Patents

Literature

100results about How to "Good static conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Epoxy static conducting anti-corrosive paint

InactiveCN101358099AFast curingExtended construction seasonAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyDiluent

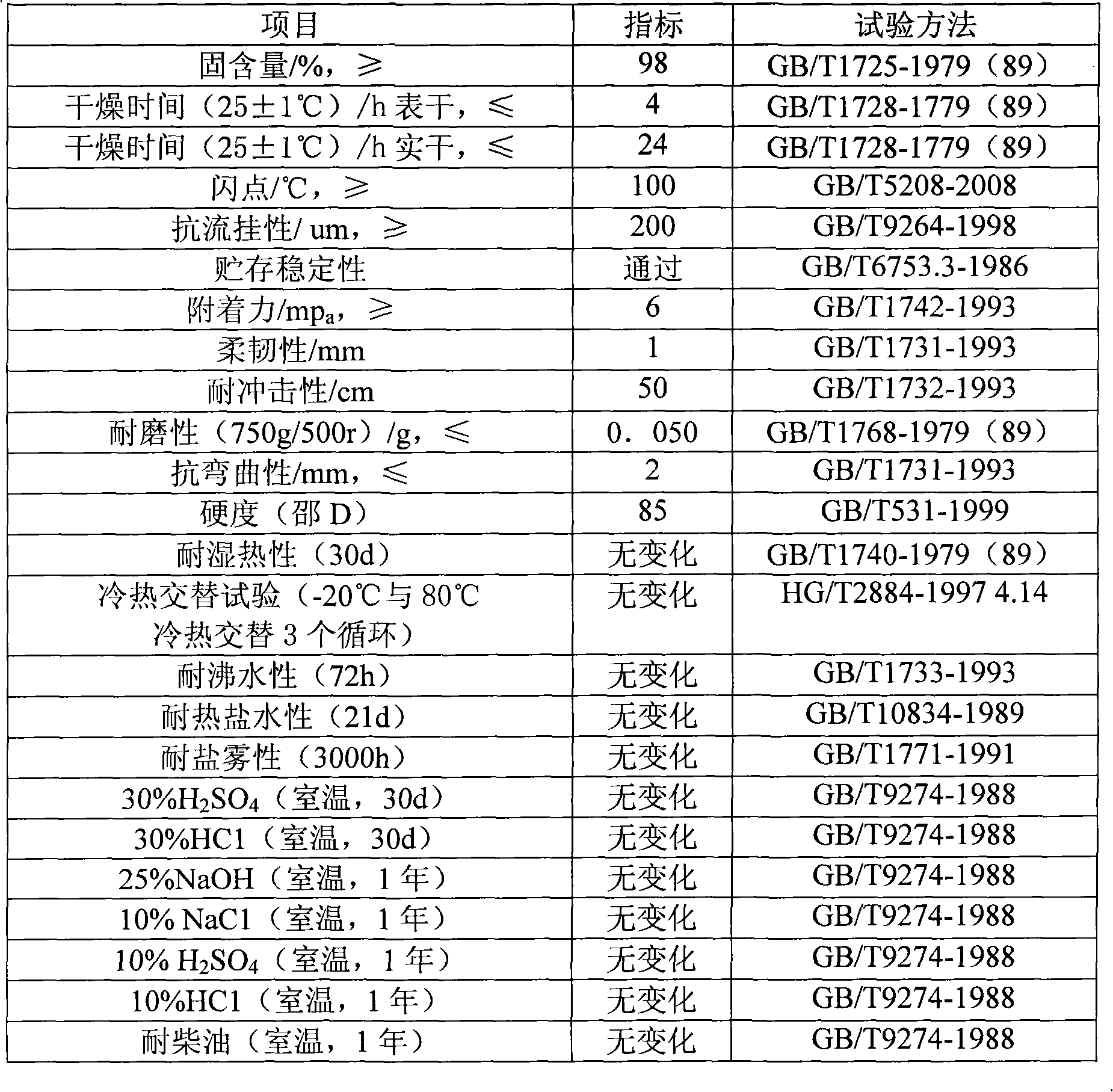

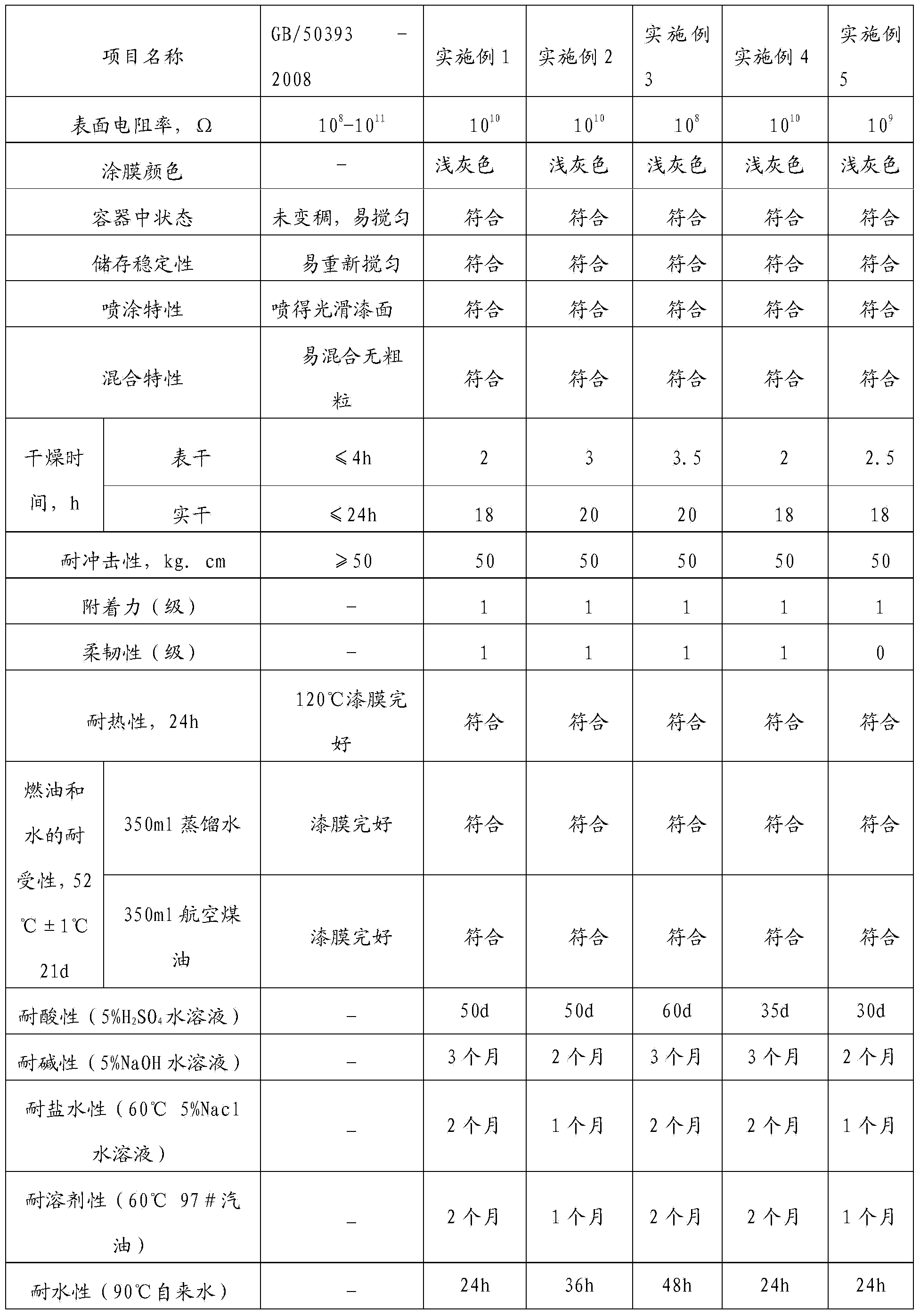

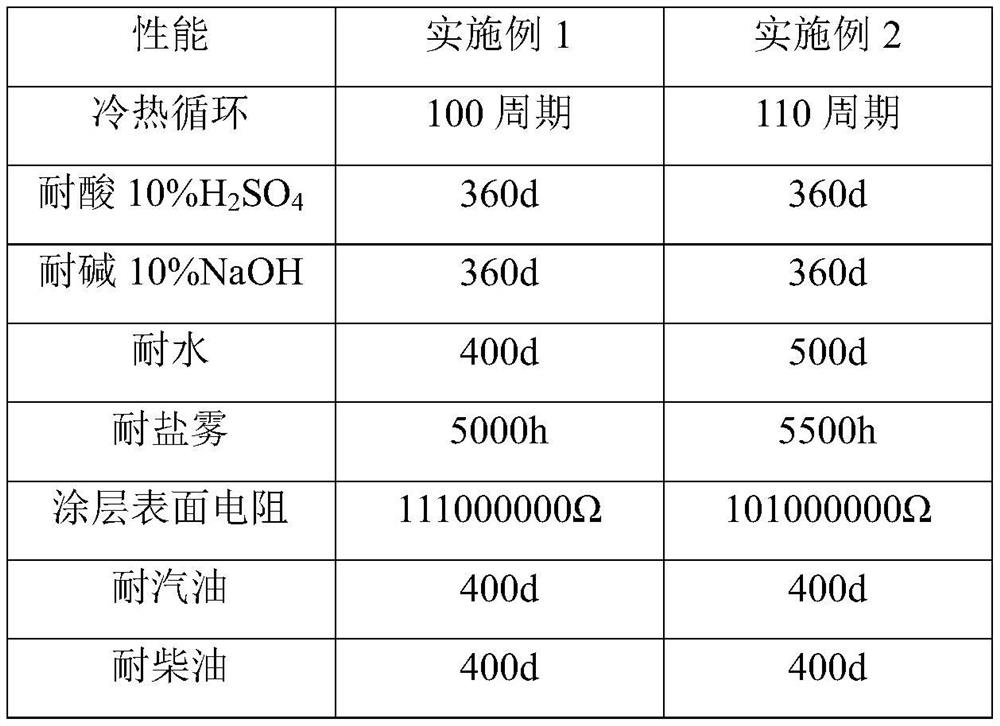

The present invention discloses a static electricity-conducting anti-corrosive epoxy coating, which comprises a component A and a component B; wherein, the component A is composed of epoxide resin, epoxy active diluent, epoxy-terminated modified urethane resin, flaky conductive mica powder and granular conductive titanium pigment; the component B is composed of modified fatty amine, modified alicyclic amine and curing accelerator; the component A and the component B are mixed according to a proportion to prepare the double-component, non-carbon static electricity-conducting anti-corrosive epoxy coating without solvent. Because the static electricity-conducting anti-corrosive epoxy coating does not use volatile liquid solvent, adopts 100 percent of solid ingredients and uses the technical scheme of polyfunctional flexibilizer and the flaky and granular composite conductive media, the static electricity-conducting anti-corrosive epoxy coating has the advantages of high safety, energy saving, environment-friendliness, good static electricity-conducting property, good anti-corrosive property, one-step spraying and filming and convenient construction, so the static electricity-conducting anti-corrosive epoxy coating is widely applicable to the field of the static electricity conduction and corrosion prevention of oil storage tanks and has a wide market prospect.

Owner:BEIJING RADIATION APPL RES CENT

Conductive epoxy resin lawn pigment and coating process thereof

InactiveCN1854217AImprove conductivityUnlimited adjustable colorsEpoxy resin coatingsElectrical resistance and conductanceEpoxy

An electrostatic-conducted epoxy-resin terrace coating and its coating process are disclosed. The coating consists of finish and primer, finish uses conductive short-staple slurry with excellent conductive and dispersing performances, and surface and volume resistances reach to 5*10(4)-1*10(6)omega, furthermore, finish utilizes composite accessory system with disperser, leveling agent, antifoaming agent and rheological agent; primer uses conductive graphite powder, and surface and volume resistances reach to 10(3)-10(4)omega. The process is carried out by pasting conductive copper foil at an interval 1m*2m, building an electrostatic dissipative leakage layer, connecting a grounding device by1000m2 with grounding resistance<4omega and composing complete electrostatic leakage system. It's simple, convenient and has excellent and long-acting electrostatic-conducting effect.

Owner:上海秀珀化工有限公司

Heavy corrosion resistant, heat insulating and static conductive coating

InactiveCN101899257AStrong adhesionGood static conductivityAnti-corrosive paintsEpoxy resin coatingsNon toxicityPetrochemical

The invention discloses a heavy corrosion resistant, heat insulating and static conductive coating, which is prepared by the following steps of: dissolving acrylic acid modified epoxy resin which is taken as a substrate into active and inactive diluents in a way of taking liquid polysulfide rubber as a toughening agent in the presence of a functional pigment and an aid to prepare a first component; preparing a second component in a way of taking cashew nut shell liquid-synthesized modified amine as a curing agent under the cooperation of an accelerator and a hydrophilic agent; and mixing the first and second components in the weight ratio of 2:1. The heavy corrosion resistant, heat insulating and static conductive coating has the characteristics of no solvent, high adhesive power, high static conductivity, heavy corrosion resistance, high heat-insulating property, environmental friendliness, non-toxicity, wet rusty thick coating capability, great coating cost reduction, and applicability to the corrosion-resistant coating of inner and outer walls of large oil tanks, ballast tanks of ships, offshore drilling platforms, bridges, open petrochemical equipment, ships, high-speed trains and the like.

Owner:北京虹霞正升装饰装修工程有限责任公司

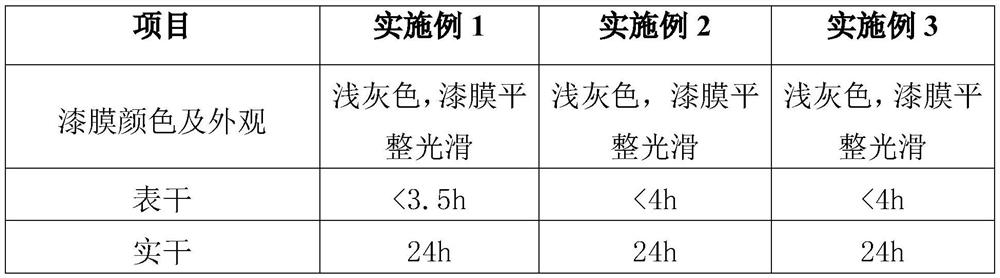

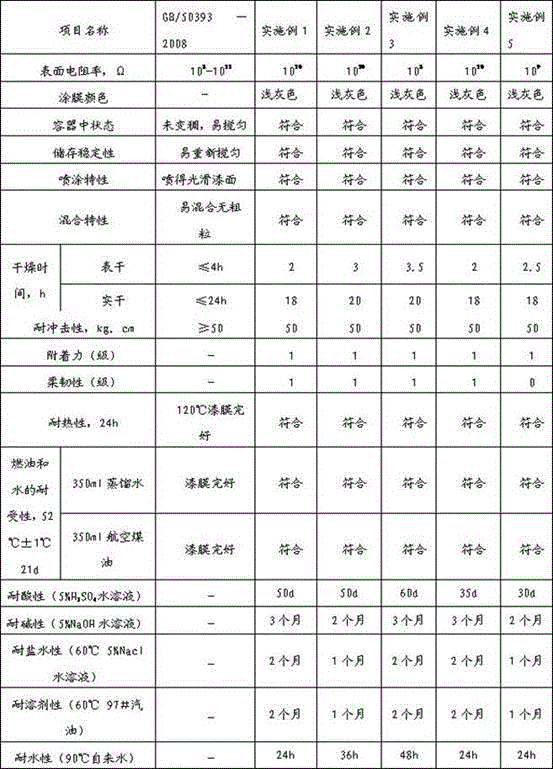

Waterborne two-component light-color in-tank electrostatic conduction anticorrosive paint and preparation method thereof

ActiveCN103756514ALight toneGood static conductivityAnti-corrosive paintsEpoxy resin coatingsEpoxyEmulsion

The invention discloses a waterborne two-component light-color in-tank electrostatic conduction anticorrosive paint, which is prepared from the following components by weight percent: 8-20% of running water, 30-45% of waterborne epoxy emulsion, 7-15% of waterborne epoxy curing agent, 8-20% of anti-rust pigment, 1-7% of white pigment, 1-7% of white filler, 8-18% of light color conductive filler, 0.1-0.3% of anti-settling agent, 0.1-0.4% of wetting dispersant A, 0.1-0.3% of wetting dispersant B, 0.8-2% of coalescing agents, 0.2-0.6% of defoamer, 0.1-0.3% of flatting agent, 0.1-0.6% of antirust agent, and 0.5-2% of thickener. The two-component waterborne epoxy resin and waterborne curing agent are taken as main film-forming matters, so that the condition that the coating has high crosslinking density and barrier property is ensured by chemical crosslinking reaction of two components.

