Coating containing quick drying agent and preparation method thereof

A fast drying and coating technology, applied in the field of coatings, can solve problems such as uneven mixing, color difference, and low efficiency, and achieve the effects of improving efficiency, saving time, and reducing color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

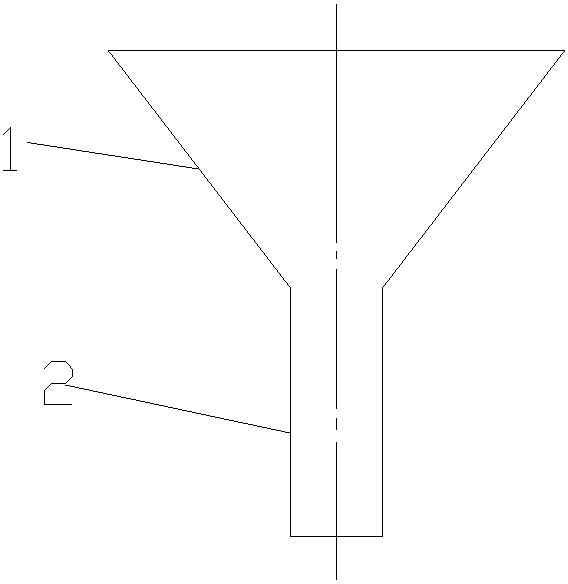

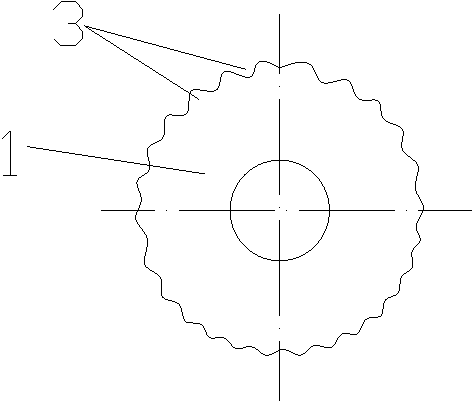

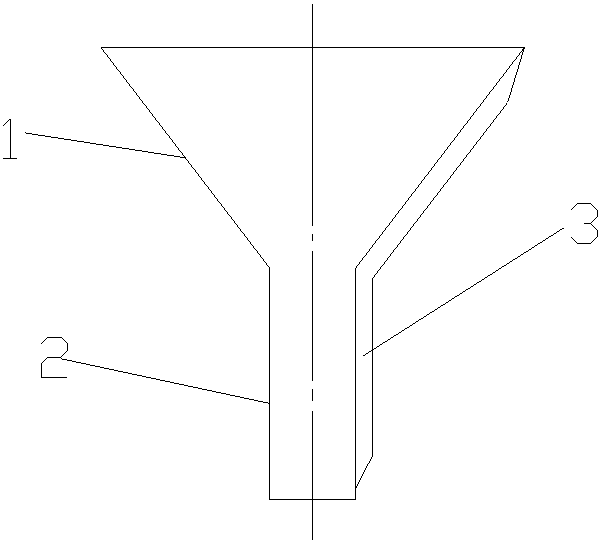

Image

Examples

Embodiment 1

[0049] The paint is made by mixing paint components and curing agent components at a mass ratio of 2:1;

[0050] Described paint composition consists of:

[0051] Polysulfide modified epoxy resin 40%, acrylic resin 5%, polydimethylsiloxane 15%, silicone 5%, high pigment carbon black 10%, butyl ester 18%, tea stem powder 5%, silane Joint agent 2%;

[0052] Described curing agent component is composed by mass fraction and is:

[0053] Aliphatic isocyanate curing agent 60%, n-butyl acetate 30%, quick drying agent 10%;

[0054] Its composition of described quick-drying agent is calculated by weight fraction:

[0055] Trimethyl orthoformate 10%, zinc isooctanoate 25%, n-butyl acetate 65%.

[0056] A method for preparing a quick-drying agent, comprising the steps of:

[0057] A. Preparation of paint components:

[0058] 1) Mix tea stem powder with silane coupling agent and stir for 10 minutes;

[0059] 2) Put 2 / 3 of the mass of n-butyl acetate into the reactor, control the t...

Embodiment 2

[0068] The paint is made by mixing paint components and curing agent components at a mass ratio of 3:1;

[0069] Described paint component is composed by mass fraction and is:

[0070] Polysulfide-modified epoxy resin 45%, acrylic resin 5%, polydimethylsiloxane 15%, polyurethane 1%, titanium dioxide 15%, cyclohexanone 14%, tea stem powder 10%, titanate couple Joint agent 5%;

[0071] Described curing agent component is composed by mass fraction and is:

[0072] Modified alicyclic amine curing agent 70%, n-butyl acetate 20%, quick drying agent 10%;

[0073] Its composition of described quick-drying agent is calculated by weight fraction:

[0074] Triethyl orthoformate 15%, dibutyltin dilaurate 15%, n-butyl acetate 70%.

[0075] A method for preparing a quick-drying agent, comprising the steps of:

[0076] A. Preparation of paint components:

[0077] 1) Mix the tea stem powder with the coupling agent and stir for 15 minutes;

[0078] 2) Put 2 / 3 of the mass of n-butyl ace...

Embodiment 3

[0087] The paint is made by mixing paint components and curing agent components at a mass ratio of 2:1;

[0088] Described paint component is composed by mass fraction and is:

[0089] Polysulfide modified epoxy resin 42%, acrylic resin 8%, polydimethylsiloxane 15%, polyacrylate 5%, organic quinacridone violet 10%, butyl glycol ether 10%, tea stem 7% powder, 3% titanate coupling agent;

[0090] Described curing agent component is composed by mass fraction and is:

[0091] Aliphatic isocyanate curing agent 60%, n-butyl acetate 25%, quick drying agent 15%;

[0092] Its composition of described quick-drying agent is calculated by weight fraction:

[0093] 12% of 2,2-dimethoxypropane, 20% of zirconium isooctanoate, 68% of n-butyl acetate.

[0094] A method for preparing a quick-drying agent, comprising the steps of:

[0095] A. Preparation of paint components:

[0096] 1) Mix the tea stalk powder with the coupling agent and stir for 20 minutes;

[0097] 2) Put 2 / 3 of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com