Method for preparing coating-proof 3D printing transfer paper

A transfer paper, coating-free technology, which is applied in the post-processing of printing, the printing of special varieties of printed matter, and the process for producing decorative surface effects. Rigidity and other problems, to achieve the effect of improving production efficiency, personalized and diversified appearance requirements, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

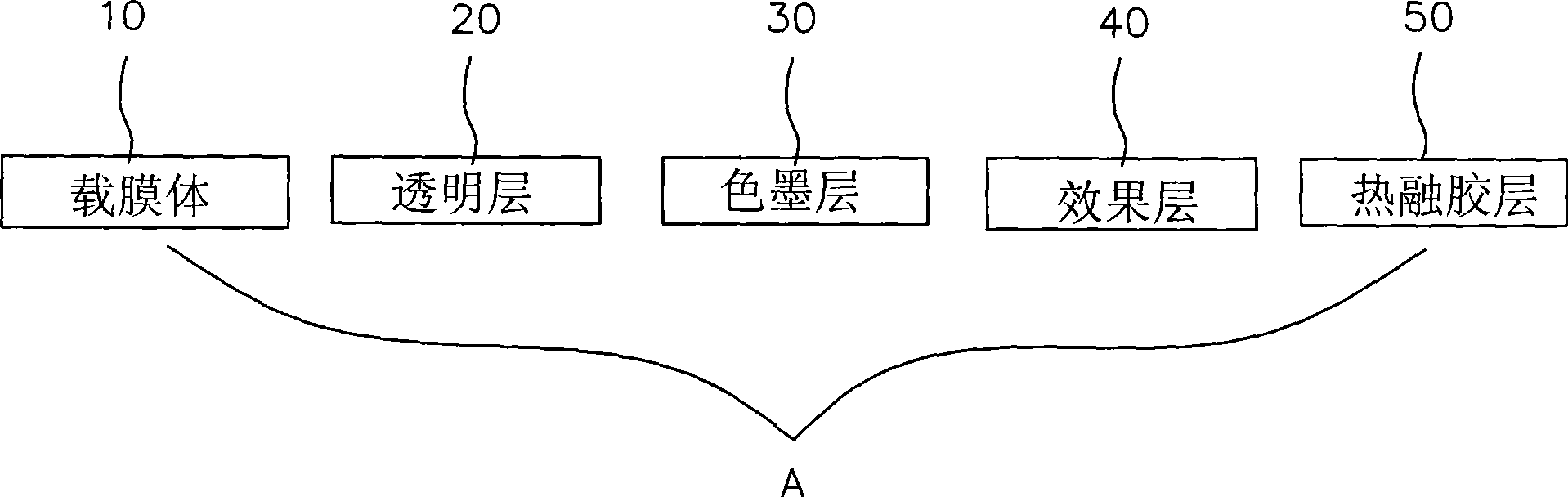

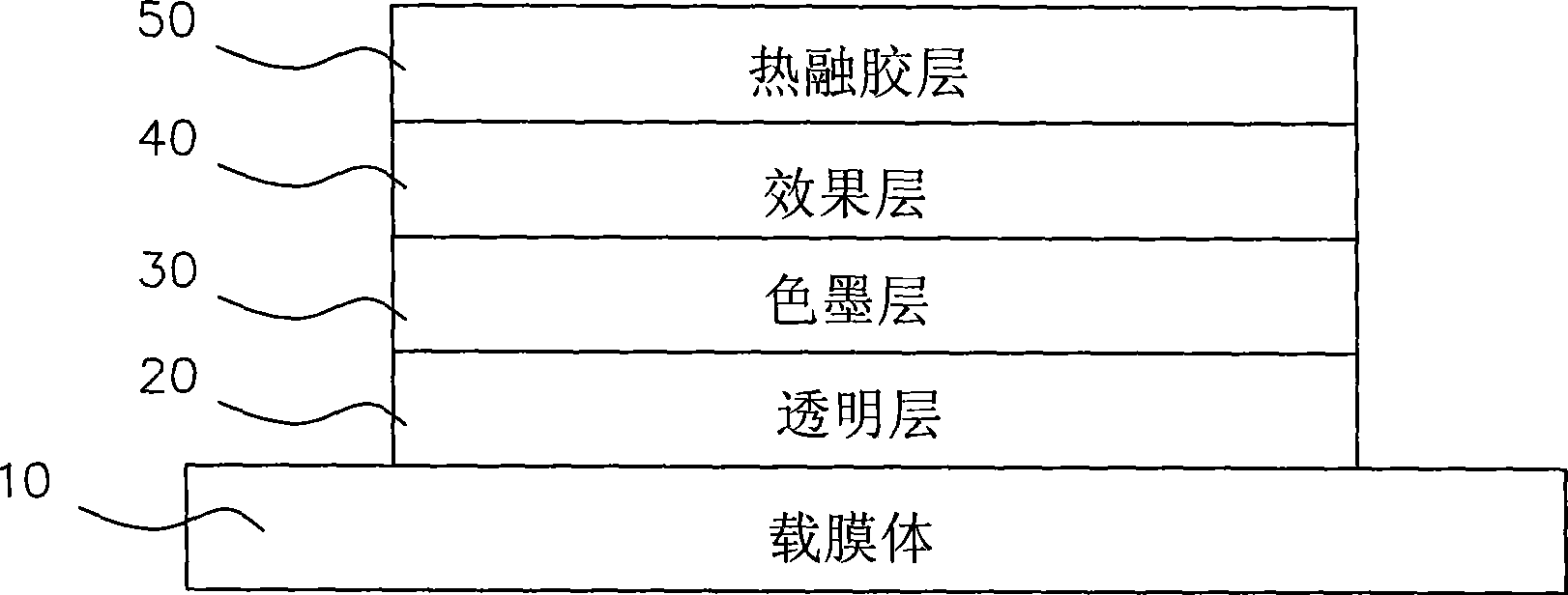

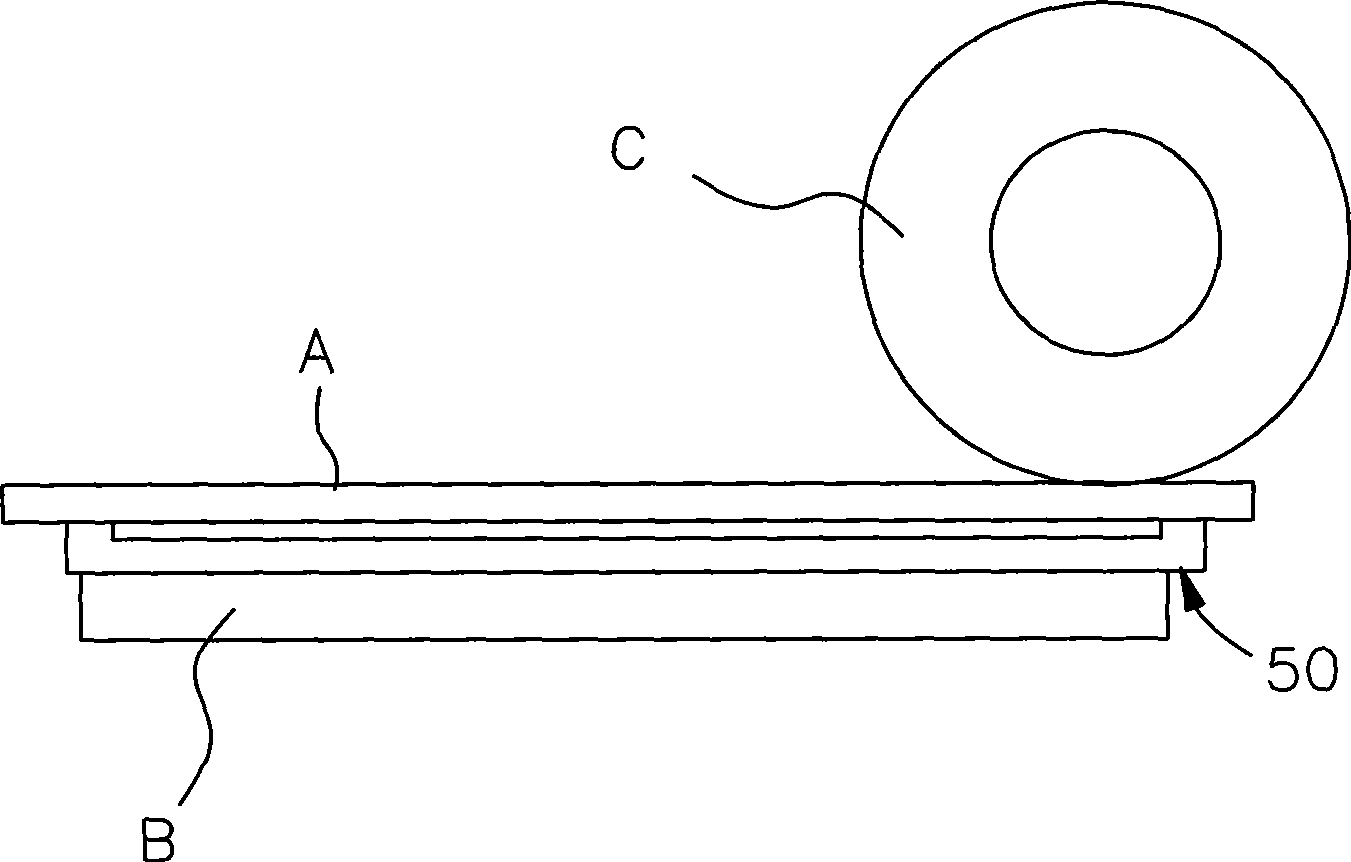

[0023] Such as figure 1 Shown is a schematic diagram of the production process of the coating-free 3D transfer paper A of the present invention, and its production steps include: providing a carrier film body 10, printing the desired pattern on a carrier film body 10 to form a transparent layer 20; A color ink layer 30 is formed on the layer 20; an effect layer 40 is produced on the surface of the color ink layer 30 by utilizing the thickness of the printing ink; and a hot-melt adhesive layer 50 is printed on the effect layer 40 .

[0024] The transfer paper A prepared by the above steps, wherein the type of the carrier film body 10 can be based on different requirements, can be acrylic (polyacrylic resin), polyester resin (polyester resin), polyvinyl acetate resin (polyacetate resin) resin), polyvinylchloride and vinyl acetate copolymer (polyvinylchloride and polymerization resin) and other chemical materials; the carrier film body 10 can be pumped into a thin film state, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com