Patents

Literature

513results about "Spraying power supply" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

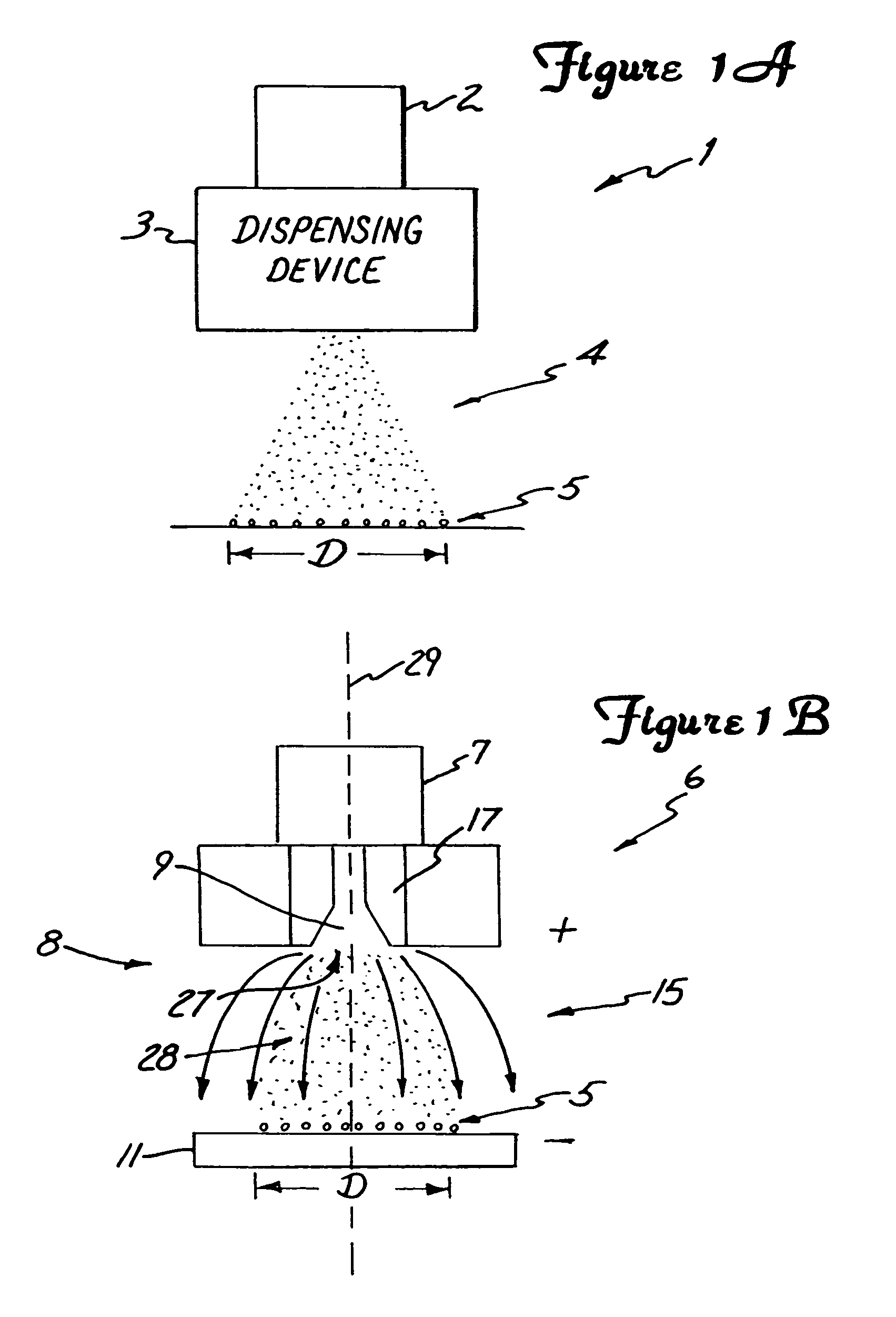

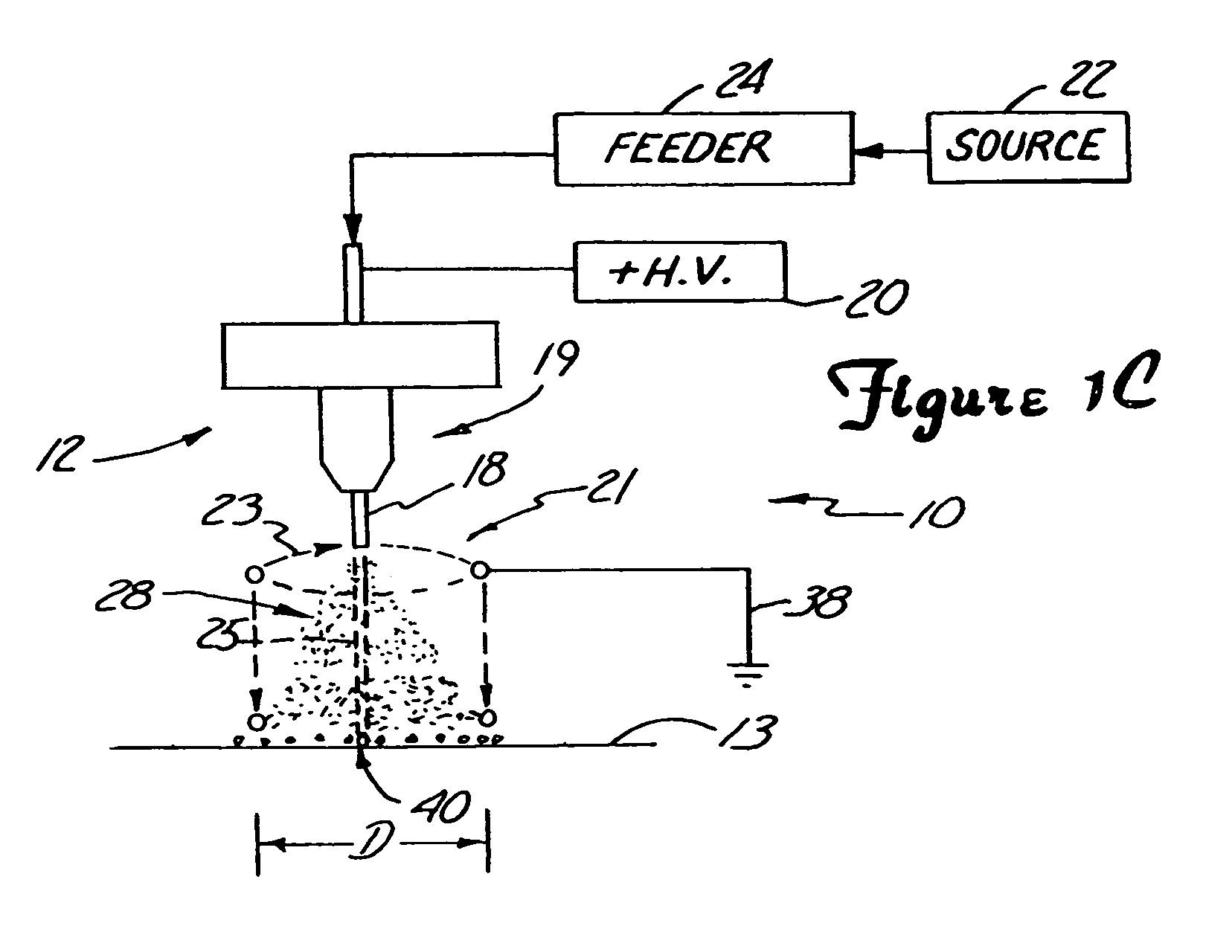

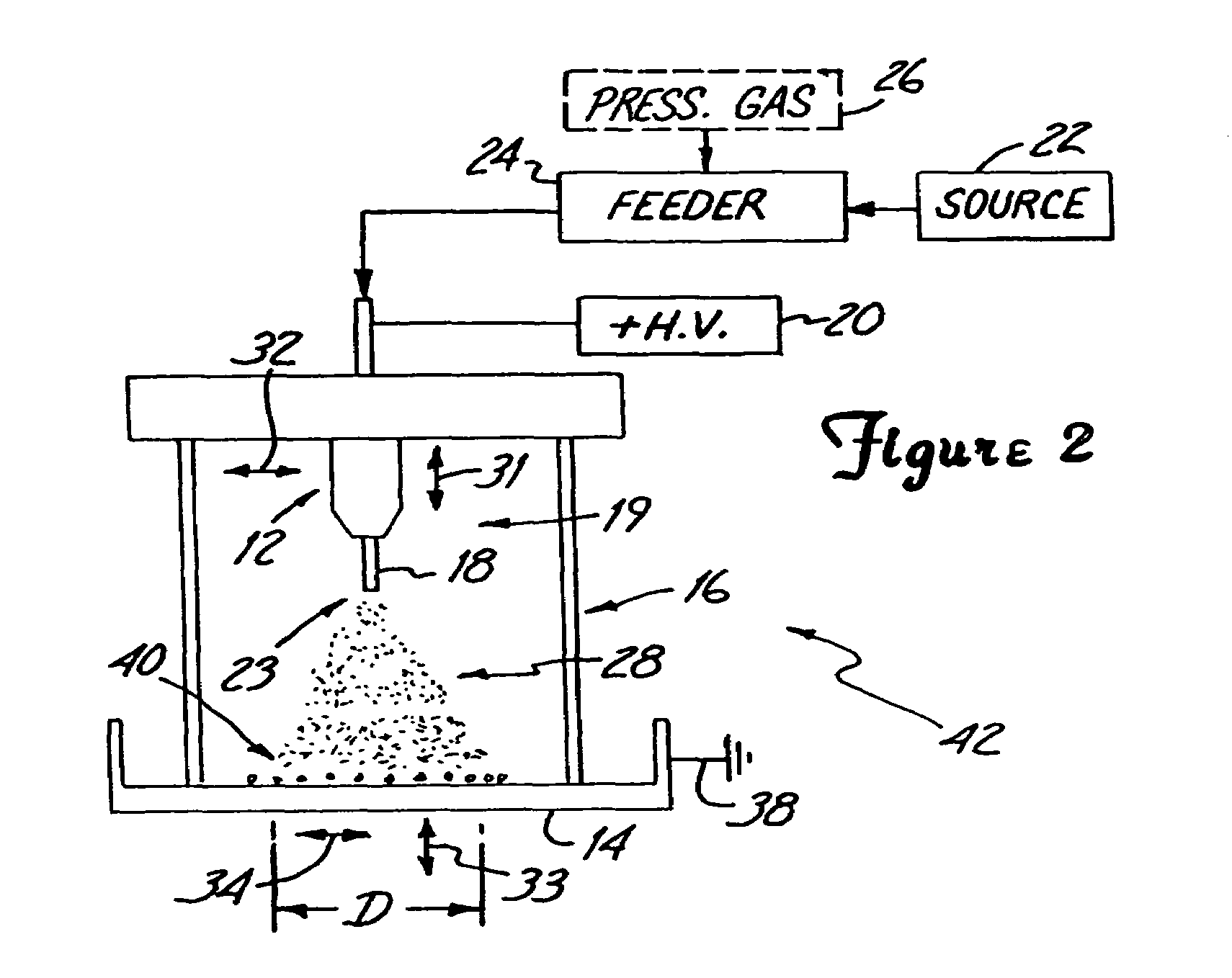

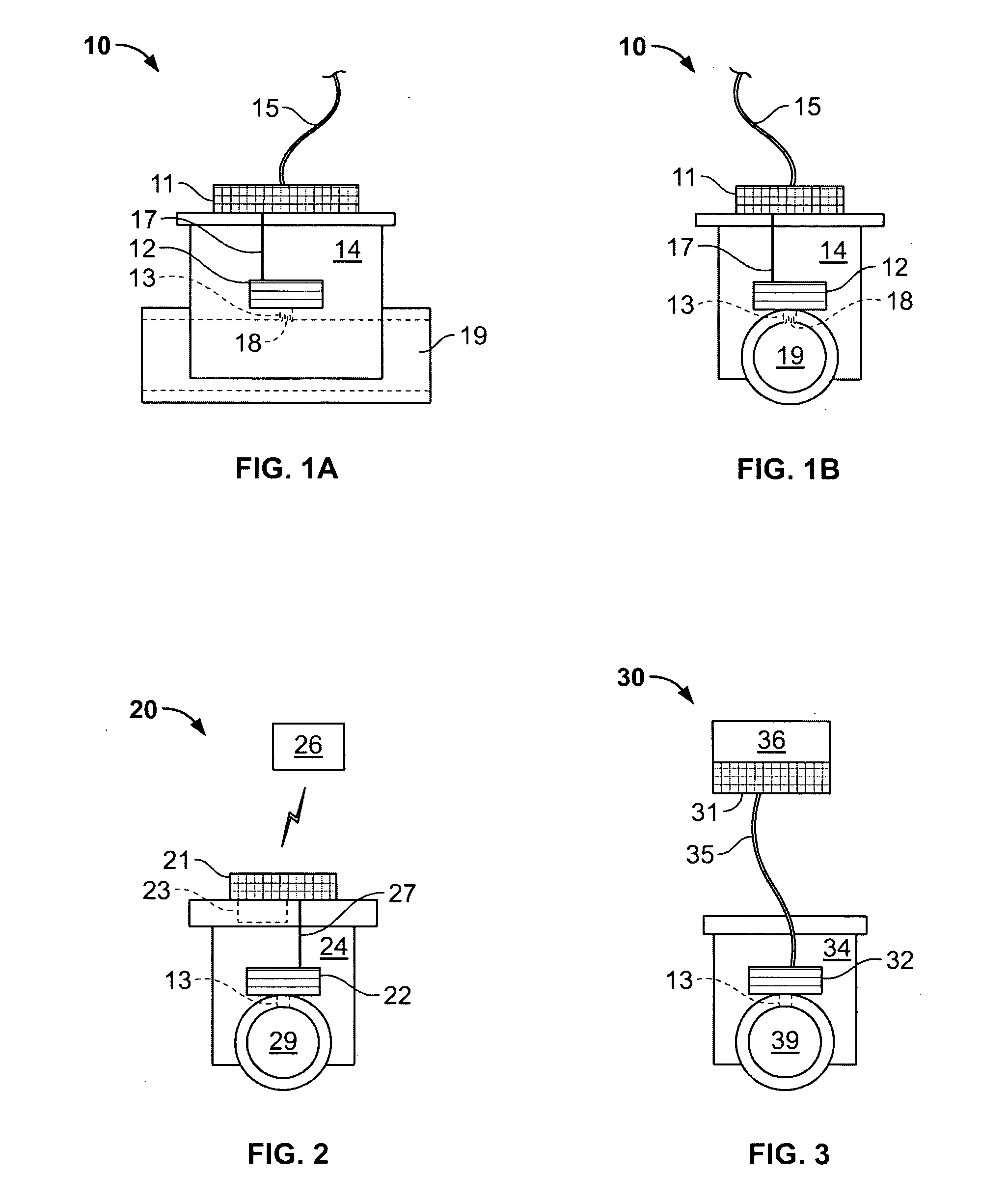

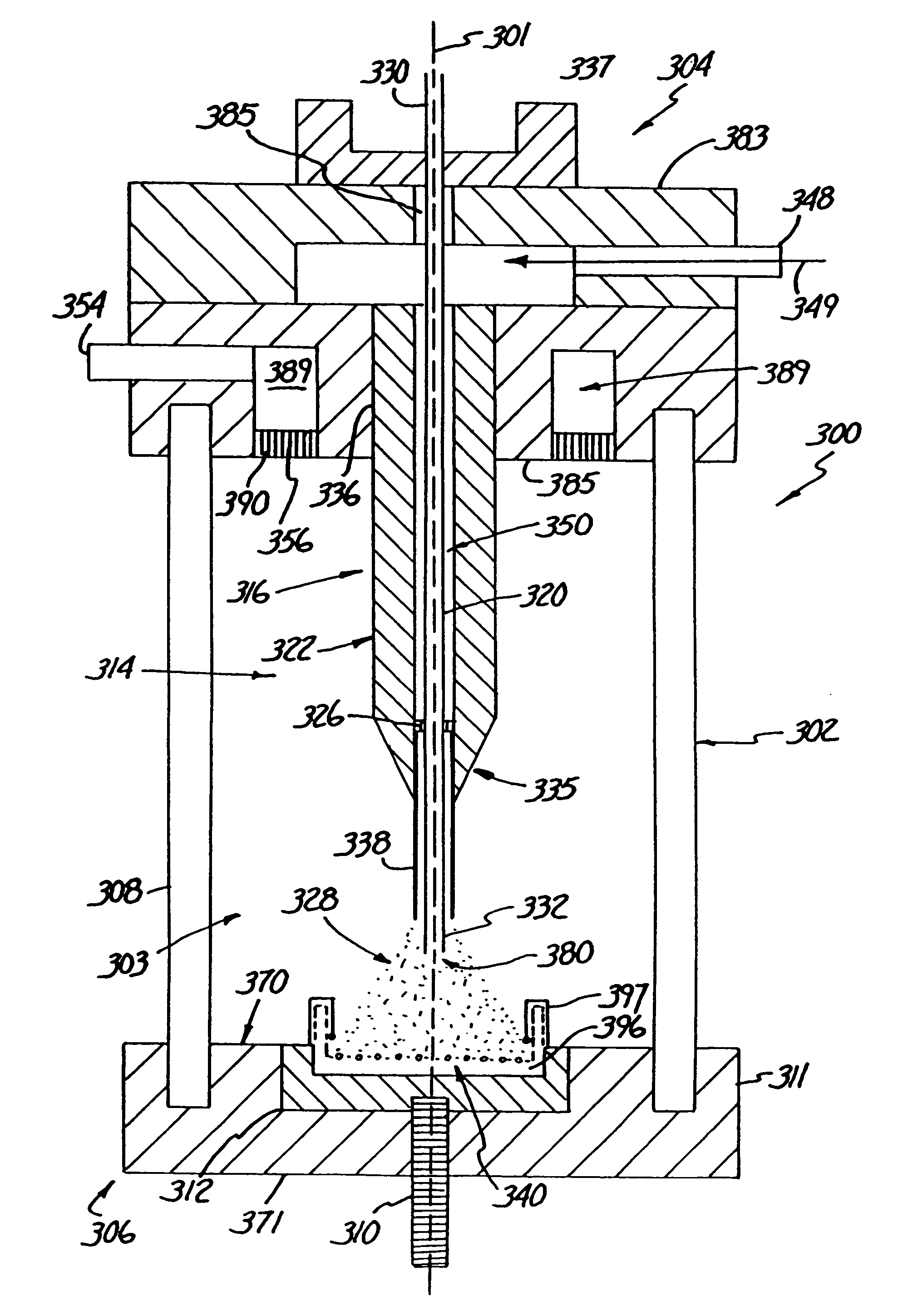

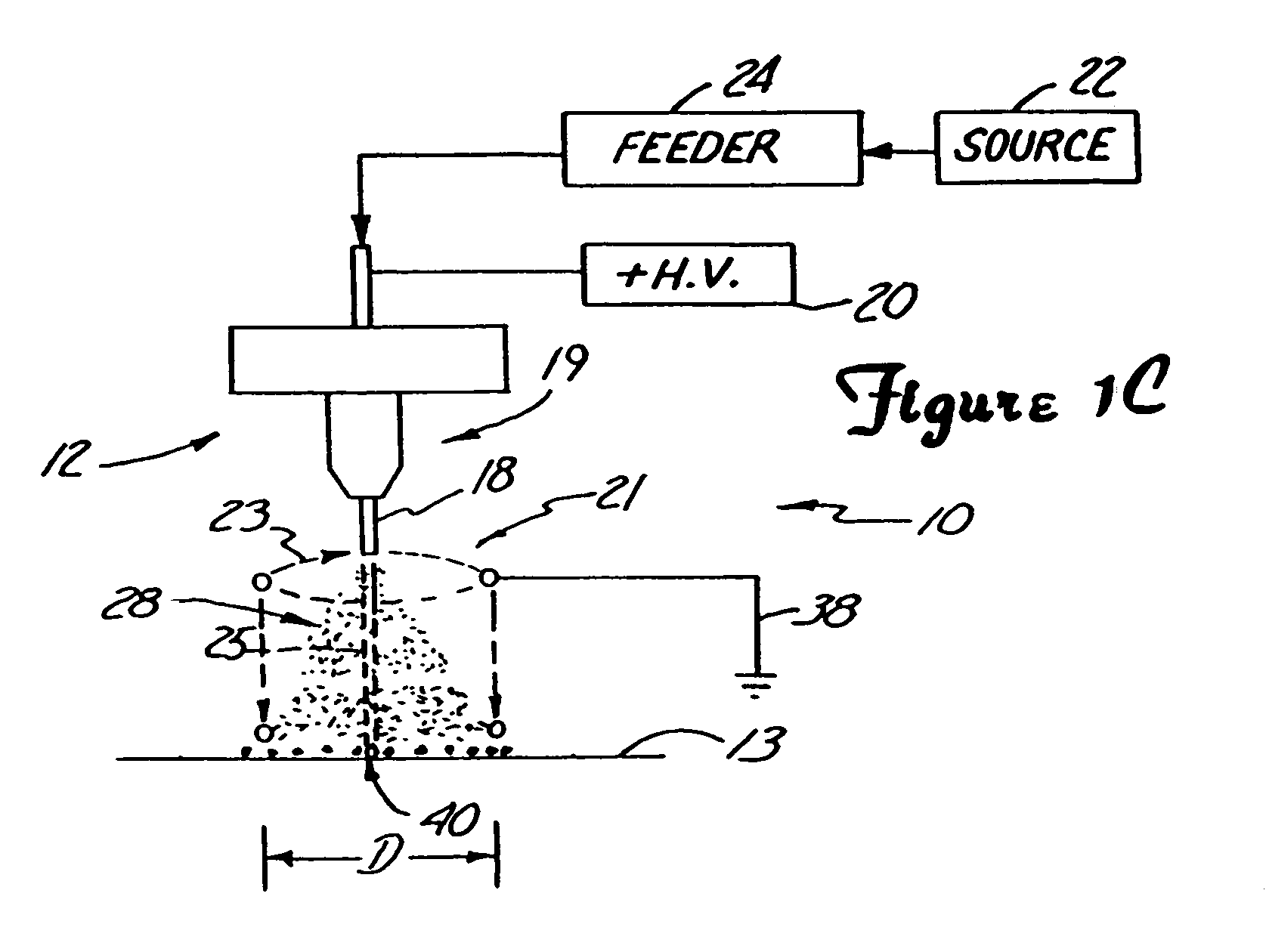

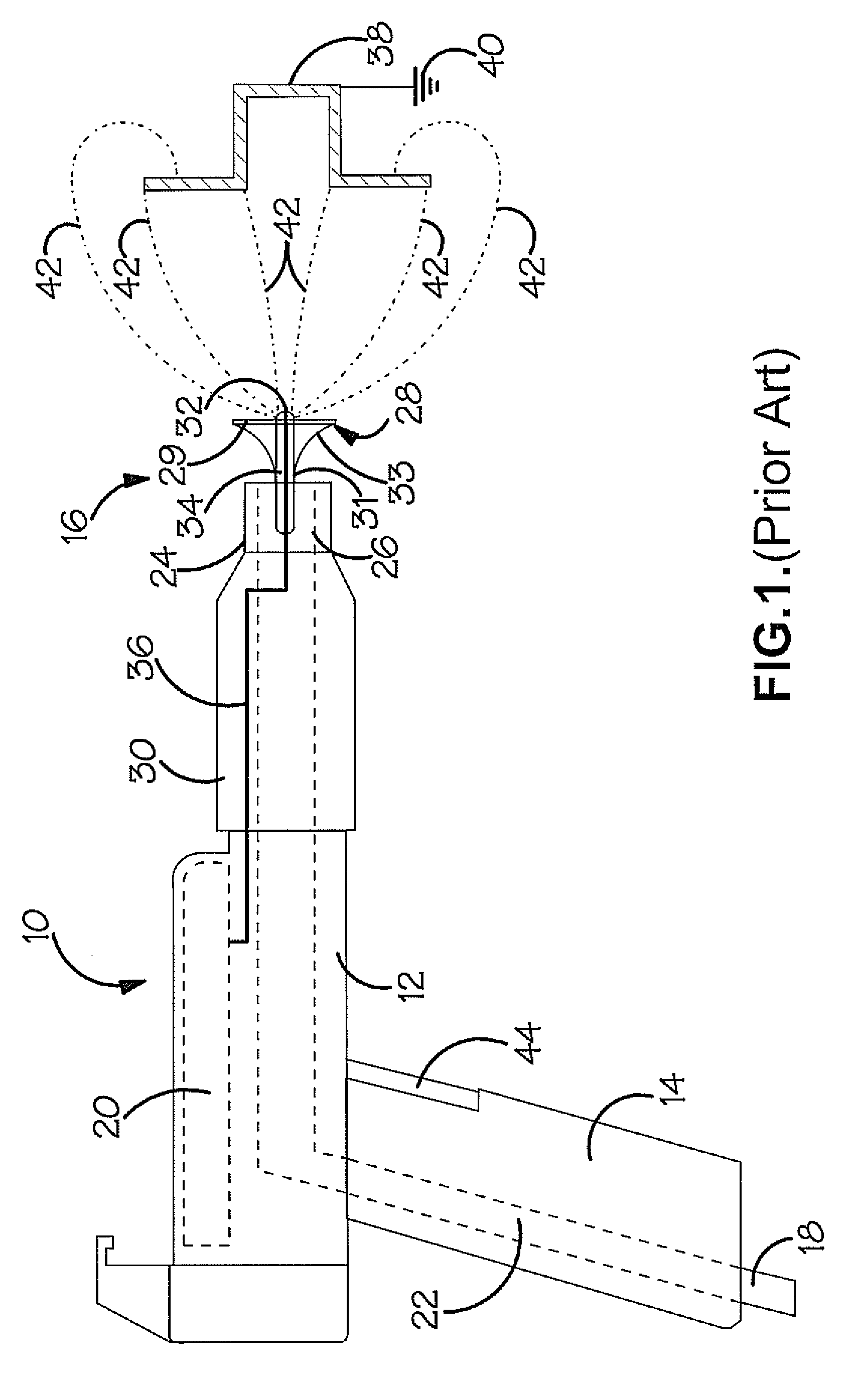

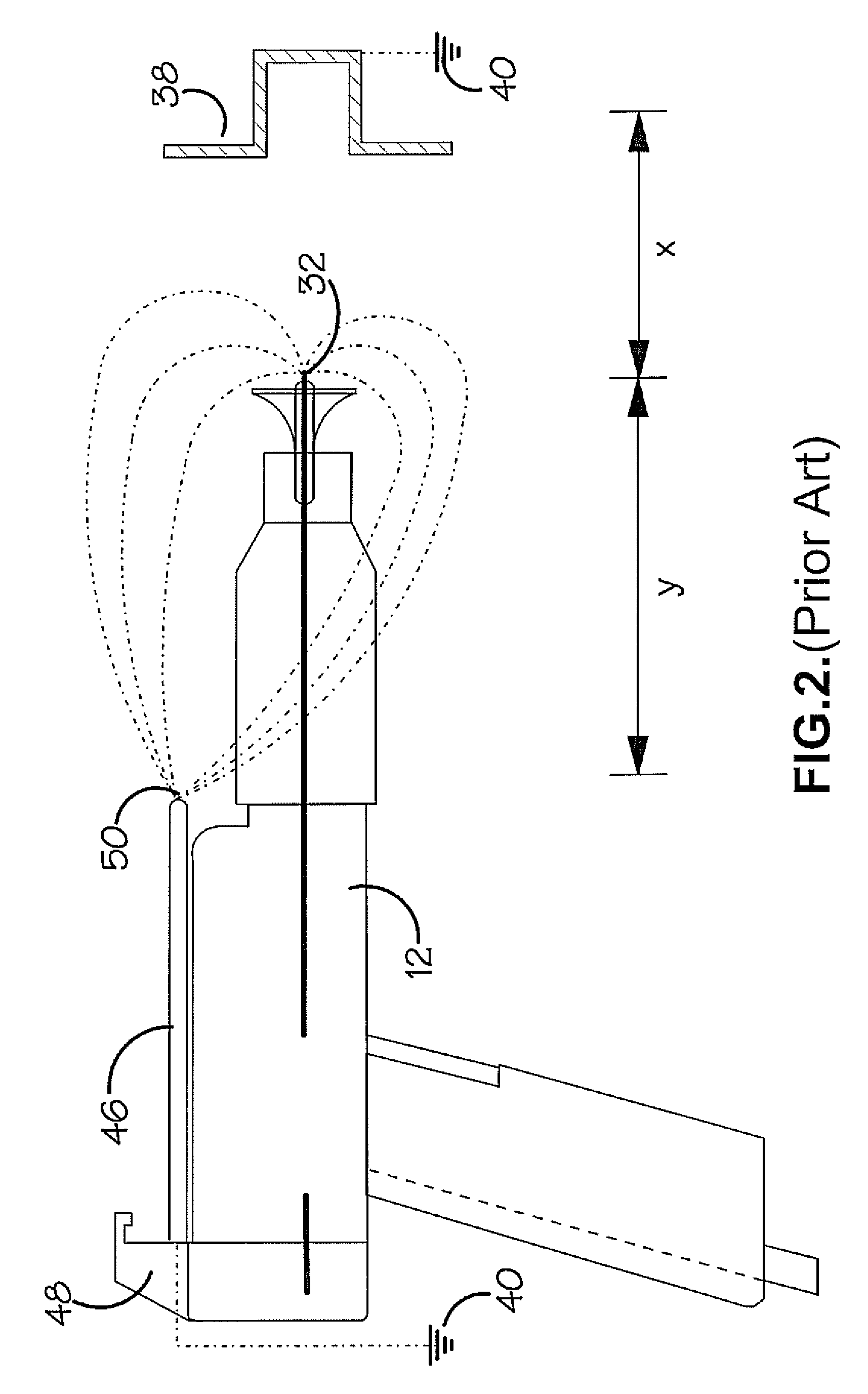

Electrospraying apparatus and method for coating particles

An electrospraying apparatus and / or method is used to coat particles. For example, a flow including at least one liquid suspension may be provided through at least one opening at a spray dispenser end. The flow includes at least particles and a coating material. A spray of microdroplets suspending at least the particles is established forward of the spray dispenser end by creating a nonuniform electrical field between the spray dispenser end and an electrode electrically isolated therefrom. The particles are coated with at least a portion of the coating material as the microdroplet evaporates. For example, the suspension may include biological material particles.

