Method for preparing alkyd resin using illegal cooking oil

A technology of alkyd resin and waste oil, which is applied in coatings, polyester coatings, etc., can solve the problems of rising paint raw materials, increasing the production cost of coatings, and difficult disposal of waste oil, and achieves excellent vividness, excellent corrosion resistance, The effect of excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Raw materials used in the following examples

[0025] Hogwash oil (removed and refined from gutter oil)

[0026] Rosin (422# Zhejiang Kaihua Jiepeng)

[0027] Glycerin (Hong Kong Three Invitations Yonglian Chemical)

[0028] Pentaerythritol (Zhengzhou Zhiyuan Chemical)

[0029] Neopentyl Glycol (Chuzhou Jinyuan Chemical Industry Co., Ltd., Anhui Province)

[0030] Accelerator (Lithium Hydroxide or Huangdan Reagent Store)

[0031] Terephthalic acid (PTA offcuts, Daqing, Heilongjiang)

[0032] Petroleum resin (C-9 Puzhou Ruike Chemical)

[0033] Mixed solvent (C9 aromatics, turpentine, coking xylene in a 1:1:1 mixture Sinopec)

[0034] Reflux solvent (Xylene Sinopec)

[0035] The proportioning of materials of each embodiment is as follows:

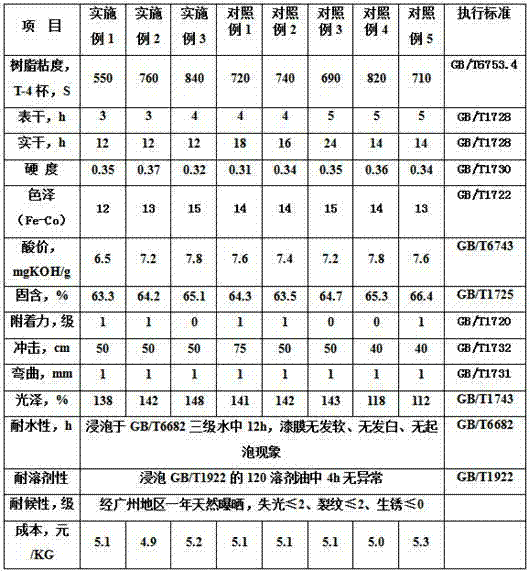

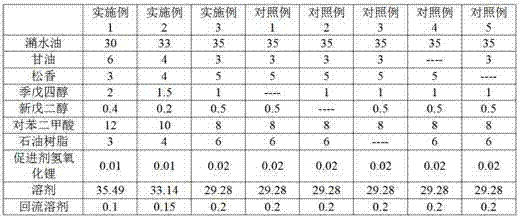

[0036] Table 1: Example proportioning, unit Kg

[0037]

[0038] The preparation method is:

[0039] 1. Put hog oil, rosin, glycerin, pentaerythritol, neopentyl glycol, and accelerators into the reaction kettle, ignite an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com