Patents

Literature

610 results about "Electrostatic coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrostatic coating is a manufacturing process that employs charged particles to more efficiently paint a workpiece. Paint, in the form of either powdered particles or atomized liquid, is initially projected towards a conductive workpiece using normal spraying methods, and is then accelerated toward the work piece by a powerful electrostatic charge.

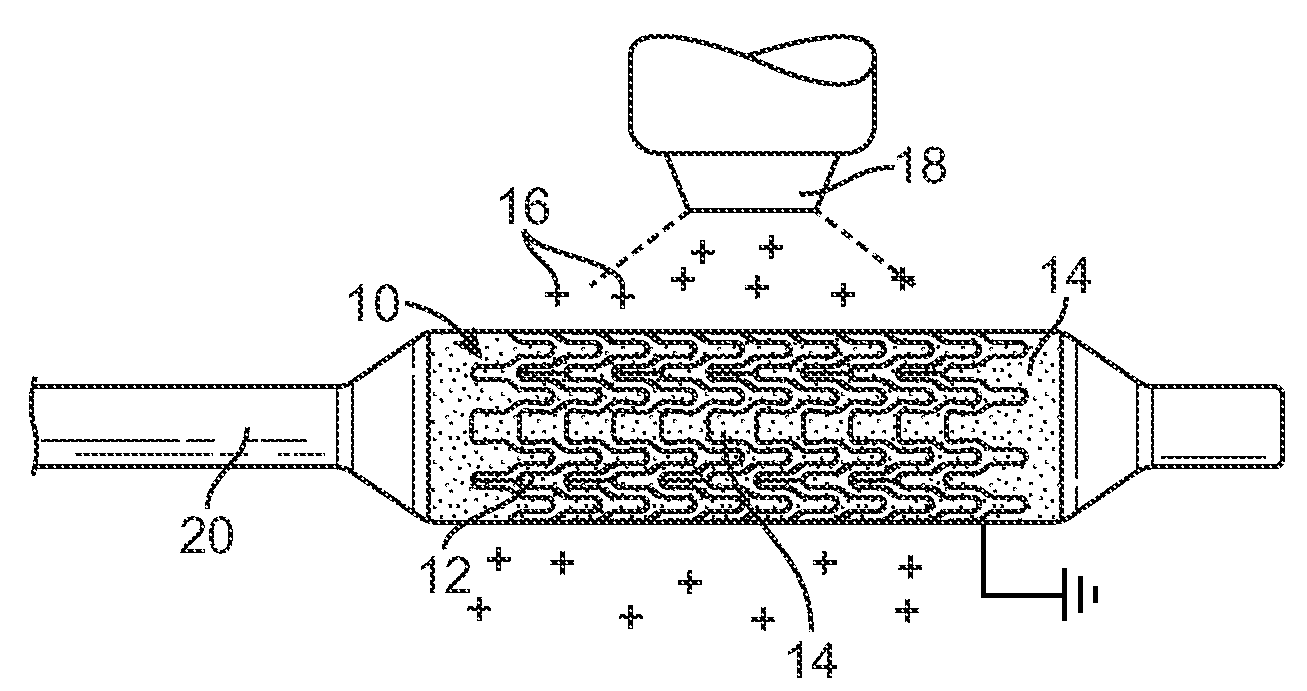

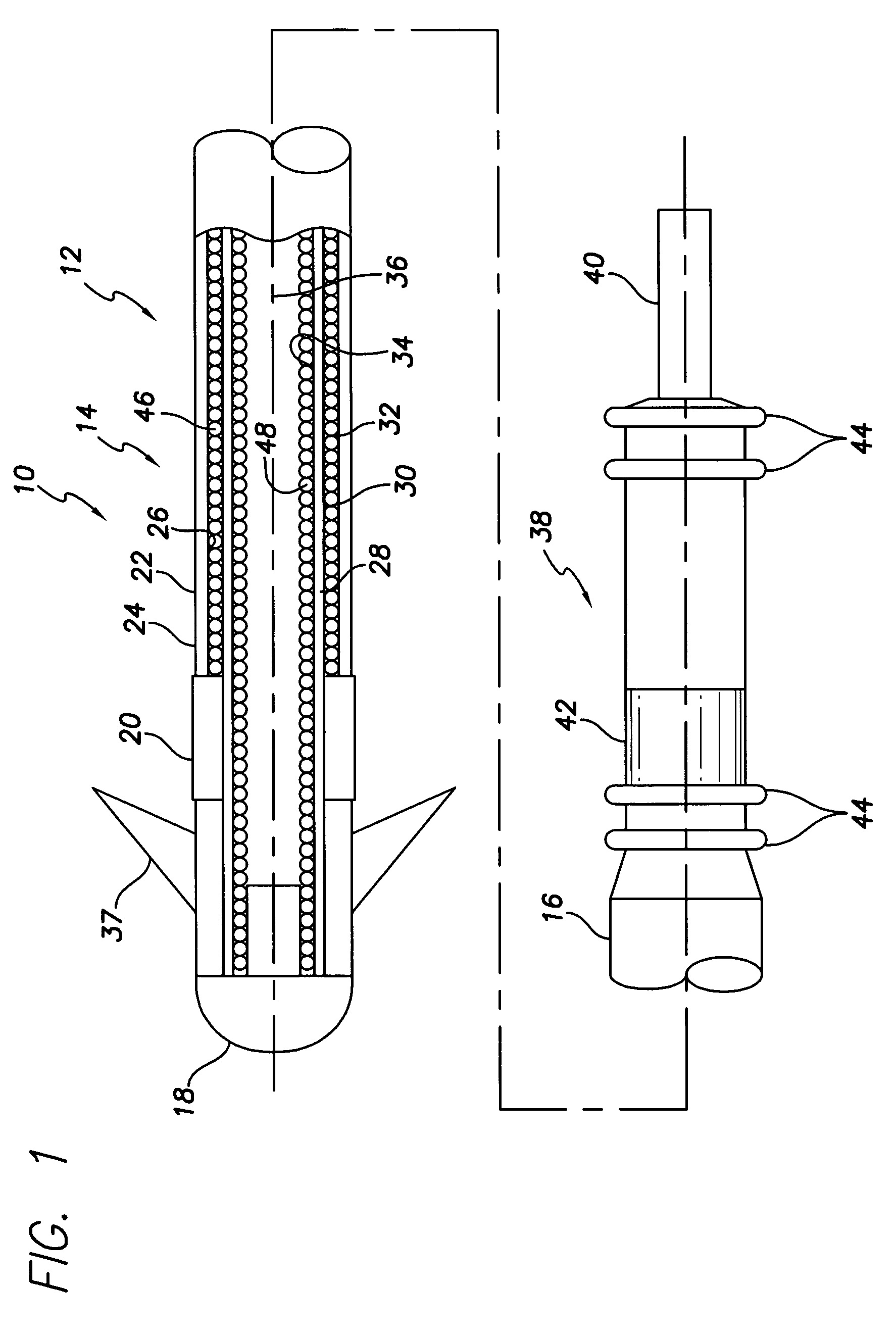

Method for electrostatic coating of a medical device

A method for electrostatic coating of medical devices such as stents and balloons is described. The method includes applying a composition to a polymeric component of a medical device which has little or no conductivity. The polymeric component could be a material from which the body or a strut of the stent is made or could be a polymeric coating pre-applied on the stent. The polymeric component could be the balloon wall. A charge can then be applied to the polymeric component or the polymeric component can be grounded. Charged particles of drugs, polymers, biobeneficial agents, or any combination of these can then be electrostatically deposited on the medical device or the coating on the medical device. One example of the composition is iodine, iodine, iodide, iodate, a complex or salt thereof which can also impart imaging capabilities to the medical device.

Owner:ABBOTT CARDIOVASCULAR

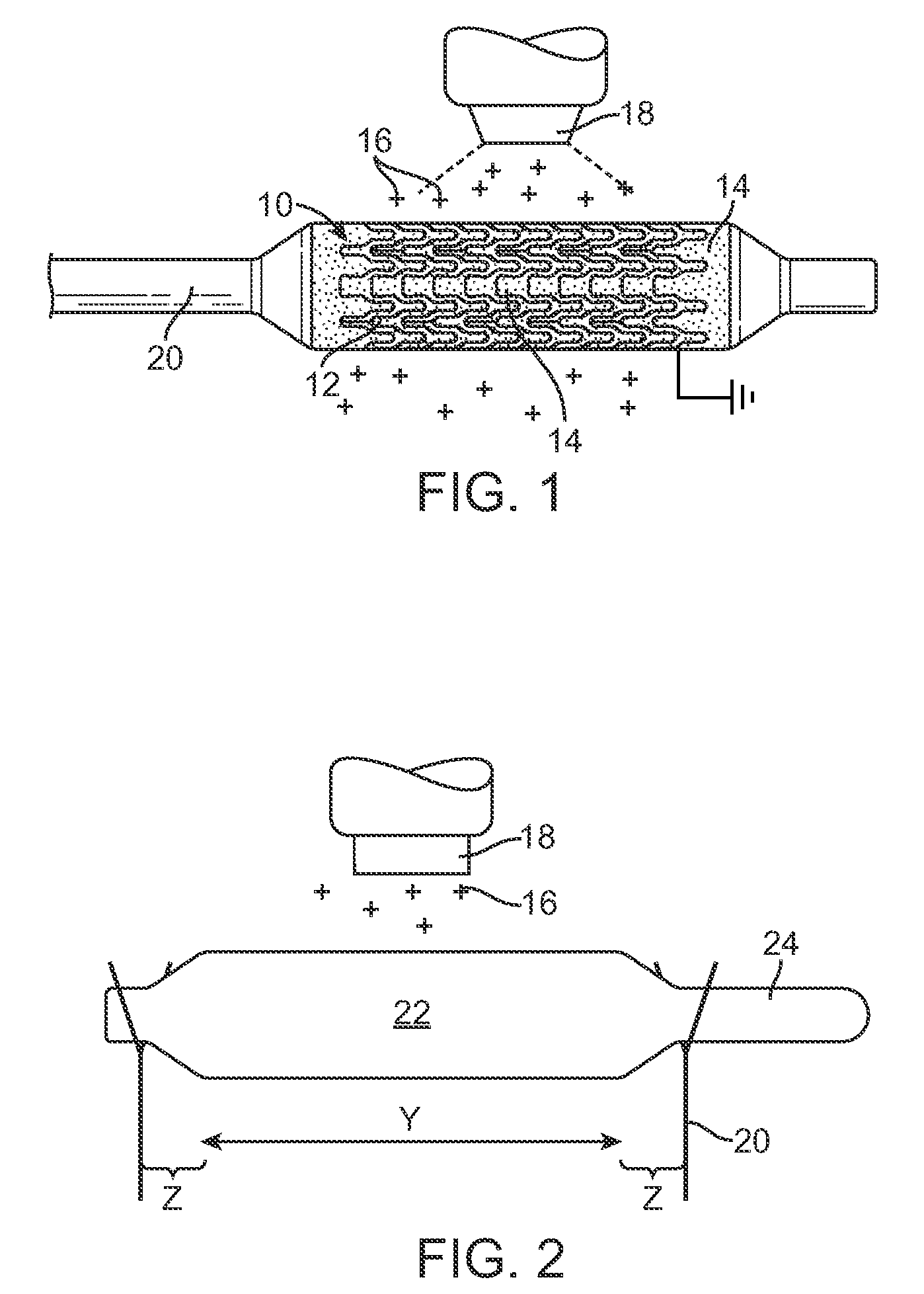

Electrostatic coating of a device

The present invention concerns bio-compatible medical devices and process for preparation thereof. The process includes electrostatically forming a first layer on a structure. The first layer can include a combination of at least one active substance and at least one polymer and / or binder. A second layer is formed on the structure to cover the first layer. The second layer can be a solvent or a combination of solvents. The evaporation of the second layer causes the first layer to reflow and bind to the structure.

Owner:BOSTON SCI SCIMED INC

Electrostatic coating of moldings with thermoplastic and crosslinkable copolyamide hot-melt adhesives

A process is described in which a nonconductive molding is electrostatically coated with a thermoplastic or crosslinkable copolyamide hot-melt adhesive. The hot-melt adhesive may be used as a fine powder with a particle size between 1 and 200 mum and have a melting point up to 160° C.

Owner:DEGUSSA AG

Foaming powder coating

InactiveCN101205425AImprove the decorative effectHigh mechanical strengthPolyurea/polyurethane coatingsPowdery paintsNon toxicityElectrostatic coating

Then invention discloses a foaming powder coating, belonging to the electrostatic coating powder coatings technical field. The coating is prepared by melting extrusion hybrid method from the following materials in weight portions: resin of 40 to 60 portions, curing agent of 0 to 24 portions, pigment and filler of 40 to 60 portions, foaming agent of 1 to 15 portions, flame retardant of 1 to 5 portions, and flow agent of 1 to 5 portions. The invention has the advantages of non-toxicity and harmlessness, no solvent contained, green and environmental protection; the coating can be directly coated on metal plates and easily operated; the foaming expansion layer has good decorative effect and high mechanic strength; the foaming powder coating of the invention can be used to produce building material products with heat insulation, heat preservation, fire proof, and sound proof effects; the building material products are economic, environmental protective, poisonless, harmless and flame retardant.