Owner:GUANGZHOU JOINTAS CHEM +1

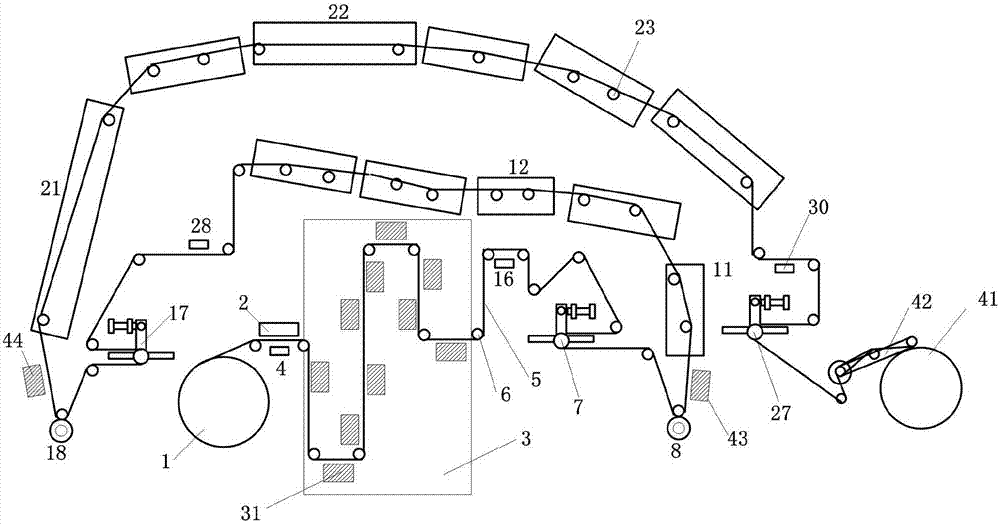

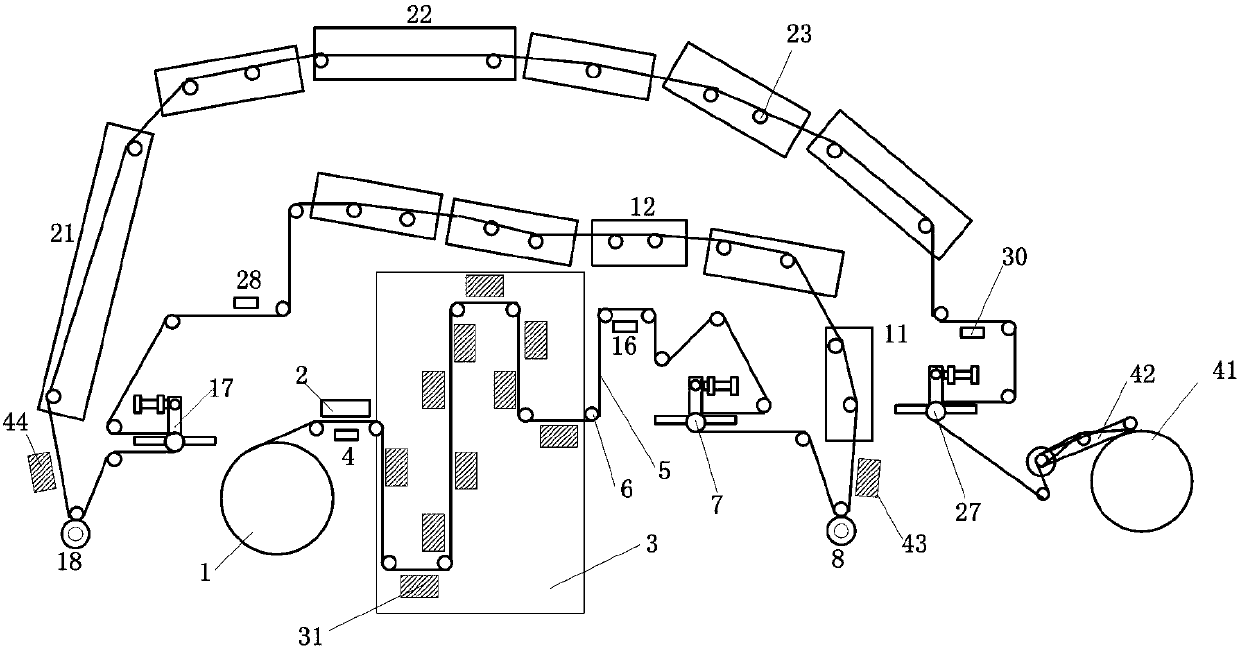

Device for coating graphene on surfaces of metal foils

ActiveCN107457141AThe glue layer is thin and uniformStrong adhesionPretreated surfacesCoatingsMetal foilCopper foil

The invention discloses a device for coating graphene on surfaces of metal foils. The device comprises a control unit, and an unwinding unit, a coating printing device, a baking unit and a winding unit arranged in sequence in a moving direction of the metal foils; the metal foils are aluminum foils or copper foils; the coating printing device comprises a pressing roller, a driving silica gel roller and a driving steel roller laminated from top to bottom; the driving silica gel roller and the driving steel roller are rotated in opposite directions by keeping a micron gap; the driving steel roller is dipped in a colloid pool with viscous materials; and a substrate is arranged between the pressing roller and the driving silica gel roller. The device realizes uniform spraying of materials with submicron thicknesses and thinner layers on the surface of the substrate to meet the thickness requirements of the graphene coated on the metal foils, and achieves excellent adhesion to effectively reduce the contact resistance between carbon particles and the metal foils.

Owner:陕西浩合机械有限责任公司

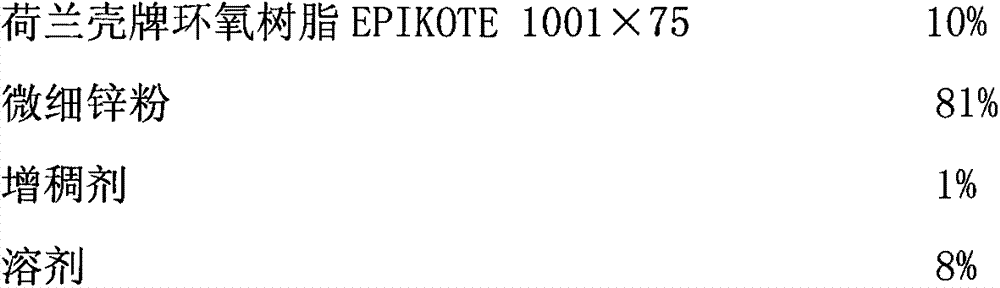

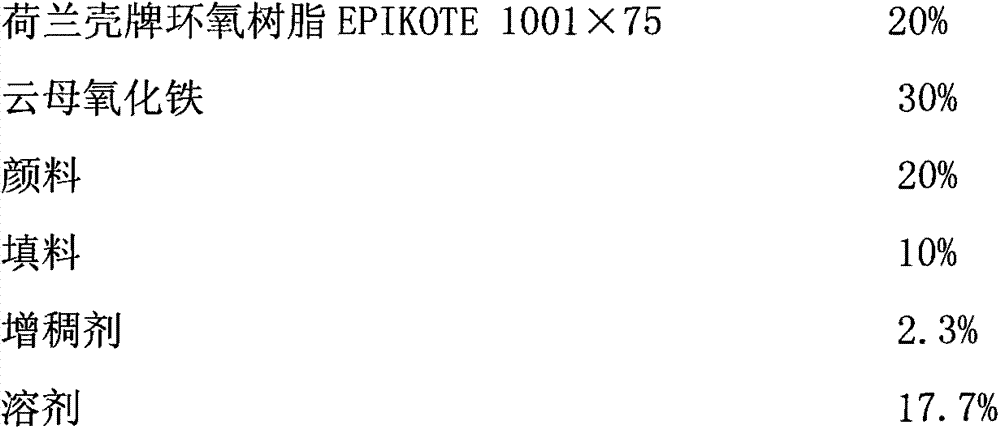

Super-weatherproof heavy-duty high-solid thermal insulating electrostatic conducting coating system

InactiveCN103497643AHigh content of zinc dustImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsHeat conductingCoating system

The invention discloses a super-weatherproof heavy-duty high-solid thermal insulating electrostatic conducting coating system and belongs to the technical field of chemical coatings. The super-weatherproof heavy-duty high-solid heat conductance barrier electrostatic coating system comprises a bottom coat, an intermediate coat and a surface coat, wherein the bottom coat is formed by coating an epoxy zinc rich primer, the intermediate coat is formed by coating an epoxy mica iron oxide paint and the surface coat is formed by coating a fluoro-carbon finish; the fluoro-carbon finish is added with hollow glass micro beads and a heat conducting powder. The electrostatic coating system provided by the invention is excellent in heavy duty, heat insulation and weather-proofing properties, high in electrostatic conductivity, high in solid content, low in volatilization, healthy and has environment-friendly effect, is long in system service life, and suitable for various steel structure facilities such as a gasoline can, a container, a steel pipe, a bridge, petrochemical equipment, a ship and a harbor facility.

Owner:浙江绿色德环保科技股份有限公司

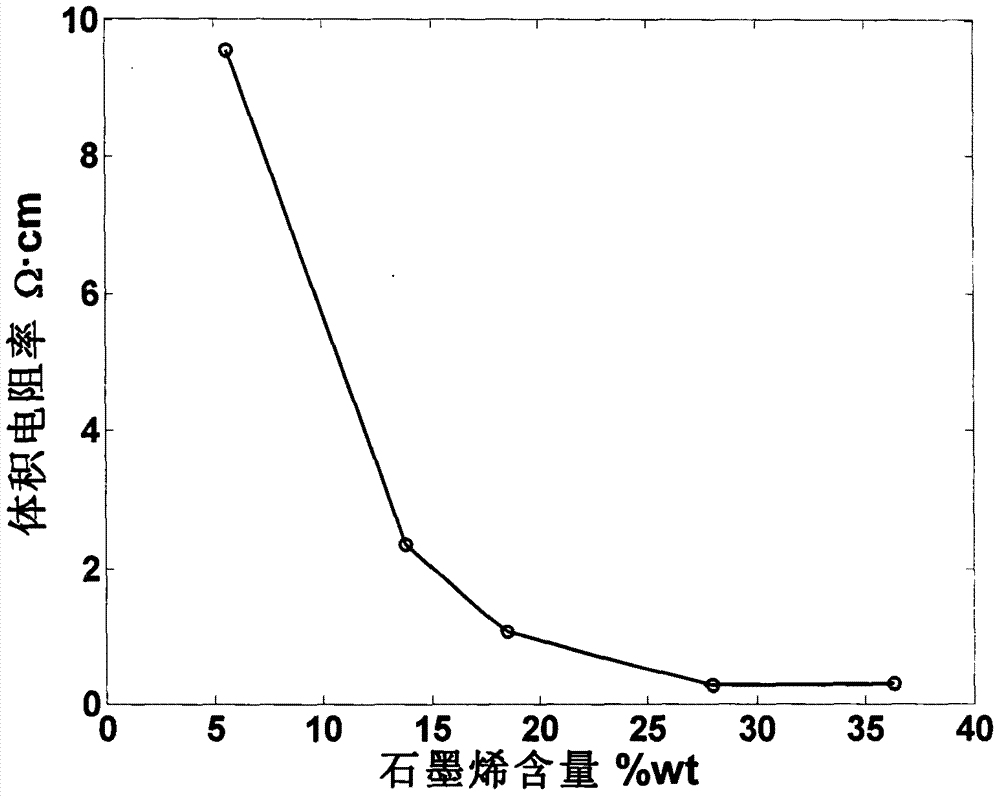

Electrostatic conductive and corrosion-resistant epoxy resin-graphene coating and preparation method thereof

InactiveCN105778709AGuaranteed long-term static conductive effectImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsEpoxyGraphene coating

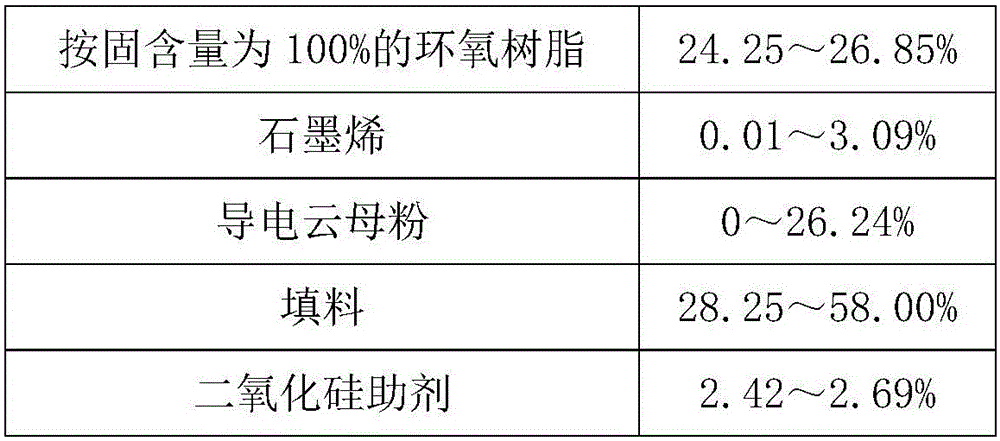

The invention relates to an electrostatic conductive and corrosion-resistant epoxy resin-graphene coating and a preparation method thereof. The coating consists of a component A and a component B, wherein the component A comprises the following components in percentage by mass: 24.25 to 26.85 percent of epoxy resin, 0.01 to 3.09 percent of graphene, 0 to 26.24 percent of conductive mica powder, 28.25 to 58.00 percent of a filler, 2.42 to 2.69 percent of a silicon dioxide auxiliary, and a solvent; the component B comprises 50 to 100 percent of a polyamide curing agent and 0 to 50 percent of butanol. The novel composite coating is prepared by utilizing a lamellar structure and high corrosion resistance, electrical conductivity and chemical stability of graphene, has a good electrostatic conduction effect and a good corrosion-resistant effect, and is long in service life, nontoxic and free of pollution. The phenomena of bubbles, cracks, spalling, chalking and digestion after 60-day acid leaching and 60-day alkaline leaching are avoided. A preparation process is simple, and a novel technology for application of graphene to electrostatic conduction and corrosion resistance is provided.

Owner:TIANJIN XITENG SCI & TECH CO LTD

Anti-flaming static electricity conducting organic silicon nano ceramic coating used for coal-mine gas drainage pipeline

InactiveCN102643605AImprove corrosion resistanceImprove mechanical propertiesCorrosion preventionAnti-corrosive paintsCeramic coatingCoal mine methane

The invention belongs to the technical field of anti-flaming static electricity conducting organic silicon nano ceramic coating, and particularly relates to anti-flaming static electricity conducting organic silicon nano ceramic coating used for a coal-mine gas drainage pipeline and a preparation method of the coating. The coating comprises the following compositions: organic silicone resin, metal oxide, silicate fillers, carbon materials, nano ceramic powders and mixed solvents. The compositions are weighed according to proportion and mixed to be prepared into thick and sticky suspension fluid. According to the anti-flaming static electricity conducting organic silicon nano ceramic coating, two technologies, namely technology of the organic coating and the nano ceramic, are combined together, a paint film is converted into the inorganic type from the organic type at high temperatures, the inorganic coating with good flame retadance, static electricity conduction, temperature resistance and mechanical property is formed on the metal base layer so as to realize the comprehensive protection for a base body. The anti-flaming static electricity conducting organic silicon nano ceramic coating can be widely applied to corrosion resistance of oil pipelines, gas pipelines and chemical equipment.