Owner:RGT UNIV OF MINNESOTA

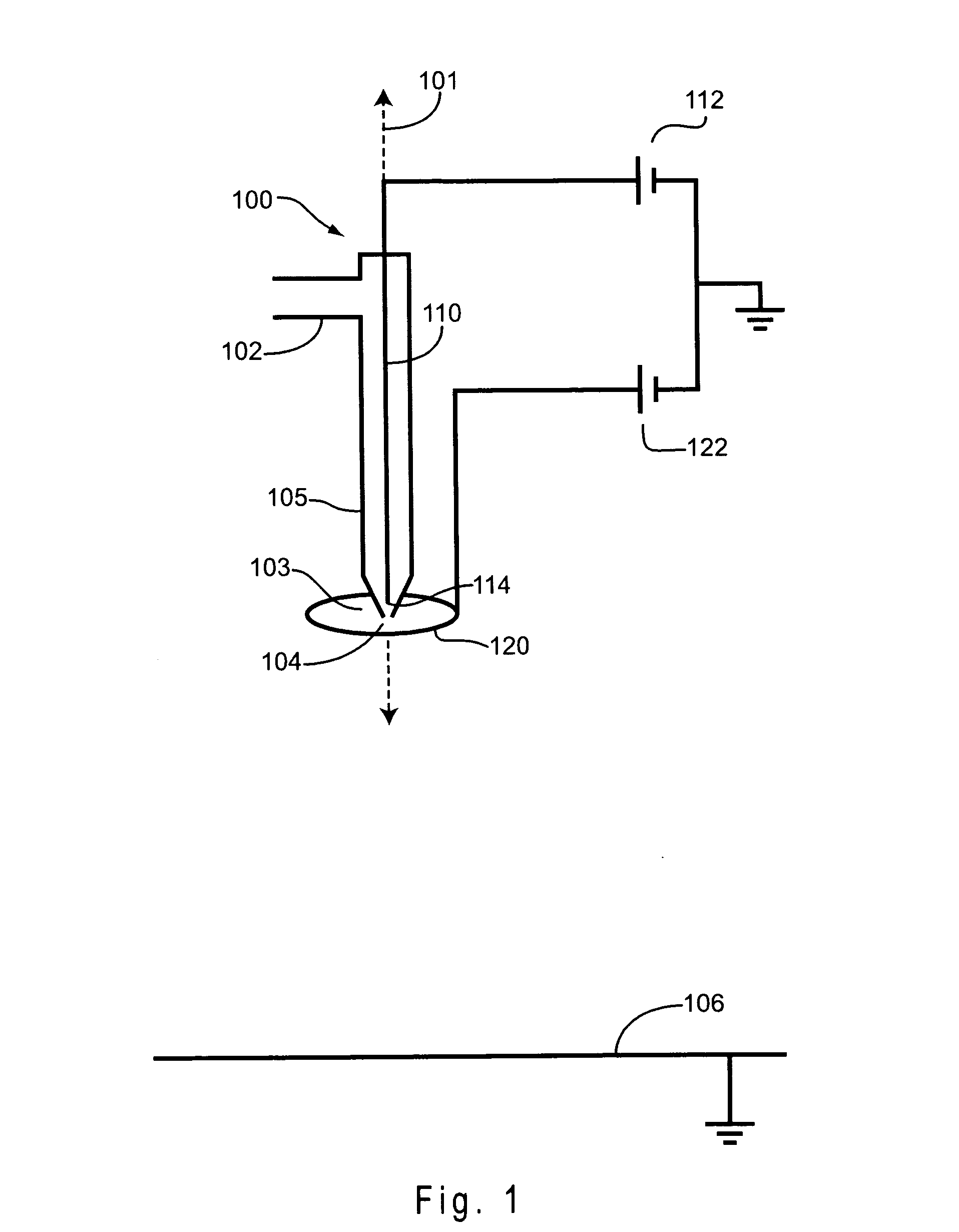

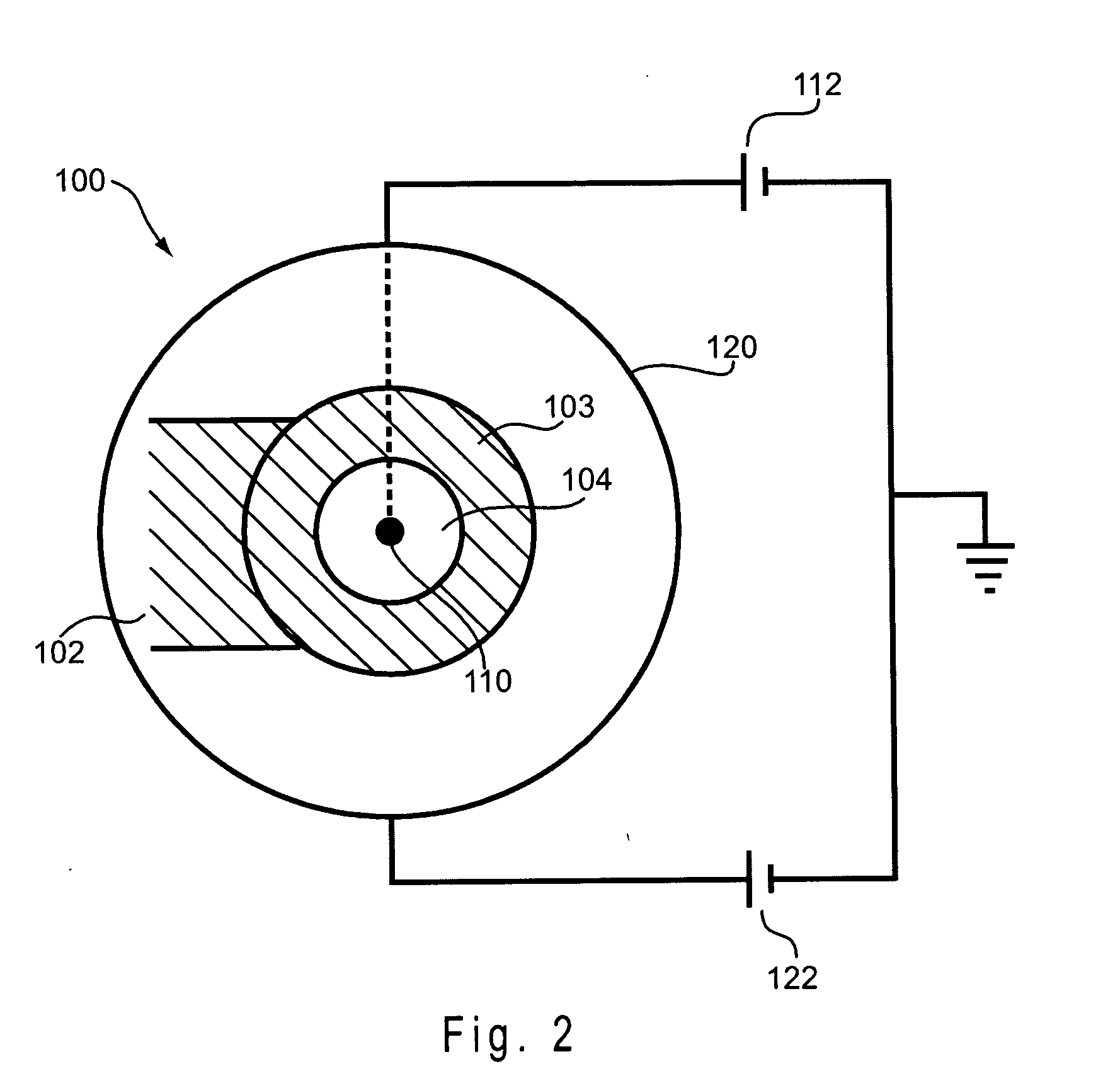

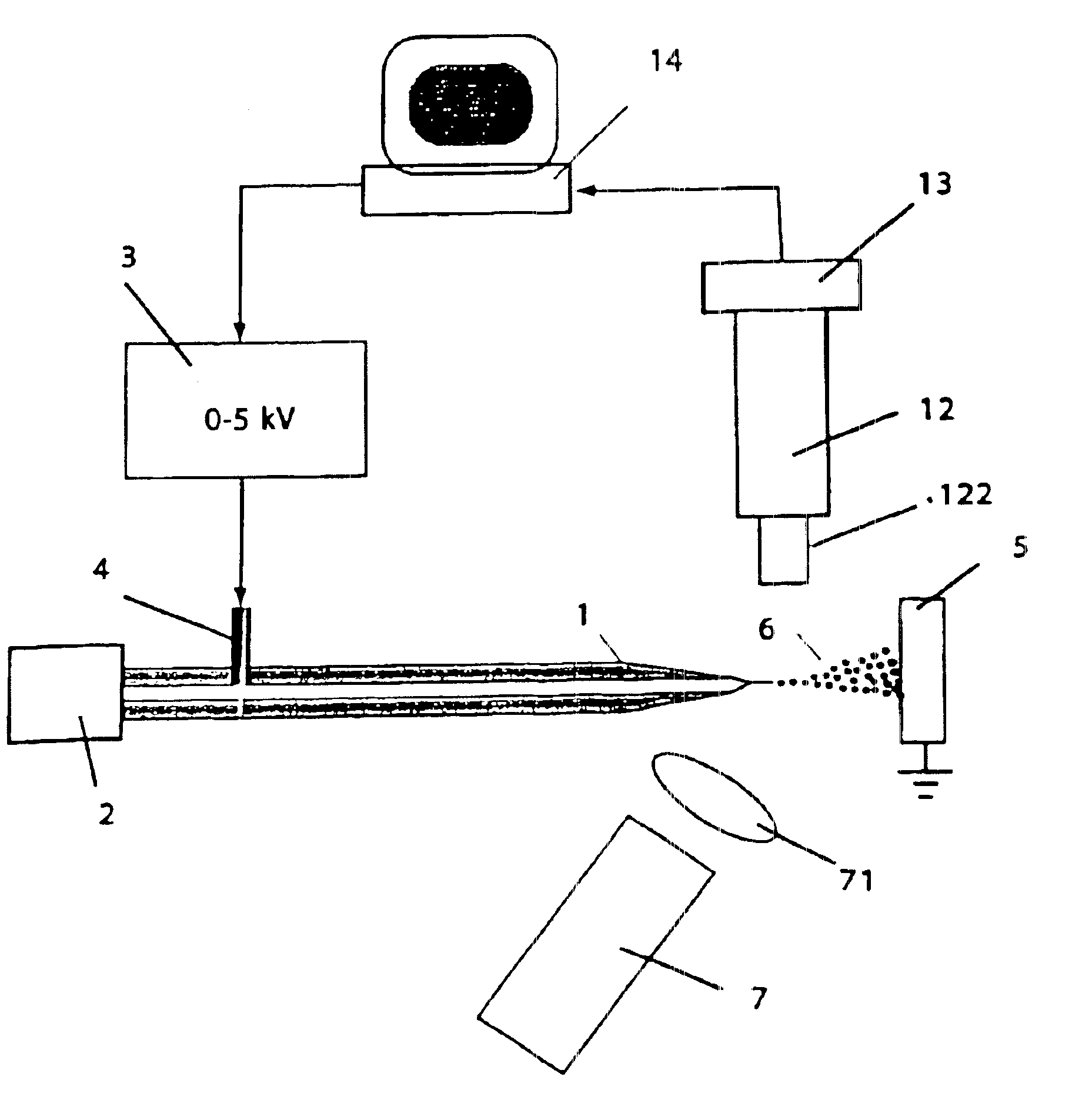

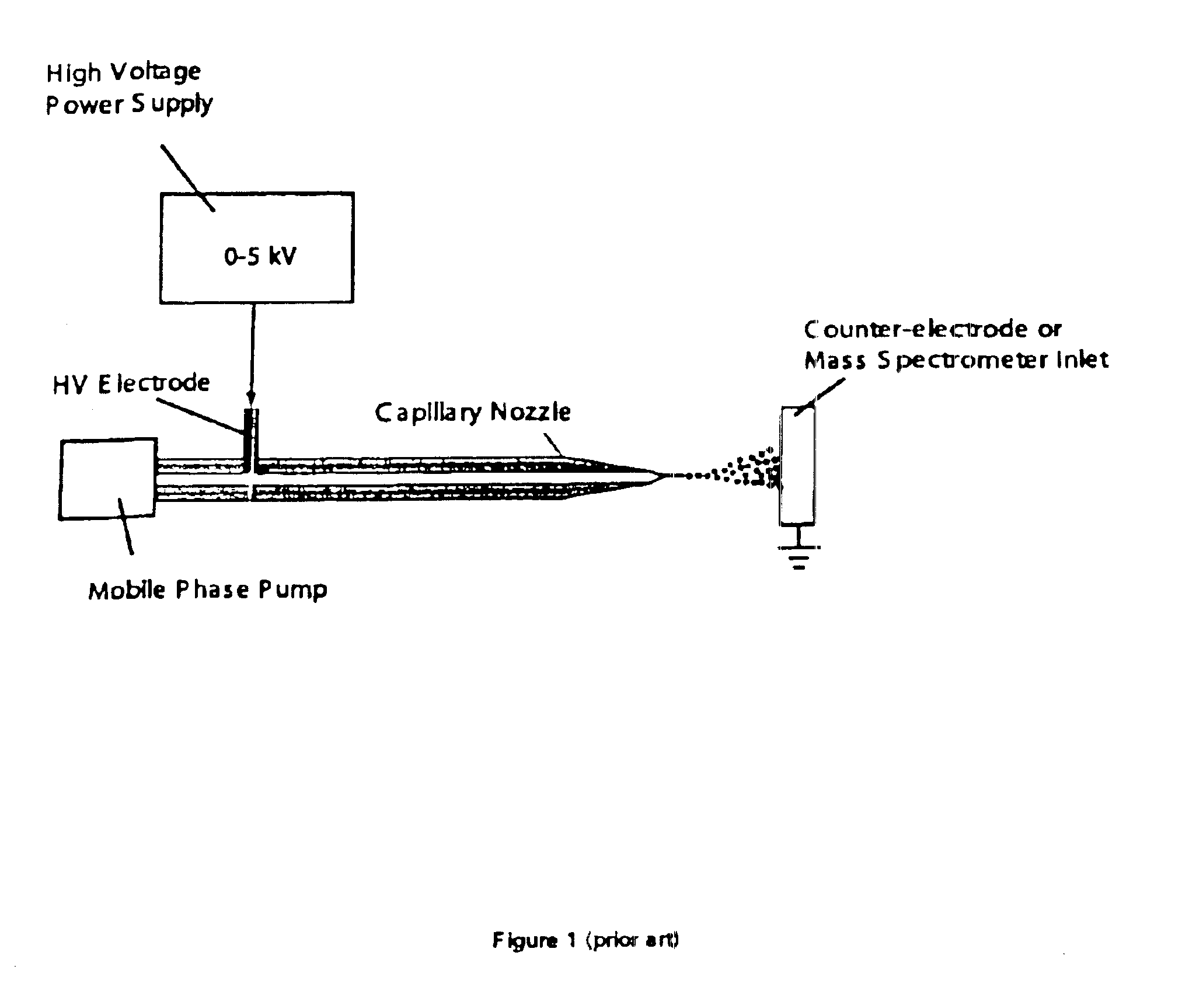

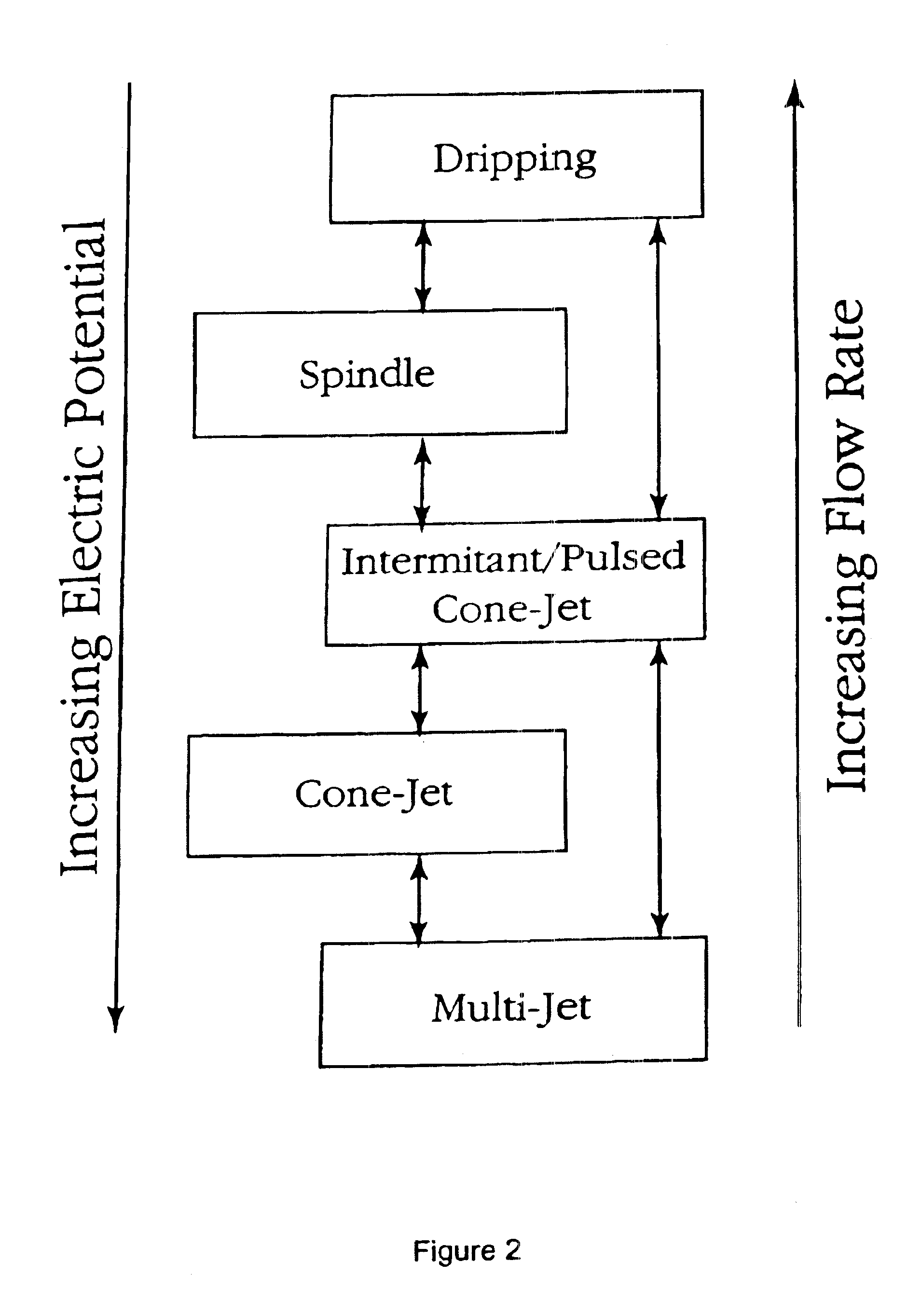

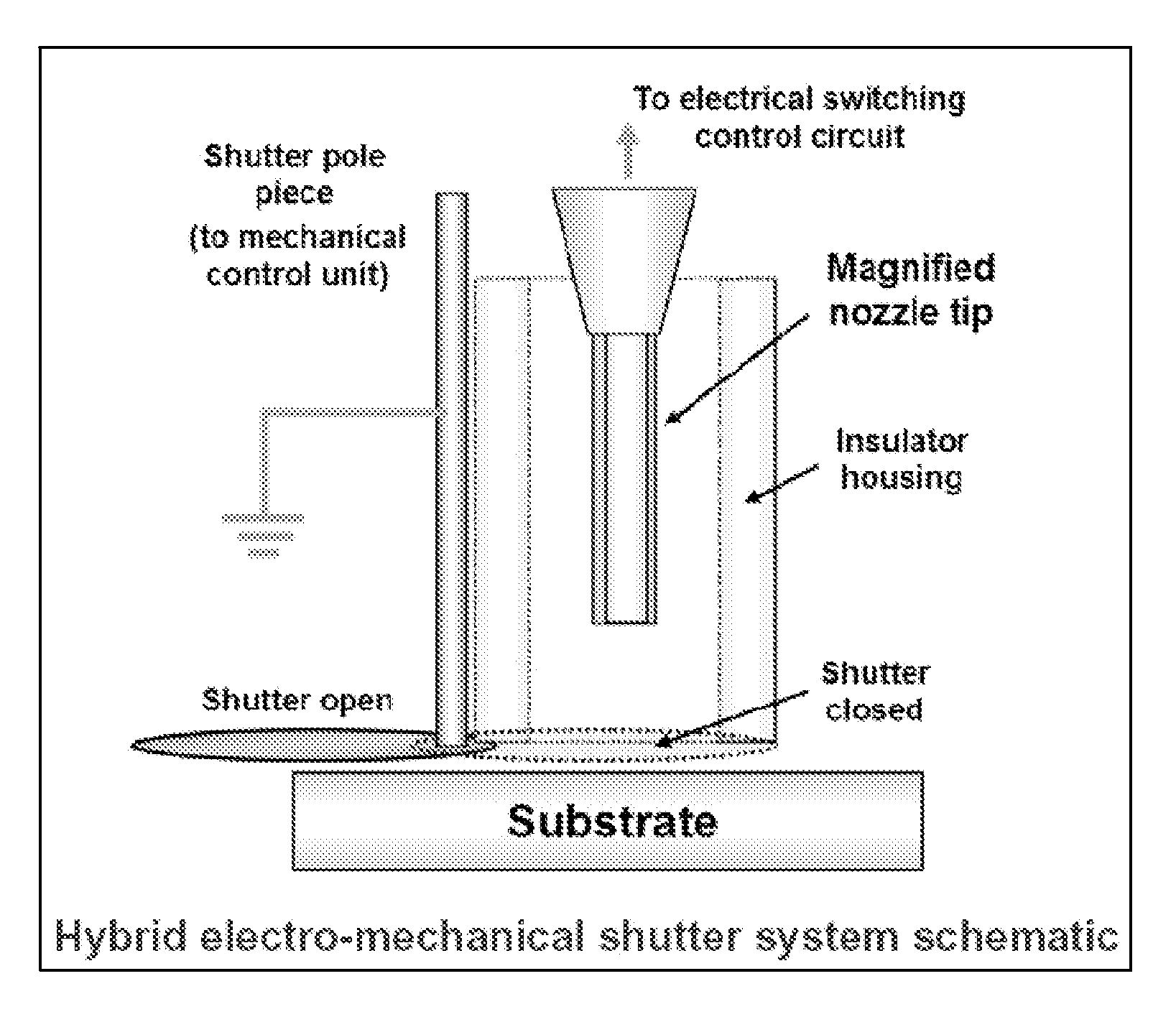

Electrohydrodynamic spraying system

An electrohydrodynamic spray apparatus includes a liquid inlet and a spray nozzle in fluid communication with the liquid inlet, where the spray nozzle has an opening downstream of the liquid inlet. An inner electrode is situated at least partially inside the spray nozzle. An outer electrode is situated external to the spray nozzle and within about 100 mm of the opening of the nozzle. The electrohydrodynamic spray apparatus can be combined with a substrate to form an electrohydrodynamic spray system. The electrohydrodynamic spray apparatus or system can be used to form nanostructures such as nanodrops, nanoparticles and thin films.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

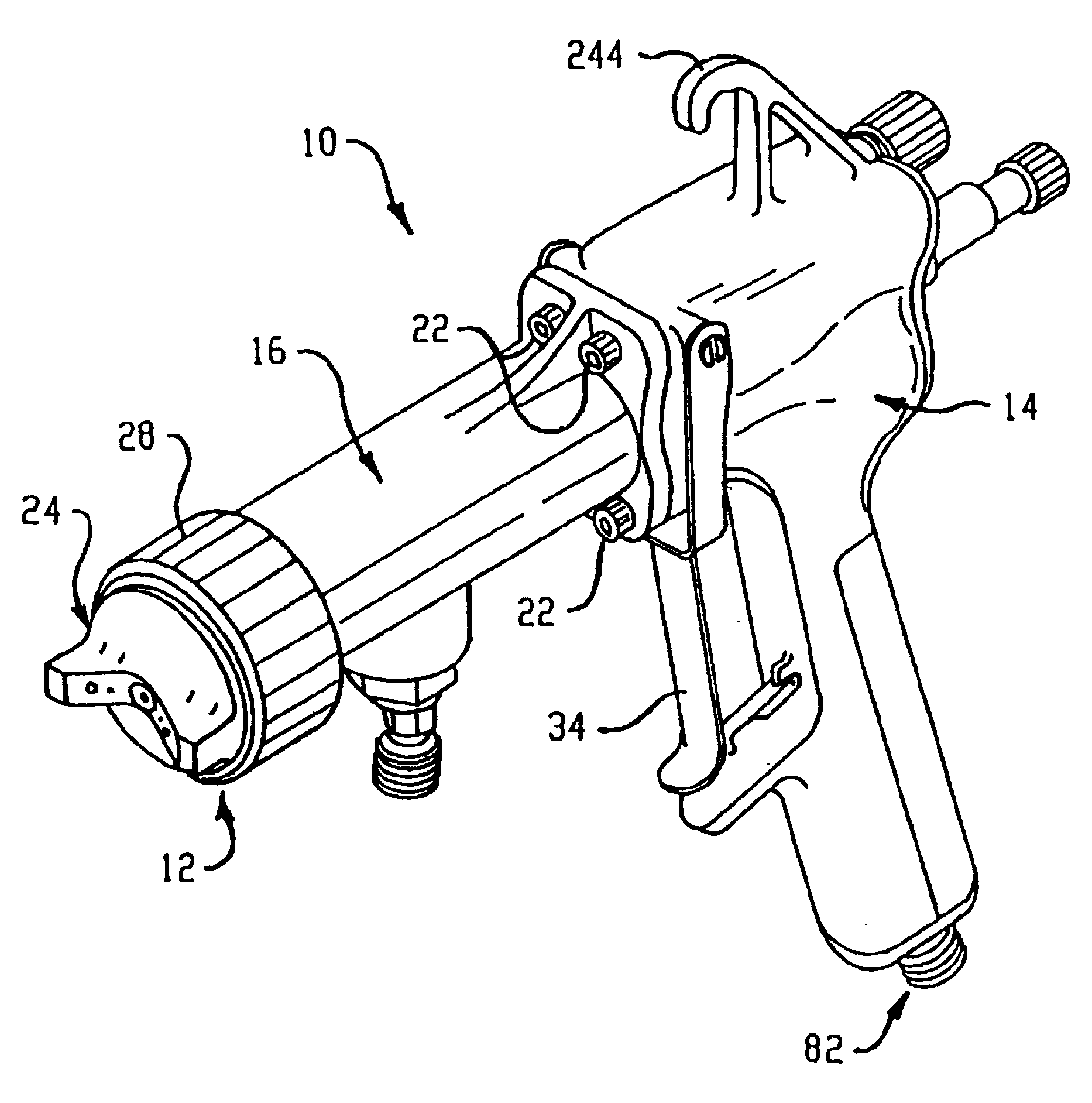

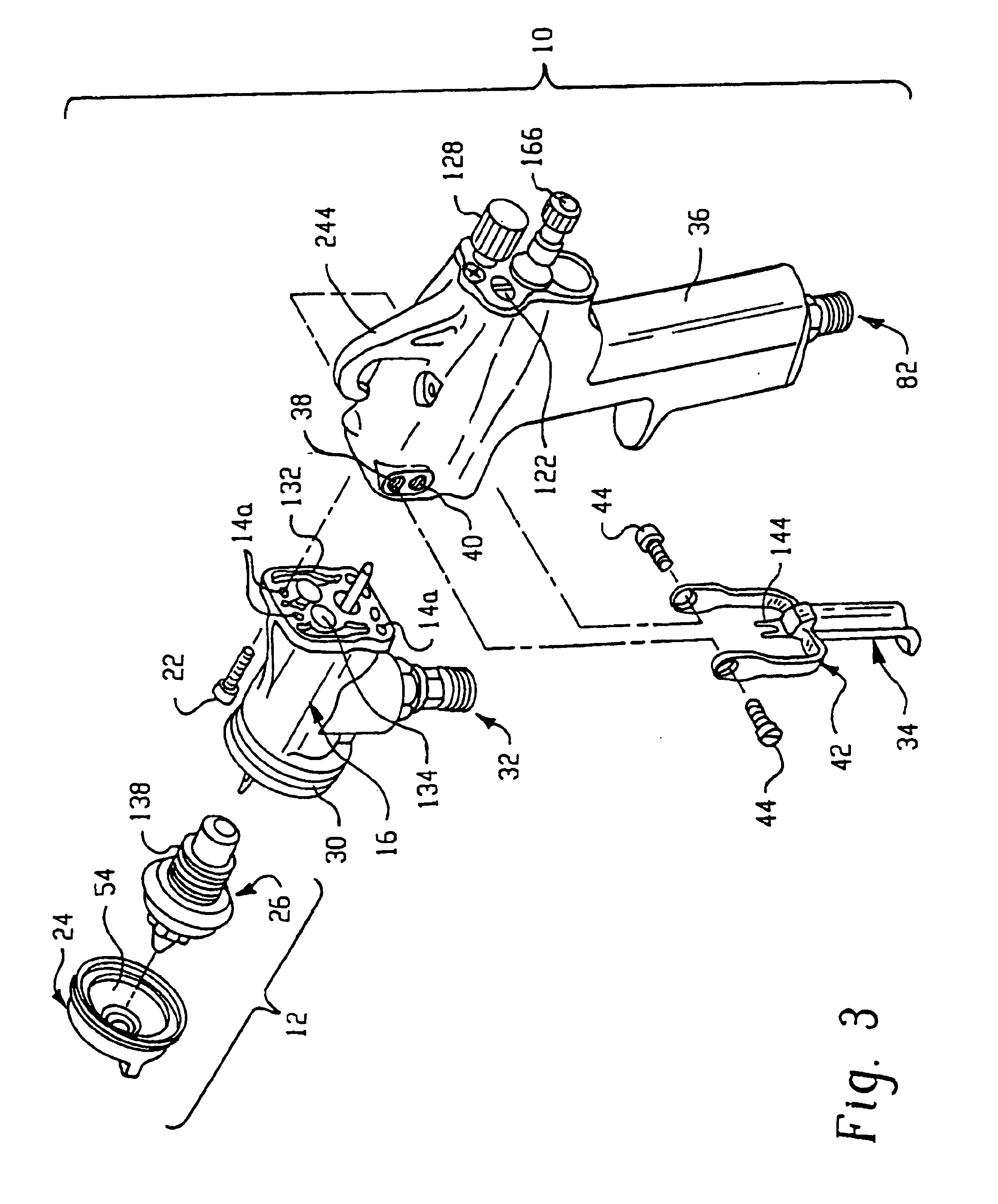

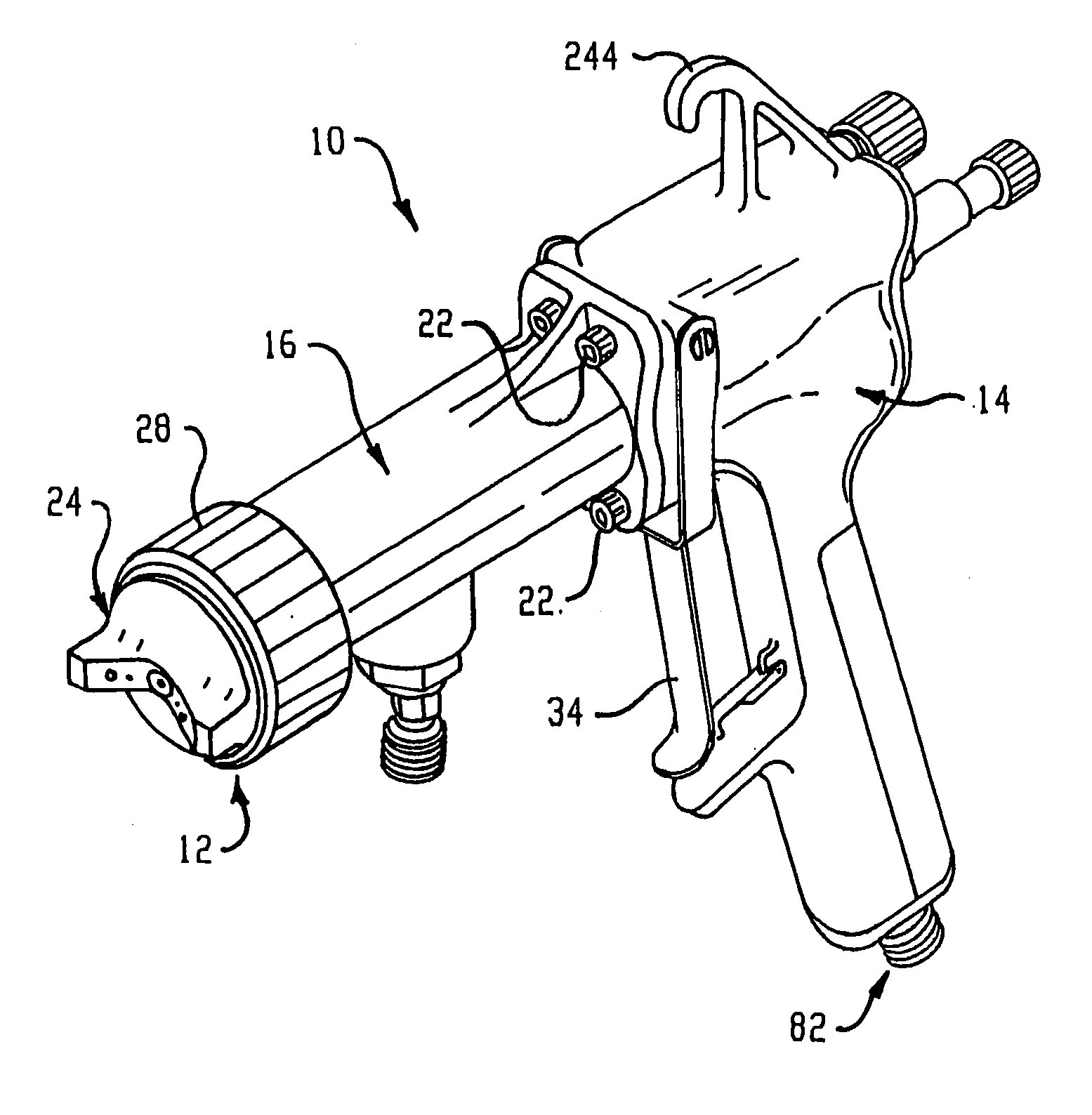

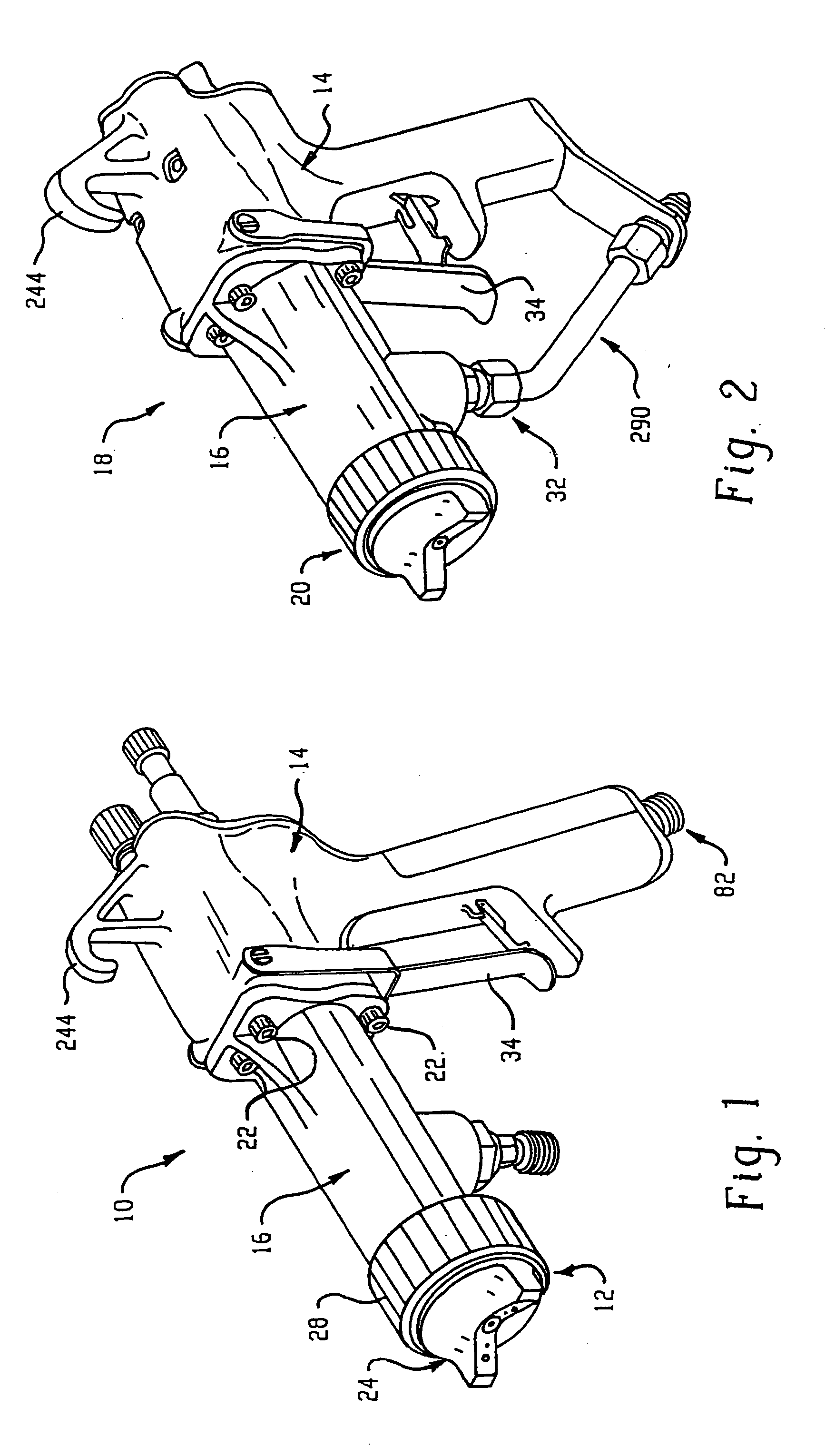

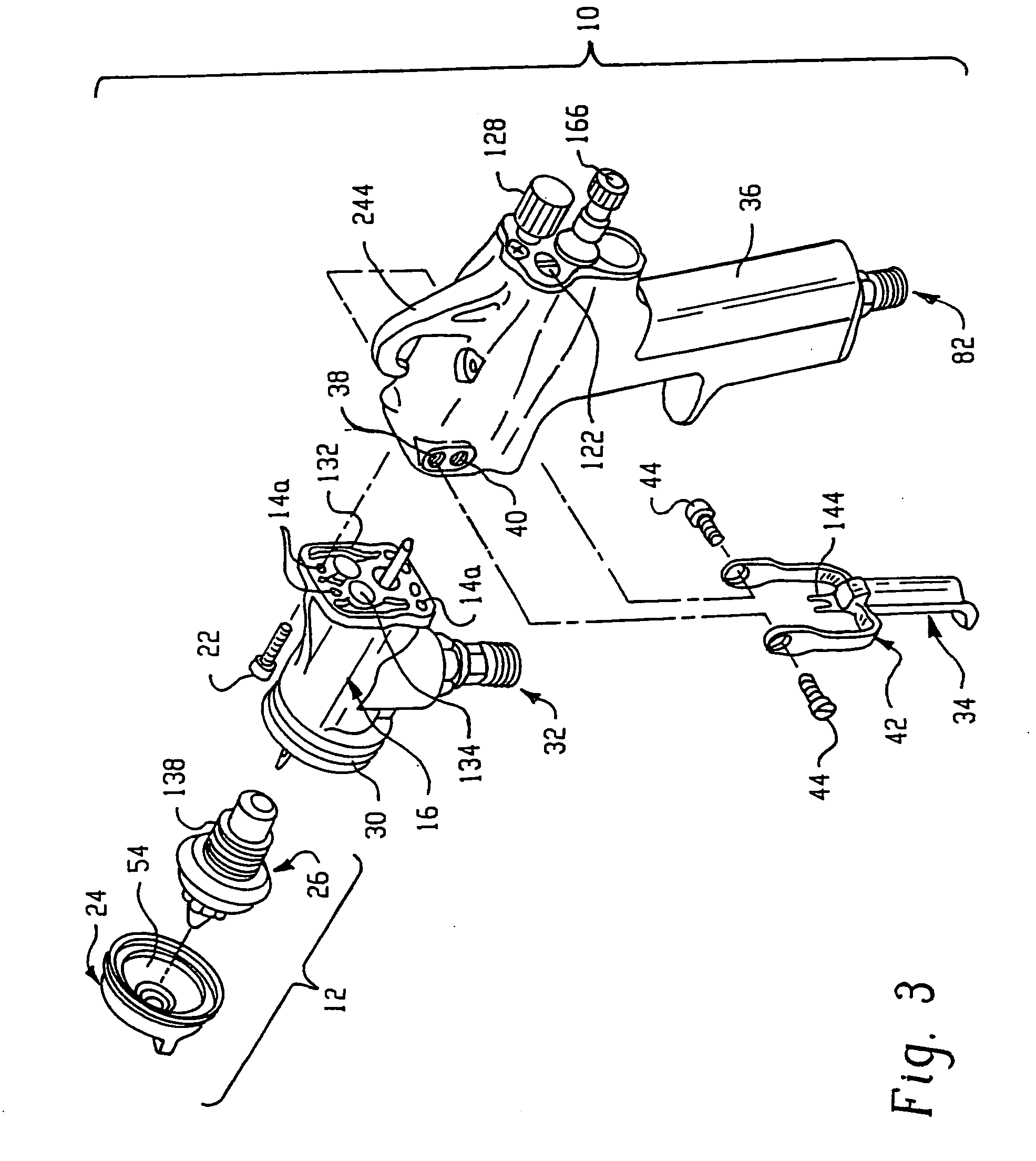

Spray gun having improved fluid tip with conductive path

InactiveUS6877681B2Reduce operator fatigueImprove ease of useBurnersSpraying power supplySpray nozzleEngineering

A modular spray gun that can be configured and built to operate using a selectable spray process. The modular spray gun includes a gun body, an extension and a selectable spray atomizing component. The basic gun body and extension are used to configure a spray gun that can operate as an air spray gun, an airless spray gun, an AAA gun or an HVLP spray gun. The modular extension can be selected to allow circulating or non-circulating operation. The modular extension also permits a variety of spray nozzle assemblies to be mounted thereon depending on the selected spray process to be used with the specific gun. The modular gun body allows selective connection of an atomizing air supply and additional components specific to a particular spray process. An indicator device and / or a relief valve is provided for spray guns using an HVLP spray process to provide an indication that the spray gun is in compliance with the maximum nozzle air pressure limit, usually less than 10 psi. A new air valve seal assembly is also provided. The modular gun design can accommodate electrostatic and non-electrostatic versions.

Owner:NORDSON CORP

Nanoelectronic capnometer adapter

InactiveUS20050245836A1Low costSmall sizeAnalysis using chemical indicatorsSpraying power supplyEngineeringNanostructure

Owner:NANOMIX

Method for feedback controlled electrospray

Owner:NEW OBJECTIVE INC

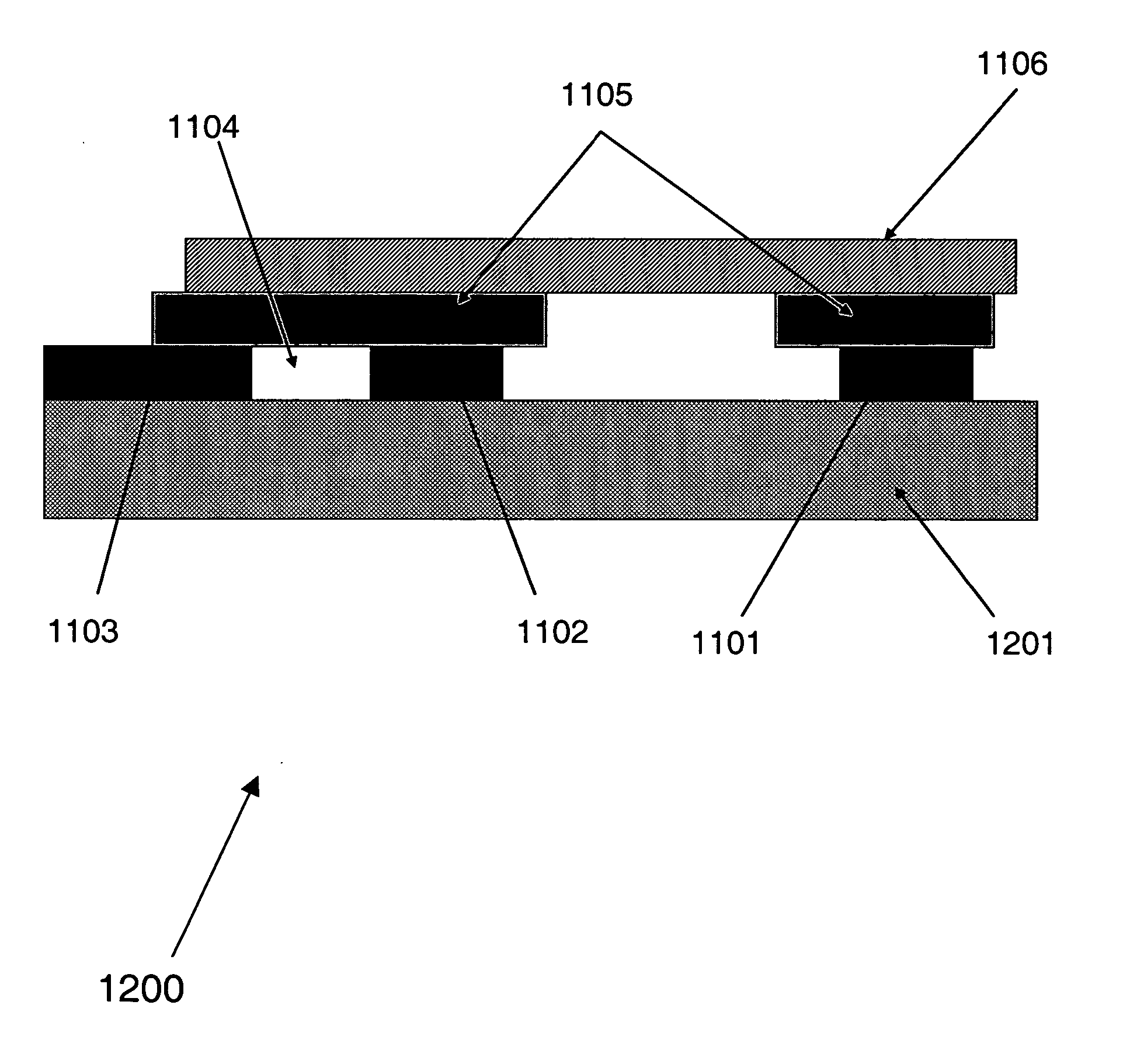

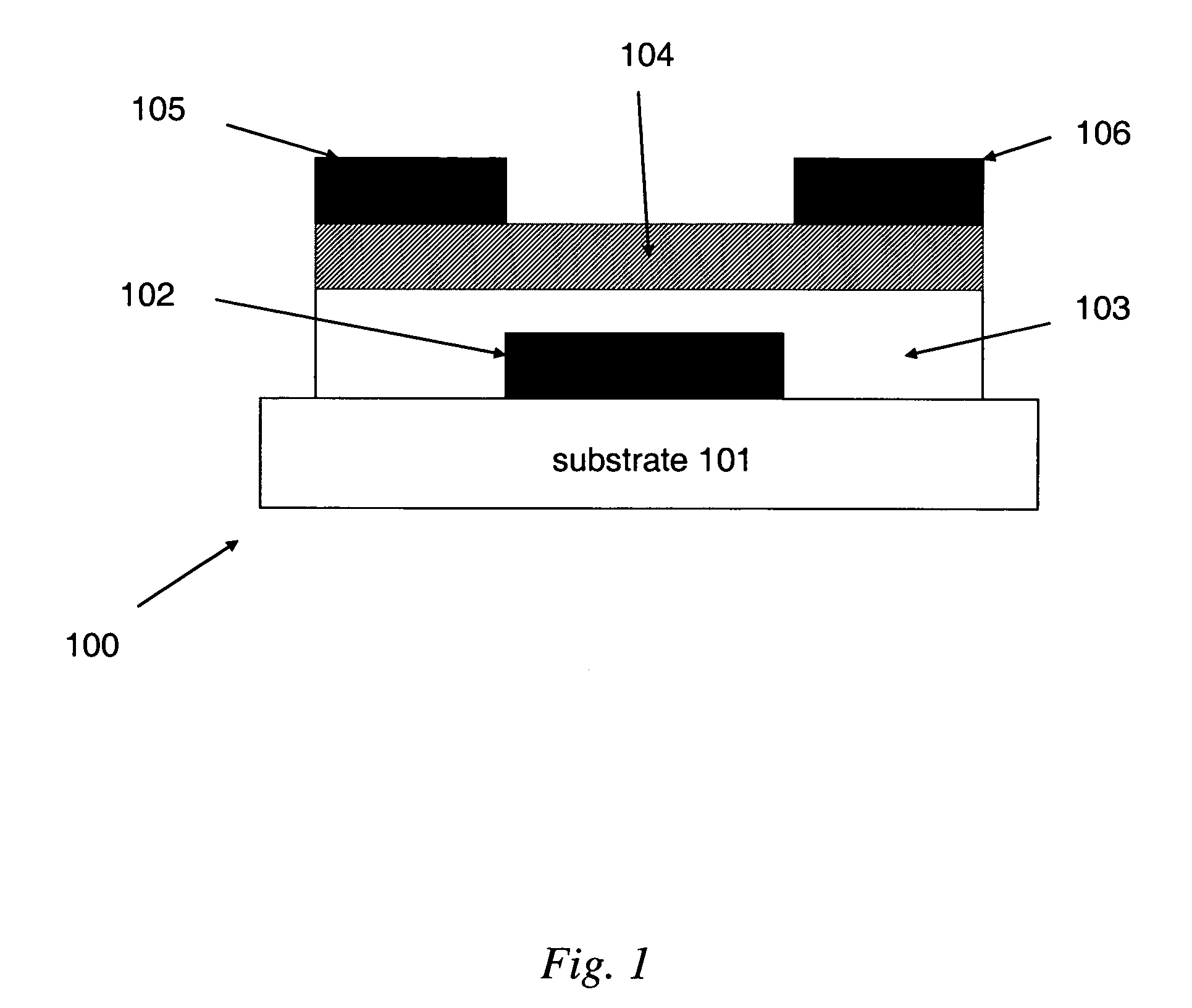

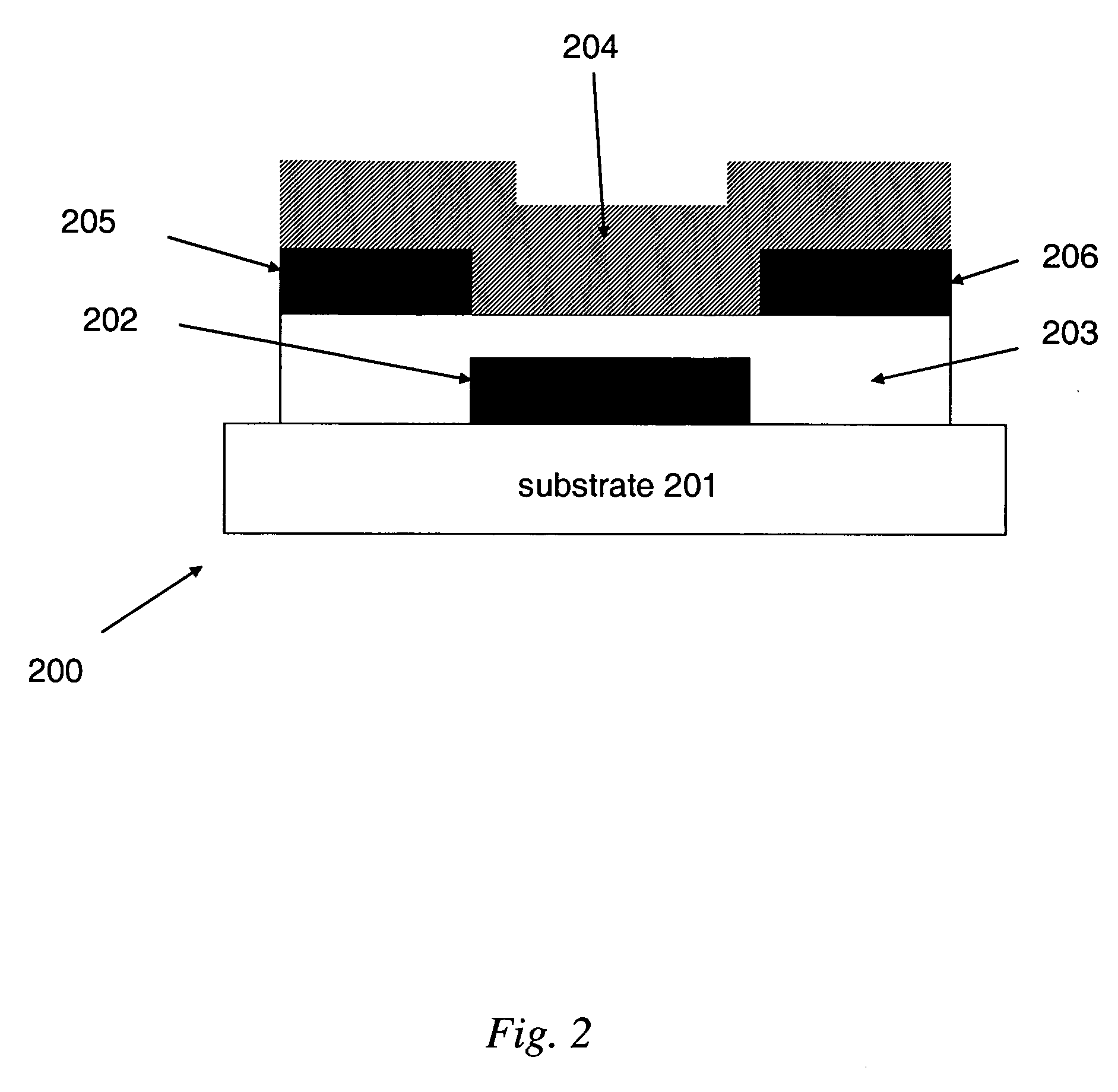

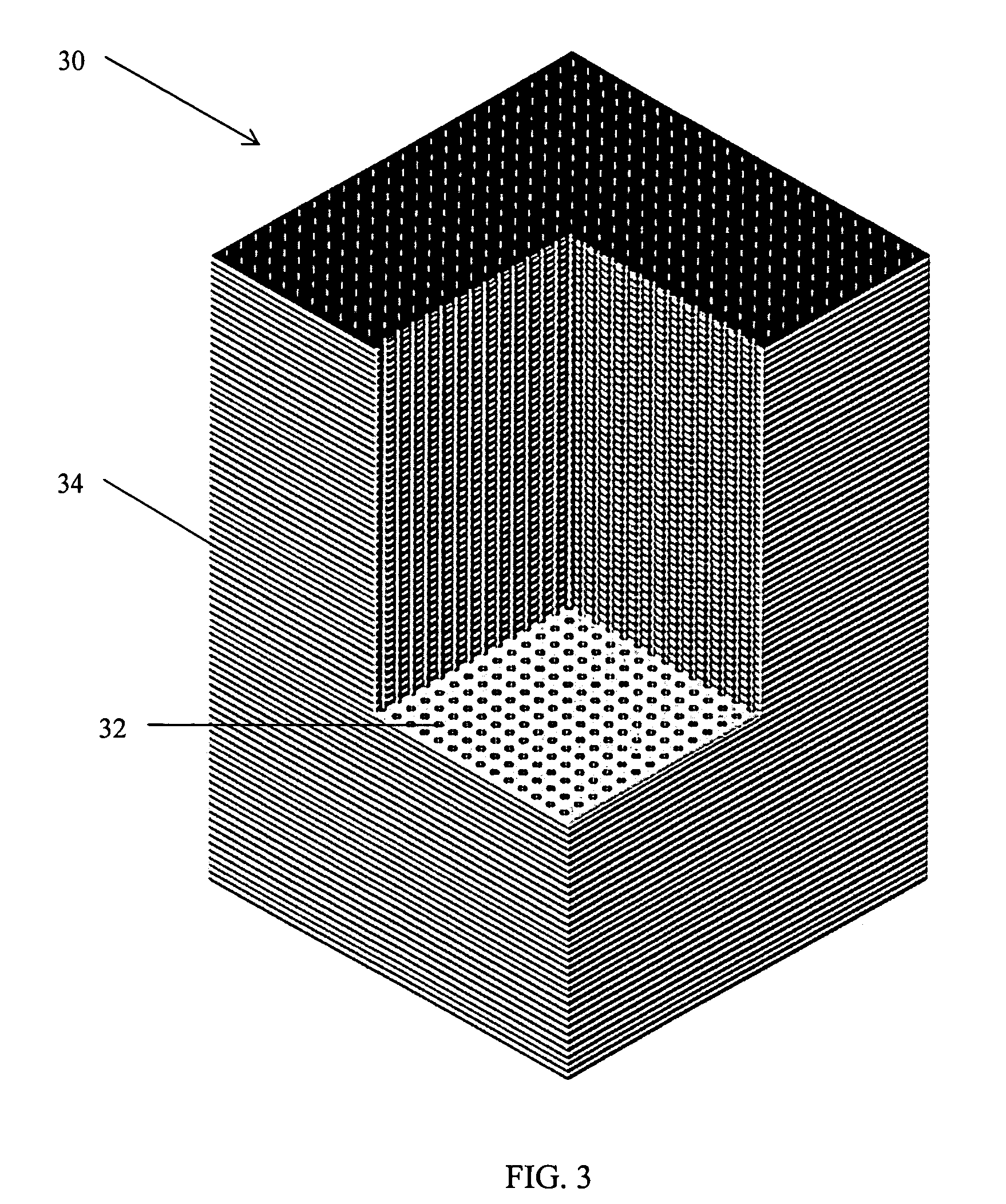

High performance field effect transistors comprising carbon nanotubes fabricated using solution based processing

InactiveUS20060081882A1Easy to disperseFacilitate such dispersalMaterial nanotechnologySpraying power supplyCarbon nanotubeField-effect transistor

The present invention is directed toward field effect transistors (FETs) and thin film transistors (TFTs) comprising carbon nanotubes (CNTs) and to methods of making such devices using solution-based processing techniques, wherein the CNTs within such devices have been fractionated so as to be concentrated in semiconducting CNTs. Additionally, the relatively low-temperature solution-based processing achievable with the methods of the present invention permit the use of plastics in the fabricated devices.

