Ferrimagnetic material and its preparation method

A ferrimagnetic and powder technology, which is applied in the field of ferrimagnetic materials and their preparation, can solve the problems of limited production and difficult realization, and achieve the effects of easy realization, low cost and simple sintering method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method with ferrimagnetic material of the present embodiment includes:

[0023] Offer Al 2 o 3 powder, CuO powder and Fe 2 o 3 powder;

[0024] the Al 2 o 3 powder, CuO powder and Fe 2 o 3 The powders are mixed in a predetermined ratio, wherein the stoichiometric molar ratio Al: Cu: Fe = 1:3:4;

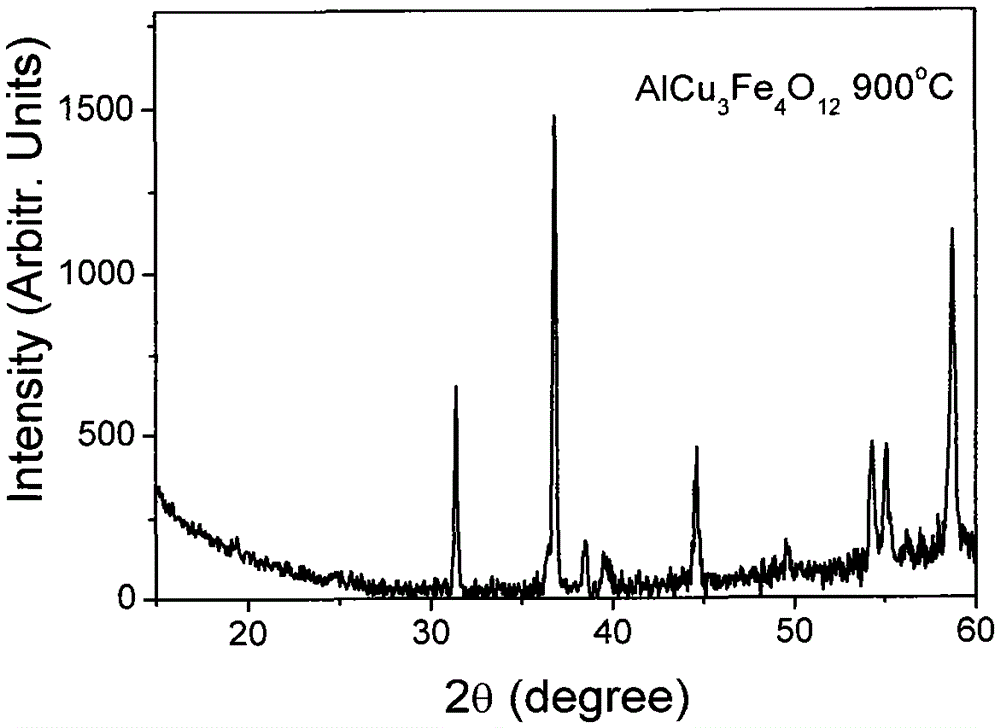

[0025] After the mixed powder is ground for a predetermined time, the ground powder is sintered in the atmospheric pressure air atmosphere at a temperature range of 700-900°C to form AlCu with ferrimagnetism. 3 Fe 4 o 12 .

[0026] in,

[0027] The Al 2 o 3 The particle size of the powder is: 300-500 mesh, the particle size of the CuO powder is: 200-400 mesh, the Fe 2 o 3 The particle size of the powder is: 200-400 mesh. But not limited to the particle sizes listed above.

[0028] The grinding time is greater than or equal to 2 hours.

[0029] The sintering time is greater than or equal to 2 hours, and the sintering time can be selected to be ...