Owner:XUZHOU ZENITH COATING

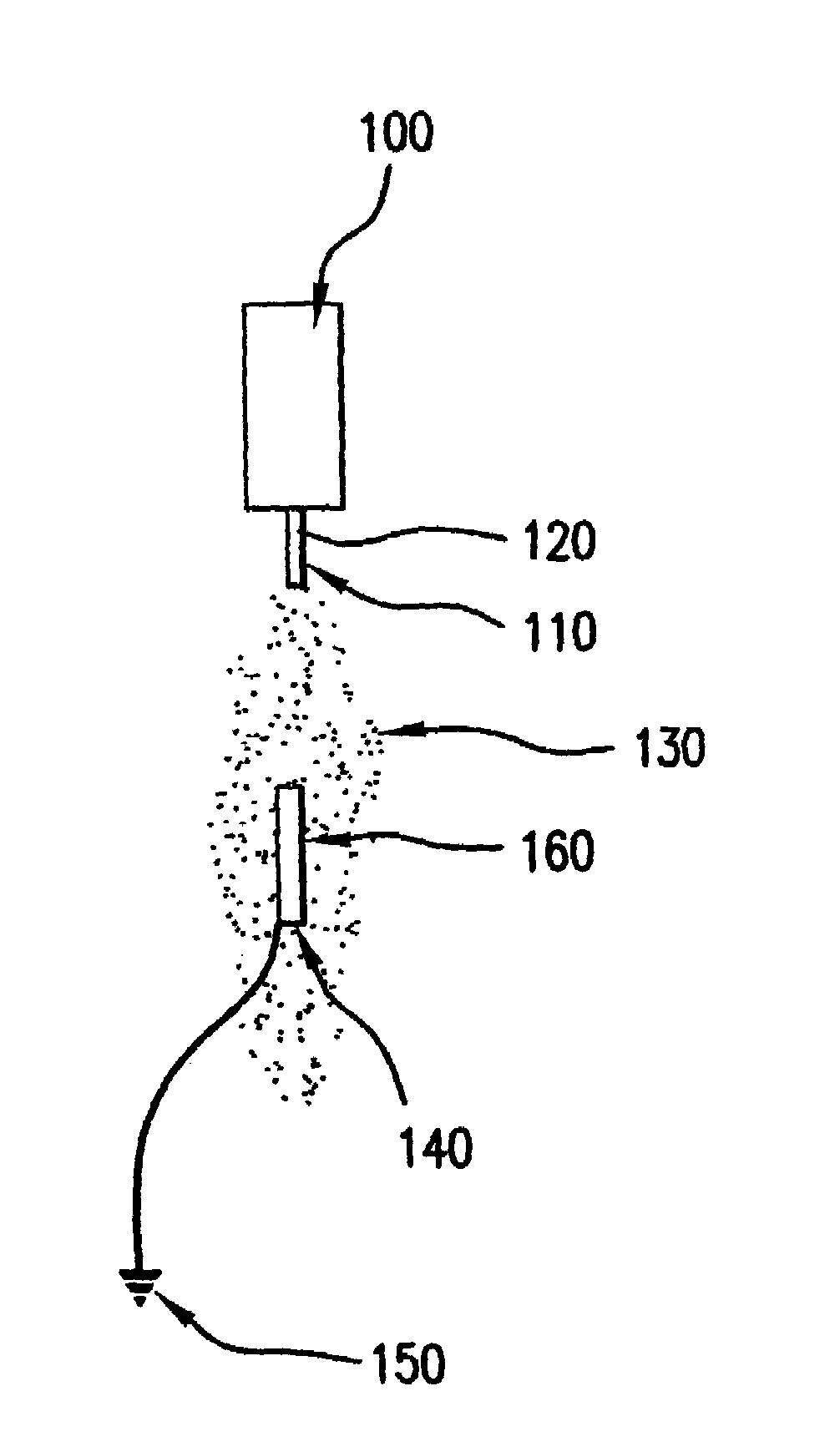

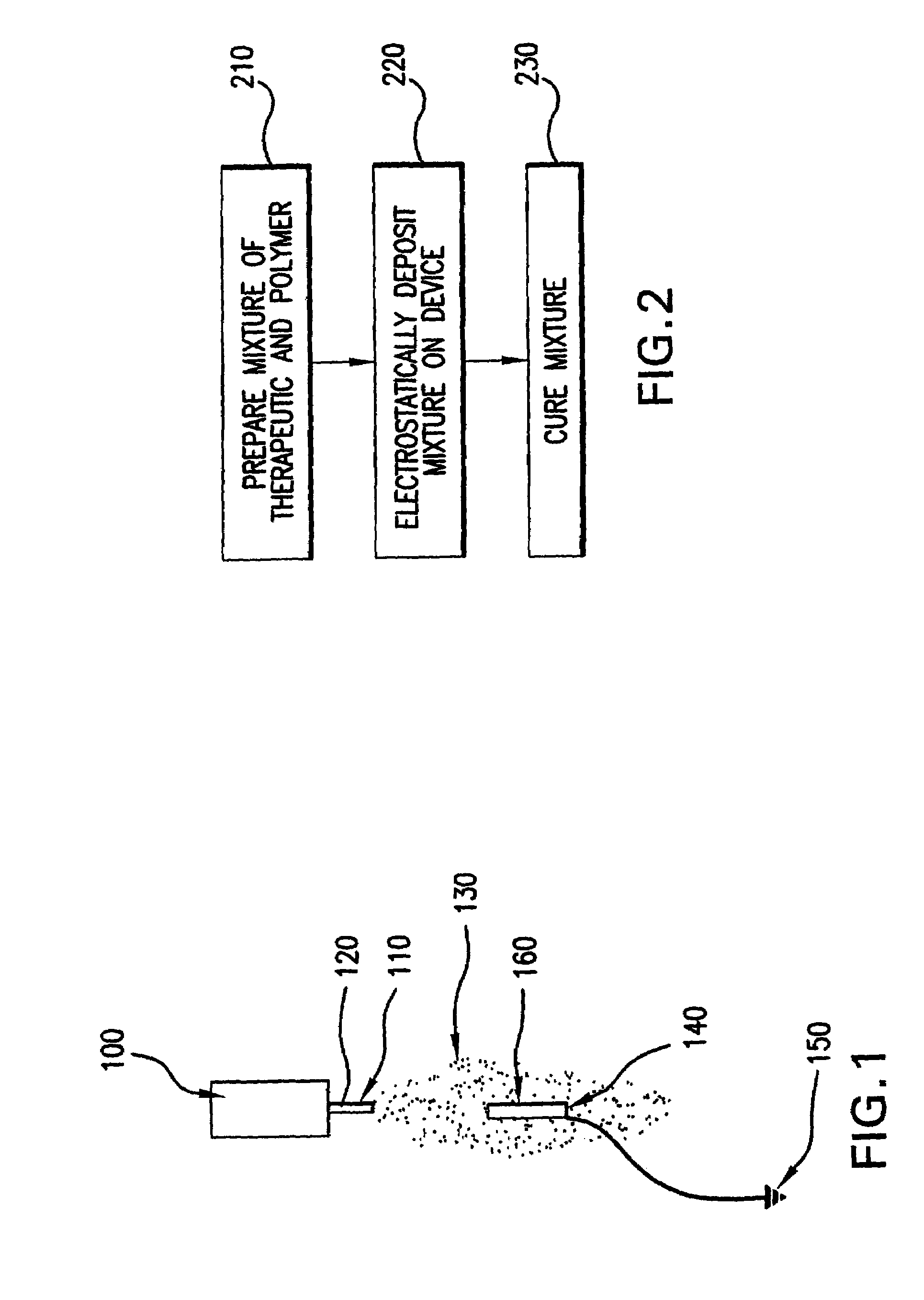

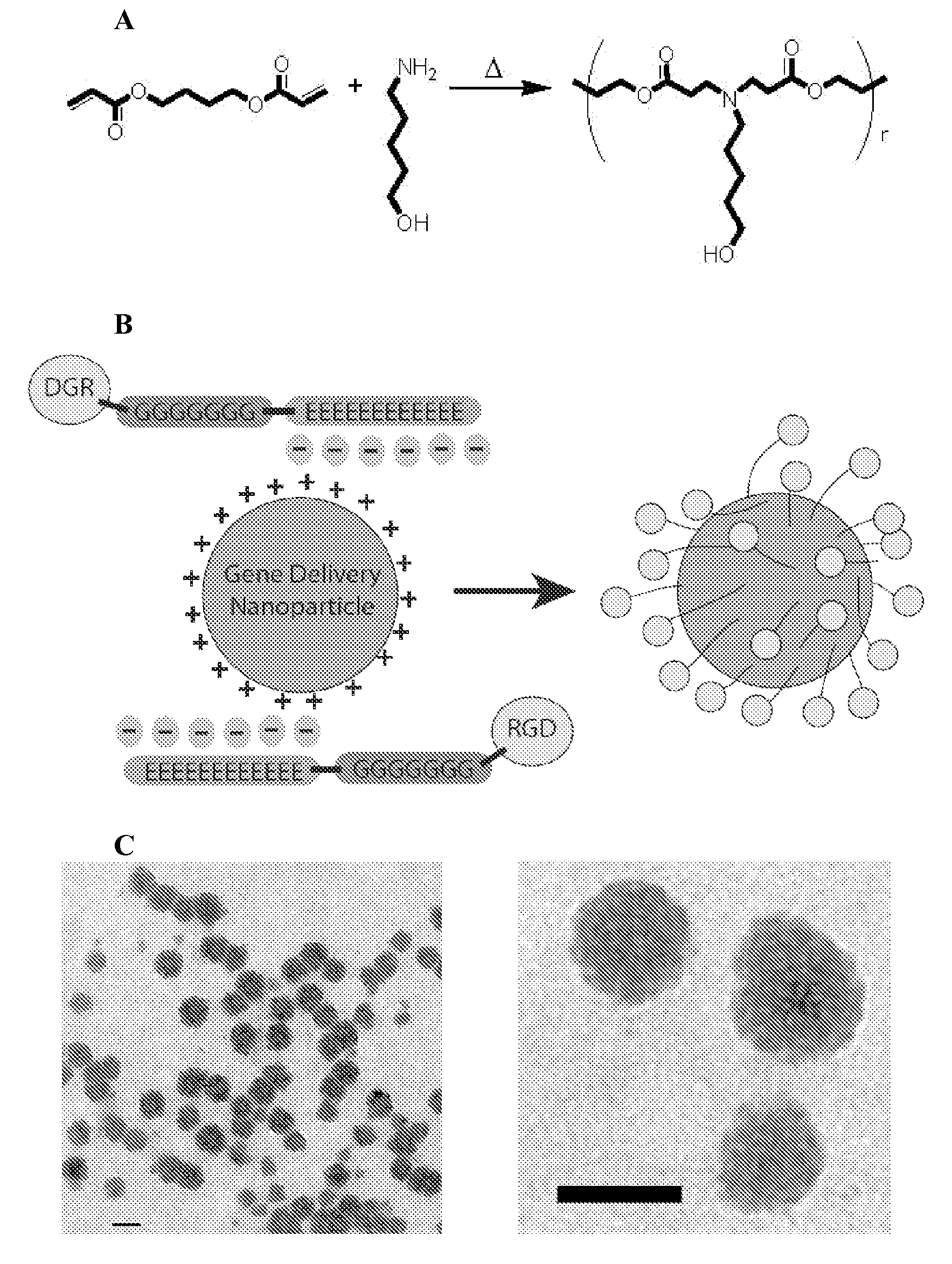

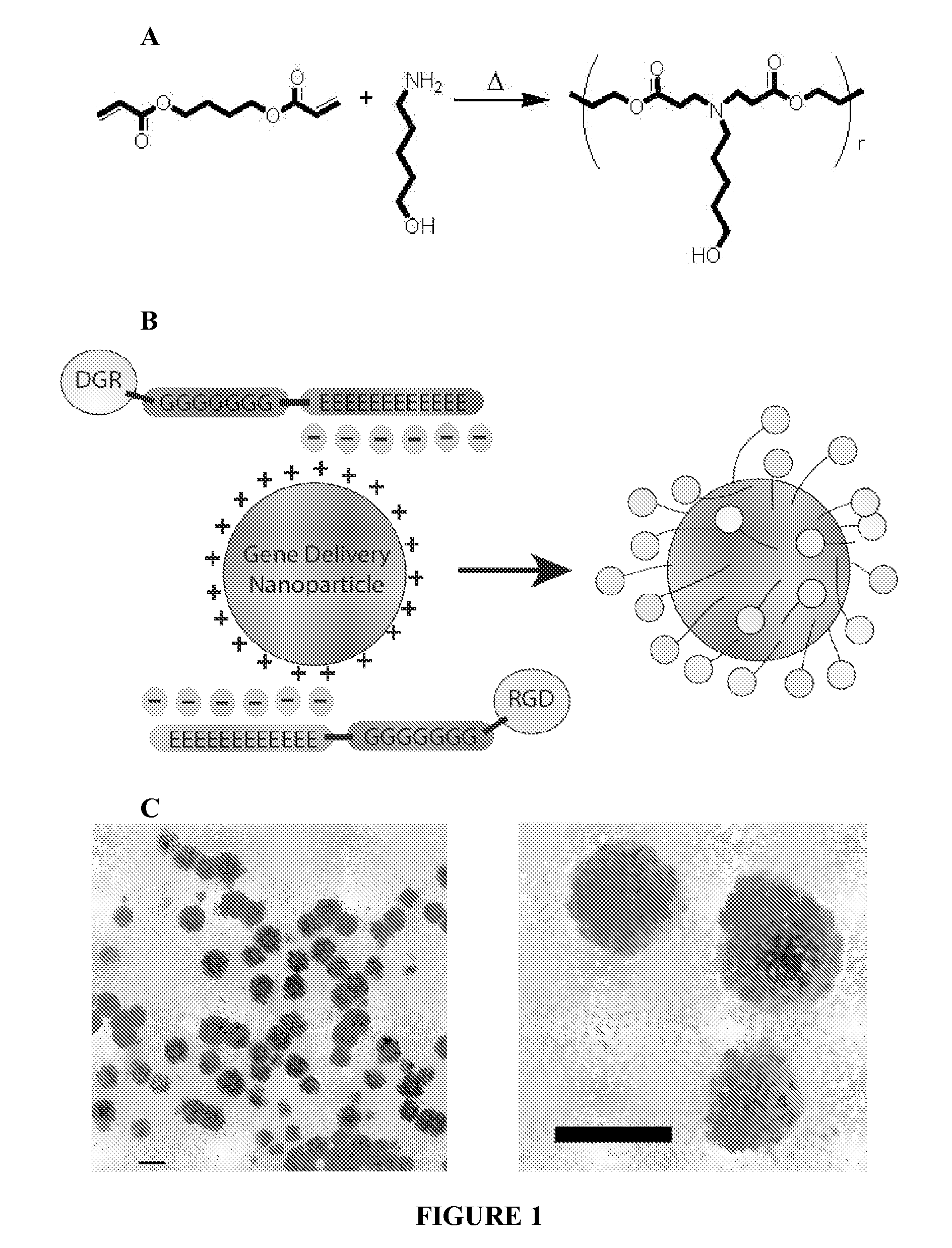

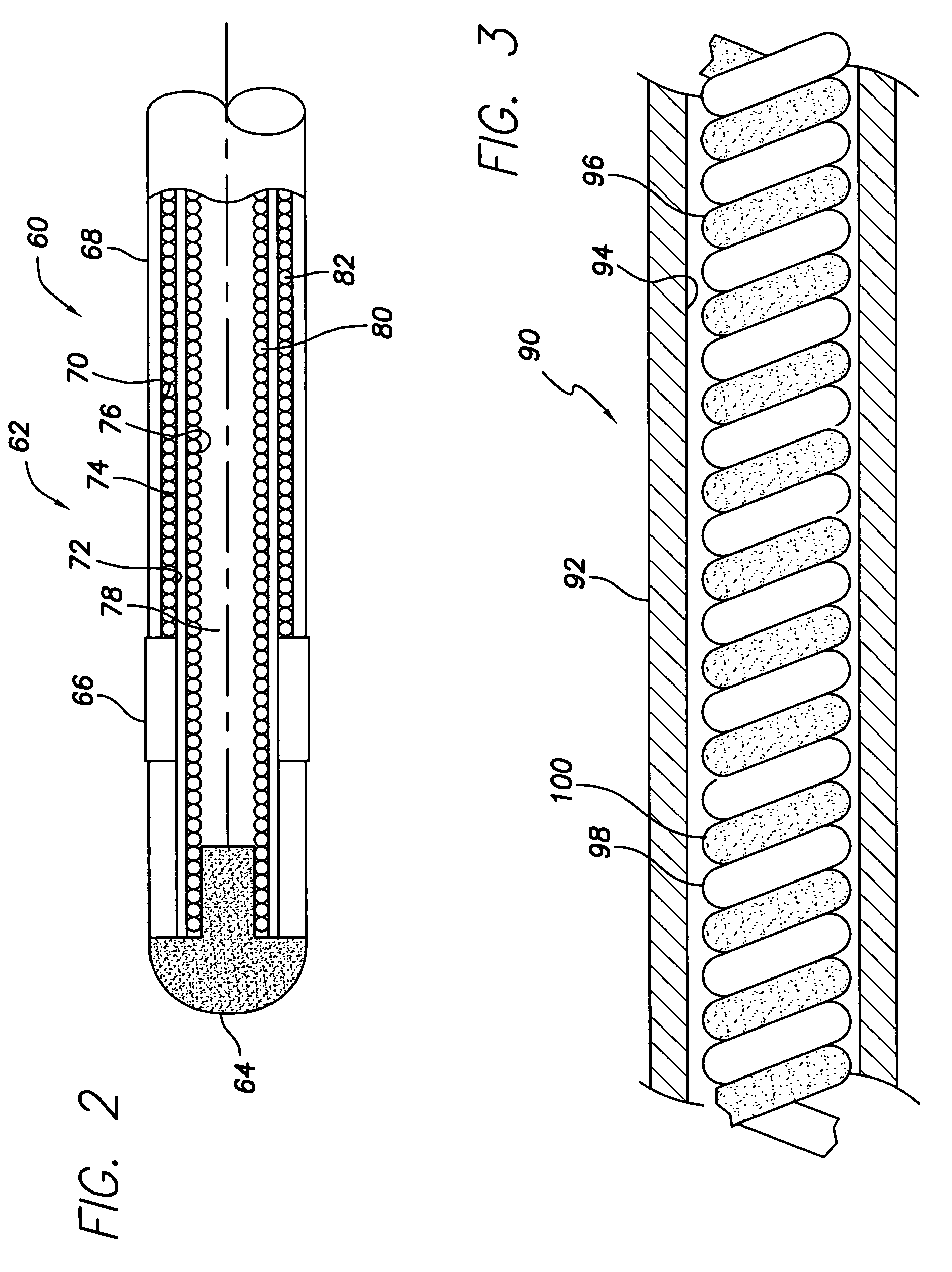

Electrostatic coating of particles for drug delivery

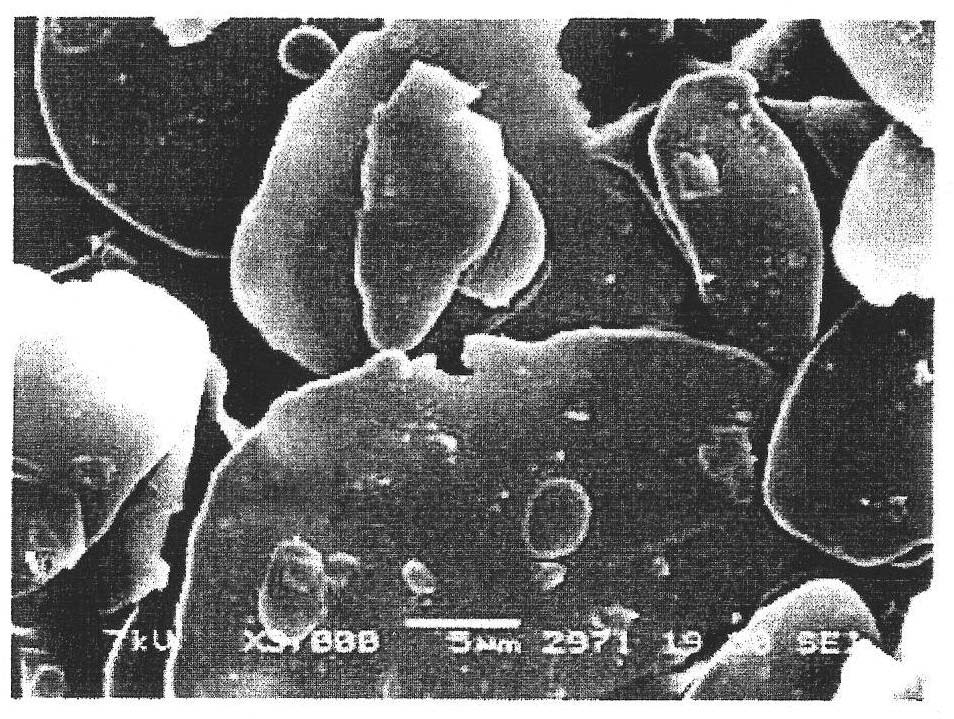

InactiveUS20100196492A1Decreased net chargeFacilitating receptor-mediated uptakeBiocidePeptide/protein ingredientsCrystallographyNanoparticle

A system for electrostatically coating particles is provided. The system is particularly well suited for coating charged drug delivery particles (e.g., nanoparticles, microparticles) with a coating of opposite charge. The coating may include a targeting moiety such as a small molecule ligand, peptide, protein, aptamer, etc. The coated particles are biodegradable and / or biocompatible, have a near neutral zeta (ξ) potential, and are stable in serum. The invention also provides pharmaceutical compositions and kits including the inventive coated particles. Methods of preparing and using the inventive particles are also included.

Owner:MASSACHUSETTS INST OF TECH

Super-thick copper circuit board solder resisting processing method

InactiveCN101959372AAvoid flat printingIncrease productivityNon-metallic protective coating applicationCrazingElectrostatic coating

The invention discloses a super-thick copper circuit board solder resisting processing method, comprising the following steps: pasting two layers of dry films with the thickness of 50 mu m when an outer-layer graph is formed; adopting a currently popular electrostatic coating process to replace the traditional plane solder resisting printing processing technique during solder resisting; adopting a manner of four times of spraying, two times of pre-baking, exposing, developing and solidifying during electrostatic spraying; obmitting the processes of pre-baking, exposing, developing and solidifying between the previous two times and the following two times of electrostatic spraying but adopting a cold wind blowing manner, wherein the thickness of the outer copper foil processed by the method is 12oz; and the printing ink thickness of the circuit board corner is 8mu m. The super-thick copper circuit board processed by the process shortens the production flow, lowers the production cost, also avoids the problem of bubbles generation caused by the fact that the air between the line can not exhaused completely in the plane printing; and as for solidifying, a segmented solidifying manner from low temperature to high temperature is adopted, which can avoid the printing ink from cracking because of over-thick printing ink, and improve the reliability of the circuit board.