Owner:北京中宇科博环保工程有限公司

Antistatic PC-ABS (polycarbonate-acrylonitrile butadiene styrene) alloy material and preparation method thereof

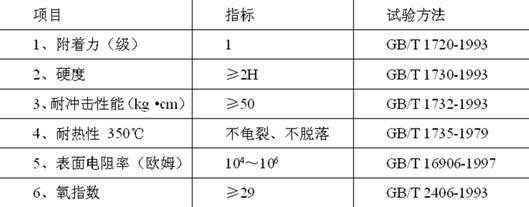

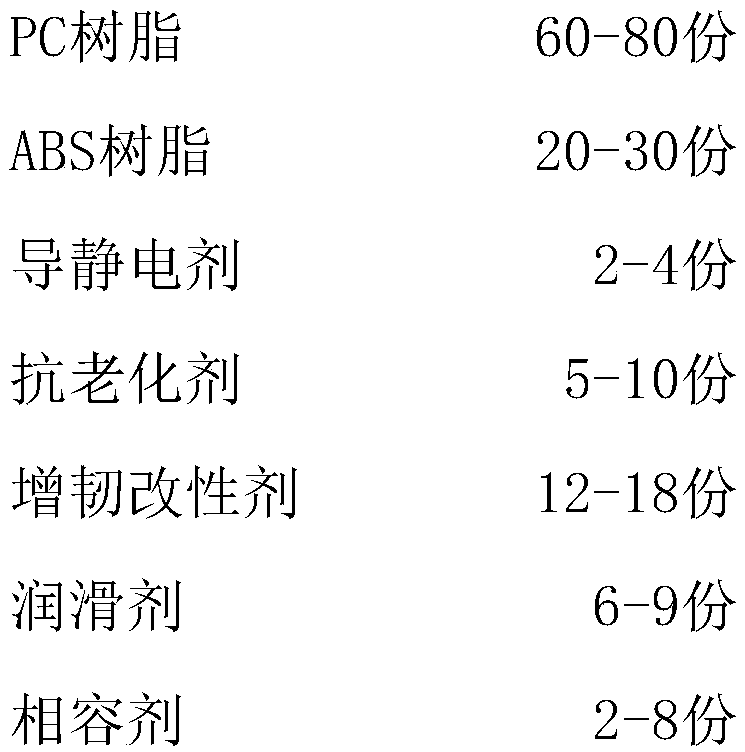

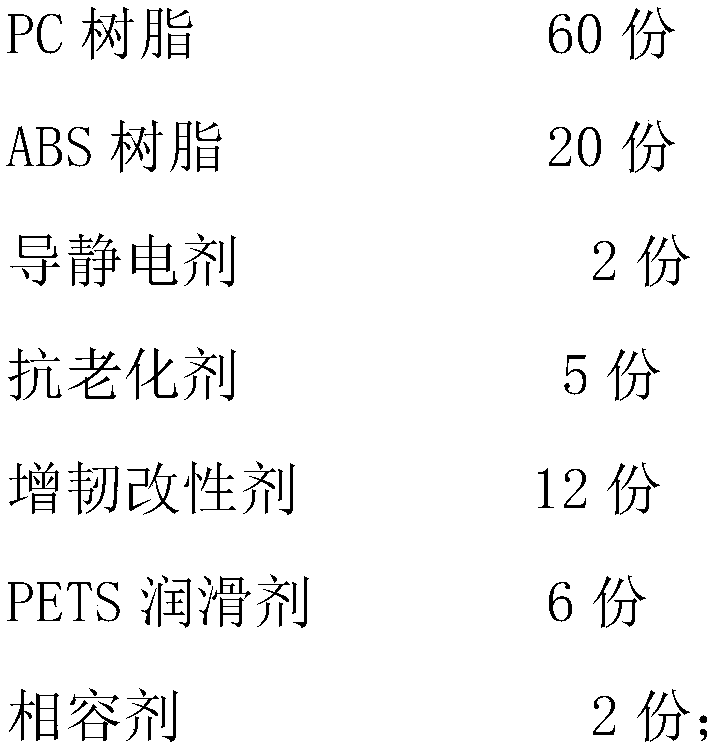

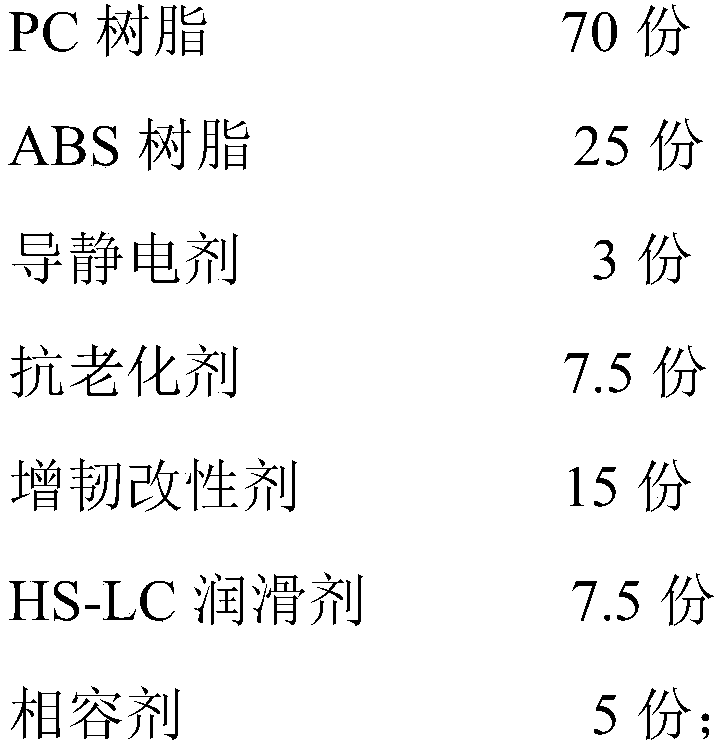

The invention relates to the technical field of alloy materials, in particular to an antistatic PC-ABS (polycarbonate-acrylonitrile butadiene styrene) alloy material and a preparation method thereof.The antistatic PC-ABS alloy material is prepared from the following raw materials in parts by weight: 60 to 80 parts of PC resin, 20 to 30 parts of ABS resin, 2 to 4 parts of a static conducting agent, 5 to 10 parts of an anti-aging agent, 12 to 18 parts of a toughening modifier, 6 to 9 parts of a lubricant, and 2 to 8 parts of a compatilizer, wherein the static conducting agent adopts graphene with 1 to 20 layers. The antistatic PC-ABS alloy material has the advantages that the surface resistivity can reach 104 ohm, the antistatic property is excellent, the antistatic effect is lasting, and the anti-impact property and tensile strength are good.

Owner:GUANGDONG GERUI NEW MATERIALS CO LTD

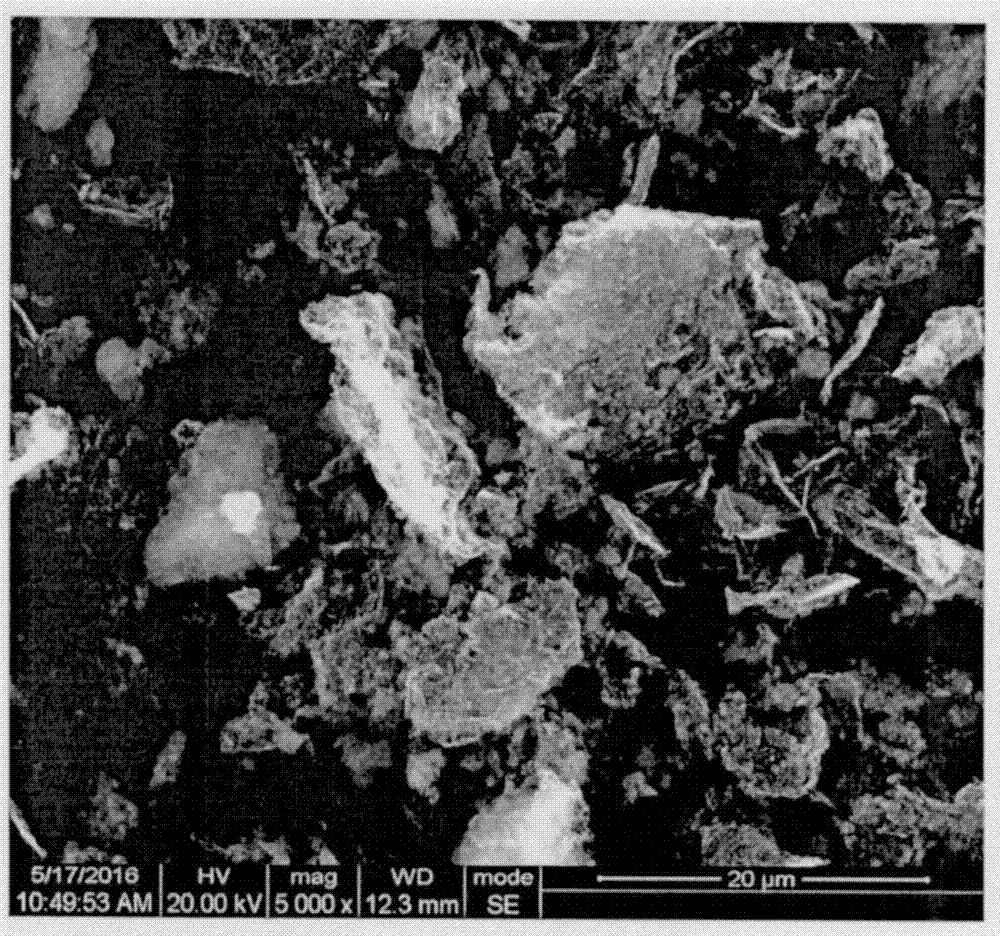

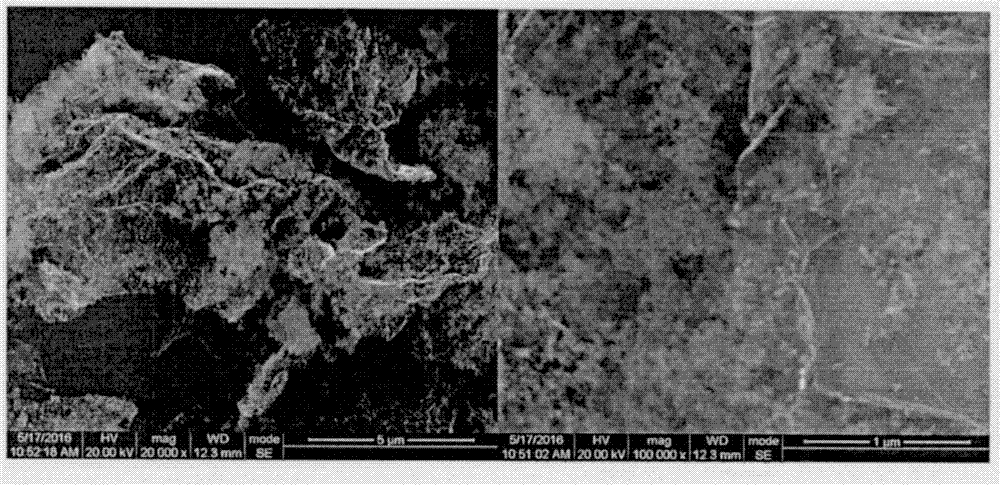

Graphene-white carbon black composite powder and preparation technology thereof

InactiveCN107541096AMaintain Monolayer DispersionImprove mechanical propertiesPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsDispersitySlurry

The invention relates to graphene-white carbon black composite powder and a preparation technology thereof. The preparation technology comprises dispersing a graphene oxide aqueous solution and whitecarbon black powder in water at a high speed to obtain uniform mixed aqueous slurry, adding a gelling agent and a surfactant into mixed aqueous slurry, adjusting pH of the solution so that graphene oxide-white carbon black hydrogel is obtained, filtering and drying the graphene oxide-white carbon black hydrogel to obtain graphene oxide-white carbon black aerogel and calcining the graphene oxide-white carbon black aerogel at a high temperature in the inert atmosphere to reduce the graphene oxide so that the graphene-white carbon black composite powder is obtained. The preparation technology issimple and reliable and realizes a low cost. The graphene-white carbon black composite powder has powder resistivity less than 100 omega. cm, graphene in the composite material has good single layer dispersity, rich pore structures are formed through layer enwinding, the white carbon black nano-particles are uniformly dispersed on the surface of the graphene layer, and the composite material has excellent electrical conductivity and thermal conductivity and can be widely used in the fields of coatings, rubber products and plastic.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI +1

