Rapid shaping device and electrostatic spraying system thereof

A molding device, electrostatic spraying technology, applied in the directions of spray discharge device, jet electric energy device, liquid supply device, etc., can solve the problems of low molding efficiency and molding accuracy, reduce splash and rebound, improve molding efficiency, reduce The effect of small loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The rapid prototyping device for nanoparticle materials according to the present invention will be described in detail below with reference to the accompanying drawings.

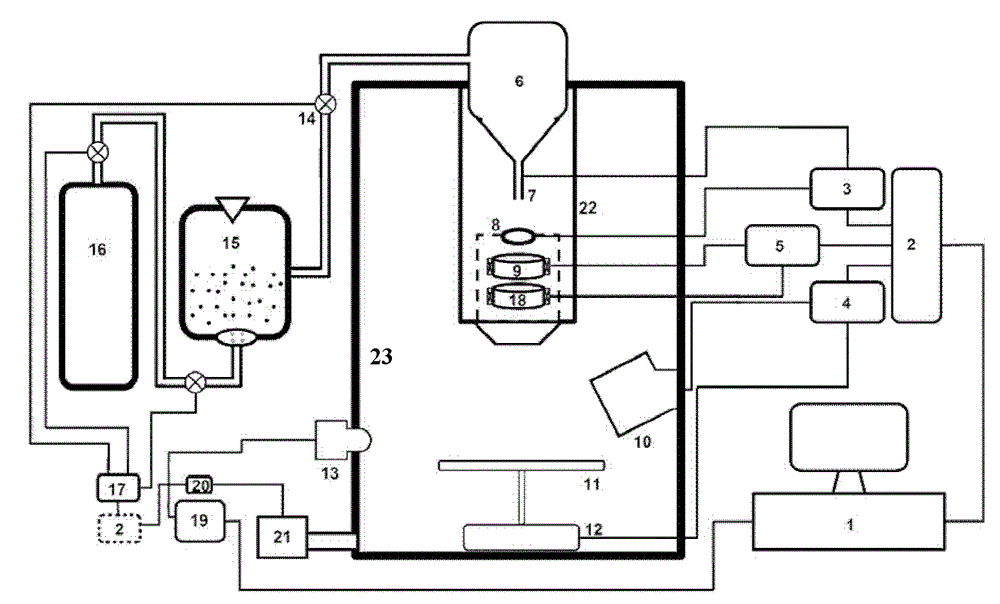

[0009] Such as figure 1 As shown, according to one embodiment of the present invention, a kind of electrostatic spraying system for the rapid prototyping device of nanoparticle material is provided, and this system can comprise: Spray head 6 and nozzle 7, and wherein, this nozzle 7 has negative Voltage.

[0010] The nozzle 7 can be, for example, a metal needle tube, through which the nanoparticle material in the spray head 6 is sprayed onto the surface of the workpiece table 11 . The spray head 6 can be made of insulating material, preferably, the insulating material can be nylon.

[0011] The system may also include an electrostatic control circuit 3 and a signal processing module 2 electrically connected to the nozzle 7; the signal processing module 2 is used to receive data from the computer 1, g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com