Electrostatic conductive and corrosion-resistant epoxy resin-graphene coating and preparation method thereof

A technology of epoxy resin and anti-corrosion coating, which is applied in the direction of epoxy resin coating, anti-corrosion coating, coating, etc., can solve the problems of high labor and material costs, complicated process, and numerous production steps, so as to improve the anti-corrosion effect and improve the preparation process Simple, excellent effect of acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] An epoxy-graphene conductive static anticorrosion coating and a preparation method thereof, comprising a component A capable of curing into a film and a component B containing a curing agent;

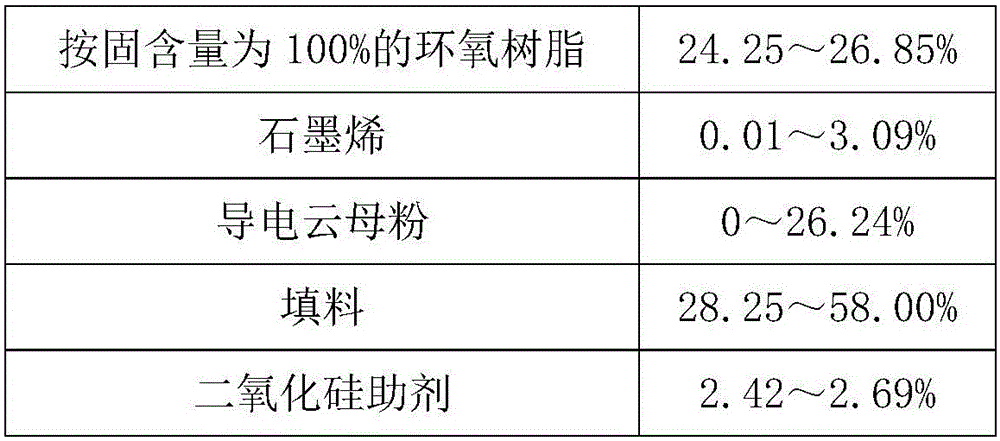

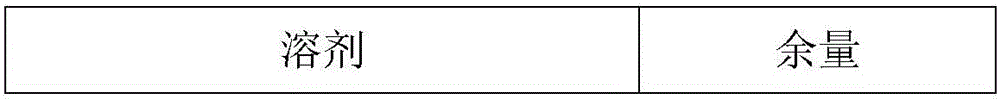

[0045] Wherein, A component comprises following component (table 1) by mass percentage:

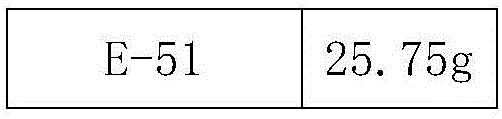

[0046] E-20

25.23g

26.24g

Titanium dioxide

28.25g

silica

2.52g

17.76g

[0047] Table 1: Group A distribution ratio table in Example 1

[0048] Wherein B component comprises following component (table 2):

[0049] Polyamide curing agent:

6.93g

3 --> Butanol:

6.93g

[0050] Table 2: Group B distribution ratio table in Example 1

[0051] The preparation method of anticorrosion coating in this implementation is:

[0052] (1) Add the epoxy resin E-20 of the formula amount of component A into the stirring container, and stir (1000r / min);

[0053] (2) Then add the xylene and t...

Embodiment 2

[0059] An epoxy-graphene conductive static anticorrosion coating and a preparation method thereof, comprising a component A capable of curing into a film and a component B containing a curing agent;

[0060] Wherein, the first component comprises the following components (table 3) by mass percentage:

[0061] E-40

26.85g

0.01g

58.00g

silica

2.69g

12.45g

[0062] Table 3: Group A allocation ratio in implementation 2

[0063] Wherein B component comprises following component (table 4):

[0064] Polyamide curing agent:

7.46g

4.98g

[0065] Table 4: Group B distribution ratio table in Example 2

[0066] The preparation method of anticorrosion coating in this implementation is:

[0067] (1) Add the epoxy resin E-40 of the formula amount of component A into the stirring container, and stir (1500r / min);

[0068] (2) Then add decane and talcum powder in t...

Embodiment 3

[0074] An epoxy-graphene conductive static anticorrosion coating and a preparation method thereof, comprising a component A capable of curing into a film and a component B containing a curing agent;

[0075] Wherein, A component comprises following component (table 5) by mass percentage:

[0076] E-44

26.29g

3.09g

Mica powder

58.00g

silica

2.63g

nonanone

10.27g

[0077] Table 5: Group A distribution ratio table in embodiment 3

[0078] Wherein B component comprises following component (table 6):

[0079] Polyamide curing agent:

7.29g

3.12g

[0080] Table 6: Group B distribution ratio table in Example 3

[0081] The preparation method of anticorrosion coating in this implementation is:

[0082] (1) Add the epoxy resin E-44 of the formula amount of component A into the stirring container, and stir (1200r / min);

[0083] (2) Then add the nonanone and mica powder of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com