Owner:GENERAL ELECTRIC CO

Electrospraying method with conductivity control

An electrospraying apparatus and / or method is used to coat particles. For example, a flow including at least one liquid suspension may be provided through at least one opening at a spray dispenser end. The flow includes at least particles and a coating material. A spray of microdroplets suspending at least the particles is established forward of the spray dispenser end by creating a nonuniform electrical field between the spray dispenser end and an electrode electrically isolated therefrom. The particles are coated with at least a portion of the coating material as the microdroplet evaporates. For example, the suspension may include biological material particles.

Owner:RGT UNIV OF MINNESOTA

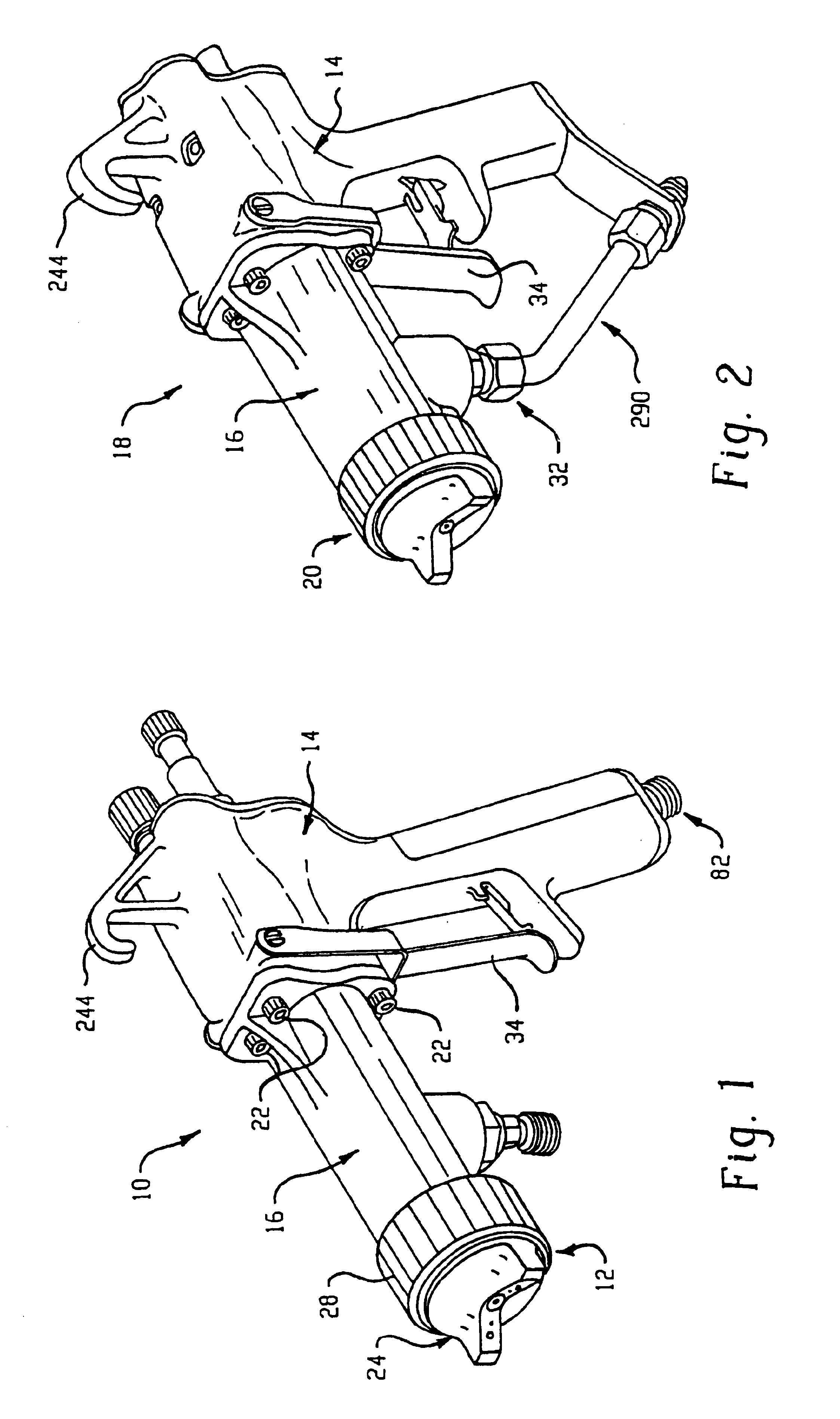

Modular fluid spray gun

InactiveUS20050189445A1Improve modularityPromote atomizationBurnersSpraying power supplySpray nozzleModular design

A modular spray gun that can be configured and built to operate using a selectable spray process. The modular spray gun includes a gun body, an extension and a selectable spray atomizing component. The basic gun body and extension are used to configure a spray gun that can operate as an air spray gun, an airless spray gun, an AAA gun or an HVLP spray gun. The modular extension can be selected to allow circulating or non-circulating operation. The modular extension also permits a variety of spray nozzle assemblies to be mounted thereon depending on the selected spray process to be used with the specific gun. The modular gun body allows selective connection of an atomizing air supply and additional components specific to a particular spray process. An indicator device and / or a relief valve is provided for spray guns using an HVLP spray process to provide an indication that the spray gun is in compliance with the maximum nozzle air pressure limit, usually less than 10 psi. A new air valve seal assembly is also provided. The modular gun design can accommodate electrostatic and non-electrostatic versions.

Owner:HARTLE RONALD J +2

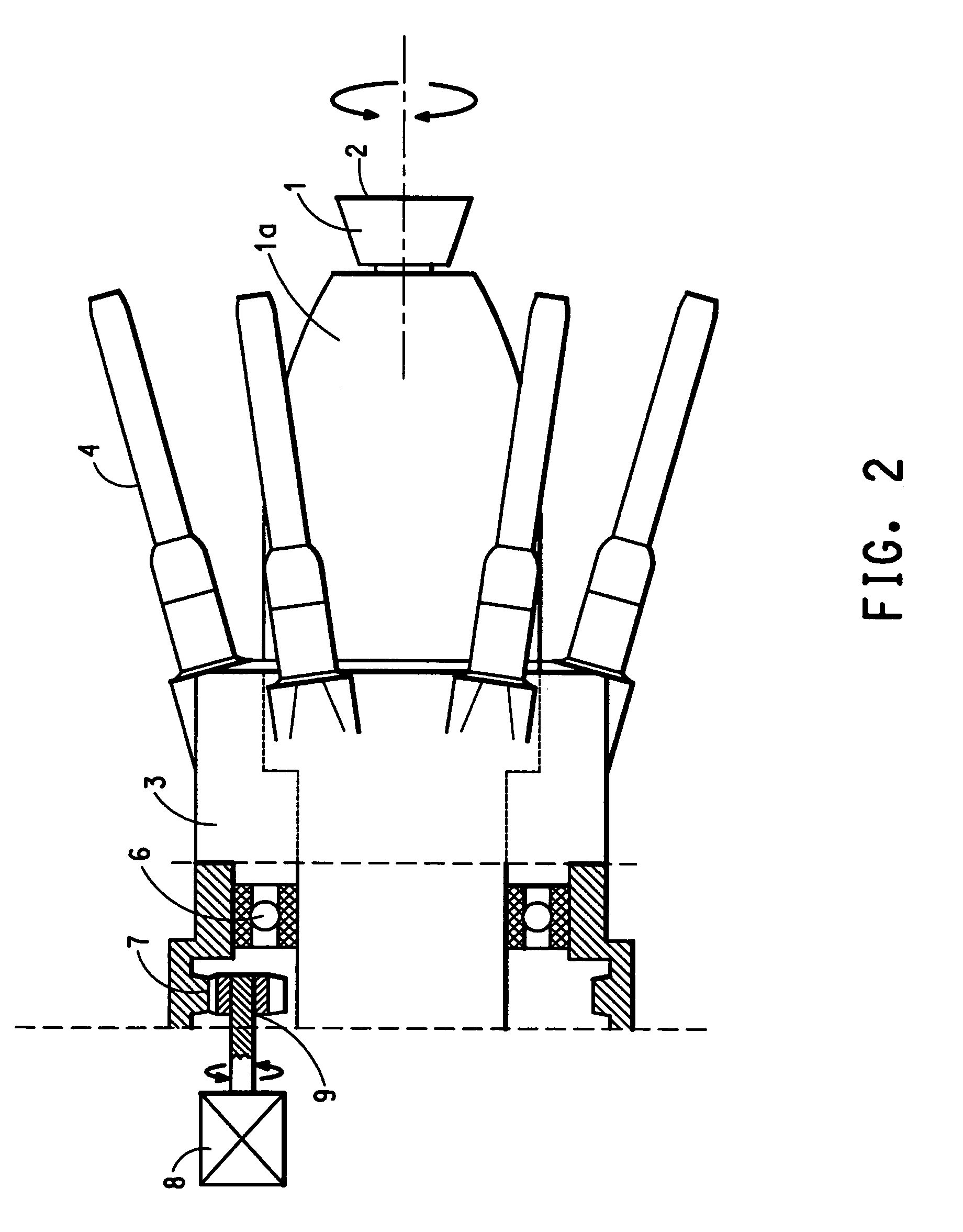

Electrostatically Atomizing Device

The present invention provides an electrostatically atomizing device capable of instantly giving an electrostatically atomizing effect without requiring a water tank. The electrostatically atomizing device includes an emitter electrode, an opposed electrode opposed to the emitter electrode, a water feeder configured to give water on the emitter electrode, and a high voltage source configured to apply a high voltage across said emitter electrode and said opposed electrode to electrostatically charge the water on the emitter electrode for spraying charged minute water particles from a discharge end of the emitter electrode. The water feeder is configured to condense the water on the emitter electrode from within the surrounding air, enabling to supply the water on the emitter electrode in a short time without relying upon an additional water tank. Thus, an atomization of the charged minute water particles can be obtained immediately upon use of the device.

Owner:MATSUSHITA ELECTRIC WORKS LTD

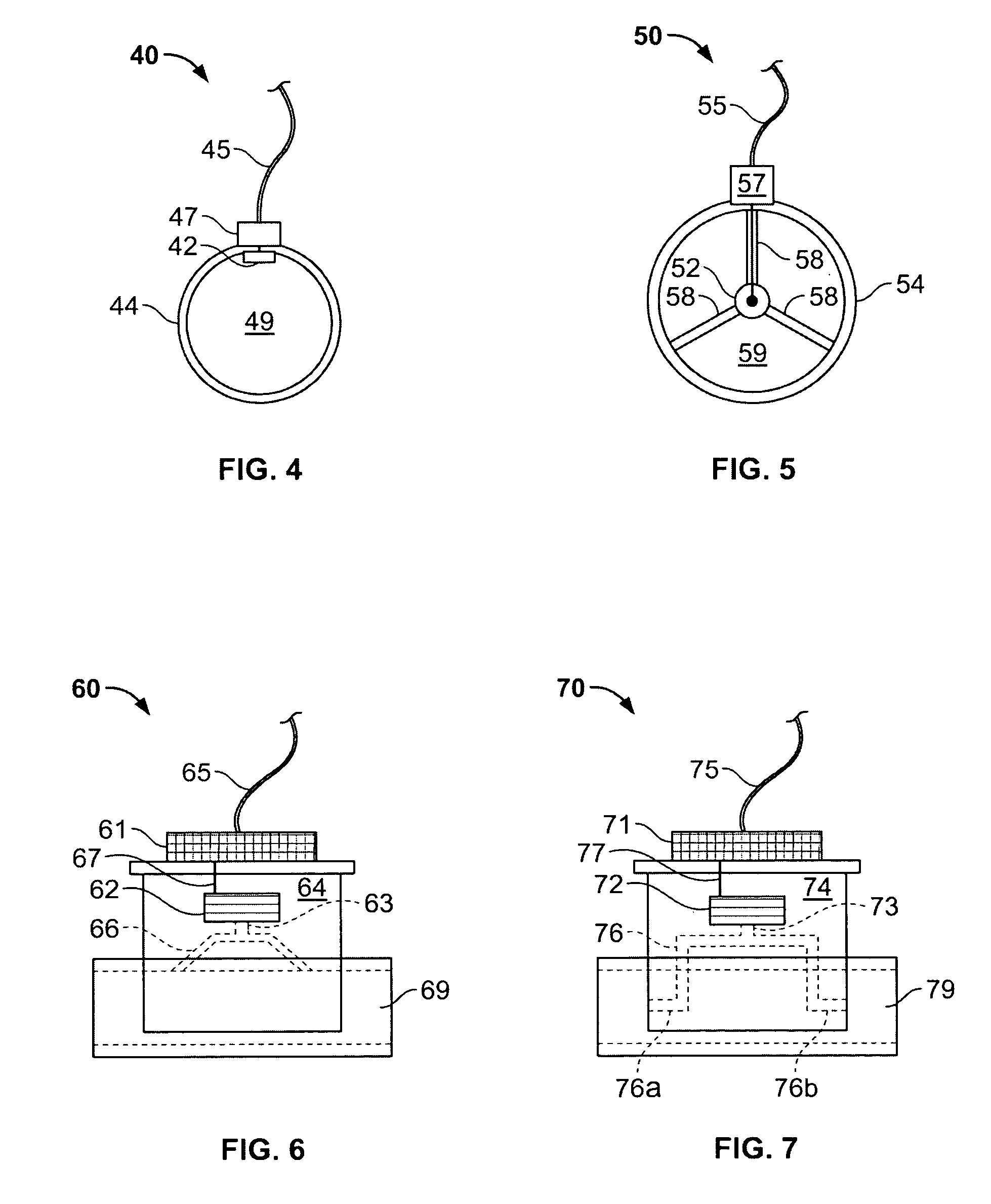

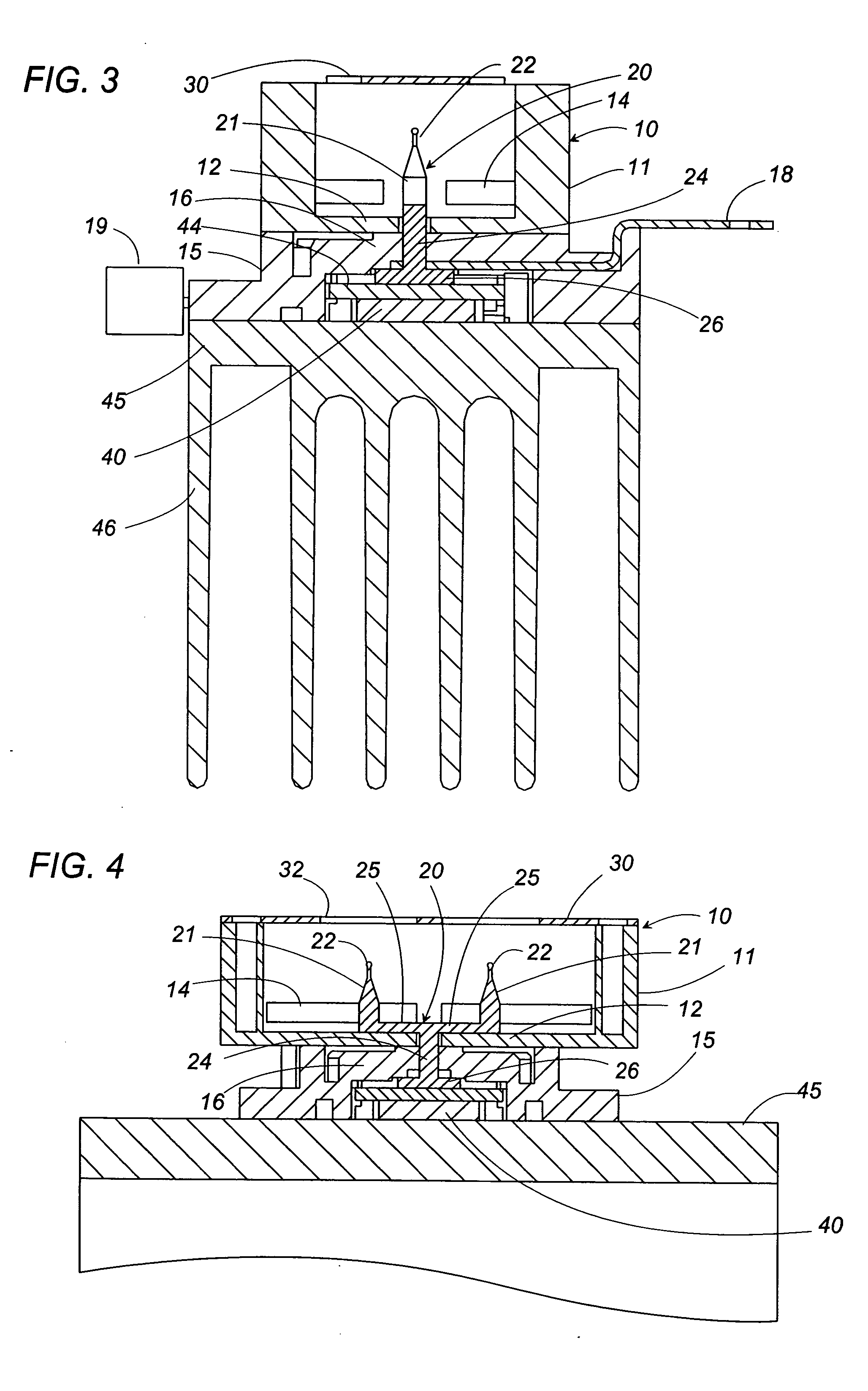

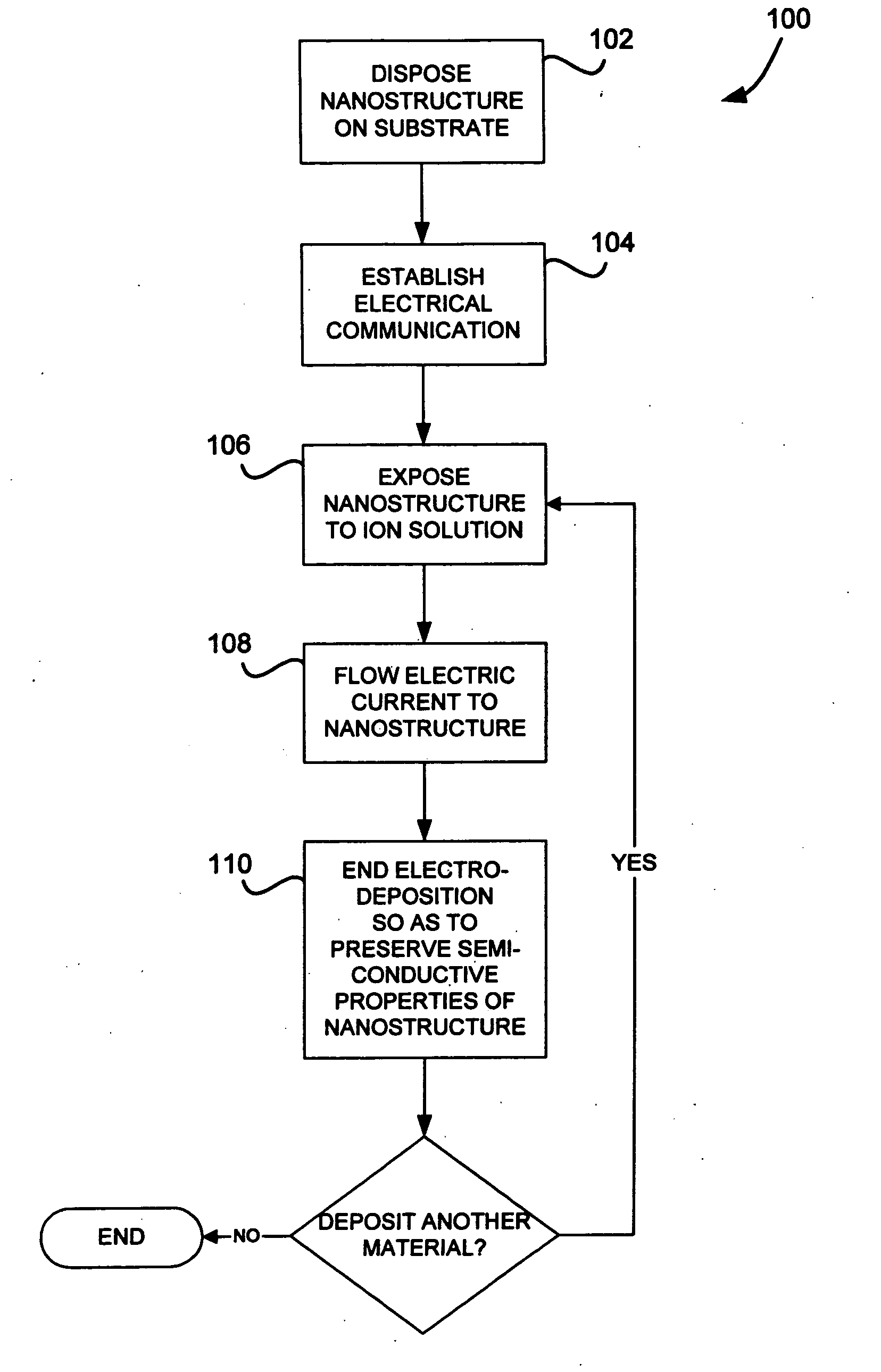

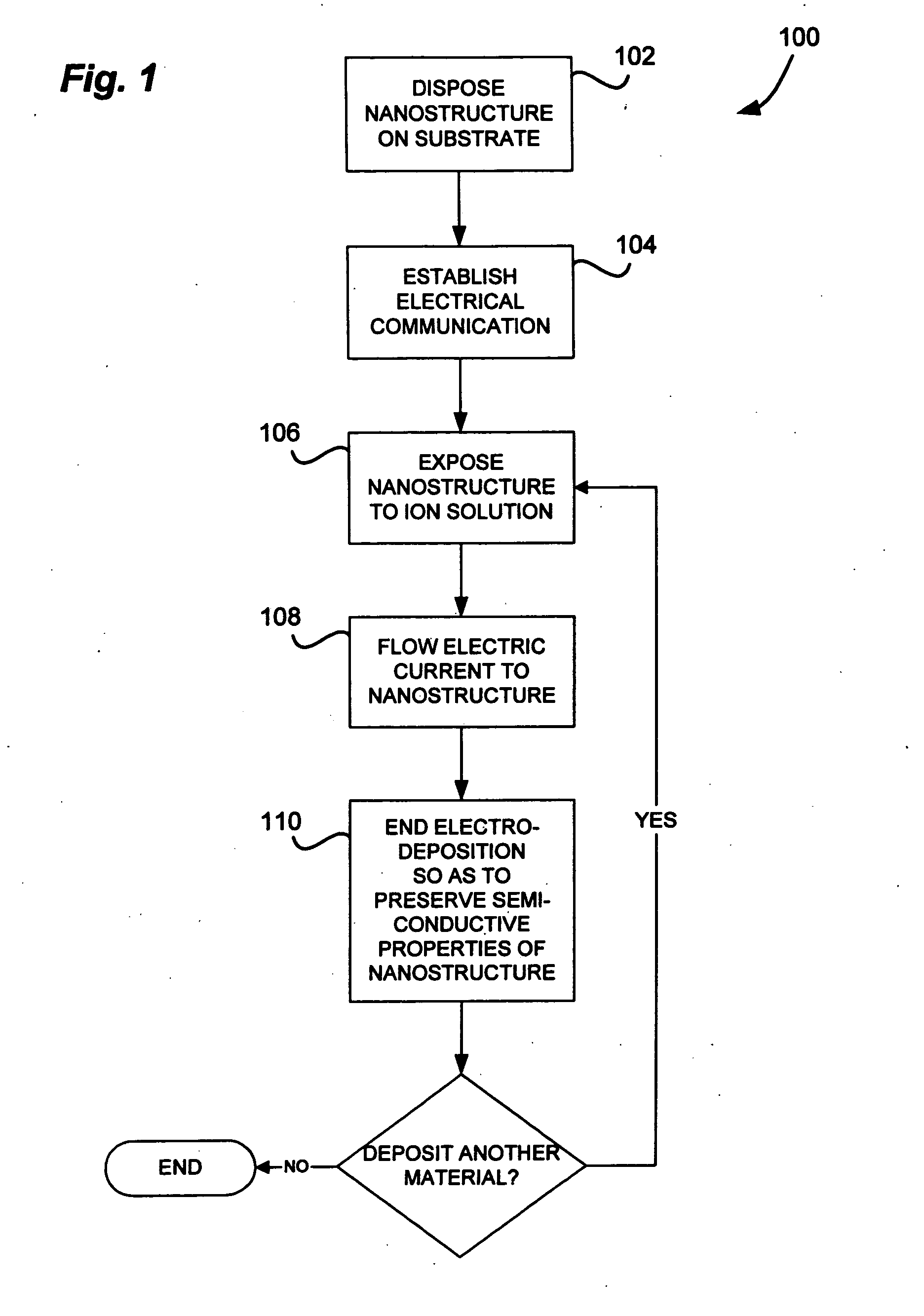

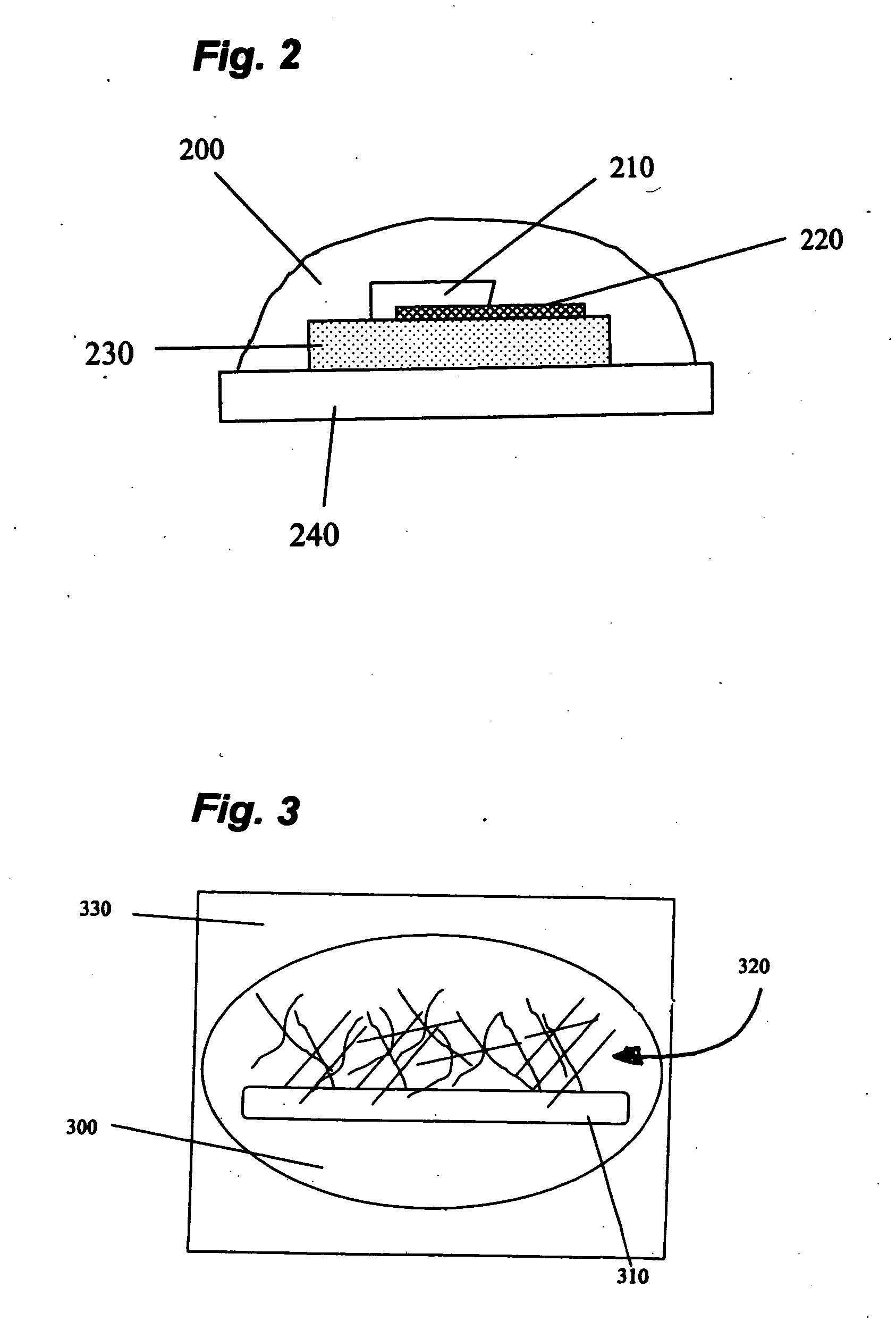

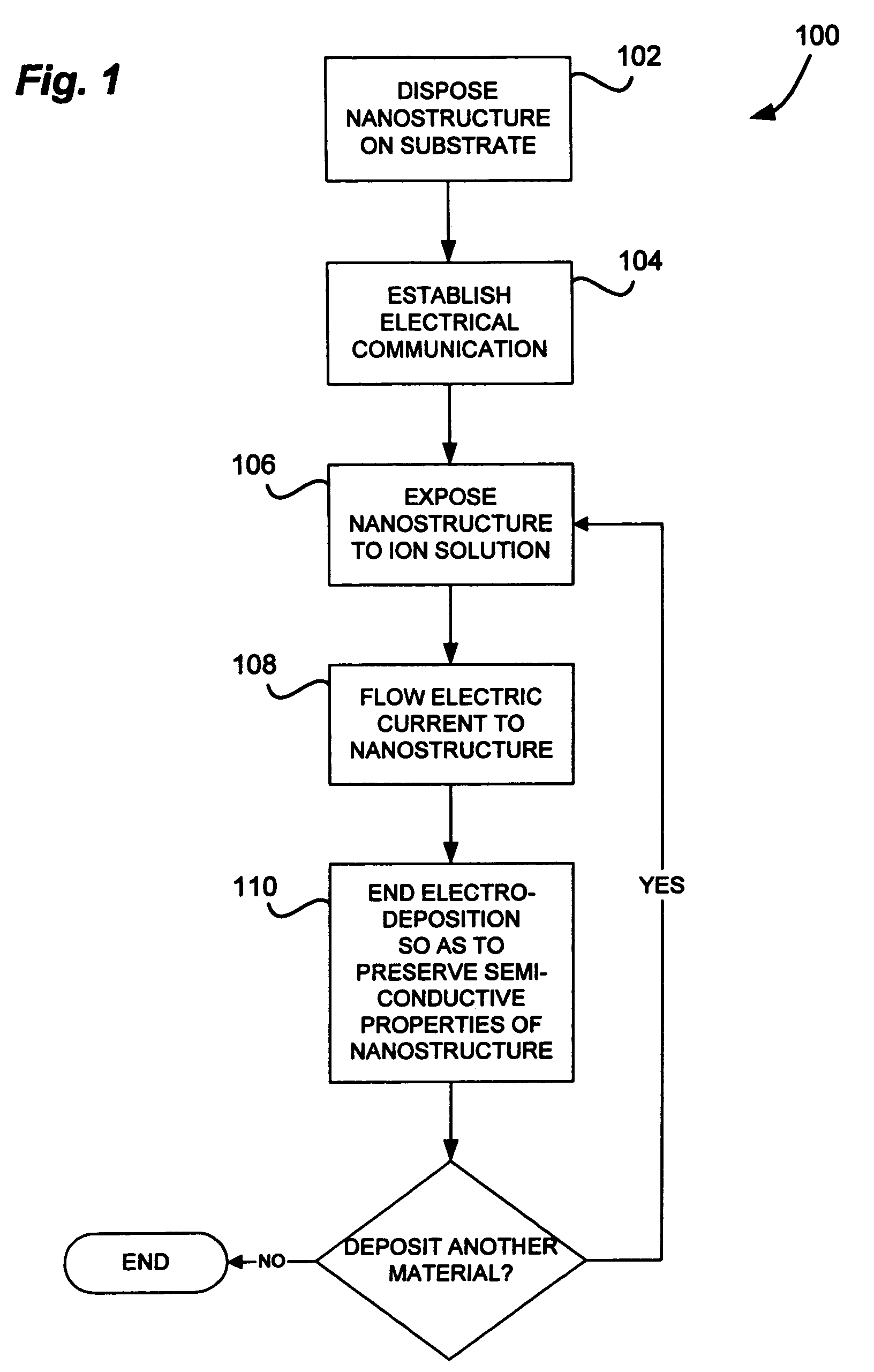

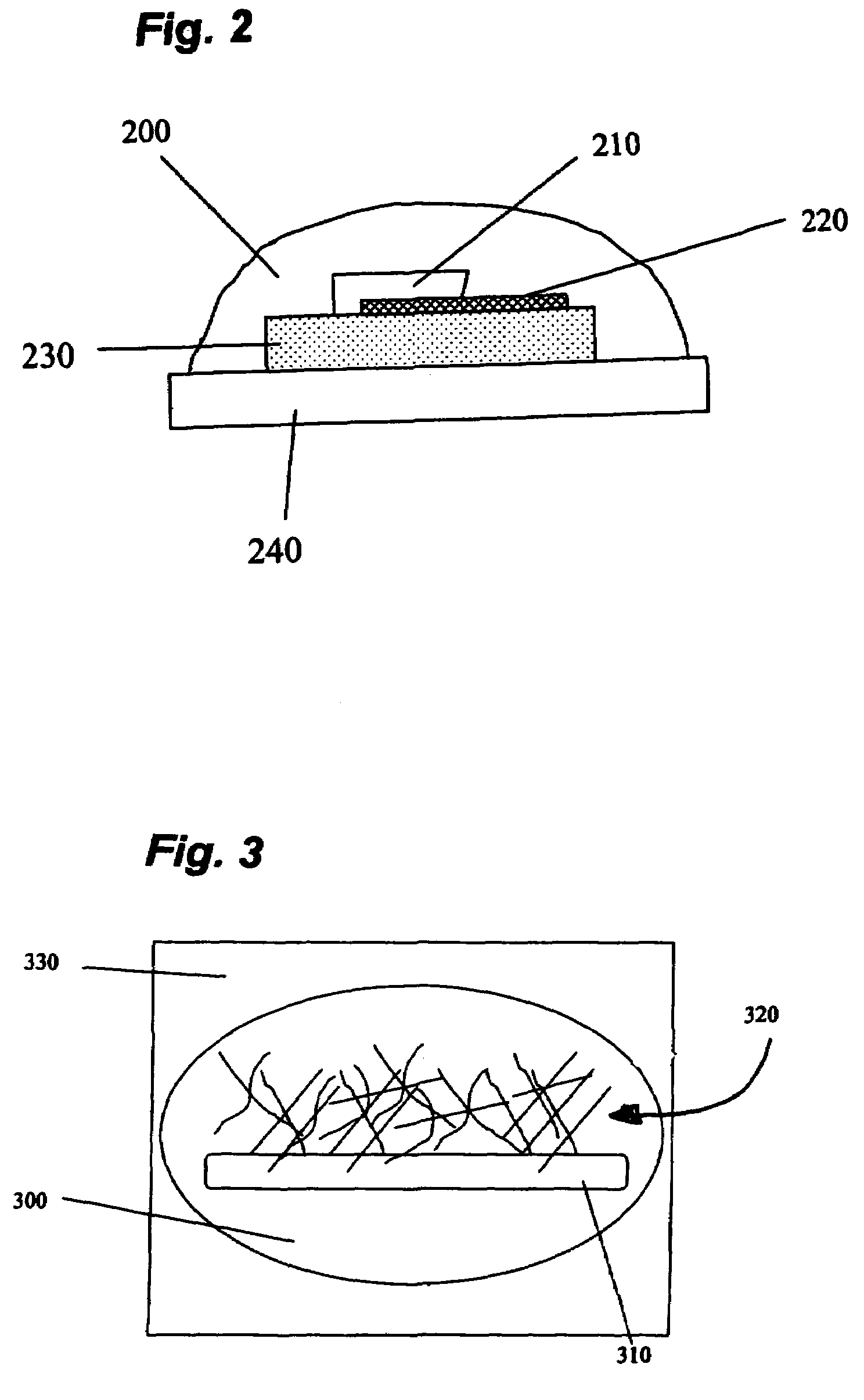

Nanostructures with electrodeposited nanoparticles

A nanoelectronic device includes a nanostructure, such as a nanotube or network of nanotubes, disposed on a substrate. Nanoparticles are disposed on or adjacent to the nanostructure so as to operatively effect the electrical properties of the nanostructure. The nanoparticles may be composed of metals, metal oxides, or salts, and nanoparticles composed of different materials may be present. The amount of nanoparticles may be controlled to preserve semiconductive properties of the nanostructure, and the substrate immediately adjacent to the nanostructure may remain substantially free of nanoparticles. A method for fabricating the device includes electrodeposition of the nanoparticles using one or more solutions of dissolved ions while providing an electric current to the nanostructures but not to the surrounding substrate.

