the corrosion-resistant layer, the high-temperature-resistant layer, the wear-resistant pimpled rubber, the ceramic polymer coating layer body, the high-temperature coating layer body, thecrystal nucleus new material layer body, a primer layer body, a coal tar enamel paint layer body, a petroleum asphalt layer body, an epoxy resin layer body, an organic silicon layer body, an inorganiccoating layer body and a fire-resistant protective coating are arranged, so that the problem that the service life of a traditional drill bit is not long enough can be solved, the service life is long, and the drill bit is worthy of popularization.

Owner:襄城伟业智能机电设备制造有限公司

Water-base fast-drying high gloss ambient crosslinking nail paint resin and preparation method thereof

InactiveCN101810548ALow in VOCsAvoid harmCosmetic preparationsToilet preparationsWater basedHazardous substance

The invention relates to a water-base fast-drying high gloss ambient crosslinking nail paint resin and a preparation method thereof. The composition components comprise n-butyl acrylate, n-butyl methacrylate, methyl methacrylate, styrene, methacrylic acid, diacetone acrylamide, adipic dihydrazide, ammonium persulfate, emulsifier OP-10, emulsifier sodium dodecyl sulfate, ammonia and deionized water. After the resin is prepared into water-base nail paint (also called nail polish), the content of volatile organic compounds is less than 20 gram per liter, the nail paint does not contain harmful substances, such as triphenyl, formaldehyde and the like, has no poison and no smell, is harmless to human bodies and has no pollution to the environment, short drying time, strong adhesion and water resistance, high brightness of the paint film, bright color and strong color retention, as the solid content of the resin is high, the paint film thickness of thin painting is guaranteed, the surface is full and smooth, and the resin is an environmental-friendly product which can protect human health and is a substitute of nitro-nail paint which is commonly used in market currently.

Owner:BEIJING CARL RES INST FOR CHEM IND

Alkyd resin wire enamel and preparation method thereof

InactiveCN103740243AImprove stabilityStrong chemical resistanceAnti-corrosive paintsPolyamide coatingsTert butylDimethyl siloxane

The invention discloses an alkyd resin wire enamel, which is characterized by being prepared from the following raw materials by weight part (kg): 12-15 of long oil length alkyd resin, 12-15 of amino resin, 12-15 of nylon 12, 1-2 of 2-hydroxy4-octyloxy benzophenone, 1-2 of methylbenzotriazole, 2-3 of 2, 6-di-tert-butyl m, p-cresol, 2-3 of monobutyltin oxide, 5-10 of propylene glycol methyl ether acetate, 3-5 of zinc naphthenate, 2-5 of polydimethylsiloxane, 1-2 of 2-thiolbenzimidazole, 14-18 of polyvinyl alcohol, 10-14 of vermiculite powder, 1-2 of an antioxidant RD, 7-9 of an assistant, 80-90 of m, p-cresol, and 100-120 of dimethylbenzene. Compared with the prior art, the processing method involved in the invention is simple, and the wire enamel paint film prepared by the invention has the advantages of good stability and strong chemical corrosion resistance, and can be applied to electric appliance in special industries to maintain good electrical insulation performance and mechanical properties. The production cost can be greatly reduced, and the work efficiency can be improved.

Owner:铜陵天河特种电磁线有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com