Foaming powder coating

A powder coating and blowing agent technology, applied in powder coating, polyester coating, coating, etc., can solve the problems of flammability, danger, environmental protection, etc., and achieve high mechanical strength, strong adhesion, uniform and fine bubbles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

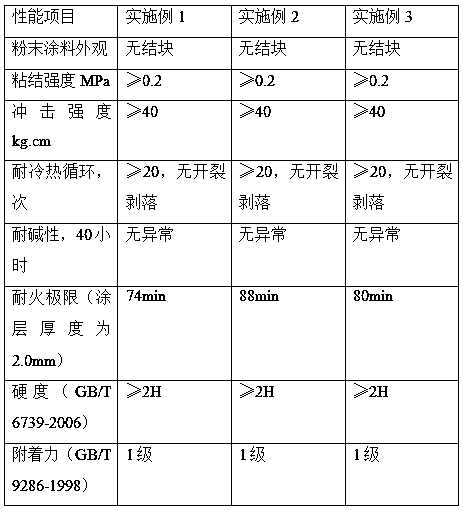

Examples

Embodiment 1

[0014] 720 parts of polyester resin, 60 parts of curing agent, 180 parts of washed kaolin, 3 parts of KH550, 5 parts of foaming agent, 1 part of pigment, 2 parts of wax powder, 0.1 part of cellulose acetate butyrate.

[0015] The preparation method of described foaming powder coating, concrete steps are:

[0016] (1) Mix polyester resin, pigment, wax powder, and cellulose acetate butyrate according to the proportion, stir for 5 minutes, and the stirring speed is 500r / min;

[0017] (2) Add the mixture of step (1) to water-washed kaolin, KH550, foaming agent and curing agent, stir at high speed for 5 minutes at a speed of 2000r / min; The foaming powder coating described above.

Embodiment 2

[0019] 750 parts of polyester resin, 70 parts of curing agent, 200 parts of washed kaolin, 5 parts of KH550, 5 parts of foaming agent, 1 part of pigment, 2 parts of wax powder, 0.1 part of cellulose acetate butyrate.

[0020] The preparation method of described foaming powder coating, concrete steps are:

[0021] (1) Mix polyester resin, pigment, wax powder, and cellulose acetate butyrate according to the proportion, stir for 5 minutes, and the stirring speed is 500r / min;

[0022] (2) Add the mixture of step (1) to water-washed kaolin, KH550, foaming agent and curing agent, stir at high speed for 7 minutes at a speed of 2000r / min; The foaming powder coating described above.

Embodiment 3

[0024] 770 parts of polyester resin, 70 parts of curing agent, 200 parts of washed kaolin, 8 parts of KH550, 5 parts of foaming agent, 1 part of pigment, 2 parts of wax powder, 0.1 part of cellulose acetate butyrate.

[0025] The preparation method of described foaming powder coating, concrete steps are:

[0026] (1) Mix polyester resin, pigment, wax powder, and cellulose acetate butyrate according to the proportion, stir for 5 minutes, and the stirring speed is 500r / min;

[0027] (2) Add the mixture of step (1) into washed kaolin, KH550, foaming agent and curing agent, stir at high speed for 8 minutes at a speed of 2000r / min; then add it to a screw extruder for extrusion, tableting, and crushing to obtain the foaming powder coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com