Owner:NANOMIX

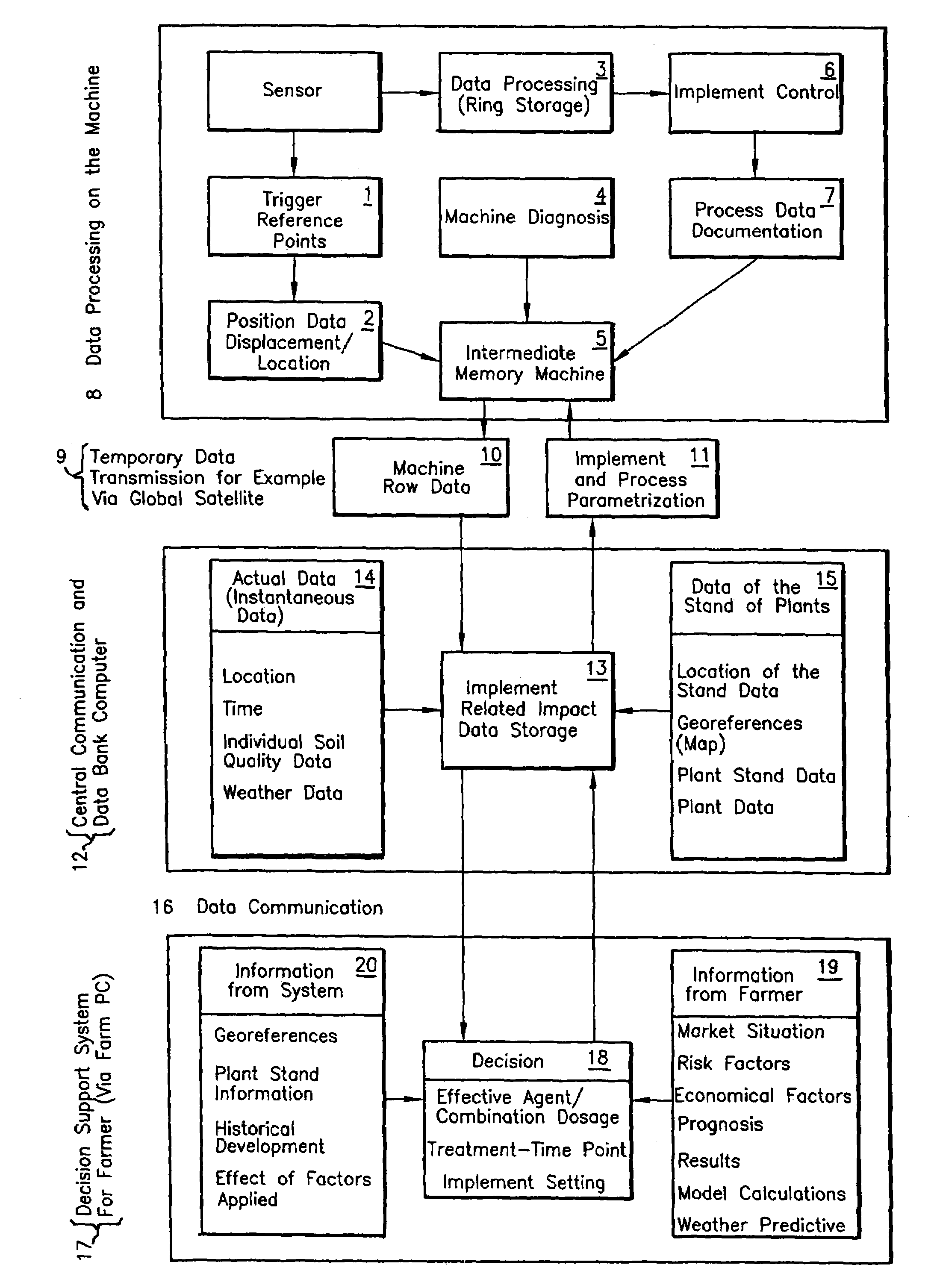

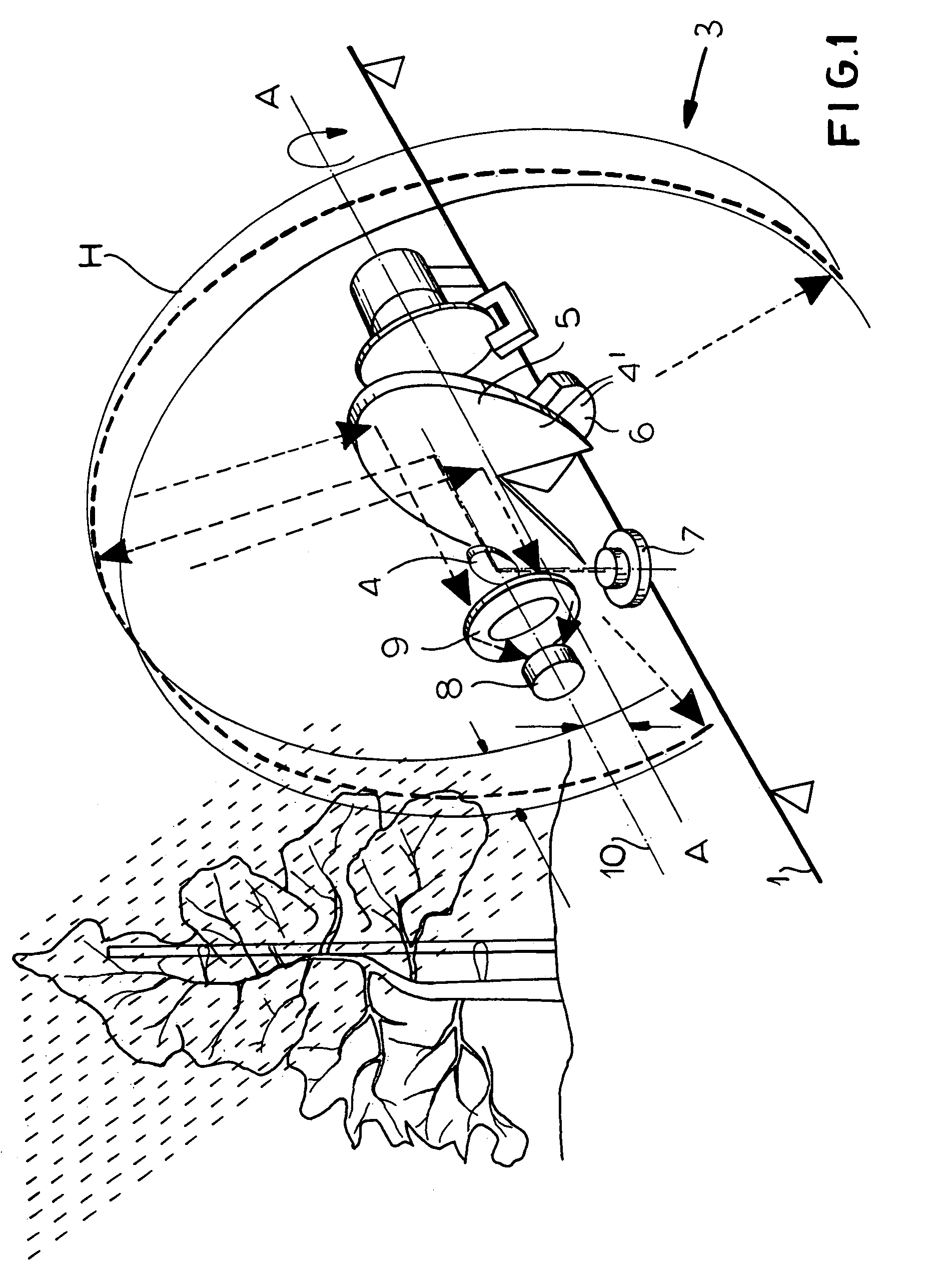

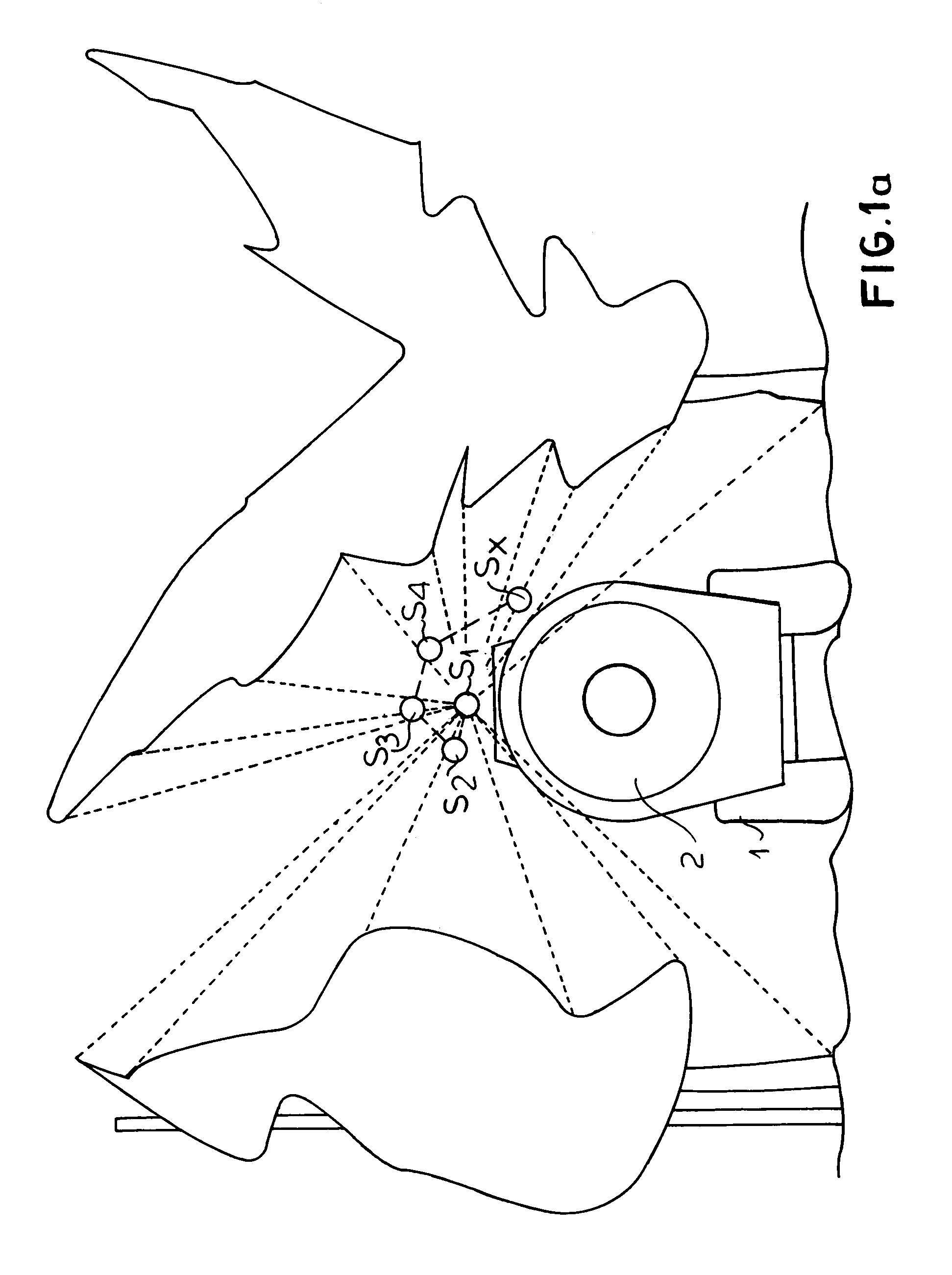

Method and system for volume-specific treatment of ground and plants

The invention relates to a method and system for volume-specific treatment of ground and plants as required. The aim of the invention is to improve a method and system as above, such that the distribution of plants is scanned with complete spatial coverage and the treatment of the ground or plant condition is efficiently controlled, by simultaneously taking account of morphological, plant physiological, equipment performance and specific local properties.

Owner:KUMMEL KNUT

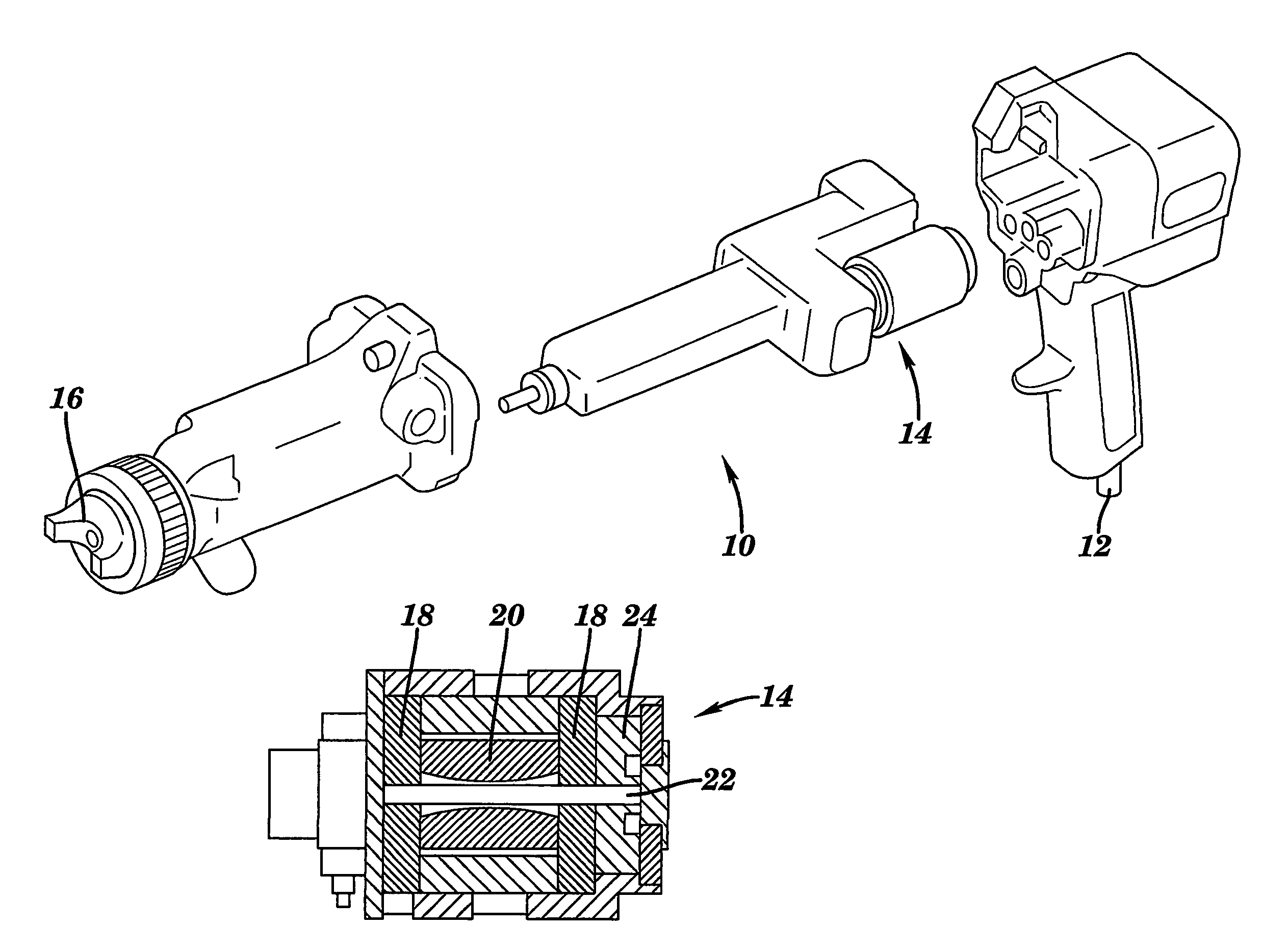

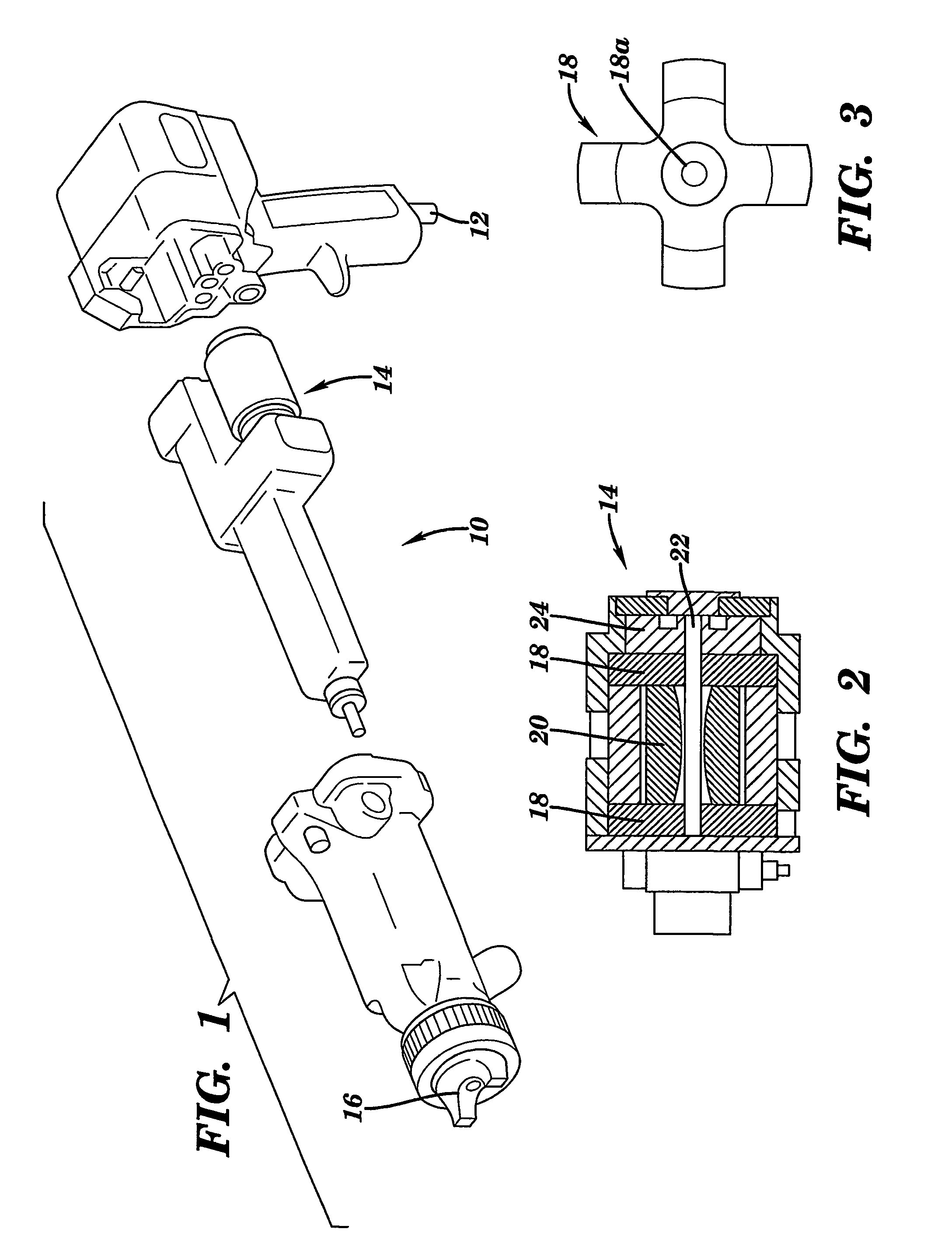

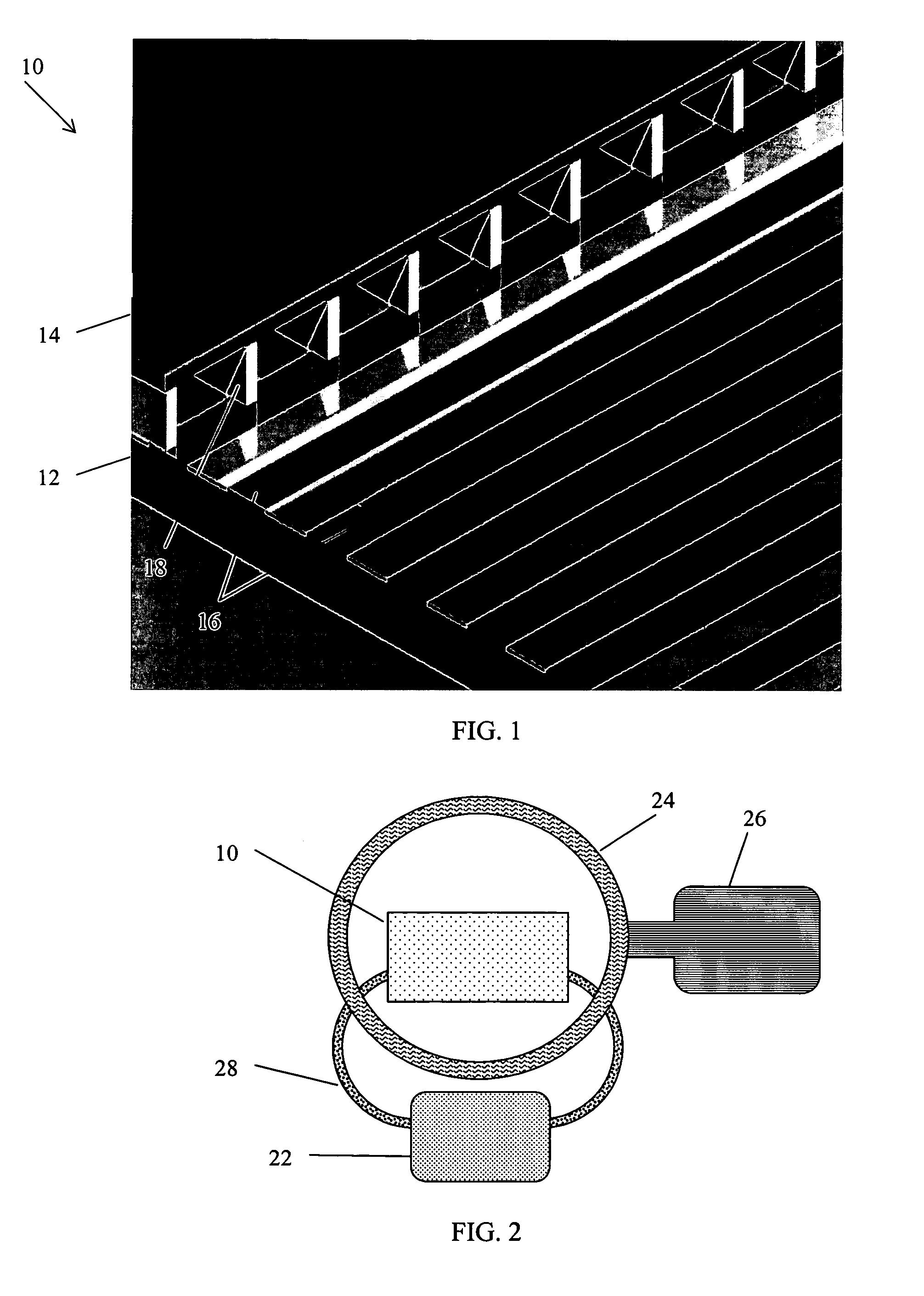

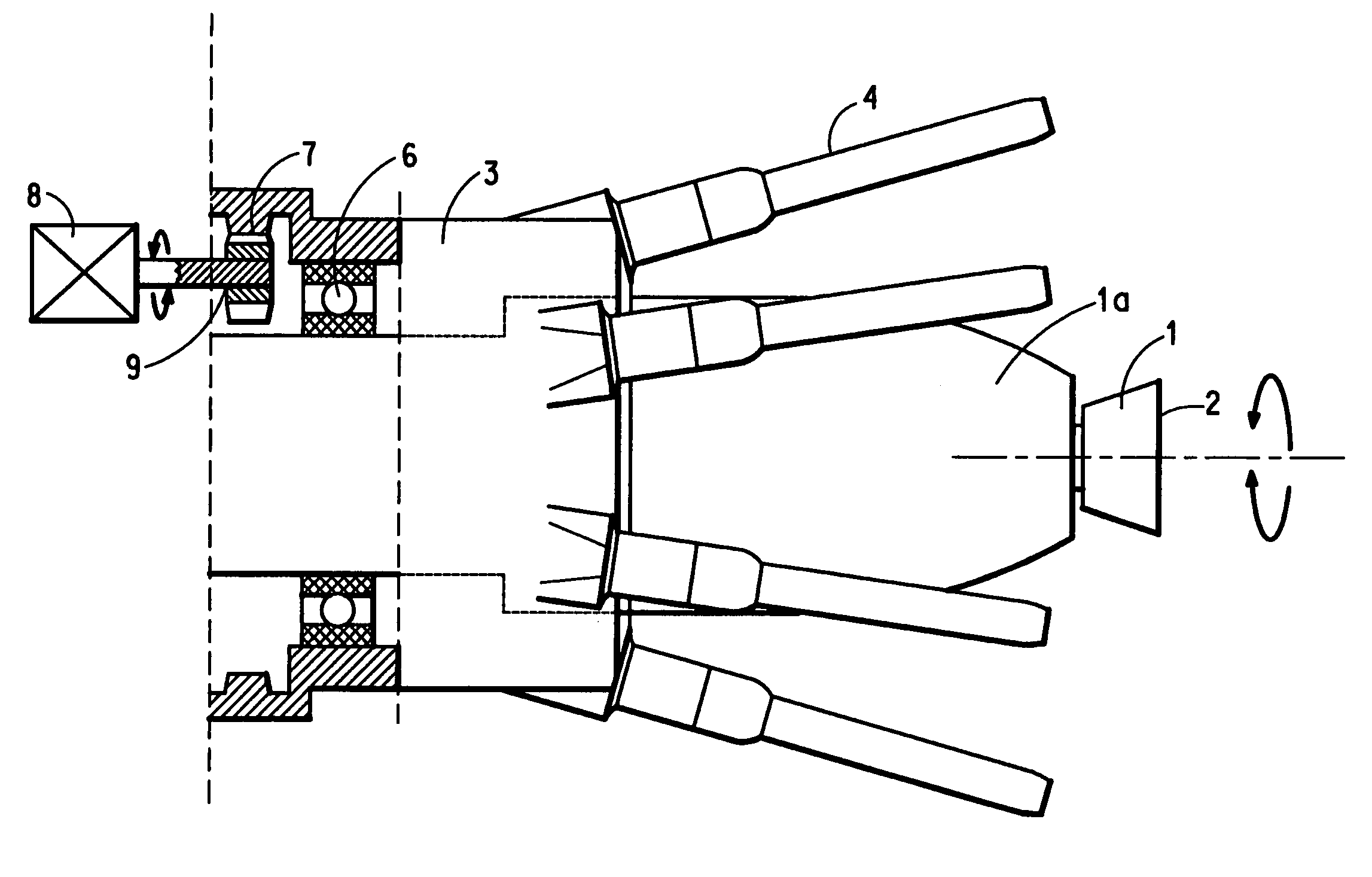

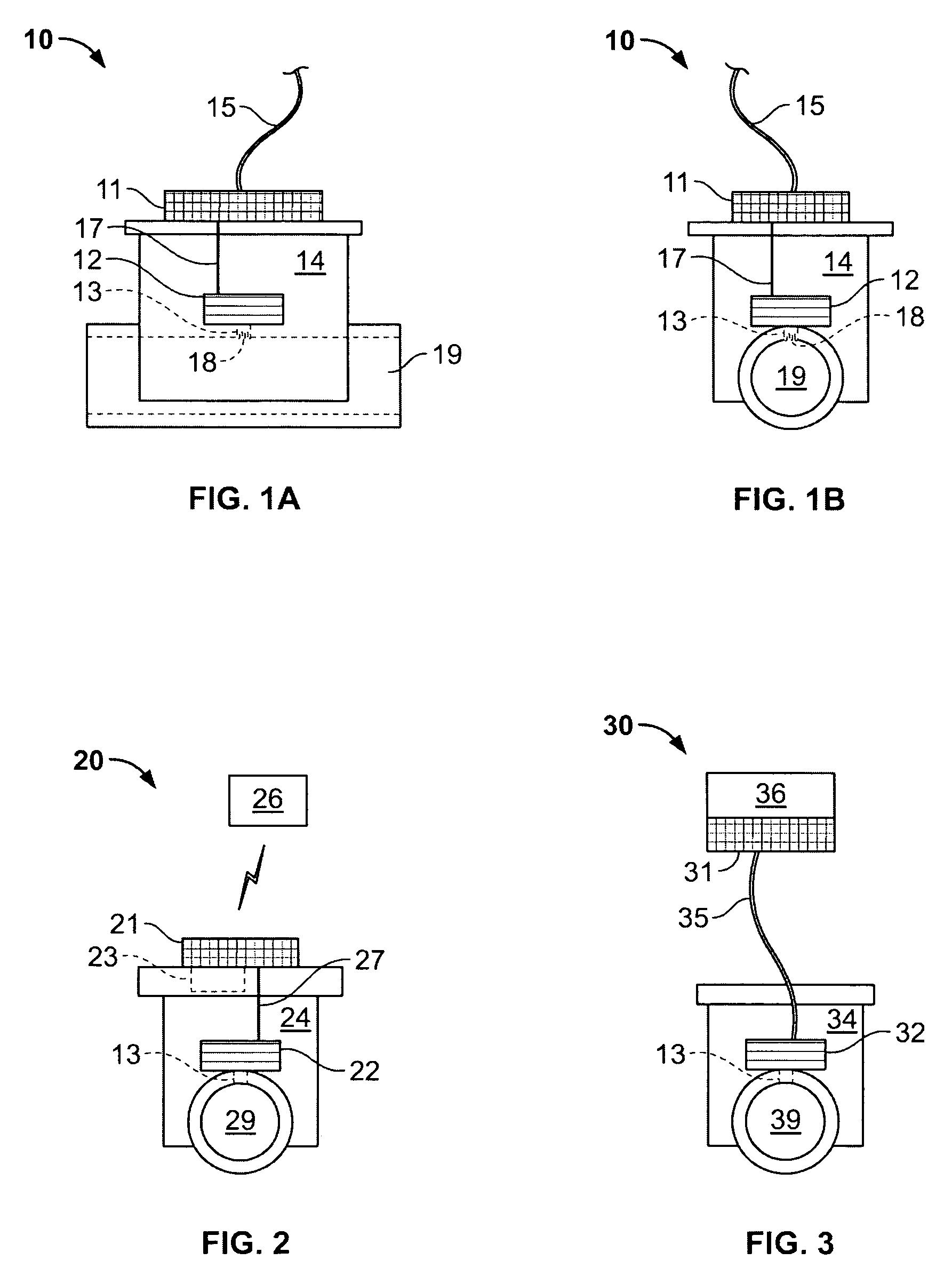

Solvent resistant bearings for self-generating electrostatic spray gun

InactiveUS7226004B2Improve bearing lifeFailure can be causedBurnersLiquid spraying plantsImpellerAlternator

An electrostatic spray gun (10) having an air powered alternator-turbine (14) with a rotating impeller (24) therein mounted in bearings (18) is provided with bearings (18) which are coated with a solvent resistant material. This coating is provided on all surfaces of the bearing (18) except for the inner diameter (18A) which contains the impeller (24). This construction prevents leaching of the oil out of the bearing (18) and into the airstream and also is resistant to paint should the spray gun (10) become immersed in such.

Owner:GRACO INC

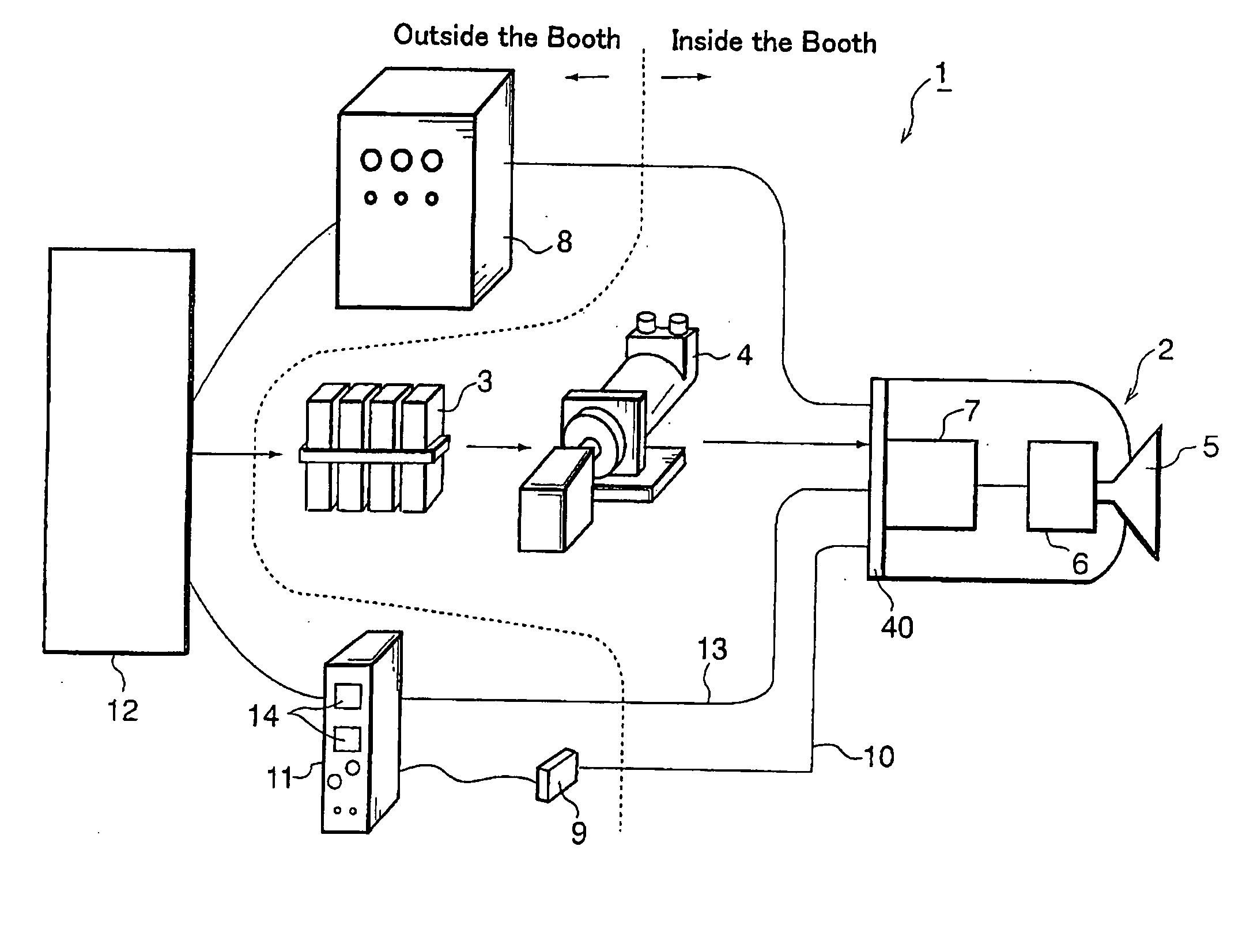

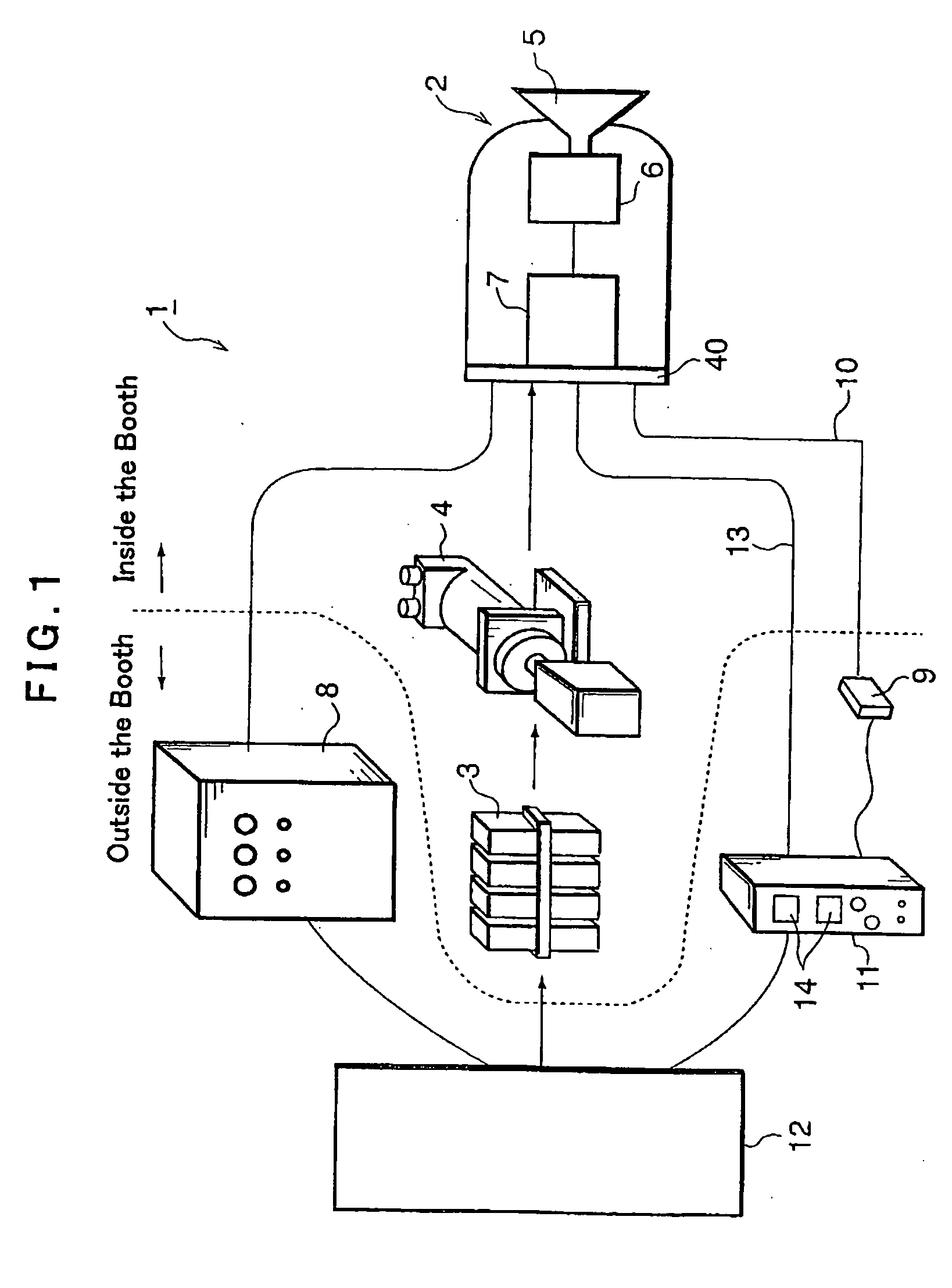

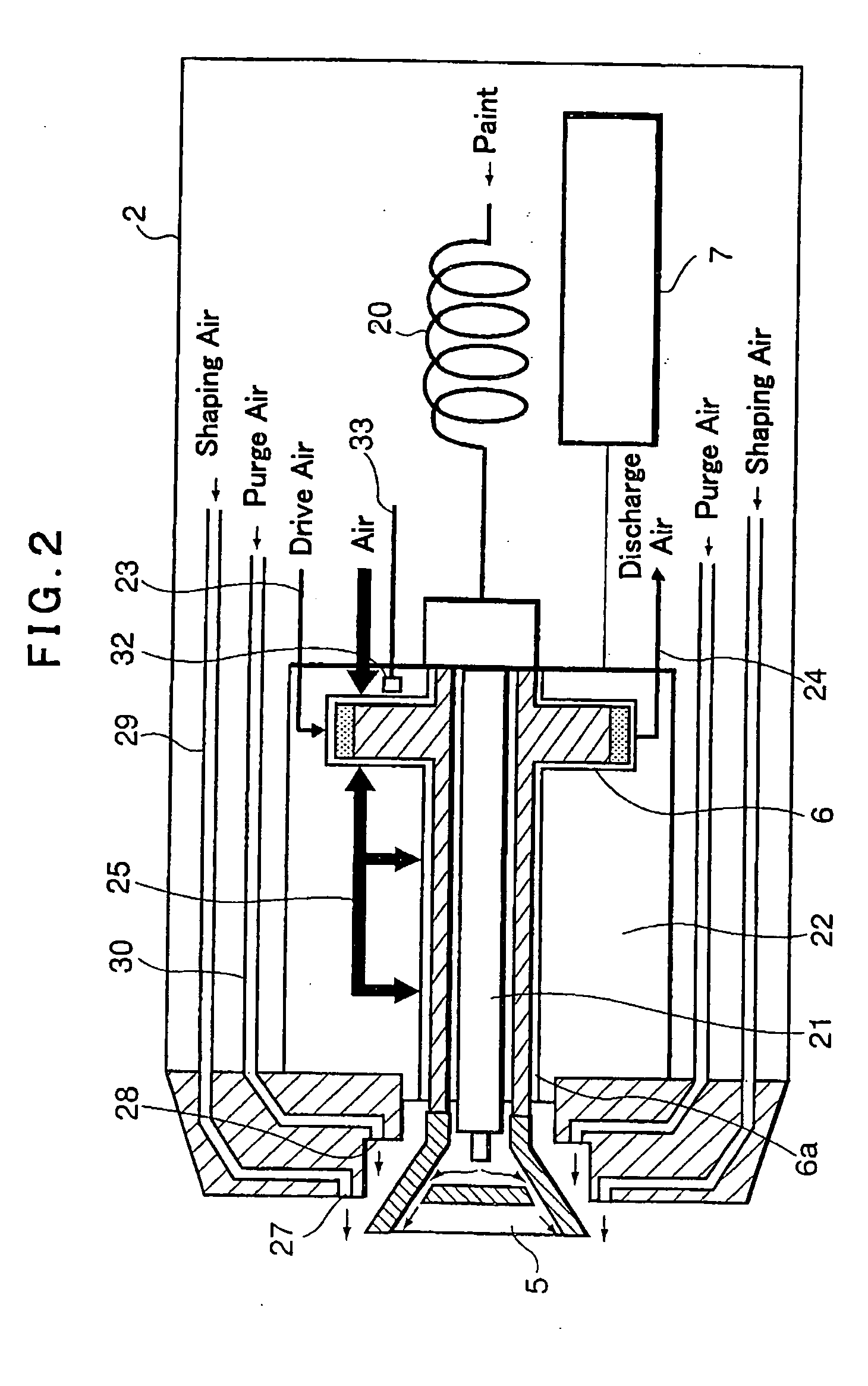

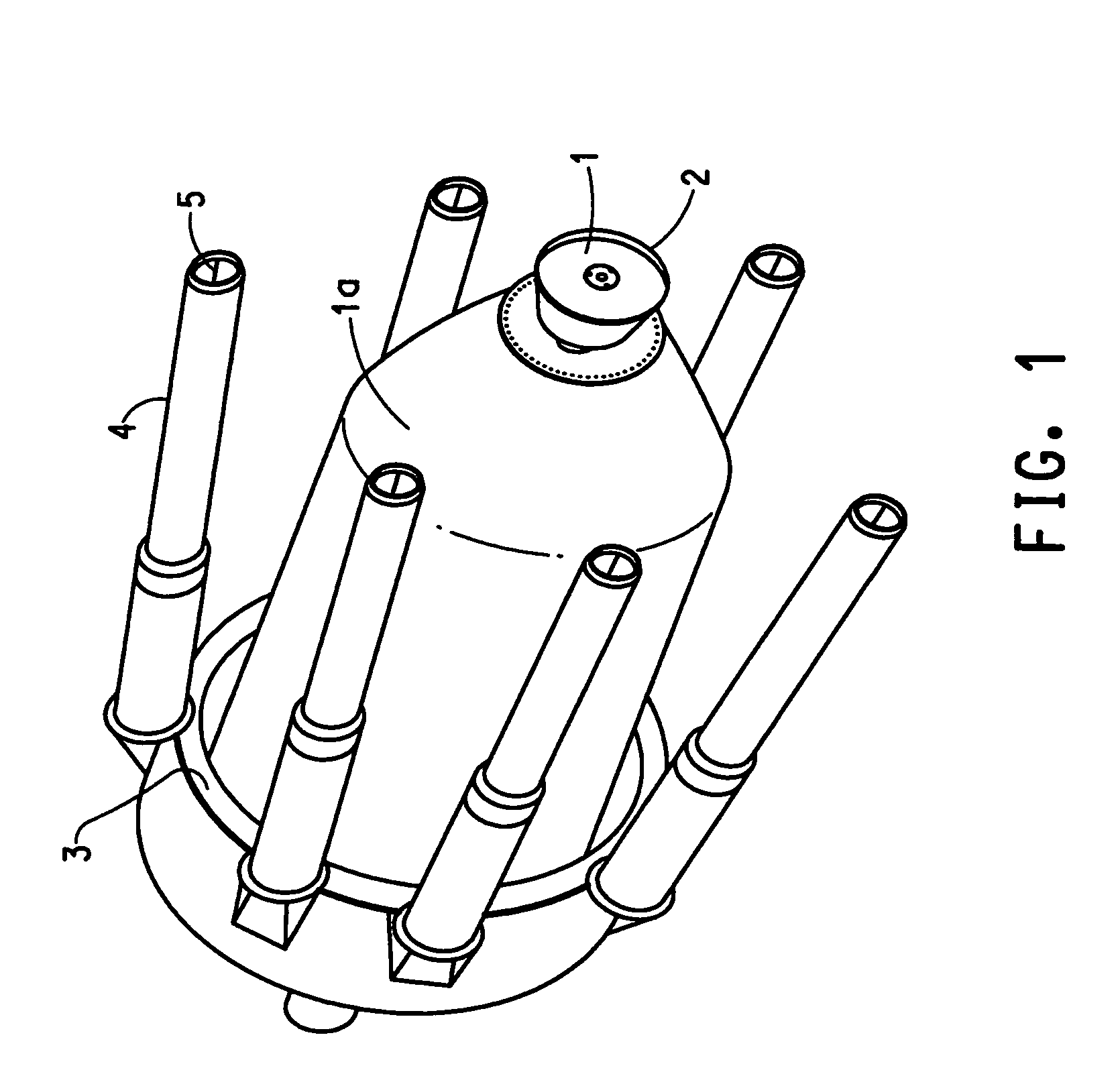

Electrostatic coating system

ActiveUS20050040262A1Guaranteed uptimeEasy to controlBurnersLiquid spraying plantsElectrostatic coatingTotal current

Total supplied current (I2) and high voltage (Vm) supplied to a rotary atomizer head (5) are detected by a total current sensor (115) and a high voltage sensor (116). Total leak current (I2) in paint paths, thinner paths and air paths inside an electrostatic atomizer (2) is detected via a metal back plate (40) of the electrostatic atomizer (2). When the total leak current value (I2) exceeds a threshold value (Ia), the level Vm of the high voltage applied to the rotary atomizer head (5) is lowered stepwise.

