A kind of high-corrosion and environment-friendly water-based epoxy curing agent and preparation method thereof

A water-based epoxy and curing agent technology, used in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor comprehensive performance and general anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

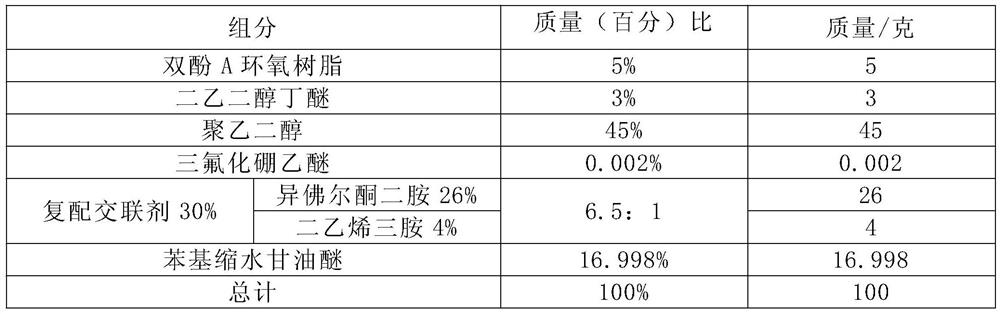

[0024] The present embodiment provides a water-based epoxy curing agent with high anticorrosion and environmental protection. The components of the curing agent and the quality of each component are as follows:

[0025]

[0026] In the present embodiment, the epoxy value of bisphenol A epoxy resin is 0.48, the molecular weight of polyethylene glycol is 4000, and the mass ratio of isophorone diamine and diethylene triamine in the composite crosslinking agent is 6.5: 1.

[0027] The present embodiment also provides a method for preparing a highly anti-corrosion and environment-friendly water-based epoxy curing agent, comprising the following steps:

[0028] (1) under normal temperature and normal state, take by weighing the bisphenol A epoxy resin of 5 grams and the diethylene glycol butyl ether of 3 grams respectively and mix, and stir and dissolve;

[0029] (2) take by weighing 45 grams of molten polyethylene glycol and add it to the first container, then add the material ...

Embodiment 2

[0033] The present embodiment provides a water-based epoxy curing agent with high anticorrosion and environmental protection. The components of the curing agent and the quality of each component are as follows:

[0034]

[0035] In the present embodiment, the epoxy value of bisphenol A epoxy resin is 0.5, the molecular weight of polyethylene glycol is 5000, and the mass ratio of isophorone diamine and diethylenetriamine in the composite crosslinking agent is 3.3: 1.

[0036] The present embodiment also provides a method for preparing a highly anti-corrosion and environment-friendly water-based epoxy curing agent, comprising the following steps:

[0037] (1) under normal temperature and normal state, respectively take by weighing 10 grams of bisphenol A epoxy resin and 5 grams of ethylene glycol tert-butyl ether and mix, and stir and dissolve;

[0038] (2) take by weighing 40 grams of molten polyethylene glycol and add in the first container, then add the material in step (...

Embodiment 3

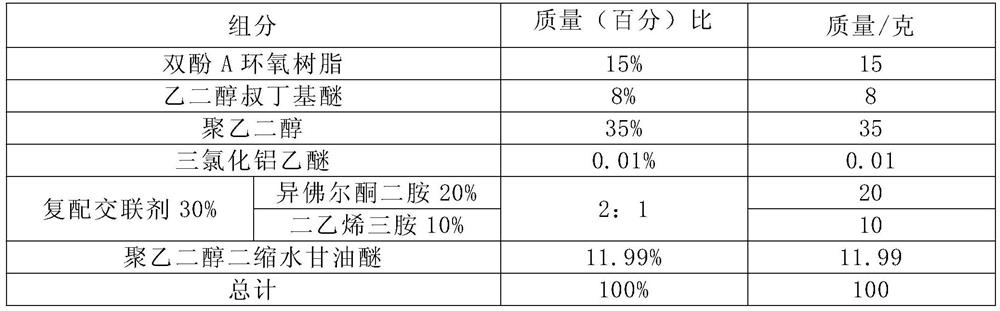

[0042] The present embodiment provides a water-based epoxy curing agent with high anticorrosion and environmental protection. The components of the curing agent and the quality of each component are as follows:

[0043]

[0044] In the present embodiment, the epoxy value of bisphenol A epoxy resin is 0.53, the molecular weight of polyethylene glycol is 6000, and the mass ratio of isophorone diamine and diethylenetriamine in the composite crosslinking agent is 2: 1.

[0045] The present embodiment also provides a method for preparing a highly anti-corrosion and environment-friendly water-based epoxy curing agent, comprising the following steps:

[0046] (1) under normal temperature and normal state, take by weighing the bisphenol A epoxy resin of 15 grams and the ethylene glycol tert-butyl ether of 8 grams respectively and mix, and stir and dissolve;

[0047] (2) take by weighing 35 grams of molten polyethylene glycol and add it to the first container, then add the material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com