Patents

Literature

30results about How to "Coating environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

UV radiation curing heat dissipation paint containing graphene and preparation method of paint

InactiveCN107955519AImprove impact resistanceHigh hardnessPolyurea/polyurethane coatingsHeat conductingGraphene

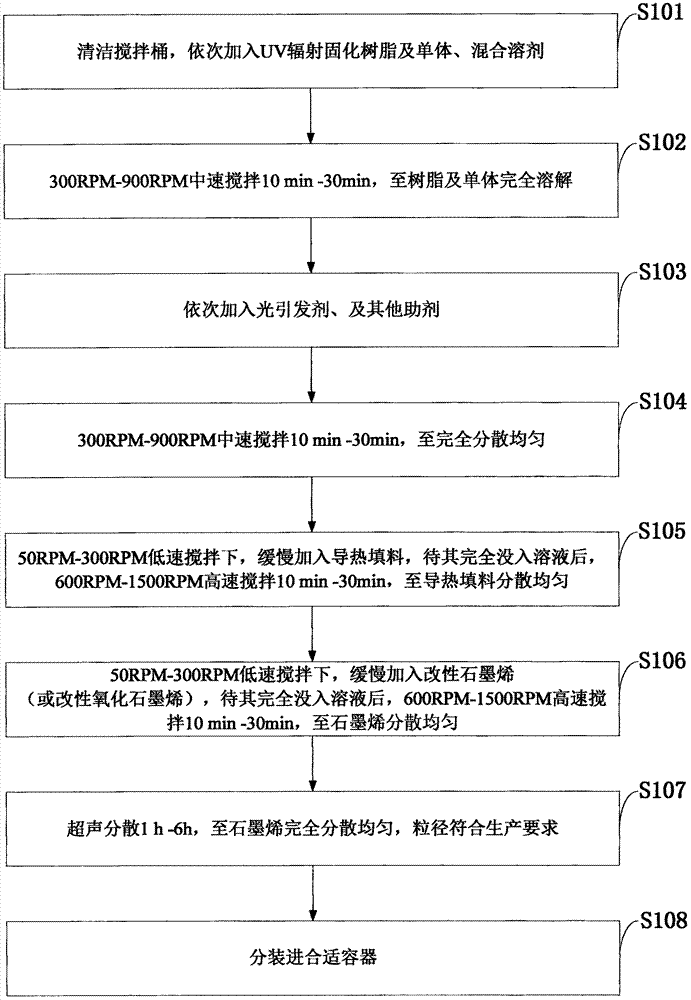

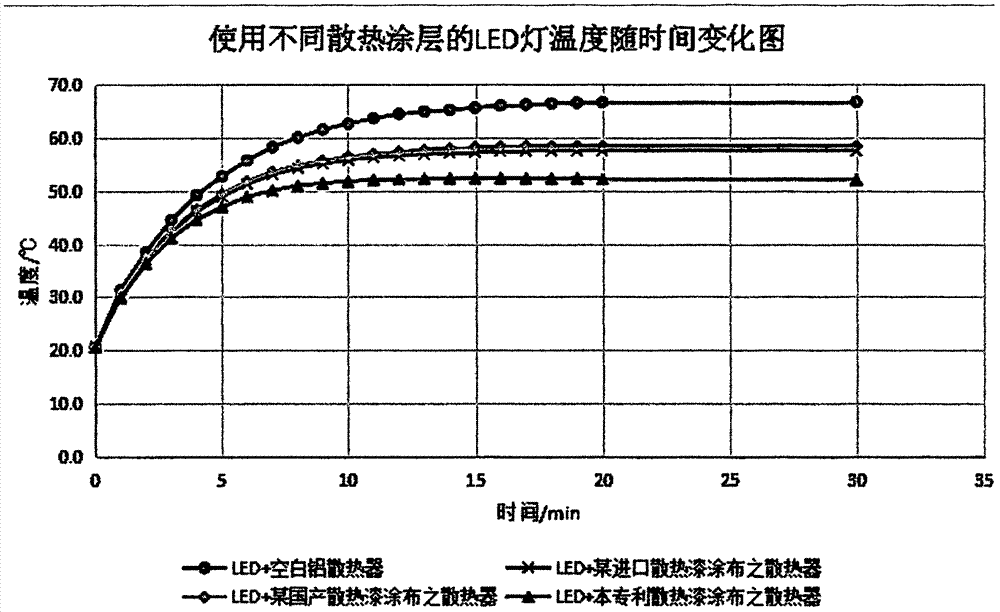

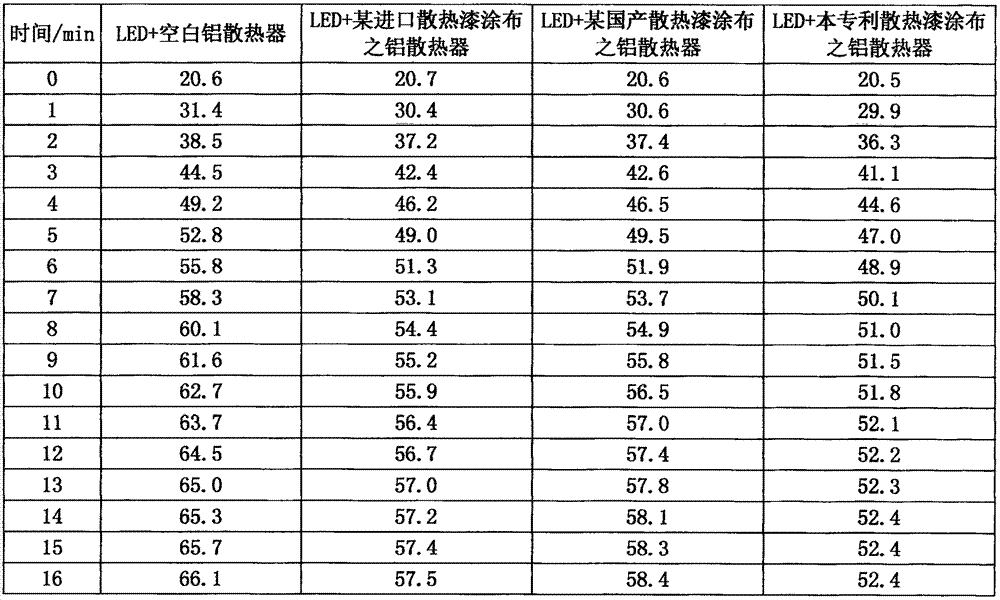

The invention belongs to the technical field of heat dissipation materials, and discloses UV radiation curing heat dissipation paint containing graphene and a preparation method of the paint. The paint comprises, by weight, 30-70% of UV radiation curing resin and monomers, 30-70% of mixed solvent, 0.1-5% of photoinitiator, 0.1-5% of auxiliary agent, 1-30% of heat-conducting filler and 0.1-5% of modified graphene or modified graphene oxide. The method comprises the steps that the UV radiation curing resin and monomers and the mixed solvent are added and stirred at a medium speed till the resinand the monomers are dissolved; the photoinitiator and other auxiliary agents are sequentially added and stirred to be dispersed; under the condition of stirring, the heat-conducting filler is added,and after being immersed in the solution, the filler is stirred till the heat-conducting filler is dispersed; under the condition of stirring, the modified graphene or the modified graphene oxide is added, and after being immersed in the solution, the modified graphene or the modified graphene oxide is stirred till the graphene is dispersed; ultrasonic dispersion is conducted till the graphene isdispersed; the product is subpackaged in containers respectively. The overall strength of a coating is improved, agglomeration of the graphene is avoided, and excellent heat conduction capability is provided.

Owner:EVERPOWER SHENG TIE (XIAMEN) GRAPHENE TECH CO LTD

Coating containing quick drying agent and preparation method thereof

ActiveCN104194566AImprove use valueCoating environmental protectionSiccativesEpoxy resin coatingsEpoxyAcrylic resin

The invention belongs to the field of coatings and particularly relates to a coating containing a quick drying agent and a preparation method thereof. The coating comprises a paint component and a curing agent component in a mass ratio of (2-3) to 1, wherein the paint component comprises the following components by mass percent: 40-50% of polysulfide modified epoxy resin, 5-10% of acrylic resin, 15-20% of polydimethylsiloxane, 1-5% of additive, 10-15% of pigment and filler, 10-20% of a solvent, 5-10% of tea stem powder and 2-5% of coupling agent; the curing agent component comprises the following components by mass percent: 60-70% of a curing agent, 20-30% of n-butyl acetate and 10-15% of quick drying agent; and the quick drying agent comprises the following components by weight percent: 10-15% of a dehydrating agent, 15-25% of drier and 60-70% of n-butyl acetate. According to the coating, the tea stem powder is added to be reacted with volatile organic gas and thus the VOCs (Volatile Organic Chemicals) released by the coating is reduced and meanwhile the quick drying agent is added so as to quickly dry the coating and coating is a solvent-type relatively environment-friendly, quick drying material.

