Glass ceramic or glass cook top with an IR-permeable undercoat

a technology of glass ceramic and undercoat, which is applied in the direction of coating, hot plate heating arrangement, application, etc., can solve the problems of only limited heat resistance, high cost of observation-preventing coating application, and troublesome appearance of these structural elements for users, so as to achieve the effect of only slightly reducing the undesirable reduction of the strength or durability of the glass ceramic cook top

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

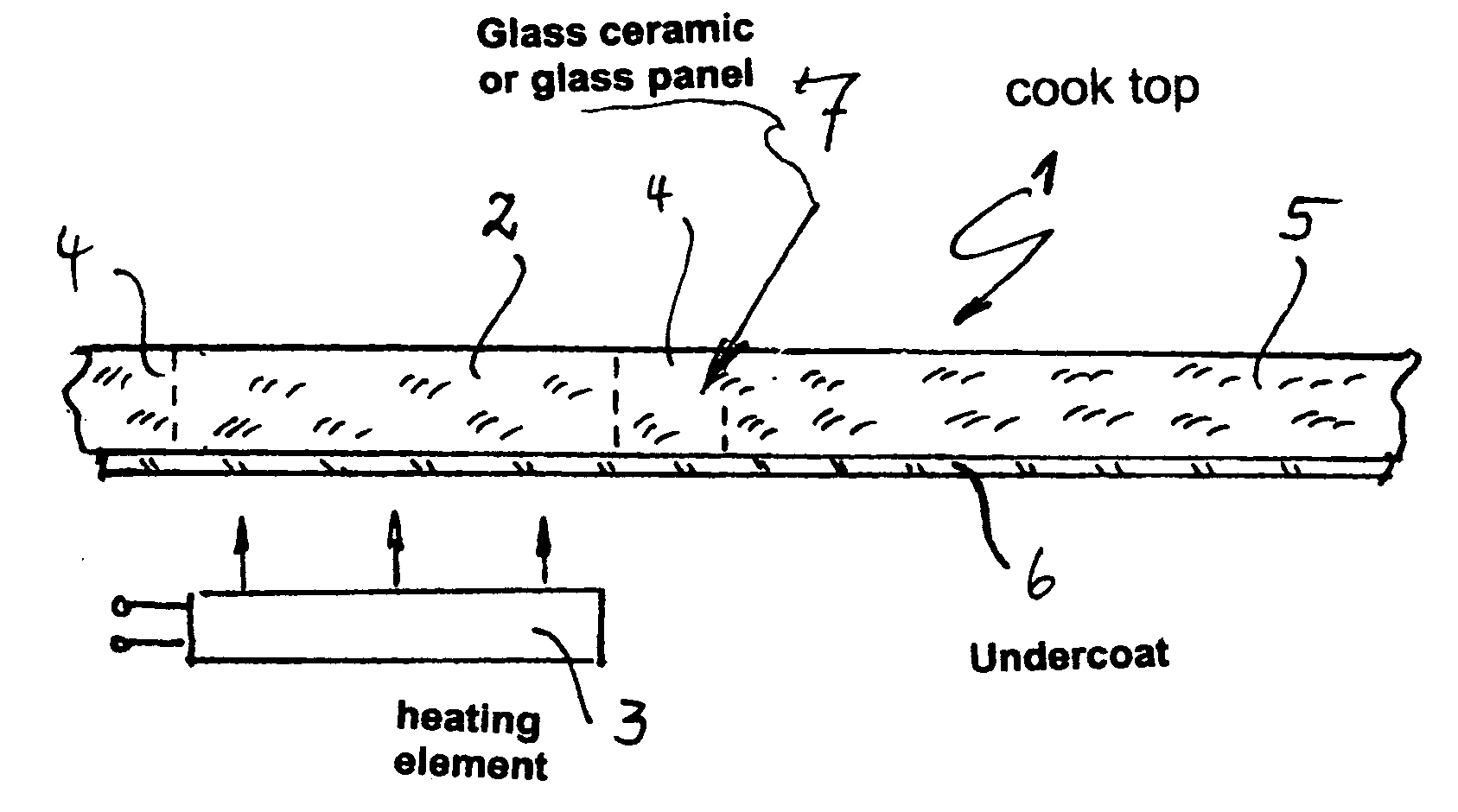

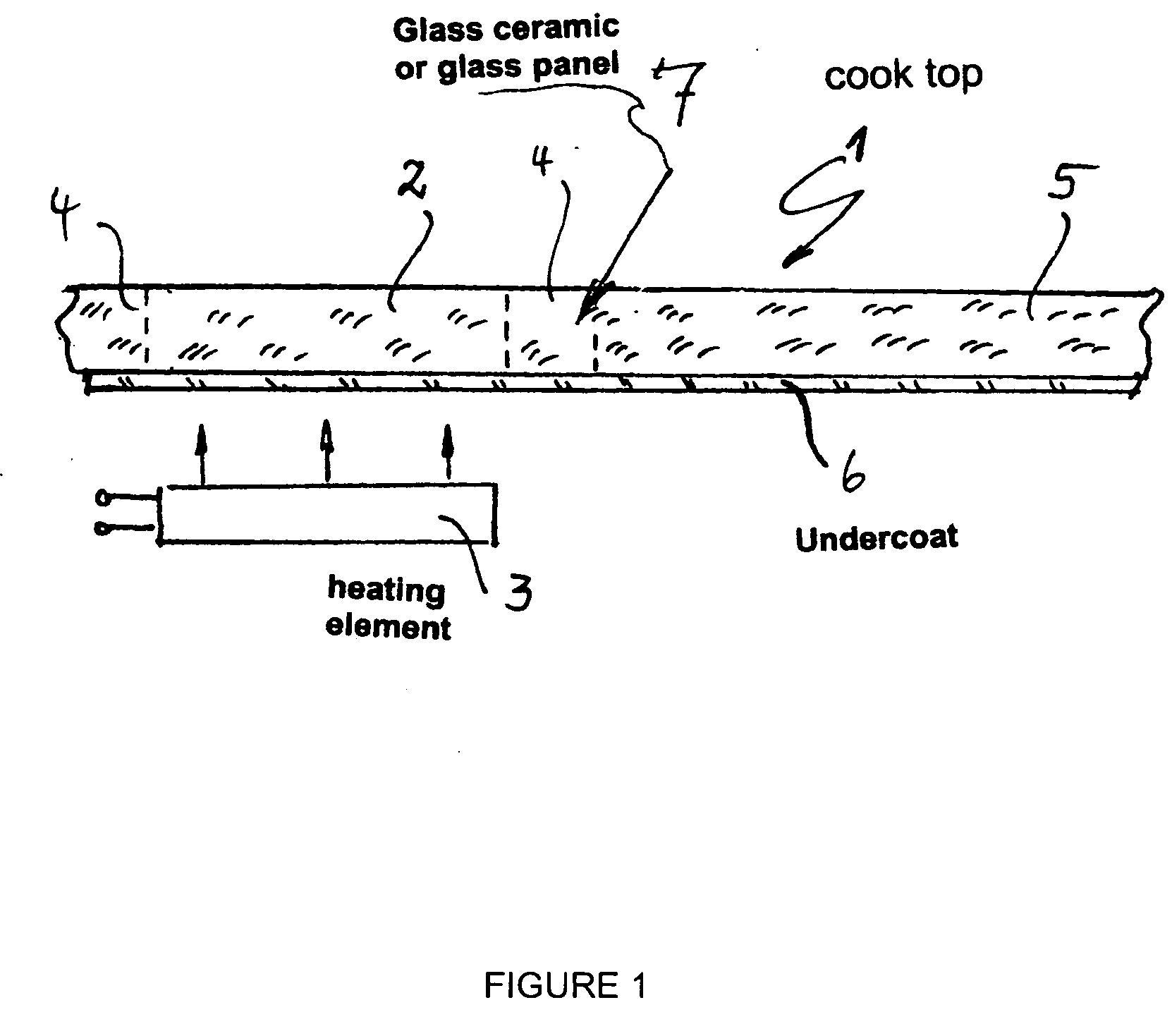

[0026] The glass ceramic cook top 1 has at least one cooking zone 2 marked with the dashed vertical lines, i.e. a heated region, which is associated with an electrically operated radiant heating element 3. The heated region typically has a temperature of greater than about 350° C. It is surrounded by a ring-shaped or annular transition zone 4 marked with dashed lines with a width of 0 to 25 mm and a cool region 5, in which the temperature is usually maintained under about 220° C.

[0027] The cook top 1 comprises a transparent, colorless glass ceramic panel 7 providing the cooking surface and an undercoat 6 on its under side. The continuous, preferably full-surface, undercoat 6 is made from inorganic enamel paint according to the invention, which is applied to the underside of the transparent colorless glass ceramic panel 7.

[0028] This continuous undercoat 6 is applied during production in the simplest manner, e.g. by screen printing. However it would be sufficient in principle to co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com