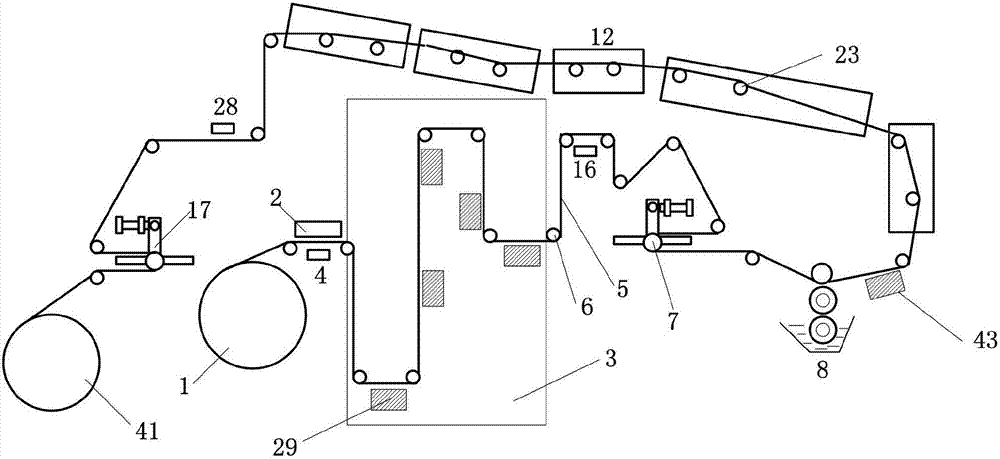

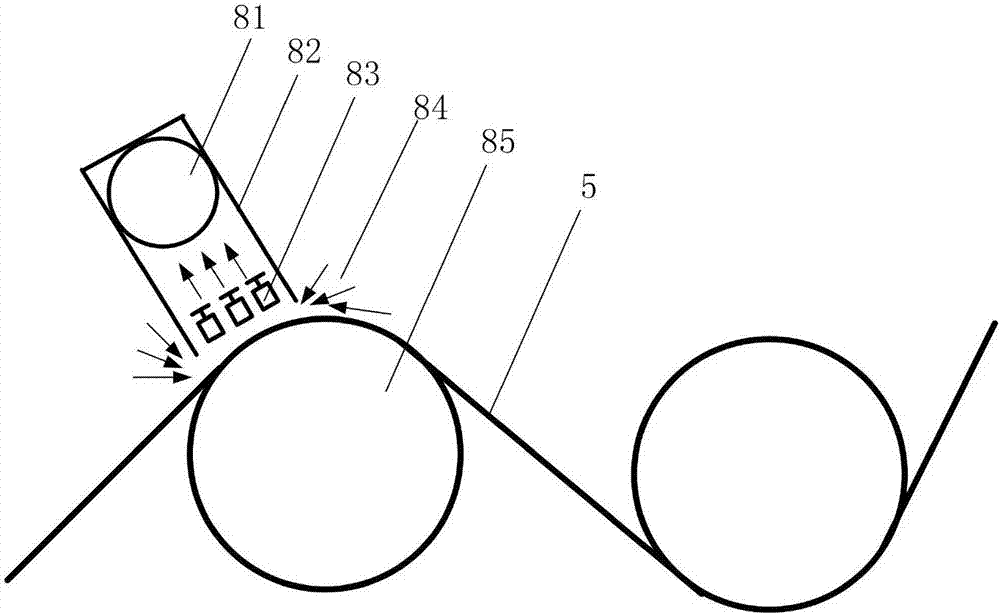

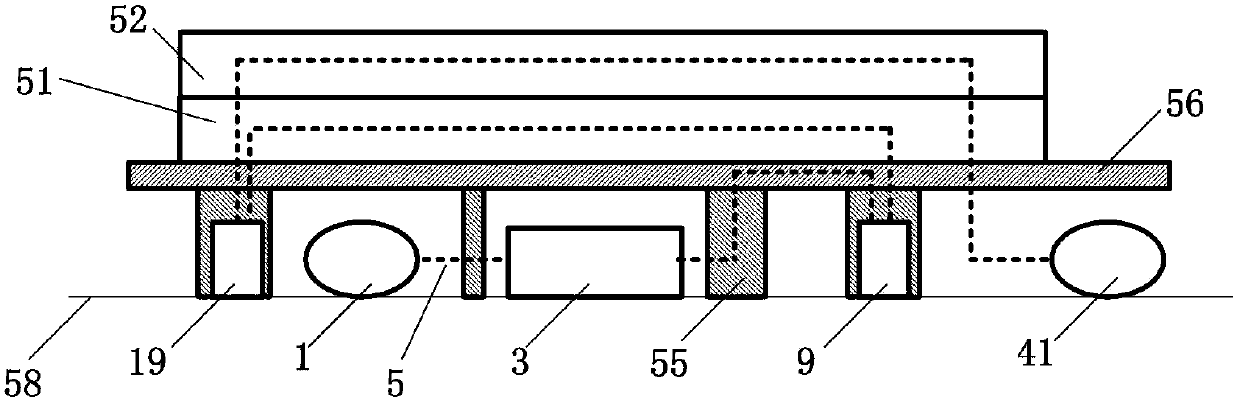

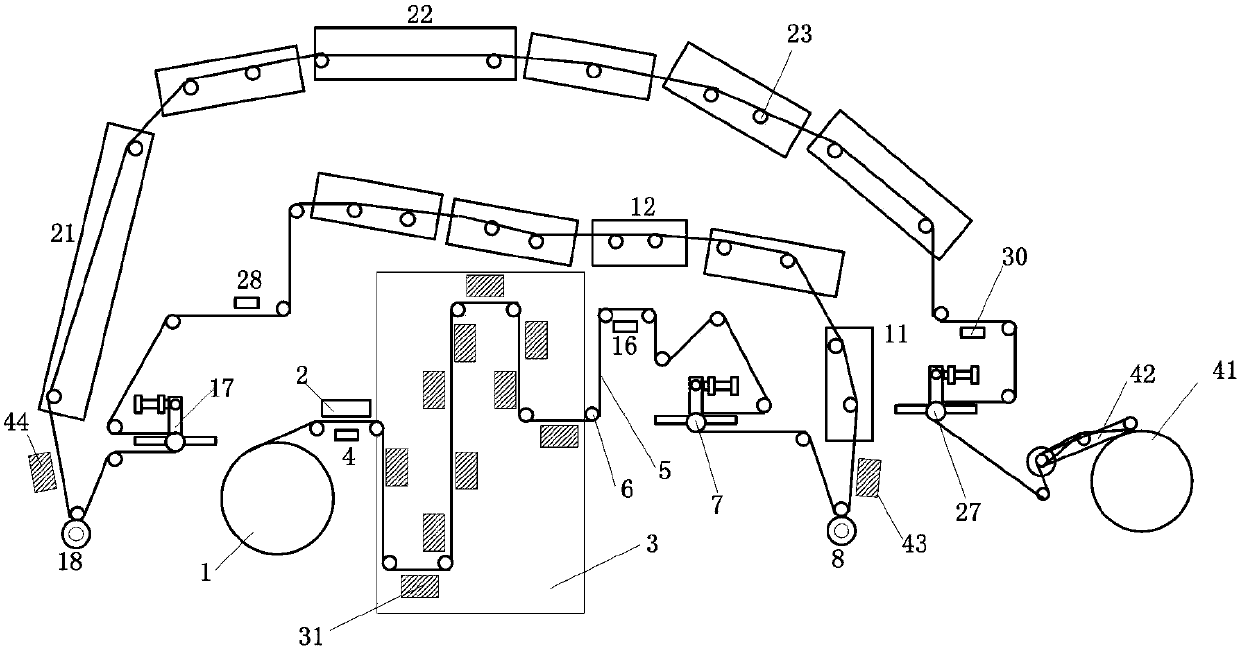

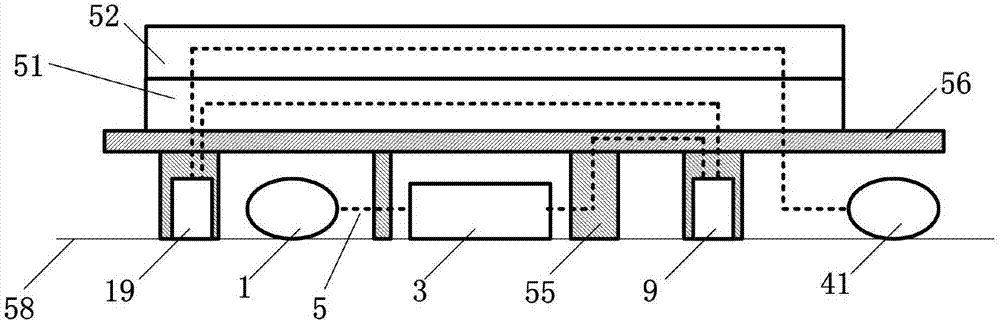

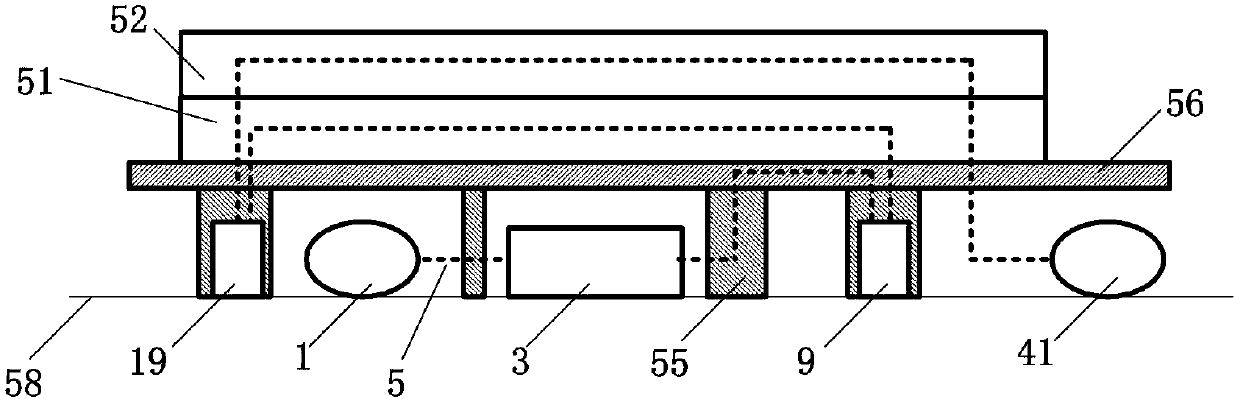

Wide-breadth pole piece two-sided position-sleeving coating machine for power battery and supercapacitor

ActiveCN107611350ALower internal resistanceImprove cycle lifeElectrode manufacturing processesPretreated surfacesCooking & bakingMetal foil

The invention discloses a wide-breadth pole piece two-sided position-sleeving coating machine for a power battery and a supercapacitor. The coating machine comprises a control unit, an unwinding unit,a high-voltage discharge processing device, a front coating device, a lower drying tunnel, a back coating device, an upper drying tunnel and a winding unit, wherein the unwinding unit, the high-voltage discharge processing device, the front coating device, the lower drying tunnel, the back coating device, the upper drying tunnel and the winding unit are arranged in sequence along a movement direction of a metal foil; the high-voltage discharge processing device includes a high-voltage box body, a negative pressure ventilation device, a high-voltage source and a plurality of long-stripped discharge electrodes; the metal foil is wound on a high-voltage discharge roll; the discharge electrodes are arranged at a front end of an opening of the high-voltage box body, and are arranged at the periphery of the high-voltage discharge roll in parallel along an axial direction of the high-voltage discharge roll; a negative pressure air outlet is formed at a rear end of the high-voltage box body;and the air outlet communicates with the negative pressure ventilation device outside. According to the coating machine, based on core technologies such as high-voltage discharge surface processing, multi-stage tension control, segmental cascaded baking and material particle trowelling, the front and back coating for an aluminum foil and a copper foil whose breadth is 1.5m, working speed is 150m / min and position-sleeving precision is plus or minus 0.3mm are implemented.

Owner:陕西浩合机械有限责任公司

Water-based silica sol gel inorganic zinc-rich primer and preparation method thereof

InactiveCN112194916AMeet Companion Application RequirementsMeet application requirementsAnti-corrosive paintsElectrically-conductive paintsChemical storagePhysical chemistry

The invention relates to the field of coatings, and provides a water-based silica sol gel inorganic zinc-rich primer and a preparation method thereof, the product is composed of a water-based silica sol gel solution, a filler, an auxiliary agent and deionized water; and zinc powder is used as another reaction component. In addition, an organosilane polymer is also added, the water-based silica solgel solution and the organosilane polymer are added into deionized water during preparation, the auxiliary agent and the filler are added, a mixture is uniformly dispersed through high-speed shearing, and a base material component is obtained through blending; during construction, the base material component and the zinc powder component are blended in proportion and stirred uniformly, and cleanwater is used for adjusting the construction viscosity for coating. The problems that in the prior art, solvent type inorganic zinc-rich primer is high in VOC, large in coating porosity, thick in coating cracking and poor in adhesion, and the strong alkali characteristic of traditional water-based alkali metal silicate inorganic zinc-rich paint has adverse effects on the environment and steel aresolved. The water-based silica sol gel inorganic zinc-rich primer is used for carbon steel anticorrosion protection in severe environments, and is also used for static electricity conduction protection in chemical storage tanks.

Owner:SHANGHAI ZHENHUA HEAVY IND CHANGZHOU COATINGS CO LTD

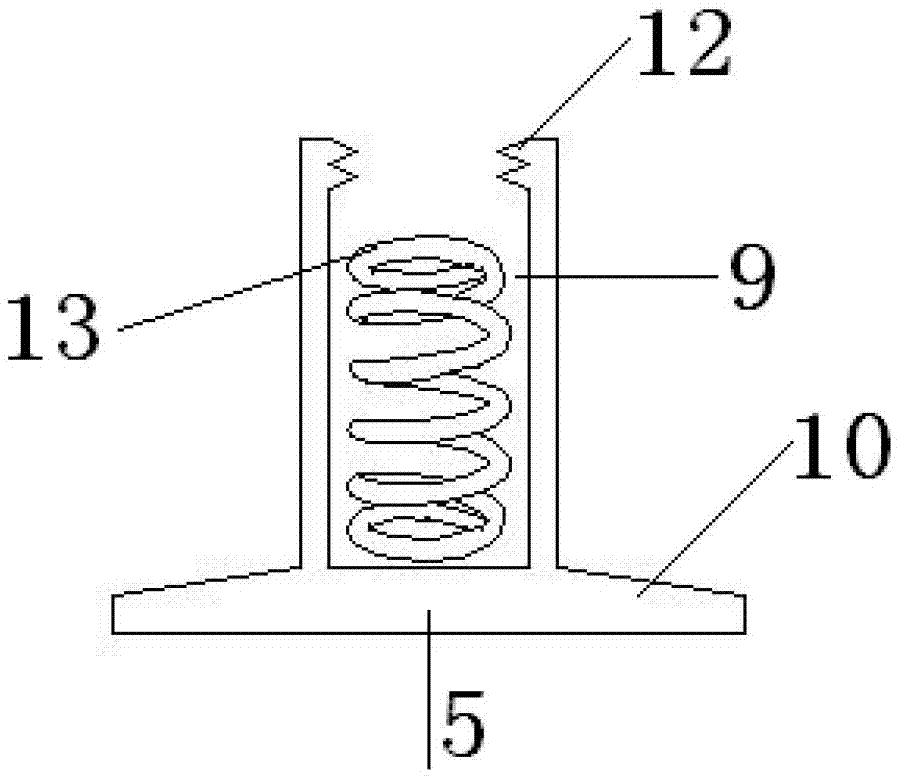

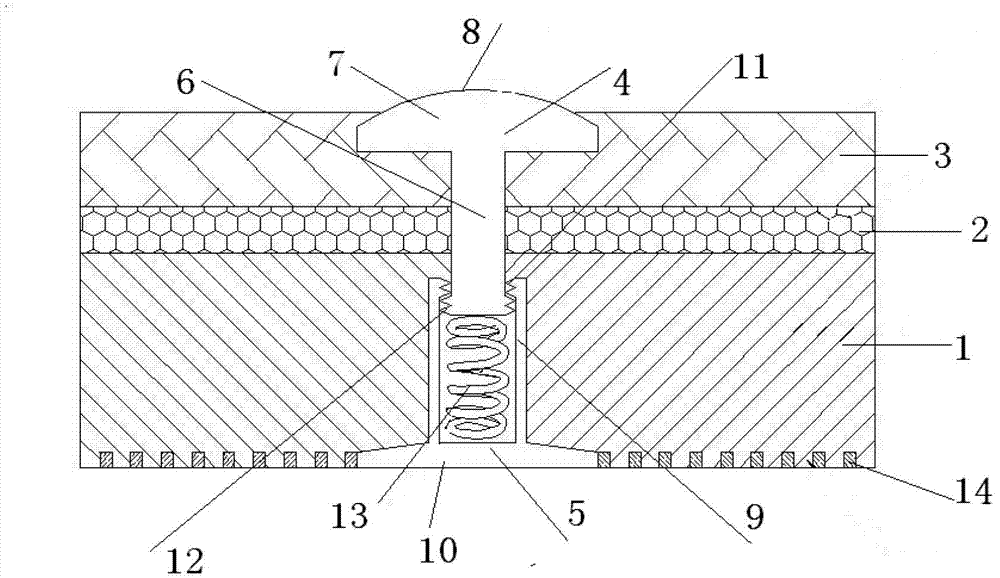

Anti-static sole and shoes applying same

The invention provides an anti-static sole which comprises an undersole and an insole, and is characterized by also consisting of a metal male bolt and a metal female bolt; the male bolt and the female bolt vertically penetrate through the undersole and the insole; the male bolt is arranged above the female bolt; the female bolt and the male bolt are mutually matched; the male bolt comprises a male bolt shaft and a male bolt cover; the top of the male bolt cover is provided with a circular arc-shaped convex hull; the circular arc-shaped convex hull is exposed outside the insole; the bottom of the undersole is provided with a mesh-like metal wire; and the female bolt is contacted with the metal wire. The invention also provides a pair of shoes which apply the anti-static soles, and the anti-static sole and the shoes have the advantages that a production process is simple, the cost is low, the processing is easy, the use is convenient, the anti-static performance is good, the shoes are comfortable to wear, and the shock-absorbing performance can be automatically adjusted according to the stress on feet.