Owner:ZHANGZHOU XIN ZHAN WANG CHEM IND

Environment-friendly paint

InactiveCN105504906ACoating environmental protectionImprove stabilityCement coatingsPortland cementRoom temperature

The invention discloses an environment-friendly paint, which comprises: lemon oil, mandarin oil, titanium dioxide, carbon black, ester gum modified alkyd resin, Portland cement, a water reducing agent, fly ash, seaweed mud, and the balance solvent. The invention also discloses a preparation method of the environment-friendly paint, and the method includes: mixing lemon oil, mandarin oil and titanium dioxide at room temperature evenly; mixing ester gum modified alkyd resin, Portland cement, the water reducing agent, fly ash and seaweed mud at room temperature evenly; and adding the stirring products into a stirring barrel in proportion, adding a solvent and performing stirring slowly, and raising the temperature from 0DEG C to 20DEG C, thus obtaining the environment-friendly paint. The environment-friendly paint provided by the invention employs lemon oil and mandarin oil two pure natural raw materials, the prepared paint is greener and more environment-friendly, and gradual heating endows the paint with high stability.

Owner:QINGDAO BAIJIANCHENG ENVIRONMENTAL PROTECTION TECH CO LTD

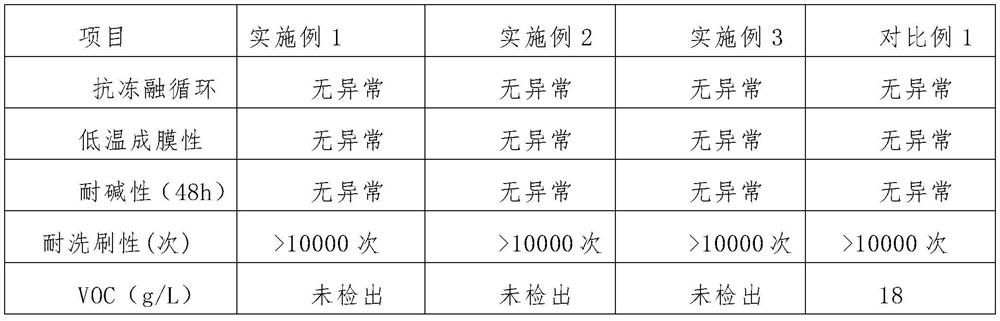

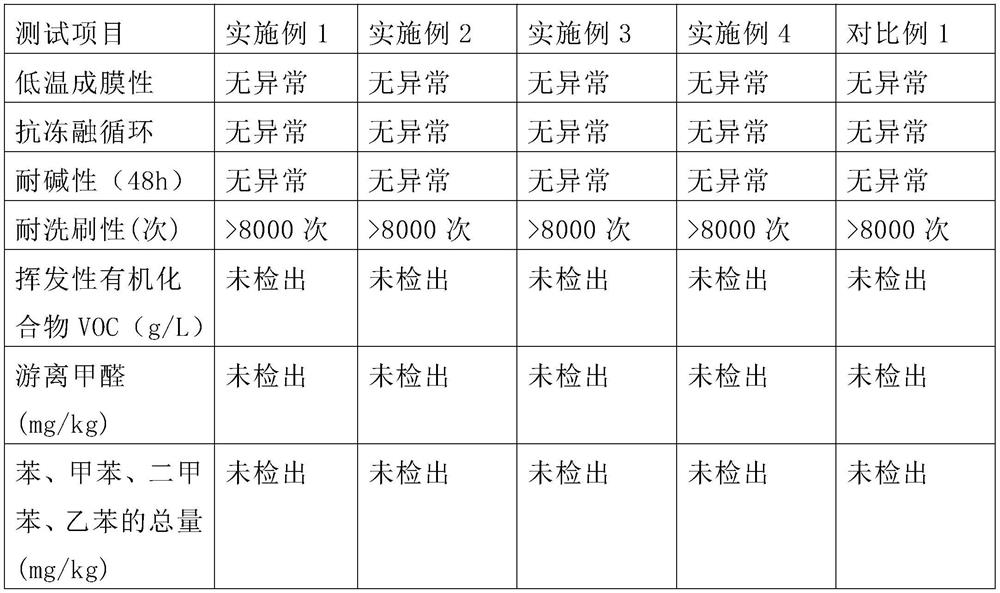

Antibacterial and antifungal shell powder coating

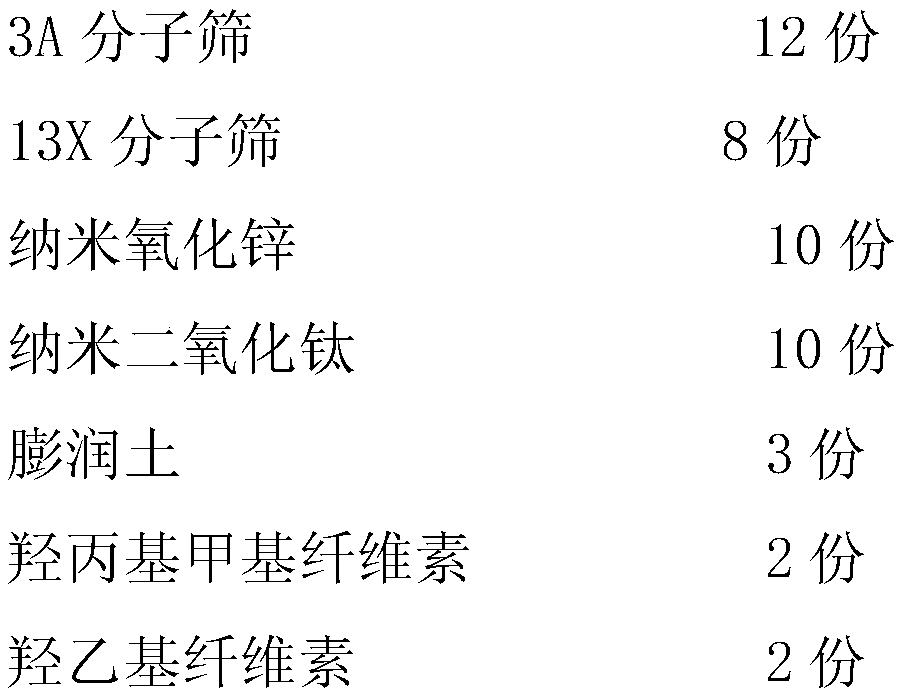

InactiveCN109054525AImprove securityNon-volatileAntifouling/underwater paintsPaints with biocidesAntifungalSodium Bentonite

The invention relates to an antibacterial and antifungal shell powder coating and belongs to technical field of interior wall coatings. The antibacterial and antifungal shell powder coating is prepared from deionized water, shell powder, emulsion, ground limestone, light calcium carbonate, titanium dioxide, antibacterial and antifungal agent and auxiliaries. The antibacterial and antifungal agentis prepared from molecular sieves, nano-zinc oxide, nanometer titanium dioxide, bentonite, hydroxypropyl methyl cellulose, and hydroxyethyl cellulose. The antibacterial and antifungal agent used in the antibacterial and antifungal shell powder coating is mostly prepared from inorganic materials, and the inorganic antibacterial and antifungal material has the characteristics of high safety, no volatility, good durability, no irritating odor, wide antimicrobial spectrum, no resistance to drugs, and good heat resistance and can have better and more durable antibacterial and antifungal effects onthe wall, causing no harm to the human body. Combined use of the antibacterial and antifungal agent in the coating and the shell powder avoids negative effects caused by organic antifungal bactericide, so that the coating is more environment-friendly and the antibacterial and antifungal effect is better and longer lasting.

Owner:吉林省金贝壳新材料科技有限公司

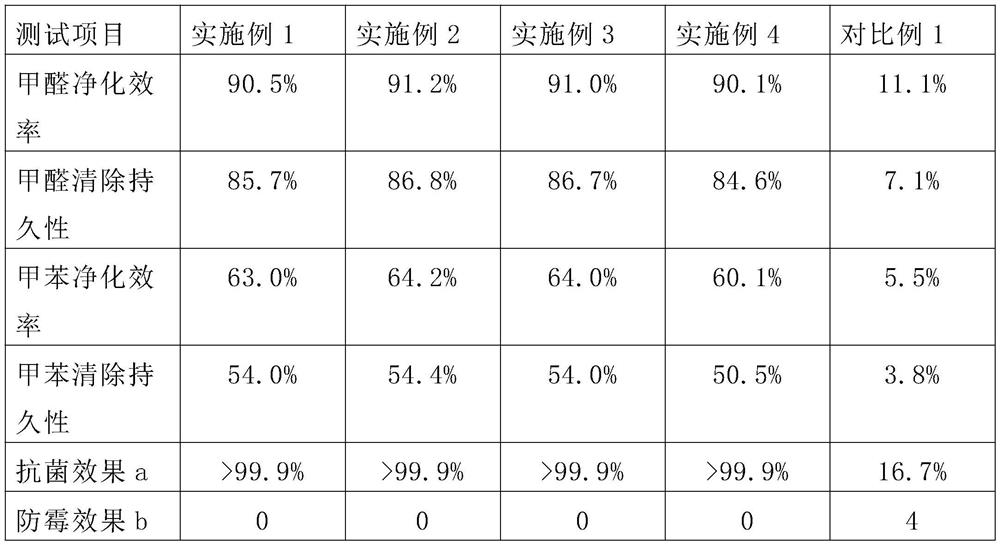

Plant environment-friendly mildew-proof antibacterial coating and preparation method thereof

