Aqueous zinc-rich flake cathode protection prime coat, preparation method and uses thereof

A cathodic protection, zinc-rich technology, used in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of not being able to be used as a primer for static-conducting anti-corrosion coatings, unable to operate continuously, and fast settling speed. Produces precipitation, saves manpower and material resources, and enhances salt spray resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

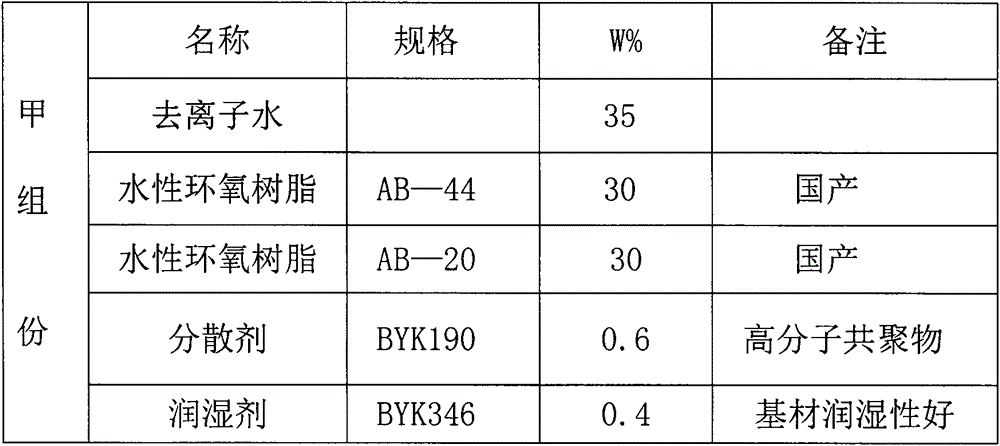

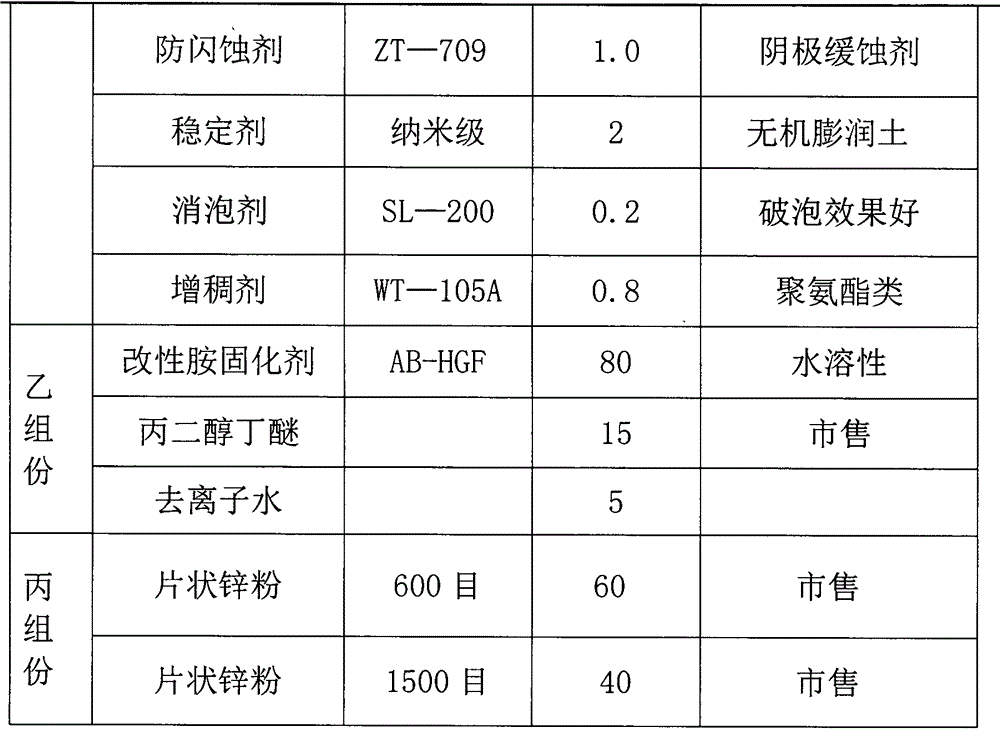

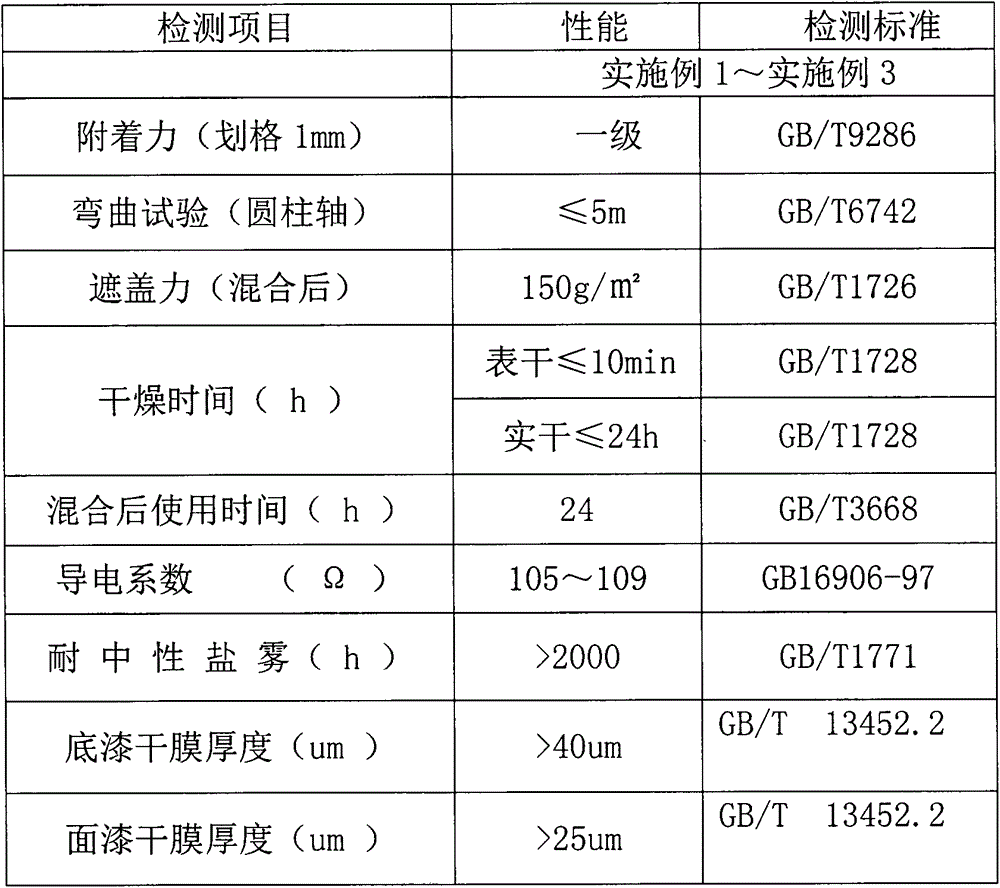

[0027] This embodiment provides a water-based zinc-rich flake cathodic protection primer, which is composed of three components: A component, B component and C component, wherein the mass ratio of A component to B component is 5:1 , the mass ratio of the sum of the mass of components A and B to the mass of component C is 5:1.

[0028] In terms of mass fraction, component A includes: 60% water-based epoxy resin, 5% additives and 35% deionized water; component B includes: 80% modified amine curing agent, 15% propylene glycol butyl Ether and 5% deionized water; component C is flaky zinc powder, and two zinc powders with different particle sizes (600 mesh and 1500 mesh) are used in combination, 600 mesh accounts for 60%, and 1500 mesh accounts for 40%.

[0029] The water-based epoxy resin is used in combination with a water-based epoxy resin with a solid content of 50% and a water-based epoxy resin with a solid content of 55%.

[0030] Auxiliaries are dispersants, wetting agents,...

Embodiment 2

[0041]This embodiment provides a water-based zinc-rich flake cathodic protection primer, which is composed of three components: A component, B component and C component, wherein the mass ratio of A component to B component is 8:1 , the mass ratio of the sum of the mass of components A and B to the mass of component C is 5:1.