Owner:MAOTAI FUJIAN SOLES CO LTD

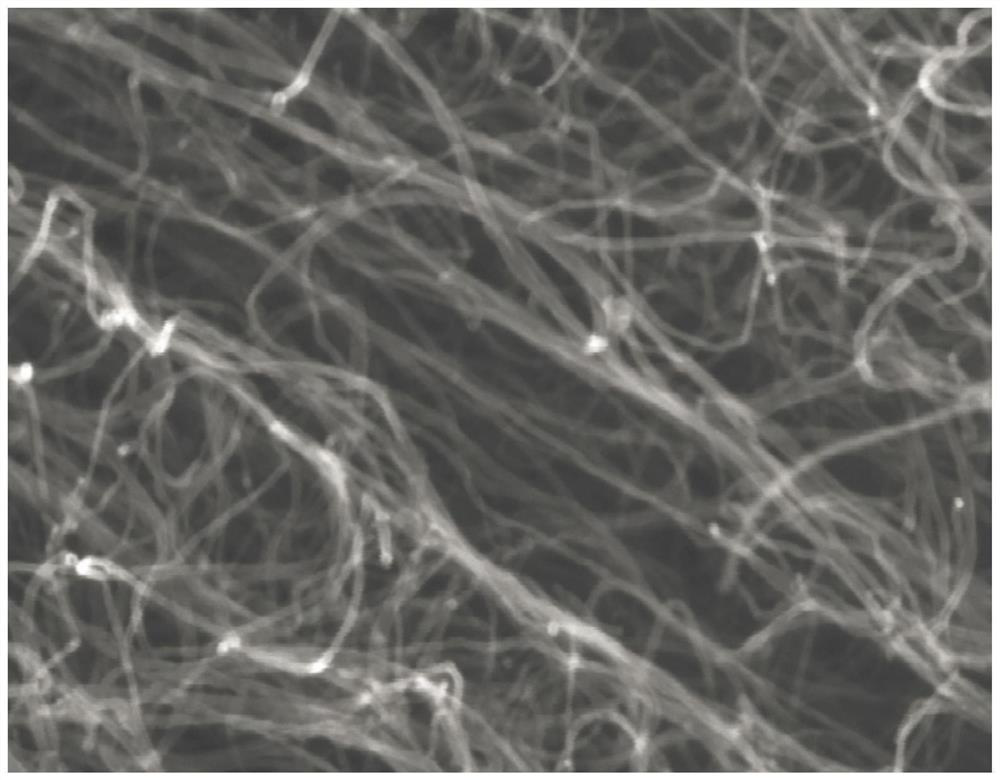

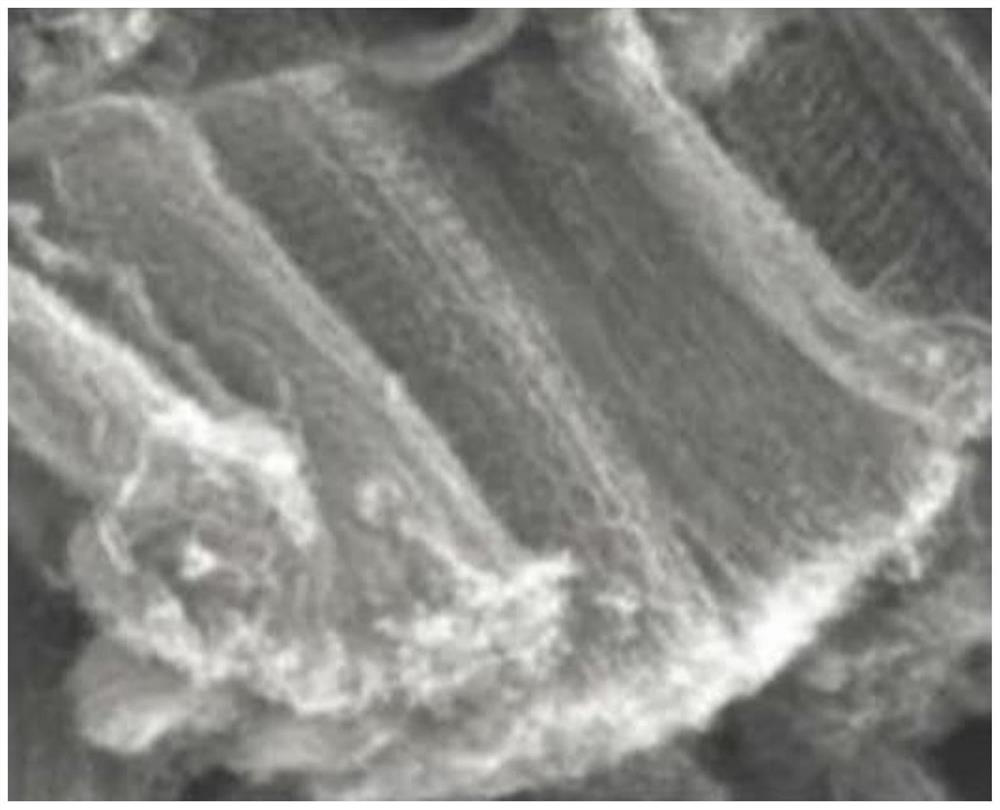

Composition, rubber compound, preparation method of rubber compound and tire

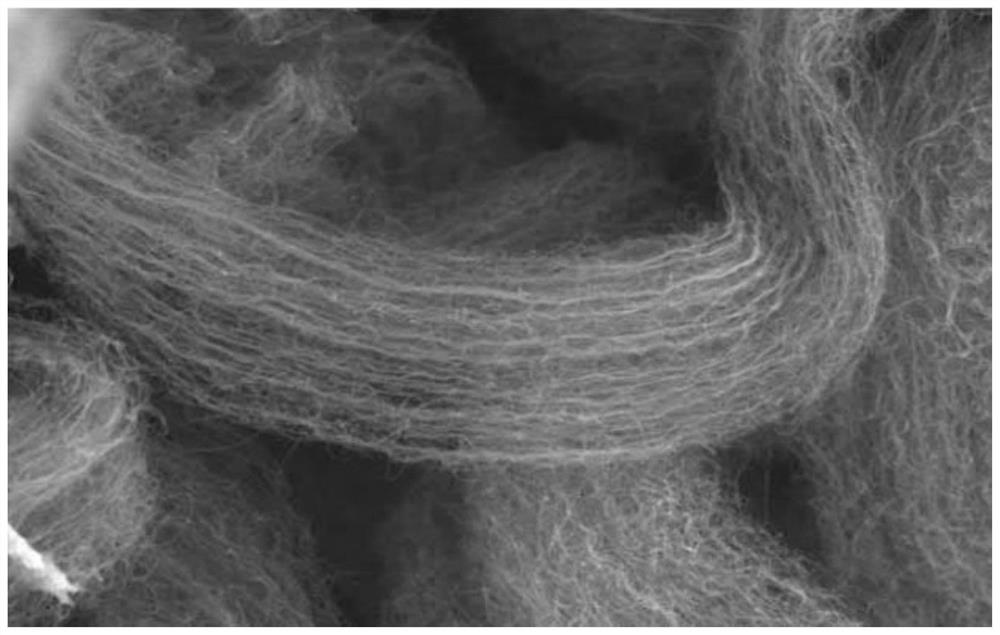

PendingCN113929989AGood static conductivityImprove wear resistanceSpecial tyresPolymer scienceCarbon nanotube

The invention provides a composition, a rubber compound, a preparation method of the rubber compound and a tire, and belongs to the technical field of tires. The composition comprises the following components in parts by weight: 100 parts of rubber, 60-150 parts of white carbon black, 0-35 parts of carbon black and 1-35 parts of carbon nanotubes. The rubber comprises 0-50 parts by weight of natural rubber, 0-50 parts by weight of butadiene rubber and 0-100 parts by weight of butadiene styrene rubber. The average tube diameter of the carbon nanotubes is 5-25 nm. The average length of the carbon nanotubes is 40-65 [mu] m. The specific surface area of the carbon nanotube is 100-360 m < 2 > / g. According to the composition disclosed by the invention, part or all of carbon black is replaced by the carbon nanotubes, and the tire prepared from the carbon nanotubes with specific average tube diameter, specific average length and specific specific surface area has relatively high static conductivity and relatively high wear resistance, so that the driving safety performance is improved, and the service life of the tire is prolonged.

Owner:RACHEM CHINA CO LTD +3

Preparation method of graphene current collector

The invention provides a preparation method of a graphene current collector. The preparation method comprises the following steps: (1) mixing graphene and a binder with a solvent to obtain a graphene suspension liquid, wherein the content of graphene in the graphene suspension liquid is 0.01 to 10 mg / mL; (2) putting the graphene suspension liquid and a substrate in a container at the same time, and then forming a graphene thin film on the surface of the substrate through self-assembling; and (3) taking the graphene thin film out together with the substrate, and carrying out processing at the temperature of 400 to 1500 DEG C under a protective atmosphere to obtain the graphene current collector.

Owner:NINGBO MORSH TECH

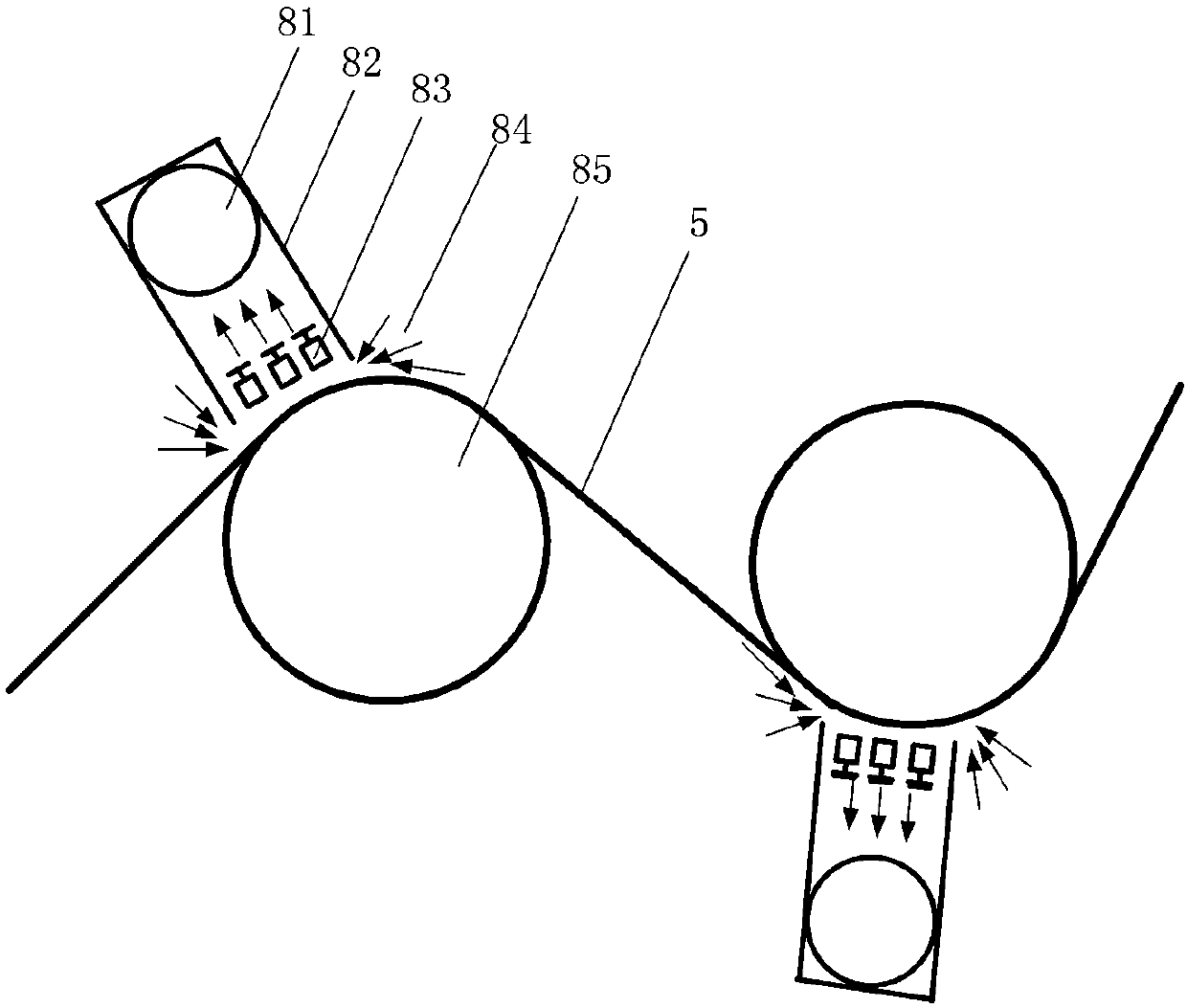

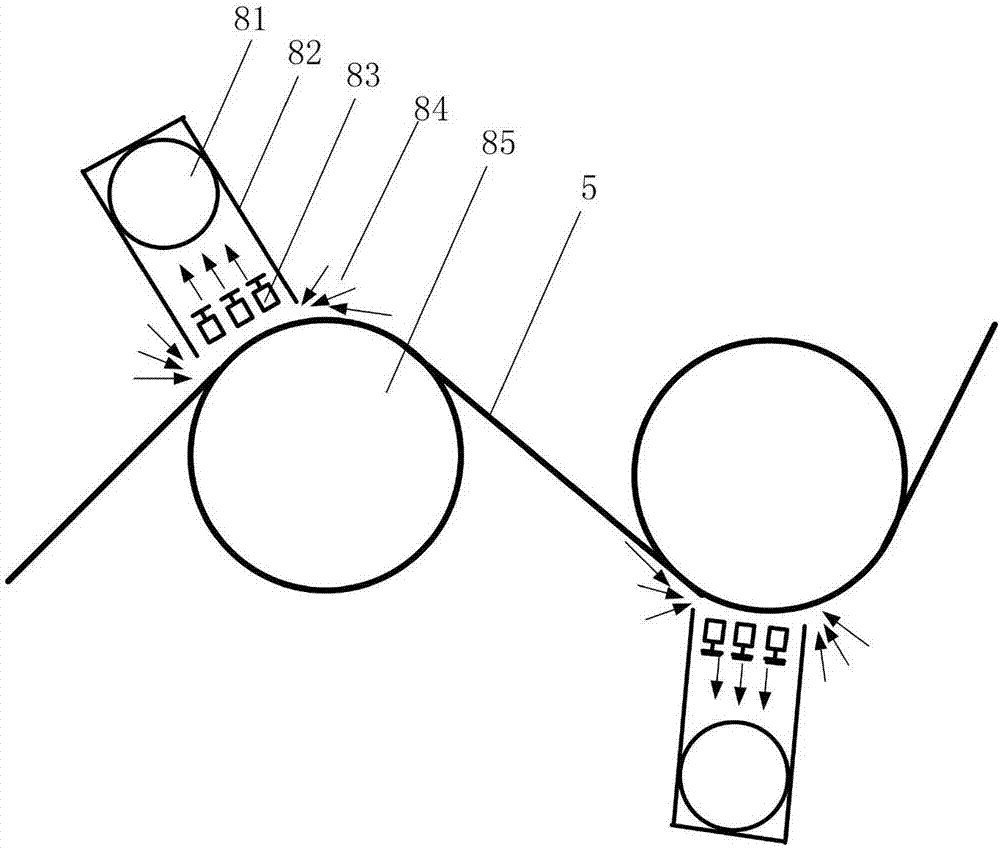

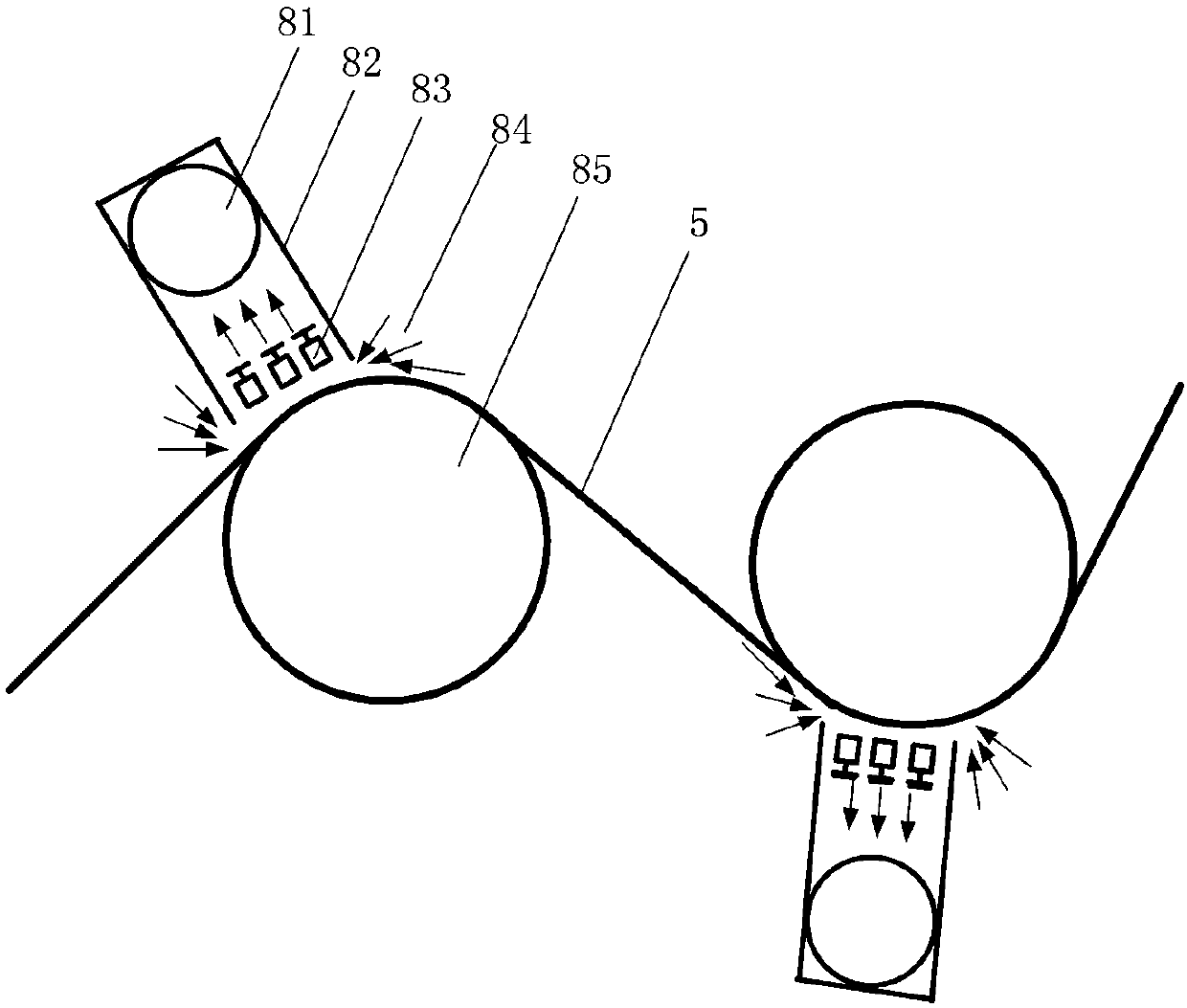

Extrusion glue leveling device of coating machine

InactiveCN107457158ALower internal resistanceImprove cycle lifeLiquid surface applicatorsCoatingsAdhesion forceMetal foil

The invention discloses an extrusion glue leveling device of a coating machine. The extrusion glue leveling device comprises a power transmission unit, a pressure adjustment unit and an extrusion glue leveling roller, wherein the extrusion glue leveling roller is arranged on a swing arm, and is fitted to the surface of a base material coated with a material in a pressing manner under the action of the pressure adjustment unit; and the extrusion glue leveling roller rotates along a direction opposite to the moving direction of the base material under the driving of the power transmission unit. According to the extrusion glue leveling device of the coating machine, the pressure-adjustable glue leveling roller is adopted to carry out extrusion for glue leveling along the opposite direction after glue is applied, so that the contact area between material particles and a substrate is further enlarged, the adhesion force is enhanced, and the conductivity characteristic of a finished carbon-coated metal foil product is improved.

