Wear-resistant static-conductive floor coating added with carbon nanotube material and preparation method of wear-resistant static-conductive floor coating

A technology of floor coatings and carbon nanotubes, applied in the direction of conductive coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of high production process control requirements, high loss rate of electrical conductivity, unstable electrical conductivity, etc., and achieve Good corrosion resistance, stable electrical conductivity and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

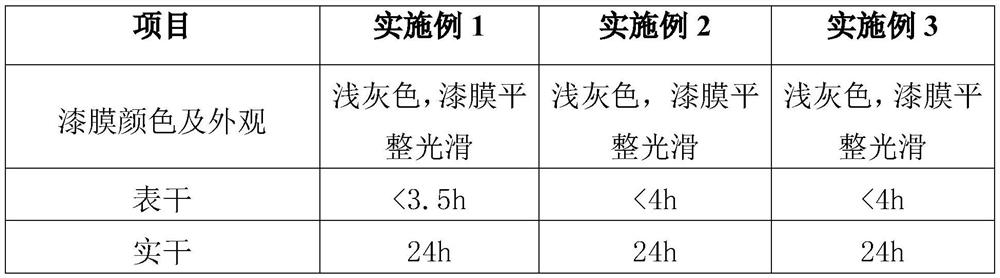

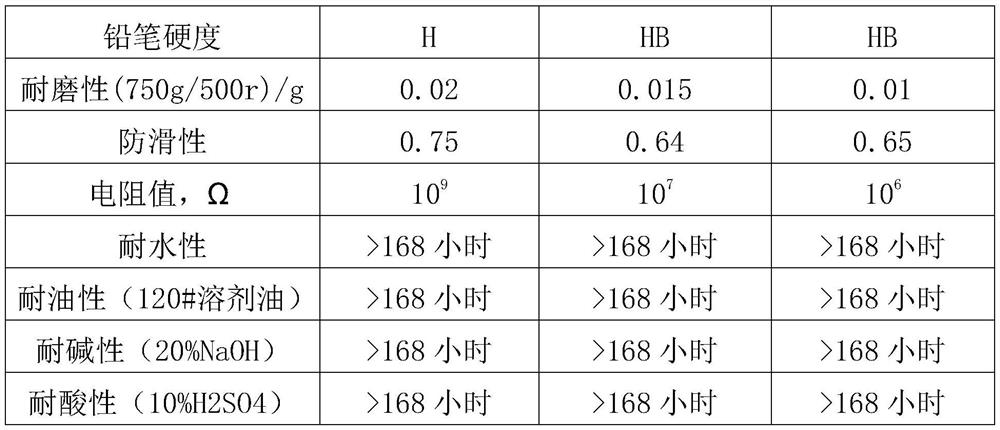

Examples

Embodiment 1

[0035] This embodiment provides a wear-resistant and conductive floor paint with added carbon nanotube material. In terms of mass percentage, the wear-resistant and conductive floor paint with added carbon nanotube material is made of the following raw materials:

[0036] Epoxy resin, 40wt%;

[0037] Xylene, 9.9 wt%;

[0038] n-Butanol, 3.5wt%;

[0039] Anti-sedimentation additive, 0.8wt%;

[0040] Solution of high molecular weight unsaturated polycarboxylic acid polymer and polysiloxane interpolymer, 0.8wt%;

[0041] Titanium dioxide, 9wt%;

[0042] Carbon black powder, 0.2wt%;

[0043] Precipitated barium sulfate, 15wt%;

[0044] Aluminum oxide powder, 10wt%;

[0045] Aminosilane, 0.3wt%;

[0046] Carbon nanotube material, 0.5wt%;

[0047] Curing agent, 10wt%.

[0048] Further, the solution of the low molecular weight unsaturated polycarboxylic acid polymer and polysiloxane interpolymer is BYK-P104.

[0049] Further, the curing agent is an aliphatic amine curing ag...

Embodiment 2

[0061] This embodiment provides a wear-resistant and conductive floor paint with added carbon nanotube material. In terms of mass percentage, the wear-resistant and conductive floor paint with added carbon nanotube material is made of the following raw materials:

[0062] Epoxy resin, 44wt%;

[0063] Xylene, 8.18wt%;

[0064] n-Butanol, 3.3wt%;

[0065] Anti-sedimentation additive, 0.6wt%;

[0066] Solution of high molecular weight unsaturated polycarboxylic acid polymer and polysiloxane copolymer, 0.7wt%;

[0067] Titanium dioxide, 10wt%;

[0068] Carbon black powder, 0.22wt%;

[0069] Precipitated barium sulfate, 12wt%;

[0070] Aluminum oxide powder, 9wt%;

[0071] Aminosilane, 0.4wt%;

[0072] Carbon nanotube material, 0.6wt%;

[0073] Curing agent, 11wt%.

[0074] Further, the solution of the low molecular weight unsaturated polycarboxylic acid polymer and polysiloxane interpolymer is BYK-P104S.

[0075] Further, the curing agent is an aliphatic amine curing age...

Embodiment 3

[0087] This embodiment provides a wear-resistant and conductive floor paint with added carbon nanotube material. In terms of mass percentage, the wear-resistant and conductive floor paint with added carbon nanotube material is made of the following raw materials:

[0088] Epoxy resin, 46wt%;

[0089] Xylene, 8.28wt%;

[0090] n-Butanol, 3.2wt%;

[0091] Anti-sedimentation additive, 0.5wt%;

[0092] Solution of high molecular weight unsaturated polycarboxylic acid polymer and polysiloxane interpolymer, 0.6wt%;

[0093] Titanium dioxide, 10wt%;

[0094] Carbon black powder, 0.22wt%;

[0095] Precipitated barium sulfate, 10wt%;

[0096] Aluminum oxide powder, 8wt%;

[0097] Aminosilane, 0.5wt%;

[0098] Carbon nanotube material, 0.7wt%;

[0099] Curing agent, 12wt%.

[0100] Further, the solution of the low molecular weight unsaturated polycarboxylic acid polymer and polysiloxane interpolymer is any one of BYK-P105, LD-1242 and Disponer904S.

[0101] Further, the curing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com