Device and method used for spraying liquid

A spraying device and liquid technology, applied in the spraying device to generate the spray to be applied to the object, can solve the problems of long working time, high energy consumption, large nozzle wear, etc., to reduce labor costs, avoid material accumulation, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

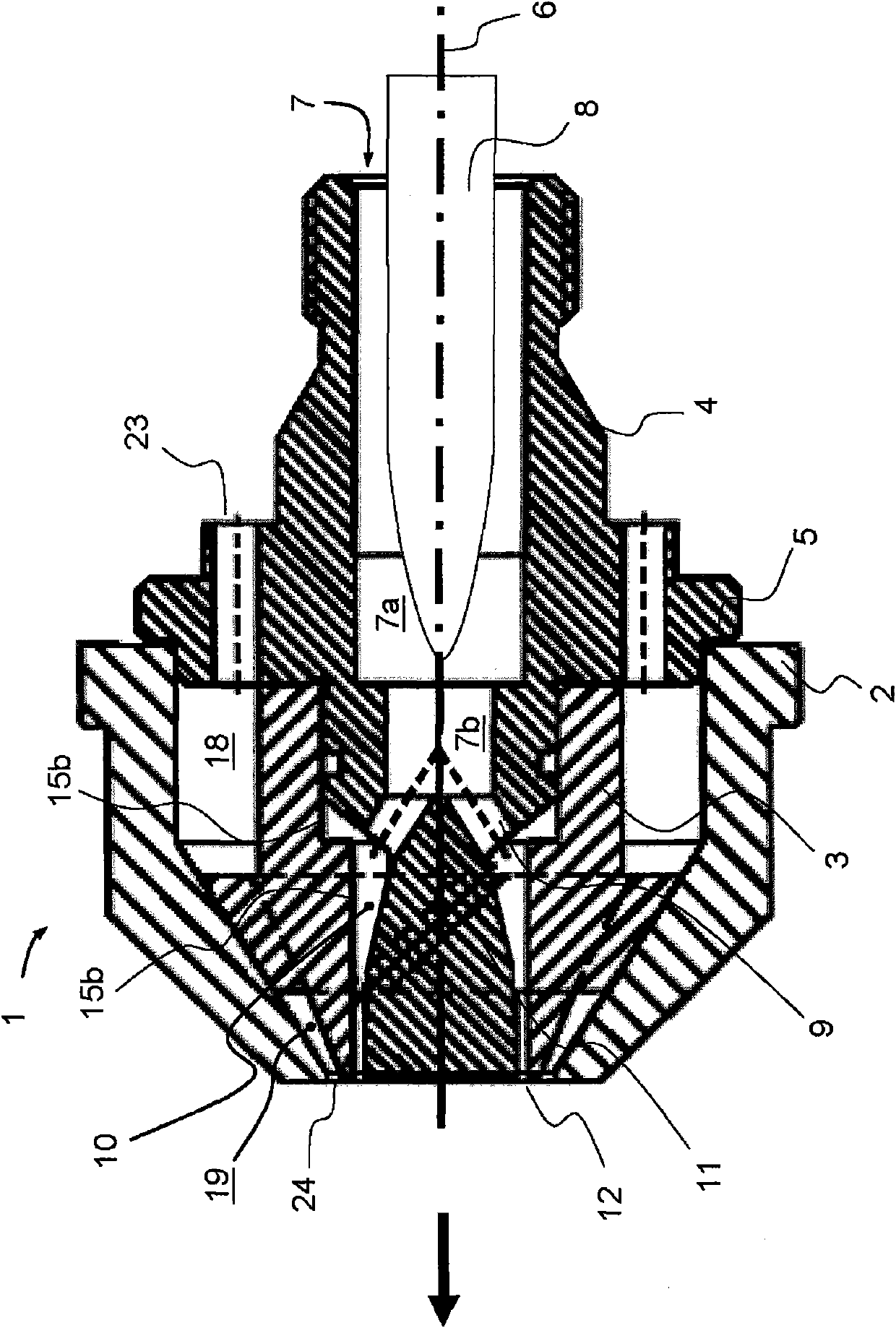

[0023] exist figure 1 A spraying device 1 with three main components—hood 2 , air guide body 3 and nozzle body 4 is shown in . figure 1 The sprinkler device 1 is shown in the assembled state, ie the hood 2 is pushed over the air guide body 3 and the air guide body is accommodated inside the hood. Furthermore, a part of the nozzle body 4 is arranged in the interior of the air guide body 3 . Furthermore, the cover 2 extends onto the flange 5 of the nozzle body 4 . Inside the nozzle body 4 there is arranged concentrically to the longitudinal axis 6 of the spraying device an opening 7 for feeding the material to be sprayed. The orifice 7 for material delivery is located in the first inner section 7a of the nozzle body 4 towards the spraying device 1 at the figure 1 The end on the left in the center extends, i.e. in the direction of spraying (in figure 1 shown by an arrow) extends. Adjacent to the first inner section 7a of the nozzle body 4 is a second section 7b whose inner d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com