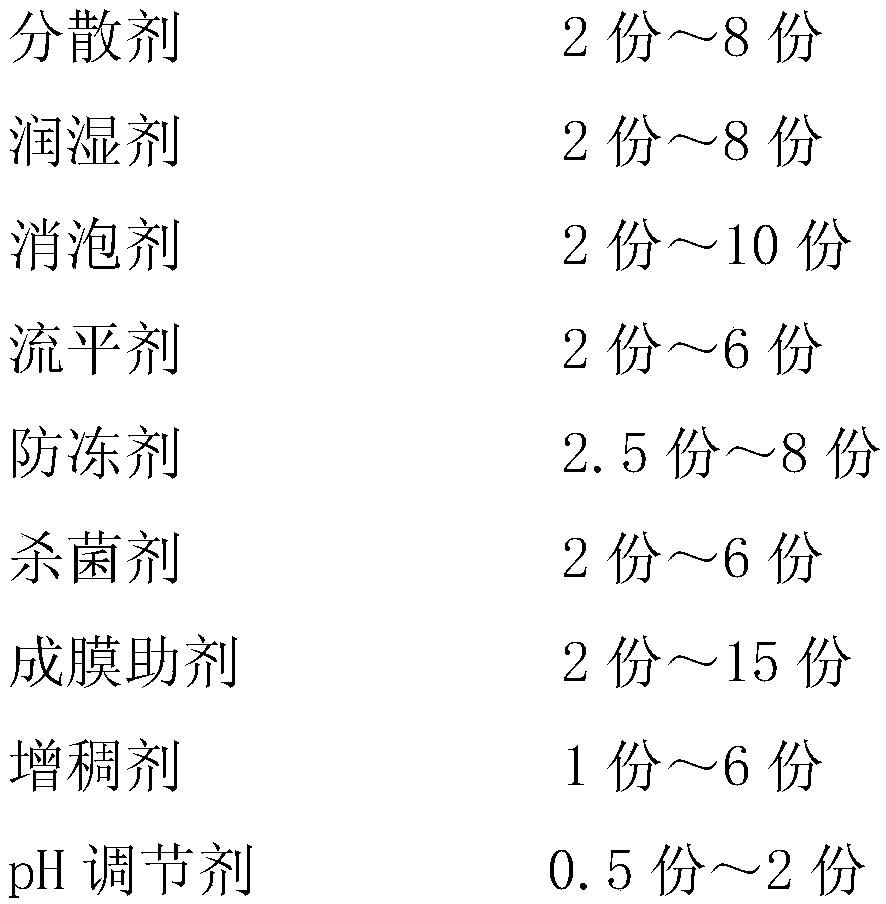

InactiveCN112300640AEfficient scavengerPaint healthAntifouling/underwater paintsPaints with biocidesBiotechnologyCellulose

The invention relates to a plant environment-friendly mildew-proof antibacterial coating and a preparation method thereof. Theo antibacterial coating is prepared from the following raw materials: water, hydroxyethyl cellulose, a water-based dispersing agent, a pH regulator, a water-based wetting agent, a natural plant antibacterial mildew-proof agent, titanium dioxide, calcined kaolin, calcium carbonate, diatomite, superfine zinc oxide, emulsion, an anti-freezing agent, a coalescing agent and a water-foaming agent. According to the invention, natural plant components are used for mould prevention and antibiosis, and in addition, the addition of a superfine zinc oxide powder can not only synergistically perform mould prevention and antibiosis, but also efficiently remove indoor formaldehyde, so that the effect of purifying the indoor environment is realized together; and natural plant components and inorganic nano materials are used for mildew prevention, antibiosis and formaldehyde removal, so that the coating is healthier and more environmentally friendly.

Owner:三棵树(上海)新材料研究有限公司

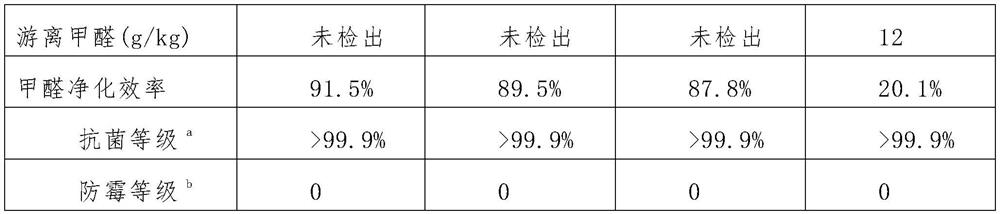

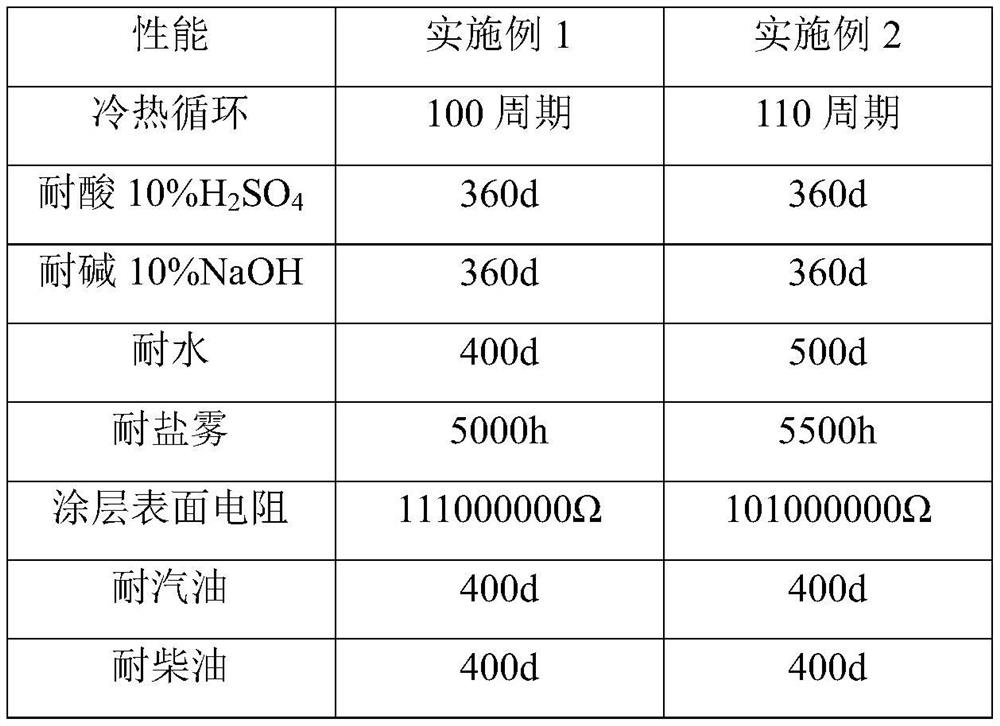

Water-based graphene static conductive anticorrosive paint and preparation method thereof

InactiveCN112521834AGood static conductivityGood adhesionGrapheneAnti-corrosive paintsFirming agentGraphite

The invention provides a water-based graphene static conductive anticorrosive paint, which belongs to the technical field of water-based paints, and is composed of a component A and a component B. Thecomponent A comprises epoxy resin, graphene filler slurry, a coalescing agent, a wetting agent, a thickening agent, distilled water, an anti-flash-rust agent and a silane coupling agent. The graphenefiller slurry comprises graphene slurry and zirconium beads; wherein the graphene slurry comprises deionized water, a dispersing agent, an organic silicon defoaming agent, a thickening agent, a coloring pigment, an antirust material, graphene powder, mica powder and titanium dioxide; the component B comprises an epoxy curing agent, deionized water and a coalescing agent. When in use, the mass ratio of the component A to the component B is 10:1-2. The invention also provides a preparation method of the water-based graphene static conductive anticorrosive paint. According to the coating disclosed by the invention, the graphene is used as a conductive filler, so that the coating has stable static electricity conduction performance through modification without influencing the corrosion resistance, and the coating has excellent heat resistance, acid and alkali resistance and excellent adhesion performance.

Owner:QINGDAO AIR NEW MATERIALS

Eco-friendly paint

InactiveCN106810917AImprove stabilityEasy to makeCement coatingsPolyester coatingsSolventCarbon black

The invention discloses an environmentally friendly coating, which comprises the following components: lemon oil, orange oil, titanium dioxide, carbon black, ester glue modified alkyd resin, Portland cement, water reducer, fly ash, seaweed mud, and other for the solvent. The invention also discloses a preparation method of the environmental protection paint, which comprises the following steps: mixing and stirring lemon oil, orange oil, and titanium dioxide at room temperature; , fly ash, and seaweed mud are mixed and stirred evenly at room temperature; the agitated material obtained above is poured into a mixing tank in proportion, added a solvent, stirred slowly, and gradually rises from 0°C to 20°C to obtain the above-mentioned Eco-friendly paint. The environment-friendly coating of the invention uses two pure natural raw materials of lemon oil and orange oil, and the prepared coating is more green and environmentally friendly, and is prepared by heating gradually so as to have high stability.