Owner:CARLISLE FLUID TECH RANSBURG JAPAN KK

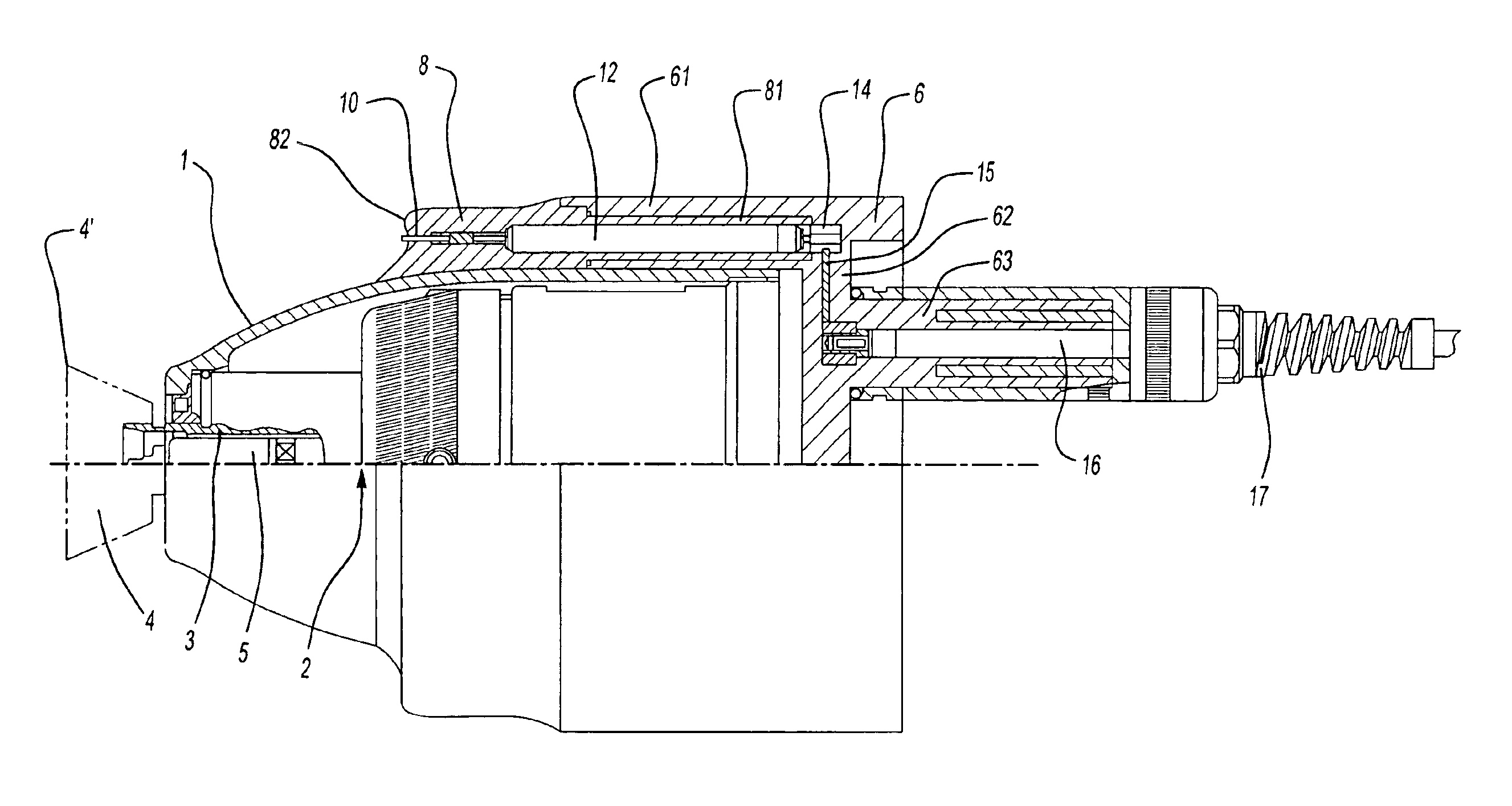

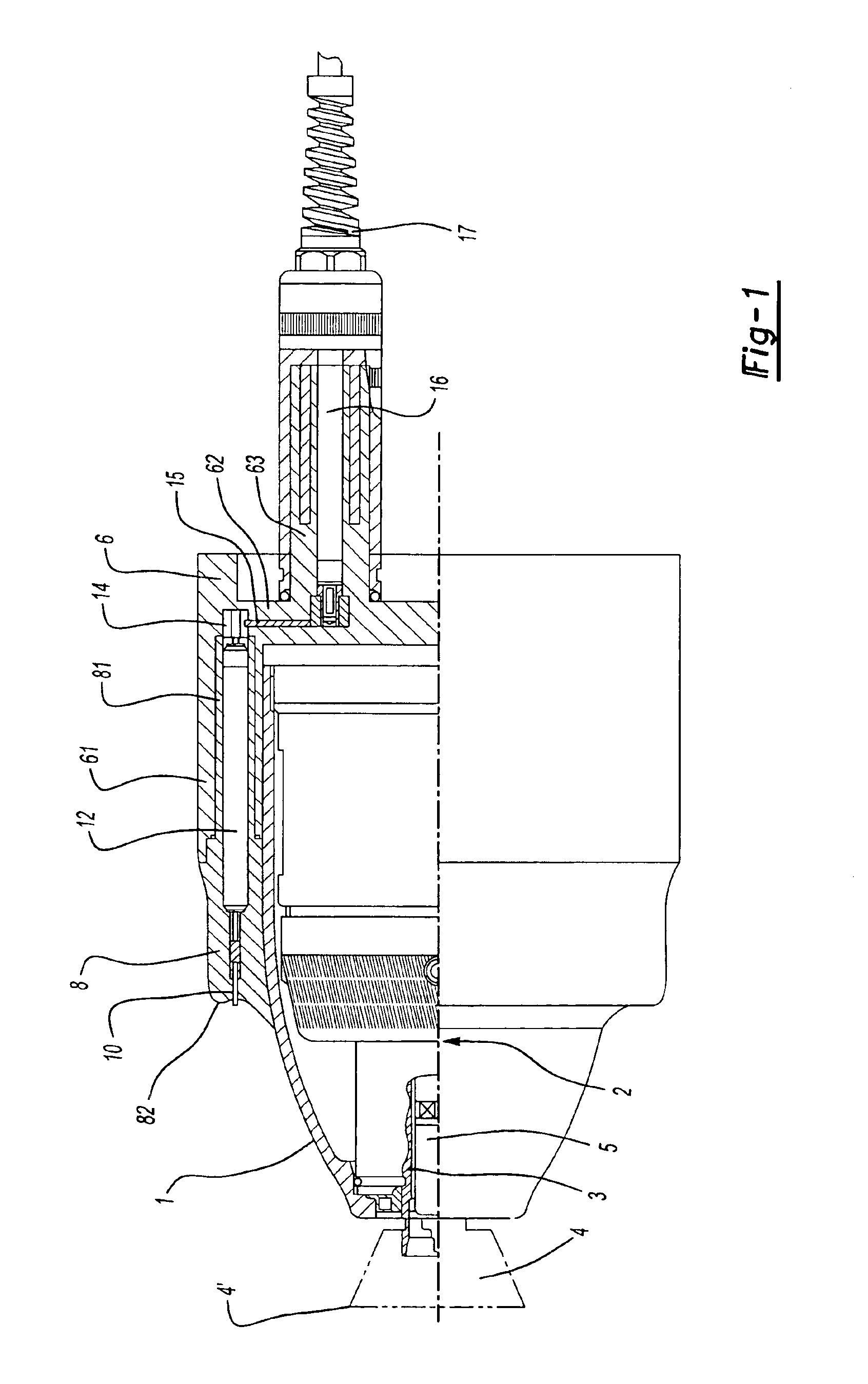

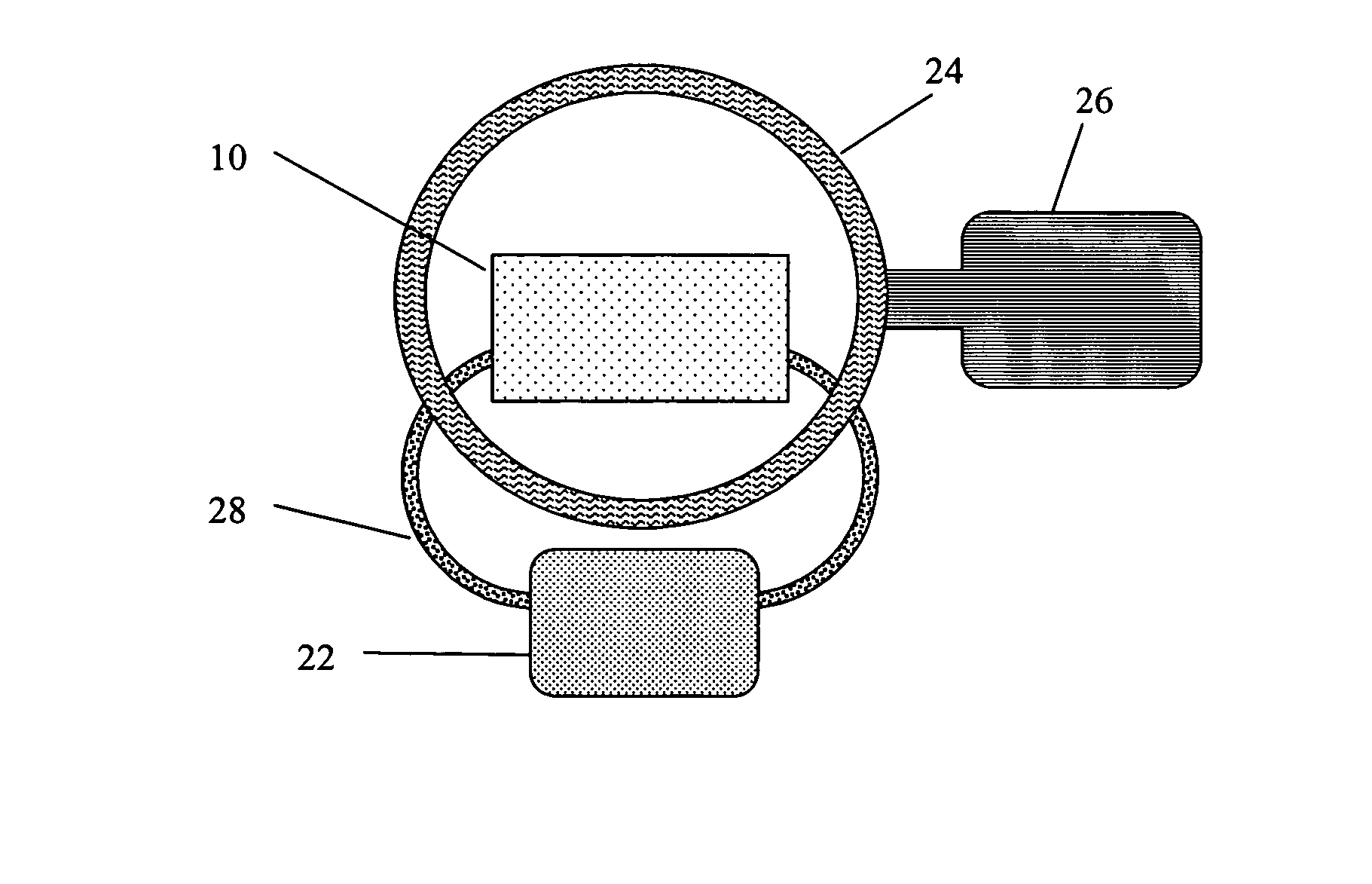

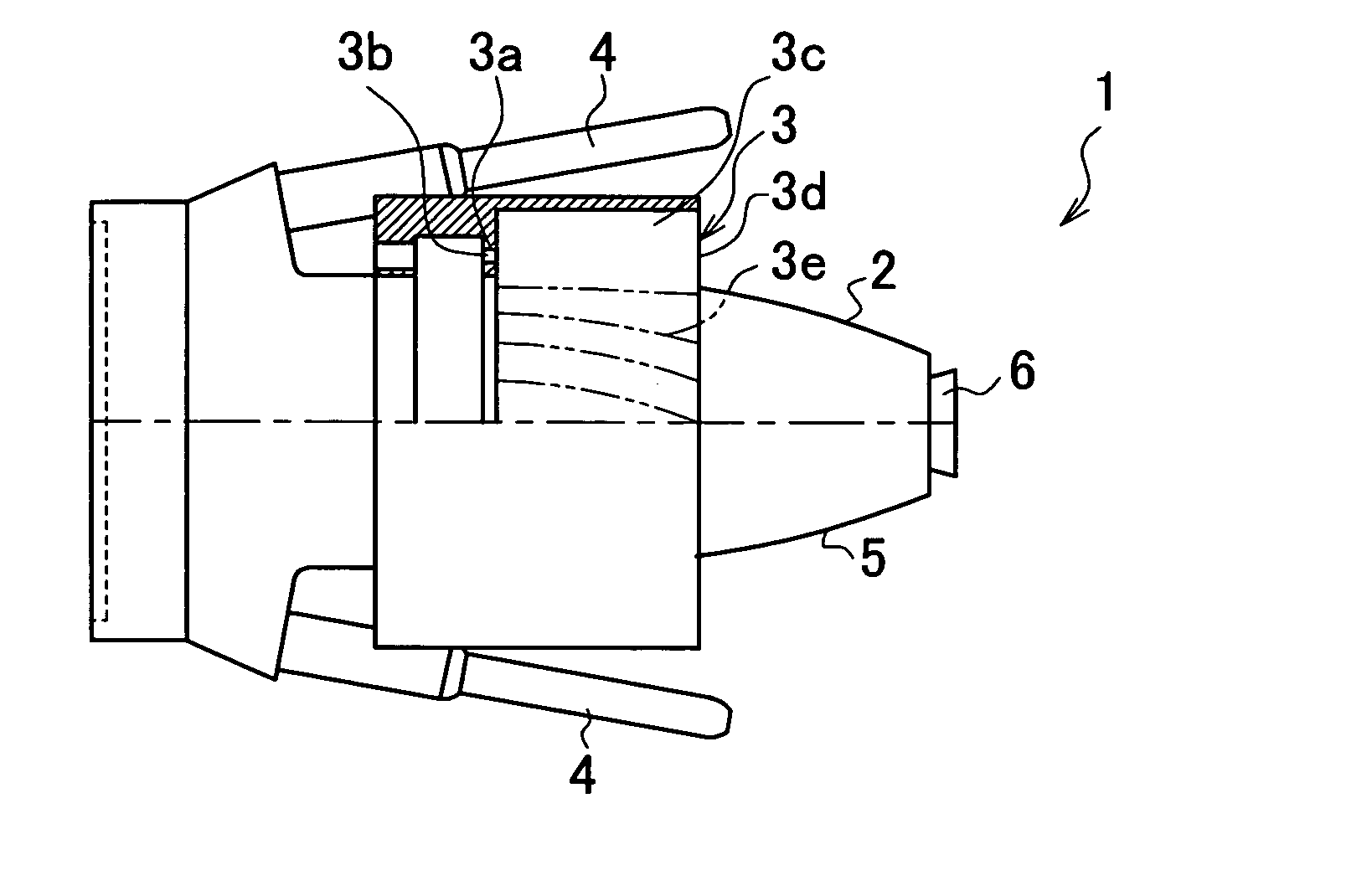

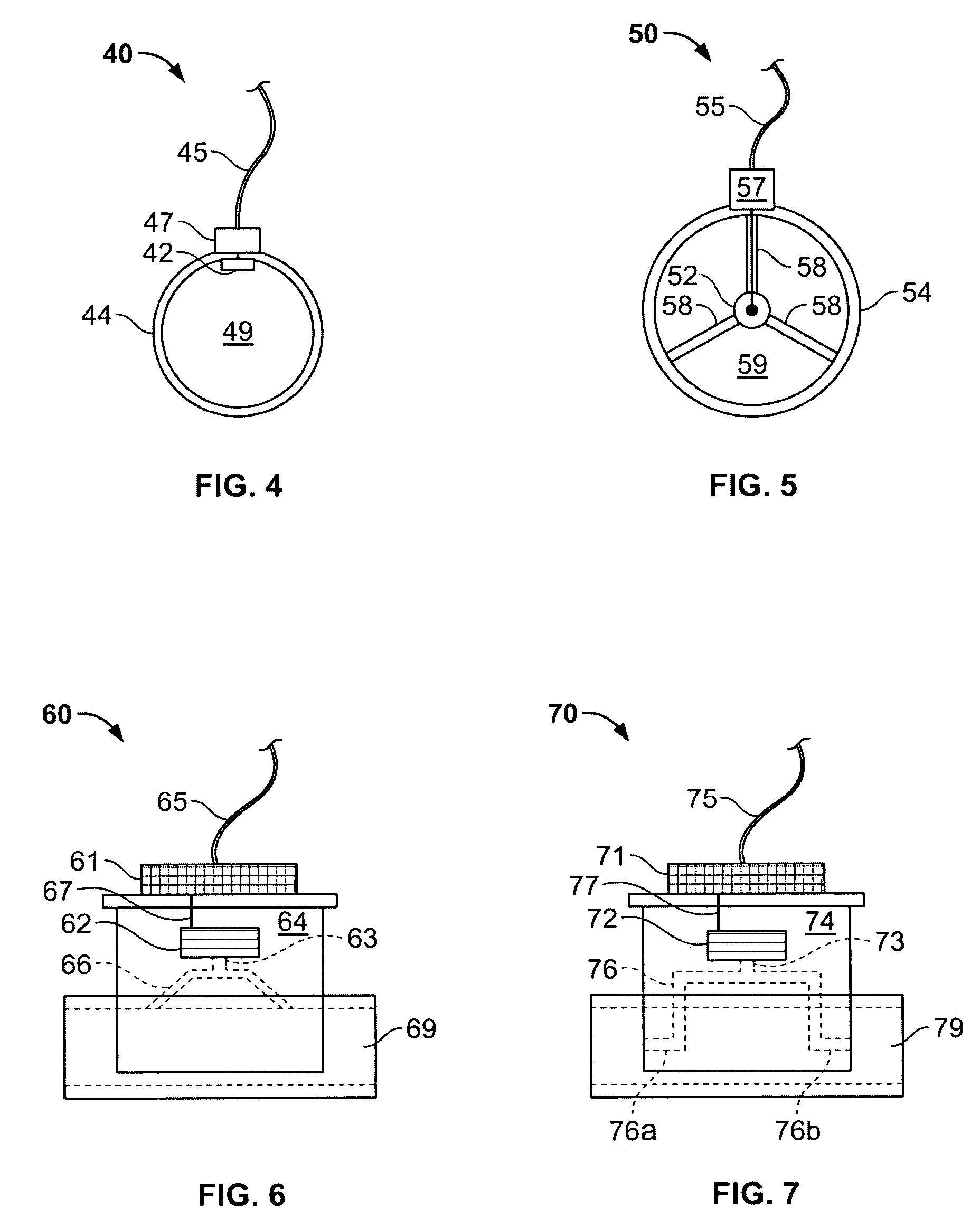

Integrated charge ring

ActiveUS6896735B2Improve application efficiencyLow self-coating tendencyBurnersLiquid surface applicatorsConductive coatingStatic electricity

For improving external charging in electrostatic atomizers for conductive coating material and for reducing the structural size of the atomizer, particularly for robot applications, the charging electrodes are embedded in a ring part made of insulating material, which is set directly on the outside of the outer housing or forms a part of the outer housing.

Owner:DURR SYST INC

Quantum vacuum energy extraction

A system is disclosed for converting energy from the electromagnetic quantum vacuum available at any point in the universe to usable energy in the form of heat, electricity, mechanical energy or other forms of power. By suppressing electromagnetic quantum vacuum energy at appropriate frequencies a change may be effected in the electron energy levels which will result in the emission or release of energy. Mode suppression of electromagnetic quantum vacuum radiation is known to take place in Casimir cavities. A Casimir cavity refers to any region in which electromagnetic modes are suppressed or restricted. When atoms enter into suitable micro Casimir cavities a decrease in the orbital energies of electrons in atoms will thus occur. Such energy will be captured in the claimed devices. Upon emergence form such micro Casimir cavities the atoms will be re-energized by the ambient electromagnetic quantum vacuum. In this way energy is extracted locally and replenished globally from and by the electromagnetic quantum vacuum. This process may be repeated an unlimited number of times. This process is also consistent with the conservation of energy in that all usable energy does come at the expense of the energy content of the electromagnetic quantum vacuum. Similar effects may be produced by acting upon molecular bonds. Devices are described in which gas is recycled through a multiplicity of Casimir cavities. The disclosed devices are scalable in size and energy output for applications ranging from replacements for small batteries to power plant sized generators of electricity.

Owner:UNIV OF COLORADO THE REGENTS OF

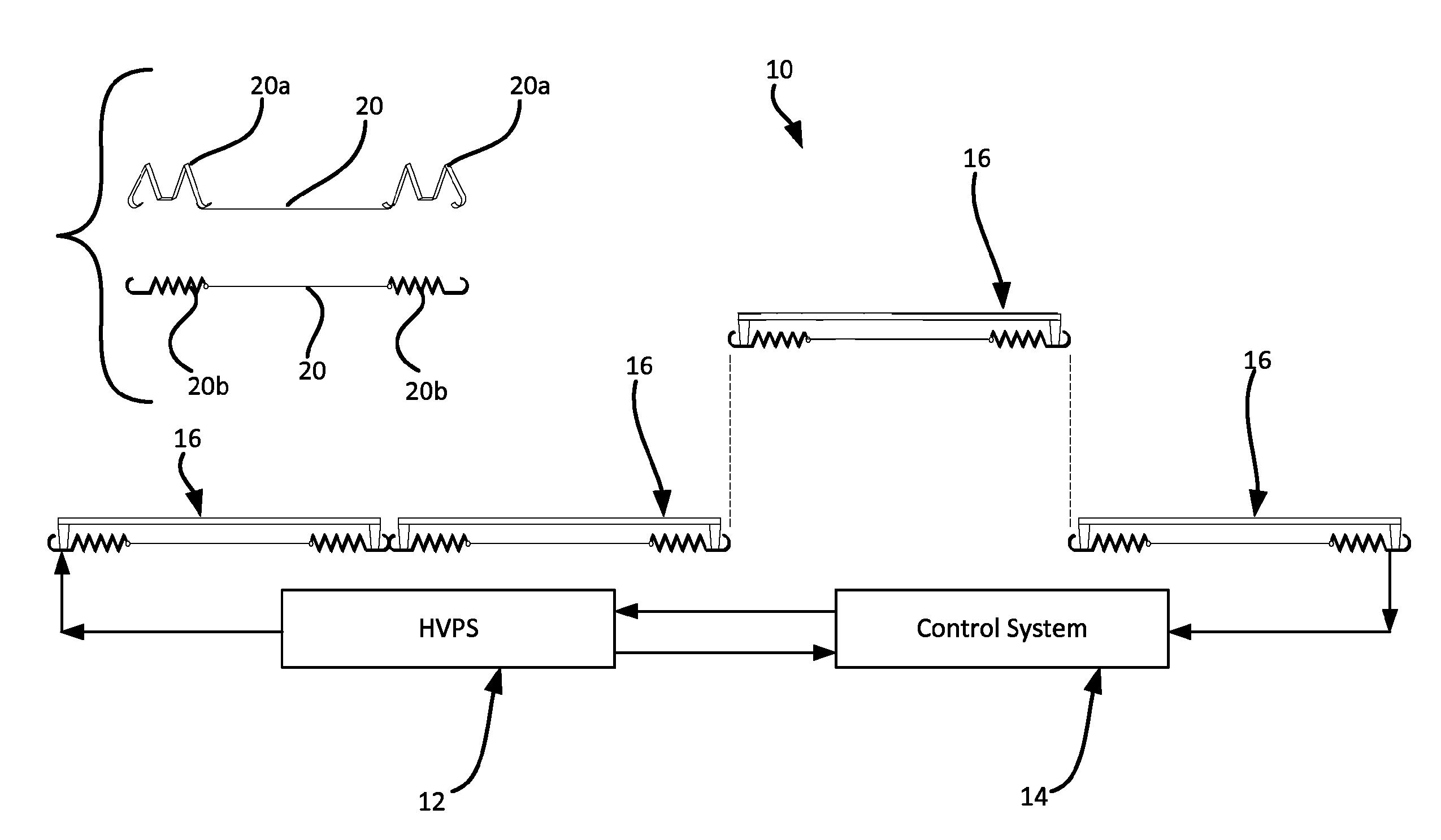

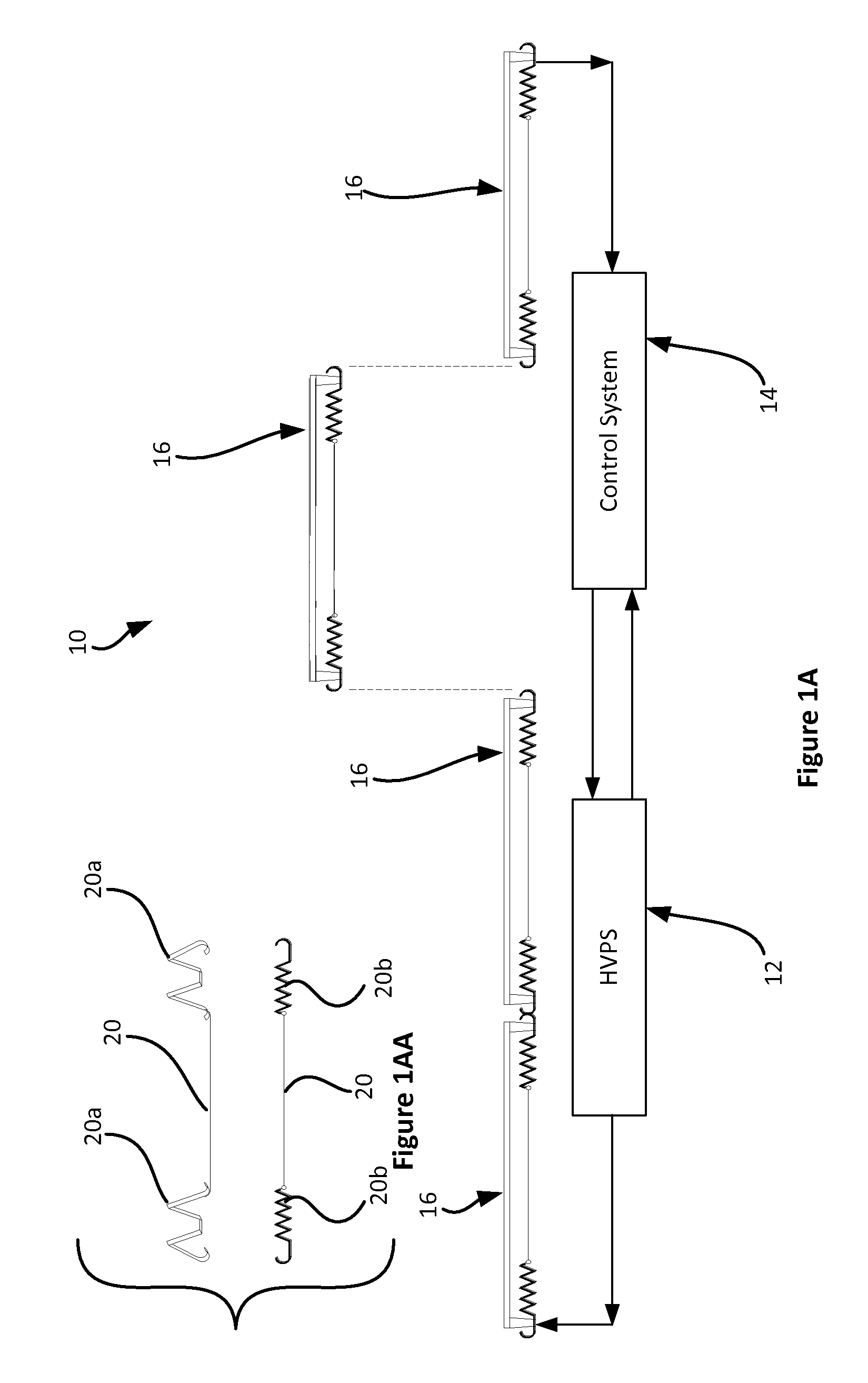

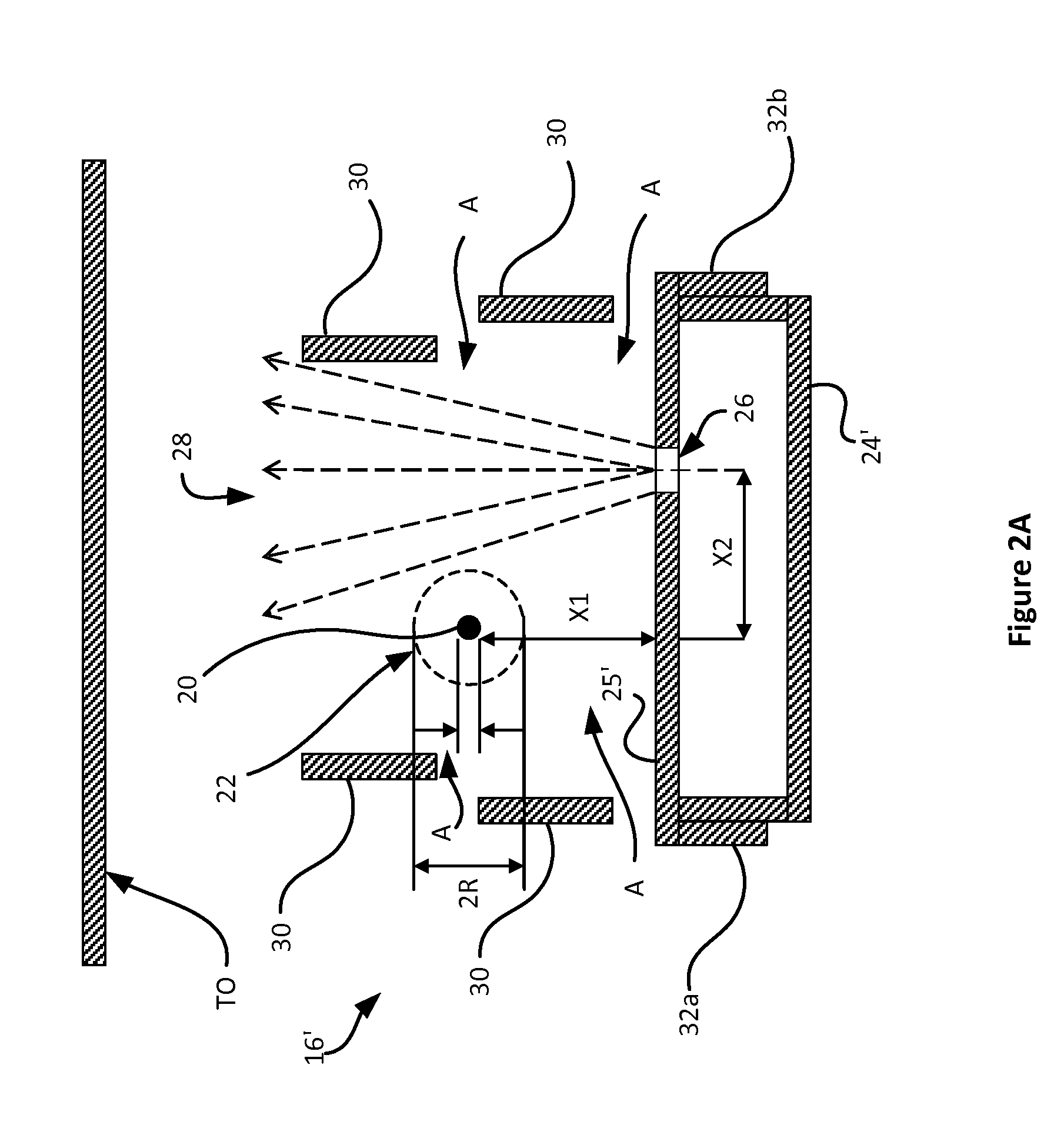

Multi-sectional linear ionizing bar and ionization cell

ActiveUS8492733B1Semiconductor/solid-state device manufacturingMaterial analysis by optical meansEngineeringLinearity

A multi-sectional linear ionizing bar with at least four elements is disclosed. First, disclosed bars may include at least one ionization cell with at least one axis-defining linear ion emitter for establishing an ion cloud along the length thereof. Second, disclosed bars may include at least one reference electrode. Third, disclosed bars may include a manifold for receiving gas or air from a source and for delivering same past the linear emitter(s) such that substantially none of the gas / air flows into the ion cloud. Fourth, disclosed bars may include means for receiving the ionizing voltage and for delivering same to the linear emitter(s) to thereby establish the ion cloud. In this way, disclosed ionizing bars may transportions from the plasma region toward a charge neutralization target without inducing substantial vibration of the linear emitter and without substantial contaminants from the gas / air flow reaching the linear emitter.

Owner:ILLINOIS TOOL WORKS INC

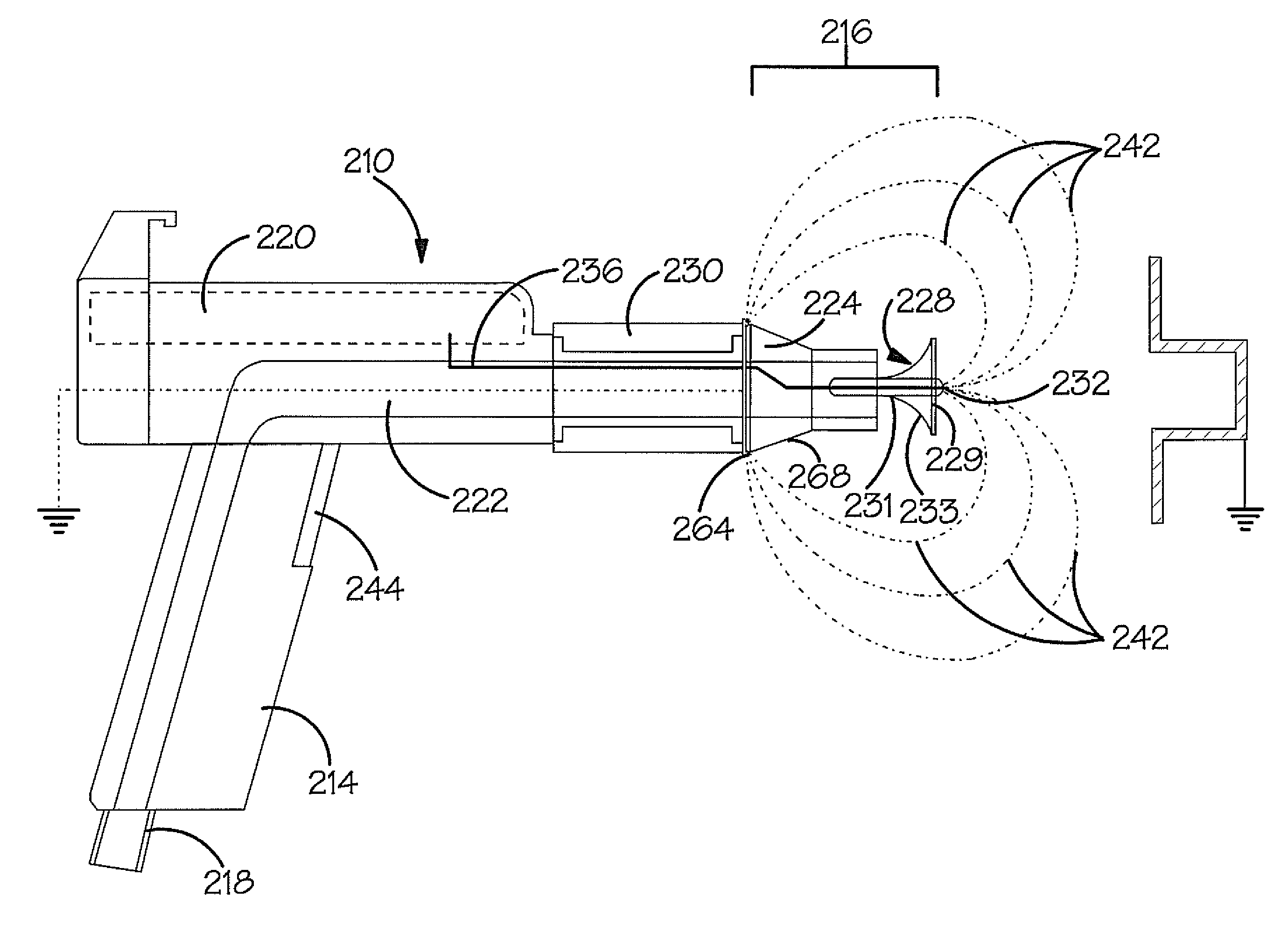

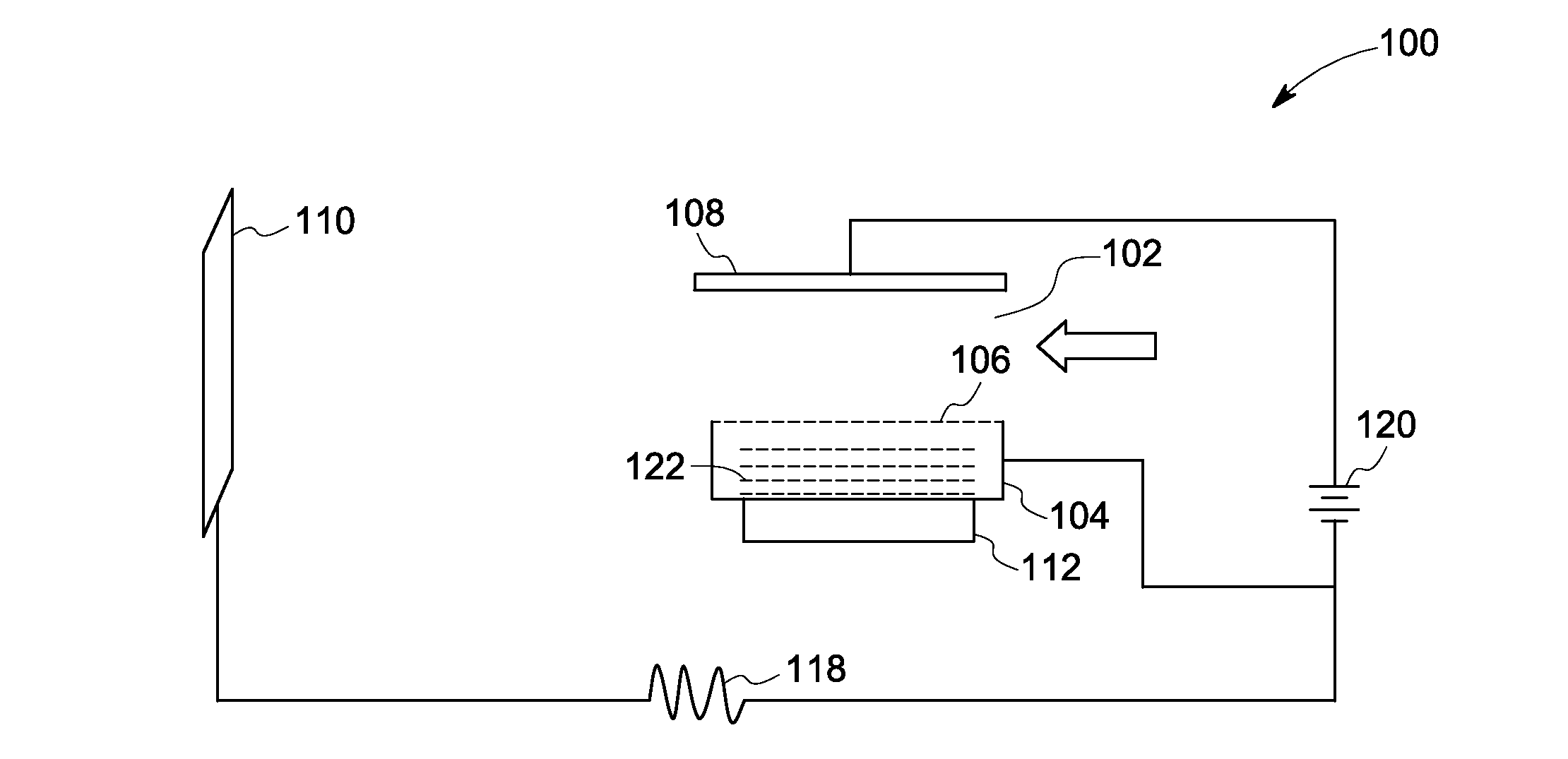

Powder spray coating discharge assembly

InactiveUS20090229517A1Reduce discharge currentImprove conductivityLiquid spraying plantsLiquid surface applicatorsSpray coatingElectrical connection

A powder spray coating discharge assembly (230, 260, 216, 228, 232) for connection to an electrostatic spray coating gun (210), the gun (210) having a gun body (212), means for connecting to a supply of coating powder and means for supplying a voltage (20) at first and second potentials respectively to first (292) and second electrical connections (294) each for connection to a respective one of a discharge electrode (232) and a counter electrode (260), the means for supplying the voltage (20) comprising: a variable voltage power supply (114) having an input connected to an electrical power source (110), an output connected to each of the first and second electrical connections (292, 294), a control circuit (128) for controlling the variable voltage power supply (20) and means (120) for sensing an output load, wherein the control circuit (128) is adapted to adjust the variable voltage power supply (20) to reduce the voltage and current in proportion to a sensed increase in load, or vice-versa.