Owner:陕西浩合机械有限责任公司

Solvent-resistant static-conducting epoxy paint

InactiveCN105086761AMeet the coating needsImprove performanceEpoxy resin coatingsElectrically-conductive paintsEpoxyChemical industry

The invention discloses a solvent-resistant static-conducting epoxy paint which is composed of a part A and a part B. The part A is composed of 20-40 parts of epoxy resin, 10-25 parts of pigment and filler, 15-25 parts of conducting material, 0.2-0.5 part of defoaming agent, 0.5-1 part of leveling agent, 1-1.5 parts of anti-settling agent and 10-15 parts of diluter. The part B is composed of 8-12 parts of modified amine curing agent. The part A and part B are reasonably matched, the epoxy paint is stable in performance and convenient for storage before use; and after being applied, the epoxy paint has the advantages of favorable static conductivity, high solvent resistance and high corrosion resistance, and completely satisfies the application demands for liquid material tanks and pipelines in petroleum and chemical industries.

Owner:ANHUI WILLY PAINT SCI & TECH LTD

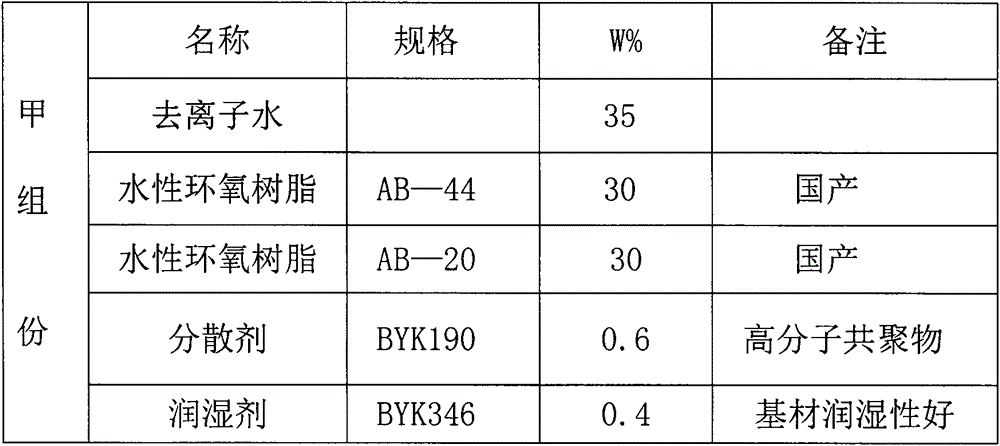

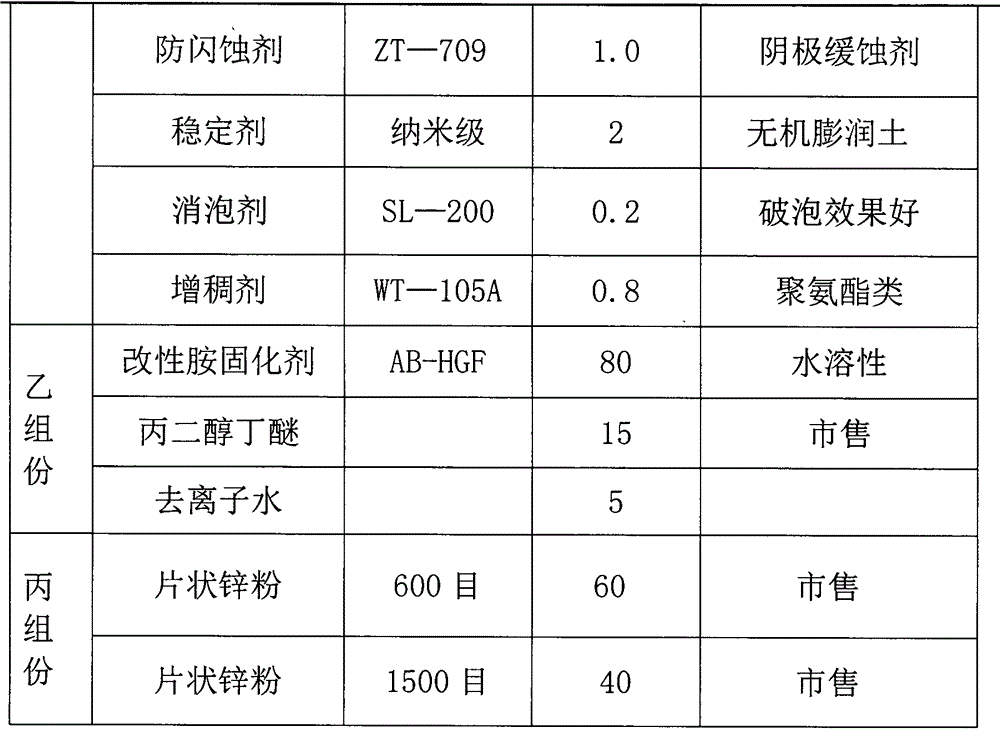

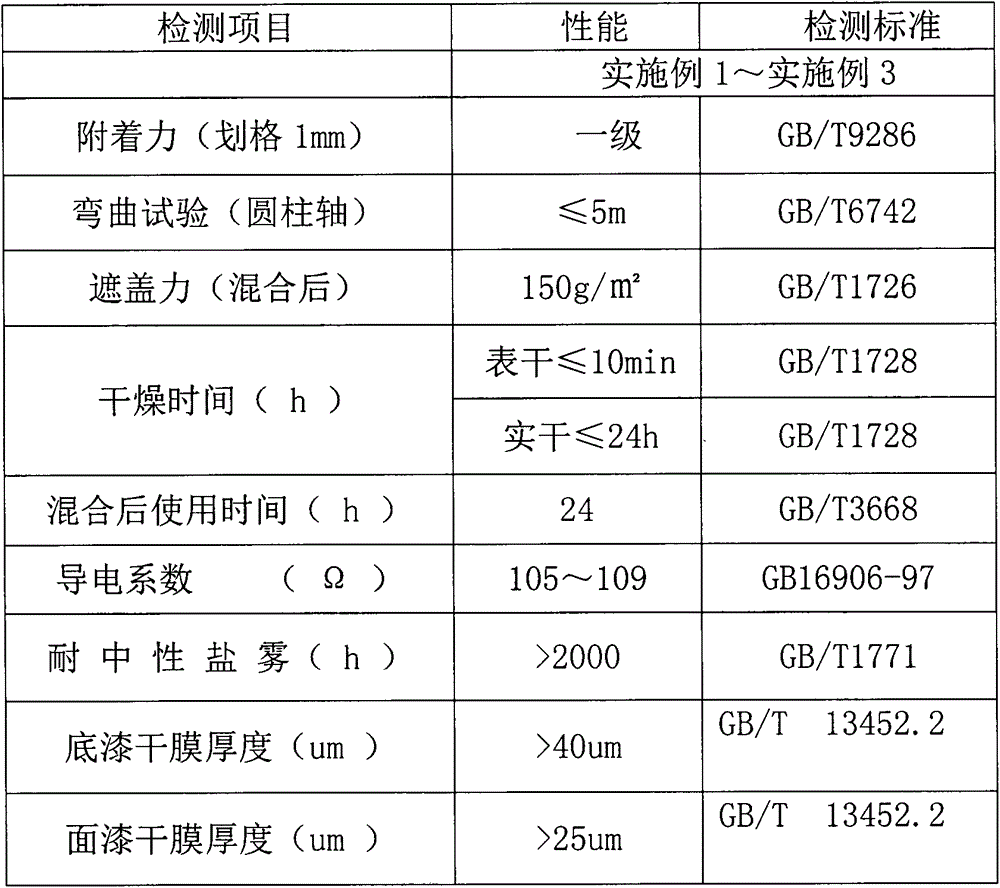

Aqueous zinc-rich flake cathode protection prime coat, preparation method and uses thereof

InactiveCN105017922AImprove conductivityReduce zinc dust contentAnti-corrosive paintsEpoxy resin coatingsPROPYLENE GLYCOL BUTYL ETHEREpoxy

The present invention discloses an aqueous zinc-rich flake cathode protection prime coat, and belongs to the technical field of heavy anti-corrosion coating materials. The aqueous zinc-rich flake cathode protection prime coat comprises a component A, a component B and a component C, wherein a mass ratio of the component A to the component B is 5:1-8:1, a mass ratio of the mass sum of the component A and the component B to the component C is 5:1, the component A comprises, by mass, 45-60% of an aqueous epoxy resin, 4-6% of an auxiliary agent, and 35-50% of deionized water, the component B comprises, by mass, 70-80% of a modified amine curing agent, 10-15% of propylene glycol butyl ether, and 5-15% of deionized water, and the component C is flaky zinc powder. According to the present invention, the salt spray resistance of the aqueous zinc-rich flake cathode protection prime coat is similar to the salt spray resistance of the aqueous zinc-rich prime coat, and the aqueous zinc-rich flake cathode protection prime coat has unique advantages in the fields of construction convenience and static electricity conducting, and further has characteristics of environmental protection, safety, and no toxicity.

Owner:镇江德昇新材料科技有限公司

Sulfur-based soil conditioner

InactiveCN106278706AImprove securityGood static conductivityCalcareous fertilisersAmmonium salt fertilisersAlkali soilAdhesive

The invention relates to the technical field of agriculture and in particular relates to a sulfur-based soil conditioner. The sulfur-based soil conditioner disclosed by the invention is composed of the following components in percentage by mass: 35-90% of sulfur, 5-60% of general chemical fertilizers and 2-10% of adhesives. The sulfur-based soil conditioner disclosed by the invention has the advantages that the soil conditioner is high in sulfur content and small in usage, large in sulfur specific surface area and good in absorption and transformation effect, and the preparation method is simple, safe to process and convenient to use; and moreover, in sulfur-free saline-alkali soil, due to a contrast test of planting seeding-watermelon, cotton and corn, 50-150kg of the sulfur-based soil conditioner disclosed by the invention is used per mu, and the yield can be increased by 12-32%.

Owner:巴州康菲能源科技有限公司

Obstructive explosionproof composite and preparation method thereof

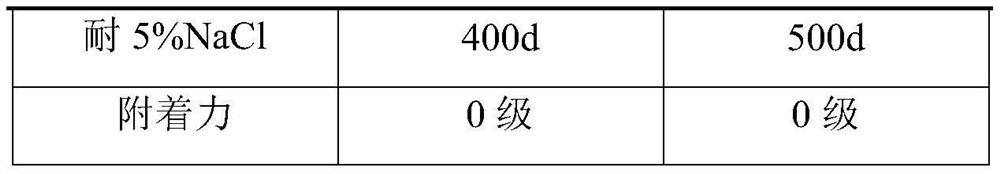

InactiveCN110385249AHigh performance against corrosion and protectionImprove corrosion resistancePretreated surfacesElectrophoretic coatingsCorrosion preventionHoneycomb

The invention discloses an obstructive explosionproof composite and a preparation method thereof. Honeycomb aluminum foil or honeycomb paper foil is used as a structural base material, and after the surface of the structural base material is coated with a coating having corrosion prevention and electric conduction function, the problems that existing metal obstructive explosionproof materials areeasy to corrode and short in use life, and cannot be used in dynamic fuel storage vessels are solved. When the honeycomb paper foil is used as the structural base material, production cost of an existing obstructive explosionproof material system can be substantially reduced, and the obtained obstructive explosionproof composite is suitably applied to large oil material storage vessels, and simultaneously the preparation method of the obstructive explosionproof composite facilitates large area popularization and usage of the obstructive explosionproof composite.

Owner:通化市安泰防爆科技有限公司

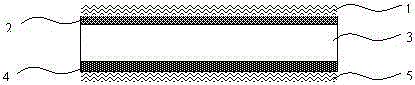

Special aluminum foil for soft package polymer lithium-ion battery film and preparation technology of special aluminum foil

ActiveCN105185927AImprove corrosion resistanceImprove barrier propertiesSecondary cellsJackets/cases materialsAdhesiveAlloy

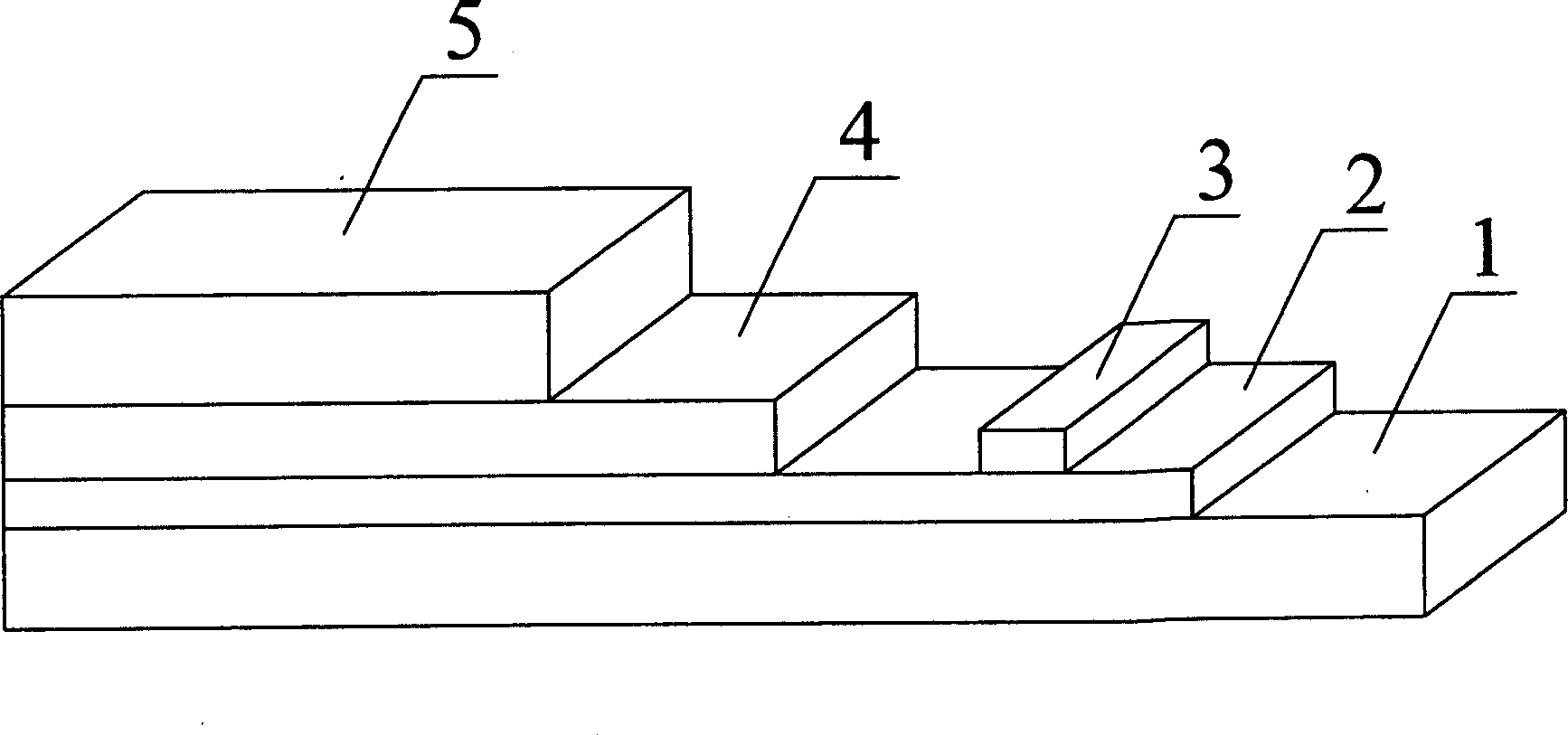

The invention relates to a special aluminum foil for a soft package polymer lithium-ion battery film. The special aluminum foil comprises a first carbon-coated layer, a first silicide layer, an aluminum foil alloy layer, a second silicide layer and a second carbon-coated layer, wherein the aluminum foil has a layered structure; and the special aluminum foil for the soft package polymer lithium-ion battery film sequentially comprises the first carbon-coated layer, the first silicide layer, the aluminum foil alloy layer, the second silicide layer and the second carbon-coated layer from inside to outside. Alloy aluminum is adopted by the aluminum foil, so that the aluminum foil has relatively good ductility. The surface of the alloy aluminum foil is subjected to siliconization, so that the barrier property and the antiseptic property of the aluminum foil can be improved. Meanwhile, a carbon coating is added to the outmost layer of the aluminum foil, so that excellent static conductivity is provided; and micro-current of active materials is collected. Therefore, the contact resistance between a positive / negative material and collected current can be greatly reduced; the adhesive ability between the positive / negative material and the collected current can be improved; and the dosage of an adhesive can be reduced to obviously improve the overall performance of a battery. The aluminum foil can meet the requirements of a soft package film material of the polymer lithium-ion battery on the ductility, the barrier property and strong caking property of the aluminum foil; and the aluminum foil material provided by the invention can be used as a raw material for preparing the soft package film.