Owner:周子童

Formaldehyde-removing antibacterial coating based on titanium-based metal organic framework material and preparation method of formaldehyde-removing antibacterial coating

InactiveCN112876994AIncrease contact rateHigh porosityAntifouling/underwater paintsPaints with biocidesCelluloseMetal-organic framework

The invention relates to a formaldehyde-removing antibacterial coating based on a titanium-based metal organic framework material and a preparation method of the formaldehyde-removing antibacterial coating. The formaldehyde-removing antibacterial coating is prepared from the following components in parts by mass: 20 to 27 parts of water, 0.2 to 0.5 part of hydroxyethyl cellulose, 0.1 to 0.3 part of a pH regulator, 0.4 to 0.7 part of a water-based dispersing agent, 0.1 to 0.3 part of a water-based wetting agent, 0.4 to 0.7 part of a water-based defoaming agent, 16 to 21 parts of titanium dioxide, 7 to 11 parts of calcined kaolin, 10 to 18 parts of ground calcium carbonate, 7 to 12 parts of silica powder, 2 to 4 parts of a titanium-based metal organic framework MIL-125-NH2, 20 to 28 parts of an emulsion. 0.6 to 1.5 parts of an anti-freezing agent, 0.5 to 1 part of a coalescing agent and 0.1 to 0.2 part of a preservative. The formaldehyde removal efficiency reaches 91%, and the durability reaches 86.7%; and the toluene removal efficiency reaches 64%, and the durability reaches 54%.

Owner:三棵树(上海)新材料研究有限公司

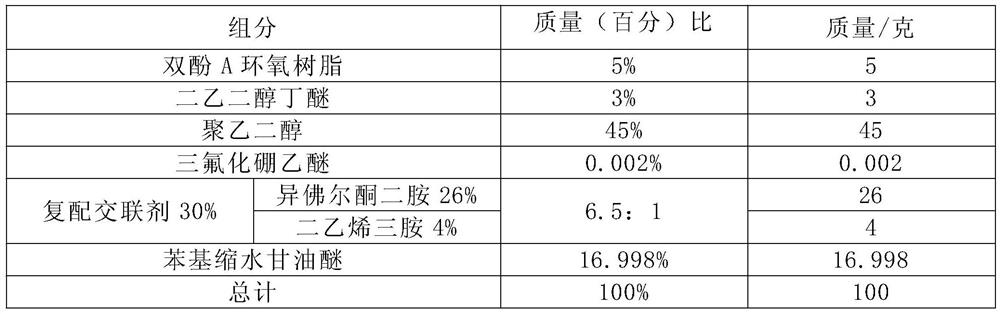

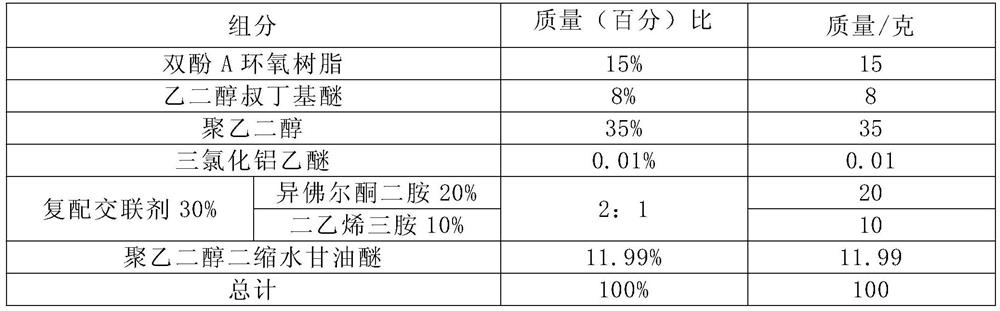

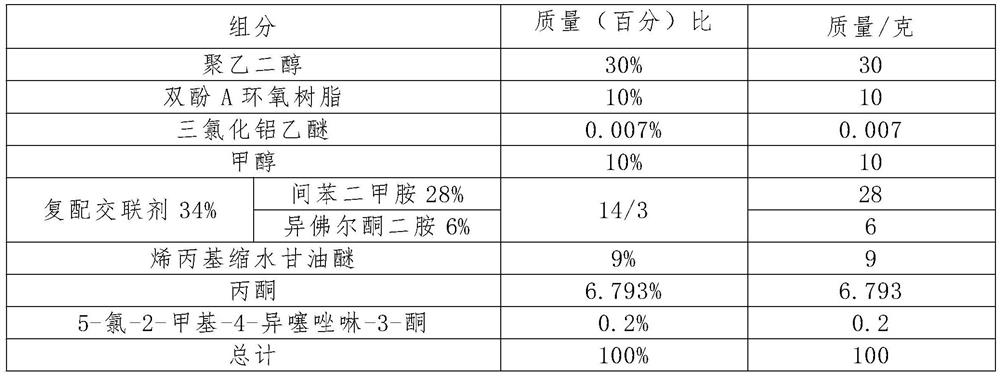

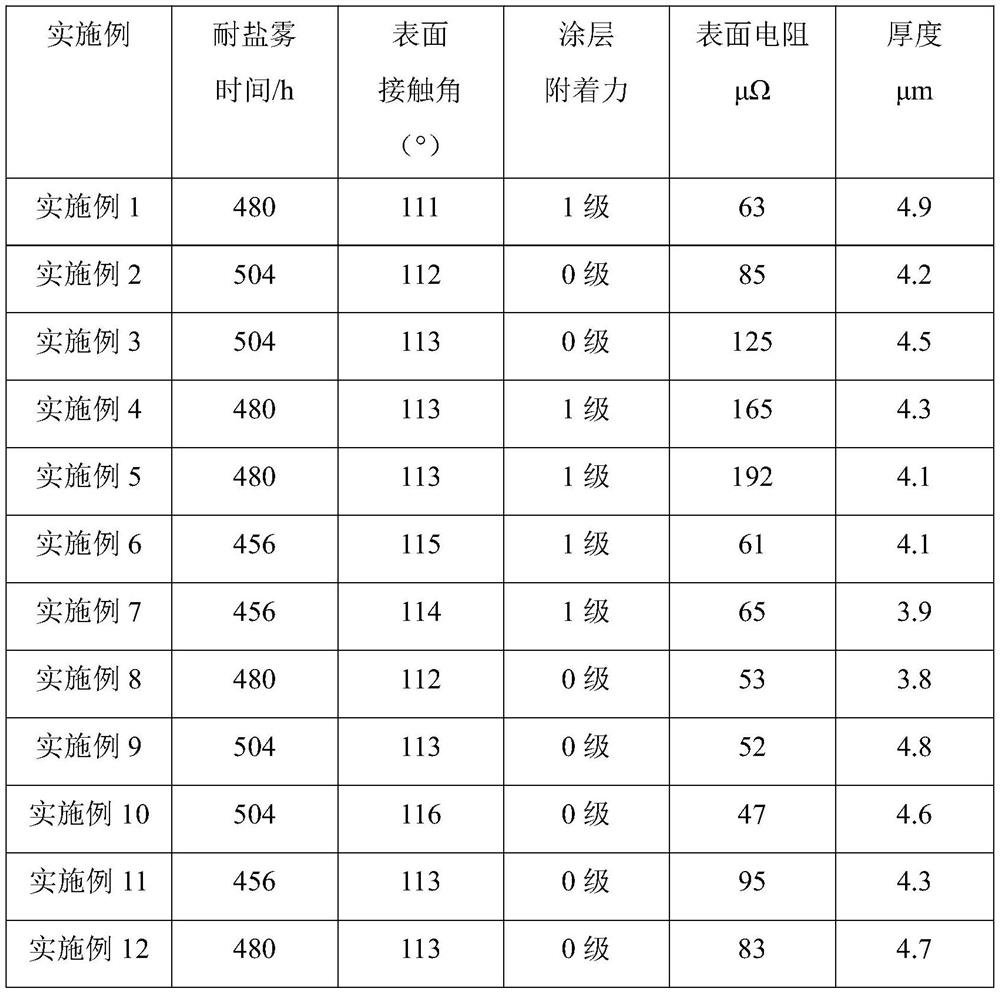

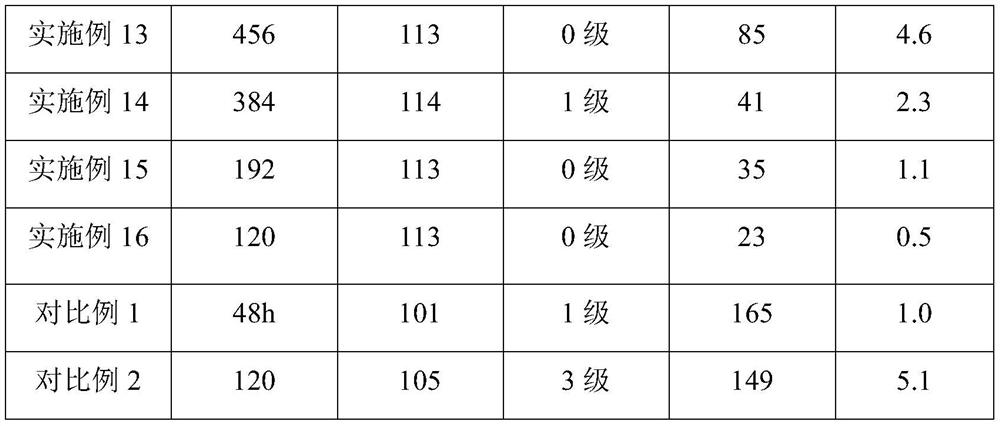

A kind of high-corrosion and environment-friendly water-based epoxy curing agent and preparation method thereof