Owner:YU TUNG INVESTMENT HLDG

Electrostatically-assisted high-speed rotary application process for the production of special effect base coat/clear coat two-layer coatings

InactiveUS7083830B2Coating suitableLiquid surface applicatorsElectric shock equipmentsMaterials scienceSpecial effects

A process for the production of special effect base coat / clear coat two-layer coatings on substrates by application of a special effect base coat layer of a liquid special effect base coat onto the substrate in one or more successive spray passes, optional drying or curing of the special effect base coat layer, followed by application of a clear coat layer and curing of the clear coat layer, wherein, at least in the final spray pass, application of the special effect base coat proceeds by electrostatically-assisted high-speed rotary application using at least one high-speed rotary coating device comprising a high-speed rotary bell, wherein an electrode ring is rotatably positioned around the high-speed rotary bell and used for external electrostatic charging of the effect base coat spray mist and performs rotational movements about the common axis of rotation with the high-speed rotary bell.

Owner:EI DU PONT DE NEMOURS & CO

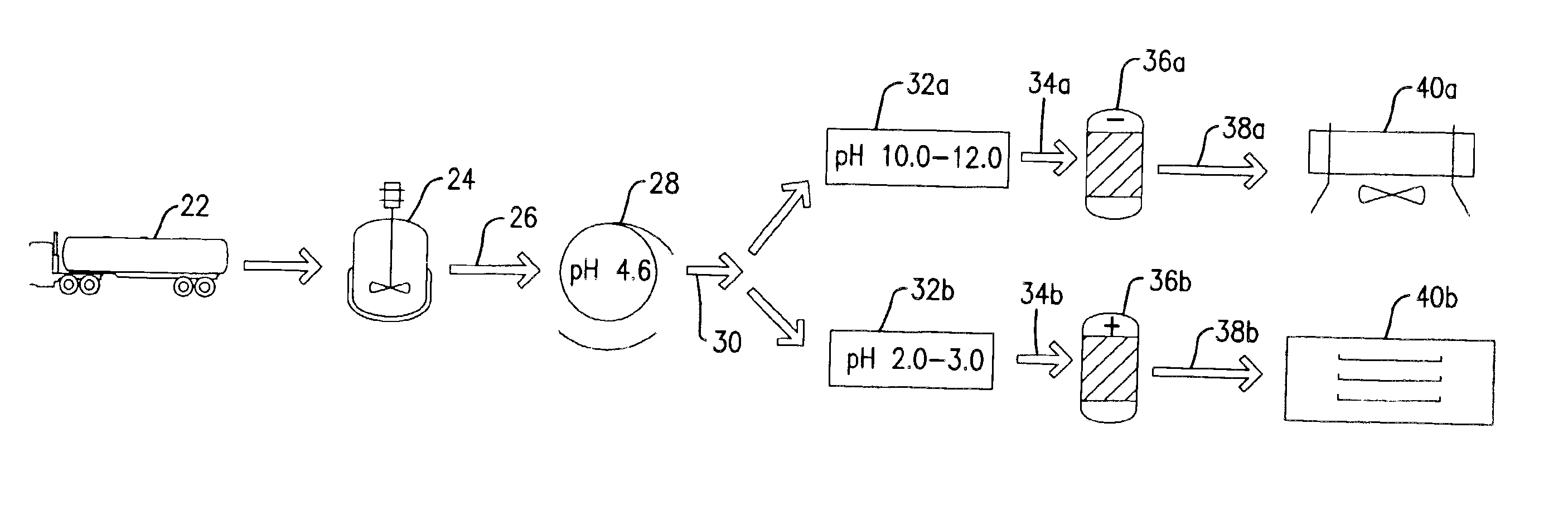

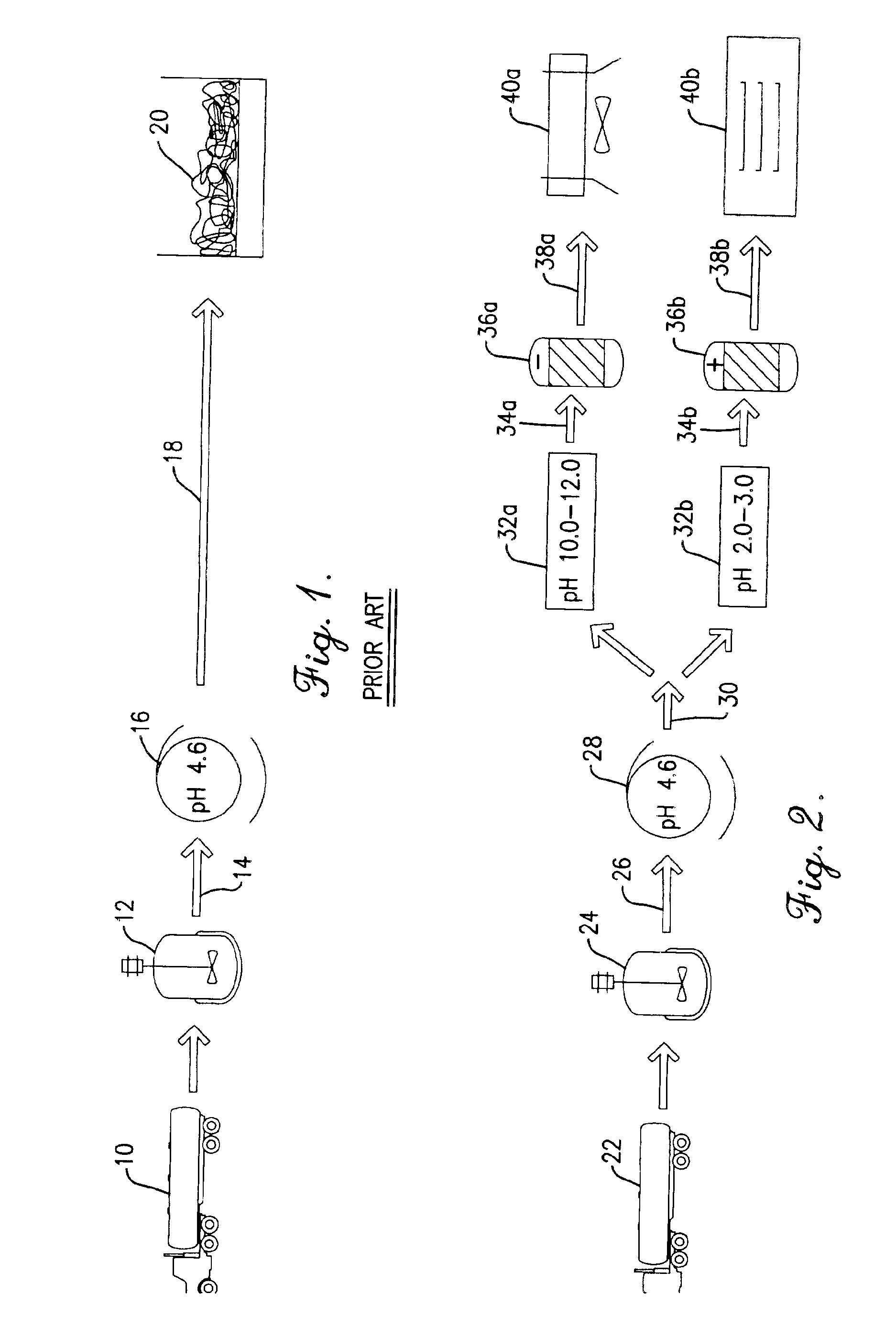

Method of producing electrostatically charged gelatin

InactiveUS6863783B2Electrostatic charge accumulationIncrease negative chargeElectrolysis componentsVolume/mass flow measurementGelatinIsoelectric point

Methods of forming electrostatically charged gelatin are provided. Gelatin is extracted by an acid extraction method (12) thereby producing a gelatin dispersion (14), the pH of which is adjusted to the isoelectric point of the gelatin. The pH of the gelatin dispersion (14) is then further adjusted (22) so as to cause the gelatin to assume an electrostatic charge.

Owner:BIG HEART PET INC

Spray coating apparatus and spray coating method

InactiveUS20050181142A1Convenient coatingAdhesion efficiency is reducedSpraying power supplySpray nozzlesSpray nozzleSpray coating

By forming an air flow in which a quantity and a blowoff angle of the air supplied toward an atomized spray paint flow don't influence a coating pattern, there are provided a coating apparatus and a coating method, each of which does not disturb the coating pattern, does not require conditions such as wind speed and temperature of a conventional coating booth, and can perform remarkable reduction in an air conditioning energy of the coating booth, prevention of scatter of a paint, and an improvement in a paint adhesion efficiency. In a spray coating apparatus which possesses a casing and an injection nozzle provided in a tip side of the casing and which forms a coating pattern by injecting paint and shaping air from the injection nozzle to thereby form a coating film on a coated object, a first adapter which blows off the air in an injection direction of the injection nozzle is provided on an substantially concentric circle of the injection nozzle, and the first adapter covers, by blowing off the introduced air while giving it a blowoff angle slanting toward a circumferential direction, an outer periphery of the coating pattern near the injection nozzle with the air.

Owner:NIPPON PAINT CO LTD +1

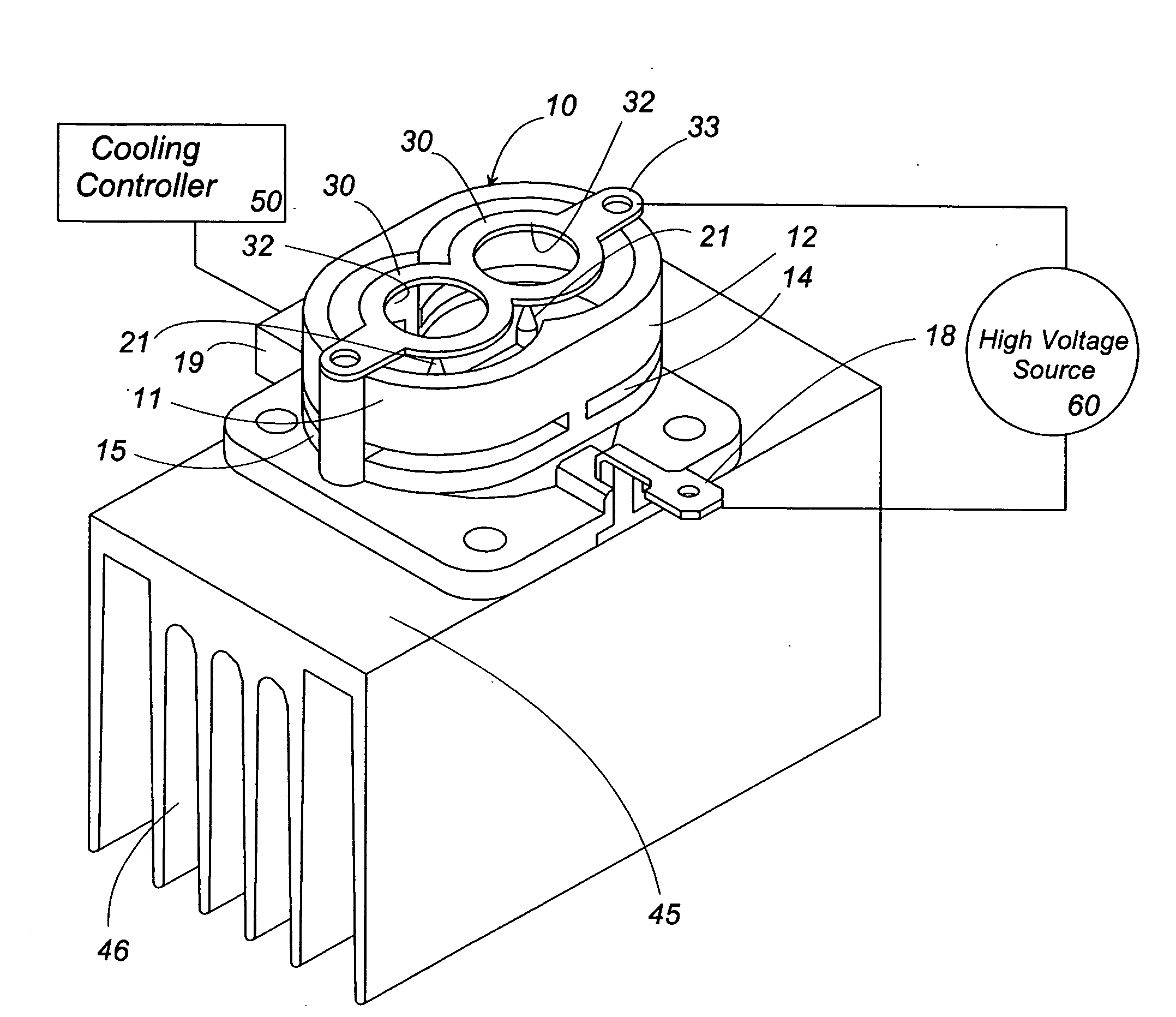

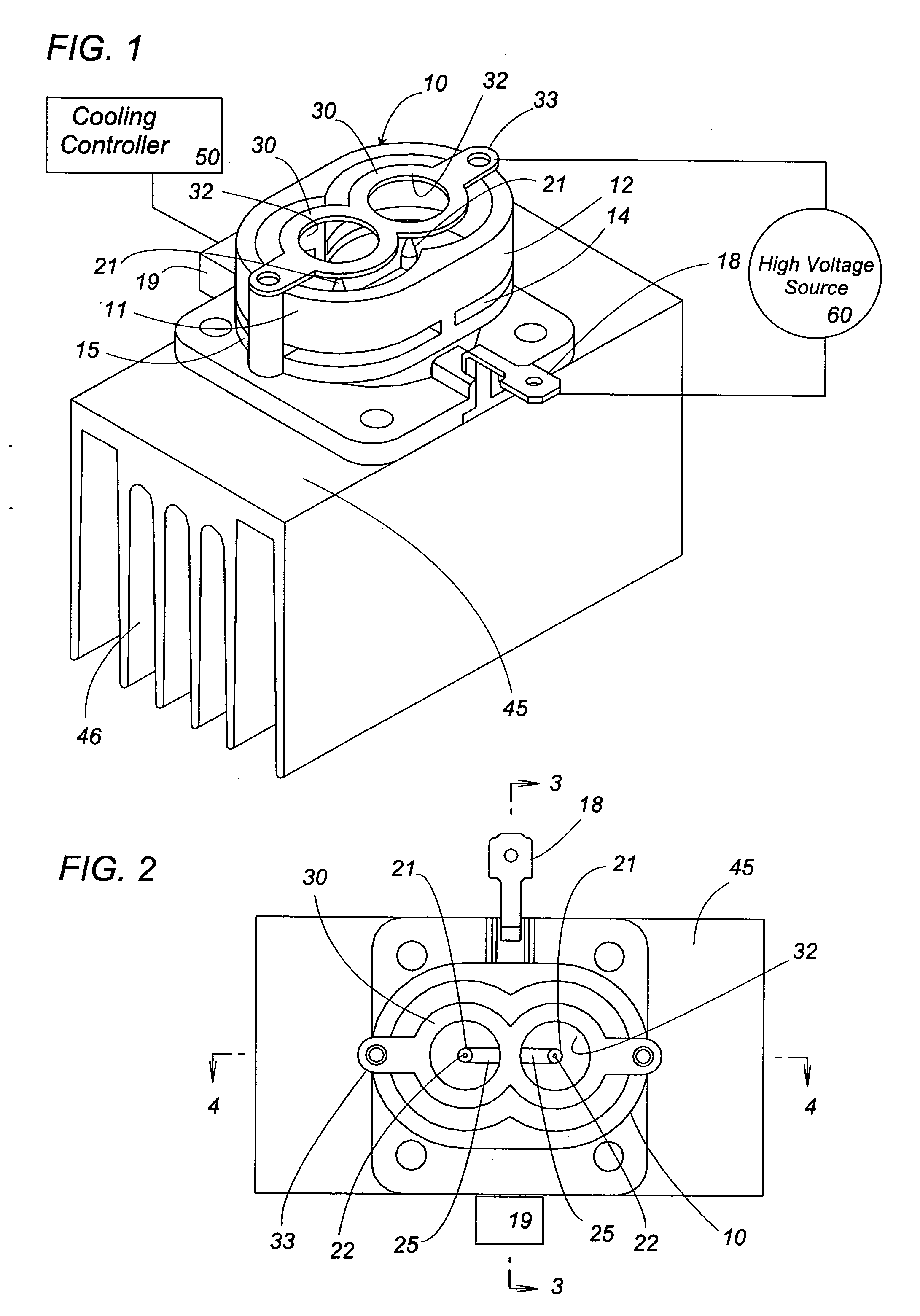

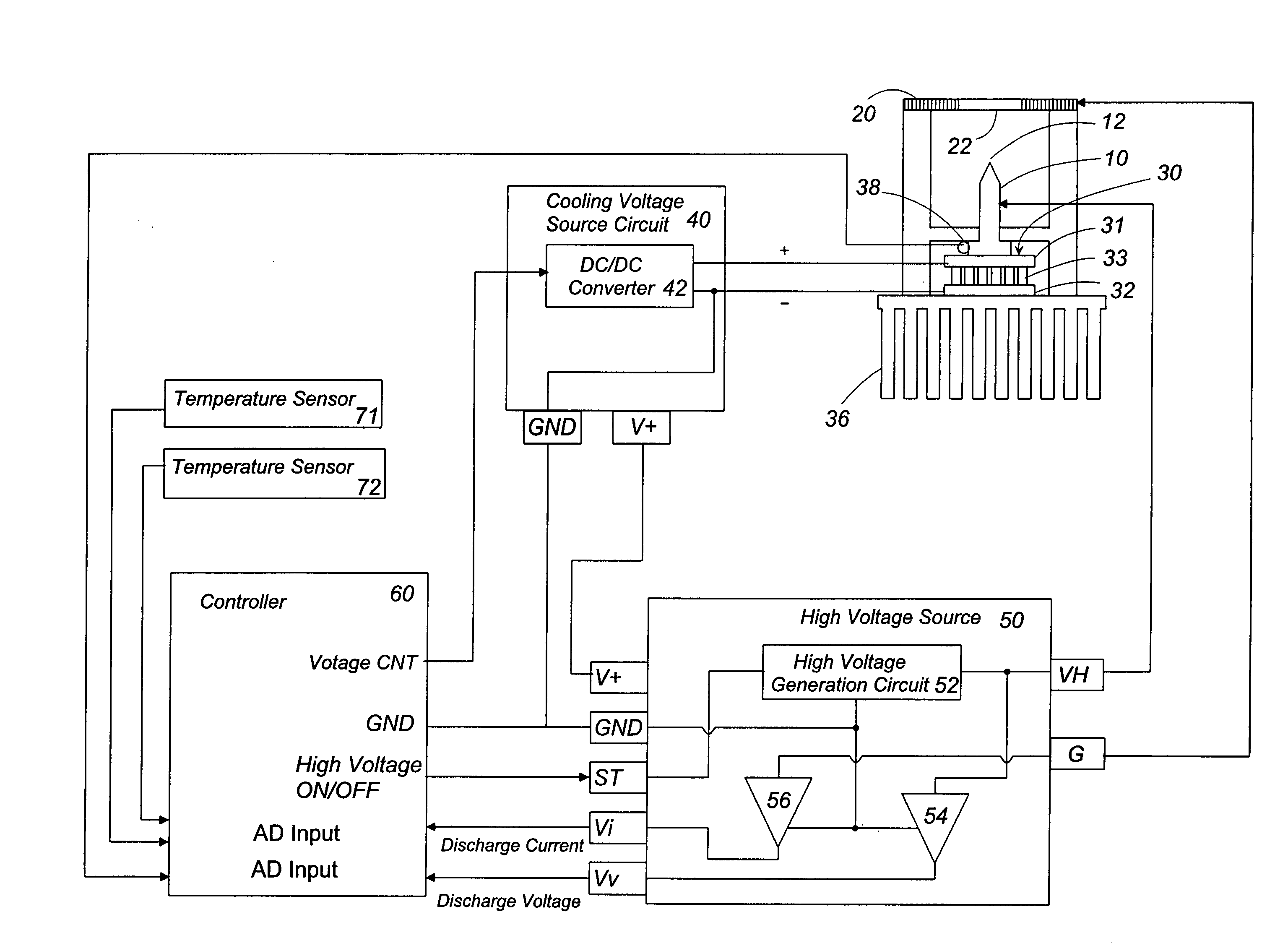

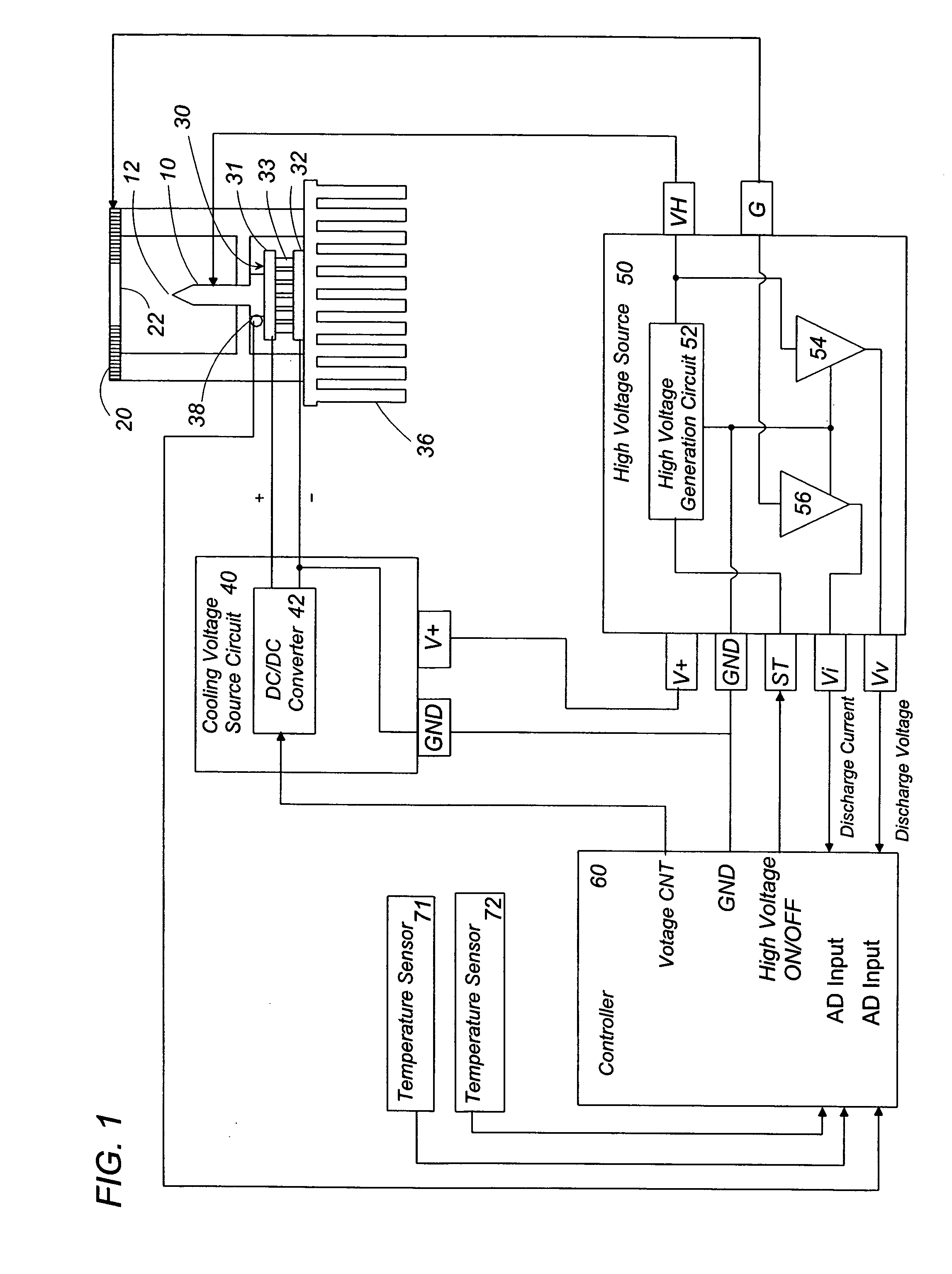

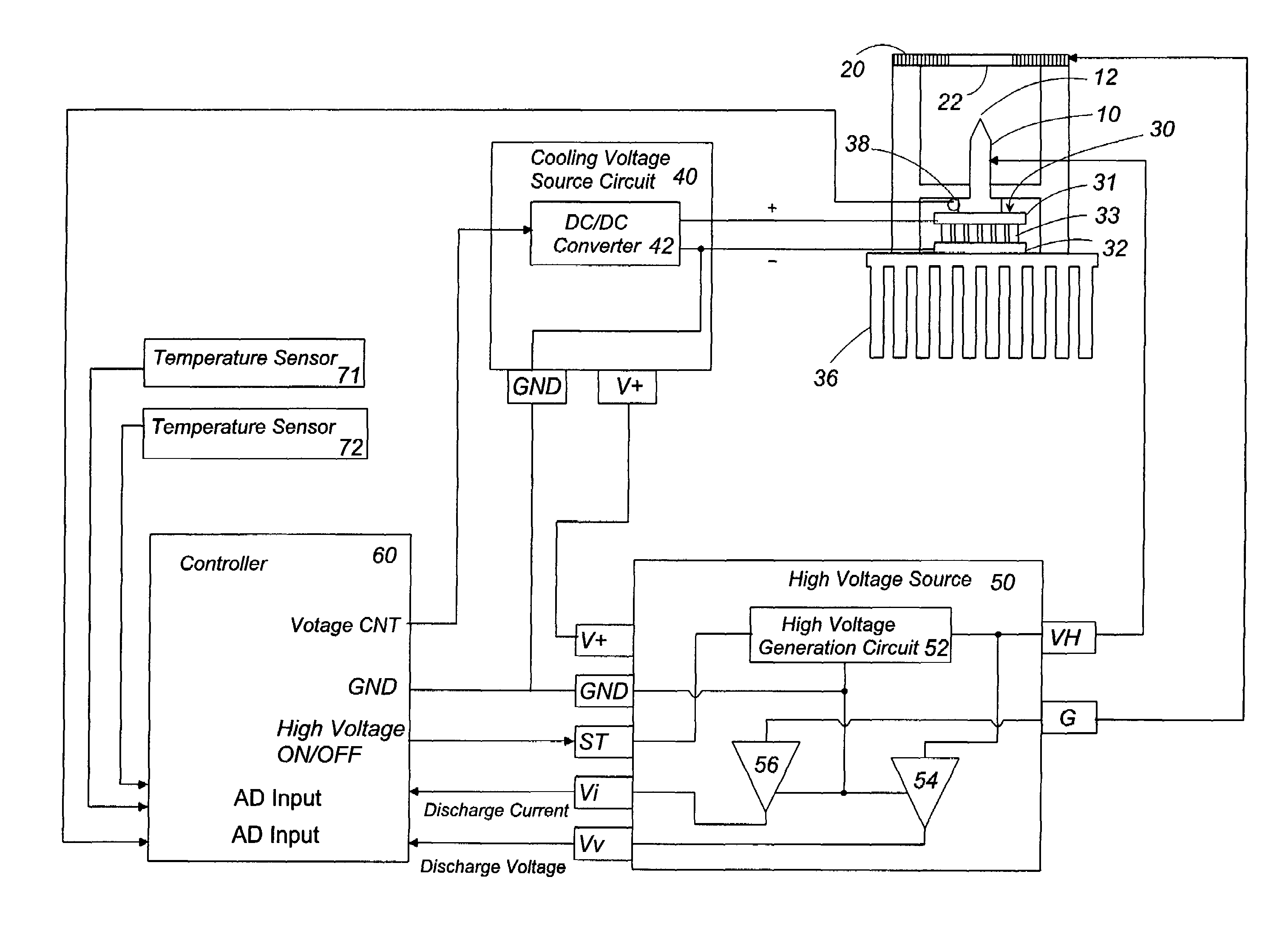

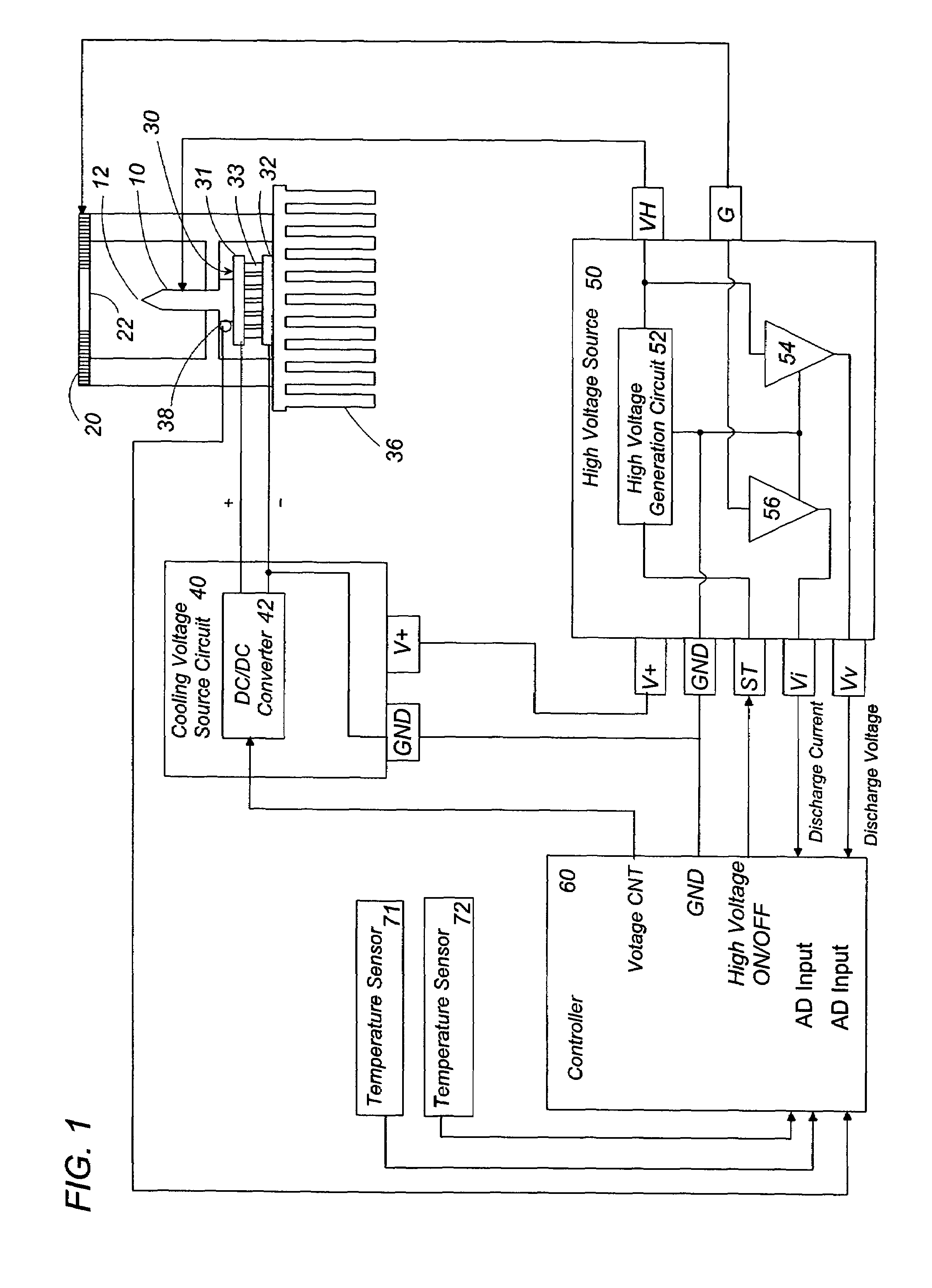

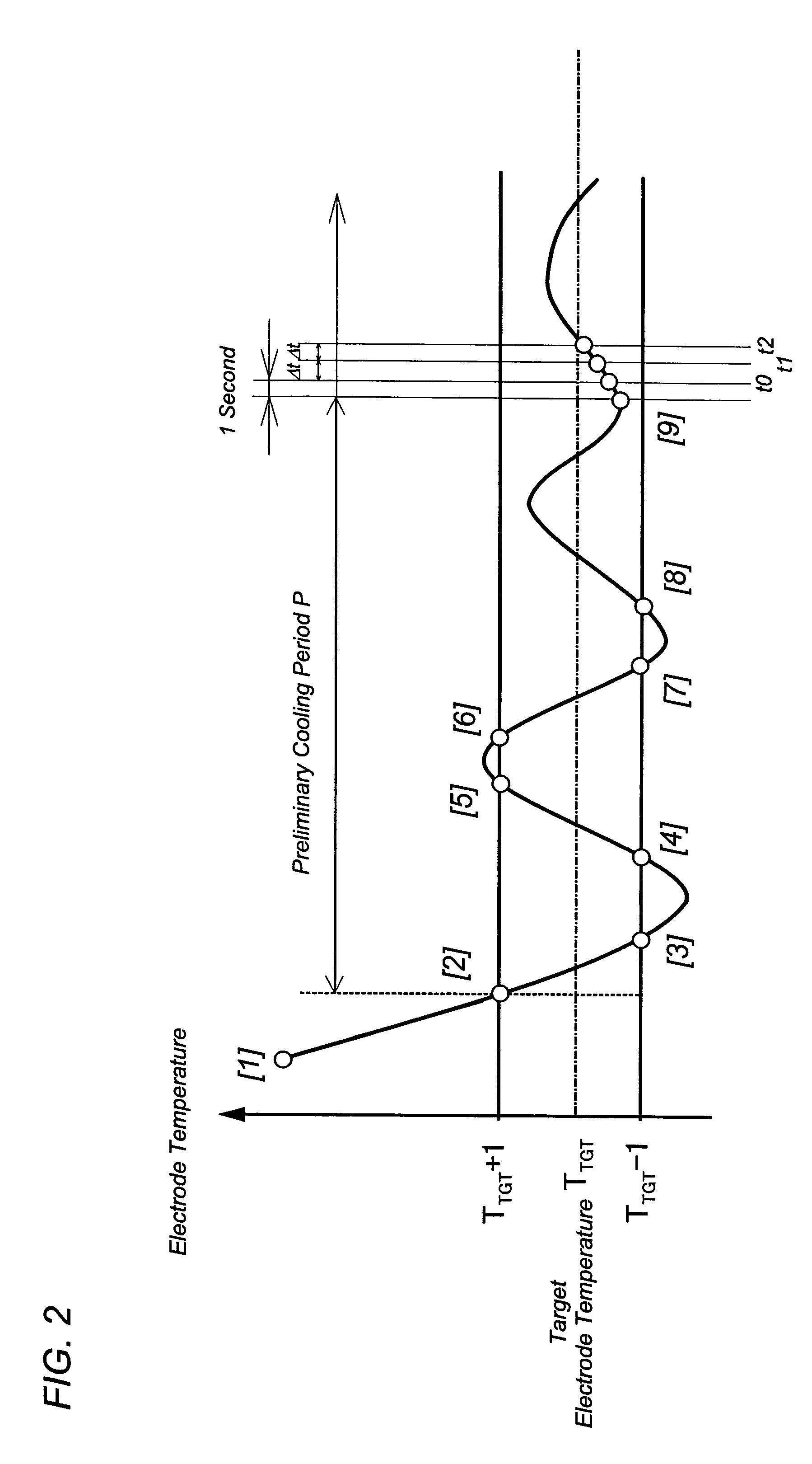

Electrostatically Atomizing Device

ActiveUS20080130189A1Guaranteed uptimeStable conditionLiquid spraying plantsSpraying power supplyHigh pressureWater particle

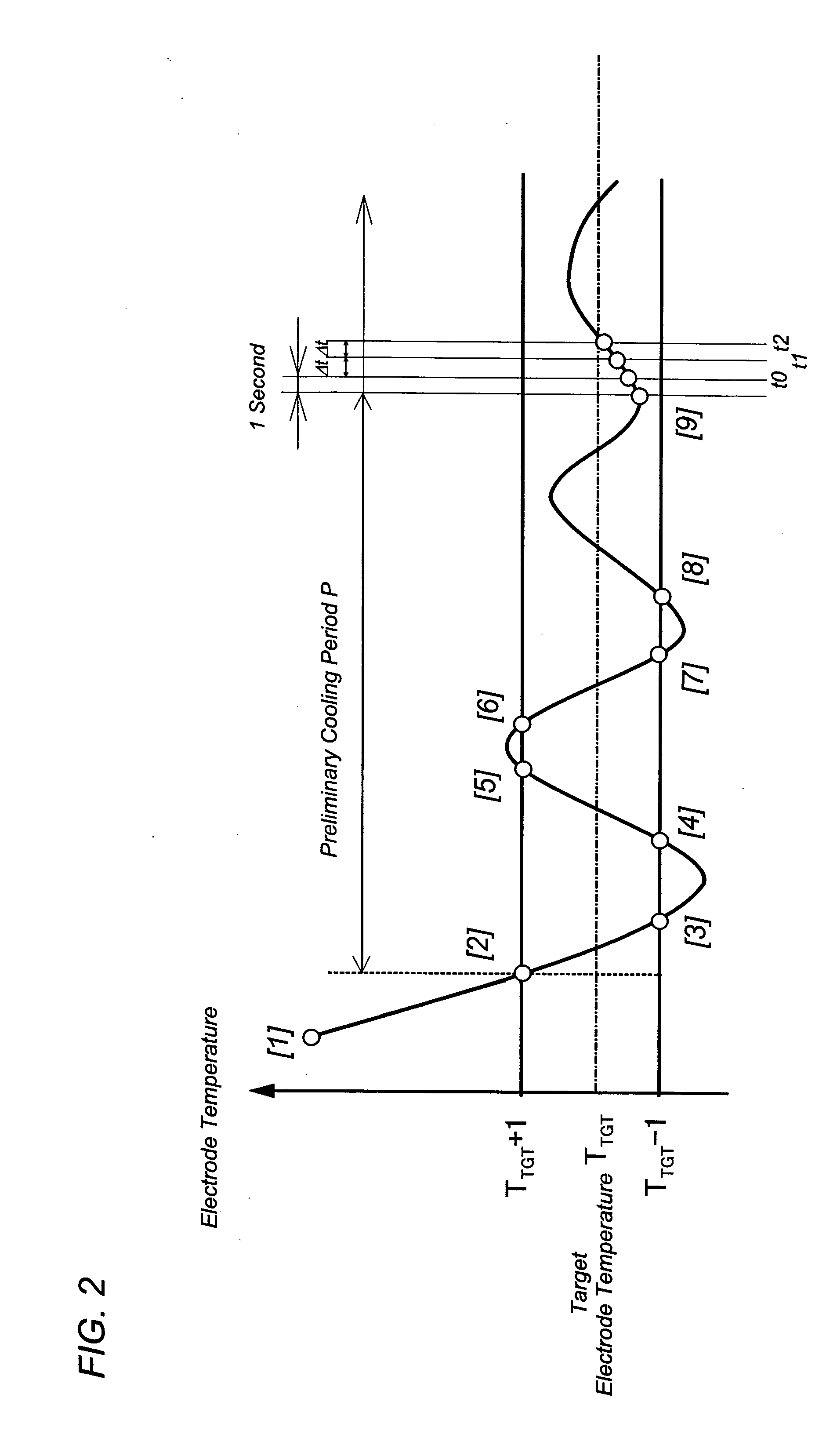

An electrostatically atomizing device includes an emitter electrode, an opposed electrode opposed to the emitter electrode, and a cooling means which condenses the water on the emitter electrode from within the surrounding air, and a high voltage source applying a high voltage across the emitter electrode and the opposed electrode to electrostatically charge the water for atomizing charged minute water particles from a discharge end of the emitter electrode. The device further includes a controller for discharging the charged minute water particles in a stable manner. The controller monitors a discharge current flowing between the two electrodes to control the cooling means for keeping the discharge current at a predetermined level, thereby regulating the atomizing amount of the charged minute particles from the emitter electrode.