Owner:大连太平洋多层线路板有限公司

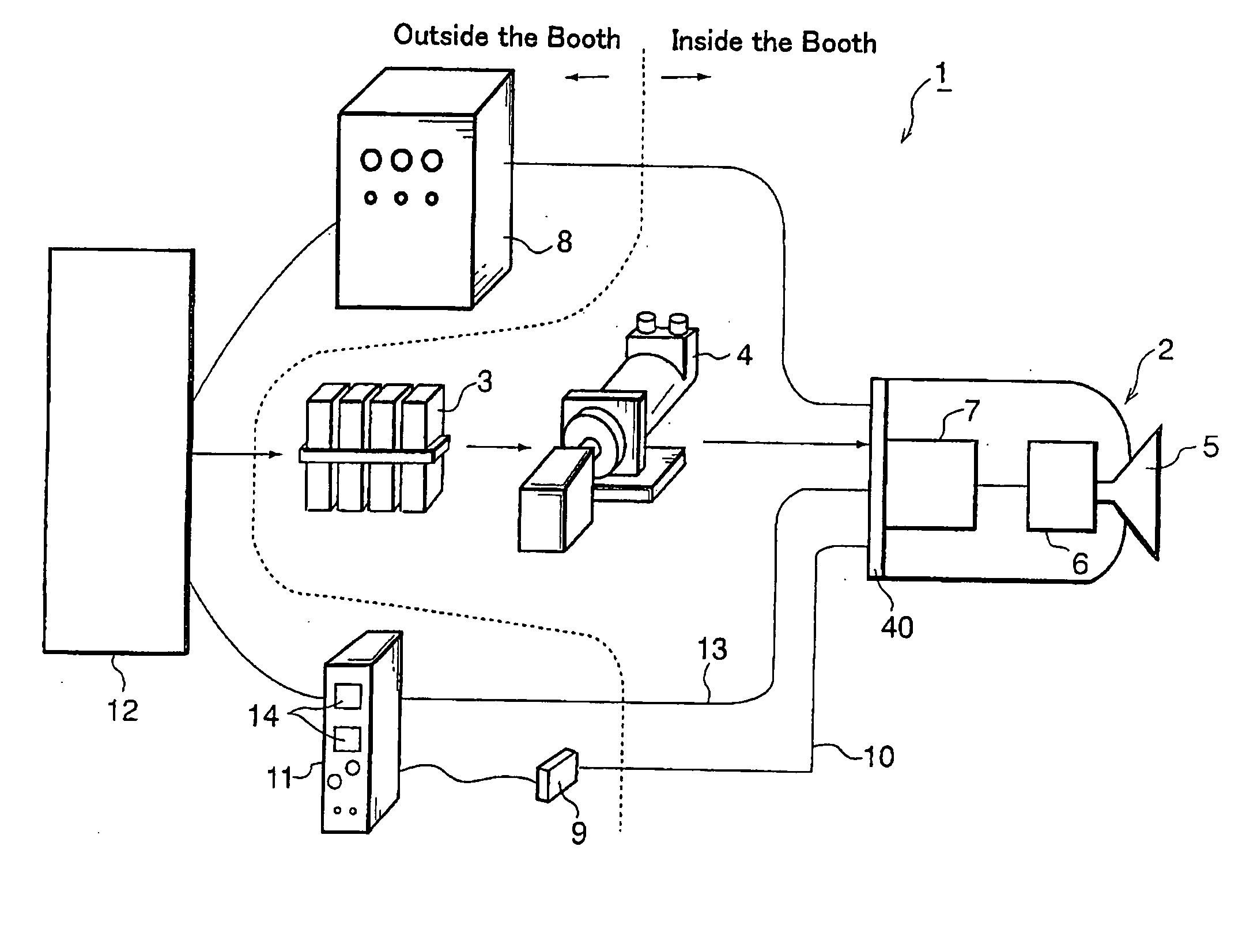

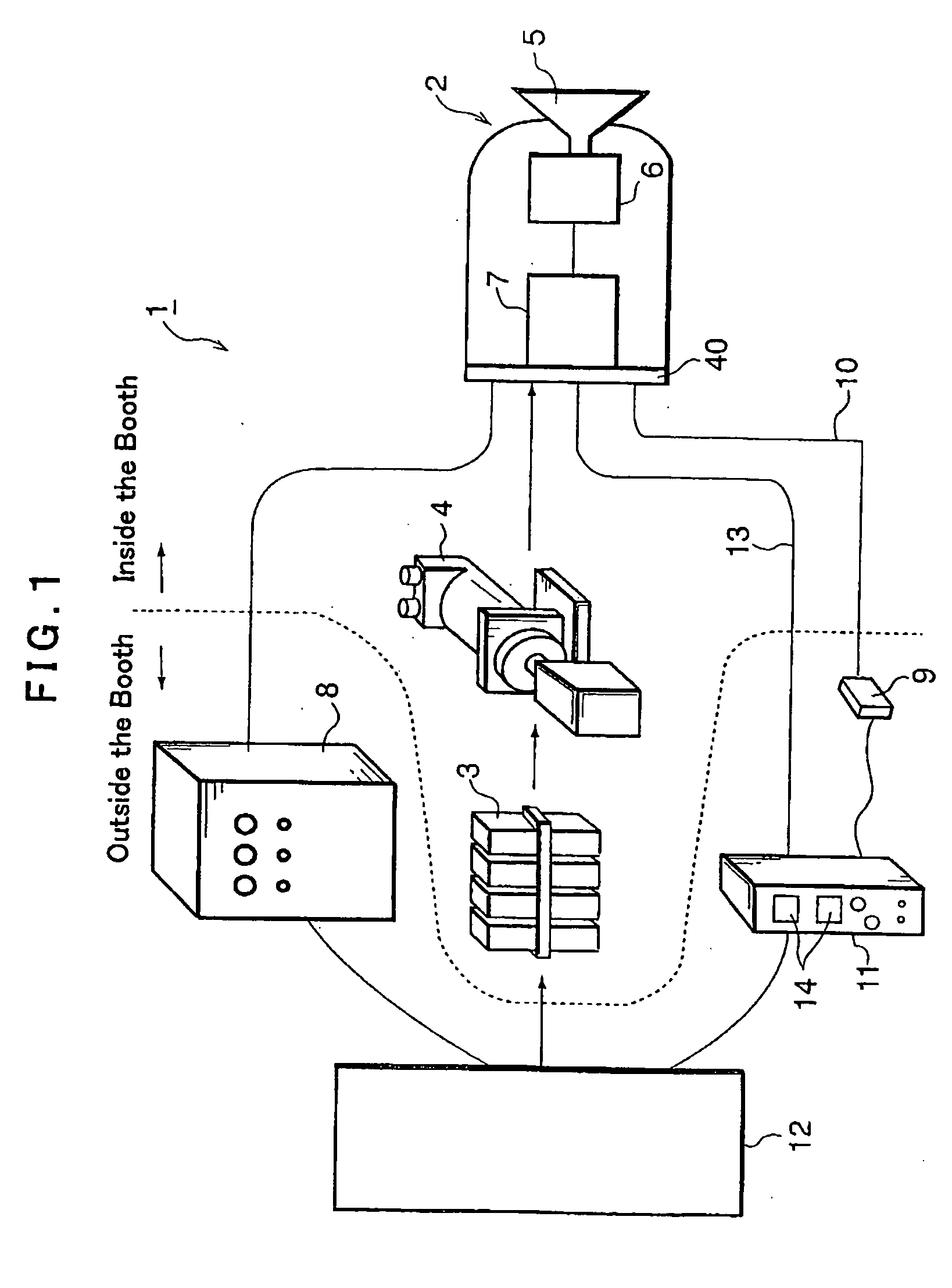

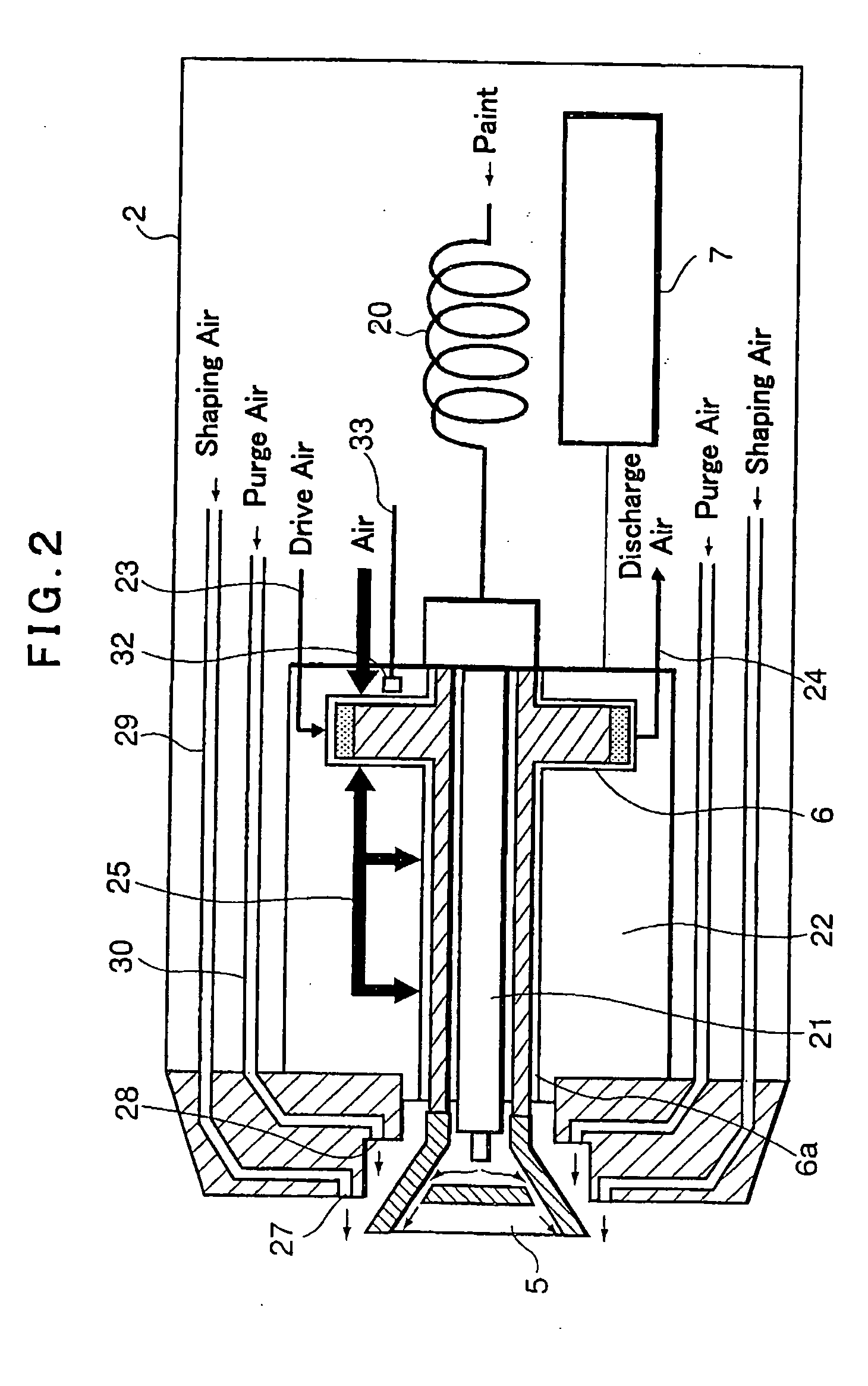

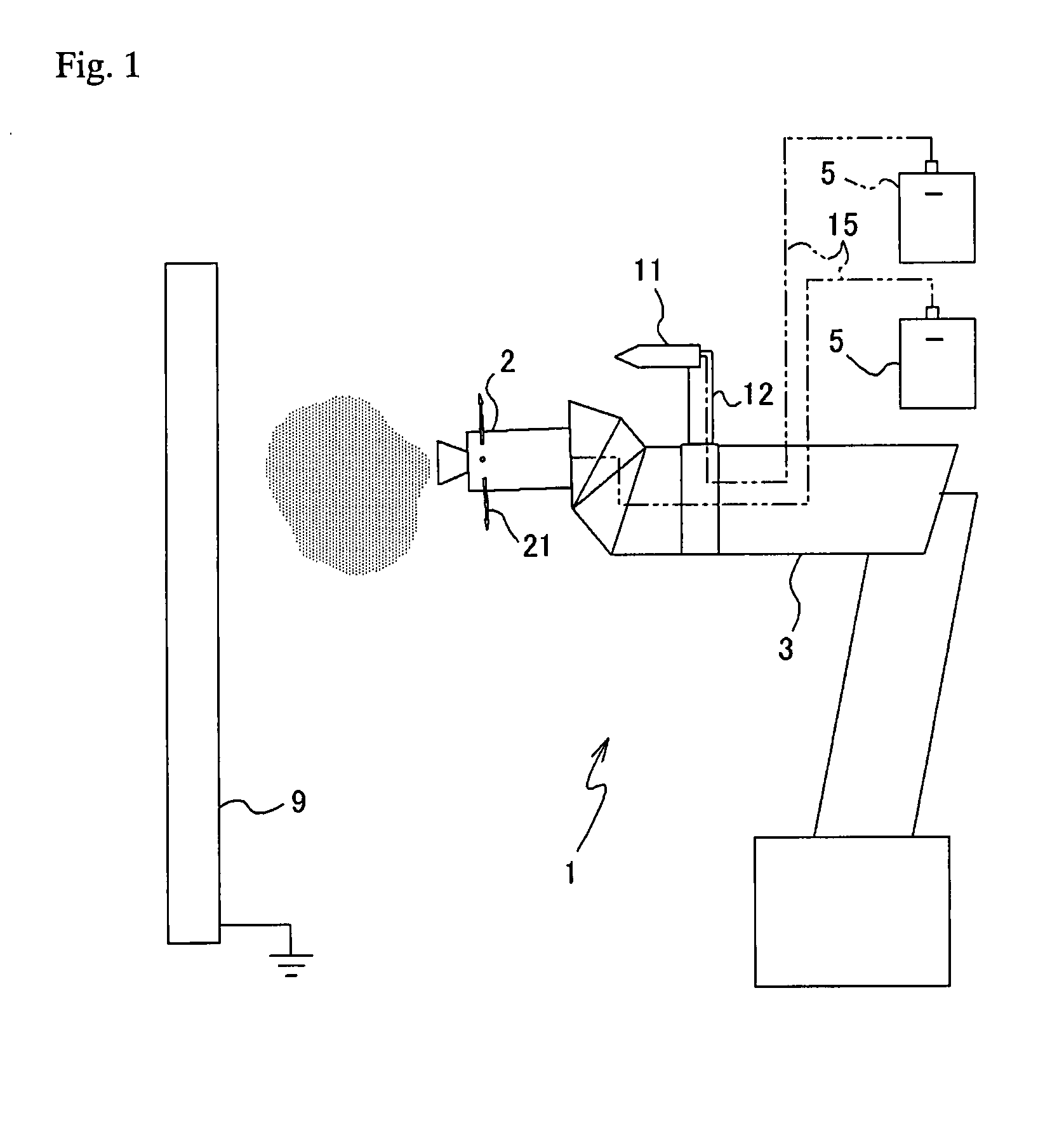

Electrostatic coating system

ActiveUS20050040262A1Guaranteed uptimeEasy to controlBurnersLiquid spraying plantsElectrostatic coatingTotal current

Total supplied current (I2) and high voltage (Vm) supplied to a rotary atomizer head (5) are detected by a total current sensor (115) and a high voltage sensor (116). Total leak current (I2) in paint paths, thinner paths and air paths inside an electrostatic atomizer (2) is detected via a metal back plate (40) of the electrostatic atomizer (2). When the total leak current value (I2) exceeds a threshold value (Ia), the level Vm of the high voltage applied to the rotary atomizer head (5) is lowered stepwise.

Owner:CARLISLE FLUID TECH RANSBURG JAPAN KK

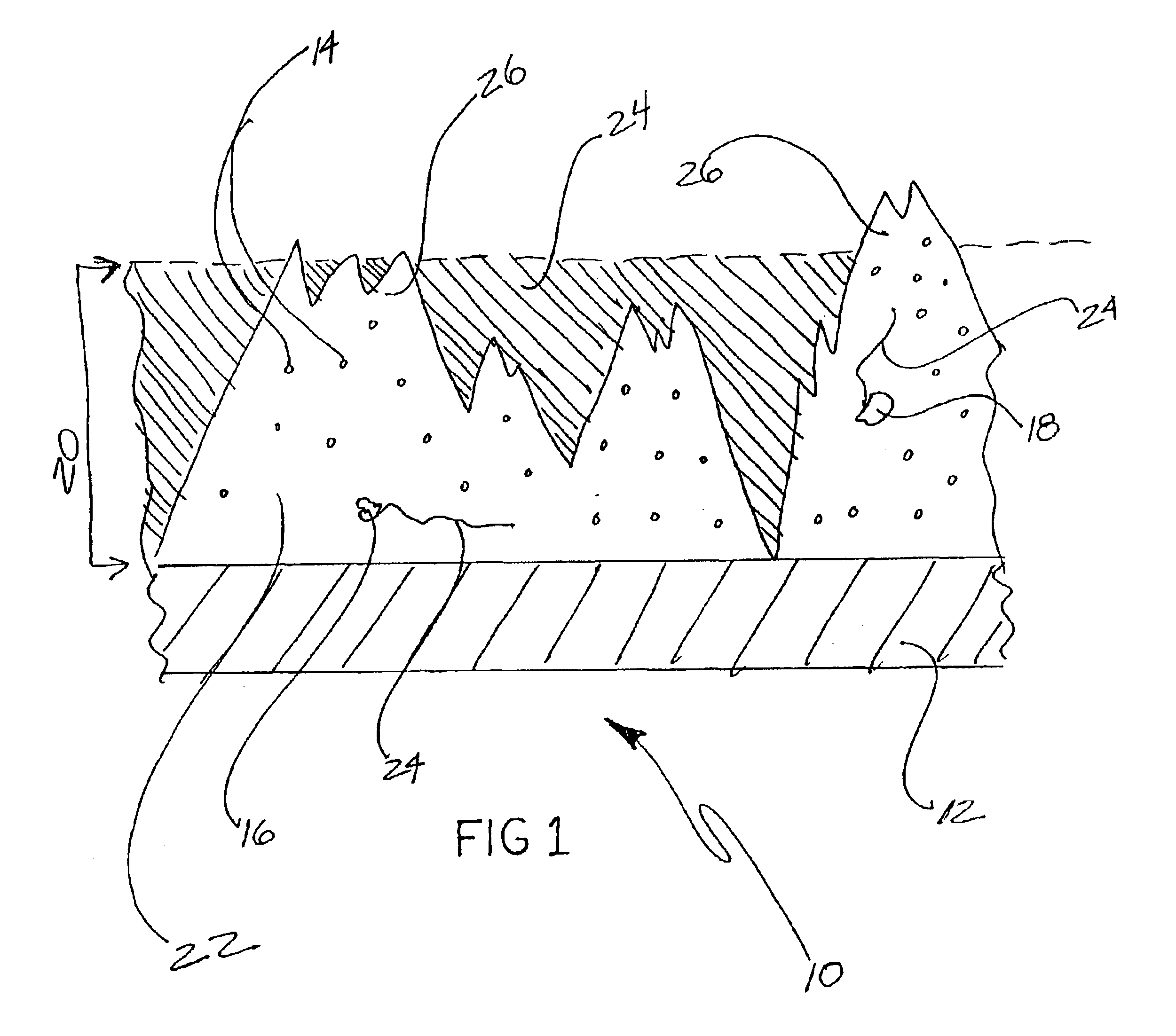

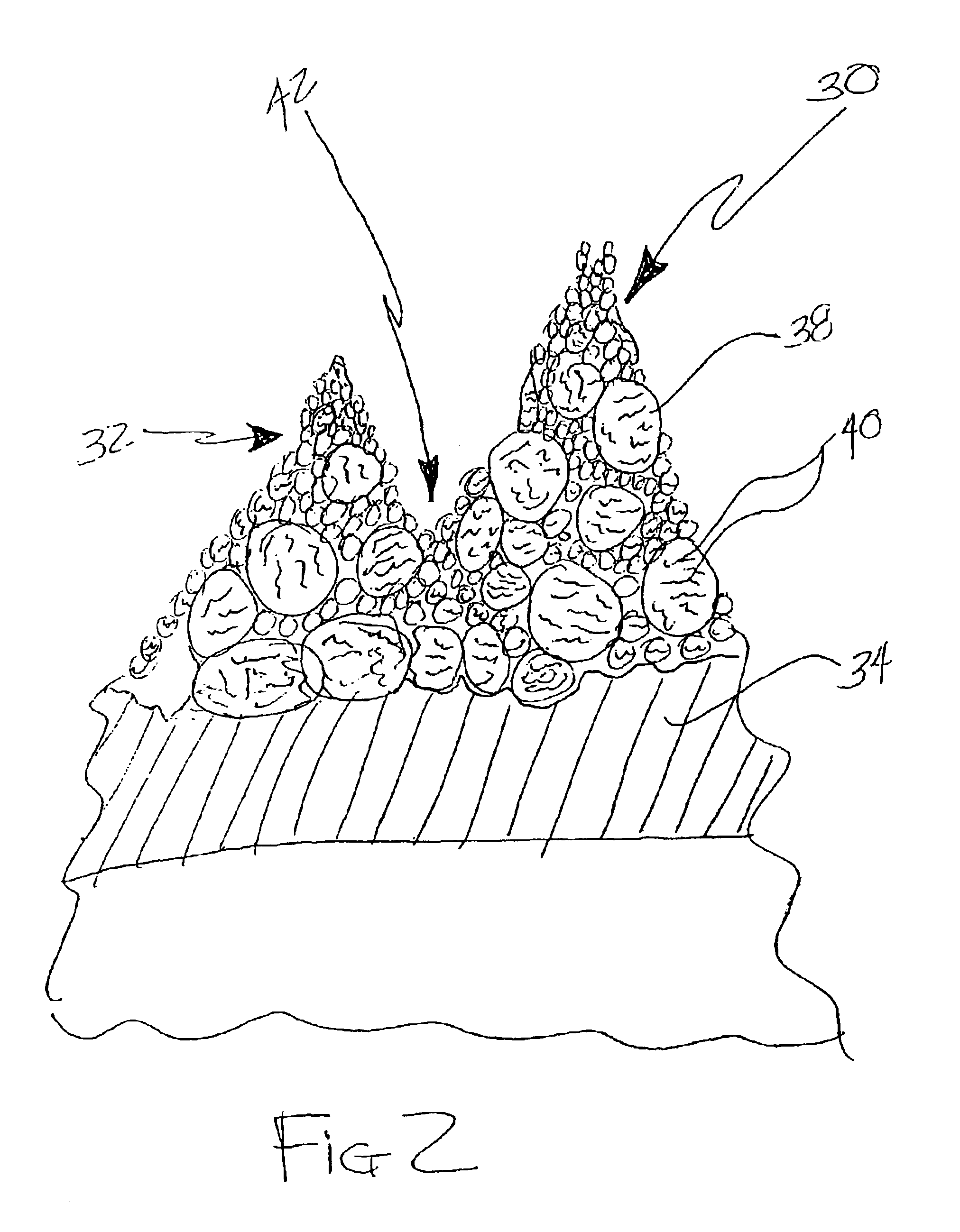

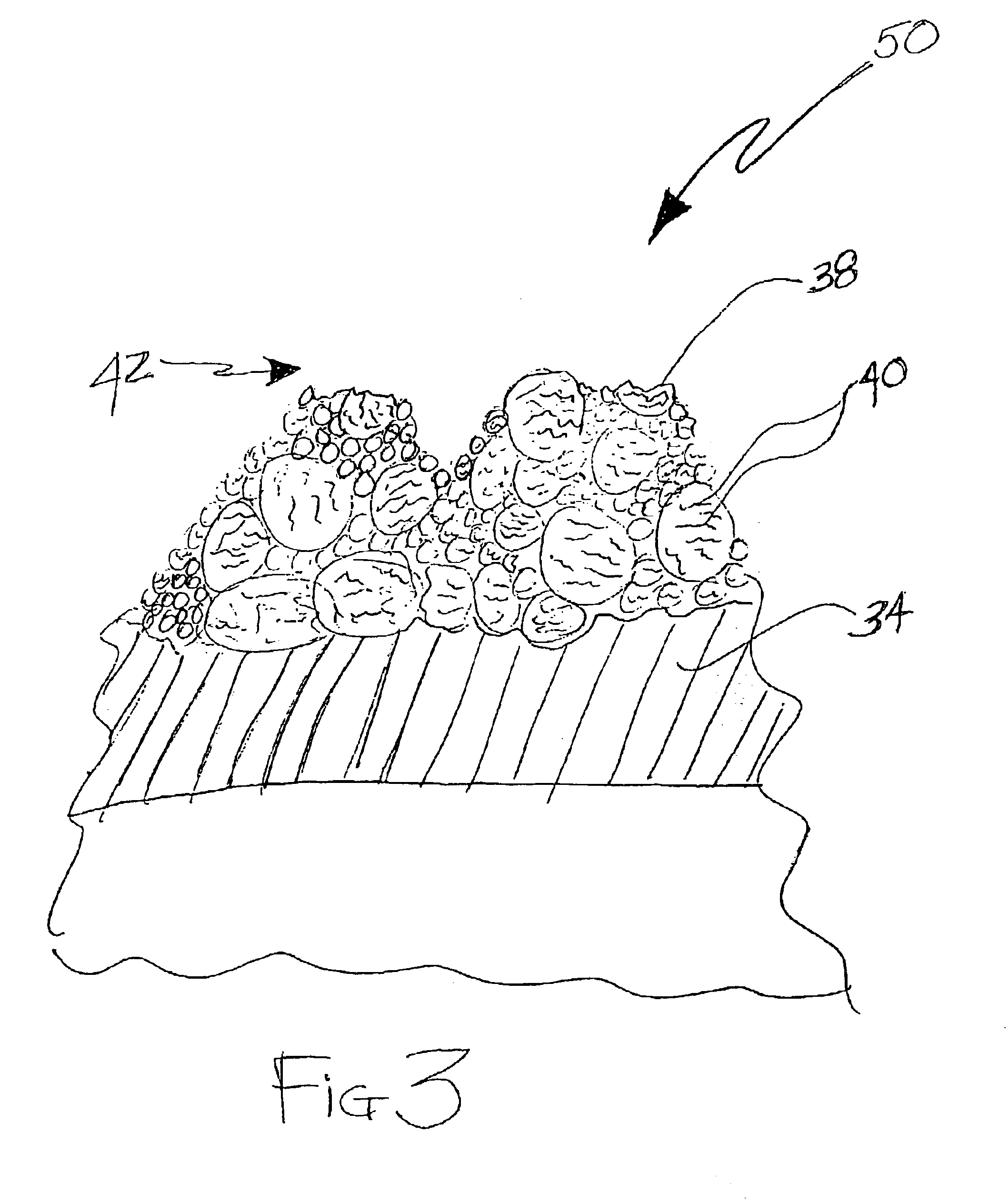

Abradable dry powder coatings, methods for making and coating, and coated articles therefrom

InactiveUS6844392B2Easy to appreciateNon-fibrous pulp additionEngine sealsElectrostatic coatingPolyresin

An abradable dry powder coating (22) composition for coating onto a surface (12) for subsequent curing to form into an abradable coating, including a powder (16) formed of uncured thermoset resin with at least 15 volume percent filler, wherein the filler does not substantially melt below the cure temperature of the resin. Method for making the coating composition includes melt-mixing the thermoset resin with at least 15 volume percent of filler, cooling the resulting mass composite, and then breaking the cooled mass composite into powder particles (16). Method of coating an article with an abradable coating includes applying the dry composite powder with the filler therein onto a substrate and curing the dry powder composition, preferably by electrostatic coating. An article is also disclosed which is coated with the abradable coating.

Owner:LINE 2 LINE INC

Powder coating capable of being thin coated and preparation process thereof

InactiveCN101519546AImprove surface propertiesGood hiding powerPolyurea/polyurethane coatingsPowdery paintsFirming agentElectrostatic coating

The invention discloses a powder coating capable of being thin coated and a preparation process thereof. The powder coating comprises 50 to 95 weight parts of binder, 0 to 2 weight parts of dispersed flowing control agent, 0 to 3 weight parts of addition agent, 0 to 45 weight parts of tinting pigment and 0 to 20 weight parts of filling, and the binder is the gross of resin and a relative firming agent. The preparation process comprises a mixing working procedure, a melting extrusion working procedure, a finely pulverizing working procedure, a fine powder removing working procedure and a screening working procedure. Compared with the prior art, the high surface property powder coating capable of being thin coated can be prepared by the selection of the binder and the dispersed flowing control agent and the easy and practical production process, not only can obtain a neat smooth high-performance coating with the surface thickness of 40 microns to 50 microns and good color covering power, but also is beneficial to the electrostatic coating of working pieces.

Owner:黄山华佳表面科技有限公司

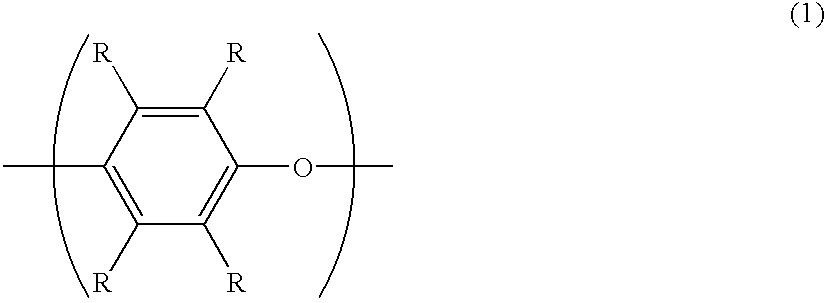

Electrically conductive resin composition and production process thereof

InactiveUS6919394B2Reduction factorExcellent surface appearanceNanotechSpecial tyresPolyamideElectrostatic coating

An electrically conductive resin composition comprising a polyamide, a polyphenylene ether, an impact modifier and an electrically conductive filler, not less than 50 wt. % of all of the filler used being preliminarily compounded with a mixture containing the impact modifier and the polyphenylene ether, wherein electrical conductivity having a level in which electrostatic coating is possible, a low coefficient of linear expansion and high surface appearance have been accomplished at the same time, and wherein generation of fines caused by pelletizing on extruding has been suppressed.