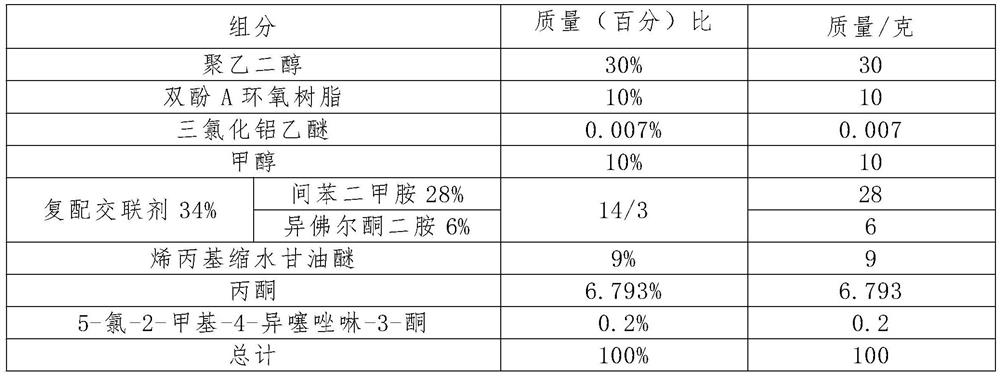

ActiveCN111849143BImprove corrosion resistanceHydrophilic and lipophilicAnti-corrosive paintsEpoxy resin coatingsPtru catalystPolyethylene glycol

The invention discloses a highly anti-corrosion and environment-friendly water-based epoxy curing agent and a preparation method thereof. The components of the water-based epoxy curing agent, calculated in mass percentage, are: 5-15% of bisphenol A epoxy resin, alcohol ether 3% to 8% of quasi-solvent, 35 to 45% of polyethylene glycol, 0.002 to 0.01% of catalyst, 28 to 32% of compound cross-linking agent and 11 to 18% of reactive diluent. Isophorone diamine and diethylene triamine in a ratio of 2 to 6.5:1. The water-based epoxy curing agent provided by the invention can effectively improve the corrosion resistance of the coating.

Owner:广州惠顺新材料有限公司

Anticorrosive mildew-proof water-based epoxy curing agent and preparation method thereof

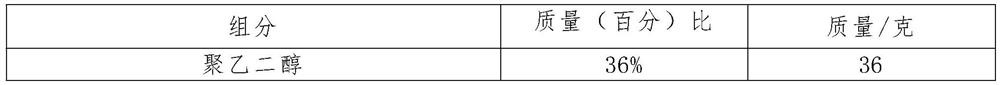

ActiveCN111777922AReduce the impactImprove toughnessAntifouling/underwater paintsPaints with biocidesXylylenePolymer science

The invention discloses an anticorrosive mildew-proof water-based epoxy curing agent and a preparation method thereof. The water-based epoxy curing agent comprises the following components in percentage by mass: 25%-36% of polyethylene glycol, 10%-20% of epoxy resin, 0.002%-0.007% of a catalyst, 5%-10% of a quenching agent, 30%-36% of a compound crosslinking agent, 5%-9% of an active diluent, 3.5%-6% of a solvent and 0.05%-0.2% of a bactericide, wherein the compound crosslinking agent comprises m-xylylene diamine and isophorone diamine in a mass ratio of 5 / 3 to 14 / 3. The water-based epoxy curing agent can effectively improve the corrosion resistance and mildew resistance of a coating, the raw material cost is not high, and the later maintenance cost of the coating is greatly reduced.

Owner:广州惠顺新材料有限公司

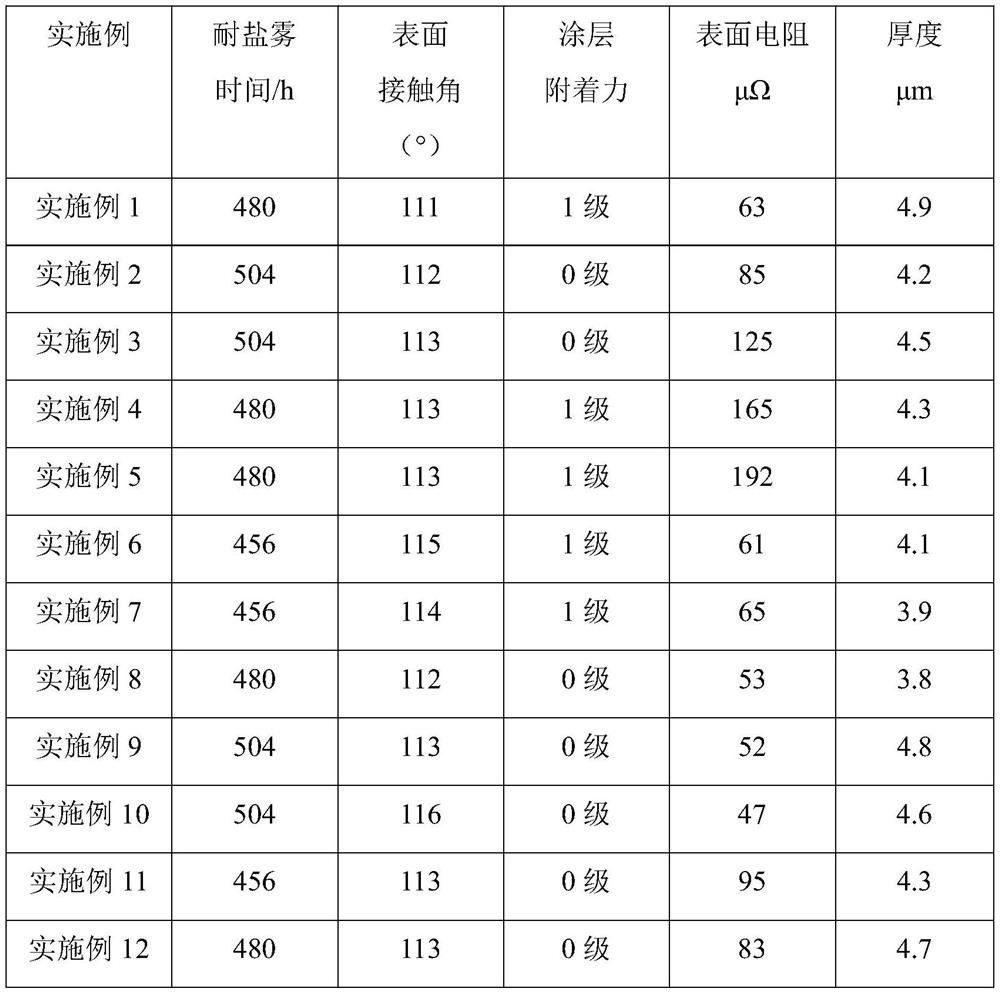

Graphene/alkane composite coating for aluminum alloy plate strip and preparation method thereof

ActiveCN111849225AImprove corrosion resistanceImprove wear resistancePretreated surfacesAnti-corrosive paintsAlkaneMaterials science

The invention belongs to the technical field of aluminum alloy plate coating materials, and particularly relates to a graphene / alkane composite coating for an aluminum alloy plate strip. The coating at least comprises alkane or cycloalkane, graphene and derivatives thereof, and a silane coupling agent, and the coating disclosed by the invention has the process characteristics of environmental protection, low cost, simple process, continuous production and the like, has the excellent performances of high corrosion resistance, high wear resistance, hydrophobicity, high coating binding force, lowsurface resistivity, long service life and the like, and is suitable for surface treatment of aluminum alloy so as to meet the requirements of an aluminum alloy material storage process, subsequent welding, coating and the like.

Owner:CHINALCO RUIMIN +1

A kind of graphene/alkane composite coating for aluminum alloy strip and preparation method thereof

ActiveCN111849225BImprove corrosion resistanceImprove wear resistancePretreated surfacesAnti-corrosive paintsAlkaneAluminium alloy

The invention belongs to the technical field of coating materials for aluminum alloy plates, and in particular relates to a graphene / alkane composite coating for aluminum alloy plates and strips. The coating of the coating contains at least alkane or cycloalkane, graphene and its derivatives, and a silane coupling agent; the coating of the present invention has technological characteristics such as environmental protection, low cost, simple process, and continuous production, and has high corrosion resistance Excellent properties such as high wear resistance, hydrophobicity, high coating adhesion, low surface resistivity, long service life, etc., suitable for surface treatment of aluminum alloys to meet the storage process of aluminum alloy materials, subsequent welding, coating, etc. need.

Owner:CHINALCO RUIMIN +1

High-corrosion-resistance environment-friendly waterborne epoxy curing agent and preparation method thereof

ActiveCN111849143AReduce the impactGuaranteed stabilityAnti-corrosive paintsEpoxy resin coatingsPolymer sciencePtru catalyst

The invention discloses a high-corrosion-resistance environment-friendly waterborne epoxy curing agent and a preparation method thereof. The waterborne epoxy curing agent comprises the following components in percentage by mass: 5 to 15% of bisphenol A epoxy resin, 3 to 8% of an alcohol ether solvent, 35 to 45% of polyethylene glycol, 0.002 to 0.01% of a catalyst, 28 to 32% of a compound cross-linking agent and 11 to 18% of a reactive diluent, wherein the compound cross-linking agent comprises isophorone diamine and diethylenetriamine in a mass ratio of (2 to 6.5): 1. The waterborne epoxy curing agent can effectively improve the corrosion resistance of the coating.