Owner:MATSUSHITA ELECTRIC WORKS LTD

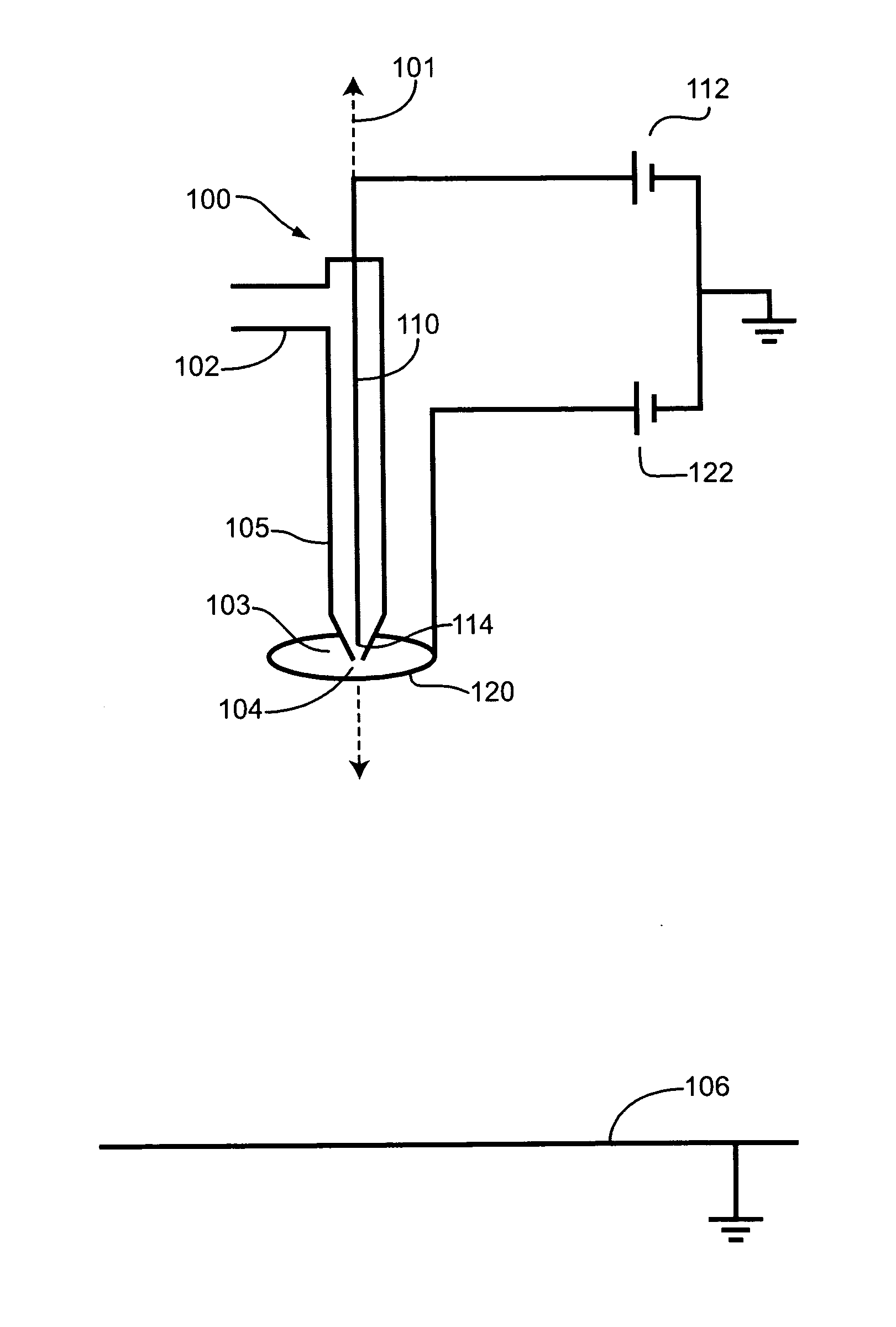

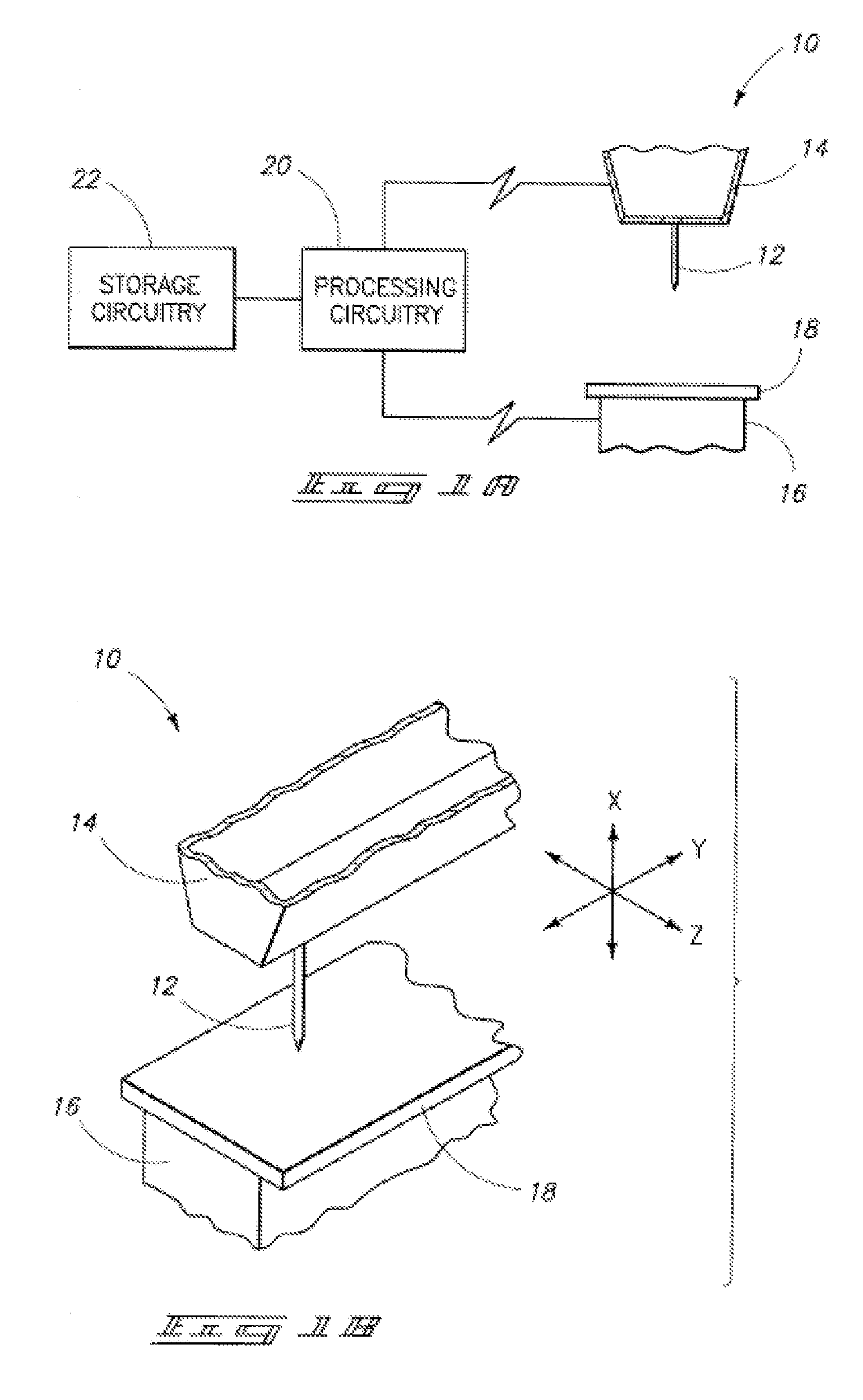

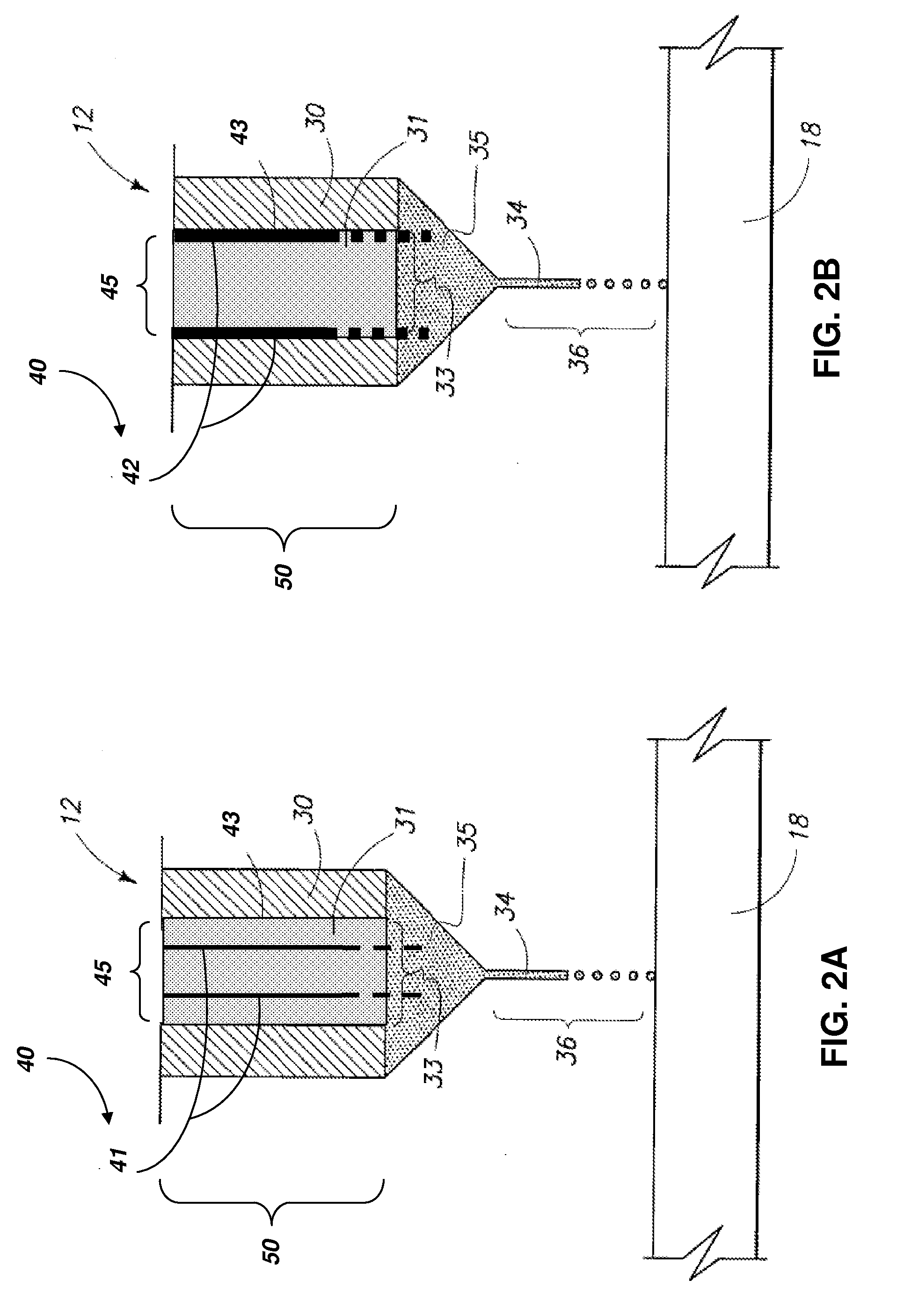

Apparatuses and methods for applying one or more materials on one or more substrates

A system that incorporates teachings of the present disclosure may include, for example, an apparatus having a tube with an ingress opening to receive a liquid, and an egress opening to release the liquid, a conductor positioned in a conduit of the tube, the conductor and the conduit having dimensions to cause a surface tension of the liquid to prevent a constant flow of the liquid from the egress opening, and a power supply coupled to the conductor to apply a charge to the liquid to overcome the surface tension and form at the egress opening a single jet stream of the liquid applicable on a substrate to create a pattern. The single jet stream can be controllable in part by a viscosity of the liquid. Additional embodiments are disclosed.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

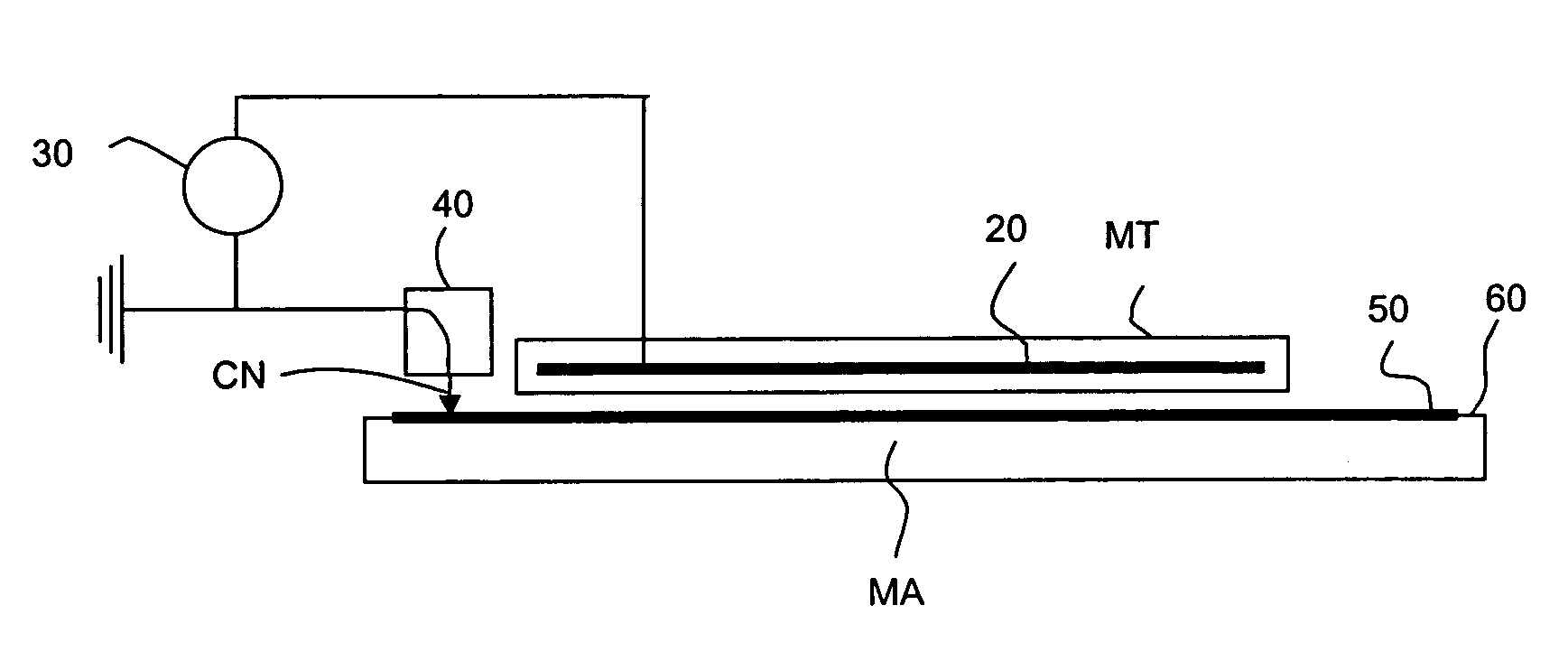

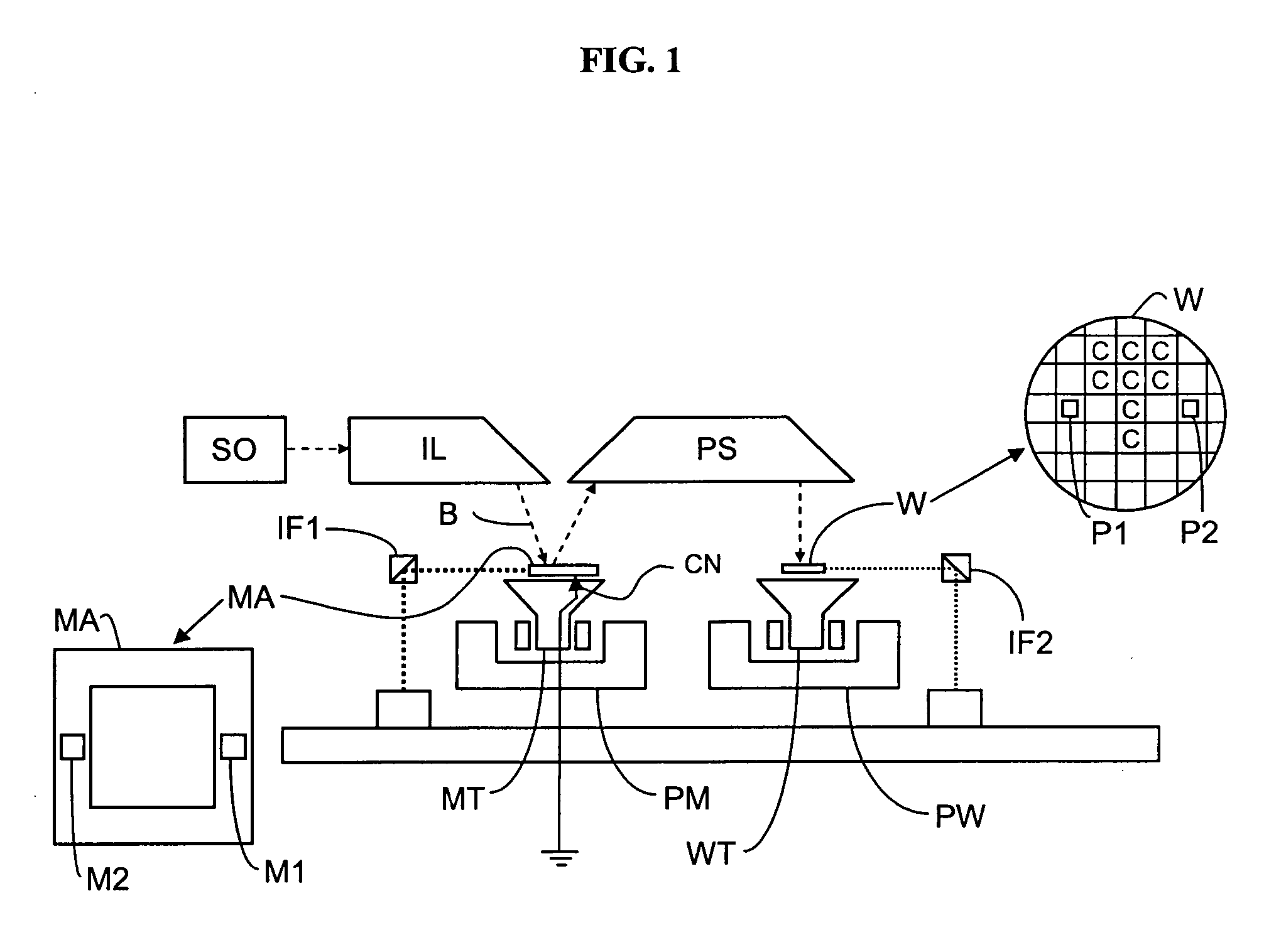

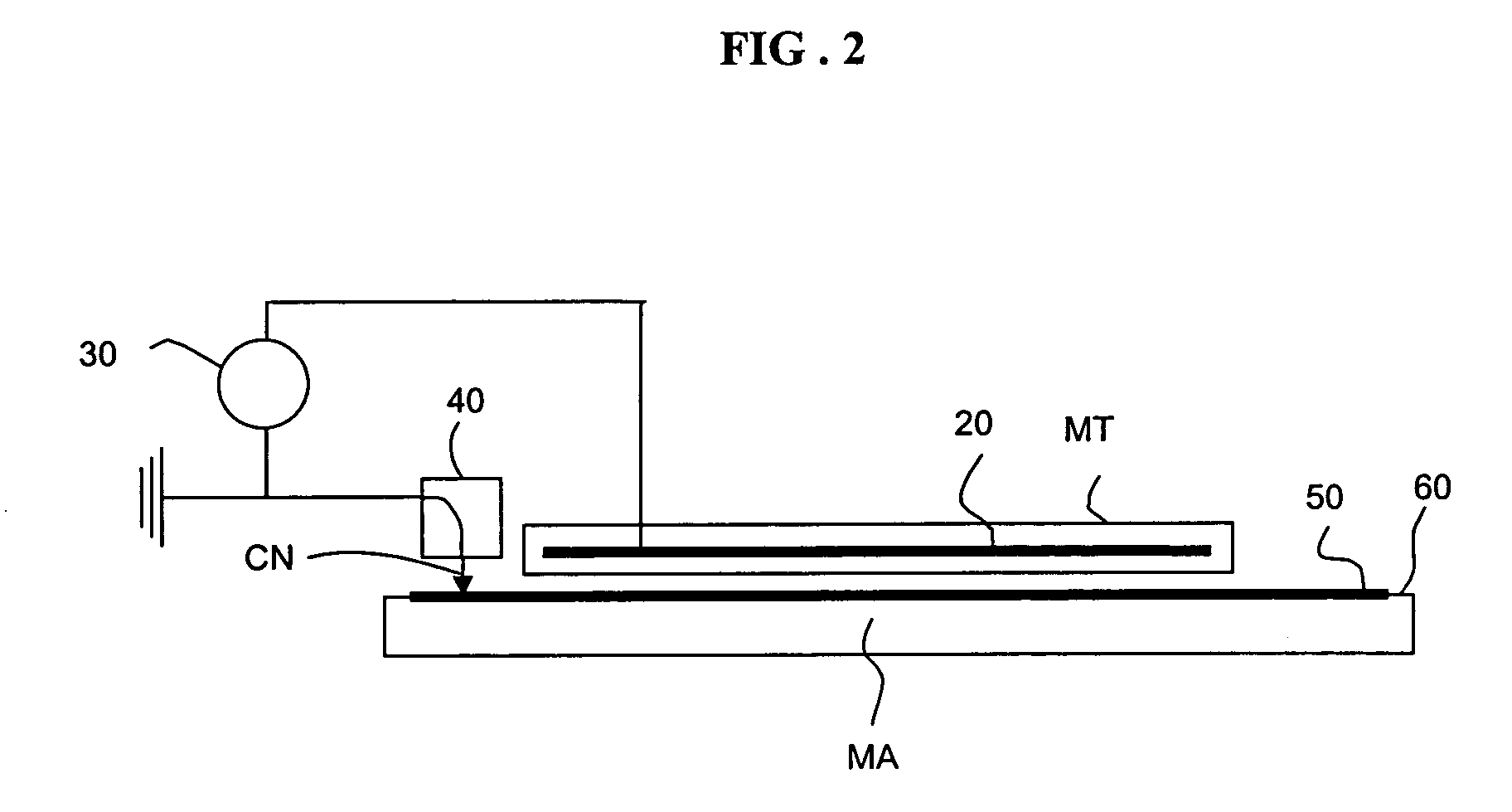

System for electrically connecting a mask to earth, a mask

A reticle includes an area provided with a conductive metal-based compound coating for electrically grounding the reticle. The reticle is suitable for use with a lithography apparatus whereby the reticle pattern is imaged using extreme ultra violet radiation. One or more conducting pins, held at zero potential, may be pressed against the conductive coating for electrically grounding the reticle either during patterning the reticle by electron beam writing or during use in the lithographic apparatus. The areas coated with the metal-based compounds are wear resistant which reduces the occurrence of particles due to damage caused by mechanical contact between the conducting pins and the conductive coating.

Owner:ASML NETHERLANDS BV

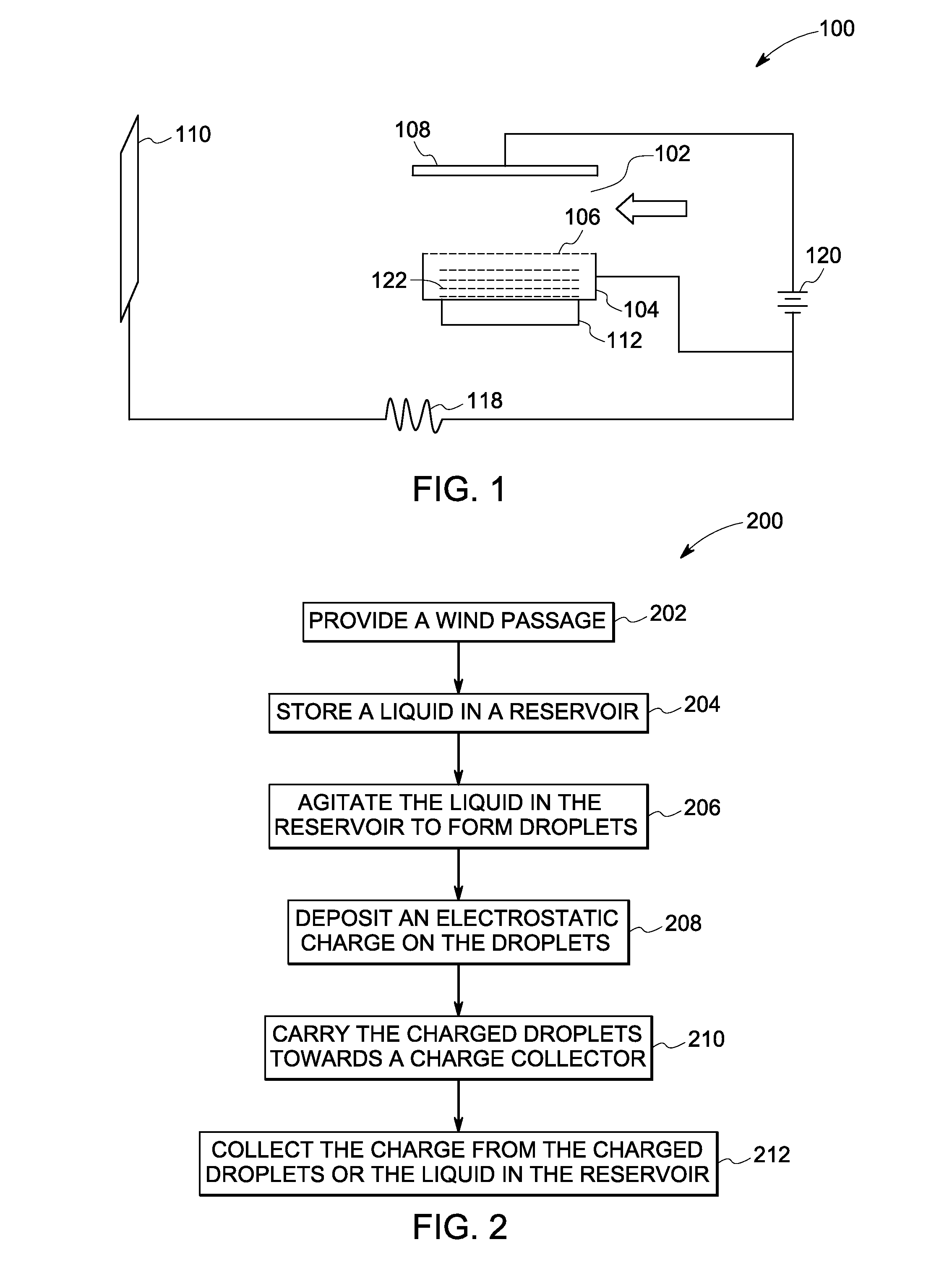

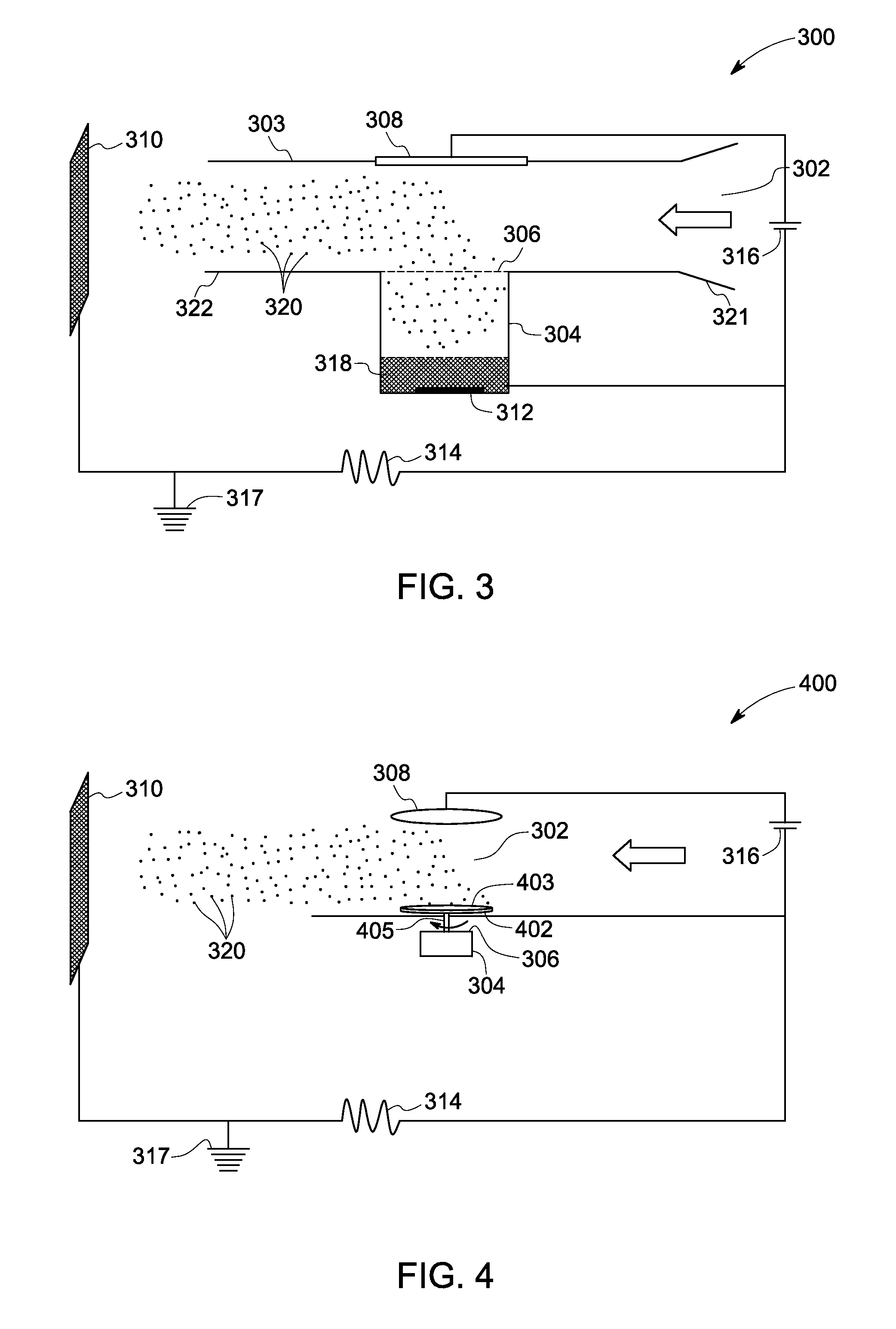

Systems and Methods for Electro-hydrodynamic Wind Energy Conversion

An electro-hydrodynamic wind energy conversion system is presented. The system includes a wind passage allowing wind flow. Further, the system includes a reservoir having an opening in communication with the wind passage and configured to hold a liquid. The system also includes an agitator coupled to the reservoir and configured to convert the liquid into droplets. Additionally, the system includes a charging system disposed substantially opposite the reservoir opening and configured to deposit an electrostatic charge on the droplets and draw the droplets into the wind passage. Moreover, the system includes a charge collector disposed at a distal end of the wind passage and configured to collect the electrostatic charge from the droplets.

Owner:GENERAL ELECTRIC CO

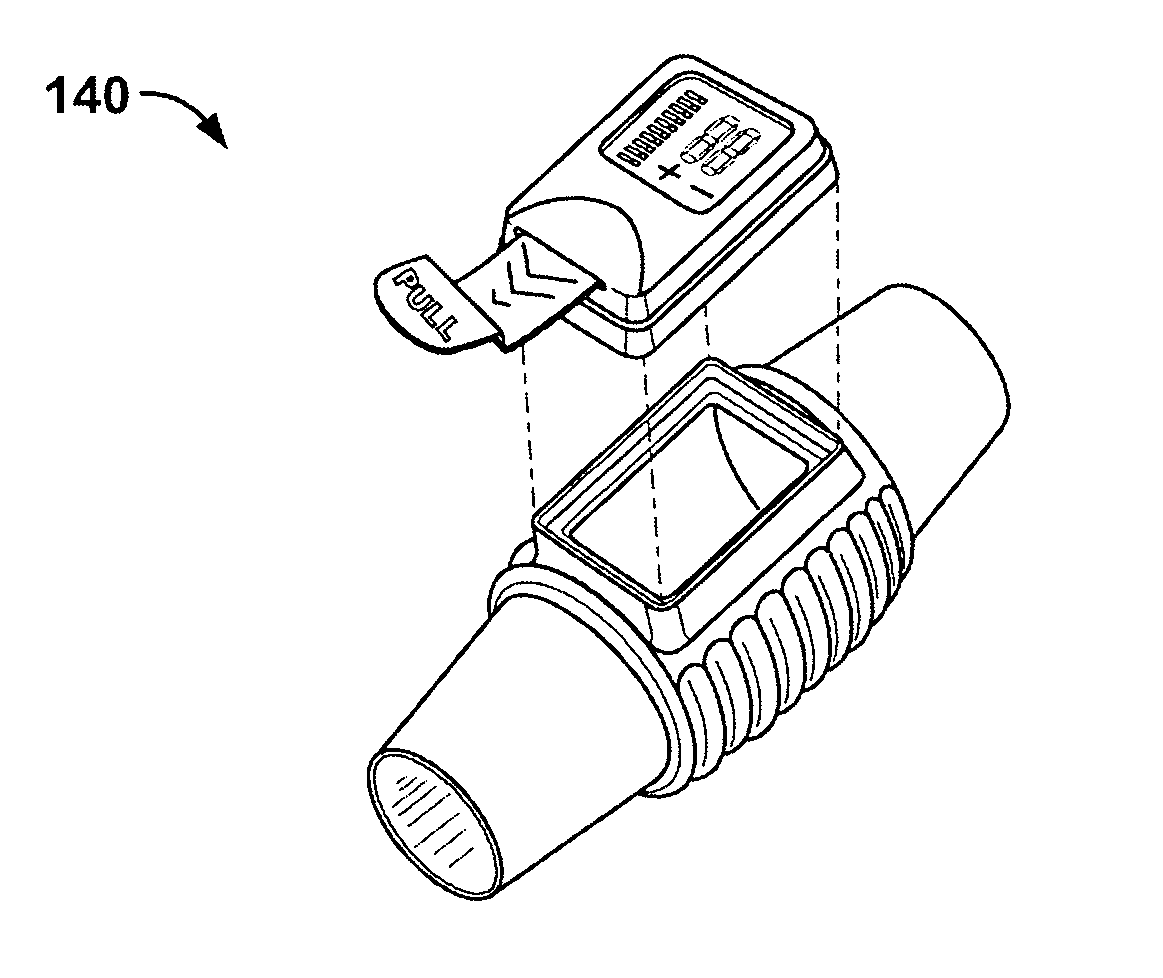

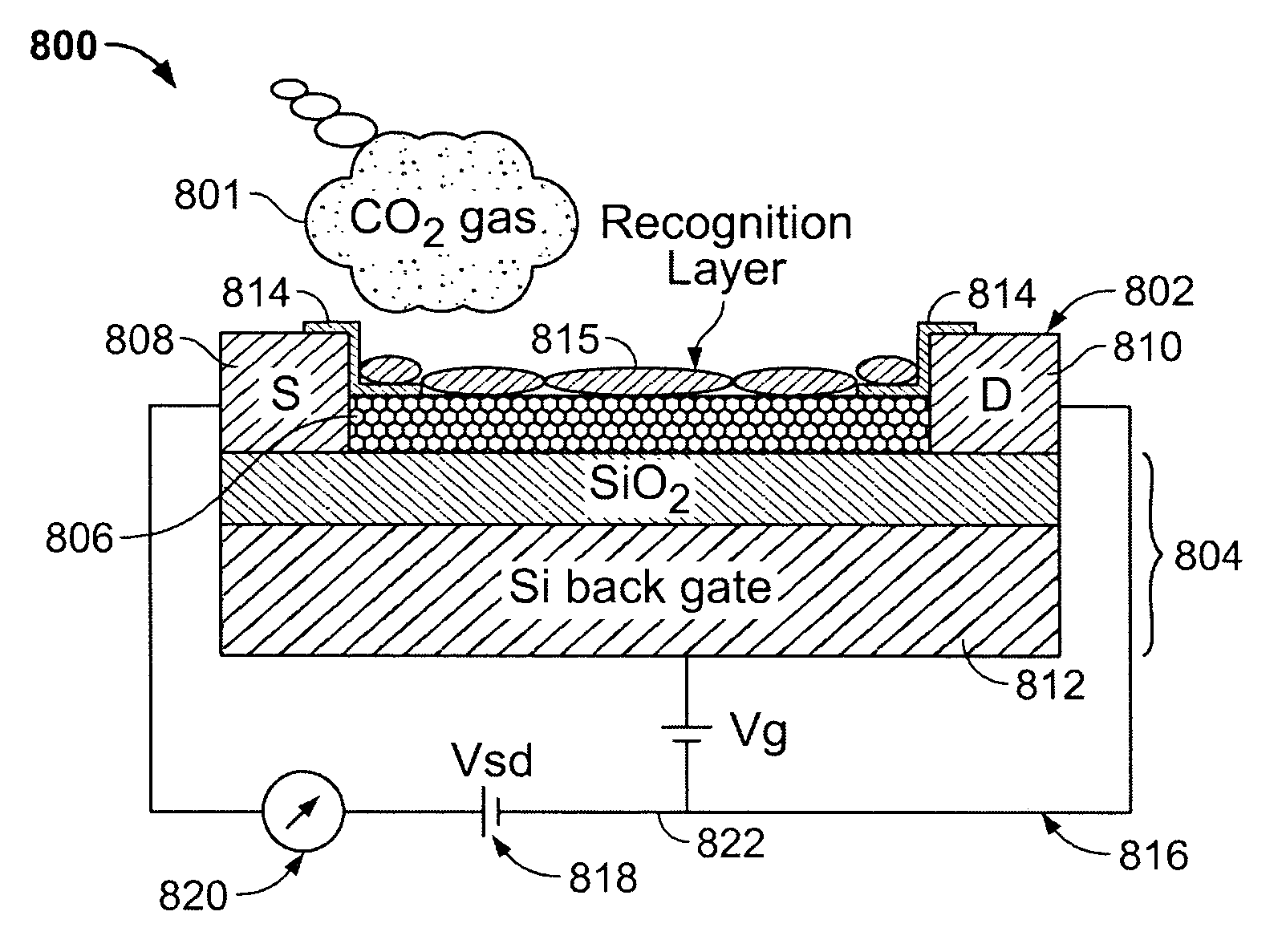

Nanoelectronic capnometer adaptor including a nanoelectric sensor selectively sensitive to at least one gaseous constituent of exhaled breath

InactiveUS7547931B2Low costSmall sizeAnalysis using chemical indicatorsSamplingAirway adaptorEnvironmental health

A capnometer adaptor includes a nanostructure sensor configured to selectively respond to a gaseous constituent of exhaled breath, such as to carbon dioxide. In certain embodiments, the adaptor includes an airway adaptor having at least one channel configured for the passage of respiratory gas; at least one nanostructure sensor in fluid communication with the passage, the sensor configured to selectively respond to at least one gaseous constituent of exhaled breath comprising carbon dioxide; and electronic hardware connected to the nanostructure sensor and configured to provide a signal indicative of a response of the sensor to the at least one gaseous constituent of exhaled breath. The sensor may be provided as a compact and solid-state device, and may be adapted for a variety of respiratory monitoring applications.

