Anticorrosive mildew-proof water-based epoxy curing agent and preparation method thereof

A water-based epoxy, anti-corrosion and anti-mildew technology, applied in anti-corrosion coatings, epoxy resin coatings, anti-fouling/underwater coatings, etc., can solve the problems of general anti-corrosion and anti-mold performance, expensive raw materials, high cost, etc., to reduce later maintenance cost, improve corrosion resistance, increase the effect of weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

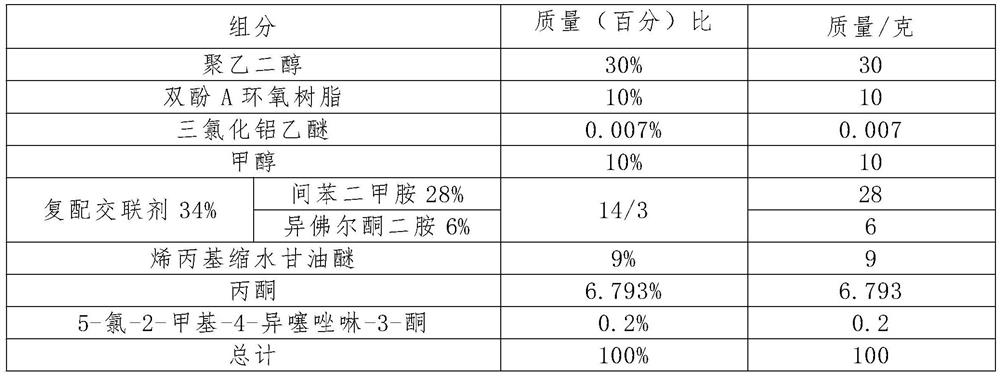

[0027] This embodiment provides a high anti-corrosion and environment-friendly water-based epoxy curing agent. The components of the curing agent and the quality of each component are as follows:

[0028]

[0029] In the present embodiment, the epoxy value of bisphenol A epoxy resin is 0.4, the molecular weight of polyethylene glycol is 4000, and the mass ratio of m-xylylenediamine and isophoronediamine in the composite crosslinking agent is 14 / 3.

[0030] Present embodiment also provides a kind of preparation method of anticorrosion and mildewproof water-based epoxy curing agent, comprises the following steps:

[0031] (1) Under the condition of stirring at normal temperature, heat 30 grams of polyethylene glycol in a water bath to 50° C. to melt, then add 10 grams of bisphenol A epoxy resin and mix evenly;

[0032] (2) Heat the material in the previous step, and after the temperature rises to 85°C, add 0.007 g of aluminum trichloride ethyl ether solution dropwise, keep w...

Embodiment 2

[0036] This embodiment provides a high anti-corrosion and environment-friendly water-based epoxy curing agent. The components of the curing agent and the quality of each component are as follows:

[0037]

[0038] In the present embodiment, the epoxy value of bisphenol A epoxy resin is 0.48, the molecular weight of polyethylene glycol is 5000, and the mass ratio of m-xylylenediamine and isophoronediamine in the composite crosslinking agent is 12 / 5.

[0039] Present embodiment also provides a kind of preparation method of anticorrosion and mildewproof water-based epoxy curing agent, comprises the following steps:

[0040] (1) Under the condition of stirring at normal temperature, heat 25 grams of polyethylene glycol in a water bath to 60° C. to melt, then add 20 grams of bisphenol A epoxy resin and mix evenly;

[0041] (2) Heat the material in the previous step, add 0.002 g of boron trifluoride ether solution dropwise after the temperature rises to 95°C, keep warm until the...

Embodiment 3

[0045] This embodiment provides a high anti-corrosion and environment-friendly water-based epoxy curing agent. The components of the curing agent and the quality of each component are as follows:

[0046]

[0047]

[0048] In the present embodiment, the epoxy value of the hydrogenated epoxy resin is 0.52, the molecular weight of polyethylene glycol is 6000, and the mass ratio of m-xylylenediamine and isophoronediamine in the compound crosslinking agent is 5 / 3.

[0049] Present embodiment also provides a kind of preparation method of anticorrosion and mildewproof water-based epoxy curing agent, comprises the following steps:

[0050] (1) Under the condition of stirring at normal temperature, heat 36 grams of polyethylene glycol in a water bath to 70 ° C for melting, then add 18 grams of hydrogenated epoxy resin and mix evenly;

[0051] (2) Heat the material in the previous step, and after the temperature rises to 100°C, add 0.004 g of aluminum trichloride ether solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com