Owner:广州惠顺新材料有限公司

Environment-friendly water-based aluminum-rich coating with long-term storage stability

PendingCN114686073ANo harm to healthCoating environmental protectionAnti-corrosive paintsPolyurea/polyurethane coatingsOrganic solventAluminium powder

An environment-friendly water-based aluminum-rich coating with long-term storage stability relates to an anticorrosive coating and comprises the following components in parts by weight: 2-15 parts of modified flaky aluminum powder, 10-65 parts of modified spherical aluminum powder, 3-20 parts of water-based resin, 0.01-1 part of an emulsifier, 5-10 parts of a dispersant, 5-20 parts of a cosolvent, 0.1-3 parts of a leveling agent, 0.1-3 parts of a wetting agent, 0.1-2 parts of an anti-settling agent, 0.01-1 part of a defoaming agent, 0.01-1 part of a thickening agent and 10-50 parts of deionized water. The use amount of toxic organic solvents is effectively reduced, and resource waste and environmental pollution are avoided. Meanwhile, silane is used as a precursor, and modified aluminum powder is prepared by adopting a sol-gel method. The problems of poor dispersibility of aluminum powder and barrel swelling due to hydrogen evolution are solved, on one hand, the adding amount of the aluminum powder in the water-based aluminum-rich coating is increased, and the corrosion resistance of the water-based aluminum-rich coating is enhanced; on the other hand, the storage stability of the water-based aluminum-rich anticorrosive paint is greatly enhanced, and the storage time is prolonged.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

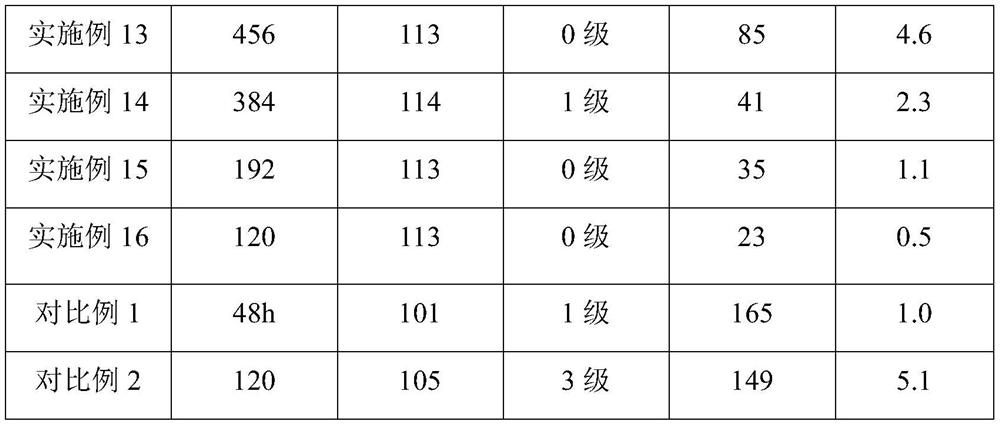

Foaming powder coating

InactiveCN107739568AStrong adhesionHigh mechanical strengthPowdery paintsPolyester coatingsWaxFoaming agent

The invention belongs to the technical field of coatings and specifically relates to a foaming powder coating which is prepared from the following raw materials in parts by weight: 720-770 parts of polyester resin, 60-80 parts of curing agent, 180-220 parts of washed kaolin, 3-7 parts of foaming agent, 1-3 parts of pigment, 1-3 parts of wax powder and 0.05-0.2 part of cellulose acetate butyrate. The coating provided by the invention is suitable for different metal building materials, and has the advantages of strong adhesive force, high coating hardness and perfect thermal insulation effect.

Owner:FUJIAN WANAN IND

Waterproof coating for ships

The invention discloses waterproof coating for ships. The waterproof coating is prepared from the following components in parts by weight: 8 to 20 parts of sodium tricyanate, 8 to 12 parts of trichloroethane, 2 to 6 parts of tetra-chlorodifluoroethane, 10 to 20 parts of benzoyl peroxide, 4 to 8 parts of perchloro-ethylene resin, 2 to 4 parts of ethyl acetate, 4 to 8 parts of hydroquinone, 10 to 16parts of urethane acrylate, 2 to 6 parts of benzoyl peroxide, 4 to 8 parts of glyceral methacrylate gel, 10 to 20 parts of vinyl acetate, 2 to 6 parts of ammonium bicarbonate, 2 to 4 parts of zirconium oxychloride and 6 to 8 parts of styrene-butadiene latex. The waterproof coating for the ships, disclosed by the invention, has the advantages of wide raw material source, low price, environment-friendly coating and few pollutants; the waterproof coating has a very good binding effect, a rapid drying speed and stable quality.

Owner:张建珍

Environment-friendly coating

InactiveCN107474739AGood film formingImprove adhesionRosin coatingsPolyether coatingsCellulose acetateSludge

The invention discloses an environment-friendly coating which is characterized by being prepared from the following components in percentage by weight: 18-30% of abietate, 7-11% of lemon oil, 5-11% of nonyl (octyl) phenol polyoxyethylene ether, 7-10% of polyvinylether, 3-8% of mandarin oil, 3-5% of calcium carbonate, 2-5% of cellulose acetate, 2-4% of talcum powder, 1-3% of titanium dioxide, 1-3% of mica iron oxide, 1-2% of algae sludge and the balance of titanium dioxide. The environment-friendly coating disclosed by the invention is non-toxic, harmless and excellent in film-forming effect and has high adhesion force, and due to the addition of the titanium dioxide and algae sludge, the coating disclosed by the invention has the effect of purifying air. Due to the two natural components, such as the lemon oil and mandarin oil, the novel coating is environment-friendly.

Owner:江苏科力特环保科技有限公司

UV-recognizable photocurable fluorescent anti-counterfeiting coating and preparation method thereof

ActiveCN108977055BStrong adhesionGood weather resistanceLuminescent paintsPolyurea/polyurethane coatingsWeather resistancePhoto irradiation

The invention provides an ultraviolet identifiable light-curing fluorescent anti-counterfeiting paint which comprises the following components: photocurable aliphatic polyurethane resin, photocurablealiphatic epoxy acrylate, photocurable active monomer, cracking visible light initiator, spherical silicon powder, a wetting agent, a defoamer, a rheological additive, a fluorescer, and a dispersant.The invention also provides a method of preparing the paint. The paint provided by the invention can use visible light with a wavelength of 405 nm to cure the paint, have fast curing speed, low energyconsumption, environmental protection and low VOC, high construction efficiency and low construction cost; the paint provided by the invention also has good adhesion to various substrates, excellentcoating film mechanical properties, good weather resistance and scratch resistance; the paint coating provided by the invention is transparent and colorless in sunlight, which does not affect the surface appearance of the paint; and blue fluorescence with 450 to 500 nm wavelength is only emitted by the coating under the ultraviolet light with 380 nm or less.

Owner:苏州佩琦材料科技有限公司

UV (Ultraviolet) cured pearly luster coating and preparation method thereof

InactiveCN109161315AFast curingReduce energy consumptionPolyurea/polyurethane coatingsEpoxy resin coatingsUltravioletMechanical property

The invention provides a UV (Ultraviolet) cured pearly luster coating which comprises the following components in parts by weight: 45-65 parts of a light-cured resin, 5-20 parts of a light-cured active monomer, 1-10 parts of a photoinitiator, 1-5 parts of a sensitizer, 0.1-0.5 part of a lubricant, 0.1-0.5 part of a defoaming agent, 0.5-2 parts of rheological additives, 3-6 parts of a mica pearly luster pigment and 0.1-0.5 part of a dispersant. The invention further provides a preparation method of the UV cured pearly luster coating. The pearly luster coating provided by the invention can be cured with UV, is high in curing speed, low in energy consumption, good in environment protection, low in VOC (Volatile Organic Compound), high in construction efficiency, low in construction cost, excellent in coating mechanical property, good in weather resistance and good in scratch resistance.

Owner:苏州佩琦材料科技有限公司

A kind of coating containing fast drying agent and preparation method thereof

ActiveCN104194566BImprove use valueCoating environmental protectionSiccativesEpoxy resin coatingsAcrylic resinFirming agent

The invention belongs to the field of coatings, in particular to a coating containing a quick drying agent and a preparation method thereof. The coating includes a paint component and a curing agent component, and the mass ratio is 2-3:1; the composition of the paint component is calculated by mass fraction: polysulfide modified epoxy resin 40-50%, acrylic resin 5-10%, Polydimethylsiloxane 15-20%, additives 1-5%, pigments and fillers 10-15%, solvent 10-20%, tea stem powder 5-10%, coupling agent 2-5%; curing agent The composition of components is calculated by mass fraction: curing agent 60-70%, n-butyl acetate 20-30%, fast drying agent 10-15%; the composition of fast drying agent is calculated by weight fraction: dehydrating agent 10-15% , Drier 15-25%, n-butyl acetate 60-70%. The invention can react with volatile organic gas to a certain extent by adding tea stem powder, and reduce the VOCs released by the coating. At the same time, it is designed with a fast drying agent, which can make the coating dry quickly. It is a solvent-based relatively environmentally friendly and fast-drying coating. .