Owner:浙江锂盾储能材料技术有限公司

Water-based graphene static conductive anticorrosive paint and preparation method thereof

InactiveCN112521834AGood static conductivityGood adhesionGrapheneAnti-corrosive paintsFirming agentGraphite

The invention provides a water-based graphene static conductive anticorrosive paint, which belongs to the technical field of water-based paints, and is composed of a component A and a component B. Thecomponent A comprises epoxy resin, graphene filler slurry, a coalescing agent, a wetting agent, a thickening agent, distilled water, an anti-flash-rust agent and a silane coupling agent. The graphenefiller slurry comprises graphene slurry and zirconium beads; wherein the graphene slurry comprises deionized water, a dispersing agent, an organic silicon defoaming agent, a thickening agent, a coloring pigment, an antirust material, graphene powder, mica powder and titanium dioxide; the component B comprises an epoxy curing agent, deionized water and a coalescing agent. When in use, the mass ratio of the component A to the component B is 10:1-2. The invention also provides a preparation method of the water-based graphene static conductive anticorrosive paint. According to the coating disclosed by the invention, the graphene is used as a conductive filler, so that the coating has stable static electricity conduction performance through modification without influencing the corrosion resistance, and the coating has excellent heat resistance, acid and alkali resistance and excellent adhesion performance.

Owner:QINGDAO AIR NEW MATERIALS

Preparation method of positive pole piece, positive pole piece and preparation method of lithium ion battery

InactiveCN107039636AReduce contact resistanceReduce dynamic internal resistanceFinal product manufactureElectrode carriers/collectorsCarbon layerWater based

The invention discloses a preparation method of a positive pole piece, a positive pole piece and a preparation method of a lithium ion battery. The preparation method of the pole piece comprises the following steps: mixing a water-based solvent and a first adhesive in a mass ratio of (100 to 200): (1 to 30) to obtain a first mixed solution; mixing a silane coupling agent of an epoxy group, a first conductive agent and the first mixed solution in a mass ratio of (10 to 30): (90 to 96): (101 to 230) to obtain a second mixed solution; milling the second mixed solution to obtain a first sizing agent, and coating the first sizing agent on the surface of an aluminum foil; baking the first sizing agent to obtain a carbon layer formed on the surface of the aluminum foil; mixing an electrode active material, a second conductive agent and a second adhesive in a mass ratio of (90 to 98): (1 to 10): (1 to 30) to obtain a third mixed solution; milling the third mixed solution to obtain a second sizing agent, and coating the second sizing agent on the surface of the carbon layer; and baking the second sizing agent to obtain an electrode active layer formed on the surface of the carbon layer. Therefore, the performance of the power battery is improved, meanwhile the cost is reduced, green and safe market requirements are met, and good electrical conductivity is guaranteed.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

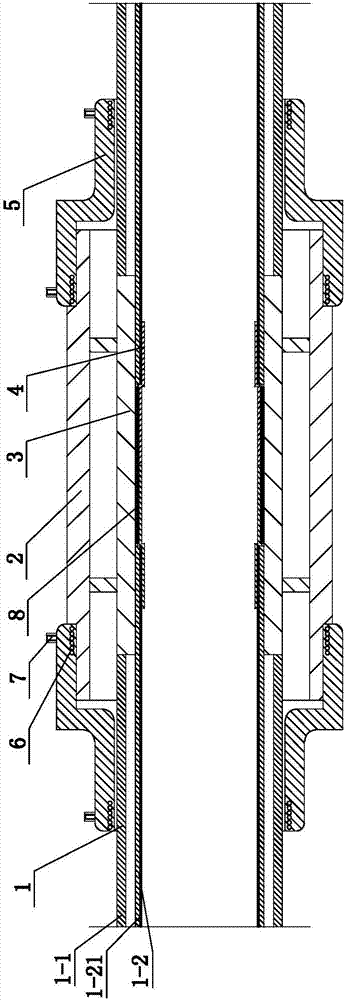

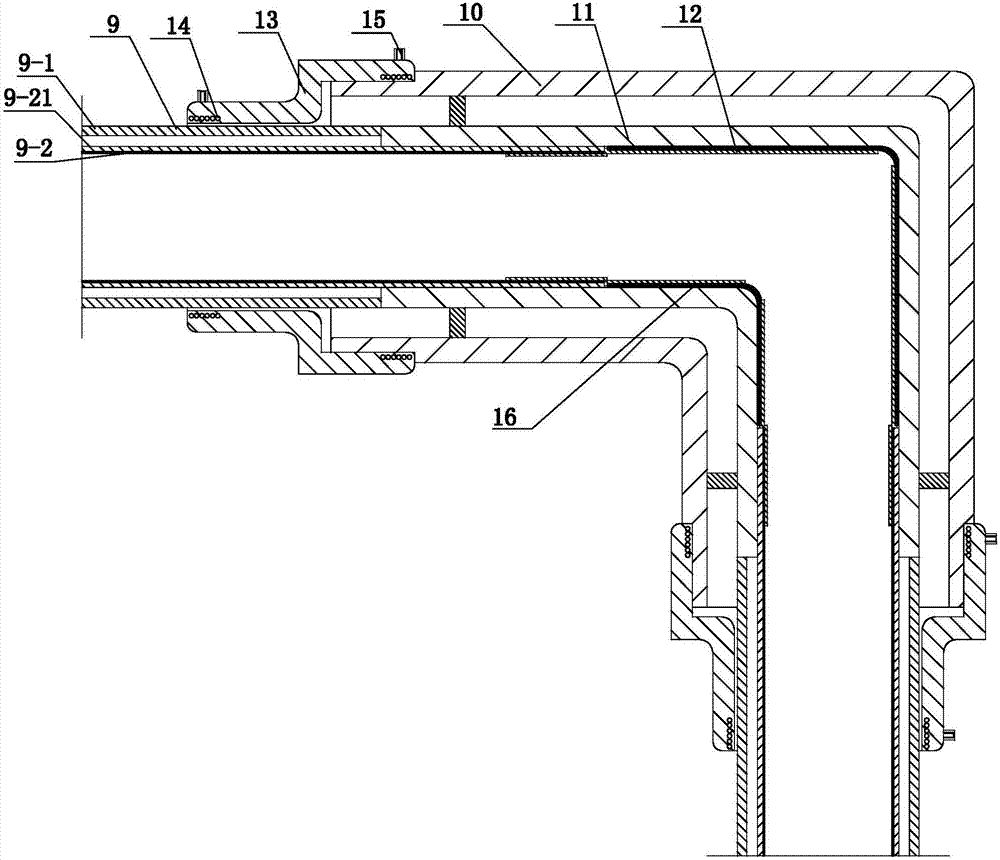

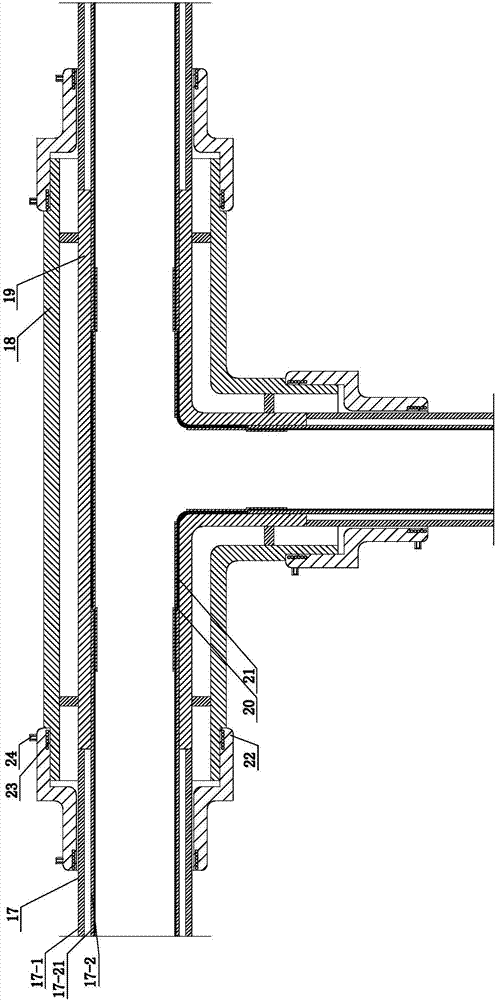

Static-conducting connecting structure of coupling for double-layered pipes

InactiveCN107191728AFirmly connectedImprove sealingBranching pipesPipe-jointsElectrical conductorCoupling

The invention discloses a static-conducting connecting structure of a coupling for double-layered pipes, and relates to the technical field of pipe connection. The structure comprises an outer connecting pipe and an inner connecting pipe which are both straight pipes. The two end ports of the inner connecting pipe are internally provided with tubular inserts correspondingly. One ends of the inserts are sleeved with the inner connecting pipe in a sealed mode, and the other ends of the insert are sleeved with inner oil conveying pipe bodies. The inner oil conveying pipe bodies are sleeved with outer oil conveying pipe bodies. The two ends of the outer connecting pipe are sleeved with connecting sleeves correspondingly. The connecting sleeves are used for enabling the outer connecting pipe and the outer oil conveying pipe bodies at the corresponding ends to be integrated in a sealed mode. The inner wall of the inner connecting pipe is coated with a second static conductor layer which is connected with the inserts in the two end ports of the inner connecting pipe at the same time. According to the static-conducting connecting structure, through the inserts arranged in the both end ports of the inner connecting pipe, and the second static conductor layer, first static-conducting layers of the inner oil conveying pipe bodies are connected, and it is guaranteed that good static-conducting performance is achieved between oil conveying pipes.

Owner:江苏法利沃环保科技有限公司

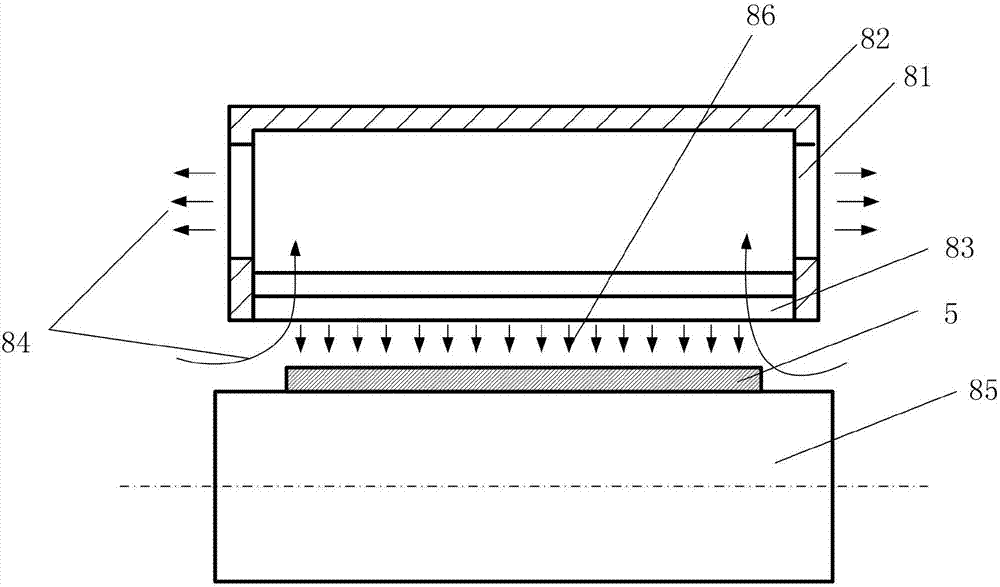

High voltage discharge processing device for metal foil surface treatment

ActiveCN107634178AImprove adhesionReduce contact resistanceElectrode manufacturing processesPretreated surfacesMetal foilElectric arc

The invention discloses a high voltage discharge processing device for metal foil surface treatment. The device includes high voltage boxes, negative pressure air extraction apparatuses, high voltagesources and several strip discharge electrodes. The metal foil is wound on high voltage discharge rollers, the discharge electrodes are disposed at the front ends of the high voltage boxes' openings,and are arranged around the high voltage discharge rollers parallelly along the axes of the high voltage discharge rollers. An interval is kept between the discharge electrodes and the metal foil to generate arcing to the metal foil, so that pits and bumps can be produced on the metal foil surface. The rear ends of the high voltage boxes are equipped with negative pressure air outlets, which are According to the high voltage discharge processing device provided by the invention, real-time on-line surface high voltage discharge etching and roughening treatment are carried out on a substrate, and uniformly distributed pits with equivalent size to coated nano graphite or carbon particles are formed on the front and back surface of the metal foil, thus improving the adhesive ability of a coating material on the metal foil surface.

Owner:陕西浩合机械有限责任公司

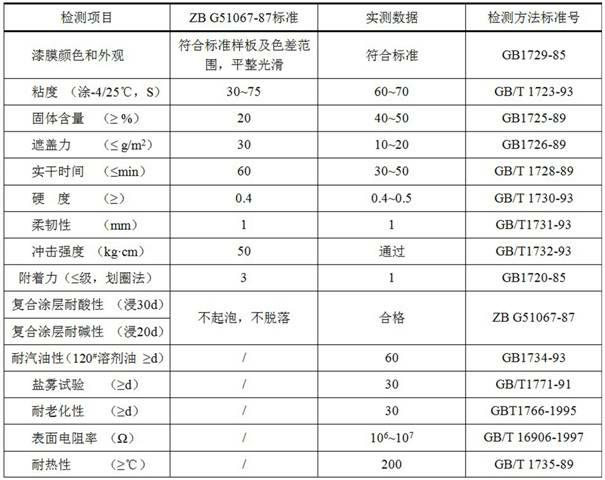

Preparation method of perchloroethylene anticorrosion static conductive coating

InactiveCN102492340AHigh impact strengthImprove adhesionAnti-corrosive paintsElectrically-conductive paintsCoated surfaceConductive coating

The invention discloses a preparation method of a perchloroethylene anticorrosion static conductive coating, which belongs to the chemical technical field. According to the invention, perchloroethylene is taken as a film former, modified phenolic resin is taken as reinforced resin, conductive graphite treated by a surface modifier is taken as a static conductive agent, the prepared anticorrosion static conductive coating possesses excellent anti-corrosive property, scalelike conductive graphite is added, the surface resistivity of the coating can be controlled at 10<6>-10<7>W, so that the thermal expansion coefficient and shrinkage of the coating are small, and the coating possesses excellent static conductive performance and anti-electromagnetic interference performance. The coating can be used for anticorrosion, flame retardation and static conduction coating on the surface of a steel structure and other metal products under scurviness environment, such as coating with anticorrosionand static conduction on the bridge, ship, train and railway facility, automobile, sea engineering facility, petroleum chemical pipeline equipment, medical health apparatus and the like.