Owner:ASAHI KASEI KK

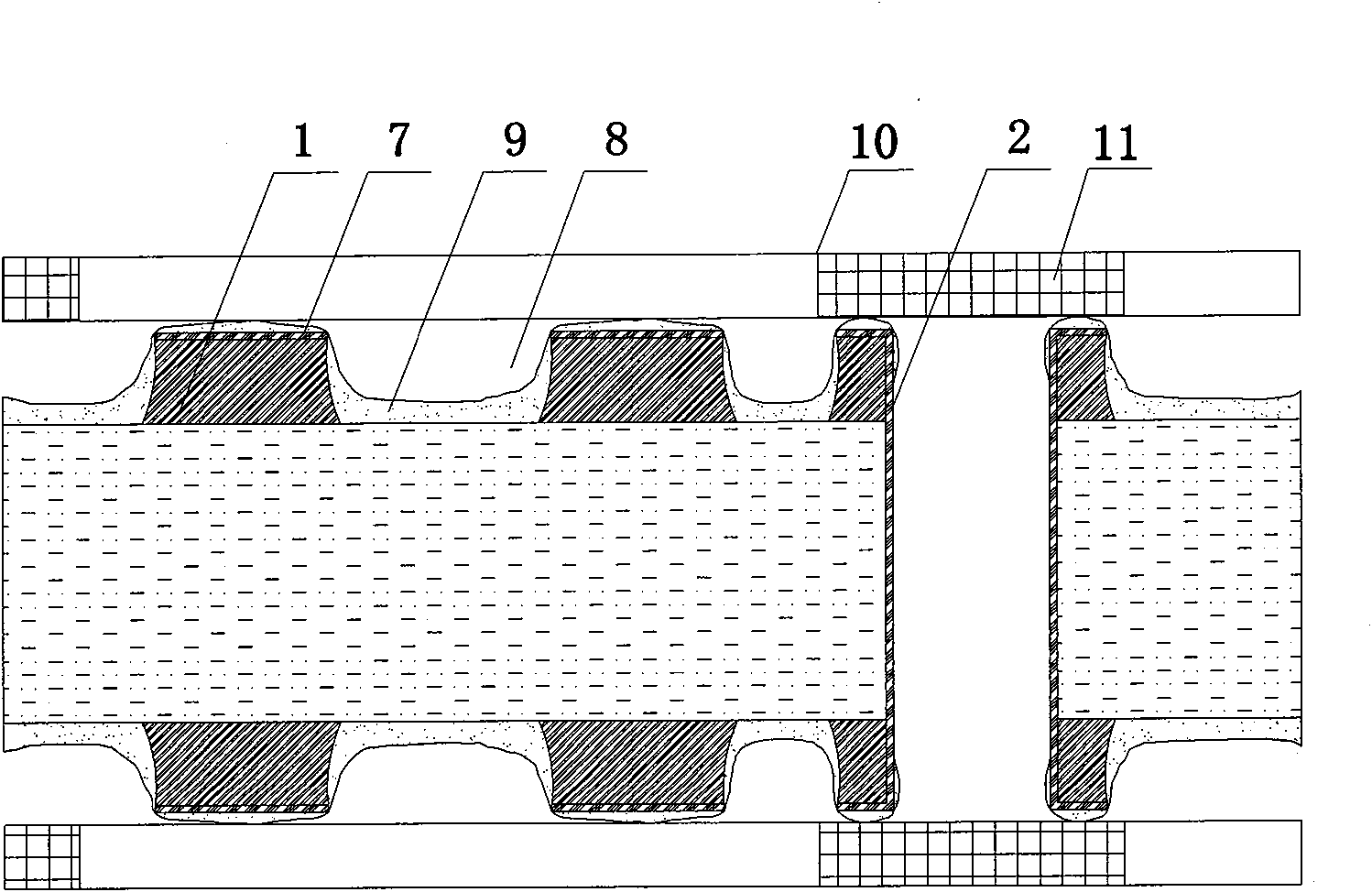

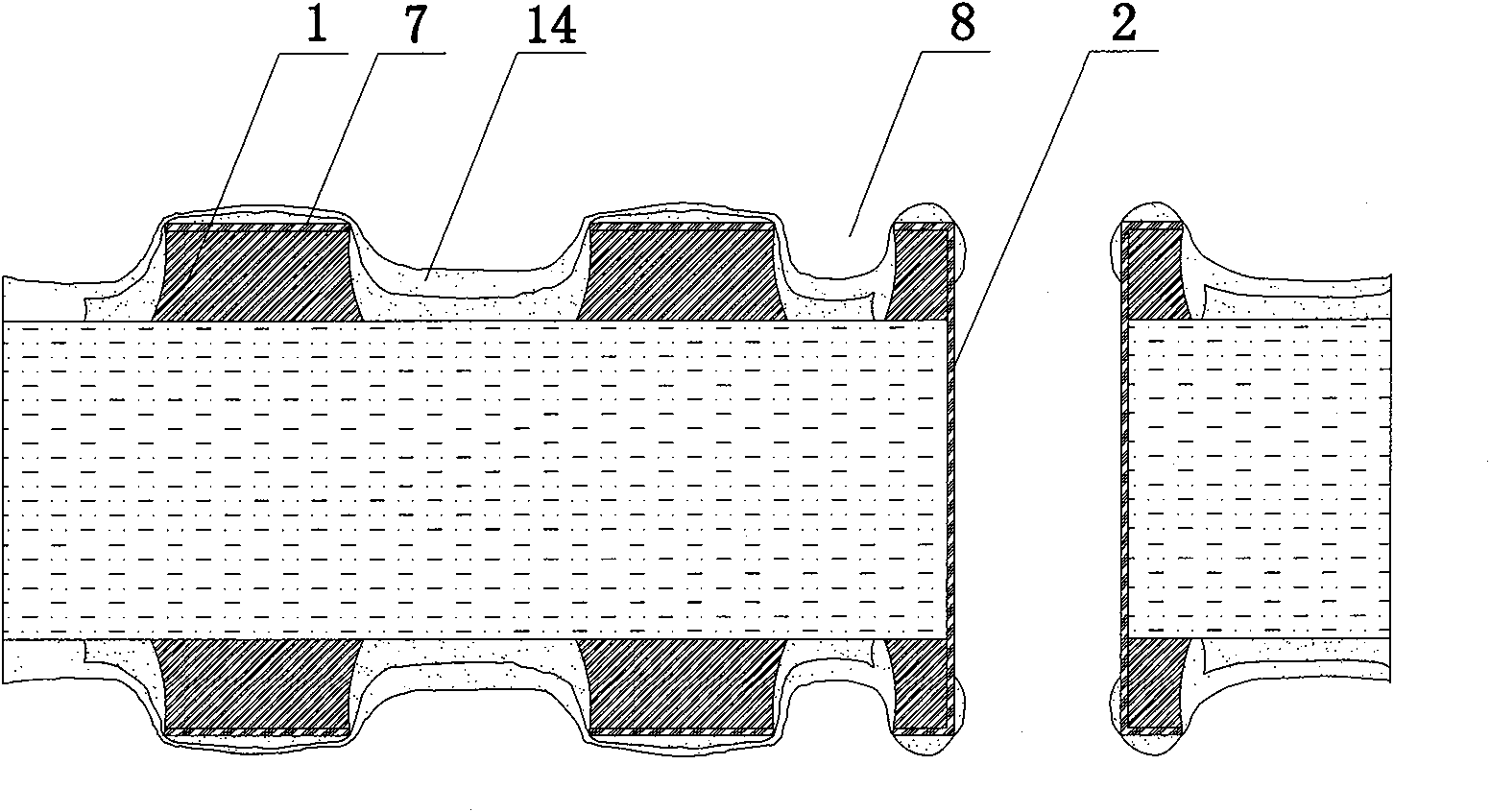

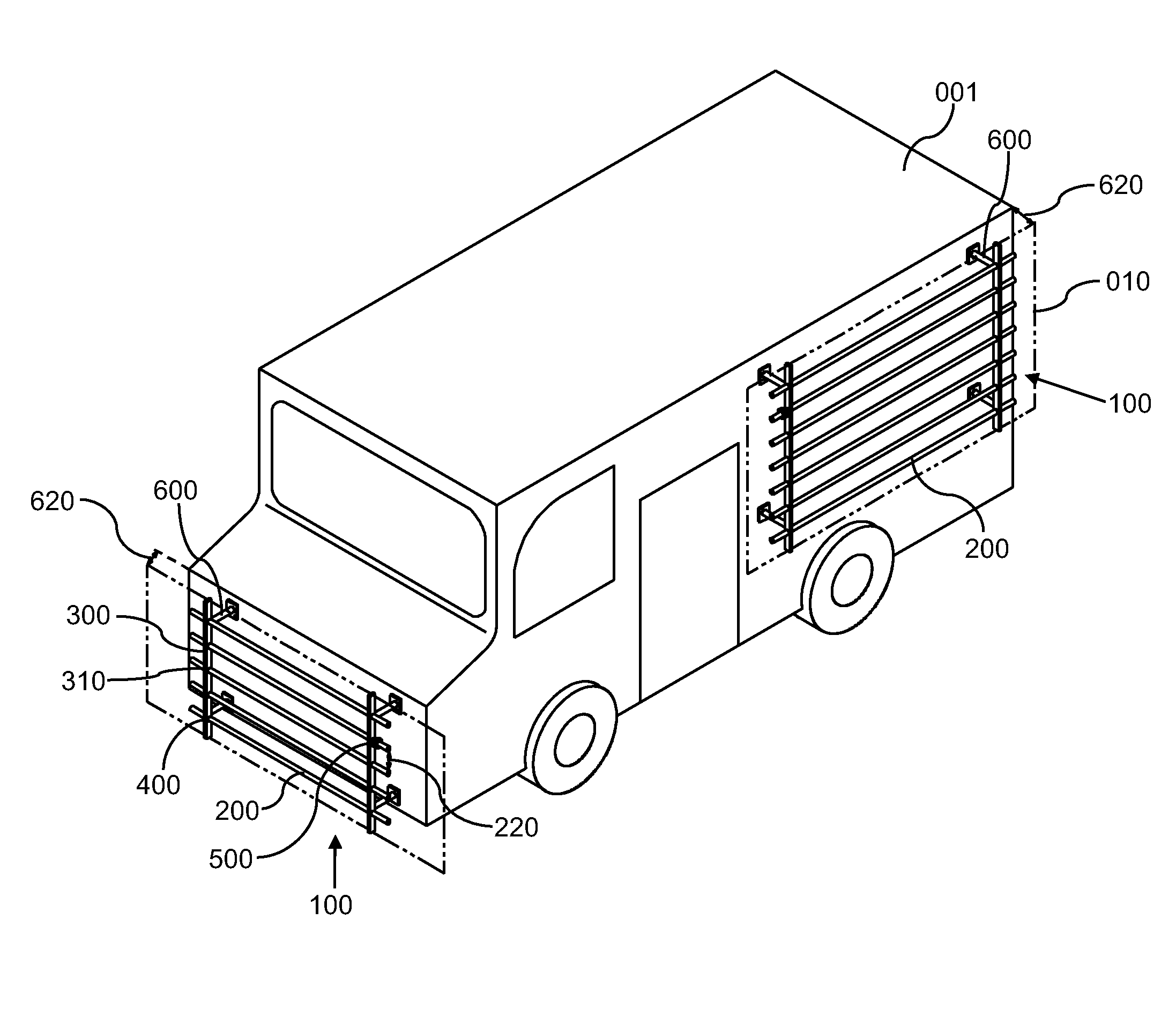

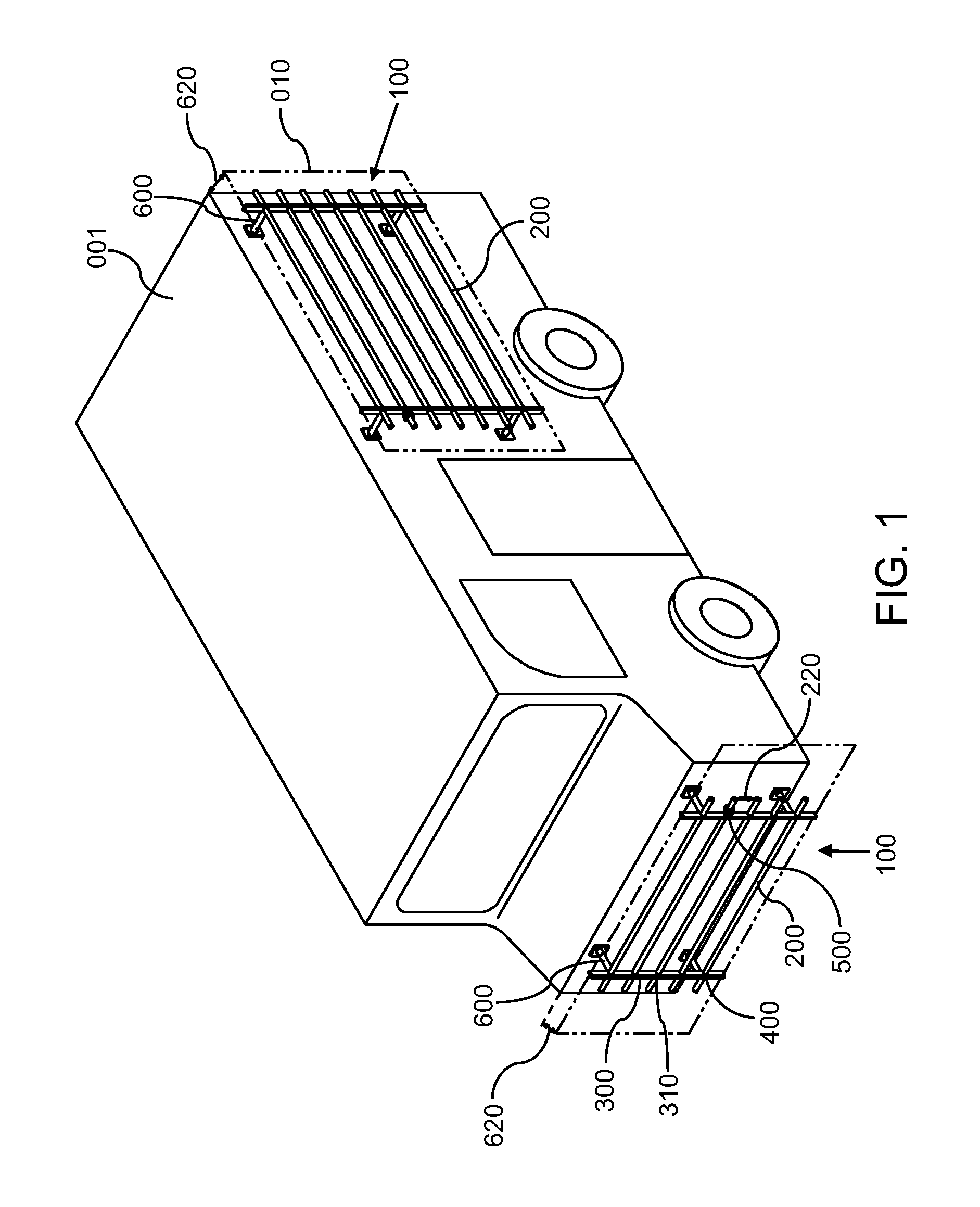

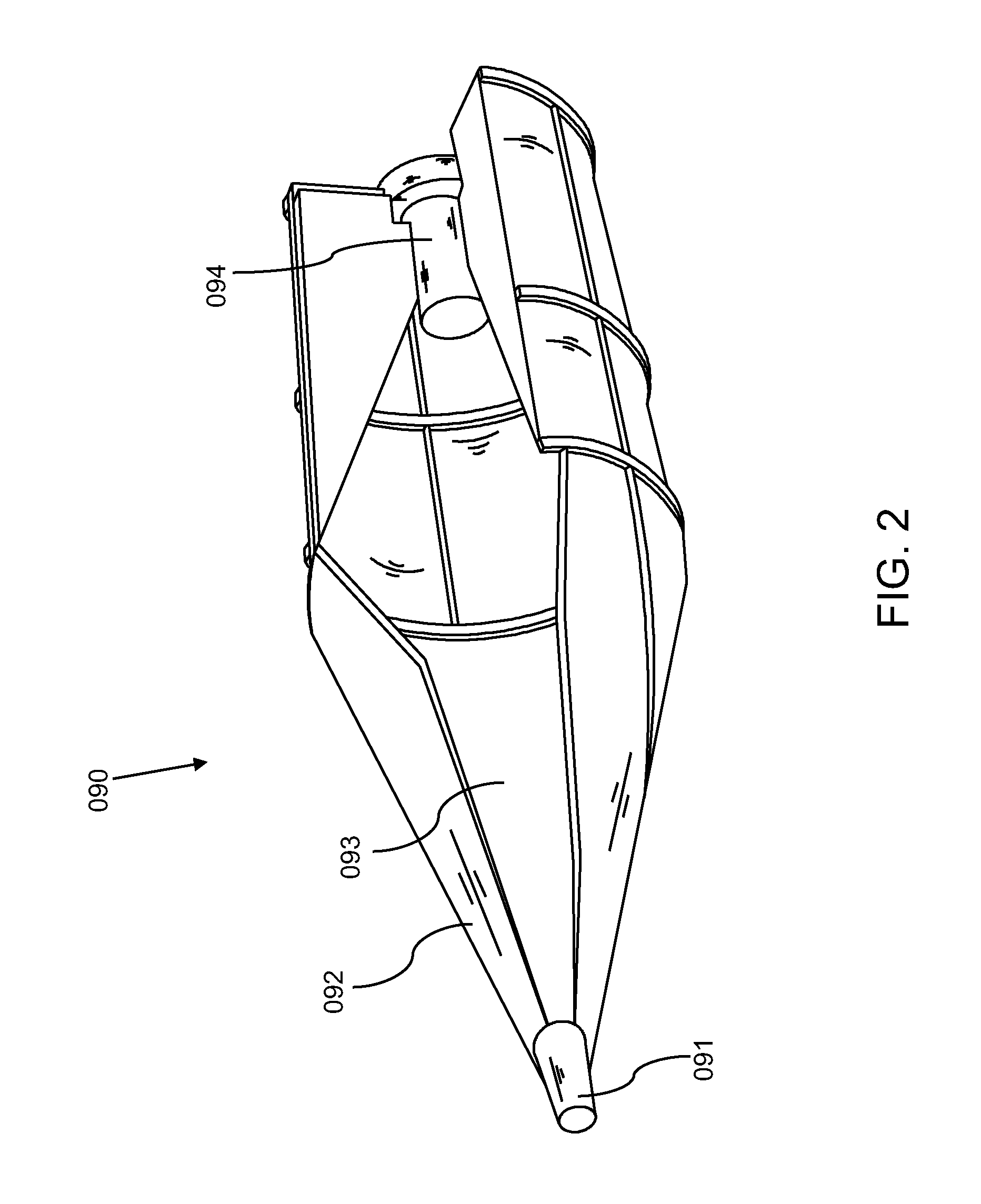

Bar armor system for protecting against rocket-propelled grenades

InactiveUS20110232472A1Optimize geometryInhibition of translationArmourArmoured vehiclesVertical barShaped charge

A bar armor system is provided for reducing damage caused by RPGs launched towards a vehicle. The bar armor system includes at least one bar array, comprised of lateral bars and vertical bars, wherein the lateral bars are set in predetermined positions so as to reduce the possibility of shaped charges being directed towards the target vehicle. Tubular shaft retainers are provided to be positioned in annular openings in the vertical bars. The lateral bars can be of a round or hexagonal cross-section, and when hexagonal lateral bars are employed, the flat surfaces of the cross-section are positioned horizontally by the tubular shaft retainers so as to minimize the area presented to an oncoming RPG, particularly when the RPG strikes at a non-normal incidence. Push washers can be employed at the outside surfaces of the vertical bars so as to hold them in position. A mounting system is provided that is capable of positioning the bar armor system at close distances to the vehicle so that the overall size and weight of the vehicle is not unduly increased by the bar armor system. The mounts can include rotary latches to provide easy installation and removal. The system can also be of an electrically-conductive unified composition so that efficient electrostatic coating techniques can be used to cover the system. The system can also be provided in the form of kits for ready installation and for more economical repair.

Owner:GENERAL ATOMICS

Flake pigment, powder paint containing the same, powder-coated film obtained by coating with the powder paint using triboelectrification electrostatic coating apparatus, painted product on which film is formed, and method of manufacturing flake pigment

ActiveUS20110008613A1Good metal effectSerious disadvantageFibre treatmentSynthetic resin layered productsPhosphateElectrostatic coating

A flake pigment according to the present invention includes a flake particle, a single-layer or multiple-layer coat covering a surface of the flake particle, and a fine particle. An outermost layer of the coat includes a copolymer including one or more type of first bond unit originating from a fluoric polymerizable monomer having fluorine and one or more type of second bond unit originating from a polymerizable monomer having phosphate group. The fine particle is fixed with the outermost layer being interposed and has a characteristic to provide triboelectrification characteristics to the flake pigment.

Owner:TOYO ALUMINIUM KK

Electrostatic conductive coating

ActiveCN105440879AGood static conductivityHigh strengthEpoxy resin coatingsElectrically-conductive paintsElectrostatic coatingMetal fibers

The invention discloses an electrostatic conductive coating, and belongs to the field of coatings. The electrostatic conductive coating comprises the following components by weight: 25-85% of high-molecular resin, 0.1-60% of an electrostatic conductive filling material, 1-60% of a solvent, and 10-50% of a curing agent; the electrostatic conductive filling material comprises at least one kind of material, which is selected from metal fibers including copper, aluminium, zinc, iron, silver, lead, titanium and magnesium. The metal fiber forms a conductive network, which is used for improving electrostatic conduction performance of the electrostatic conductive coating, and the conductive network can be used as reinforcement for enhancing strength of the electrostatic conductive coating, so that strength, toughness, compactness and wear resistance of the electrostatic conductive coating are improved. Cooperative complex formulation between components for preparing the electrostatic conductive coating is effected, so that an electrostatic conductive anticorrosion coating with high strength and high toughness is formed by the electrostatic conductive coating which is provided by the embodiment.

Owner:BC P INC CHINA NAT PETROLEUM CORP

Implantable medical leads and devices having carbon nanotube-based anti-electrostatic coatings and methods for making such leads and devices

InactiveUS7551967B1Good dispersionTransvascular endocardial electrodesHeart defibrillatorsElectricityCarbon nanotube

An implantable medical lead for transmitting electrical signals between an implantable medical device and selected body tissue comprises a lead body having a distal end portion, a proximal end and an electrically insulating, elongated housing connecting the distal end portion and the proximal end. The proximal end of the lead body carries an electrical connector assembly adapted to be electrically connected to the implantable medical device and the distal end portion of the lead body carries at least one electrode electrically coupled to a terminal contact on the connector assembly. The lead comprises at least one surface susceptible during use of the lead to the accumulation of electrostatic charges, the at least one surface having a coating comprising carbon nanotubes.

Owner:PACESETTER INC

Method for directly preparing metal oxide/silver nanowire composite conductive network

InactiveCN104575864AHigh mechanical strengthHigh visible light transmittanceCable/conductor manufactureOxygen plasmaElectrostatic coating

The invention relates to a method for directly preparing a metal oxide / silver nanowire composite conductive network, belongs to the technical field of transparent conductive thin films and anti-static coating layers, and aims to solve the technical problem that the technology for preparing a silver nanowire / inorganic metal oxide composite conductive thin film by two steps in the prior art is complicated. The method comprises the following steps: preparing a soluble metal oxide precursor solution; mixing the prepared metal oxide precursor solution with dispersion liquid of a silver nanowire to obtain soluble metal oxide / silver nanowire mixing dispersion liquid, and forming a film on the upper surface of a substrate by a wet processing technology; finally performing high-temperature annealing, ultraviolet ozone irradiation or oxygen plasma treatment to obtain the metal oxide / silver nanowire composite conductive network. According to the method, the metal oxide / silver nanowire composite conductive network is prepared in one step, so that the preparation technology is greatly simplified, and the production cost is reduced; the prepared composite conductive network is high in mechanical strength, higher in visible light transmittance and lower in square resistivity.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