Owner:ZHANGZHOU XIN ZHAN WANG CHEM IND

Environmental-friendly bactericidal paint

InactiveCN106893444ALow costHigh activityAntifouling/underwater paintsPaints with biocidesPolyvinyl butyralEpoxy

The invention provides environmental-friendly bactericidal paint which is composed of the following raw materials in parts by weight: 20-30 parts of an epoxy resin, 5-10 parts of environmental-friendly paint, 15-16 parts of nonylphenol, 1-3 parts of polyvinyl butyral, 2-4 parts of sodium hydroxide, 4-6 parts of rare earth ions, 1-3 parts of titanium dioxide and 5-10 parts of allylthiourea. The bactericidal paint disclosed by the invention has the advantages that because the paint contains the rare earth ions, the bactericidal effect is excellent. The raw material cost is low, the activity of the finished product is high, and the paint has extremely high activities on various bacteria, fungi and saccharomycetes and can solve a series of problems caused by fungus pollution such as product demulsification, deterioration, mildewing, fermentation, stinking and the like. The environmental-friendly bactericidal paint does not contain any formaldehyde or formaldehyde released substances, is wide in application range, can be widely applied to places such as residences, hospitals, electric appliances, dining halls and the like, has the effects of coatings, can achieve the effects of effectively preventing bacterial breeding and reducing damage of bacteria on coating production performance and has an effect of protecting the environment.

Owner:TIANJIN JINCHANG TECH DEV

Novel environment-friendly coating

InactiveCN111440474AEasy to recycleIncrease profitEmulsion paintsActivated charcoal powderActive agent

The invention provides a novel environment-friendly coating, and relates to the technical field of coatings. The novel environment-friendly coating, calculated in parts by weight, is prepared from thefollowing materials: 18 to 20 parts of nano silicon dioxide, 18 to 20 parts of nano titanium dioxide, 20 to 40 parts of titanium dioxide, 31 to 43 parts of an auxiliary agent, 40 to 60 parts of emulsion paint, 25 to 40 parts of deoxygenated water, 5 to 15 parts of activated carbon powder, 10 to 15 parts of color paste, 18 to 20 parts of white carbon black, 7 to 13 parts of an active agent, 3 to 4parts of nano silver and 8 to 12 parts of metal oxide. The nano silicon dioxide and the nano titanium dioxide are matched without any illumination condition; harmful substances such as formaldehyde can be actively decomposed; the activated carbon powder can actively absorb the harmful substances such as formaldehyde to enable the coating to be energy-saving, the white carbon black carrier can fixthe nano titanium dioxide, loss of nano titanium dioxide powder particles is prevented, the utilization rate of the nano titanium dioxide is increased, the white carbon black carrier is easy to recycle, and the coating is enabled to be environment-friendly.

Owner:SHENZHEN GASU ADORN DESIGN ENG

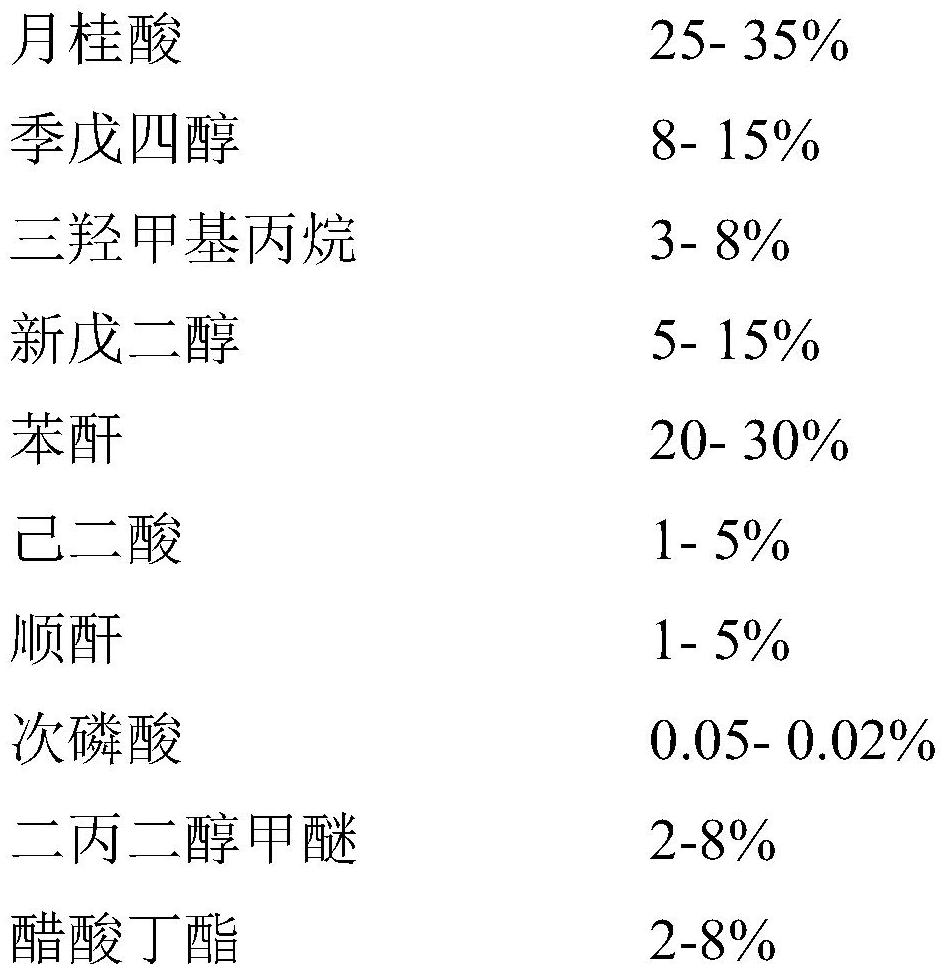

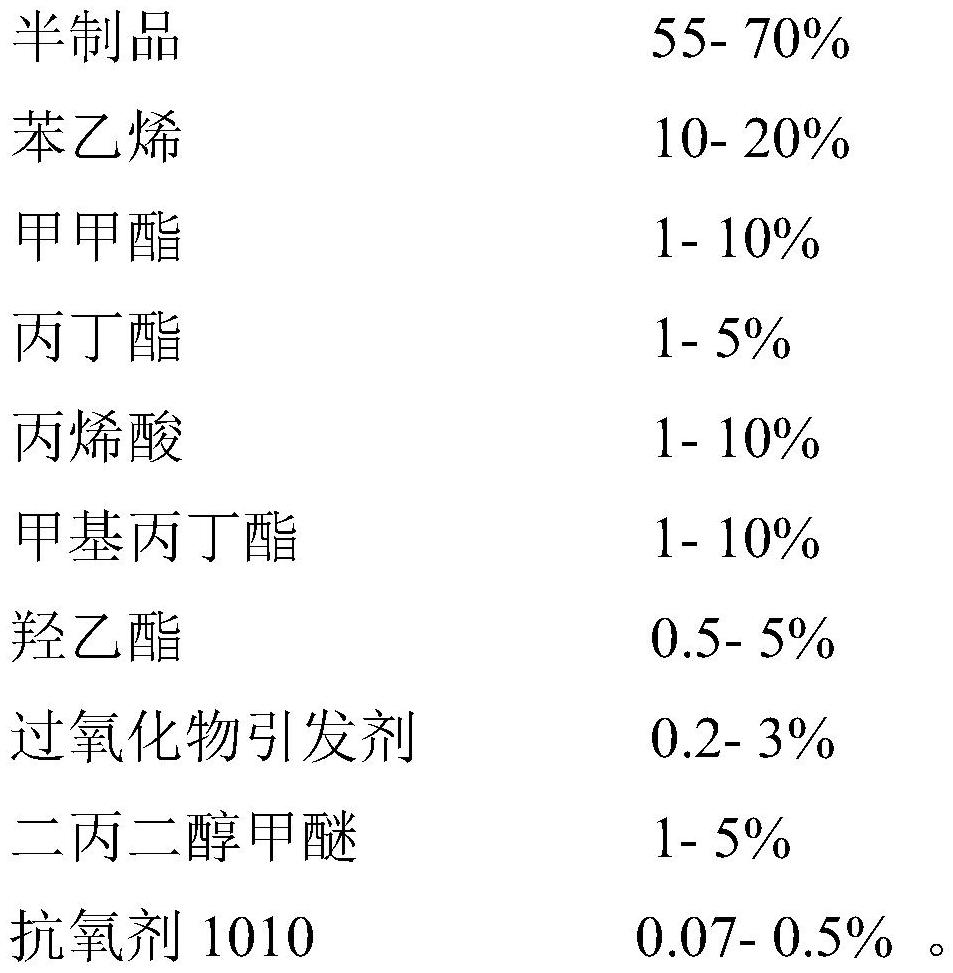

Acrylic acid modified water-based stoving varnish alkyd resin and preparation method thereof

InactiveCN111777749AReduce colorDoes not cause chromatic aberrationCoatingsPolymer scienceSolid content

The invention discloses acrylic acid modified water-based stoving varnish alkyd resin and a preparation method thereof, the acrylic acid modified water-based stoving varnish alkyd resin comprises a semi-finished product and a finished product, the acrylic acid modified alkyd resin is high in solid content, high in gloss, high in hardness, excellent in performance and environment-friendly, and therequirements of market users are greatly met.