Owner:LANZHOU PETROCHEM COLLEGE OF VOCATIONAL TECH

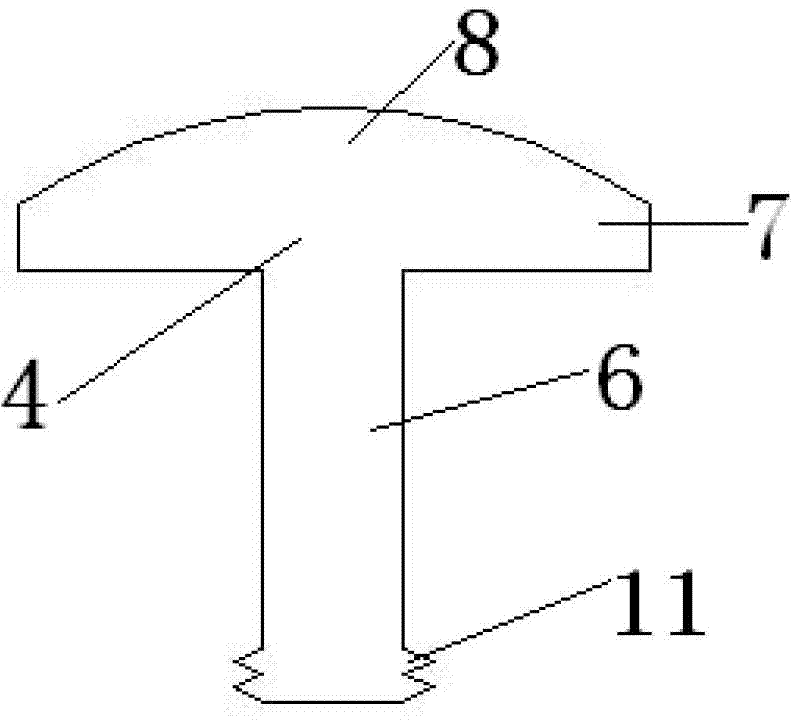

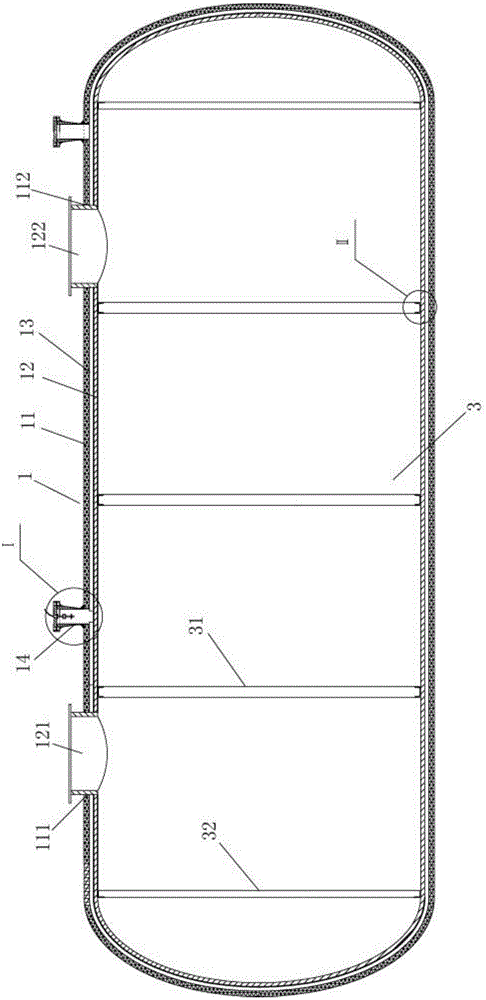

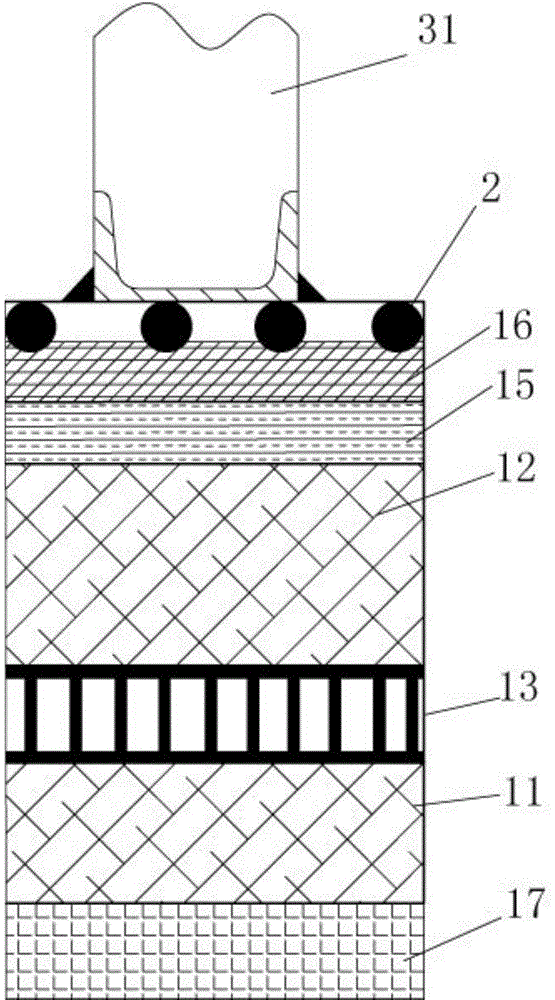

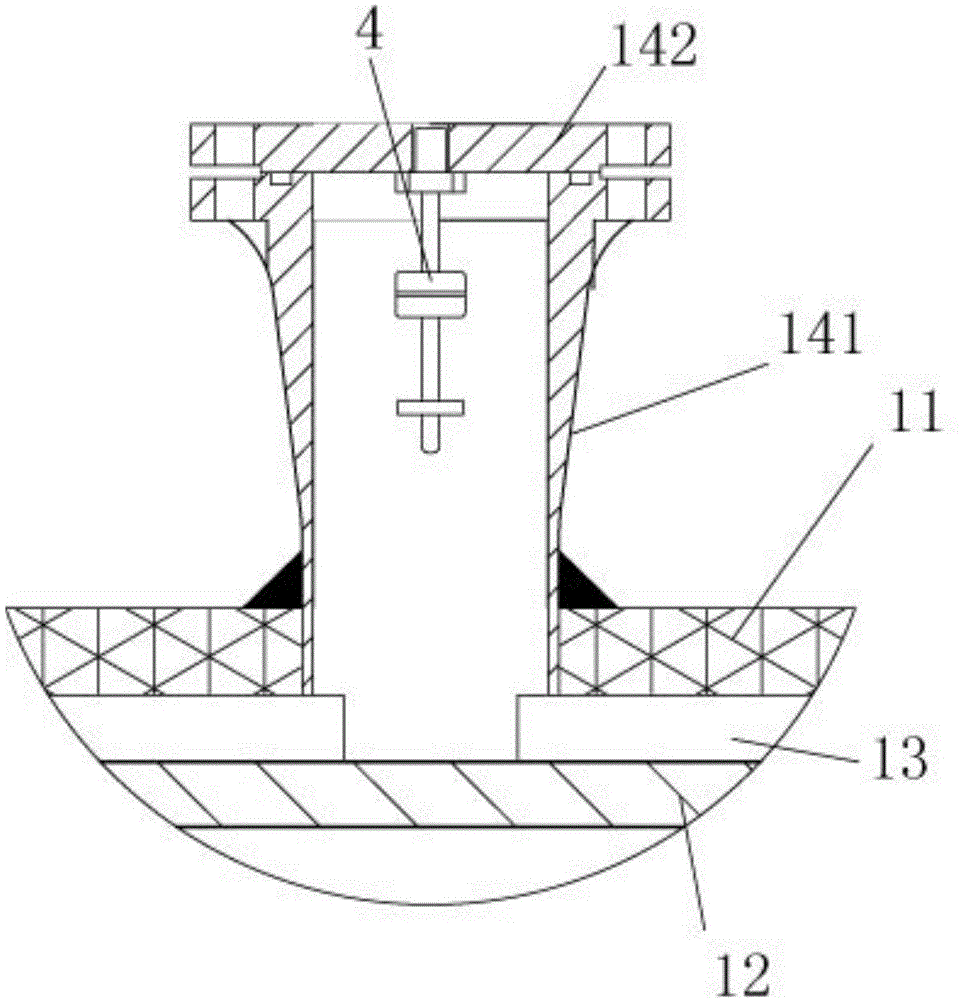

3DFF tank structure used for double-layer oil storage tank made by glass fiber reinforced plastics

InactiveCN105480600ASimple structureGood static conductivityLarge containersUnderwater structuresGlass fiberEngineering

The invention discloses a 3DFF tank structure used for a double-layer oil storage tank made by glass fiber reinforced plastics. The 3DFF tank structure comprises a tank body (1) including an outer shell (11) and an inner shell (12). The inner shell (12) is put inside of the outer shell (11). The 3DFF tank structure is characterized in that a flexible conductive layer (2) is fixed on an inner wall of the inner shell (12); a reinforced rib structure is further fixed on the inner wall of the inner shell (12); and a clearance cavity is arranged between the outer shell (11) and the inner shell (12) and provided with a clearance layer (13). The a 3DFF tank structure used for a double-layer oil storage tank made by glass fiber reinforced plastics is simple in structure, low in weight, high in strength, fine in corrosion resistance, stable in structure and long in service lifetime.

Owner:JIANGYIN FUREN HIGH TECH

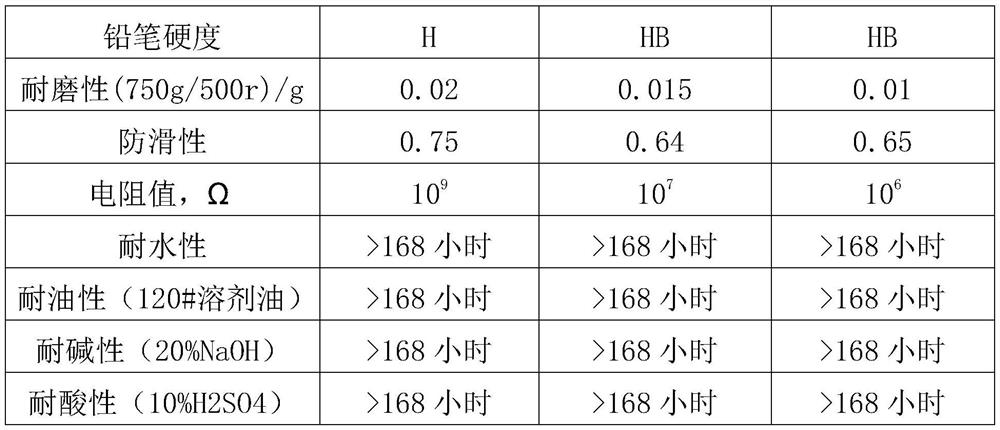

Wear-resistant static-conductive floor coating added with carbon nanotube material and preparation method of wear-resistant static-conductive floor coating

InactiveCN112094571AGood dispersionImprove conductivityAnti-corrosive paintsEpoxy resin coatingsEpoxyXylylene

The invention discloses a wear-resistant static-conductive floor coating added with a carbon nanotube material and a preparation method of the wear-resistant static-conductive floor coating. The wear-resistant static-conductive floor coating is prepared from the following raw materials: 40-50wt% of epoxy resin; 8-15 wt% of xylene; 3-5 wt% of n-butyl alcohol; 0.5 wt%-1wt% of an anti-settling auxiliary agent; 0.5-1 wt% of a solution of a low molecular weight unsaturated polycarboxylic acid polymer and polysiloxane copolymer; 8-15 wt% of titanium dioxide; 0.1 to 5 wt% of carbon black powder; 8-15wt% of precipitated barium sulfate; 8-15 wt% of alumina powder; 0.2 to 0.5 weight percent of amino silane; 0.5 wt%-1wt% of a carbon nano tube material; and 10-20 wt% of a curing agent. The wear-resistant static-conductive floor coating added with the carbon nanotube material prepared according to the invention has better electrical conductivity and corrosion resistance, and can meet the application requirements in the field of wear-resistant static-conductive floor coatings.

Owner:湖北吉人水性汽车涂料有限公司

Preparation method of organic titanium precursor polymer TPP-I (Triphenyl Phosphate) and application thereof in electrostatic conductive coating

InactiveCN108530647AHigh surface activityImprove surface activityAnti-corrosive paintsEpoxy resin coatingsEpoxyBond cleavage

The invention provides a preparation method of an organic titanium precursor polymer TPP-I (Triphenyl Phosphate) and the application thereof in electrostatic conductive coatings and belongs to the technical field of preparation and application of new materials. The preparation method of the organic titanium precursor polymer TPP-I includes the steps of placing a mixture of titanium hydride powder,epoxy resin, nanodispersant, titanate coupling agents, silane coupling agents and solvent in a ball mill reaction tank for ball milling reaction under ultrasonic conditions, allowing titanium powderto initiate the chemical bond of the polymer and the lattice bond cleavage on the surface of titanium nanoparticles during a nanocrystallization process, producing ions or groups of extremely high surface activity, degrading polymers into small molecular oligomers that can conduct graft polymerization at high temperatures and pressures, realizing molecular structure reforming and obtaining the organic titanium precursor polymer TPP-I. The organic titanium precursor polymer TPP-I can be used for preparing primers and topcoat for the electrostatic conductive coatings.

Owner:IANGSU JINLING SPECIAL PAINT CO LTD

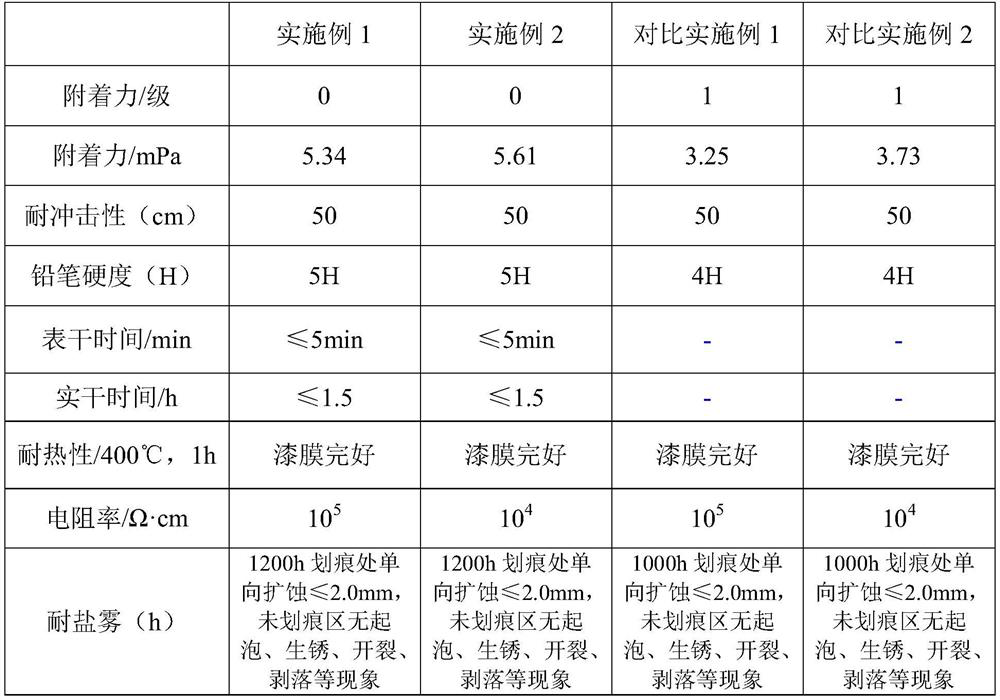

Water-based two-component light-colored anti-static anti-corrosion paint in tank and preparation method thereof

ActiveCN103756514BLight toneGood static conductivityAnti-corrosive paintsEpoxy resin coatingsEpoxyWater based

The invention discloses a water-based two-component light-colored anti-static anti-corrosion paint in a tank. The composition of the water-based two-component light-colored anti-static anti-static paint in a tank is as follows: 8-20% of tap water, water-based epoxy Emulsion 30-45%, water-based epoxy curing agent 7-15%, anti-rust pigment 8-20%, white pigment 1-7%, white filler 1-7%, light-colored conductive filler 8-18%, anti-settling agent 0.1-0.3%, wetting and dispersing agent A 0.1-0.4%, wetting and dispersing agent B 0.1-0.3%, film-forming aid 0.8-2%, defoamer 0.2-0.6%, leveling agent 0.1-0.3%, Anti-flash rust agent 0.1-0.6%, thickener 0.5-2%. The invention uses a two-component water-based epoxy resin and a water-based curing agent as the main film-forming substances, and the chemical cross-linking reaction of the two components ensures that the coating has high cross-linking density and protective performance.

Owner:GUANGZHOU JOINTAS CHEM +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com