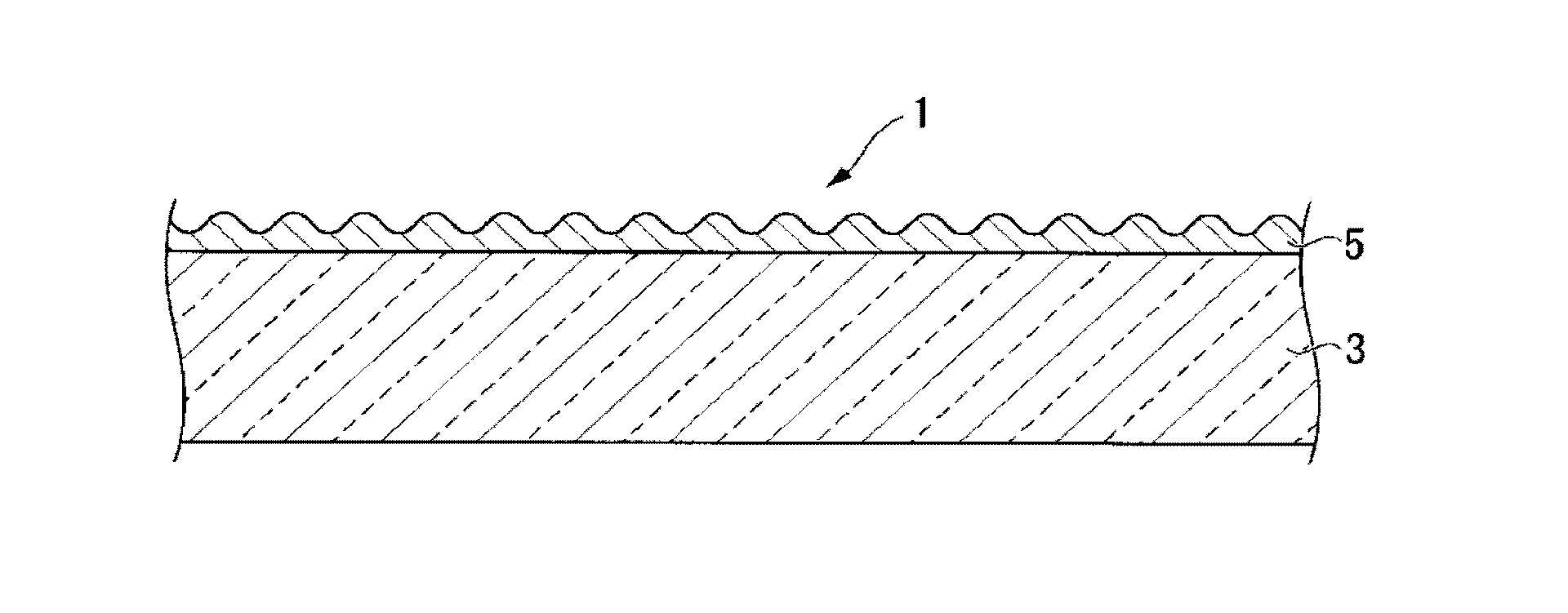

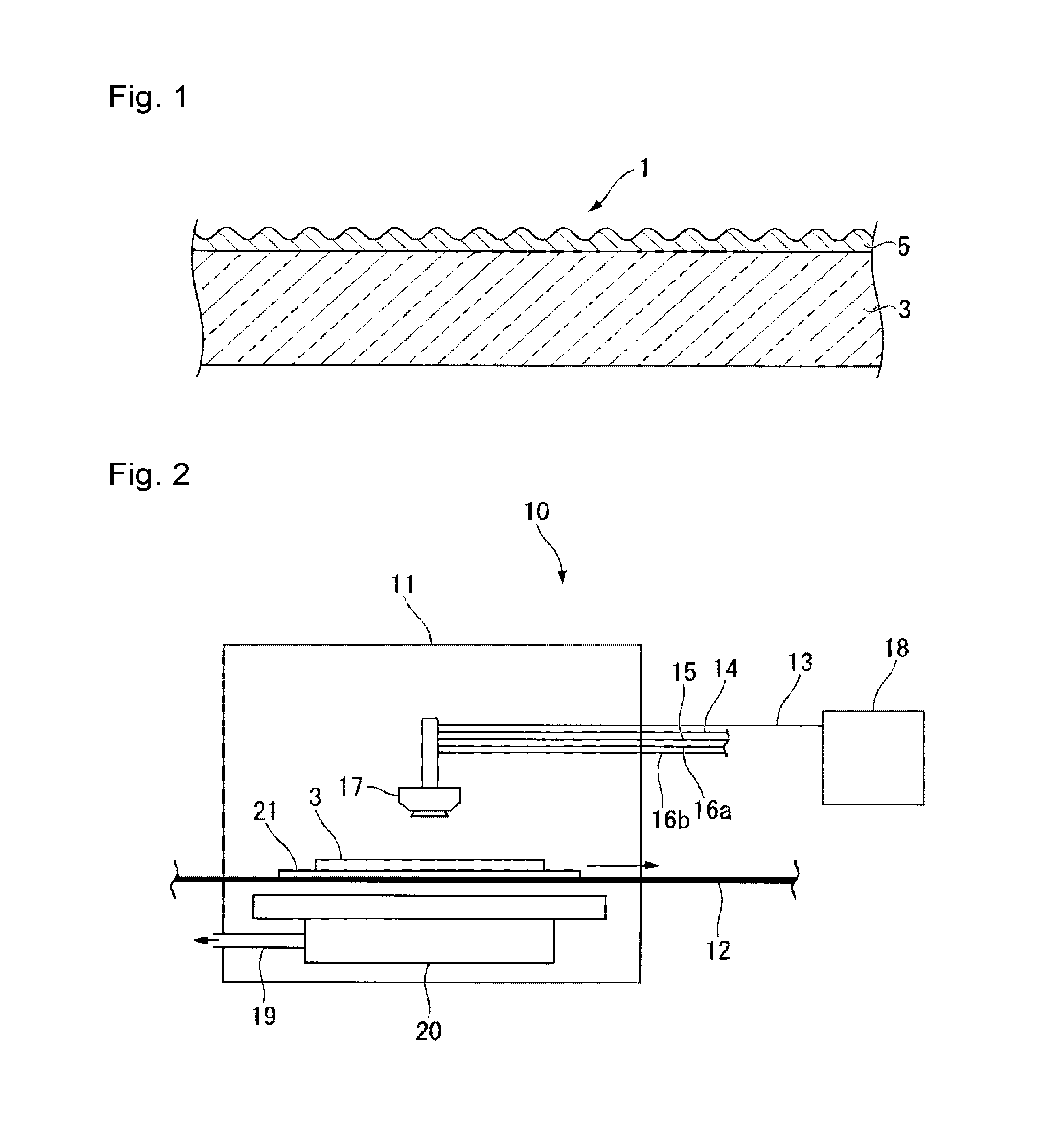

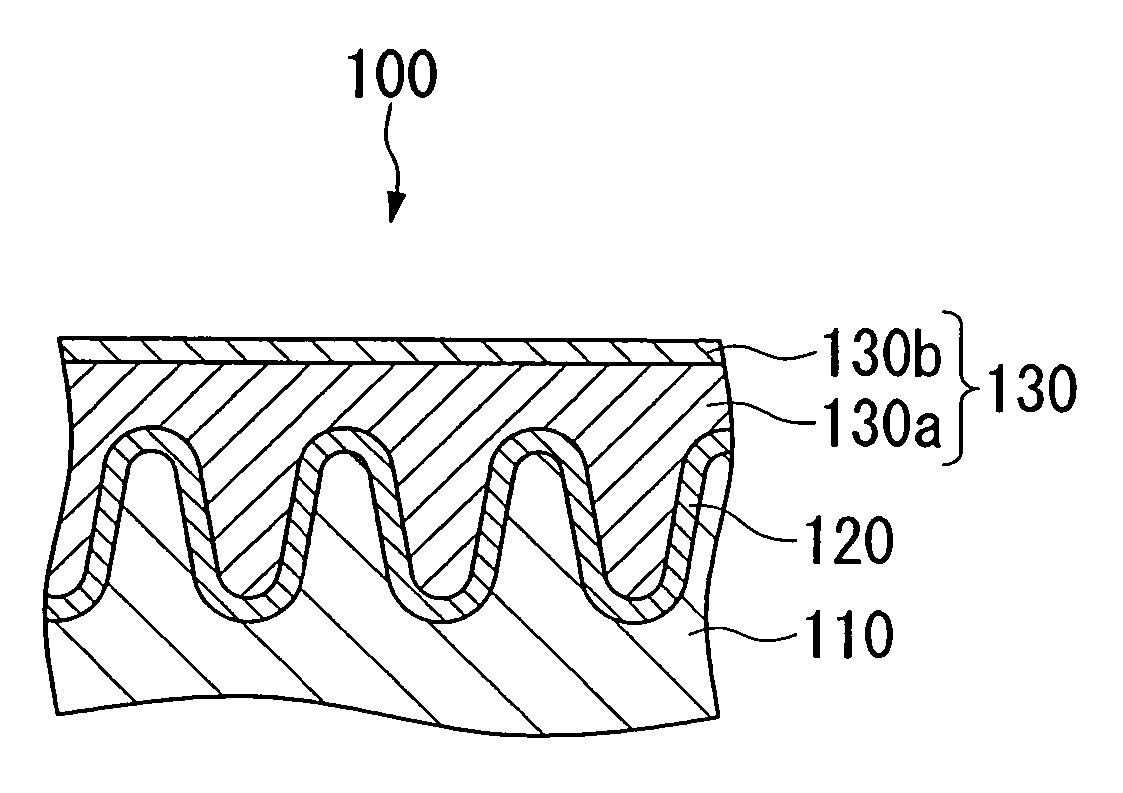

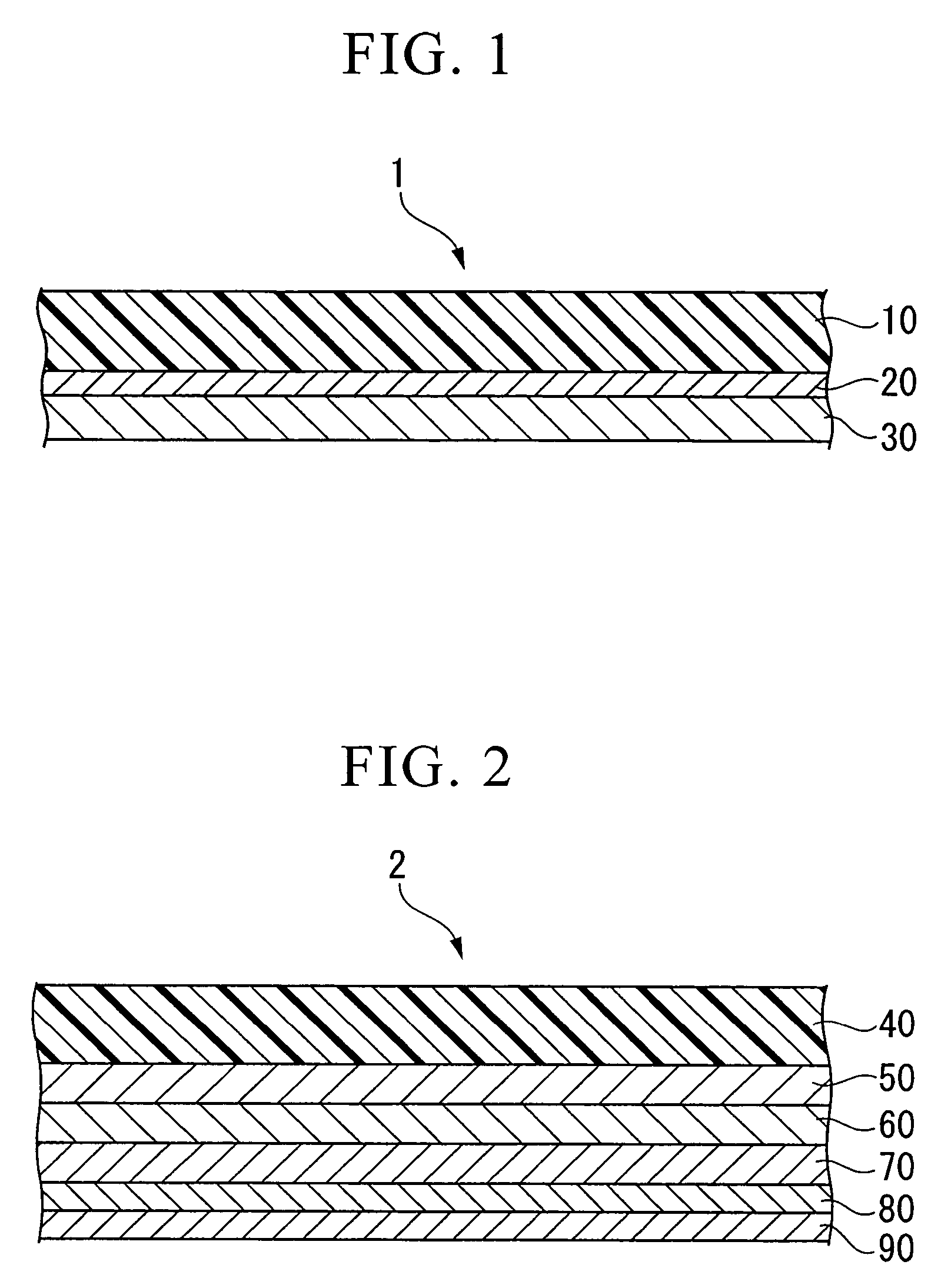

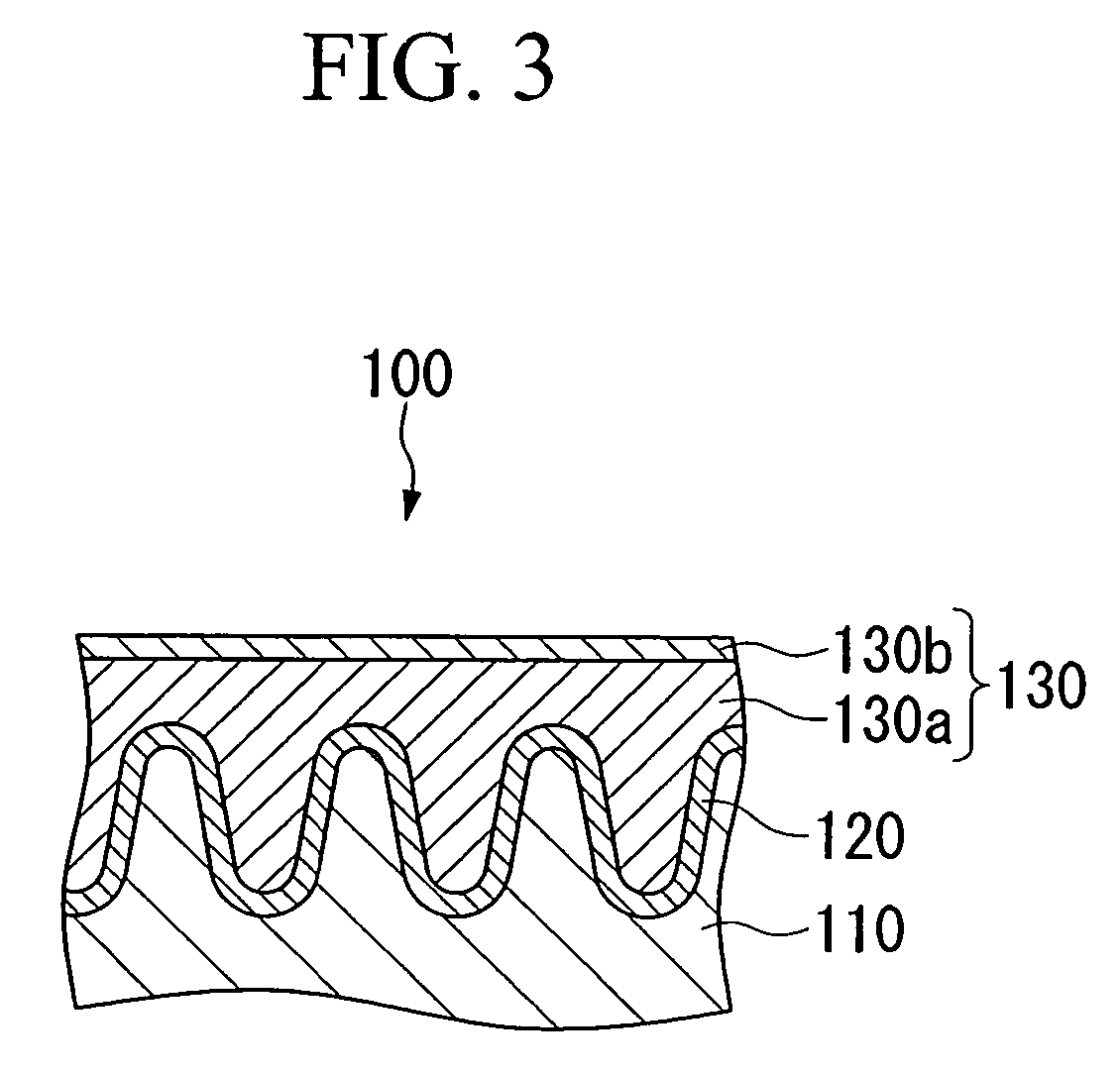

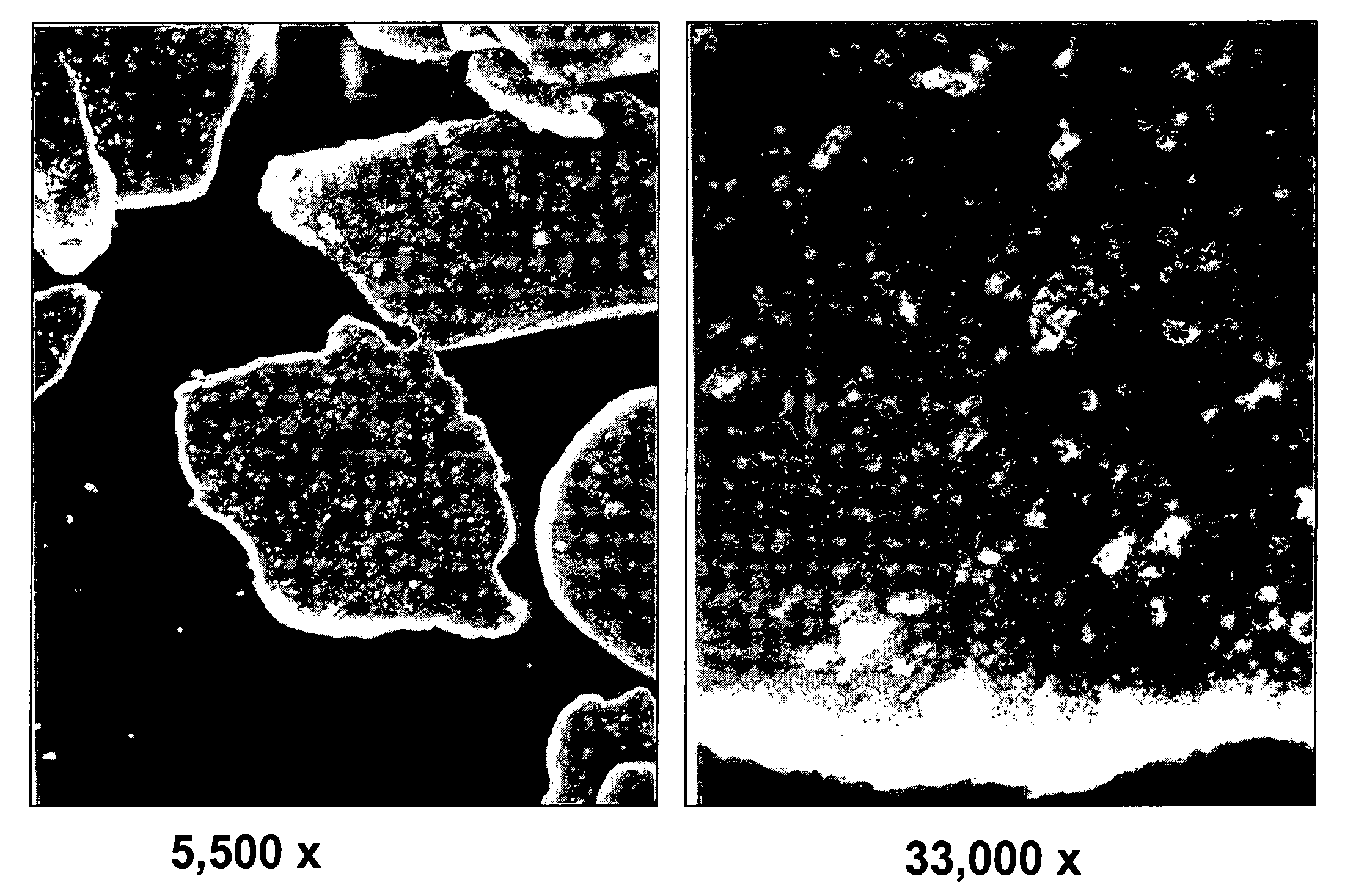

Antiglare film-coated substrate, method for its production, and article

ActiveUS20170021383A1Improve performanceShort timeDiffusing elementsMovable spraying apparatusLiquid mediumBoiling point

To provide a production method capable of producing an antiglare film-coated substrate having excellent antiglare performance in a short time, an antiglare film-coated substrate having excellent antiglare performance, and an article provided with the substrate. A method for producing an antiglare film-coated substrate 1 comprising a substrate 3 and an antiglare film 5 formed on the substrate 3, characterized by comprising a step of preparing a coating composition comprising at least one of a silica precursor (A) and particles (C), and a liquid medium (B), wherein the liquid medium (B) contains a liquid medium (B1) having a boiling point of at most 150° C. in an amount of at least 86 mass % based on the total amount of the liquid medium (B), a step of electrically charging and spraying the coating composition by using an electrostatic coating apparatus having an electrostatic coating gun having a rotary atomizing head, to apply it on the substrate 3 to form a coating film, and a step of firing the coating film to form an antiglare film 5.

Owner:ASAHI GLASS CO LTD

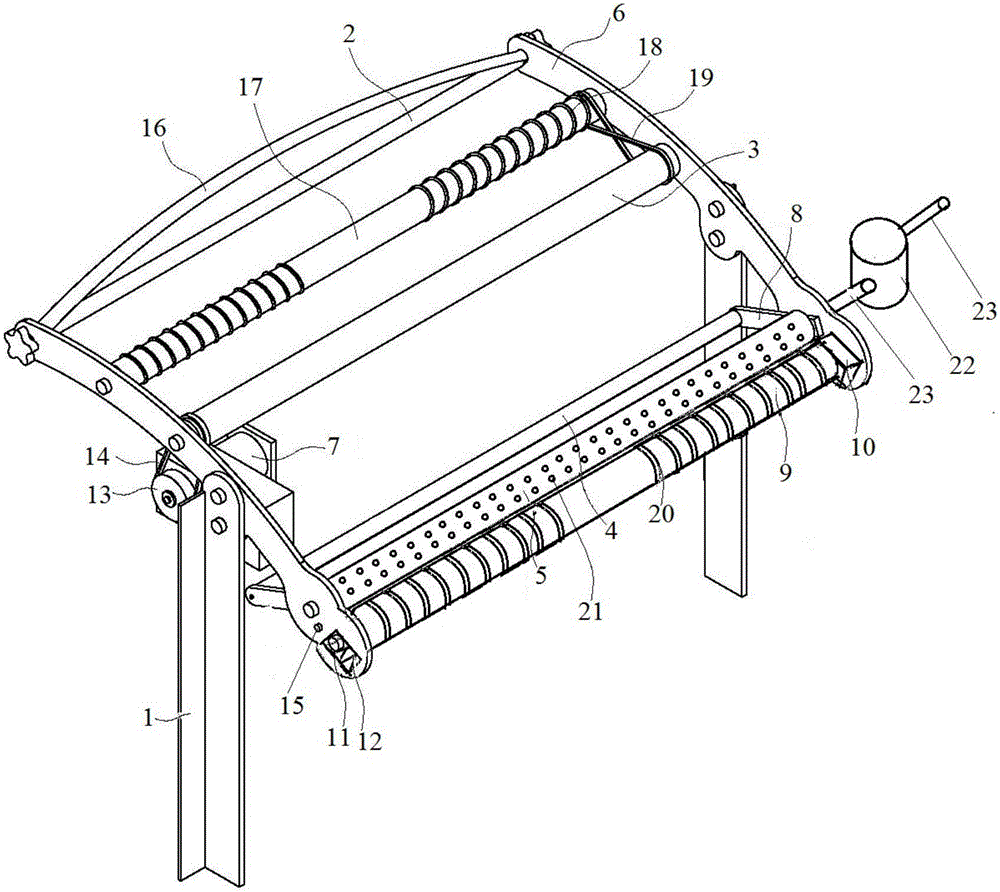

Anti-fold cloth feeding device for cloth spreading machine

InactiveCN106006163ASimple structureEasy to operateUnfolding thin materialsWebs handlingElectrostatic coatingMechanical engineering

The invention relates to an anti-wrinkle cloth feeding device of a spreading machine. The front end of the device is provided with a cloth pressing roller parallel to the cloth discharging roller. The two ends of the cloth pressing roller are embedded in the slider through bearings. The sliding block is slidingly matched with the chute arranged on the end of the cross bar of the frame, and a spring is arranged between the sliding block and the end of the chute; the cloth outlet roller and / or pressing roller are hollow rollers, and the hollow roller There are several ventilation holes evenly arranged on the wall, one end of the hollow roller is provided with a plugging head, and the other end of the hollow roller is connected to the steam source through an air pump and a pipeline; an antistatic coating is provided on the surface of the press roller, and the corresponding cloth passes through The cloth guide roller is driven by the cloth feed roller to convey to the tension roller, and is sent out from between the cloth outlet roller and the cloth pressure roller. The cloth adjusting device of the cloth spreader has the characteristics of relatively simple structure, convenient operation, smooth output cloth, can eliminate static electricity on the cloth surface, and is safe and reliable to use.