example 1

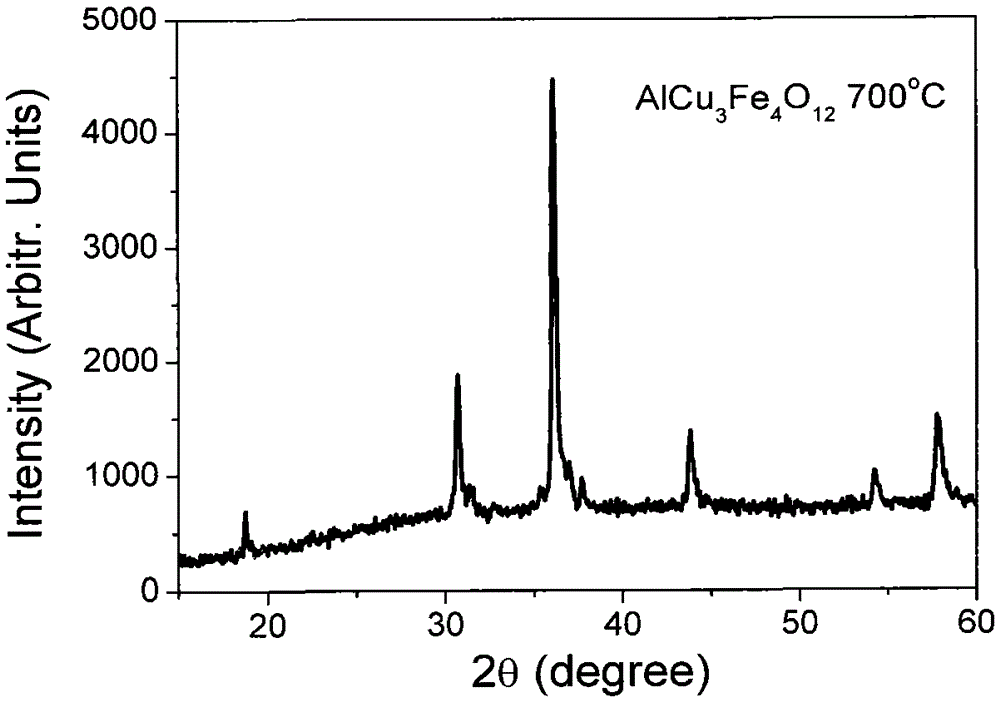

[0033] Example 1--preparation of ceramic AlCu 3 Fe 4 o 12

[0034] Powdered Al 2 o 3 , CuO and Fe 2 o 3 Weigh the raw materials according to the stoichiometric molar ratio Al: Cu: Fe = 1: 3: 4; then put the three kinds of powders into the mortar and grind for 2 hours, and press them under the pressure of 200 MPa in a uniaxial direction tablet press to form a diameter of 10 mm and a height of 10 mm. 10mm cylinder. In an air atmosphere furnace, sinter at 700°C for 8 hours, and then cool down to room temperature naturally in the air.

[0035] For the phase analysis of the XRD pattern corresponding to the product, see figure 1 , figure 1 The XRD results show the formation of pure cubic AlCu 3 Fe 4 o 12 (There are no impurity phases and starting material peaks in XRD).

example 2

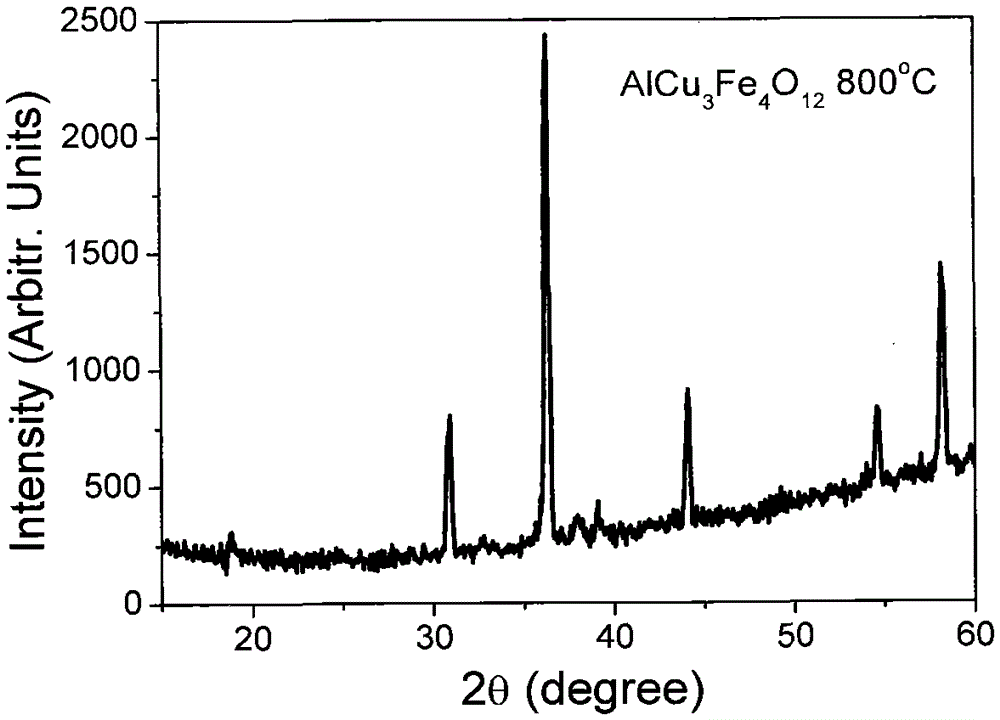

[0036] Example 2--preparation of ceramic AlCu 3 Fe 4 o 12

[0037] The difference from Example 1 is that the sintering temperature is 800°C and the sintering time is 6h. For the phase analysis of the XRD pattern corresponding to the product, see figure 2 , figure 2 The XRD results show the formation of pure cubic AlCu 3 Fe 4 o 12 (There are no impurity phases and starting material peaks in XRD).

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com