[0042] In terms of mass fraction, component A includes: 45% water-based epoxy resin, 6% additives and 49% deionized water; component B includes: 70% modified amine curing agent, 15% propylene glycol butyl Ether and 15% deionized water; component C is flaky zinc powder, which is used in combination with zinc powders of three different particle sizes (800 mesh, 1000 mesh and 1200 mesh), 800 mesh accounts for 40%, and 1000 mesh accounts for 30%. %, 1200 purposes accounted for 30%.

[0043] The selected solid content of waterborne epoxy resin is 50%.

[0044] Auxiliaries are dispersants, wetting agents, anti-flash corrosion agents, stabilizers, defoamers a...

Embodiment 3

[0052] This embodiment provides a water-based zinc-rich flake cathodic protection primer, which is composed of three components: component A, component B and component C, wherein the mass ratio of component A to component B is 6:1 , the mass ratio of the sum of the mass of components A and B to the mass of component C is 5:1.

[0053] In terms of mass fraction, component A includes: 52% water-based epoxy resin, 4% additives and 44% deionized water; component B includes: 75% modified amine curing agent, 12% propylene glycol butyl Ether and 13% deionized water; component C is flake zinc powder, which is used in combination with zinc powders of three different particle sizes (700 mesh, 1400 mesh, 900 mesh and 1300 mesh), 700 mesh accounts for 30%, 1400 mesh The purpose accounts for 30%, the 900 purpose accounts for 20%, and the 1300 purpose accounts for 20%.

[0054] The solid content of the waterborne epoxy resin is 52%.

[0055] Auxiliaries are dispersants, wetting agents, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com