Owner:SHAGNHAI YIN SCI&TECH CO LTD

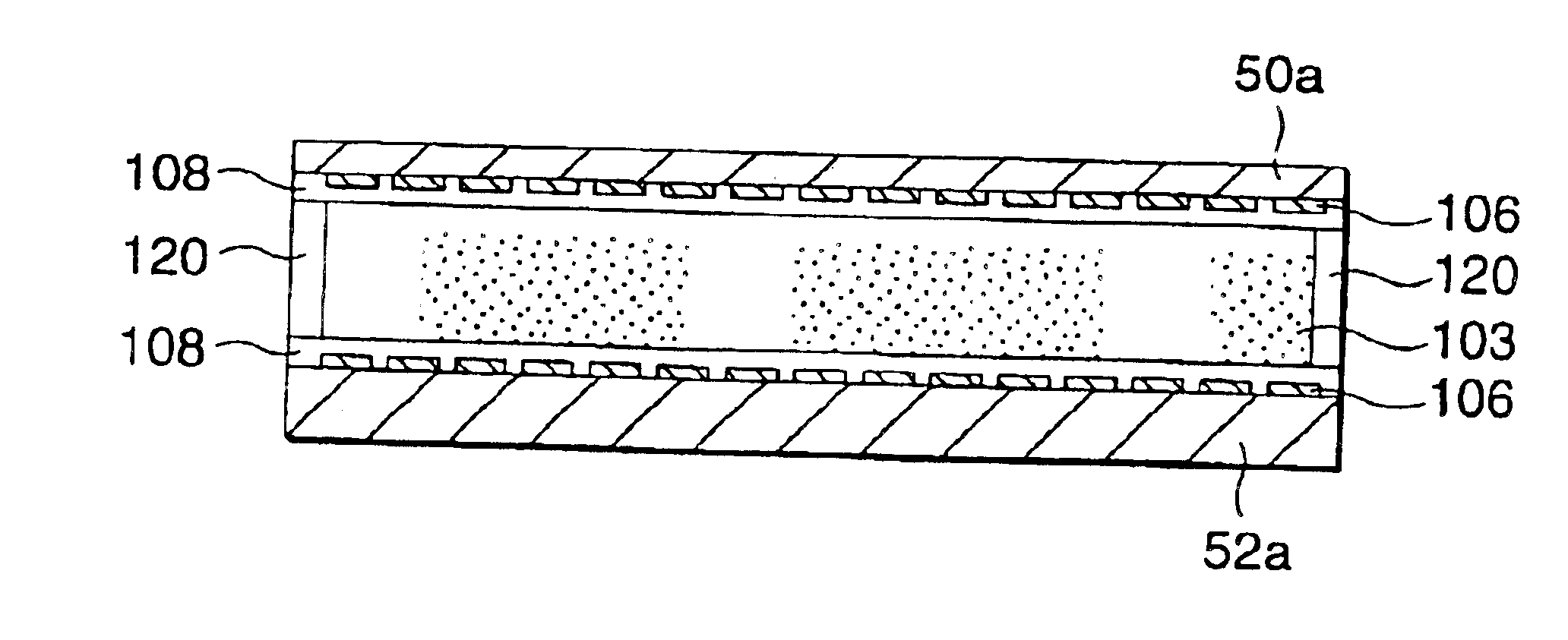

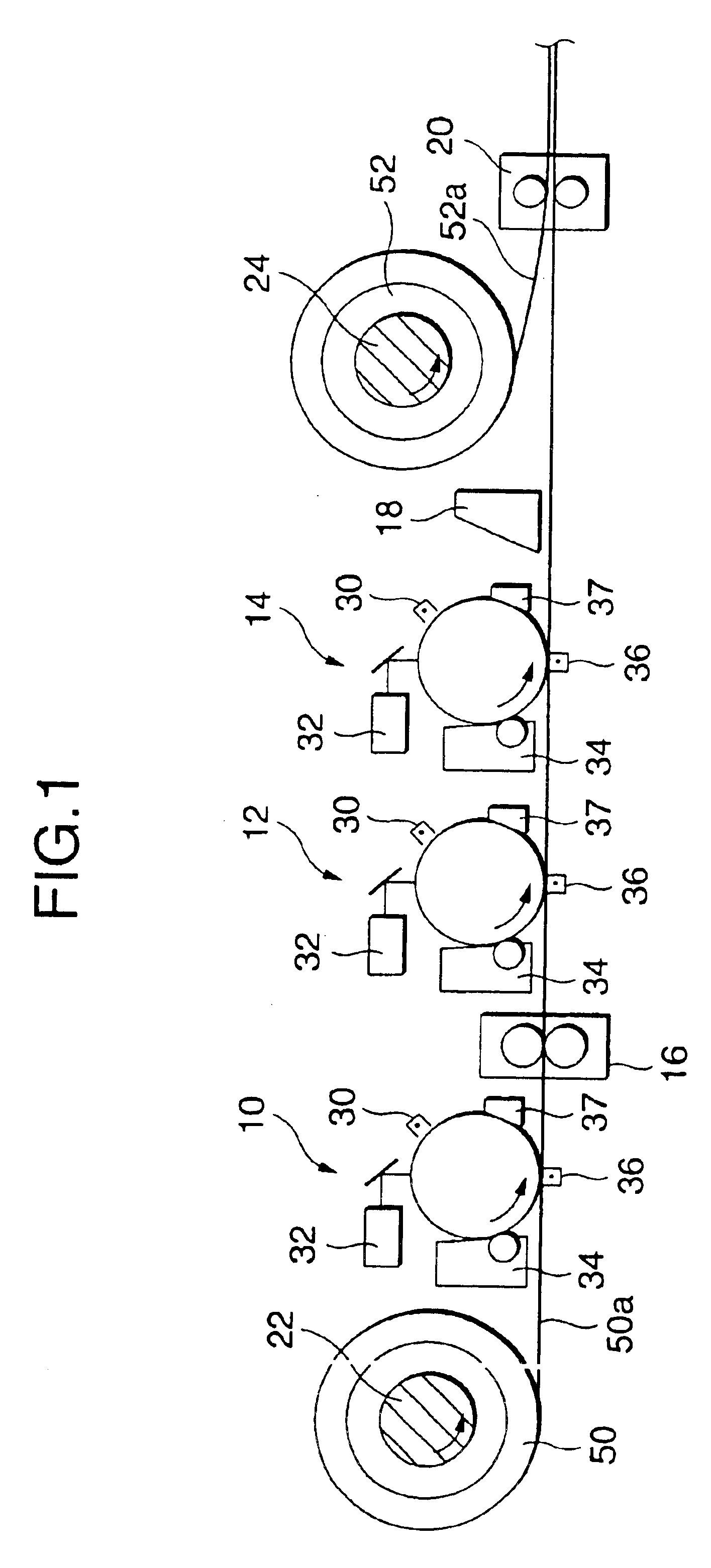

Method for manufacturing image displaying medium

InactiveUS6842278B1Simple processSludge treatmentTelevision system scanning detailsElectrostatic coatingEngineering

A method for manufacturing an image displaying medium is provided in that a display element in the form of powder can be filled between facing substrates. After patterning spacer particles on a first flat substrate supplied from a first film roller set on a first roller shaft by a first electrostatic coating device, they are fixed by a first fixing device to form a spacer on the first flat substrate, and then black particles are coated, on the entire surface by a second electrostatic coating device. After coating white particles thereon by a third electrostatic coating device, the black particles and the white particles on the upper part of the spacer are removed by a blade, and a second flat substrate supplied from a second film roller set on a second roller shaft is superimposed, followed by fixing the upper part of the spacer and the second flat substrate by a second fixing device.

Owner:E INK CORPORATION

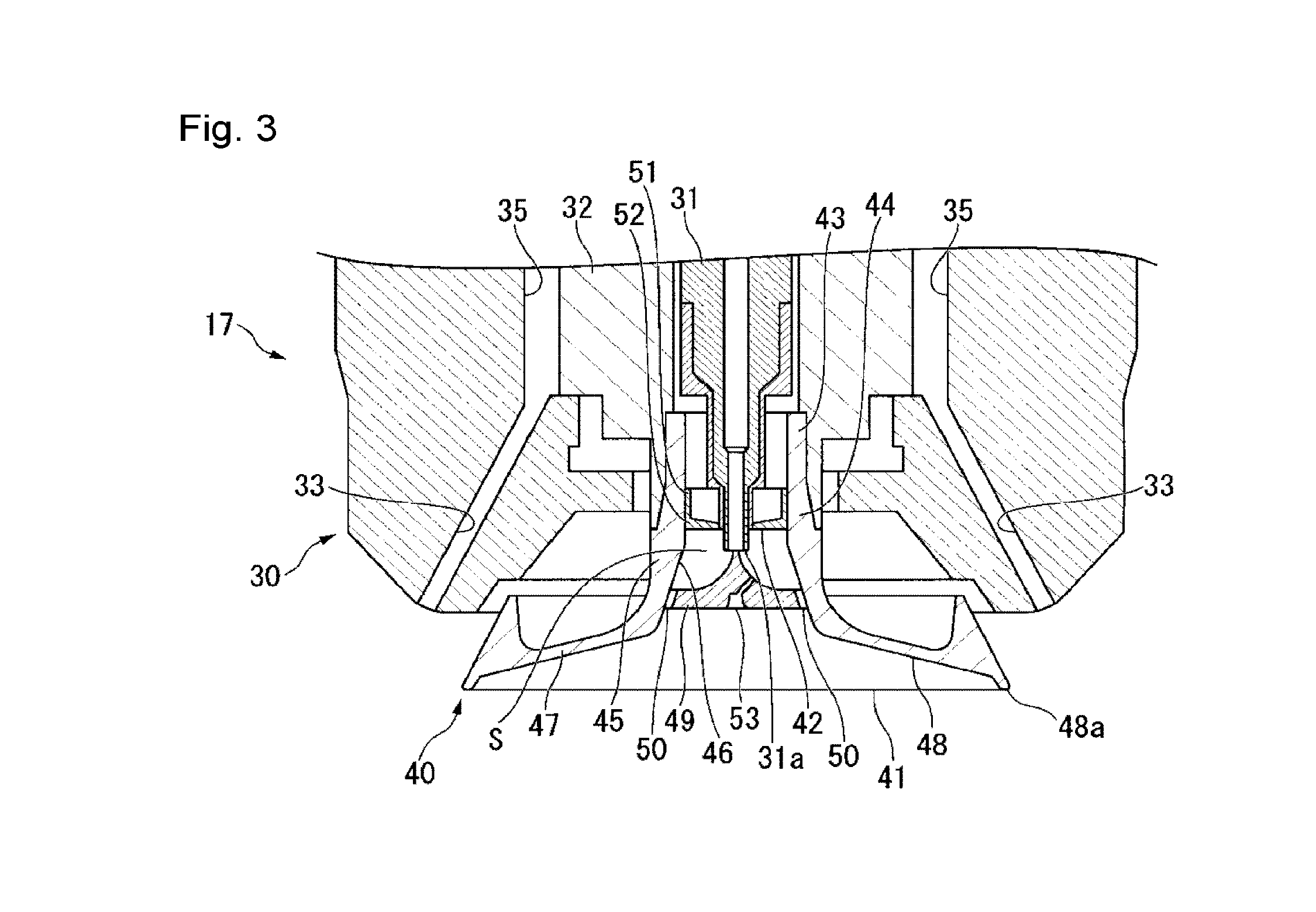

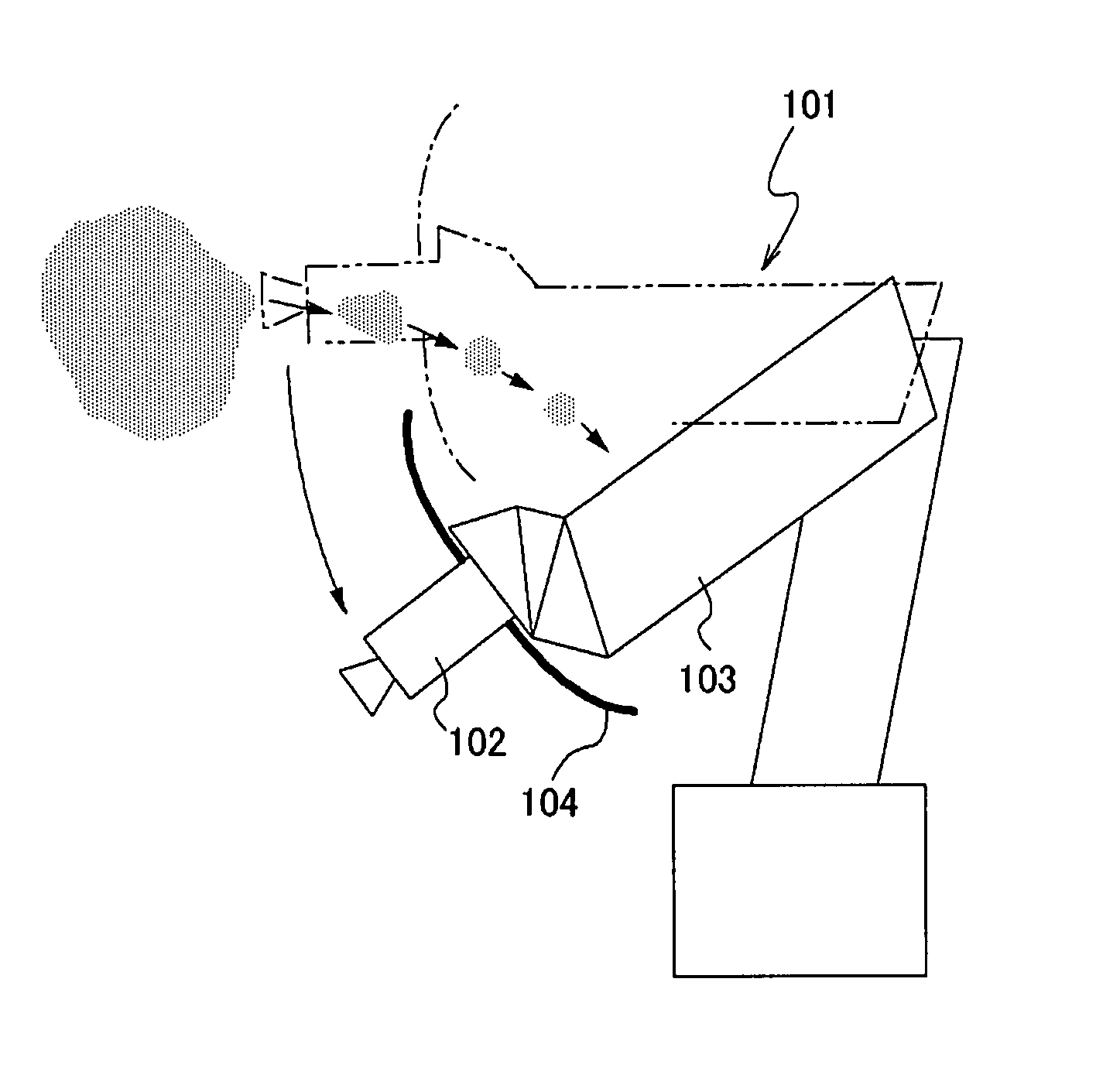

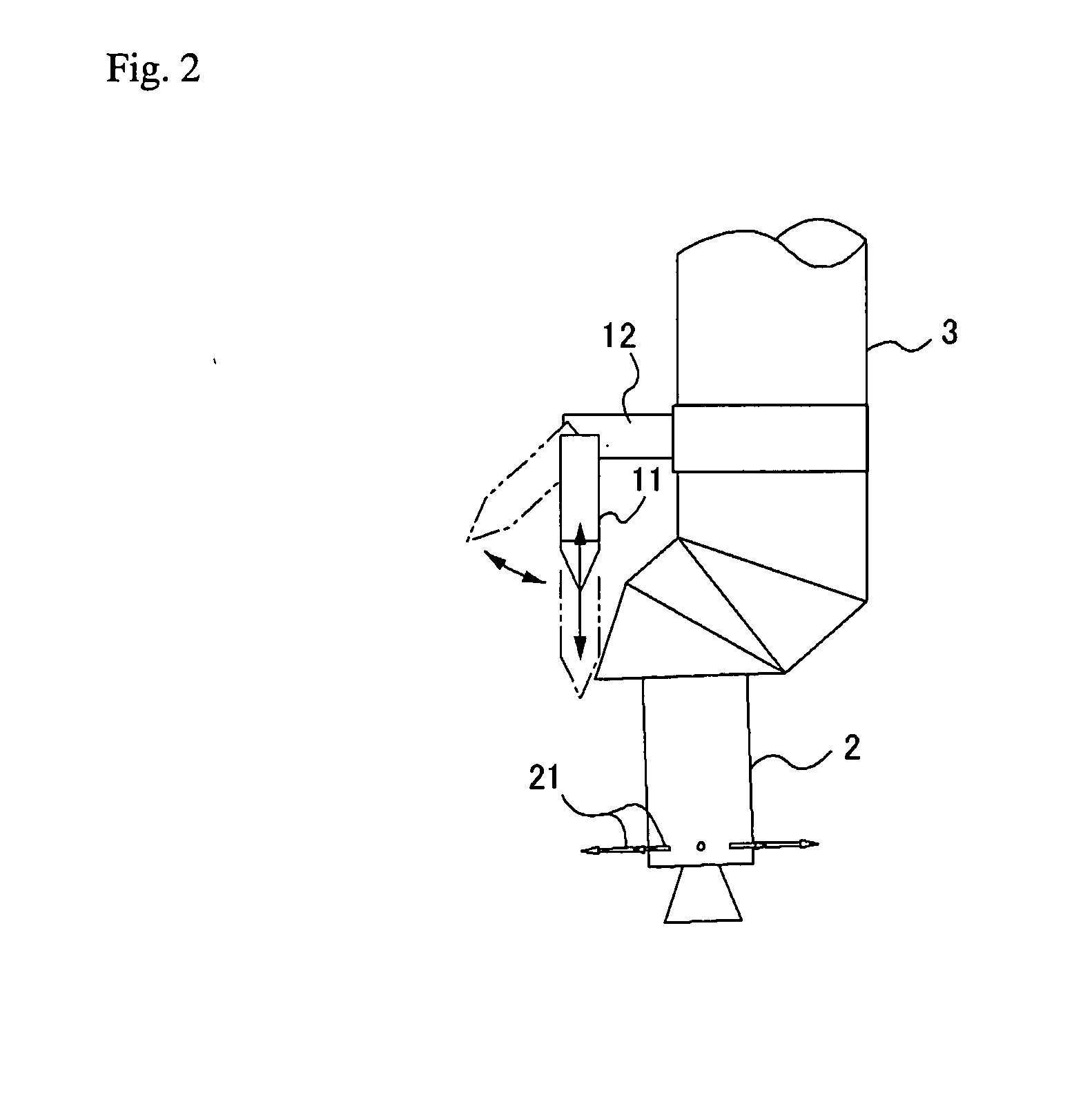

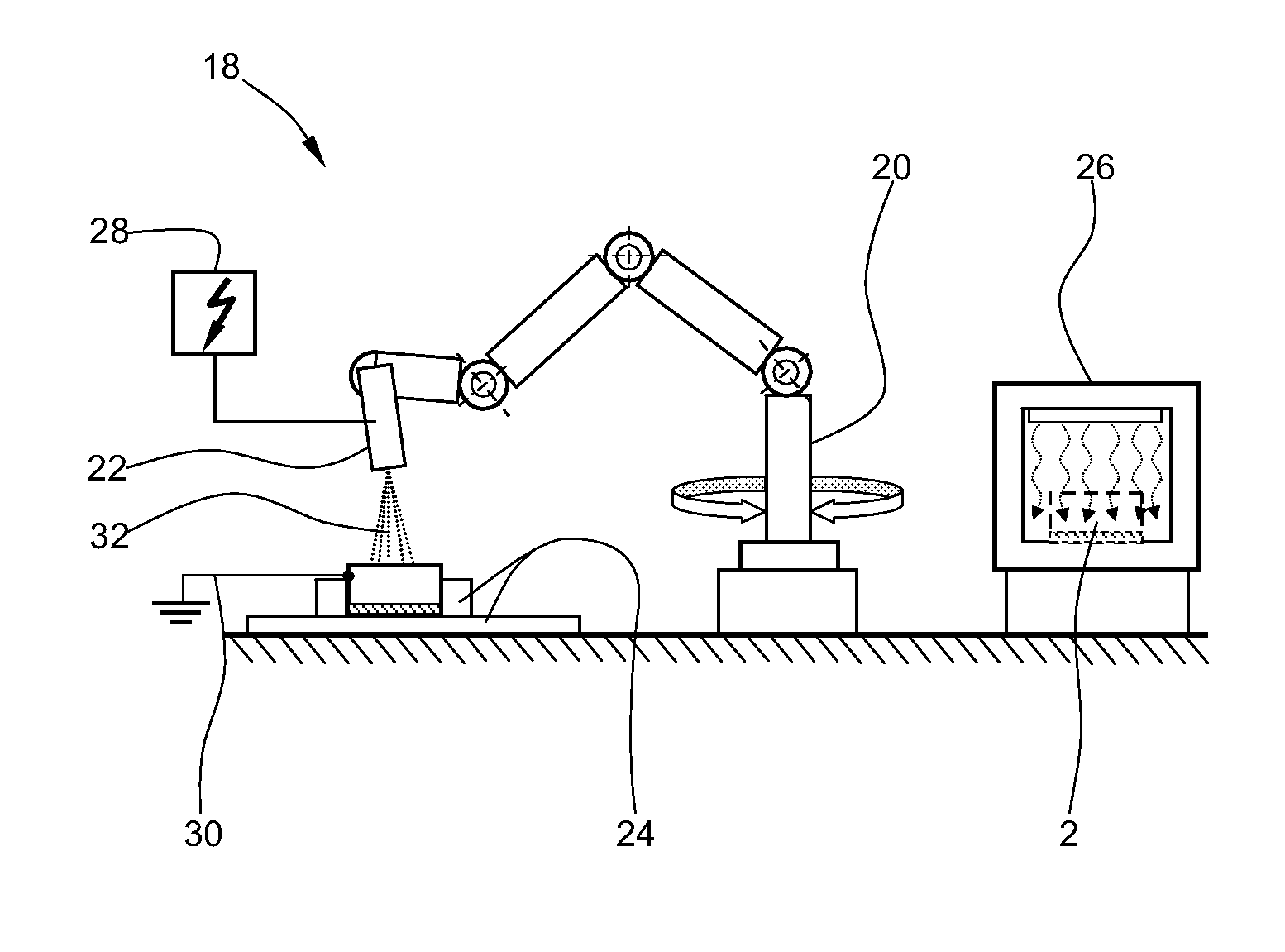

Electrostatic Coating System

InactiveUS20080178802A1High effect preventing dirtPrevent adhesionBurnersLiquid surface applicatorsElectrical polarityElectrostatic coating

An electrostatic coating system (1) comprising a coating gun (2) for spraying a coating material toward an article (9) to be coated, and a robot arm (3) for moving the coating gun (2) with respect to the article (9) to be coated wherein a voltage is applied to the coating gun (2). A needle-like electrode (11) which is an electrostatic electrode having a pointed end applied with a voltage having the same polarity as that of the voltage applied to the coating gun (2), is attached to the coating gun (2) or the robot arm (3).

