Renewable alkyd resin with high solid portion and preparation method of enamel paint

A technology of alkyd enamel and alkyd, applied in the field of coatings, can solve problems such as poor performance, achieve the effect of reducing VOC, wide source of raw materials and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with specific embodiment, typical but non-limiting embodiment of the present invention is as follows:

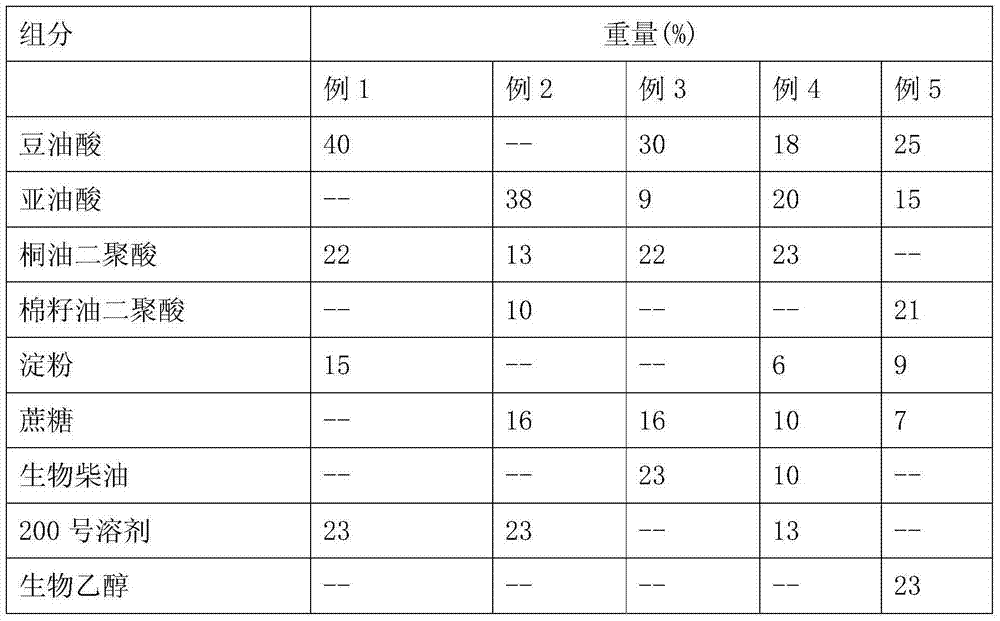

[0033] The formulation components and mass percentages of the renewable, high-solid alkyd resin used in the present invention are shown in Table 1.

[0034] Table 1. Resin formulations

[0035]

[0036] Renewable, high solids alkyd resins Examples 1 to 5 were prepared as follows:

[0037] Put the vegetable oleic acid, vegetable oil dimer acid and polysaccharide in the reaction kettle, start stirring, add the solvent to raise the temperature and reflux, raise the temperature to 200-220°C for esterification, until the acid value drops to 5-10mgKOH / g as the end point, cool down To 120-130 DEG C, add the formulated amount of solvent to get a renewable, high-solid alkyd resin with a solid content of 75%.

[0038] In the present invention, the indicators of renewable, high-solid alkyd resin example 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com