Owner:HUALUN NALU NEW MATERIALS

Modified water-based baking varnish alkyd resin with high comprehensive performance and preparation method thereof

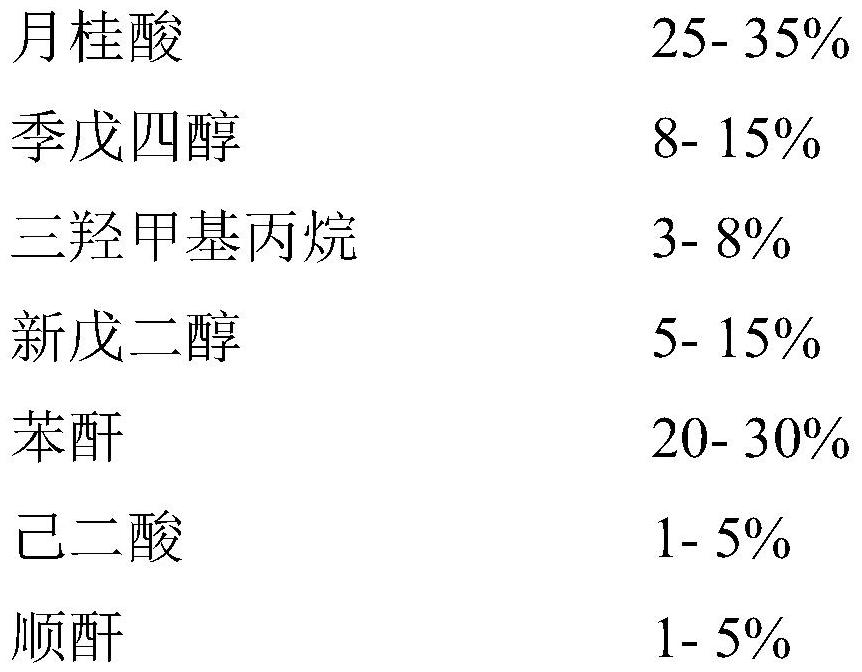

PendingCN113214437AImprove flexibilityImprove yellowing resistanceCoatingsComposite materialAnoxomer

The invention relates to modified water-based baking varnish alkyd resin with high comprehensive performance and a preparation method of the modified water-based baking varnish alkyd resin. The preparation method comprises the following steps: (1) reacting glycidyl tertiary carboxylic ester with polyhydroxy alkane and a catalyst to form a first semi-finished product; (2) reacting the obtained first semi-finished product with polybasic acid, polyhydric alcohol, saturated fatty acid, an inorganic antioxidant, a reflux solvent and a first diluting solvent to obtain a second semi-finished product; and (3) reacting the obtained second semi-finished product with a second diluting solvent, an organic antioxidant, an acrylate compound, a monomer and an initiator to finally obtain the modified water-based baking varnish alkyd resin with high comprehensive performance. The obtained modified water-based baking varnish alkyd resin has good comprehensive performance such as good flexibility, glossiness, hardness, wear resistance and chemical resistance, the raw materials are easy to obtain in the market, the price is relatively low, and the produced product has better market competitiveness.

Owner:JIANGSU HUALUN CHEM +1

A kind of anticorrosion and antimildew water-based epoxy curing agent and preparation method thereof

ActiveCN111777922BImprove corrosion resistanceGood anti-fouling and anti-mildew performanceAntifouling/underwater paintsPaints with biocidesPolymer sciencePtru catalyst

The invention discloses an anti-corrosion and mildew-proof water-based epoxy curing agent and a preparation method thereof. The components of the water-based epoxy curing agent are calculated by mass percentage: polyethylene glycol 25-36%, epoxy resin 10- 20%, catalyst 0.002-0.007%, quencher 5%-10%, compound cross-linking agent 30-36%, active diluent 5-9%, solvent 3.5-6%, and fungicide 0.05-0.2%, all The composite crosslinking agent includes m-xylylenediamine and isophoronediamine in a mass ratio of 5 / 3-14 / 3. The water-based epoxy curing agent provided by the invention can effectively improve the corrosion resistance and mildew resistance of the paint, and the cost of raw materials is not high, which greatly reduces the later maintenance cost of the paint.

Owner:广州惠顺新材料有限公司

Coating for furniture

InactiveCN109021827ALong term protectionExtended service lifePolyurea/polyurethane coatingsAcrylic resinToxic material

The invention discloses a coating for furniture, wherein the coating for furniture includes the following components in parts by weight: 16-29 parts of a fluorocarbon modified acrylic emulsion, 14-26parts of a polyurethane emulsion, 7-16 parts of zinc stearate, 13-27 parts of epoxidized polydibutene resin, 26-37 parts of castor oil, 10-26 parts of butyl etherified amino resin, 14-29 parts of acrylic resin, 21-29 parts of mica powder, 15-26 parts of talc powder and 17-26 parts of titanium dioxide. The coating disclosed by the invention is more environmentally friendly, does not produce toxic substances, and is more conducive to human body health.

Owner:SICHUAN AIYIJIA FURNITURE CO LTD

Photocurable silver powder paint and preparation method thereof

InactiveCN109251639AImprove mechanical propertiesGood weather resistancePolyurea/polyurethane coatingsPaints with free metalsHydrogenPhotosensitizer

The invention provides photocurable silver powder paint, which is composed of the following components (by weight): 50-70 parts of photocurable resin, 10-15 parts of a photocurable active monomer, 0.5-5 parts of pyrolysis type visible light initiator, 1-3 parts of a hydrogen abstraction type visible light initiator, 1-5 parts of a photosensitizer, 4-7 parts of a silver powder orientation agent, 0.1-0.5 part of a wetting agent, 0.1-0. 5 part of an antifoaming agent, 0.5-2 parts of a rheological additive, 3-6 parts of silver powder, and 0.1-0.5 part of a dispersing agent. The invention also provides a method for preparing the above photocurable silver powder paint. The coating of the powder paint can be cured by the use of visible light with a wavelength of 405 nm. The curing speed is fast;energy consumption is low; environment is protected and VOC is low; construction efficiency is high; and construction cost is low. In addition, the coating has excellent mechanical properties, good weather resistance and scratch resistance.

Owner:苏州佩琦材料科技有限公司

Protective paint and preparation method thereof

The invention discloses protective paint and a preparation method thereof. The protective paint is prepared from the following formula ingredients in parts by mass: 30 to 35 parts of methylbenzene, 30 to 35 parts of methacrylic acid, 30 to 35 parts of butyl acrylate, 10 to 15 parts of phosphate acrylate, 10 to 15 parts of methacrylic acid, 10 to 15 parts of acetyl, 5 to 14 parts of hexafluorobutyl, 5 to 10 parts of methacrylic acid, 5 to 10 parts of methyl ester, 5 to 7 parts of ,ethoxy-2-propyl propanoate, 3 to 5 parts of n-butyl acetate, 1 to 2 parts of antifoaming agents and 1 to 2 parts of flatting agents. The protective paint provided by the invention has the advantages of no toxicity and environment protection.

Owner:钦州市高新技术产业服务中心

Silver-zinc oxide formaldehyde-removing coating and preparation method thereof

InactiveCN112442294ALarge specific surface areaReduce usageAntifouling/underwater paintsPaints with biocidesCellulosePtru catalyst

The invention relates to a silver-zinc oxide antibacterial formaldehyde-removing coating and a preparation method thereof. The coating is prepared from the following components in parts by mass: 25-30parts of water, 0.3-0.5 part of hydroxyethyl cellulose, 0.1-0.3 part of a pH regulator, 0.5-0.8 part of a water-based dispersant, 0.1-0.3 part of a water-based wetting agent, 0.4-0.7 part of a water-based defoamer, 15-18 parts of titanium dioxide, 8-12 parts of calcined kaolin, 10-15 parts of calcium carbonate, 8-15 parts of diatomite, 2-5 parts of silver zinc oxide, 17-23 parts of emulsion, 0.5-1 part of a coalescing agent and 0.5-1 part of an antifreezing agent. The ultra-small-size silver zinc oxide material is beneficial to increase of the specific surface area of the catalyst, reductionof the use amount of the catalyst and improvement of the catalytic effect.

Owner:三棵树(上海)新材料研究有限公司

Coating for ships

The invention discloses a coating for ships. The coating for ships comprises, by weight, 10 to 20 parts of benzoyl peroxide, 4 to 8 parts of perchloroethylene resin, 2 to 4 parts of ethyl acetate, 4 to 8 parts of hydroquinone, 10 to 16 parts of urethane acrylate, 2 to 6 parts of benzoyl peroxide, 4 to 8 parts of glyceryl methacrylate gel, 10 to 20 parts of vinyl acetate, 2 to 6 parts of ammonium hydrogencarbonate, 2 to 4 parts of zirconium oxychloride and 6 to 8 parts of styrene-butadiene latex. The coating for ships in the invention uses widely available and cheap raw materials, is friendly to environment, produces few pollutants, and has good bonding effect, fast drying speed and stable quality.

Owner:张建珍

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com