Owner:TOYOTA JIDOSHA KK +1

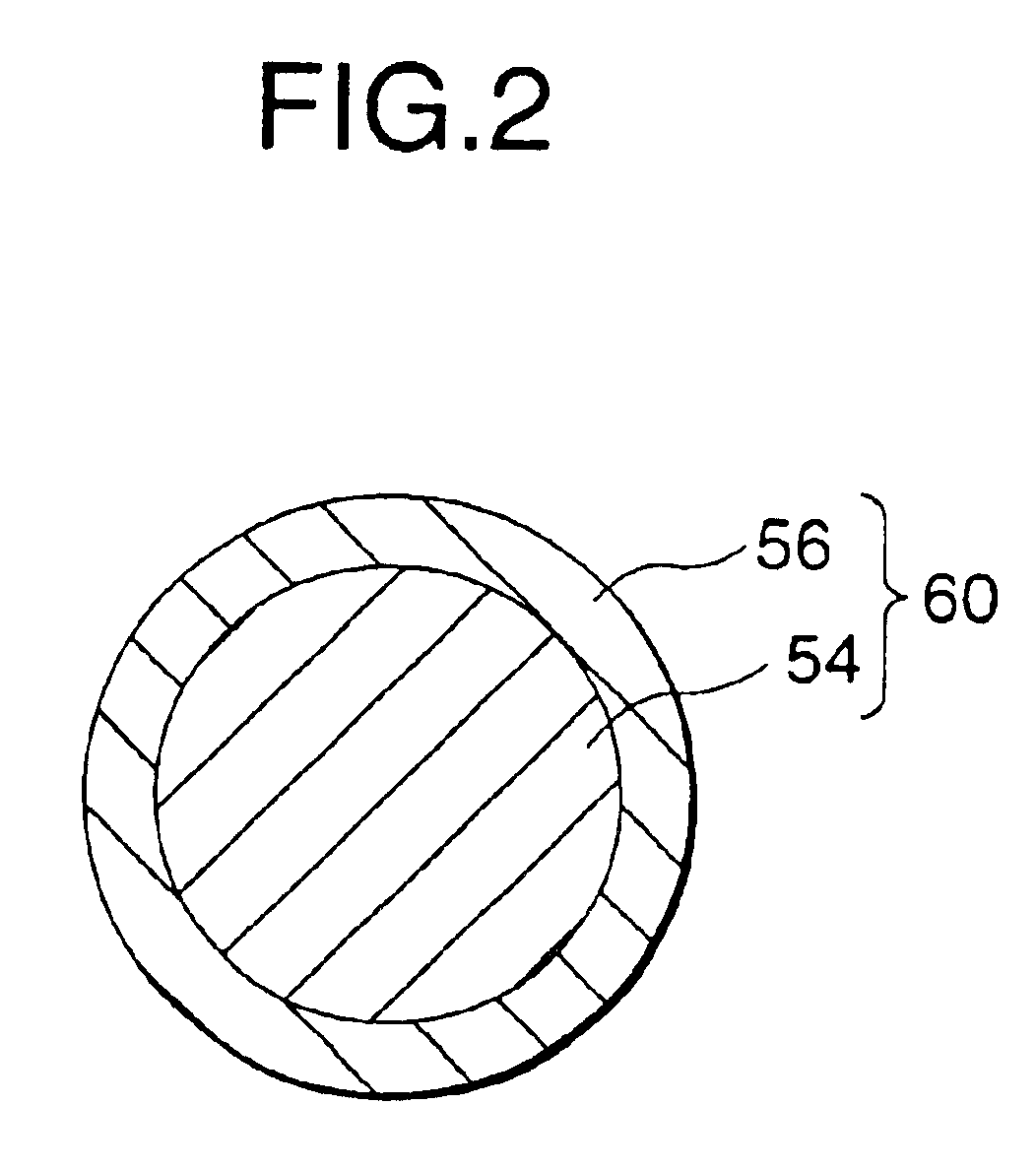

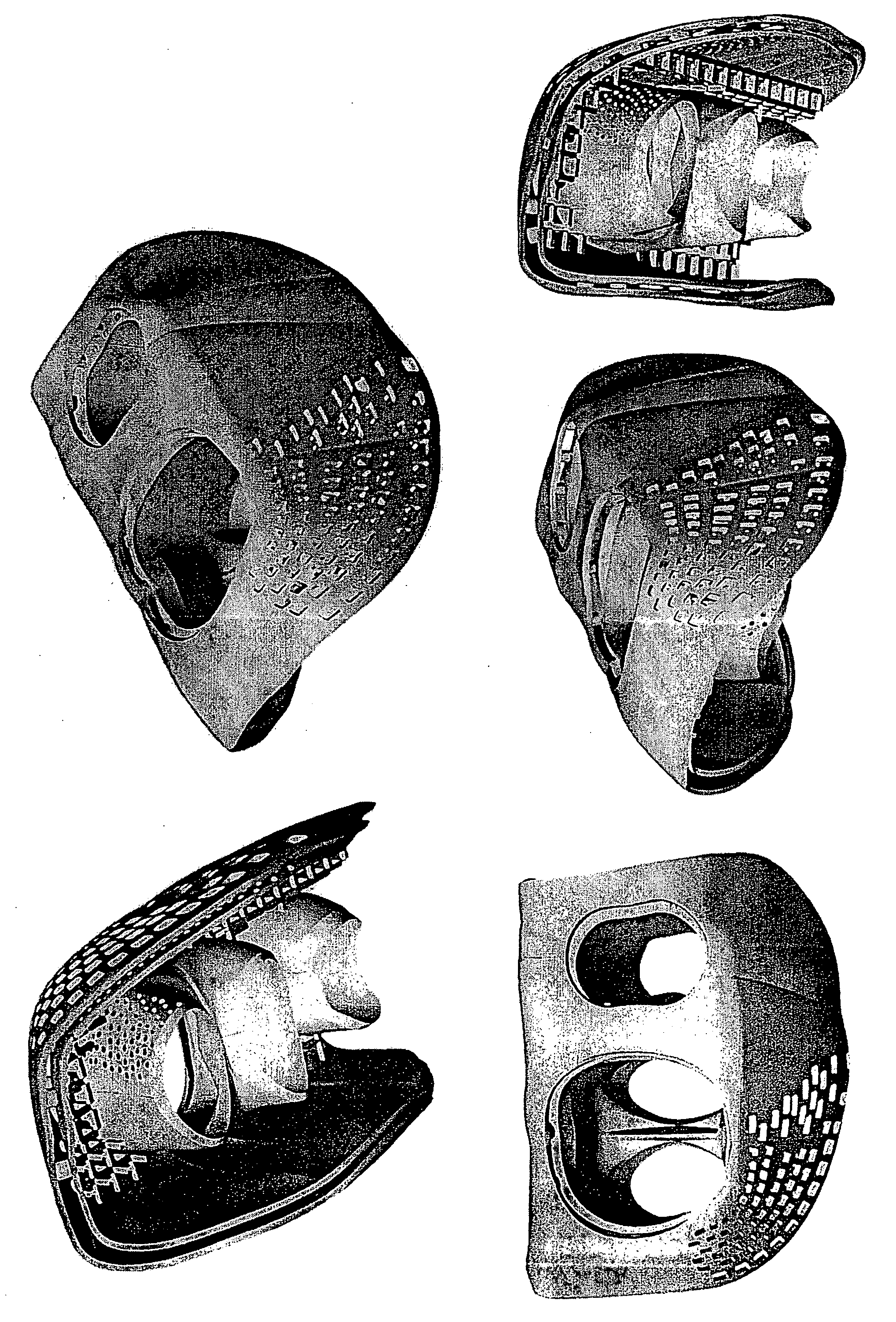

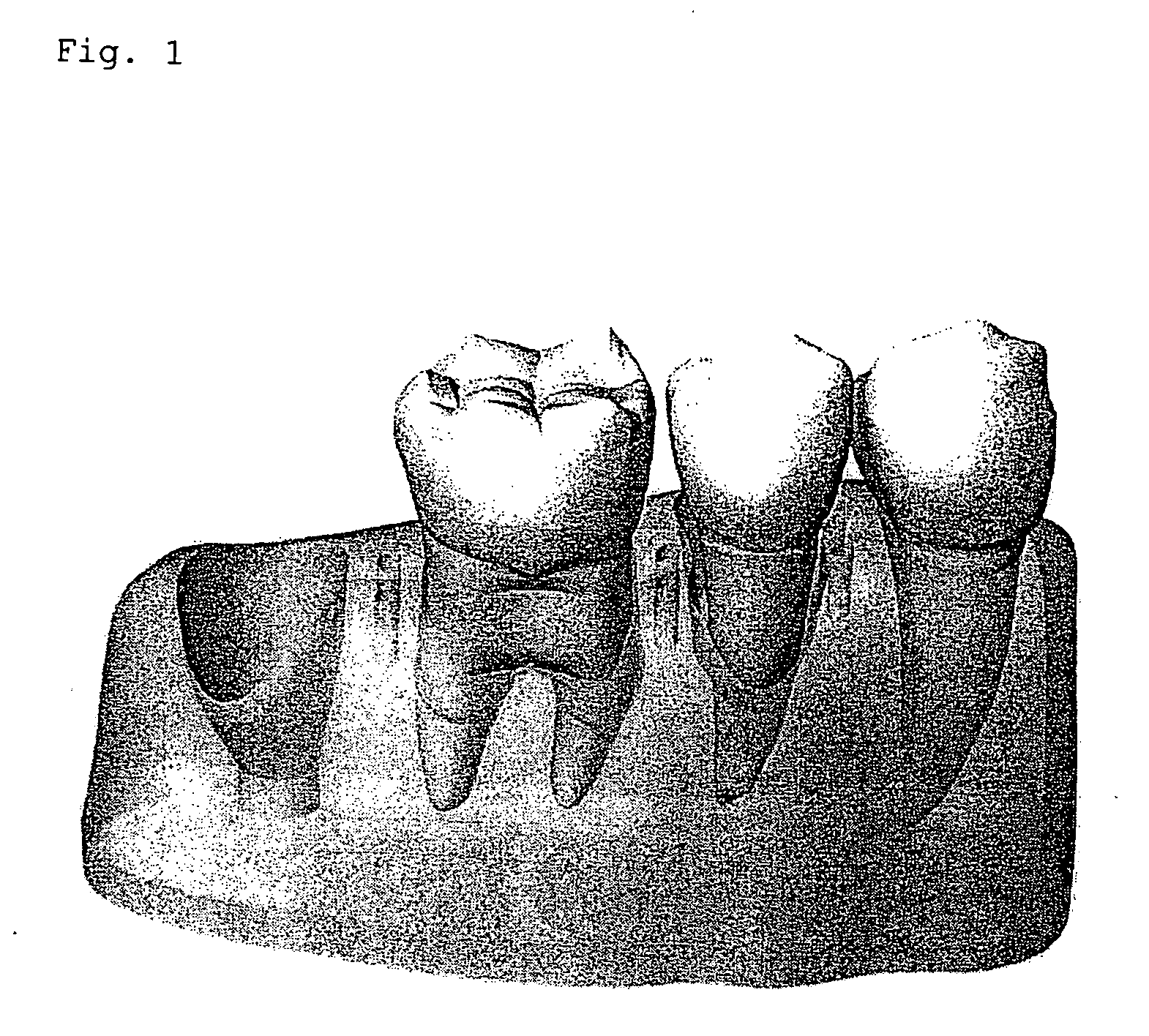

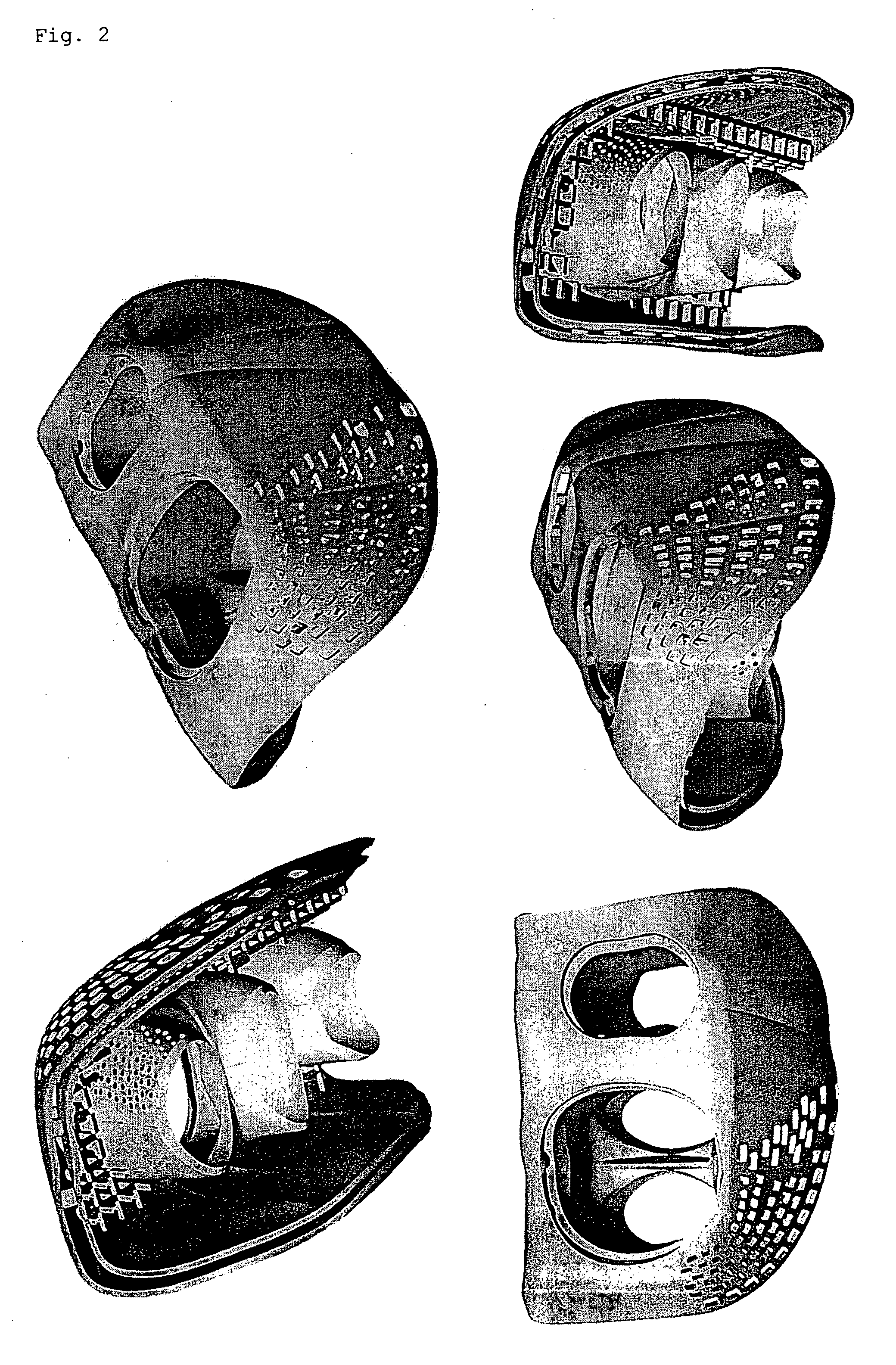

Biocompatible Membrane and Process for Producing the Same

InactiveUS20070231364A1Simple stepsEasy to fixDental implantsImpression capsSelective laser sinteringManufacturing technology

The present invention provides a biocompatible membrane which has a configuration that conforms well to an affected part and can be used in fields such as dentistry, oral surgery, orthopedics, etc., by a compatible membrane production process in which a biocompatible material is subjected to a lamination forming process or a powder electrostatic coating process. Examples of lamination forming processes include (a) selective laser sintering, (b) powder adherence, (c) fused deposition molding, (d) laminated object manufacturing, and (e) optical molding. The biocompatible membrane is useful as, for example, a tissue regeneration membrane or a bone regeneration membrane for periodontal tissue, bone tissue, and like tissue regeneration treatment.

Owner:SUNSTAR SUISSE SA

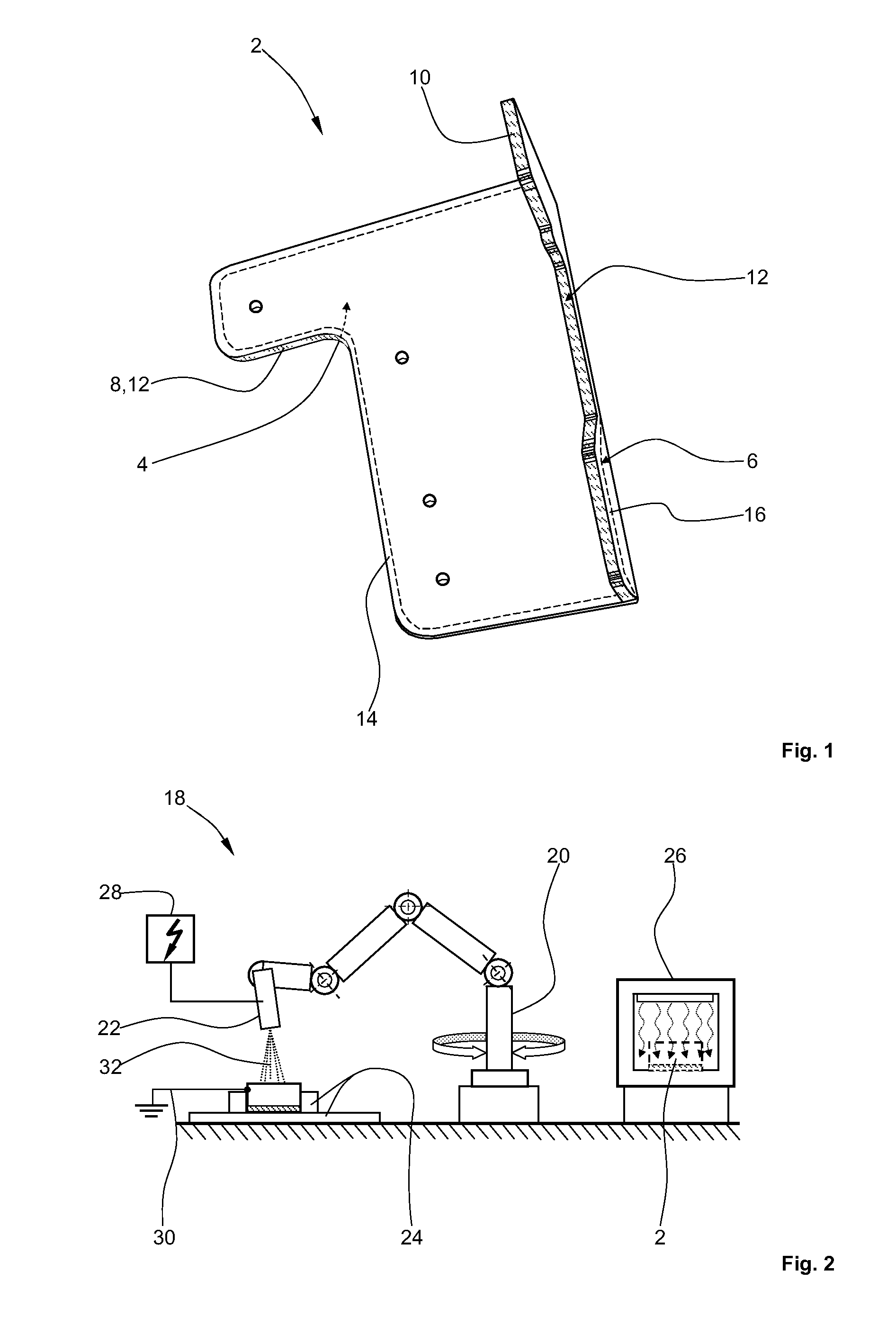

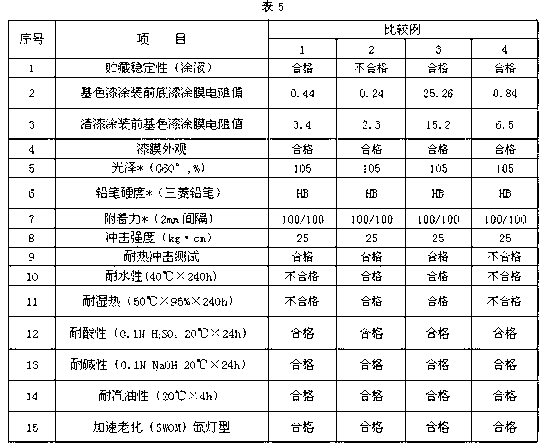

Method for edge sealing a component, device for implementing the method, as well as edge-sealed component

ActiveUS20110159229A1Superior fashionMaterial nanotechnologyLiquid surface applicatorsThermoplasticCross-link

A method for edge sealing a fiber-reinforced component formed from a carbon fiber-reinforced thermoplastic or duroplastic plastic material includes electrostatic coating of at least one section of an edge of the component with a thermoplastic powder so as to form a powder coating; and fusing and cross-linking the powder coating in a furnace so as to create a smooth edge seal.

Owner:AIRBUS OPERATIONS GMBH

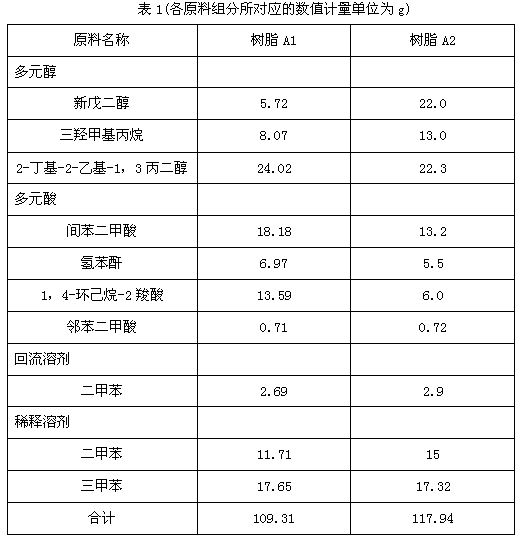

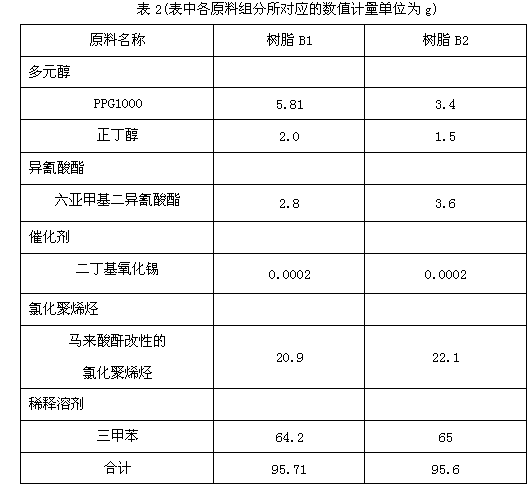

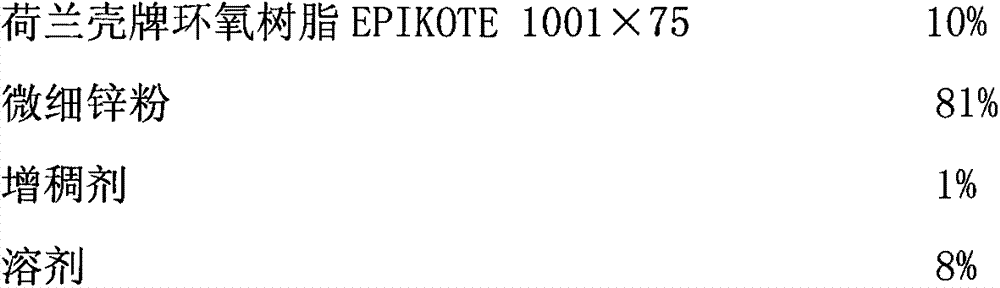

Conducting primer for electrostatic coating of plastic base material and preparation method thereof

ActiveCN102838909AReduce dosageConductive realization of electrostatic coatingEpoxy resin coatingsElectrically-conductive paintsEpoxyPolyolefin

The invention discloses a conducting primer for electrostatic coating of a plastic base material and a preparation method thereof. The conducting primer comprises the following components in parts by weight: 5-10 parts of thermoplastic acrylic resin, 5-10 parts of polyester resin, 0.5-2 parts of epoxy resin, 40-60 parts of mixed solvent, 0-2 parts of pigment dispersing agent, 3-10 parts of rutile titanium dioxide pigment, 0.5-3 parts of conductive carbon black pigment, 0.5-2 parts of gas-phase silicon dioxide, 10-20 parts of polyolefin resin, 0-0.5 part of leveling agent, 0-0.5 part of defoaming agent and 5-15 parts of high-boiling-point aromatic hydrocarbon solvent. The invention also comprises the preparation method of the conducting primer for electrostatic coating of the plastic base material. The conducting primer disclosed by the invention has the advantages of good single-component stability, good adhesive force with multiple plastic base materials, good water resistance and humidity-heat resistance, excellent heat-shock resistance and lower cost.

