Enamel coating heating tube and manufacture for electric water heater

An electric water heater and a manufacturing method technology, applied to water heaters, ohmic resistance heating parts, heating elements, etc., can solve the problems of destroying the enamel layer, damaging the insulating material of the insulating terminal, coating the enamel on the electric heating pipe, etc. Layer dense, extended protection time, strong bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

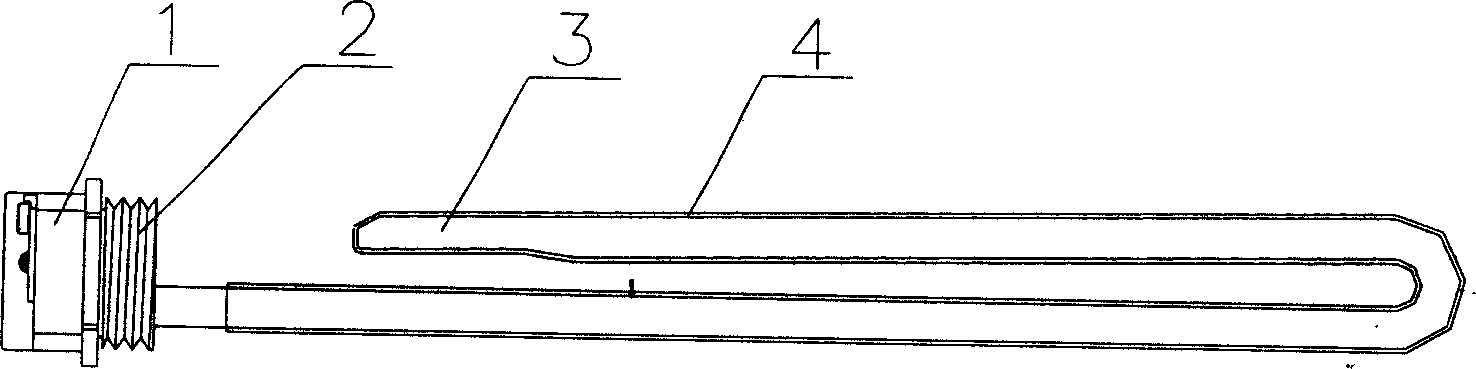

[0025] This embodiment is an electric water heater enamel coating (also known as Jingui) heating tube with a power of 2 kilowatts, which is manufactured by the following steps:

[0026] 1) Put the heating wire into the metal tube, and fill it with quartz sand insulating and heat-conducting material;

[0027] 2) Install insulating terminals at both ends to isolate the heating wire from the metal tube shell;

[0028] 3)' lengthen and reduce the diameter of the metal pipe;

[0029] 3) Bend the assembled metal tube into a U shape;

[0030] 4) Dip the outer surface of the metal tube into the enamel slurry to coat, and the coating thickness is controlled at 0.4-0.6mm;

[0031] 5) Electric heating, according to the enamel sintering process, the electric heating temperature is controlled at 800-900°C, and the holding time is 10 minutes (usually controlled at 8-12 minutes), so that the enamel paint coated on the outer surface of the metal tube is sintered into a dense and solid ename...

Embodiment 2

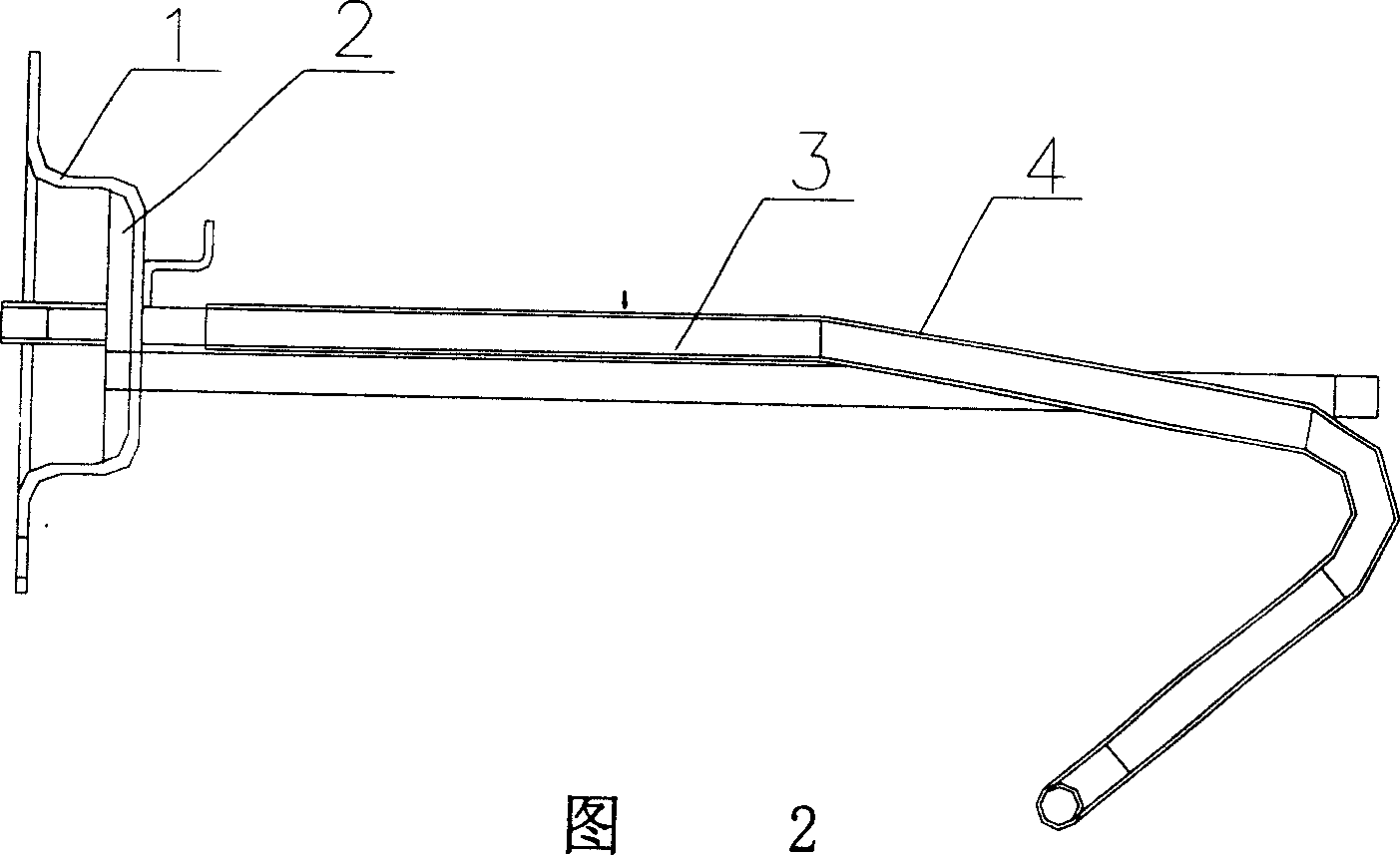

[0035] This embodiment is an enamel-coated heating tube for an electric water heater of 1.5 kilowatts, and its manufacturing method is basically the same as that of the embodiment, except that:

[0036] 1), the metal tube shell 3 is bent into an L shape, and the insulating terminal 1 is firmly connected with the bowl-shaped flange joint 2 for installation;

[0037] 2), the enamel paint is applied to the surface of the L-shaped metal tube shell 3 by spraying;

[0038] 3) Due to its low electric power, it is necessary to take heat preservation measures when heating with electricity.

[0039] Its use effect is the same as that of Embodiment 1, and will not be described in detail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com