Owner:NANOMIX

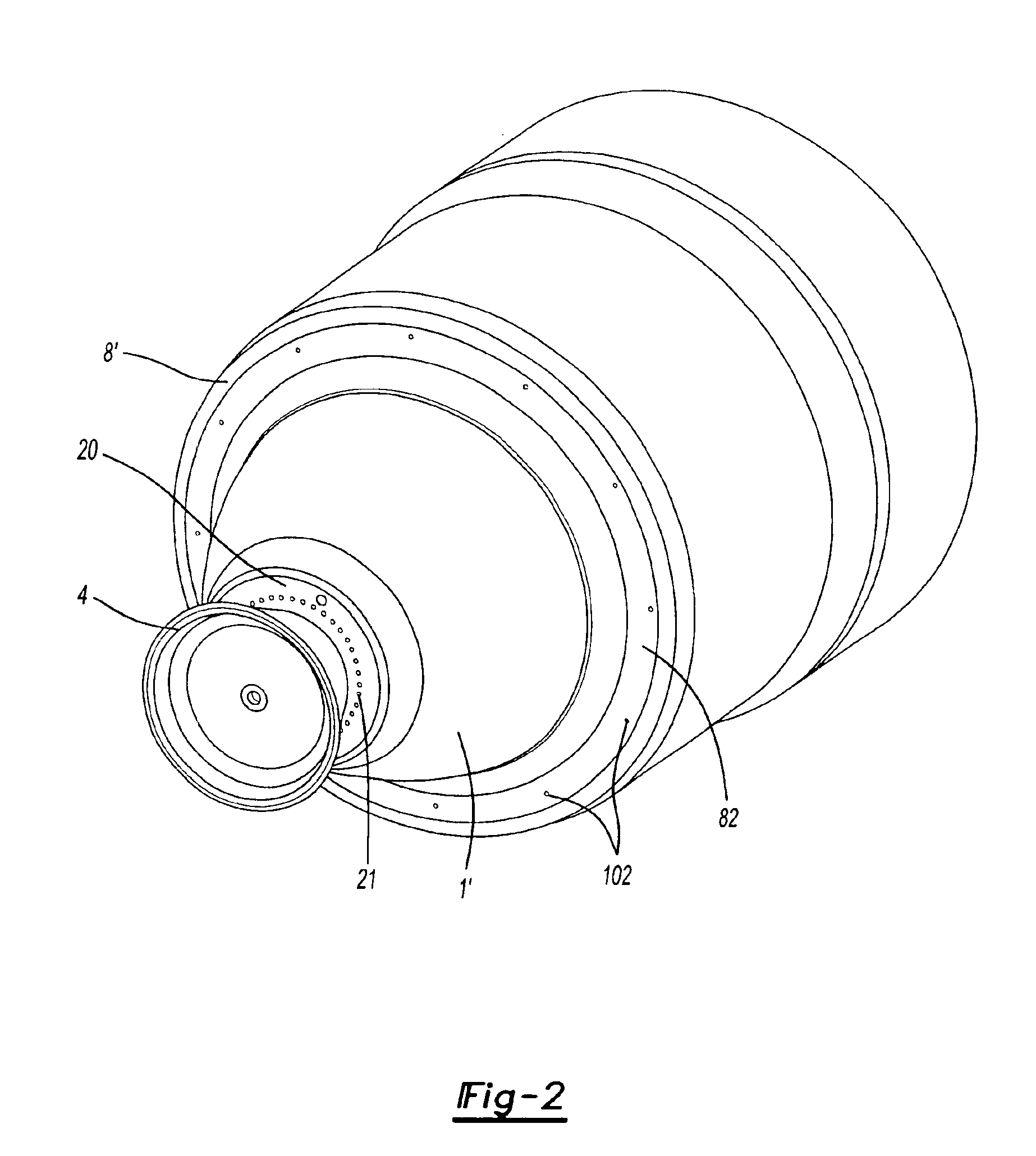

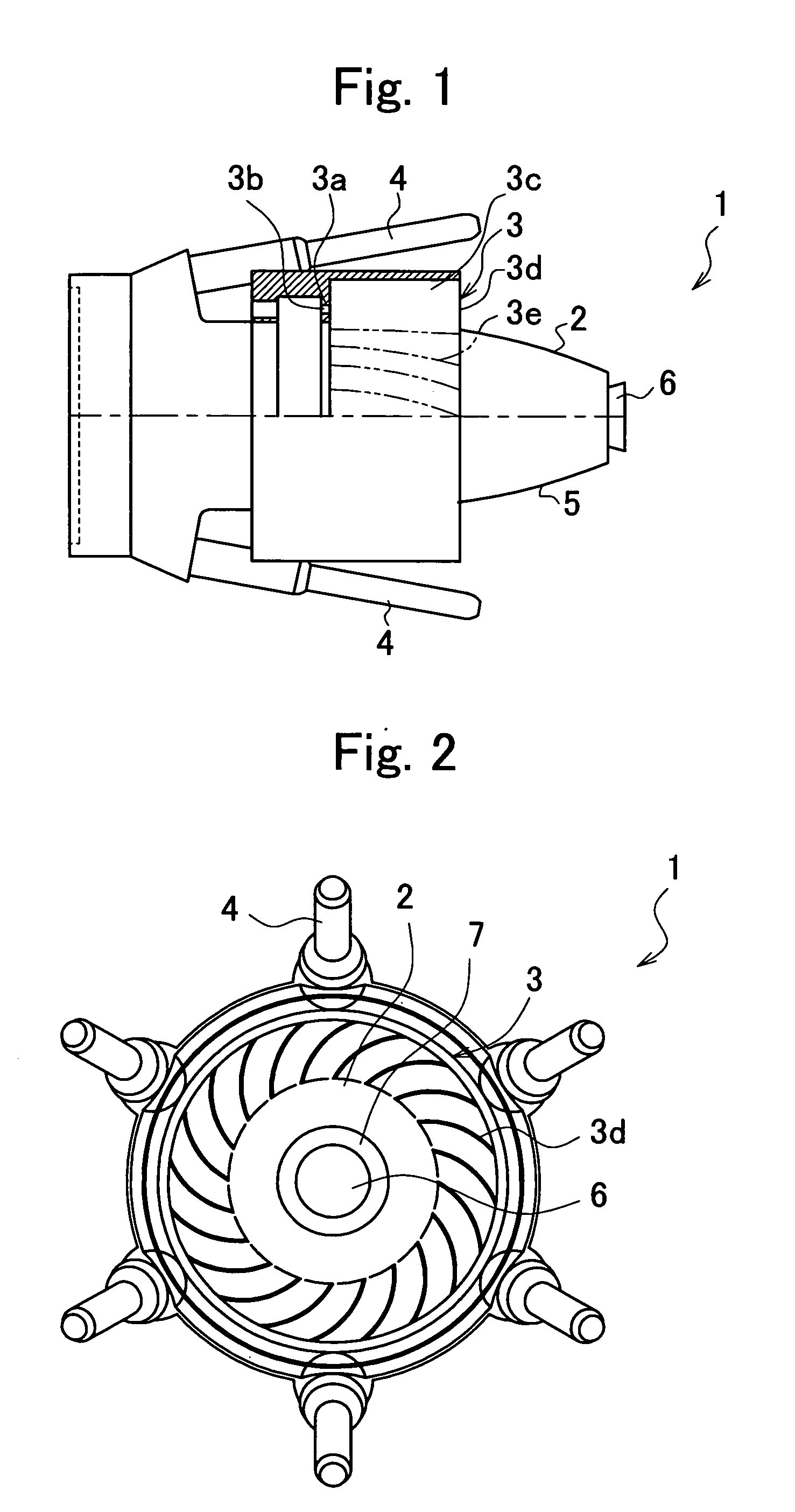

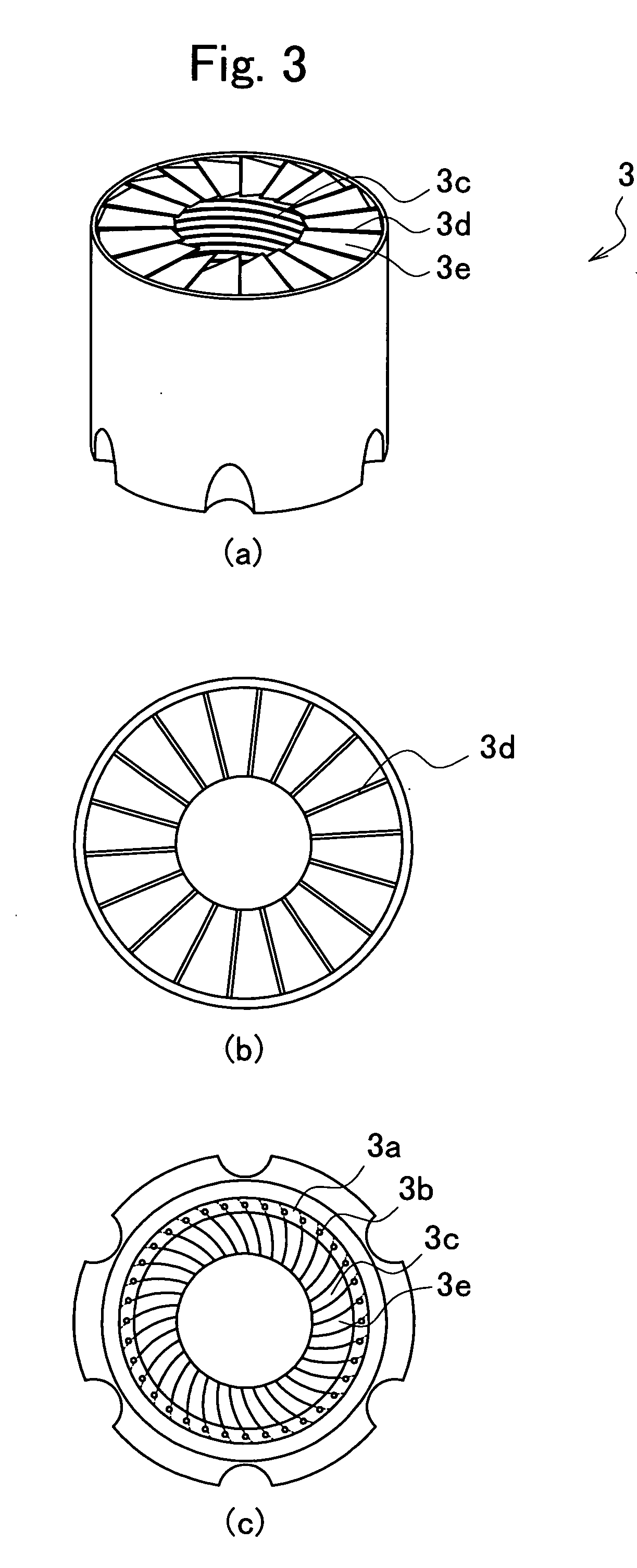

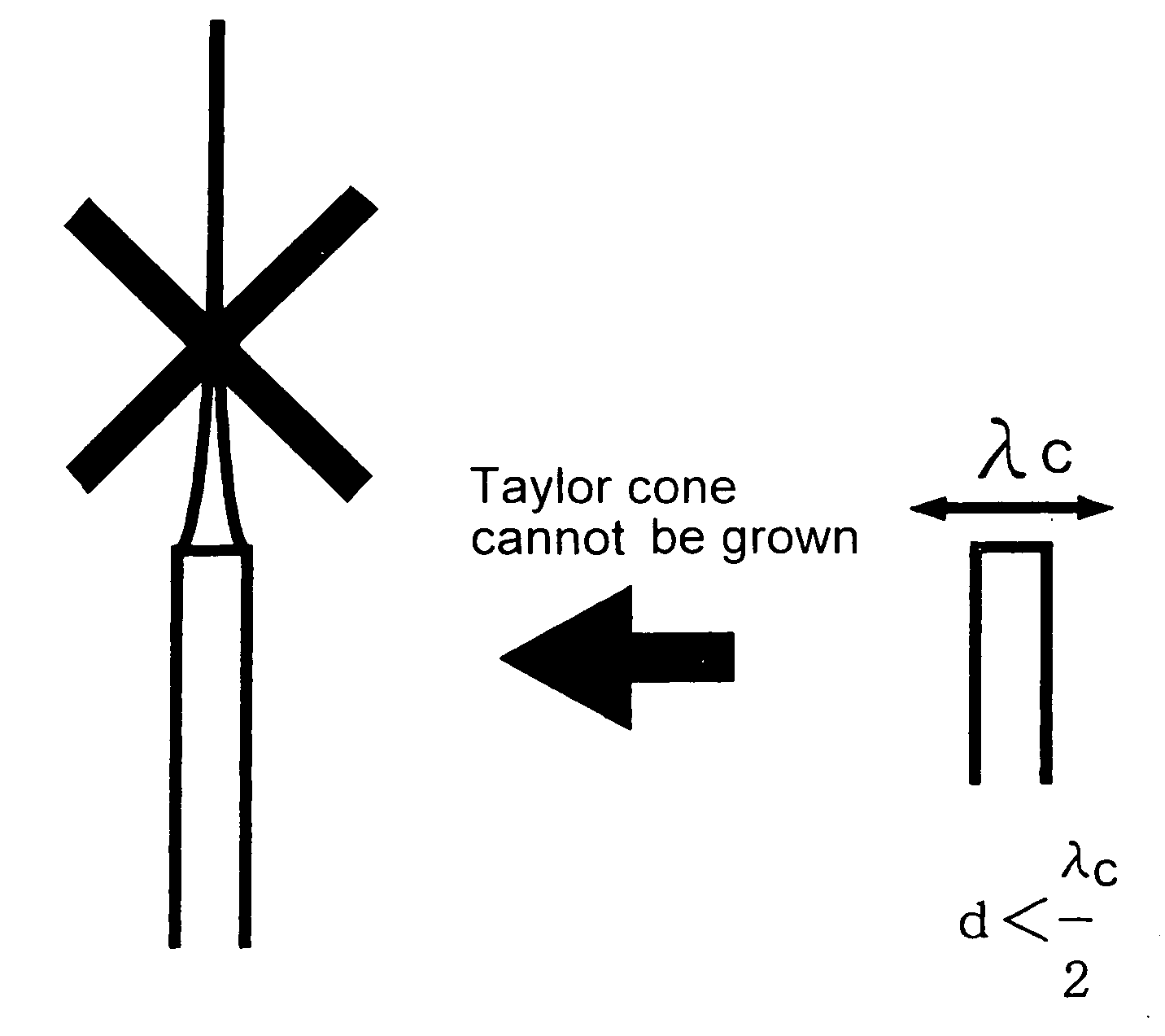

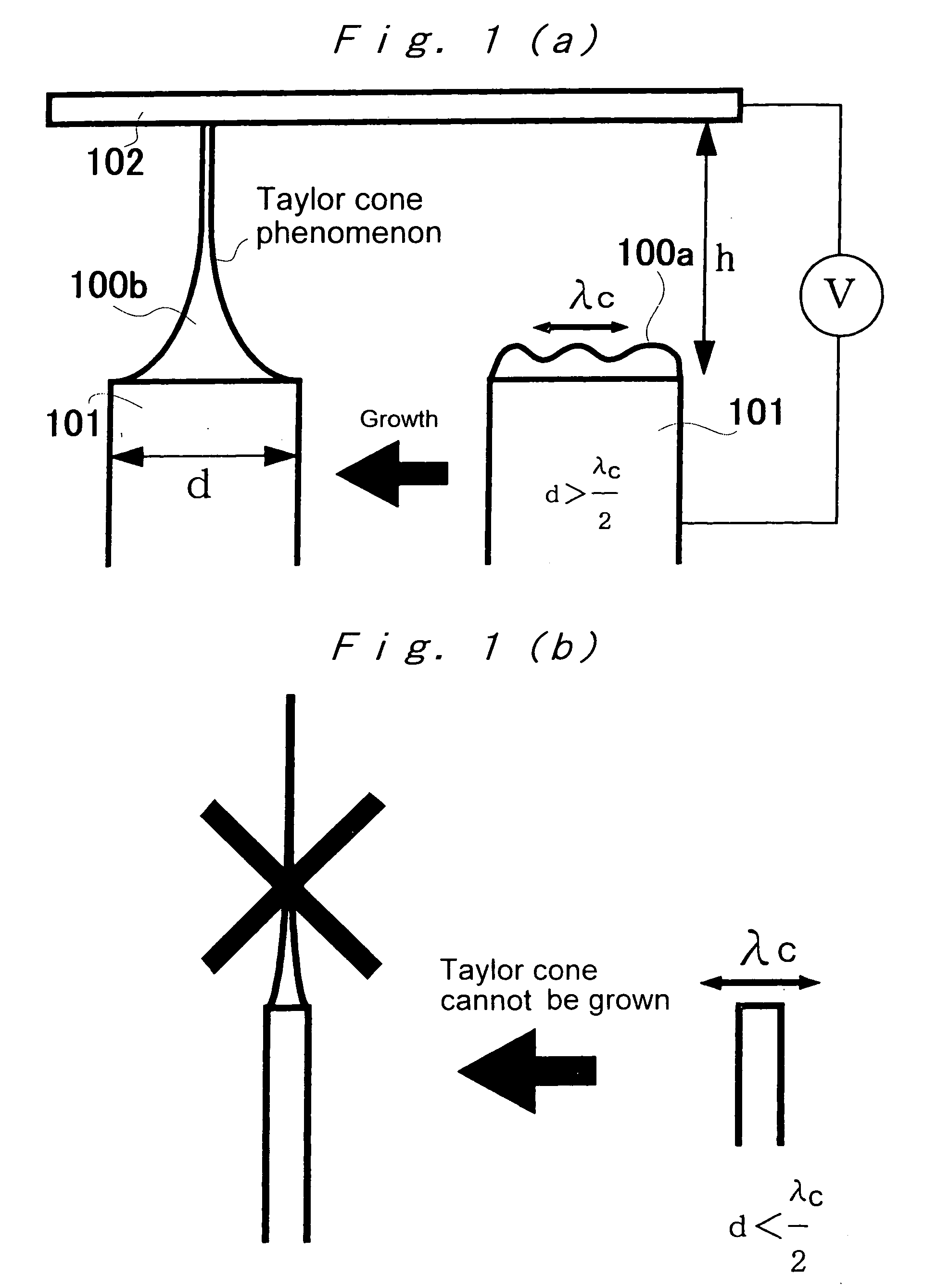

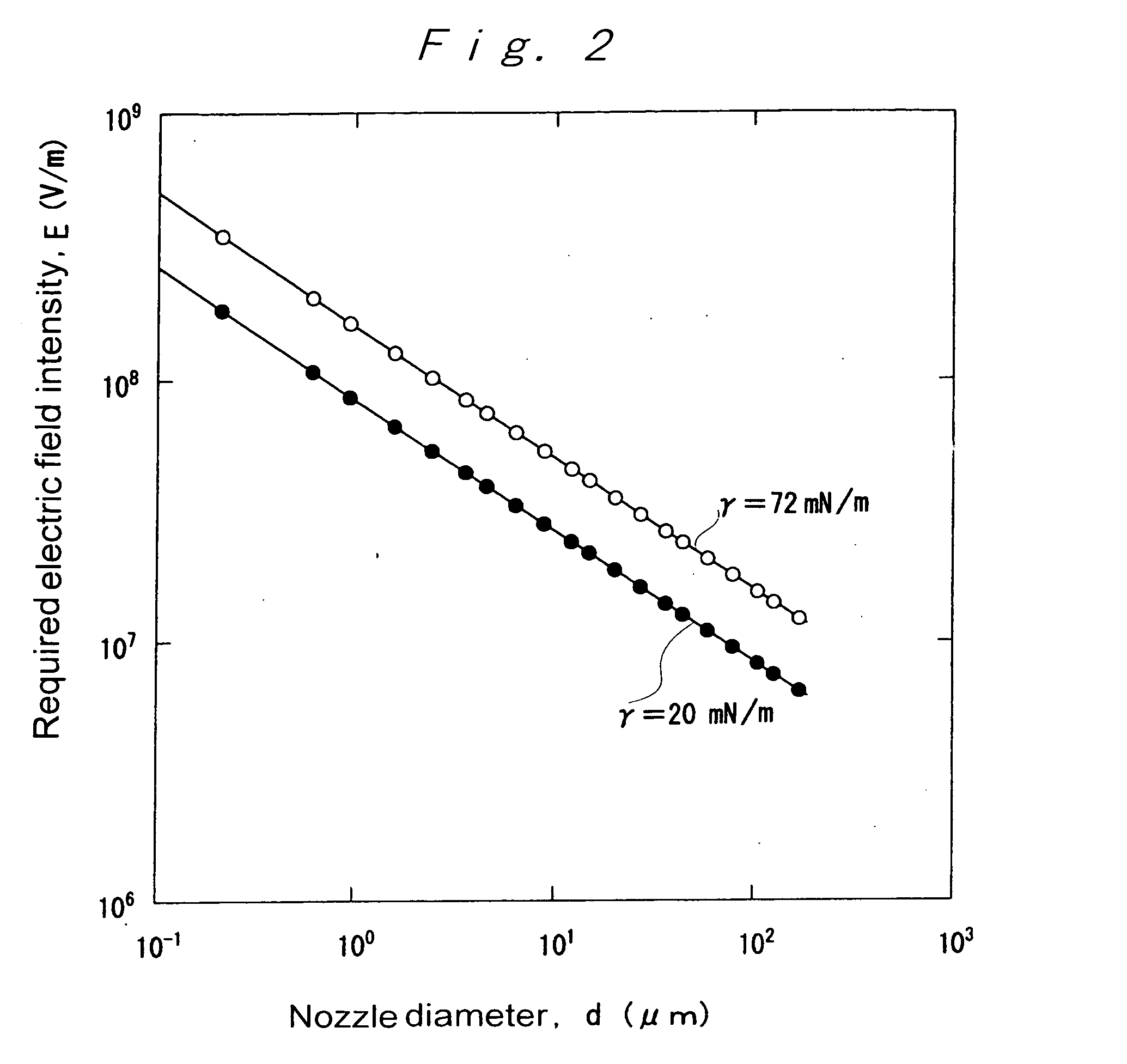

Ultrafine fluid jet apparatus

ActiveUS20050116069A1Improve the immunityReduce the overall diameterBurnersLiquid spraying plantsElectrical field strengthEvaporation

An ultrafine fluid jet apparatus comprising a substrate arranged near a distal end of an ultrafine-diameter nozzle to which a solution is supplied, and an optional-waveform voltage is applied to the solution in the nozzle to eject an ultrafine-diameter fluid droplet onto a surface of the substrate; wherein an electric field intensity near the distal end of the nozzle according to a diameter reduction of the nozzle is sufficiently larger than an electric field acting between the nozzle and the substrate; and wherein Maxwell stress and an electro-wetting effect being utilized, a conductance is decreased by a reduction in the nozzle diameter or the like, and controllability of an ejection rate by a voltage is improved; and wherein landing accuracy is exponentially improved by moderation of evaporation by a charged droplet and acceleration of the droplet by an electric field.

Owner:SIJTECH +1

Electrostatically atomizing device

ActiveUS7567420B2Stable conditionReduce necessityLiquid spraying plantsSpraying power supplyHigh pressureWater particle

An electrostatically atomizing device includes an emitter electrode, an opposed electrode opposed to the emitter electrode, and a cooling means which condenses the water on the emitter electrode from within the surrounding air, and a high voltage source applying a high voltage across the emitter electrode and the opposed electrode to electrostatically charge the water for atomizing charged minute water particles from a discharge end of the emitter electrode. The device further includes a controller for discharging the charged minute water particles in a stable manner. The controller monitors a discharge current flowing between the two electrodes to control the cooling means for keeping the discharge current at a predetermined level, thereby regulating the atomizing amount of the charged minute particles from the emitter electrode.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Nanostructures with electrodeposited nanoparticles

Owner:NANOMIX INC

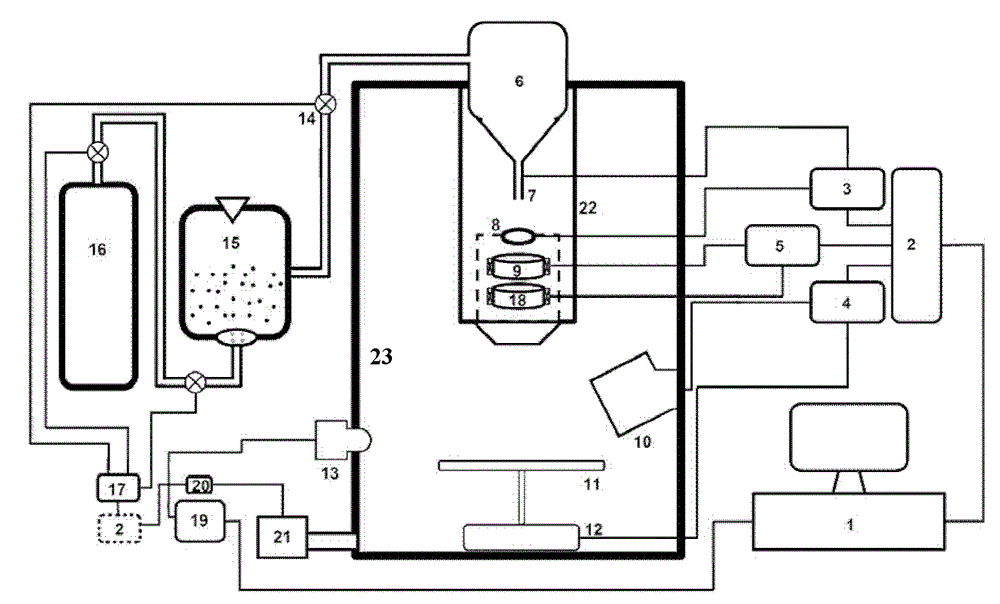

Rapid shaping device and electrostatic spraying system thereof

InactiveCN102744172AReduce lossReduce splashLiquid supply arrangementsSpraying power supplyNanoparticleSpray nozzle

The invention discloses an electrostatic spraying system of a rapid shaping device used for a nano particle material. The system comprises a spraying head (6) and a spraying nozzle (7). The system is characterized in that the spraying nozzle (7) has negative voltage. The electrostatic spraying system enables the nano particle material to be adsorbed on the surface of a workpiece under the action of a high voltage electrostatic field; and therefore, splashing and resilience are remarkably decreased, the consumption of the nano particle material is reduced greatly, and the shaping efficiency is improved.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

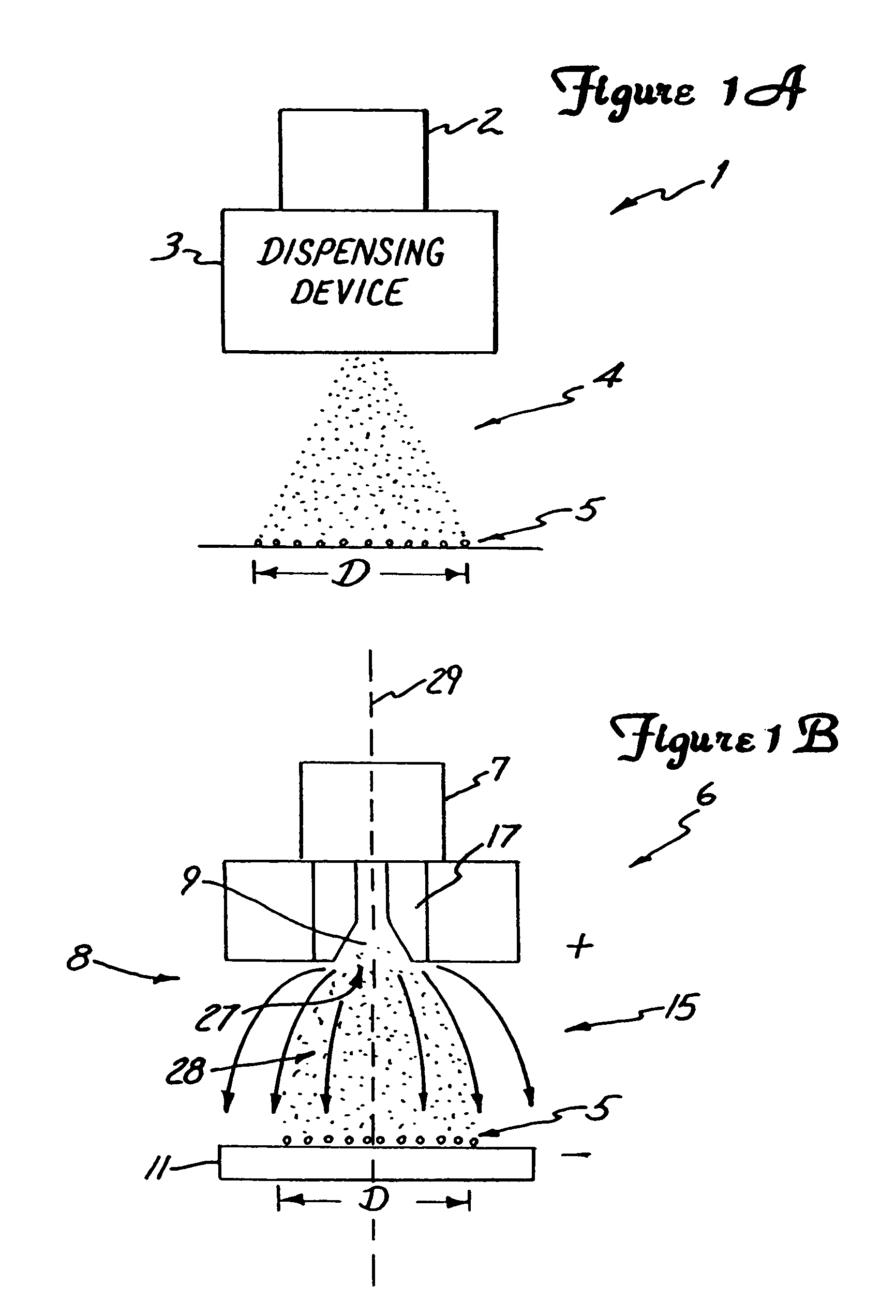

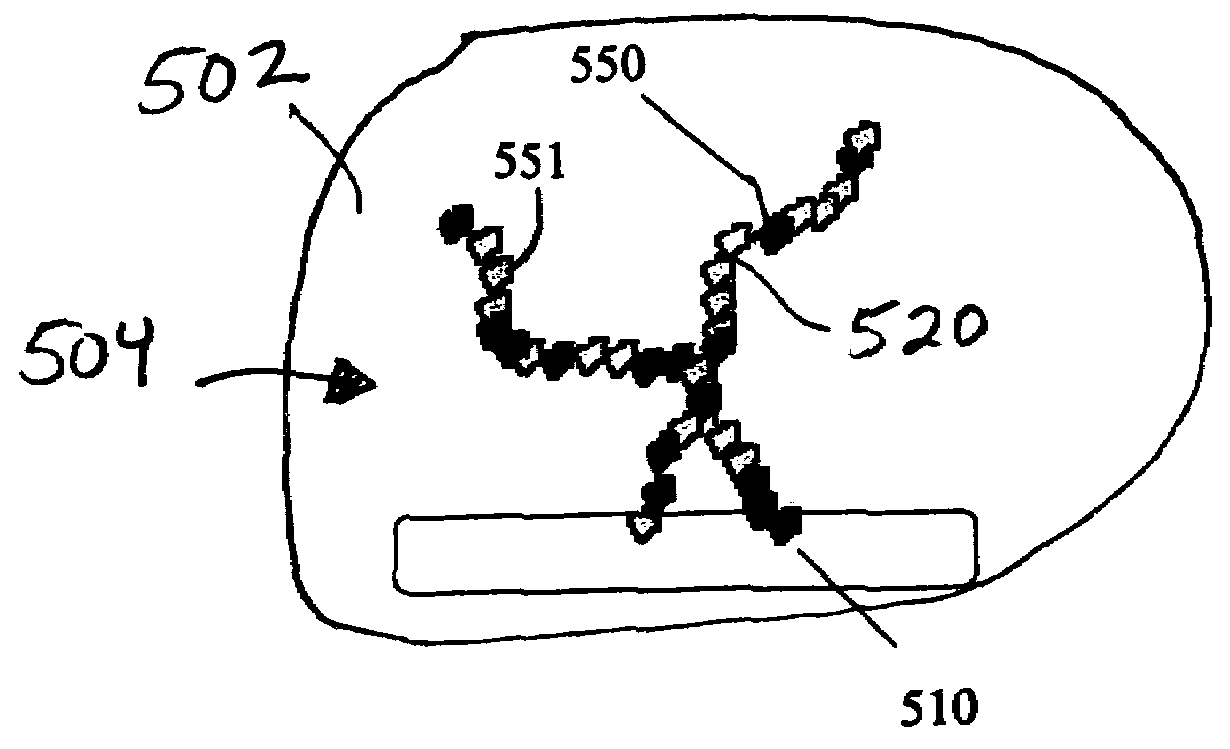

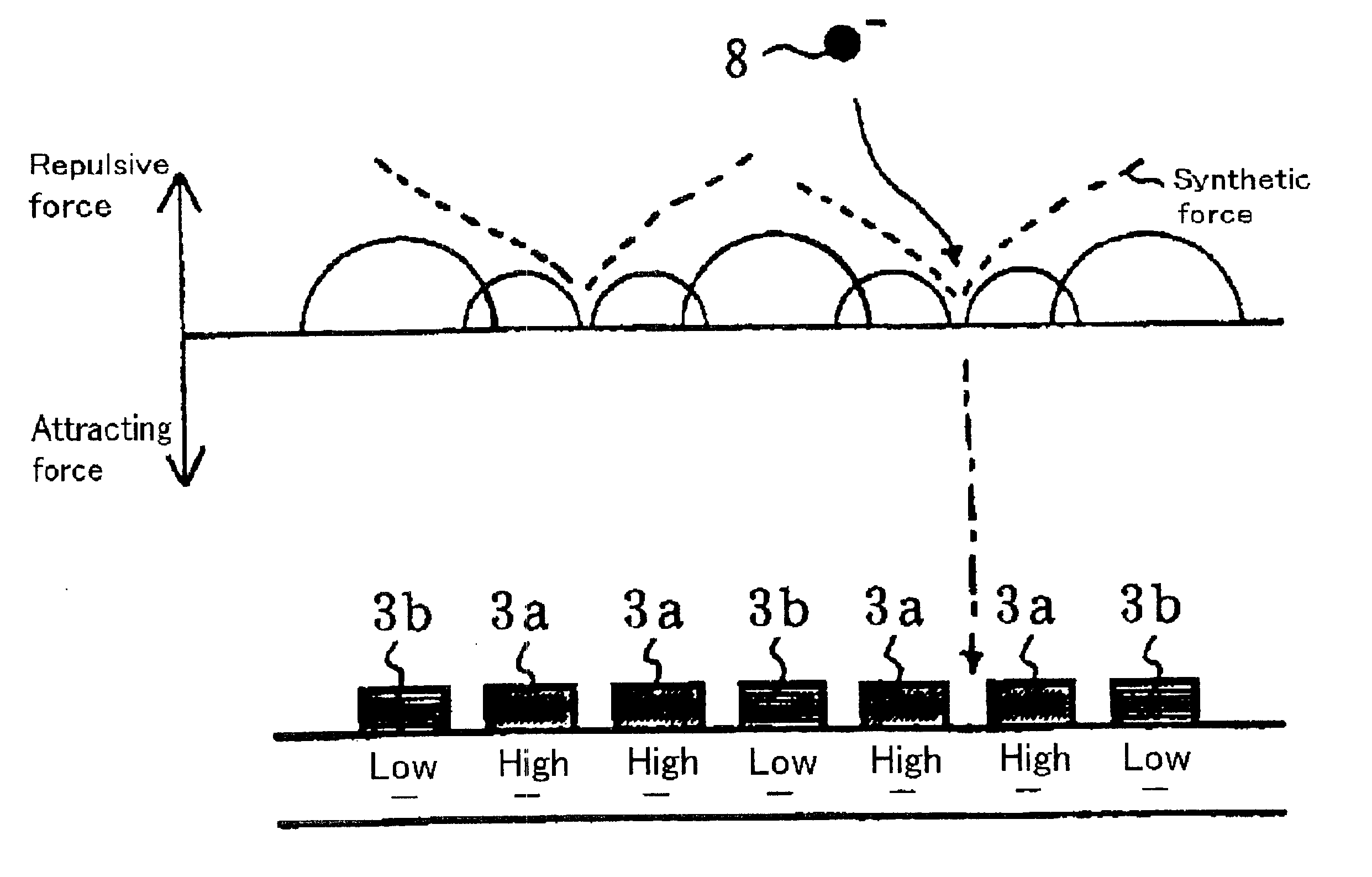

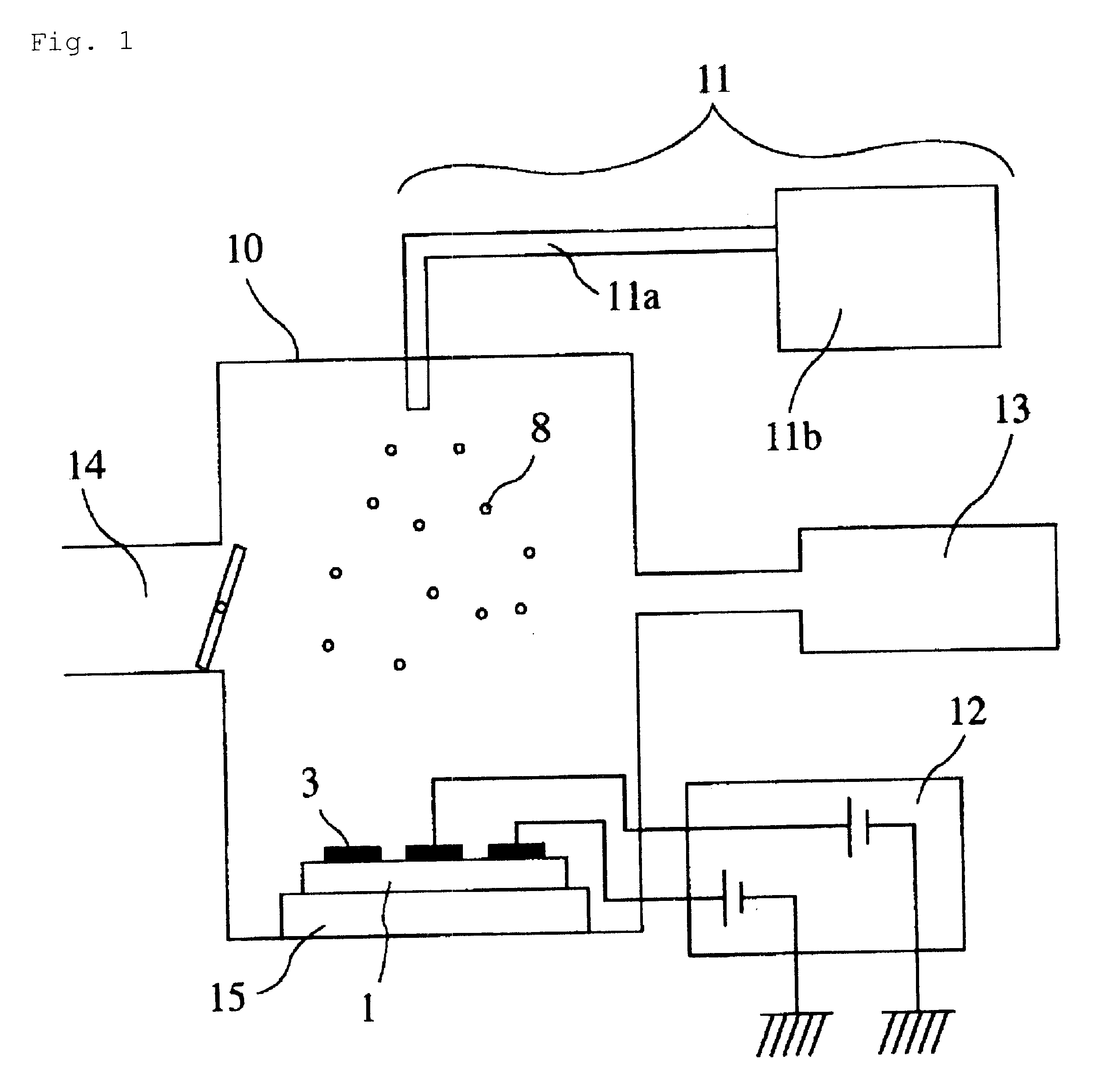

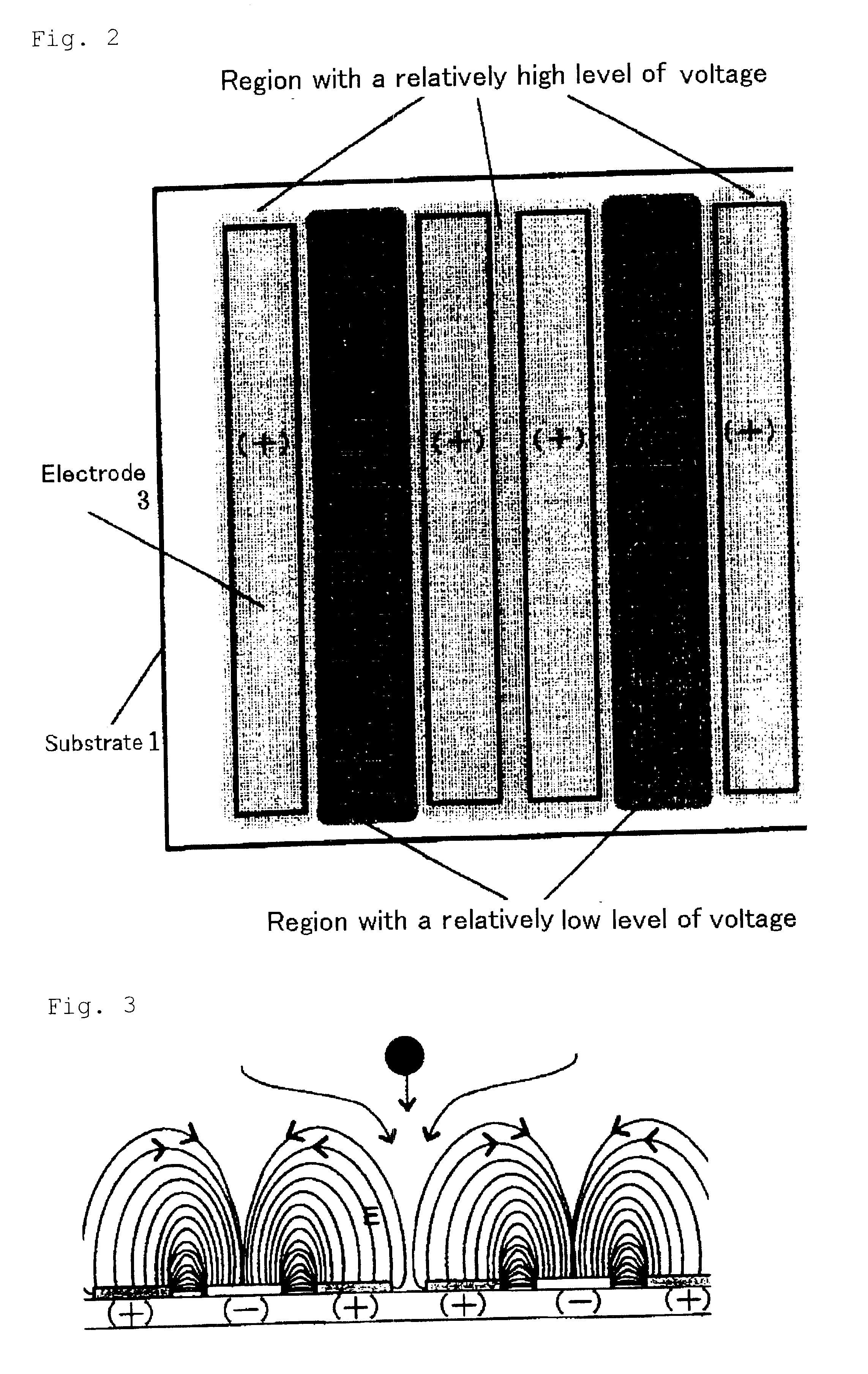

Spacer microparticle spraying apparatus and method for fabricating a liquid crystal display

InactiveUS6649221B1Proper disposalPrevent short-circuitingLiquid surface applicatorsSpraying power supplyLiquid-crystal displayEngineering

Provided is a spacer microparticle spraying apparatus capable of selectively disposing spacer microparticles in electrode gaps where no pixels are present even on a substrate carrying an array of stripe electrodes in use for the STN liquid crystal display device, to a spacer particle spraying method and a method of manufacturing a liquid crystal display device which utilize said apparatus. The spacer microparticle spraying apparatus for selective disposition of a charged spacer microparticle on a substrate carrying a plurality of electrodes includes a spraying chamber adapted to accommodate the substrate, a spacer microparticle supply means for supplying the spacer microparticle into the spraying chamber and spraying it on the substrate, and a voltage application means for applying voltages to the electrodes disposed on the substrate, wherein the voltage application means is capable of applying different levels of voltages to the electrodes respectively.

Owner:SHARP KK

Popular searches

Genetic material ingredients Granulation by liquid drop formation Biomass after-treatment Tissue/virus culture apparatus Vector-based foreign material introduction Stress based microorganism growth stimulation Specific use bioreactors/fermenters Other foreign material introduction processes Liquid spraying apparatus Antibody medical ingredients

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com