Owner:湖南湘江关西涂料有限公司

Conductive composition and production method thereof, antistatic coating material, antistatic coating, antistatic film, optical filter, and optical information recording medium, and capacitors and production method thereof

ActiveUS7842196B2High conductivity and flexibility and adhesionEasy to manufactureHybrid capacitor separatorsHybrid capacitor electrolytesConductive polymerElectrostatic coating

A conductive composition comprises a π conjugated conductive polymer, a polyanion, and a hydroxy group-containing aromatic compound containing two or more hydroxy groups. An antistatic coating material comprises the conductive composition and a solvent. An antistatic coating is produced by applying the antistatic coating material. A capacitor comprises an anode composed of a porous valve metal body; a dielectric layer formed by oxidizing a surface of the anode; and a cathode formed on the dielectric layer, wherein the cathode has a solid electrolyte layer comprising the conductive composition.

Owner:SHIN-ETSU POLYMER CO LTD

Indoor decorative metal powdery paints

InactiveCN101157816ARich sourcesLow pricePowdery paintsEpoxy resin coatingsEpoxyElectrostatic coating

The invention relates to an indoor decorative metal powder coating, pertaining to the powder coating technique field of electrostatic coating. The coating is made from raw materials according to the following weight proportion: 20 to 30 percent of epoxy resin (E-12), 20 to 30 percent of indoor polyester resin, 0.8 to 5 percent of flow agent, 1 to 2 percent of metal pigment PCR214, 0.1 to 0.3 percent of metal pigment PC100, 0 to 2 percent of metal pigment PCR212, 0 to 50 percent of filler, 0.1 to 5 percent of conventional pigment, 0.2 to 0.4 percent of benzoin and 0.1 to 0.2 percent of fumed silica, wherein, the resins, the conventional pigment, the filler and various addition agents are all common types and specifications in powder coating. The invention has the beneficial effects of simple production and application, innocuity, no pollution, and rich raw material resources with low cost.

Owner:XUZHOU ZENITH COATING

Powder coating precursors and the use thereof in powder coating compositions

InactiveUS20050014865A1Improve compatibilityGood lookingPigmenting treatmentMicaElectrostatic coatingPigment

A laminar pigment which has hydrolyzed silane coupling agent treated surface is used as a pigment for a powder coating composition. By combining the pigment with a powdery film-forming polymer, a film-forming composition, which can be applied by electrostatic coating is produced. With the addition of leveling agent to the silane treated products, the spray properties of effect pigments are improved. The products of this invention are useful in all types of automotive and industrial paint applications.

Owner:ENGELHARD CORP

Flake pigment, powder coating material containing the flake pigment, powder coated film obtained by coating with frictional electrification-type electrostatic coating apparatus using the powder coating material, coated product with the powder coated film, and process for producing flake pigment

InactiveCN101965384AStable triboelectric characteristicsSuppress color unevennessChemical recyclingPowdery paintsPhosphateElectrostatic coating

Disclosed is a flake pigment characterized in that the flake pigment comprises flake particles, a film having a single-layer or multilayer structure and covering the surfaces of the flake particles, and fine particles, the outermost layer of the film contains a copolymer comprising one or more kinds of first bonding units derived from a fluorine-containing fluorine-type polymerizable monomer and one or more kinds of second bonding units derived from a phosphate group-containing polymerizable monomer, and the fine particles are fixed through the outermost layer and have such properties that impart frictional electrification properties to the flake pigment.

Owner:TOYO ALUMINIUM KK

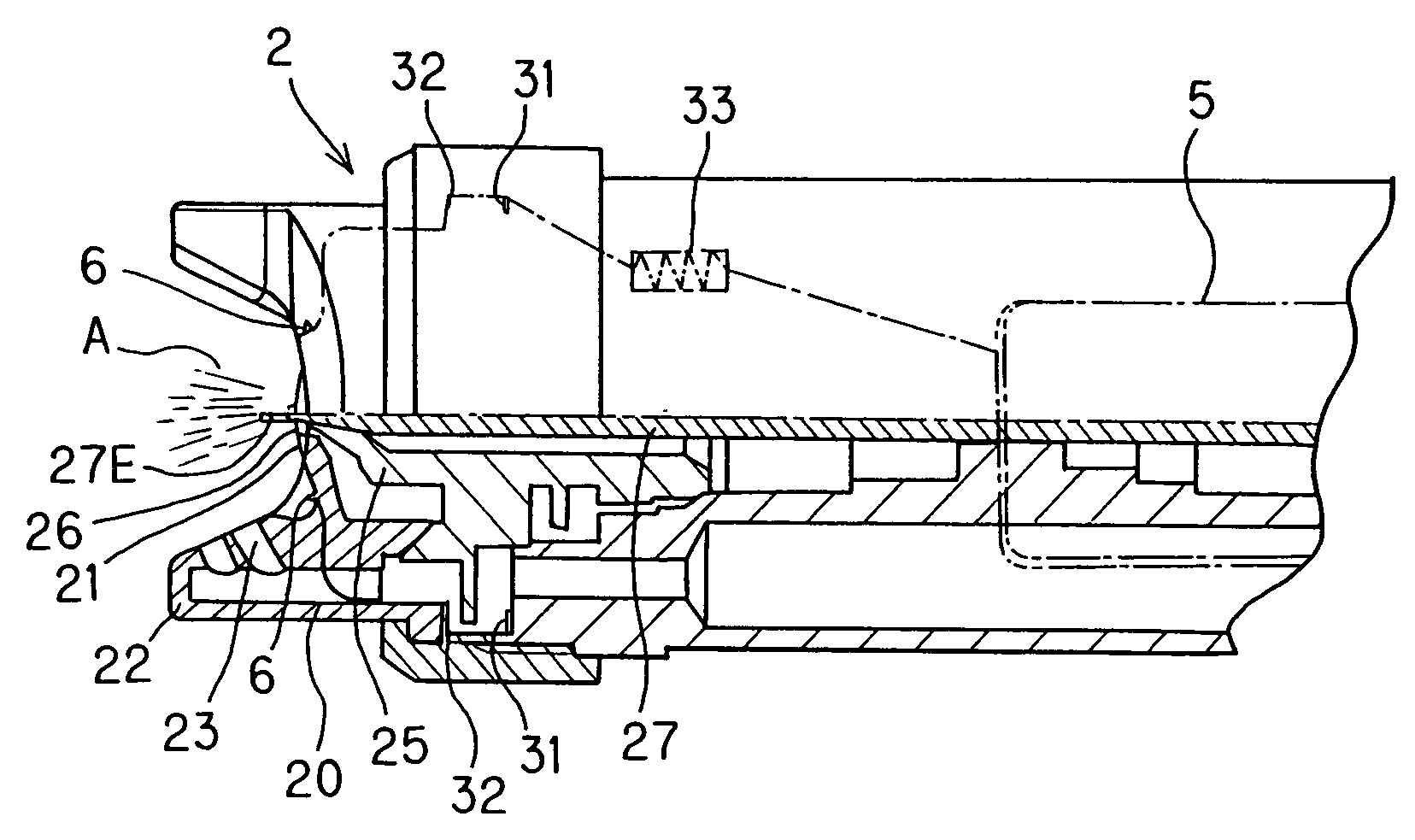

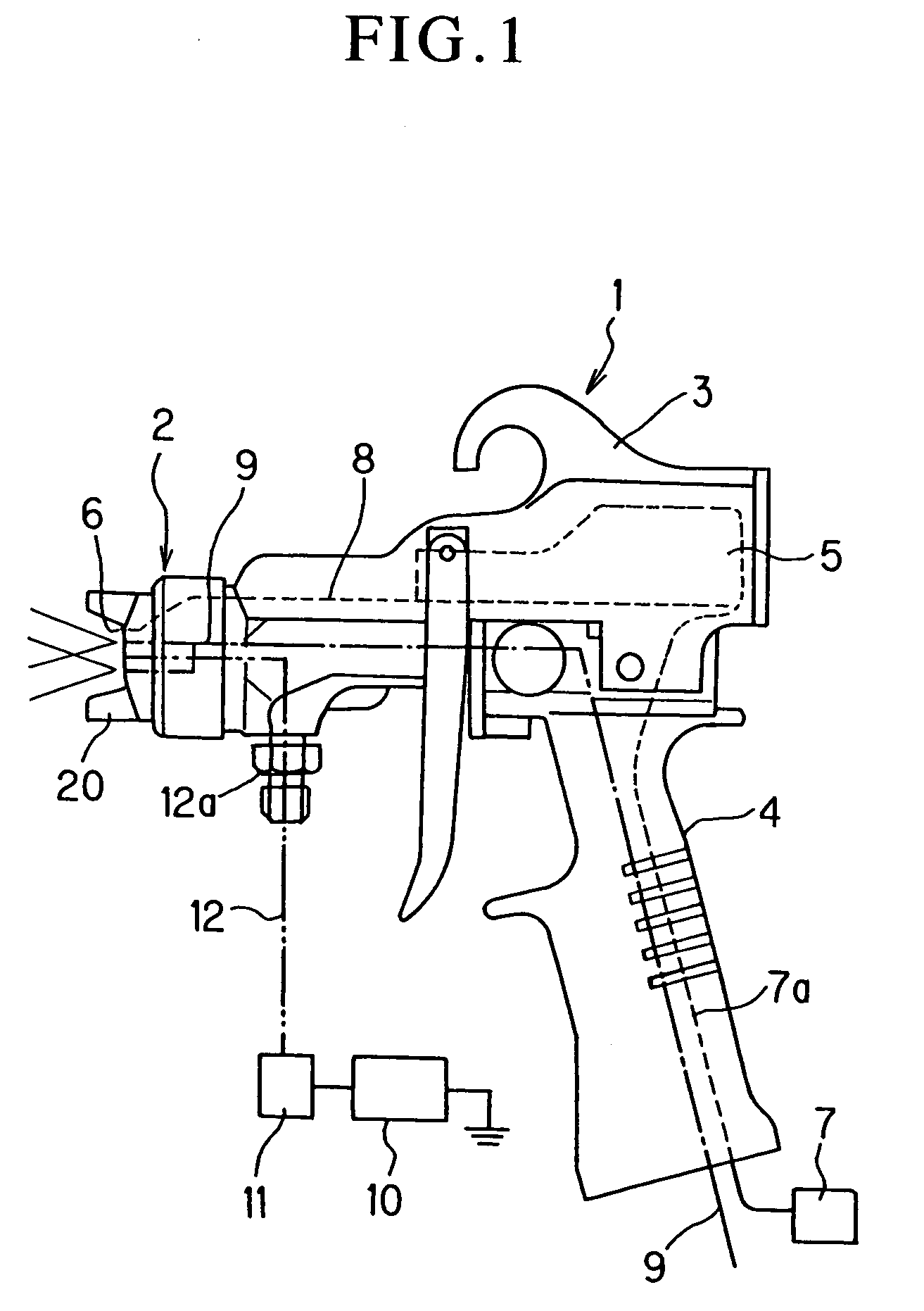

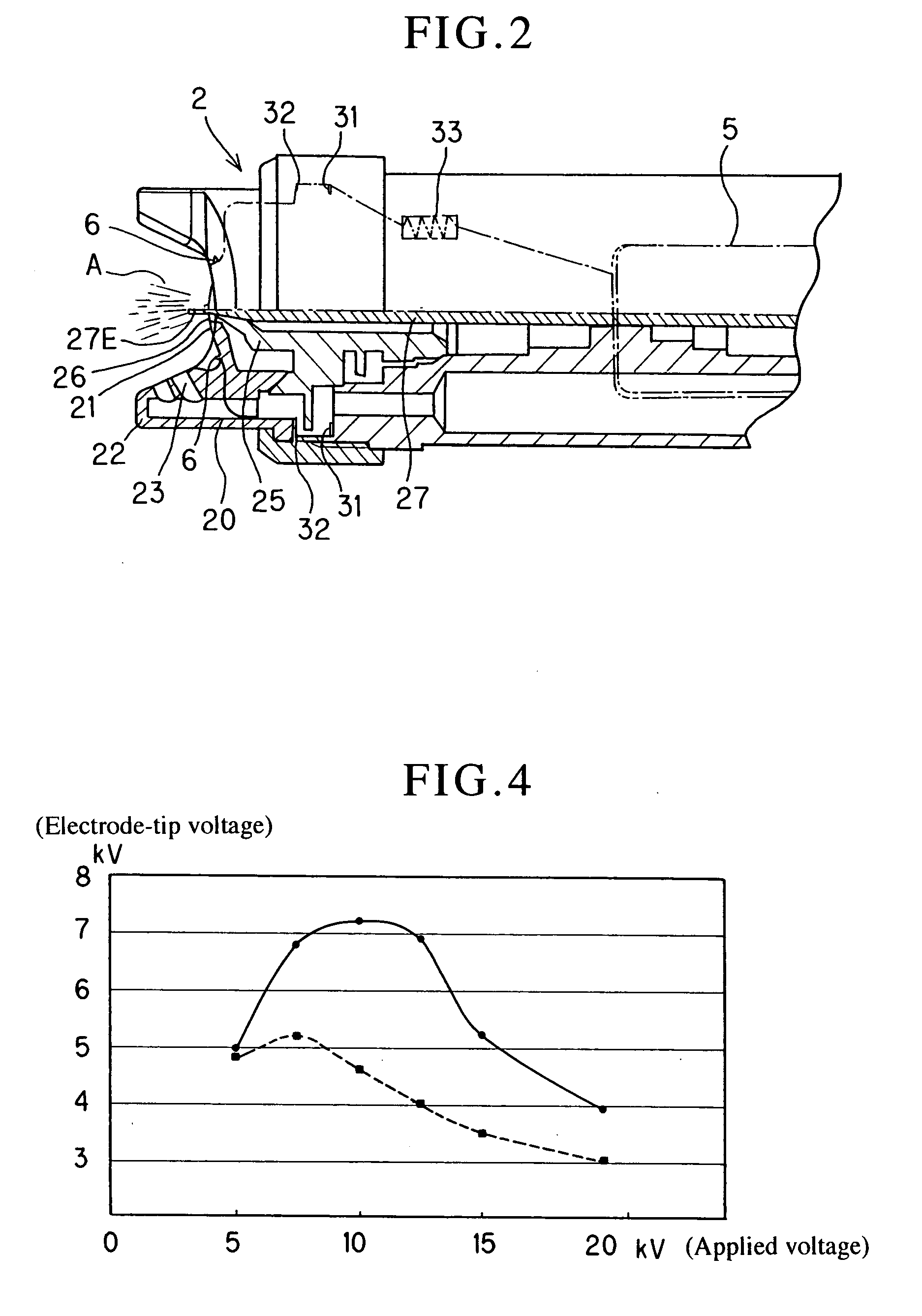

Electrostatic Coating Spray Gun and Electrostatic Coating Method

InactiveUS20080213499A1Easy to operateImprove securityLiquid surface applicatorsLiquid spraying apparatusElectricityLow voltage

When conductive paint is coated by electrostatic coating, the electrostatic charging has many problems. The external electrode is prevailingly used in most of the electrostatic coating spray guns but has many problems in operability, safety, practical usability, etc. when the guns are designed compact. The electrostatic coating spray guns need to be improved in operability, safer with electrostatic charging at a lower voltage, and smaller in structure. To solve such problems, there is provided an improved electrostatic coating spray gun (1) in which an atomizer (2) is provided at the front end thereof to atomize paint jet from a paint nozzle (25) disposed at the center of the atomizer (2) and electrostatically charge the atomized paint particles at a high voltage for attraction to an object to be coated, set at ground potential, charging electrodes (6) as external electrodes are provided on the inner front surface of an air cap (20) or the inner surface of the air cap (20) and a compressed air passage is formed between a paint jet port (26) at the ground potential and the charging electrodes (6). At charging, compressed air prevents discharge from the charging electrodes toward the paint at the ground potential to efficiently ensure ionizing discharge with necessary potential being retained at the charging electrodes (6) and effective charging of paint particles. Since voltage drop is thus prevented, a lower voltage may be used for necessary charging of the paint particles.

Owner:ANEST IWATA CORP

Cold-spraying-zinc anticorrosive paint with graphene and method for preparing cold-spraying-zinc anticorrosive paint

InactiveCN105566973AGood effectImprove adhesionAnti-corrosive paintsElectrically-conductive paintsElectrostatic coatingGraphene

The invention relates to cold-spraying-zinc anticorrosive paint with graphene and a method for preparing the cold-spraying-zinc anticorrosive paint. The cold-spraying-zinc anticorrosive paint comprises, by weight, 75-85 parts of zinc powder, 2-3 parts of organic resin, 15-25 parts of solvents, 0.1-2 parts of the graphene, 0.1-1 part of dispersing agents and 0.1-1 part of anti-settling agents. The method for preparing the cold-spraying-zinc anticorrosive paint includes weighing raw materials according to the weight, mixing the graphene, the dispersing agents and a part of the solvents with one another and ultrasonically uniformly dispersing the graphene, the dispersing agents and the solvents; mixing the organic resin with the residual solvents for dissolving; adding dispersed graphene liquid into dissolved resin liquid, and uniformly dispersing at a high speed to obtain mixed liquid; adding the zinc powder and the anti-settling agents into the mixed liquid, and uniformly dispersing at a high speed to obtain the cold-spraying-zinc anticorrosive paint with the graphene. The cold-spraying-zinc anticorrosive paint and the method have the advantages that coatings are good in adhesion and impact resistance and excellent in anticorrosive performance; the cold-spraying-zinc anticorrosive paint comprises single components and is convenient to construct; the cold-spraying-zinc anticorrosive paint is excellent in antistatic property and applicable to the antistatic coatings.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

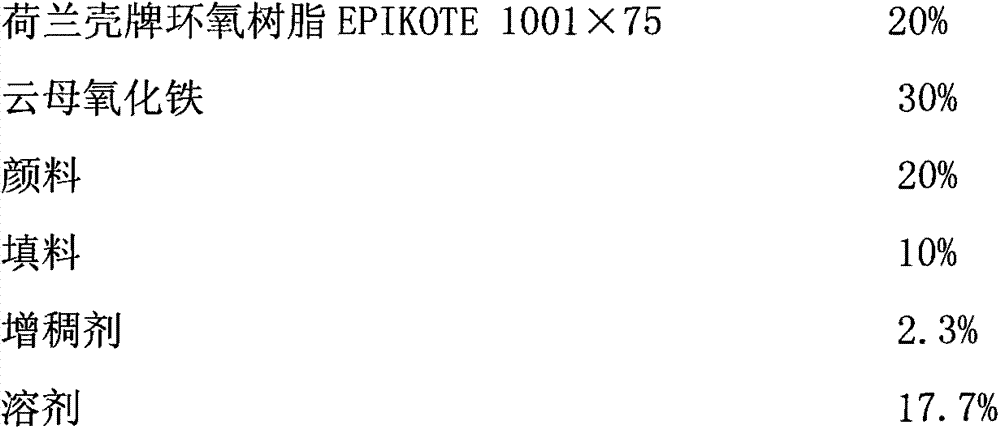

Super-weatherproof heavy-duty high-solid thermal insulating electrostatic conducting coating system

InactiveCN103497643AHigh content of zinc dustImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsHeat conductingCoating system

The invention discloses a super-weatherproof heavy-duty high-solid thermal insulating electrostatic conducting coating system and belongs to the technical field of chemical coatings. The super-weatherproof heavy-duty high-solid heat conductance barrier electrostatic coating system comprises a bottom coat, an intermediate coat and a surface coat, wherein the bottom coat is formed by coating an epoxy zinc rich primer, the intermediate coat is formed by coating an epoxy mica iron oxide paint and the surface coat is formed by coating a fluoro-carbon finish; the fluoro-carbon finish is added with hollow glass micro beads and a heat conducting powder. The electrostatic coating system provided by the invention is excellent in heavy duty, heat insulation and weather-proofing properties, high in electrostatic conductivity, high in solid content, low in volatilization, healthy and has environment-friendly effect, is long in system service life, and suitable for various steel structure facilities such as a gasoline can, a container, a steel pipe, a bridge, petrochemical equipment, a ship and a harbor facility.

Owner:浙江绿色德环保科技股份有限公司

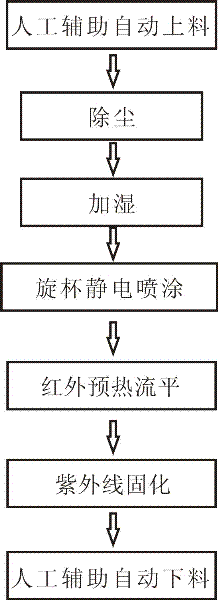

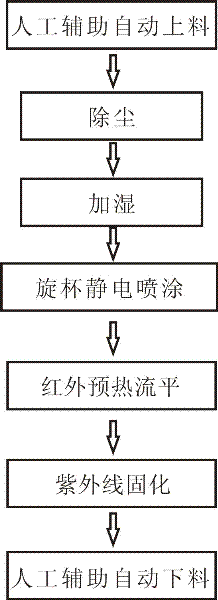

Production process of electrostatic coating on wooden doors

InactiveCN102266846AReduce pollutionReduce labor intensityPretreated surfacesCoatingsElectrostatic coatingUltraviolet lights

Disclosed in the present invention is a production process for electro-statically coating a wood door, which comprises the following steps: loading material, removing dust, humidifying, spraying, leveling and preheating, solidifying, and unloading material. The process is characterized in that, in the step of removing dust, a conveying chain is used for conveying a workpiece into a sealed dust-removing chamber, a rotating brush is used for removing dust from the two sides of the workpiece, and an air drafting cover is used for absorbing and collecting the dust swept from the workpiece into a dust collecting box which is filled with water; in the step of spraying, an electro-static spraying mode is adopted for spraying a polyurethane ultraviolet light solidifying coating on the workpiece. The spraying mode can be used for promoting the use ratio of the coating, reducing the VOC emission, and obtaining a more uniformly coated layer.

Owner:GUANGDONG RUNCHENG CHUANGZHAN WOODWORKING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com