Water-based graphene static conductive anticorrosive paint and preparation method thereof

A technology of water-based graphene and anti-corrosion coatings, applied in anti-corrosion coatings, conductive coatings, graphene, etc., can solve the problems of excellent electrical conductivity, decreased coating anti-corrosion protection performance, high VOC content, etc., and achieve excellent electrostatic conductivity and excellent adhesion performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The preparation process of described graphene powder is as follows:

[0067] Add 80 parts of iron balls, 20 parts of dry ice, and 100 parts of 300-mesh graphite powder into a 5L tube tank. The process adopts a decompression operation with a speed of 1200r / min. After grinding for 48 hours, cool it for 8 hours and take it out to obtain product 1; in the reaction kettle Add dilute hydrochloric acid, add product 1, remove iron, freeze-dry and set aside to obtain graphene powder, the above raw materials are by weight;

[0068] The B component is composed of the following raw materials: 30 parts of epoxy curing agent, 3 parts of deionized water, 2 parts of film-forming aids, the above raw materials are calculated in parts by weight;

[0069] When in use, the A component and the B component are mixed evenly according to the mass ratio of 10:1-2, and then add 5% deionized water of the total mass of the A component and the B component, and use the Construction by spin coating. ...

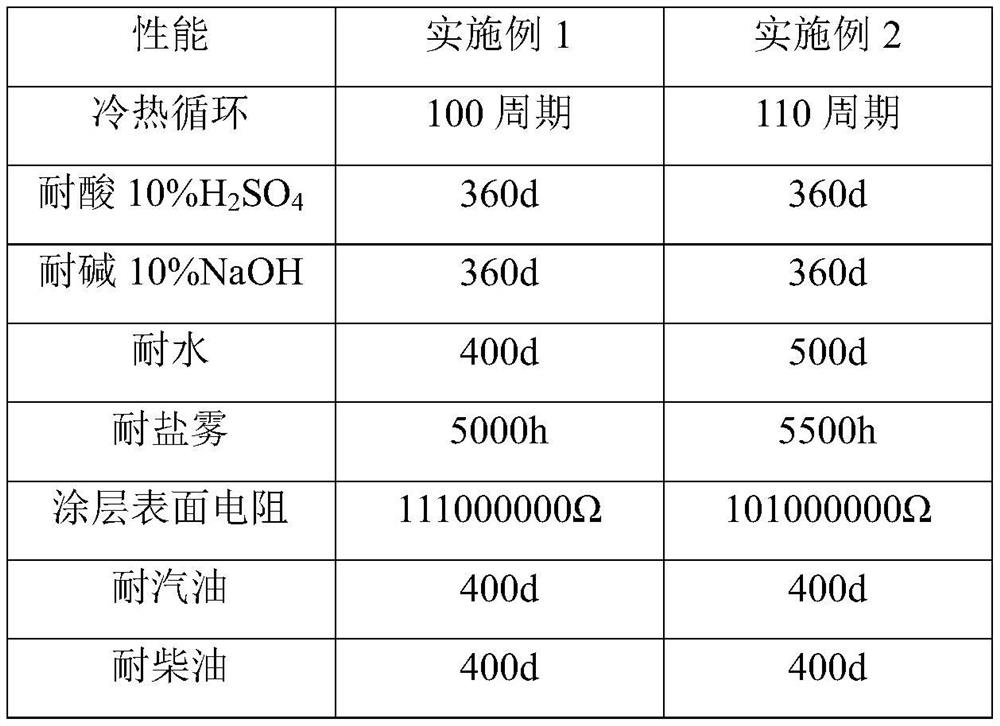

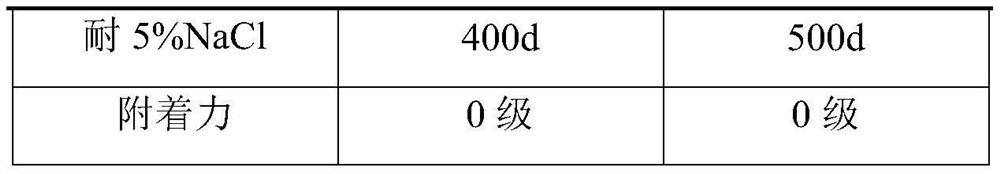

Embodiment 1

[0085] A water-based graphene conductive anti-static coating for oil storage tanks, the preparation process is as follows:

[0086] (1) Preparation of component A

[0087] (1) The preparation of graphene powder: by weight, in 5L tube tank, add 80 parts of iron balls, 20 parts of dry ice, 100 parts of 300 mesh graphite powders, the process adopts decompression operation, and the rotating speed is 1200r / min, Grinding for 48 hours, cooling for 8 hours, taking out the product 1; adding dilute hydrochloric acid to the reaction kettle, adding the product 1, removing iron, and freeze-drying for later use to obtain graphene powder;

[0088] (2) Preparation of graphene slurry: in parts by weight, add 20.6 parts of deionized water, 16 parts of dispersant, 0.3 part of organosilicon defoamer, 0.1 part of thickener in the grinding tank, at a speed of 700r / min Disperse for 15 minutes, then add 1 part of coloring pigment and 17 parts of anti-rust material sequentially while stirring, and th...

Embodiment 2

[0096] (1) The preparation of graphene powder: by weight, in 5L tube tank, add 80 parts of iron balls, 20 parts of dry ice, 100 parts of 300 mesh graphite powders, the process adopts decompression operation, and the rotating speed is 1200r / min, Grinding for 48 hours, cooling for 8 hours, taking out the product 1; adding dilute hydrochloric acid to the reaction kettle, adding the product 1, removing iron, and freeze-drying for later use to obtain graphene powder;

[0097] (2) Preparation of graphene slurry: in parts by weight, add 17 parts of deionized water, 20 parts of dispersant, 0.3 part of organosilicon defoamer, 0.1 part of thickener in the grinding tank, at a speed of 700r / min Disperse for 15 minutes, then add 1 part of coloring pigment and 15 parts of anti-rust material sequentially while stirring, and then add 4 parts of graphene powder, 17 parts of mica powder, and 25.6 parts of titanium dioxide and mix evenly to obtain graphene slurry;

[0098] (3) Preparation of gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com